Clamping mechanism for automatic glass edger

A technology of clamping mechanism and edging machine, which is applied in the direction of machine tools suitable for grinding the edge of workpieces, parts of grinding machine tools, grinding machines, etc., and can solve the problem that the clamping force cannot be too large, the glass is loose or shifted, and the grinding is affected Quality and other issues to achieve the effect of preventing loosening or shifting, preventing glass damage, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

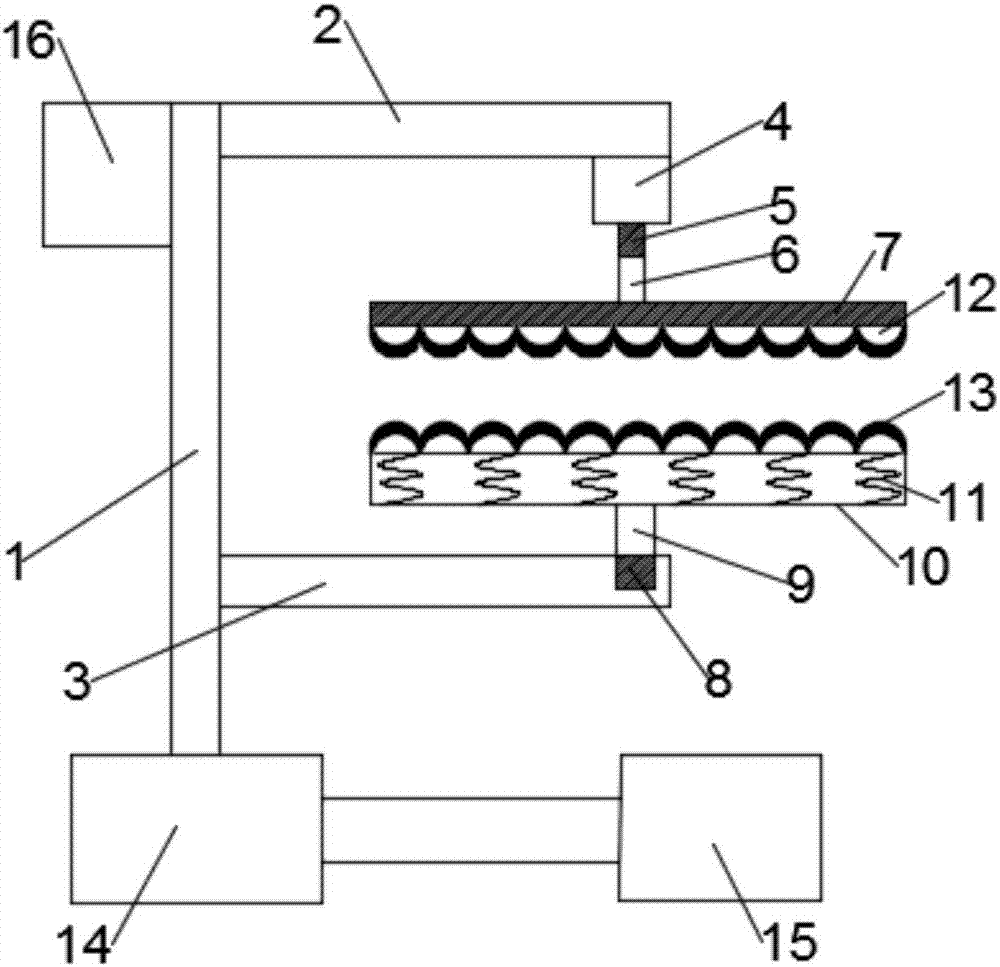

[0021] Such as figure 1 As shown, the present invention provides a clamping mechanism for an automatic glass edging machine, including a bracket 1, the bottom end of the bracket 1 is fixedly connected with a mobile base 14, and the side of the mobile base 14 is provided with a cylinder 15, so that The cylinder 15 is fixed, and the output end of the cylinder 15 is fixedly connected to the mobile base 14, so that the mobile base 14 can reciprocate under the drive of the cylinder 15, which is convenient for glass edging. The side of the support 1 is fixedly connected with a horizontal setting The first support rod 2 and the second support rod 3, and the first support rod 2 is located directly above the second support rod 3, the side top of the bracket 1 is fixedly connected with a counterweight 16, and the counterweight 16 is located The opposite positions of the first support rod 2 and the second support rod 3 can prevent the clamping mechanism from tilting and prevent deviation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com