Edge polishing follow-up device of edge polishing machine

A technology of a follower device and an edging machine, which is applied in the direction of a grinding frame, a machine tool suitable for grinding the edge of a workpiece, and parts of a grinding machine tool. It can solve the problems of manual adjustment of the grinding height of the edging wheel and achieve The plane is flat and smooth, easy to use, and the effect of high edging efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

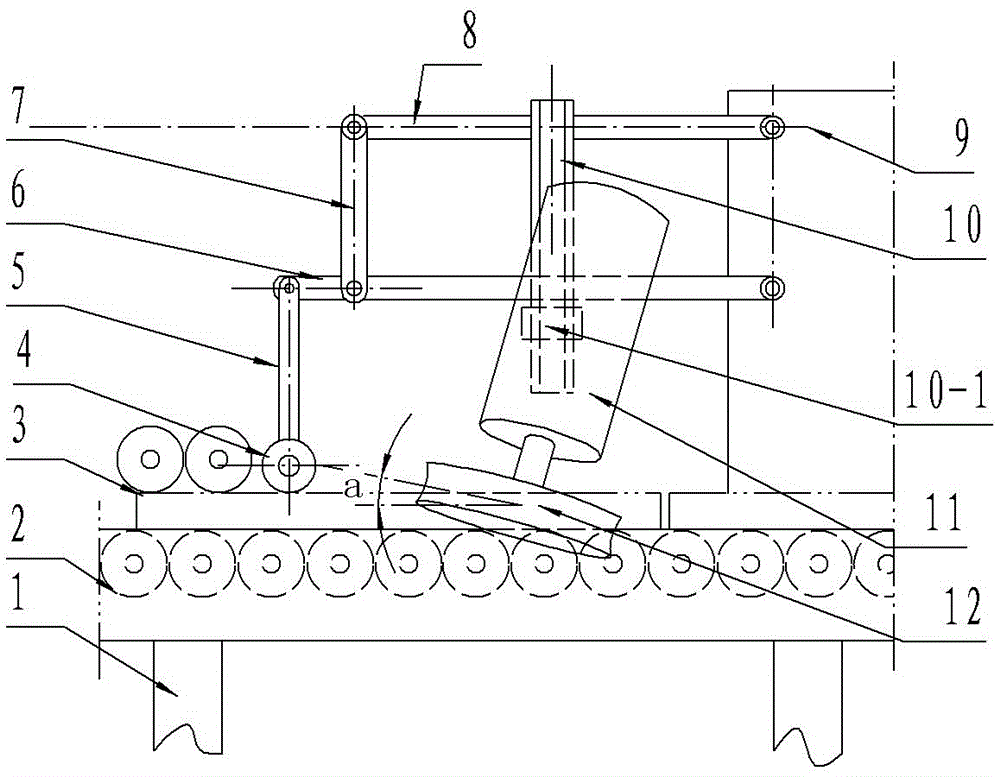

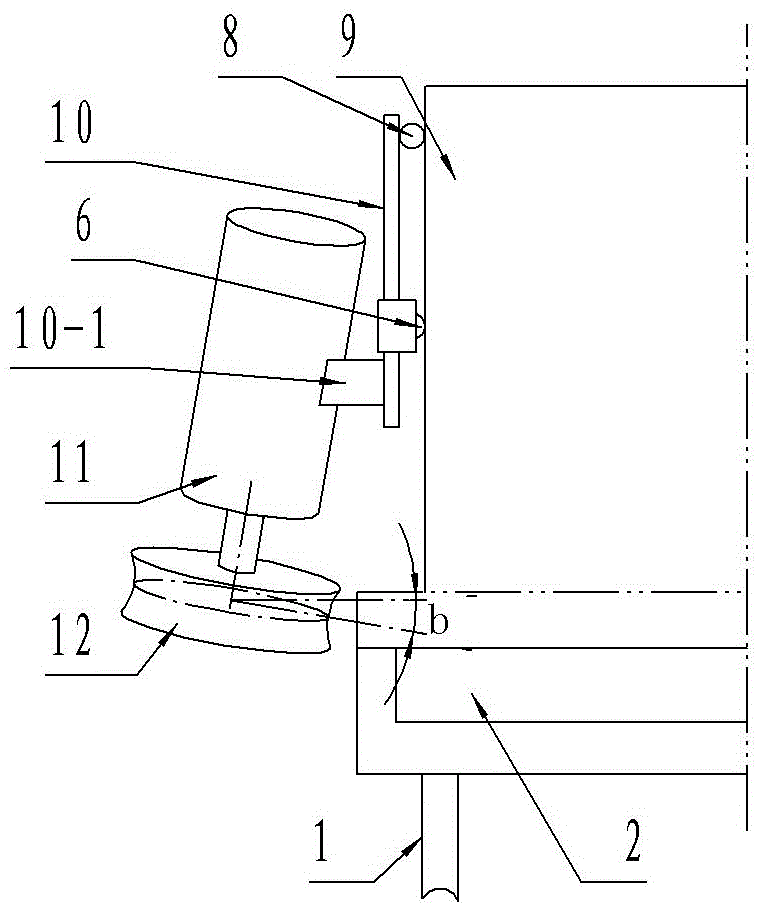

[0014] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

[0015] Such as figure 1 , figure 2 The edging follow-up device of the edging machine shown includes a conveying channel 2 with a bracket 1, and an edging grinding wheel 12 is arranged on one side of the conveying channel 2, and the center plane of rotation of the edging grinding wheel 12 is connected to the conveying channel 2. The plane forms an included angle a, a=15°, the edging grinding wheel 12 is inclined downward at the part close to the conveying channel, the inclination angle b=1°, the edging grinding wheel 12 is installed on the power output shaft of the motor 11, the edging grinding wheel 12 It forms an edging machine with the motor 11. When the edging wheel 12 grinds the edge of the slate, during the movement of the conveying channel 2, there is an angle between the edging wheel 12 and the moving direction of the slate 3, so that the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com