High-precision edge grinding device for monocrystalline silicon epitaxial wafer

An epitaxial wafer and high-precision technology, which is applied in the direction of machine tools, grinding machines, and grinding workpiece supports suitable for grinding the edge of workpieces, and can solve problems such as abnormal processes, excessive edge deposition, and low processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

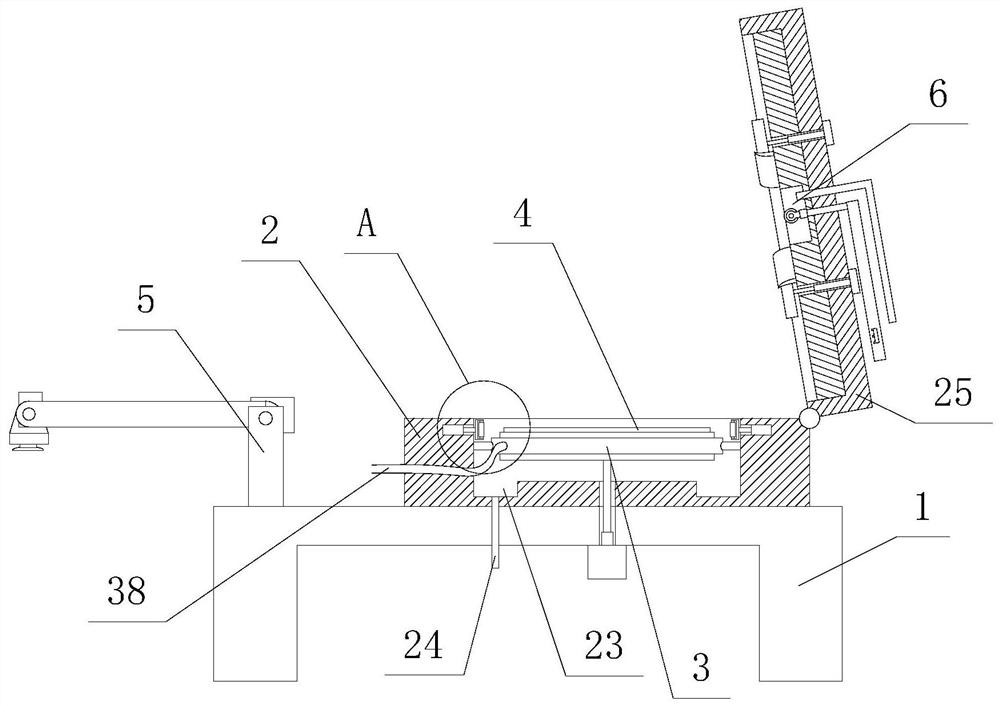

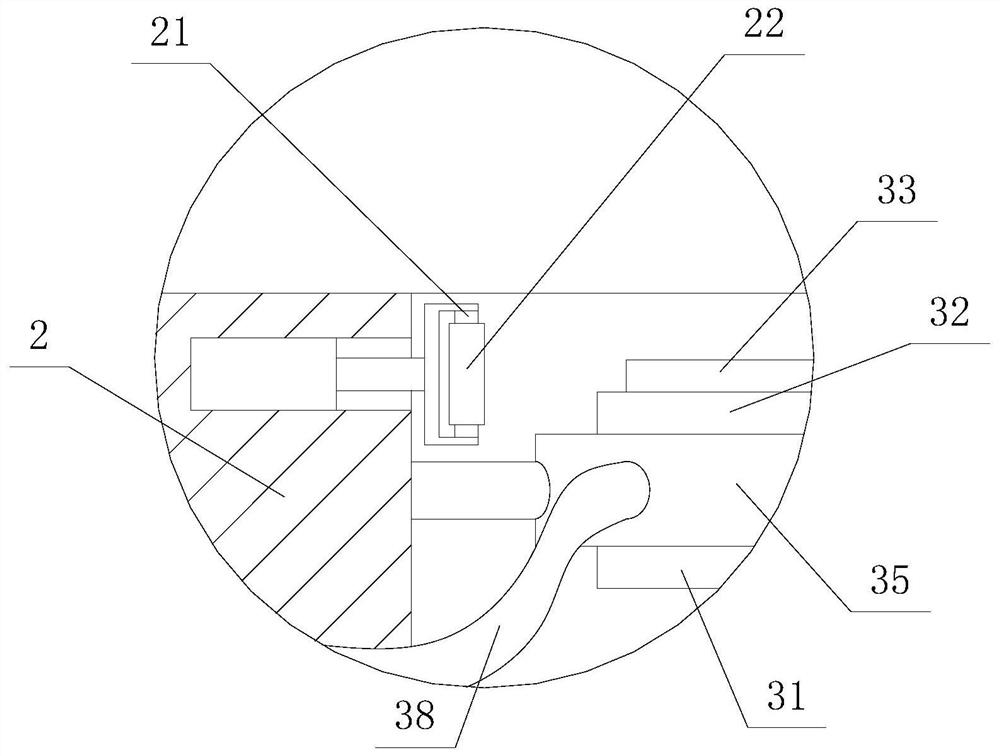

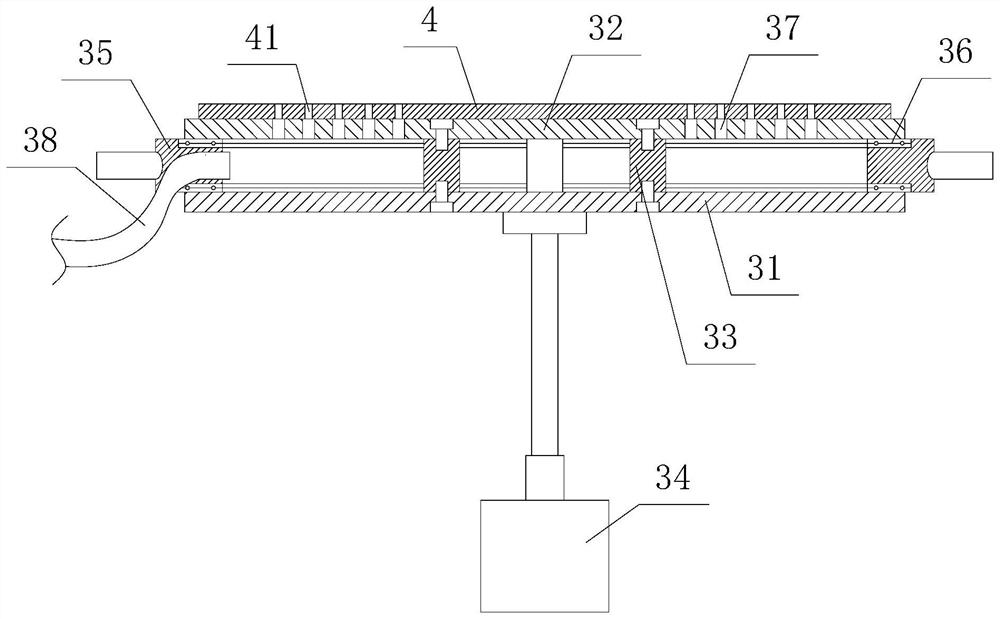

[0024] Such as Figure 1 to Figure 7 As shown, the high-precision edging device for monocrystalline silicon epitaxial wafers provided in this embodiment includes a machine platform 1, a carrier 2, a pick-up device 5 and a polishing mechanism 6, and the carrier 2 is installed on the machine platform 1, and the The middle part of the bearing seat 2 is processed with a turntable 3 for placing epitaxial wafers. A gasket 4 is installed on the surface of the turntable 3. A plurality of air holes 41 are processed on the gasket 4. The turntable 3 includes a lower support plate 31, an upper support plate Plate 32, support column 33, motor 34, snap ring 35 and end face bearing 36, described upper support plate 32 is installed on the lower support plate 31 through support column 33, and upper support plate 32 is processed with a plurality of communicating with vent hole 41 Through hole 37, a motor 34 is installed in the middle part of the bottom surface of the lower support plate 31, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com