Dry-wet type edge grinding wheel and manufacturing method thereof

A kind of edging wheel, dry and wet technology, applied in the direction of abrasive materials, grinding devices, manufacturing tools, etc., can solve the problems of environmental protection, cost saving, poor grinding performance of edging wheel, short practical life, etc., and achieve improvement Grinding wheel sharpness, high edging efficiency, and the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

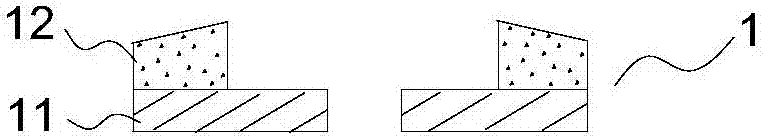

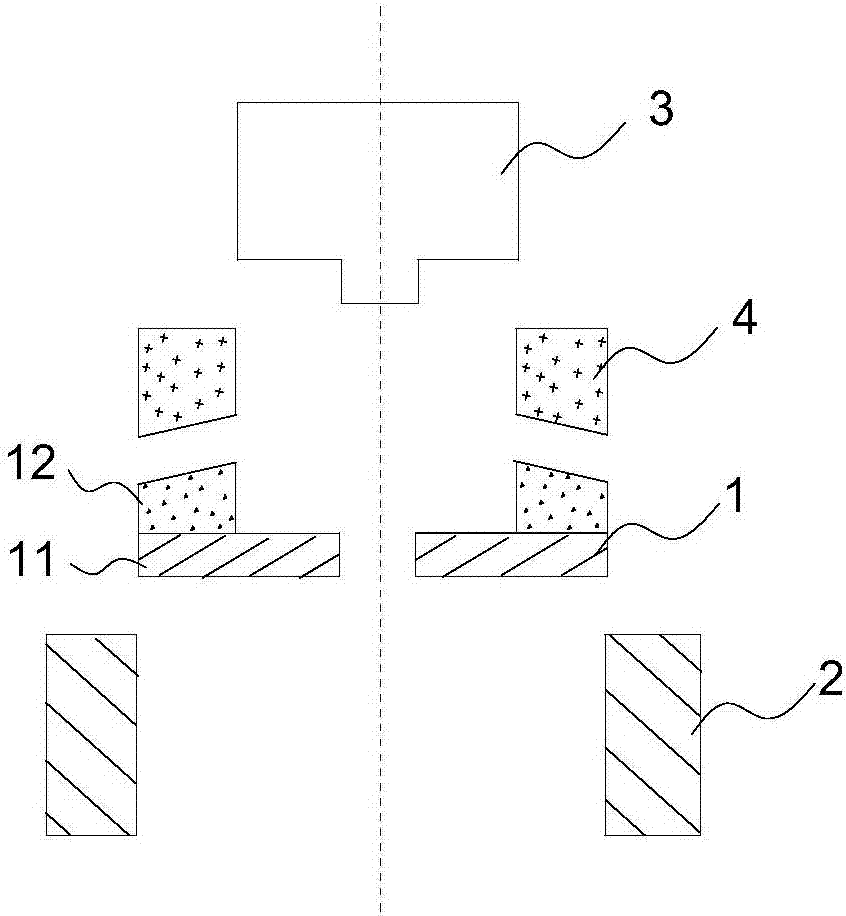

[0039] Such as figure 1 As shown, a dry-wet type edging wheel 1 includes a base body 11 and a grinding block 12 fixedly connected to one side of the base body, and the grinding block is formed by pressing the following powders by weight: 100 parts of diamond, 40 parts of silicon carbide, 800 parts of iron powder, 500 parts of copper powder, 120 parts of mixed alloy powder for improving sharpness. The mixed alloy powder is composed of the following components: 60 grams of boron carbide, 50 grams of silicon powder, and 10 grams of graphene.

Embodiment 2

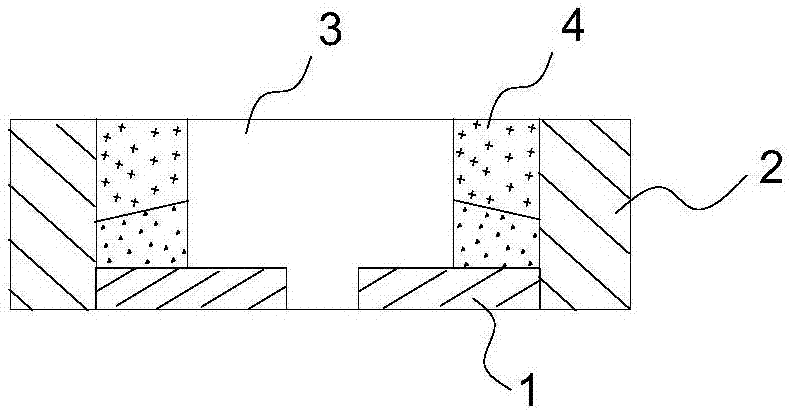

[0041] A dry-wet edging wheel, comprising a base 1 and a grinding block 2 fixedly connected to one side of the base, the grinding block is formed by pressing the following powder by weight: 100 parts of diamond, 20 parts of silicon carbide , 600 parts of iron powder, 400 parts of copper powder, 100 parts of mixed alloy powder for improving sharpness. The mixed alloy powder is composed of the following components: 60 grams of boron carbide, 50 grams of silicon powder, and 10 grams of graphene.

Embodiment 3

[0043] A dry-wet type edging wheel, comprising a base body and a grinding block fixedly connected to one side of the base body, the grinding block is formed by pressing the following powder materials in parts by weight: 100 parts of diamond, 60 parts of silicon carbide, iron 1000 parts of copper powder, 600 parts of copper powder, 140 parts of mixed alloy powder for improving sharpness.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com