Efficient dezincification edge grinding machine

A kind of edging machine, high-efficiency technology, applied in the direction of grinding frame, machine tool suitable for grinding workpiece edge, grinding machine, etc., can solve the problems of high labor intensity, galvanized sheet damage, long processing time, etc., and achieve edging Good effect, low labor intensity and high edging efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments.

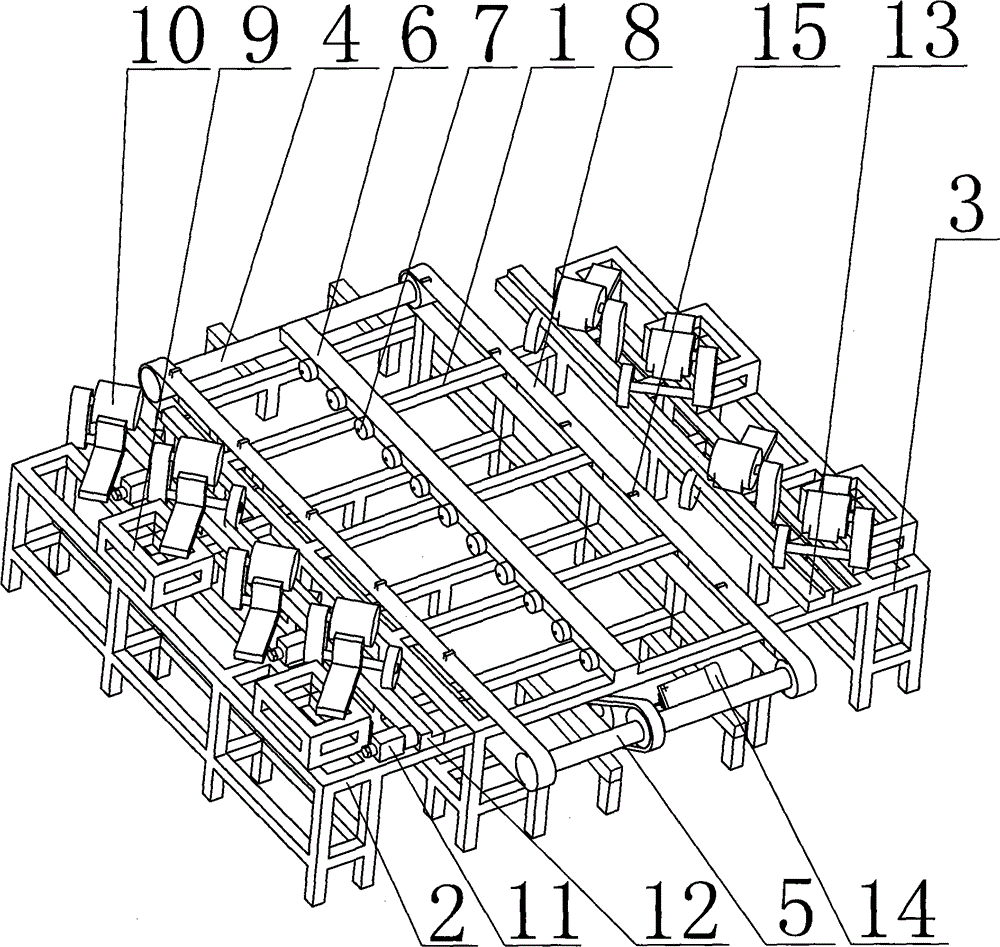

[0012] Such as figure 1 As shown, the present invention discloses a high-efficiency dezincification edging machine, including a frame one 1, a frame two 2, a frame three 3, a rotating shaft 4, a rotating shaft 2 5, a support rod 6, a pulley 7, and a transmission chain 8. Pad block 9, angle grinder 10, adjusting screw 11, edging guide rod one 12, edging guide rod two 13 and motor 14, frame two 2 and frame three 3 are respectively fixed on frame one 1 On the left and right sides of the frame one 1, the front and rear ends of the frame one 1 are parallelly fixed with the first rotating shaft 4 and the second rotating shaft 5, and the middle position is fixed with a support rod 6, and the supporting rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com