Full-automatic spoon edge grinding machine

An edging machine, fully automatic technology, applied in the direction of machine tools suitable for grinding workpiece edges, parts of grinding machine tools, grinding machines, etc., can solve the problems of increasing the risk of operators, poor quality of spoon edging, and spoon edging quality impact and other issues, to reduce the impact of spoon edging, reduce the burden, and ensure the effect of edging quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

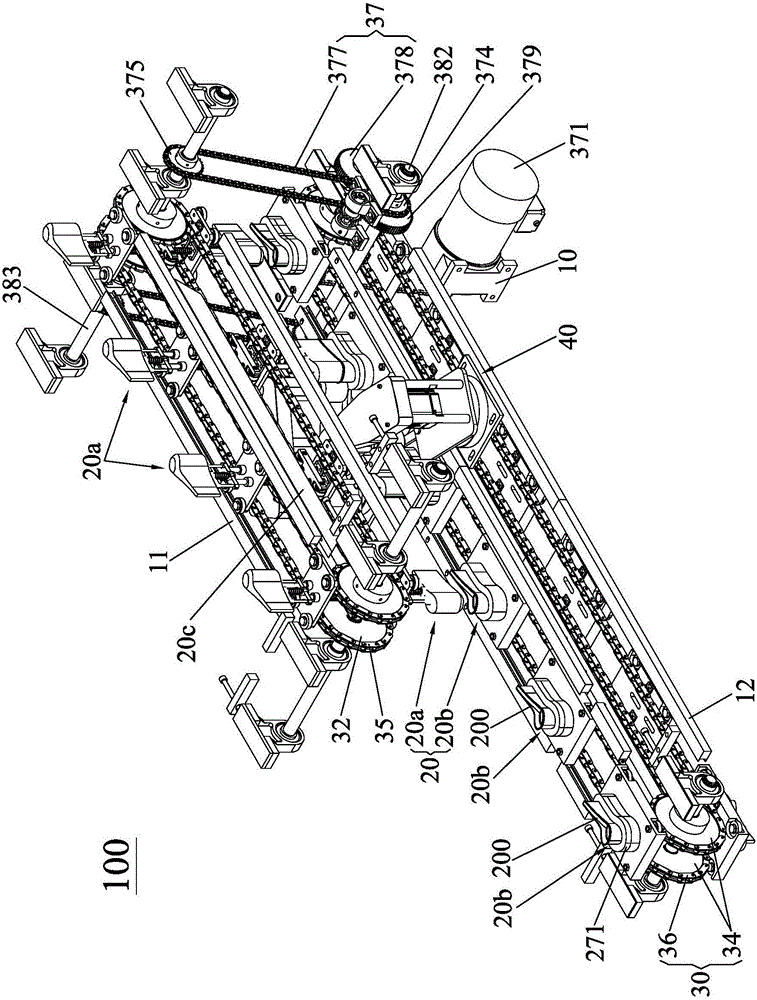

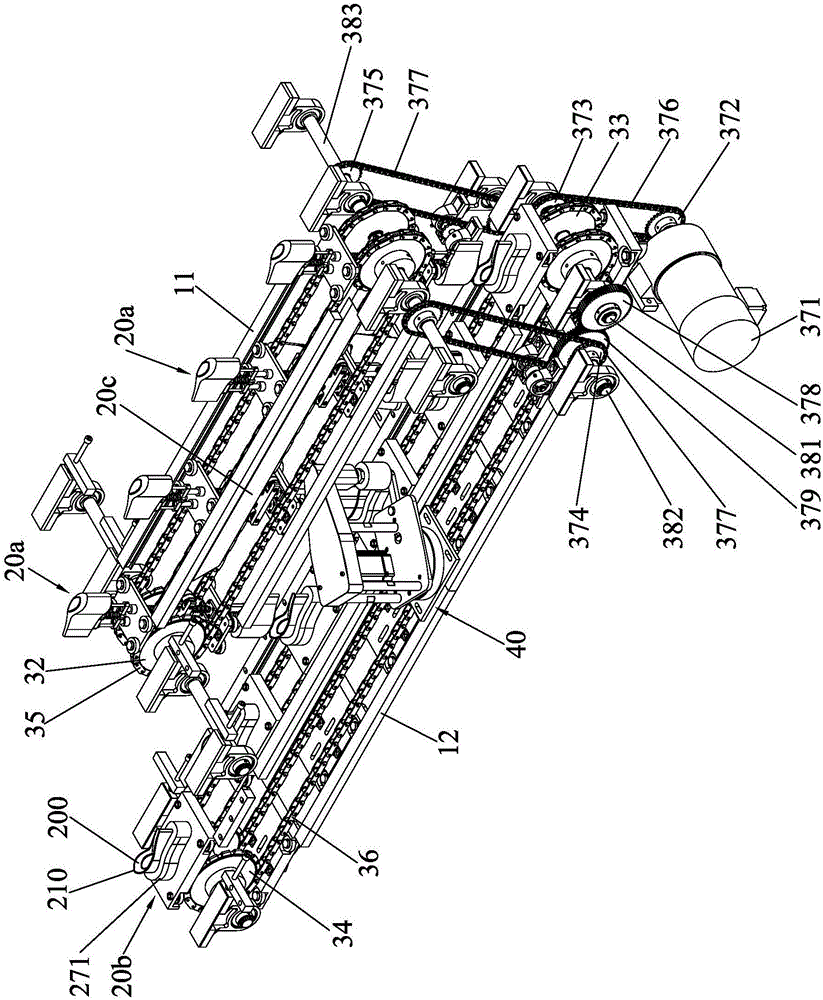

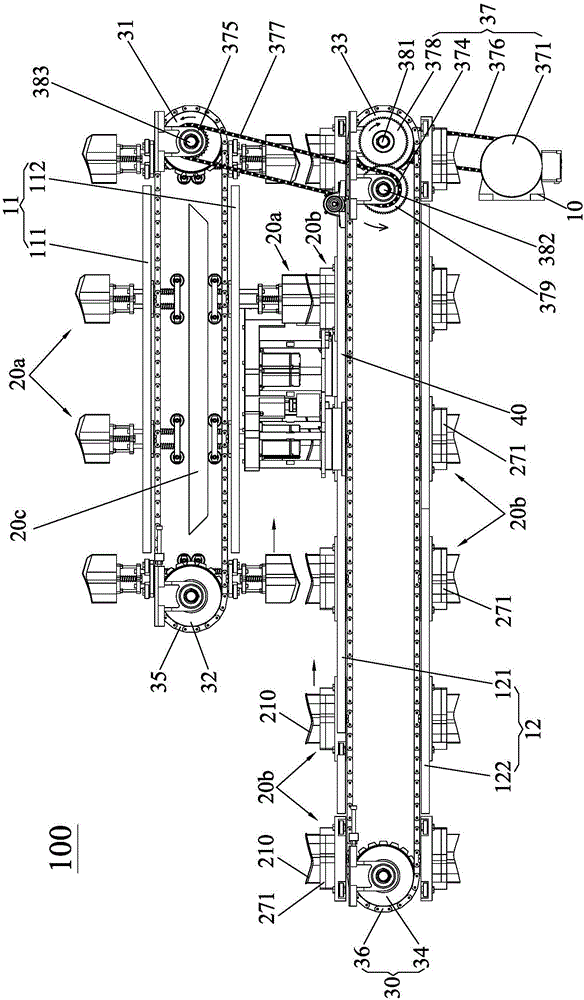

[0031] In order to describe the technical content and structural features of the present invention in detail, further description will be given below in conjunction with the implementation and accompanying drawings.

[0032] see Figure 1 to Figure 3 , the automatic spoon edging machine 100 of the present invention is used for edging the edge 210 of the spoon 200, so that the edge 210 of the spoon 200 is smoothed to form a product that is put on the market. Wherein, the automatic spoon edging machine 100 of the present invention includes a frame 10 , a clamping device 20 , a driving device 30 and a grinding device 40 . The frame 10 is provided with an upper guide rail 11 and a lower guide rail 12 which are parallel to each other and spaced apart along the up and down direction of the frame 10; specifically, as figure 1 or image 3 As shown, the upper guide rail 11 and the lower guide rail 12 are vertically arranged and parallel to each other, and the two are separated by a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com