Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

146results about How to "Improve bleaching efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing alkyl glycoside

InactiveCN1775790ALight colorMild reaction conditionsSugar derivativesOrganic-compounds/hydrides/coordination-complexes catalystsReaction temperaturePotassium

The invention discloses a new method for preparing alkyl indicant, technically characterized in making ultramicro pulverization processing on anhydrous glucose or crystal water containing glucose, then reacting with C8-C20 high grade alcohol under the existence of organic sulphonic acid catalyst, vacuum dehydrating and obtaining alcohol solution of alkyl indicant, then neutralizing acdic catalyst with organic acid sodium or potassium salt, vacuum distilling to eliminate excessive high grade alcohol, using chelating agent or sodium silicate to screen Fe ions, Mn ions and other ions, using tetraacetyl ethylene diamine as oxydol activating agent, bleaching alkyl indicant solution, and finally using hydrogen peroxide enzyme to eliminate the residual hydrogen peroxide from the products. The advantages of the invention: the reaction temperature is low and the reacting time is short, the process is simple and convenient, the production cost is low, and the prepared alkyl indicant is colorless or approximately colorless, transparent, peculiar smell-free, and stable to store.

Owner:NORTHWEST UNIV(CN)

Zero residual base normal-pressure or low-pressure boiling high-concentration pulp preparing method by using base process

InactiveCN101215794ARapid responseNo residual alkaliDigestersNon-macromolecular organic additionHigh concentrationSodium metasilicate

The invention relates to a method for boiling high concentration pulping in normal pressure or low pressure by an alkaline method with zero residual alkaline, and the method comprises adding accelerating agent in the boiling process and utilizing a double screw to rub and squeeze a pulper, leading pulp making and boiling process with an alkaline method to go on in normal pressure or low pressure, and leaving no residual alkaline in black liquor, leading pulp to always keep a higher density in the pulping process of boiling, washing and bleaching, and the pulp which is prepared can meets the requirement of paper making. Accelerating agent chooses one or a plurality of magnesium hydrate, potassium hydrate, sodium metasilicate, sodium sulfide, sodium sulfite, ammonium sulfite and carbamide. Special-purpose pulping boiling equipment and high-pressure boilers are not needed by pulping paper mills through utilizing the invention, in the process of pulping, pulp always keeps higher density, and black liquid has high density, little numbers and low energy consumption, alkaline recovery project with great investment is not needed to be built, and the invention enables black liquid to prepare fertilizer or other chemical products with high quality, and the invention is suitable for popularizing and applying.

Owner:晏永祥

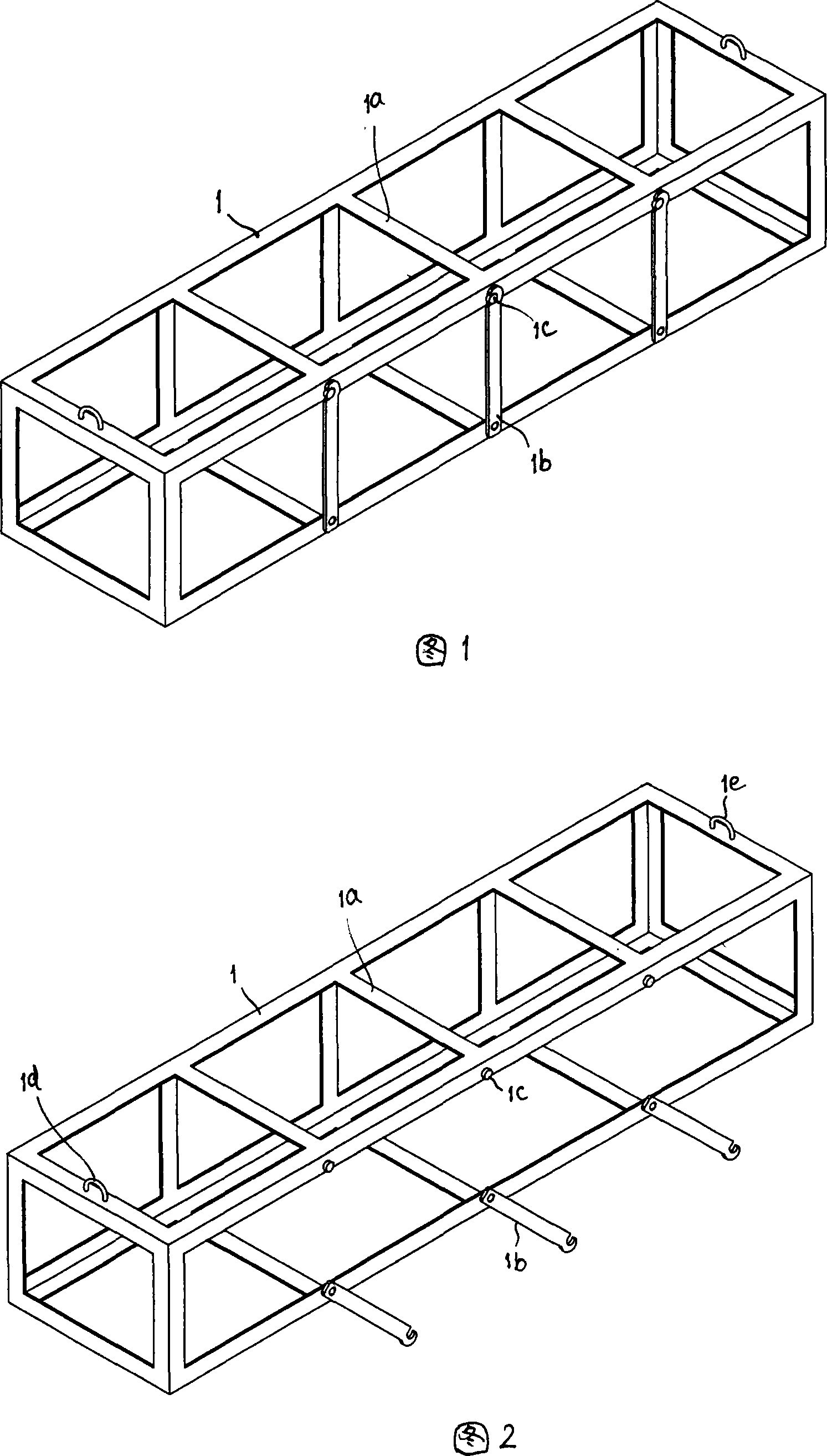

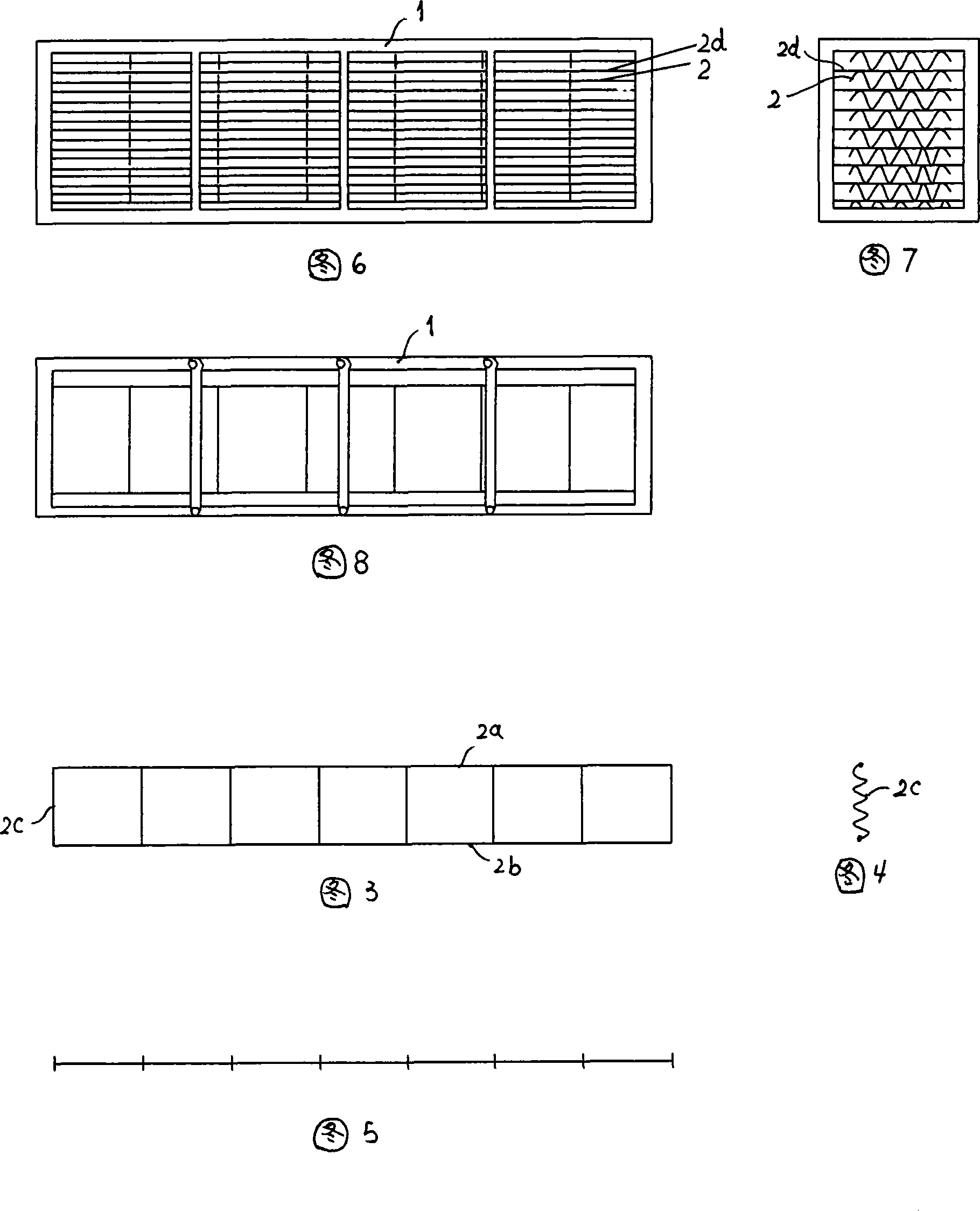

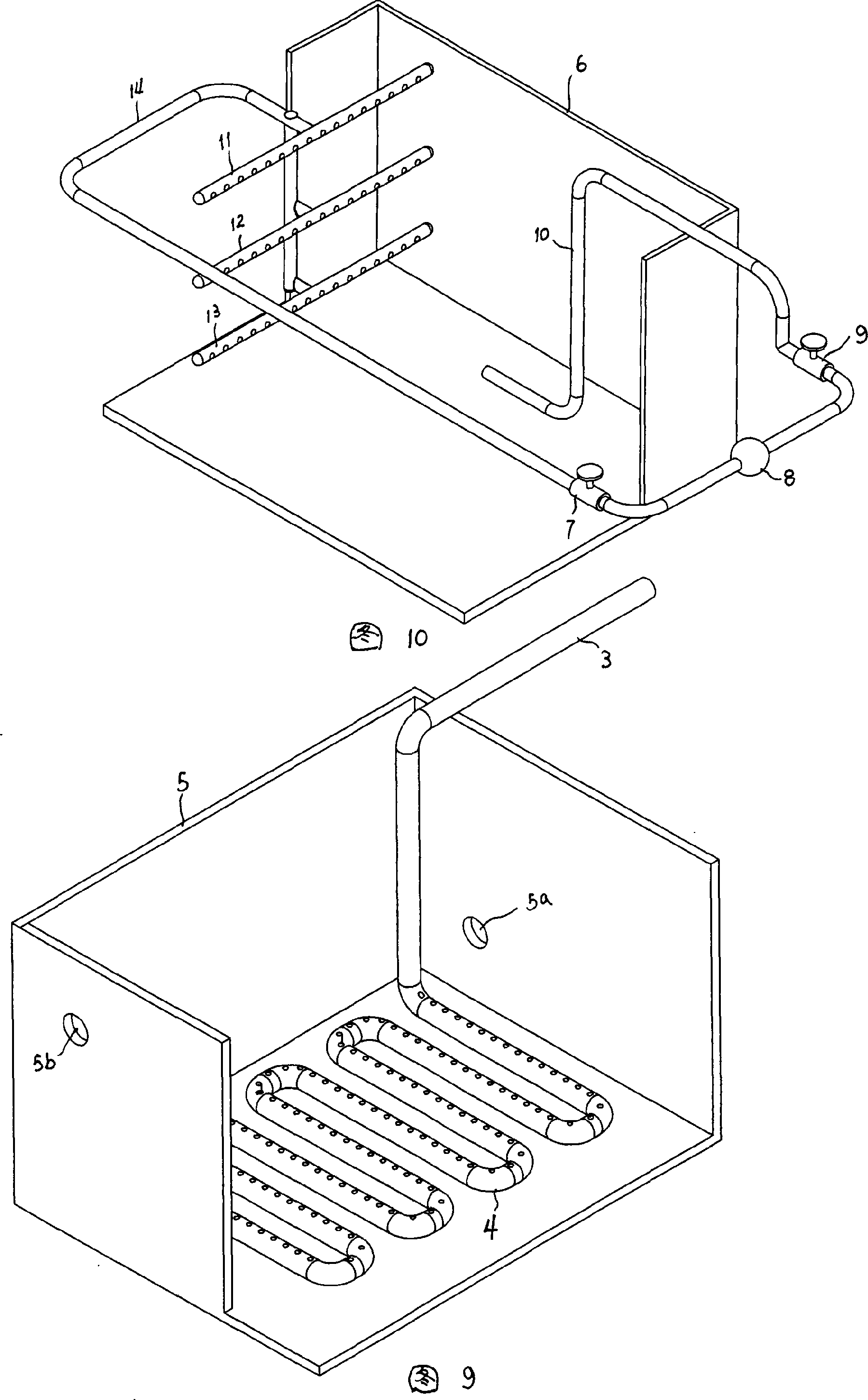

Wood surface bleaching technology and its special-purpose apparatus

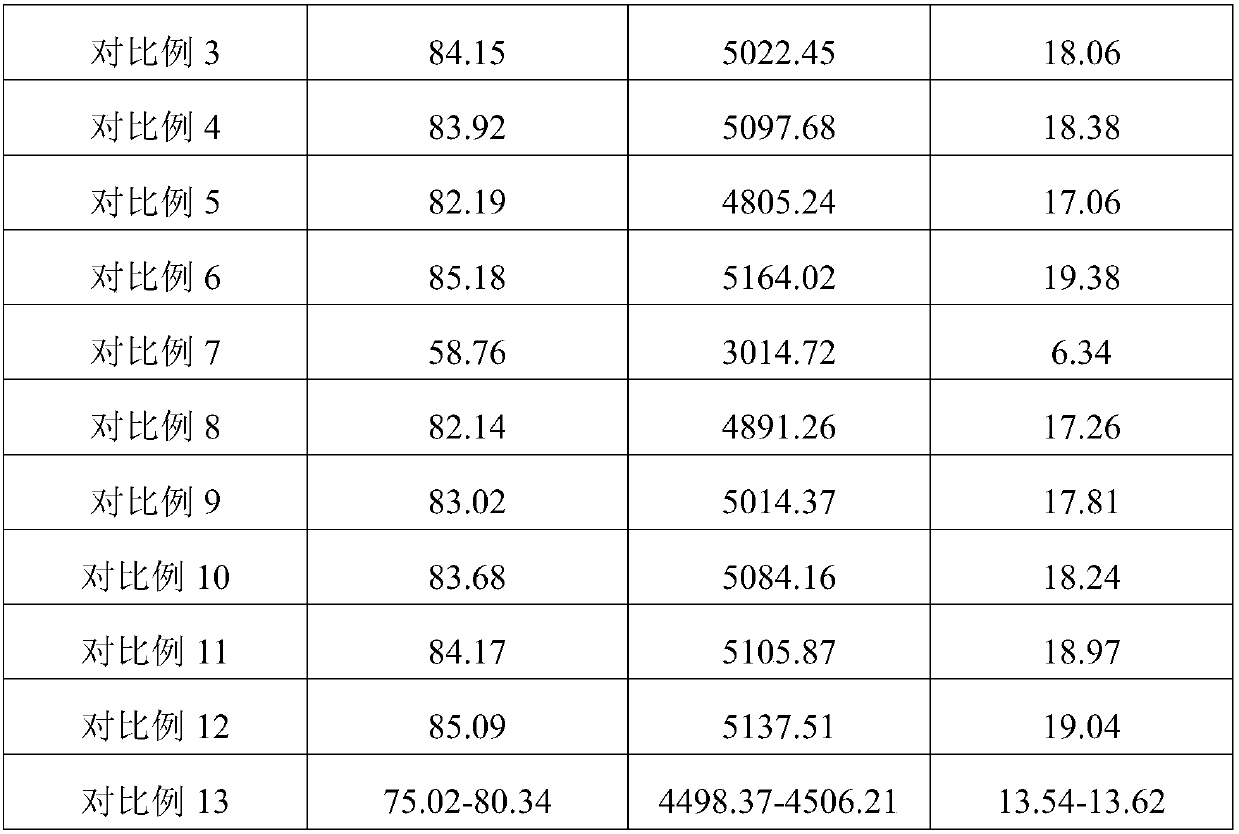

InactiveCN101121278AReduce bleaching effectImprove bleaching efficiencyWood treatment detailsOXALIC ACID DIHYDRATEOxalate

A bark bleaching process; the steps are as follows that hydrogen peroxide, sodium hydroxide, sodium silicate and magnesium chloride are taken in I bleacher according to a certain proportion to make bleaching liquid: the bark is encased in a bark bleaching frame and the frame is soaked in the bleacher; a pump is adopted to continuously circulate the bleaching liquid in the bleacher; at the same time, steam is input for heating the bleaching liquid and the temperature is kept constant between 60 to 70 Celsius degrees; the constant temperature is kept for 4 to 6 hours; the bark bleaching frame is taken out of the in I bleacher and put into II bleacher filled with oxalic acid solution; a liquid compulsory circulation device is used to make the liquid in the bleacher continuously circulate; the bark bleaching frame is taken out after the frame is soaked for continuous 30 minutes; the bleaching frame is washed with pressed clean water and the drying treatment is implemented at last. The present invention also discloses a special bark bleaching frame and snakelike parting strip for angle steel welding. The present invention boasts of low investment on equipment, high production efficiency and excellent bleaching effect.

Owner:CHENGDU CANYA WOOD IND

Poplar ultrasonic chemical mechanical pulping technique

ActiveCN106120418ALarge specific surface areaHigh bonding strengthPulping with organic compoundsMultistage pulping processChemistryPre treatment

The invention relates to a poplar ultrasonic chemical mechanical pulping technique. The pulping technique includes the steps: performing ultrasonic pretreatment on steamed poplar pulp after first stage impressafining; performing xylanase pretreatment on the pulp after the ultrasonic pretreatment; soaking the pulp in soda hydrogen dioxide solution after pretreatment; performing second stage impressafining after soaking; performing second stage soaking on the pulp in the soda hydrogen dioxide solution after the second stage impressafining; performing first stage refining on the pulp with the soaking liquid; performing high concentrated storage and bleaching after the first stage refining; and performing second stage refining to obtain high-brightness high-yield high-strength chemical mechanical pulp. The poplar ultrasonic chemical mechanical pulping technique can improve the mechanical pulping performance of fast-growing poplar, enlarge the application range of poplar high-yield pulp, improve the performance of poplar paper pulp, and improve the use value of the poplar.

Owner:QILU UNIV OF TECH

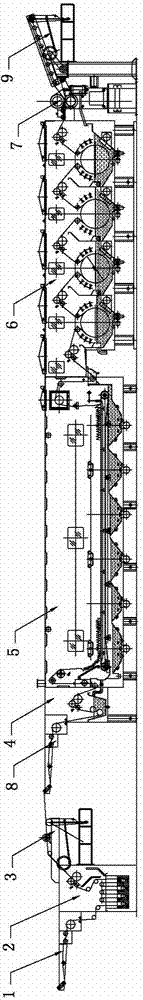

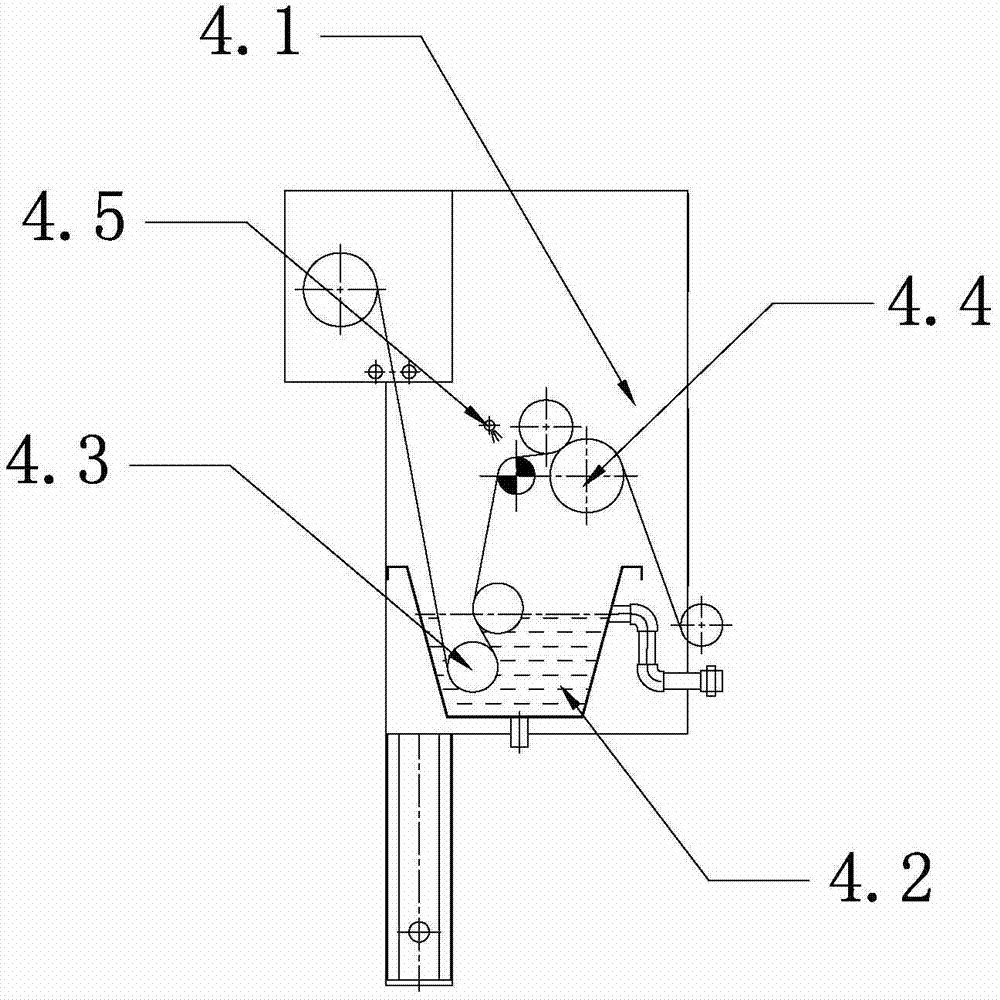

Open-width cotton-knitted cloth refining and bleaching combination machine

ActiveCN103789951AReduce energy consumptionShorten bleaching timeTextile storage in superimposed formSucessive textile treatmentsPulp and paper industryEnergy consumption

The invention relates to an open-width cotton-knitted cloth refining and bleaching combination machine. The open-width cotton-knitted cloth refining and bleaching combination machine is characterized by comprising a cold heap processing cloth feeding frame, a cold heap processor, a cold heap processing cloth discharging frame, a dipping mill, a steamer, a four-wheeled drum washing machine, a mangle device, a post-processing cloth feeding frame and a post-processing cloth discharging frame. The cold heap processing cloth feeding frame is arranged in front of the cold heap processor. The cold heap processing cloth discharging frame is connected behind the cold heap processor. The post-processing cloth feeding frame is connected behind the cold heap processing cloth discharging frame. The dipping mill, the steamer, the four-wheeled drum washing machine, the mangle device and the post-processing cloth discharging frame are sequentially connected behind the post-processing cloth feeding frame. The open-width cotton-knitted cloth refining and bleaching combination machine has the advantages of being capable of lowering energy consumption, shortening bleaching time and improving bleaching efficiency.

Owner:JIANGYIN FUDA DYEING & FINISHING UNITED MACHINERYCO

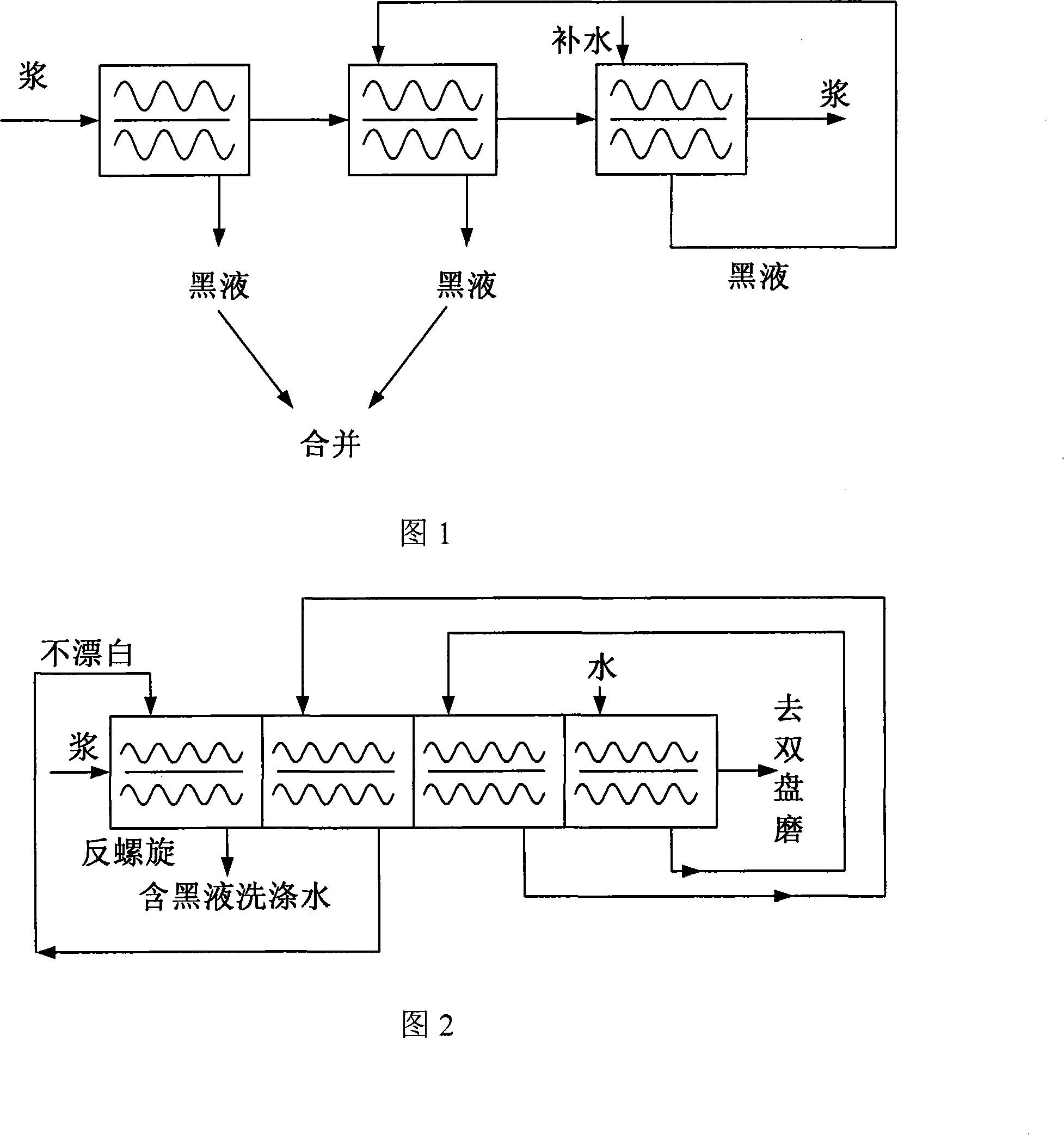

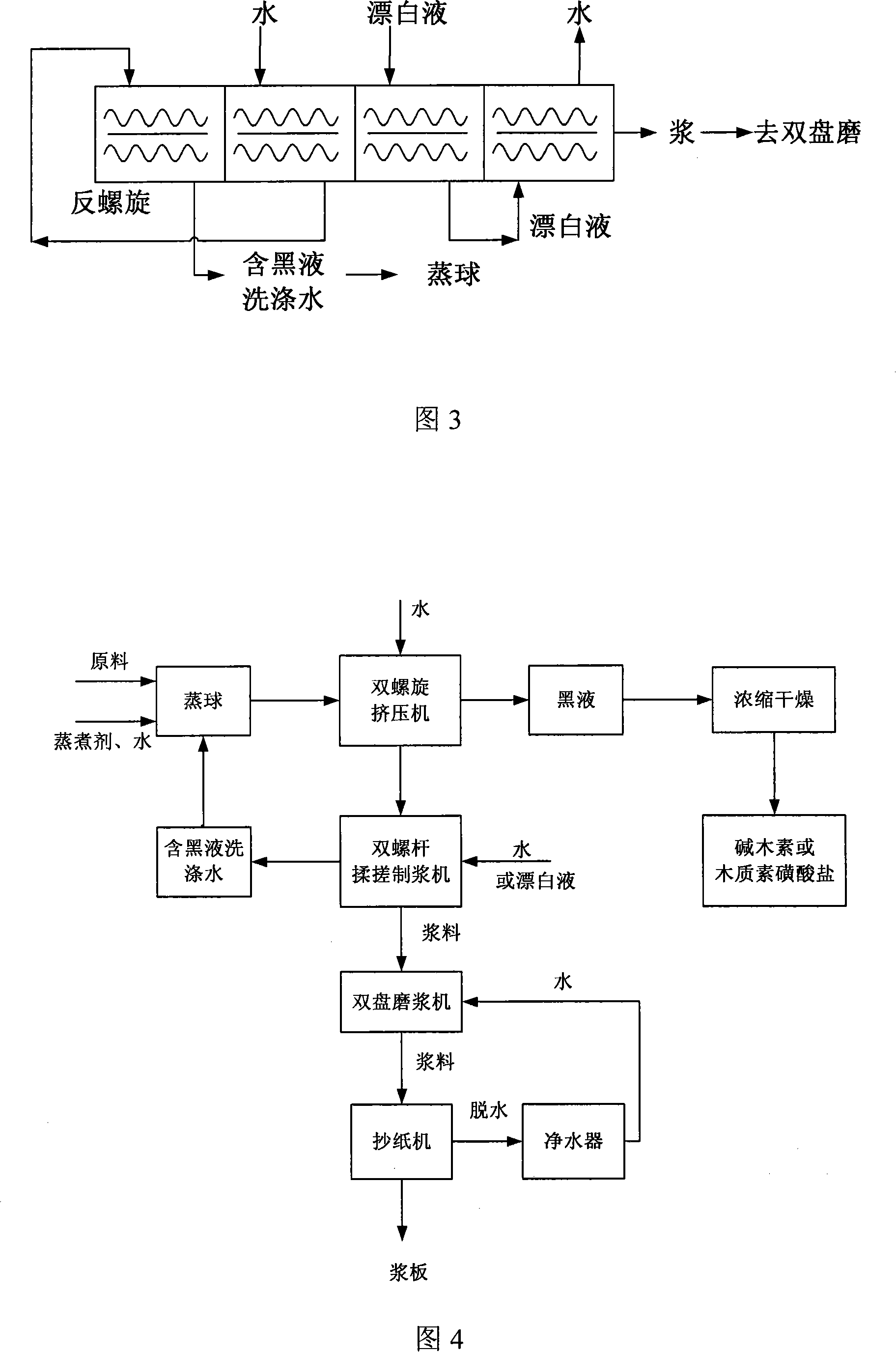

Pulping method with zero discharge of sewage water

InactiveCN101220565AHigh extraction rateLess investmentPulp liquor regenerationWashing/displacing pulp-treating liquorsPolyesterBlack liquor

The invention discloses a pulp making method for discharging sewage thoroughly which includes the following steps: pulping material, steam cooking agent and catalyst are mixed evenly and put into a spherical digester and the mixture is cooked by steam; the cooked material is squeezed by passing through a plurality of twin-screw extruders connected in series so as to extract black liquid and obtain the pulp material, and the black liquid obtained from the last twin-screw extruder is squeezed sequentially after returning to the former twin-screw extruder, while the black liquid obtained from a first and a second twin-screw extruders is merged straightly, and the merged black liquid is concentrated and dried to obtain alkali lignin and or lignosulfonate; the pulp material is delivered into a twin-screw rubbing and kneading pulper, the polyester washing is carried out in multiple-section series while the pulp is grinded, or the polyester washing is carried out in multiple-section series and bleached in multiple-section series, the washing water is returned to the washing process in the former section, and finally the residuary black liquid is obtained, that is the washing water coming from the first washing process; then, the residuary black liquid is returned to the pulping material or the spherical digester; the pulp material is refined in a dual-disk refining machine by adding water, then a pulp plate is made after the refined pulp material enters a paper machine. Meanwhile, the removed water circulates to the dual-disk refining machine or other processes needing the water by the pure water treatment.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Method for bleaching cashmere loose fiber

Owner:NINGXIA RONGCHANG CASHMERE IND GROUP

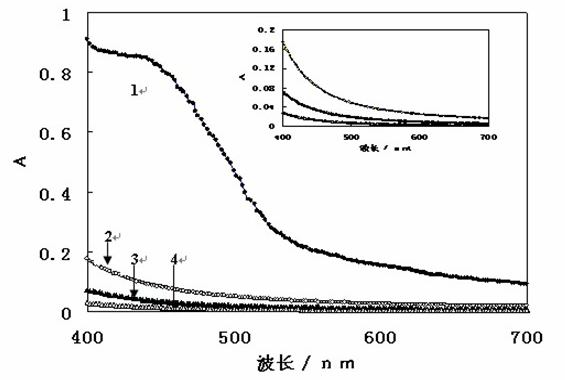

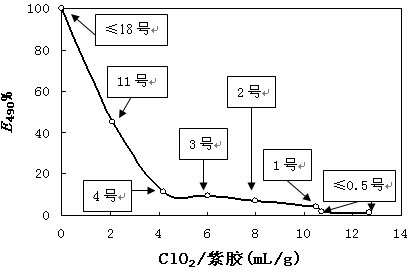

Method for beaching shellac using chlorine dioxide and alcohol solvent, and application thereof

InactiveCN102408832AImprove stabilityImprove bleaching efficiencyCosmetic preparationsToilet preparationsSolventEthanol

The invention discloses a method for beaching shellac using chlorine dioxide and an alcohol solvent. The method comprises the following steps of: dissolving shellac using the alcohol solvent into solution, adding chlorine dioxide to the solution under the condition of constant temperature and stirring the solution for bleaching for certain time, thereby obtaining bleached shellac solution; adding dilute sulphuric acid to the bleached shellac solution so that the bleached shellac is separated out, and then repeatedly washing the bleached shellac until the pH of washing water is neutral; and drying the shellac at the room temperature, thus obtaining the bleached shellac, wherein the absorbance of the ethanol solution in the position of 490 nm can be reduced to 1.6% of the raw material shellac, while the color index thereof can be reduced to be less than 0.5#; and other technical indexes are capable of meeting the requirements of the refined bleached shellac level I. The method is characterized in that: bleaching conditions are mild; a non-alkaline condition is adopted; the bleaching temperature is low; the dosage of an acidic precipitator is low; the color index of the obtained bleached shellac is low; and accurate control and regulation can be performed by adjusting the dosage of the chlorine dioxide, etc; therefore, the application of the bleached shellac in special fields can be extended.

Owner:KUNMING UNIV OF SCI & TECH

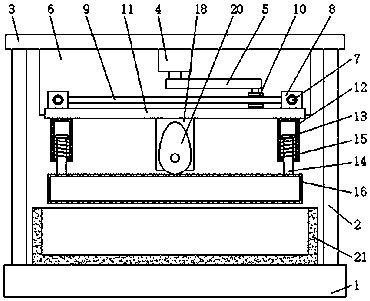

Linen fiber bleaching device for textile production

InactiveCN111826839AImprove bleaching efficiencyReduce lossTextile treatment machine arrangementsTextile treatment carriersFlax fibrePulp and paper industry

The invention discloses a linen fiber bleaching device for textile production and relates to the technical field of textile production. In order to solve the problem that the bleaching time is difficult to control and linen fibers are easy to damage when the linen fibers are soaked in a solution to be stirred, the linen fiber bleaching device specifically comprises a shell, a plurality of supporting frames are fixedly installed at the bottom of the shell, driving mechanisms are fixedly installed on the two sides of the top of the shell, a capping mechanism is fixedly installed between the topends of the two driving mechanisms, and bleaching sections extending downwards are arranged in the middle sections of the driving mechanisms. According to the linen fiber bleaching device for textileproduction, a bleaching solution is in contact with a heating mechanism when being sprayed out; the linen fibers are heated and cooked; the linen fiber bleaching efficiency is improved; the linen fibers are drained; a bleaching solution is recycled; the loss of the solution is reduced; the situation that the working environment is affected due to solution dripping is avoided; raw materials can becontinuously bleached due to the fact that the raw materials enter from one end and exit from the other end, and the linen fiber bleaching processing efficiency is improved.

Owner:宣城红妆美人床上用品有限公司

Method for alkaline hydrogen peroxide bleaching of paper pulp

The invention relates to a method for alkaline hydrogen peroxide bleaching of paper pulp. Chitosan with deacetylation degree bigger than 80% is added in the alkaline hydrogen peroxide bleaching process of high yield pulp or deinked pulp to act as the stabilizer of the hydrogen peroxide, and the dosage of the chitosan is 0.5-5kg per ton pulp; and hydrogen peroxide, sodium hydroxide and sodium silicate are added at the same time of bleaching. By adding chitosan in the alkaline hydrogen peroxide bleaching of the paper pulp, the method can improve the bleaching efficiency of the hydrogen peroxide and the whiteness of the paper pulp.

Owner:山东济清科技服务有限公司

Salix mongolica sulfate pulp bleaching process

The invention relates to a salix mongolica sulfate pulp bleaching process belonging to the technical field of a paper pulp bleaching process. The process comprises the following steps: boiling and washing pulp, and carrying out AU series xylanase pretreatment at 48-50 DEG C under the condition that the pH value is 6.5-7; washing, and carrying out chlorine dioxide bleaching; washing, and carrying out cellulase treatment at 50-55 DEG C under the condition that the pH value is 5.5-6.5; and washing, carrying out hydrogen peroxide bleaching, and washing to obtain high-whiteness high-strength salix mongolica bleaching sulfate pulp. Under the short-time bleaching process conditions, the invention improves the bleaching property of the paper pulp, increases the bleaching yield and strength property of the paper pulp, reduces the consumption of bleaching chemical agent, lessens the environmental pollution, improves the utility value of the fast growing shrub salix mongolica sulfate pulp, and widens the application range of the salix mongolica sulfate pulp, thereby solving the resource and environment problems hampering the development of the paper making industry in China.

Owner:QILU UNIV OF TECH

Method for improving hydrogen peroxide bleaching efficiency of paper pulp

InactiveCN102363929ALow bleaching efficiencyImprove bleaching efficiencyPulp bleachingChemical/chemomechanical pulpEthylene diamineActive agent

The invention discloses a method for improving hydrogen peroxide bleaching efficiency of paper pulp, and belongs to the technical field of pulp preparation and papermaking. According to the method, a urea active agent and a chelating agent are simultaneously added in the alkali hydrogen peroxide bleaching process of chemical mechanical pulp or waste paper ink removed pulp, the consumption of the urea is 2.0 to 20 kilograms per ton of pulp, the consumption of ethylene diamine tetraacetic acid (EDTA) or diethylenetriamine pentaacetic acid (DTPA) serving as the chelating agent is 1 to 10 kilograms per ton of pulp, and hydrogen peroxide, sodium hydroxide and sodium silicate are simultaneously added during bleaching. In the alkali hydrogen peroxide bleaching process of the paper pulp, the urea serving as the active agent is added at the same time of adding the chelating agent, so that the hydrogen peroxide bleaching efficiency can be improved. Compared with a method without adding the urea serving as the active agent during bleaching, the method has the advantages that: the whiteness of the bleached pulp is obviously improved after the urea is added during bleaching, and the physical strength of the bleached pulp is basically as same as that of the pulp when the urea is not added.

Owner:MCC PAPER YINHE

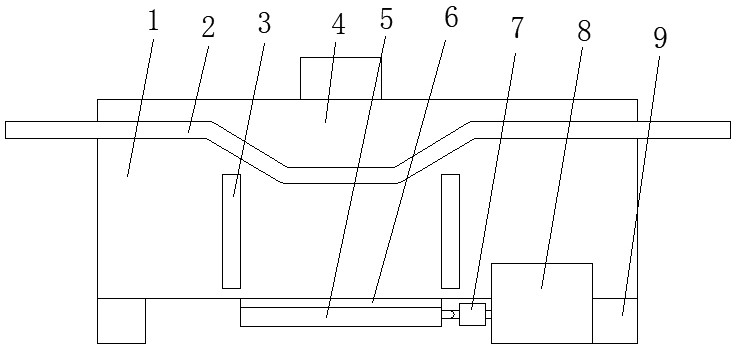

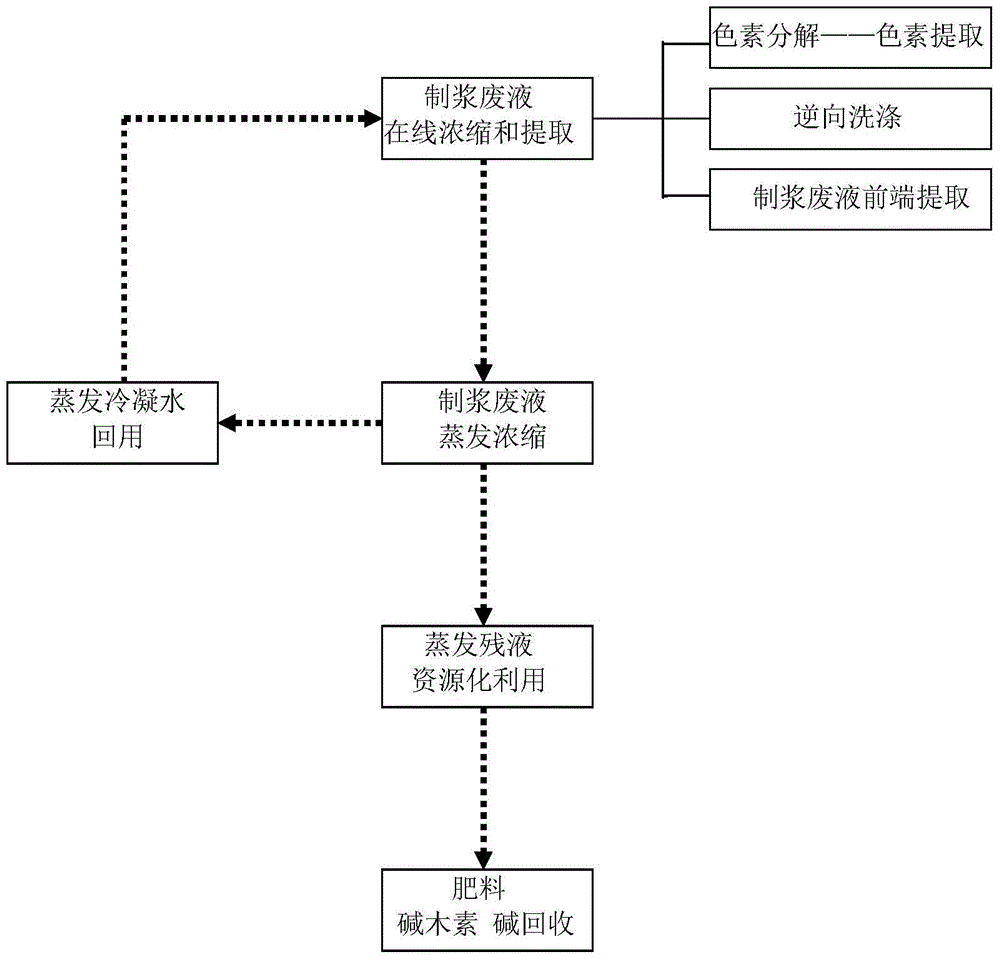

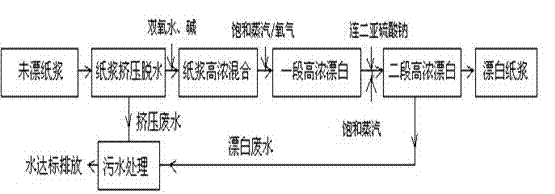

Zero discharge process of pulping waste liquid of all-cotton straw pulp

ActiveCN104928965AImprove bleaching efficiencyReduce pollution loadWashing/displacing pulp-treating liquorsPulp de-wateringHigh concentrationDecomposition

The invention discloses a zero discharge process of pulping waste liquid of all-cotton straw pulp. The process includes firstly performing front-end high concentration extraction of pulping waste liquid, then performing evaporation and concentration of the high concentration pulping waste liquid, recycling evaporation and condensation water, and recycling evaporation residue fluid, so as to realize the zero discharge of the pulping waste liquid finally. The front-end high concentration extraction of the pulping waste liquid includes cotton stalk raw material pigment decomposition, pigment extraction and reverse washing, and front-end extraction.

Owner:白博

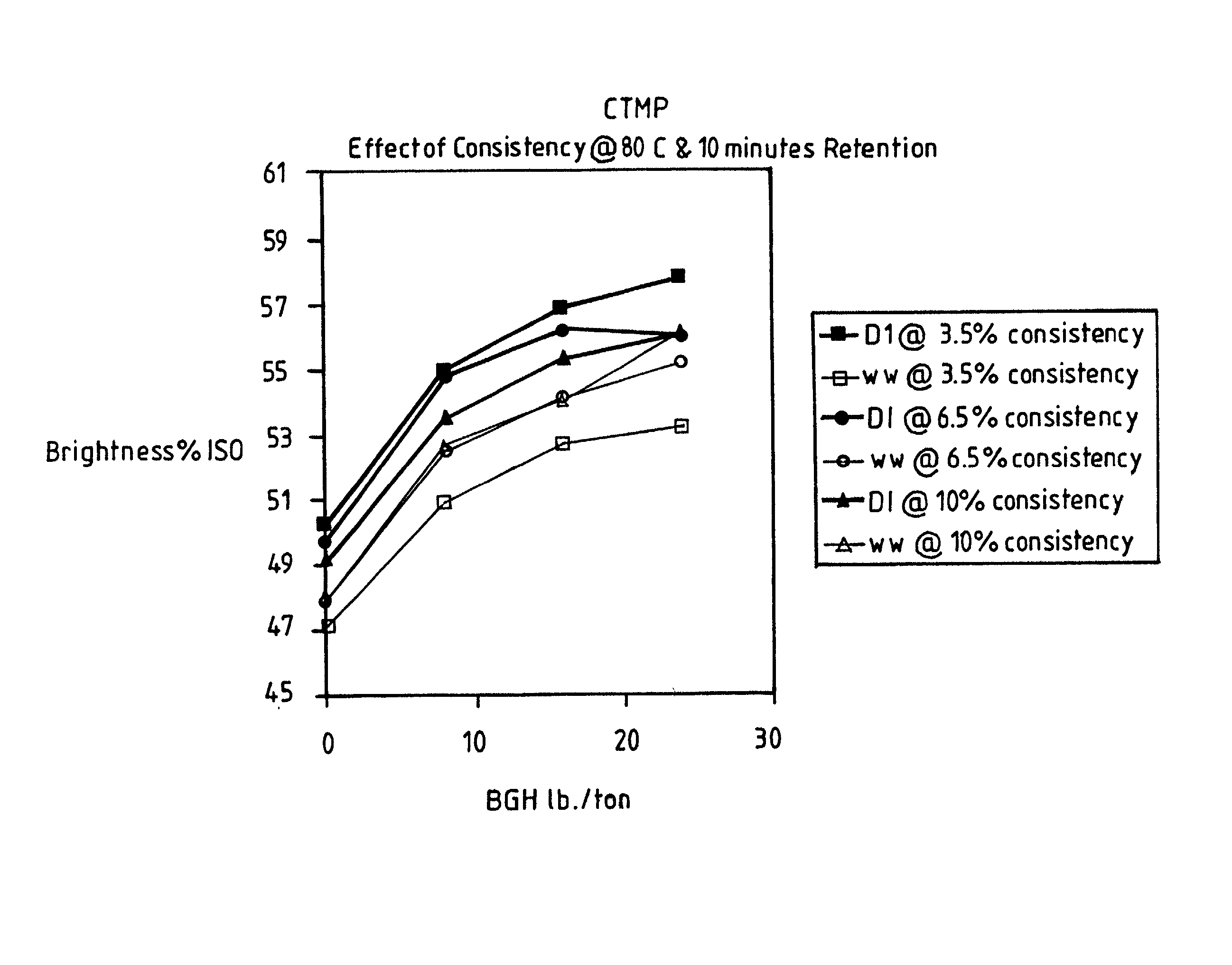

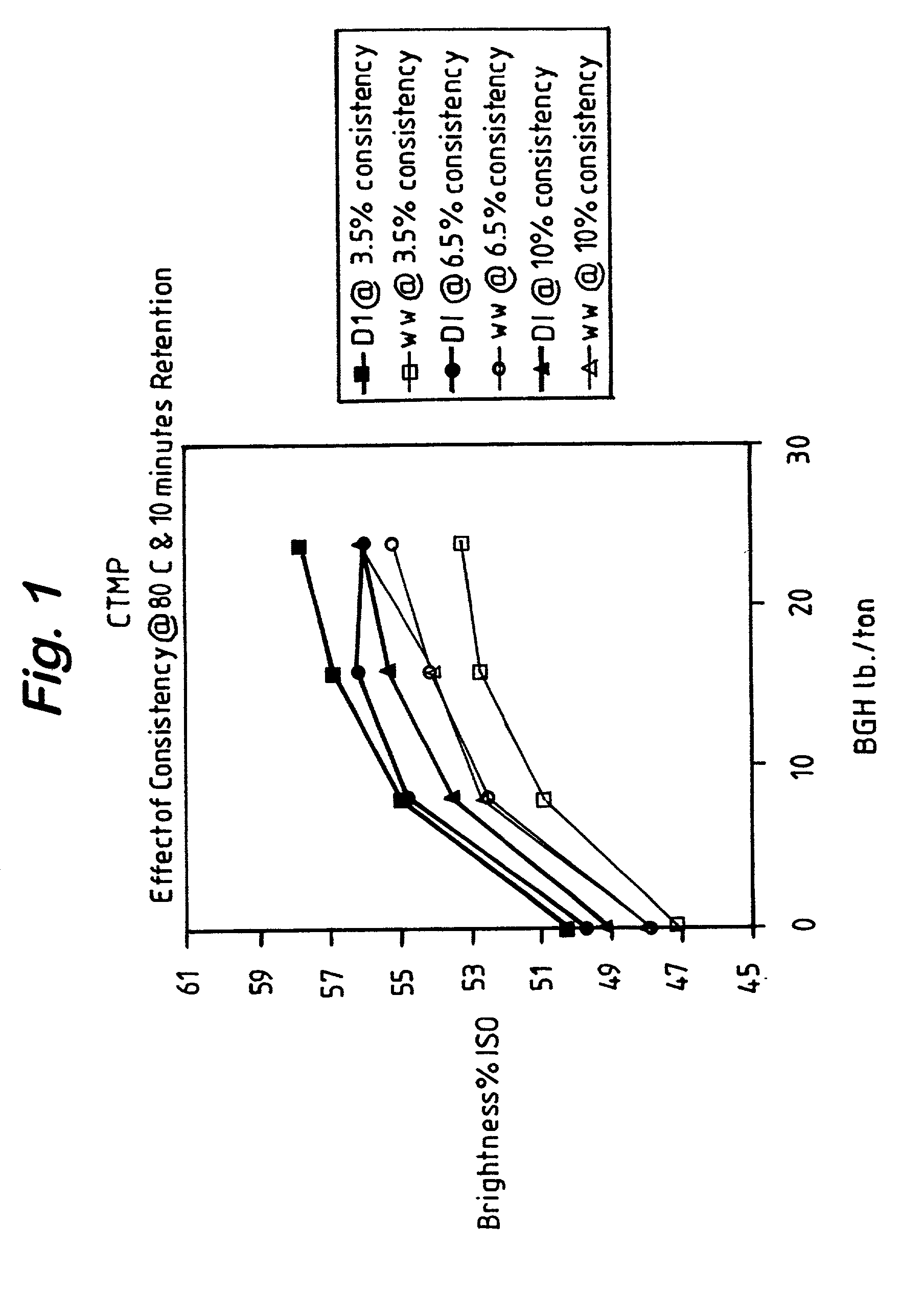

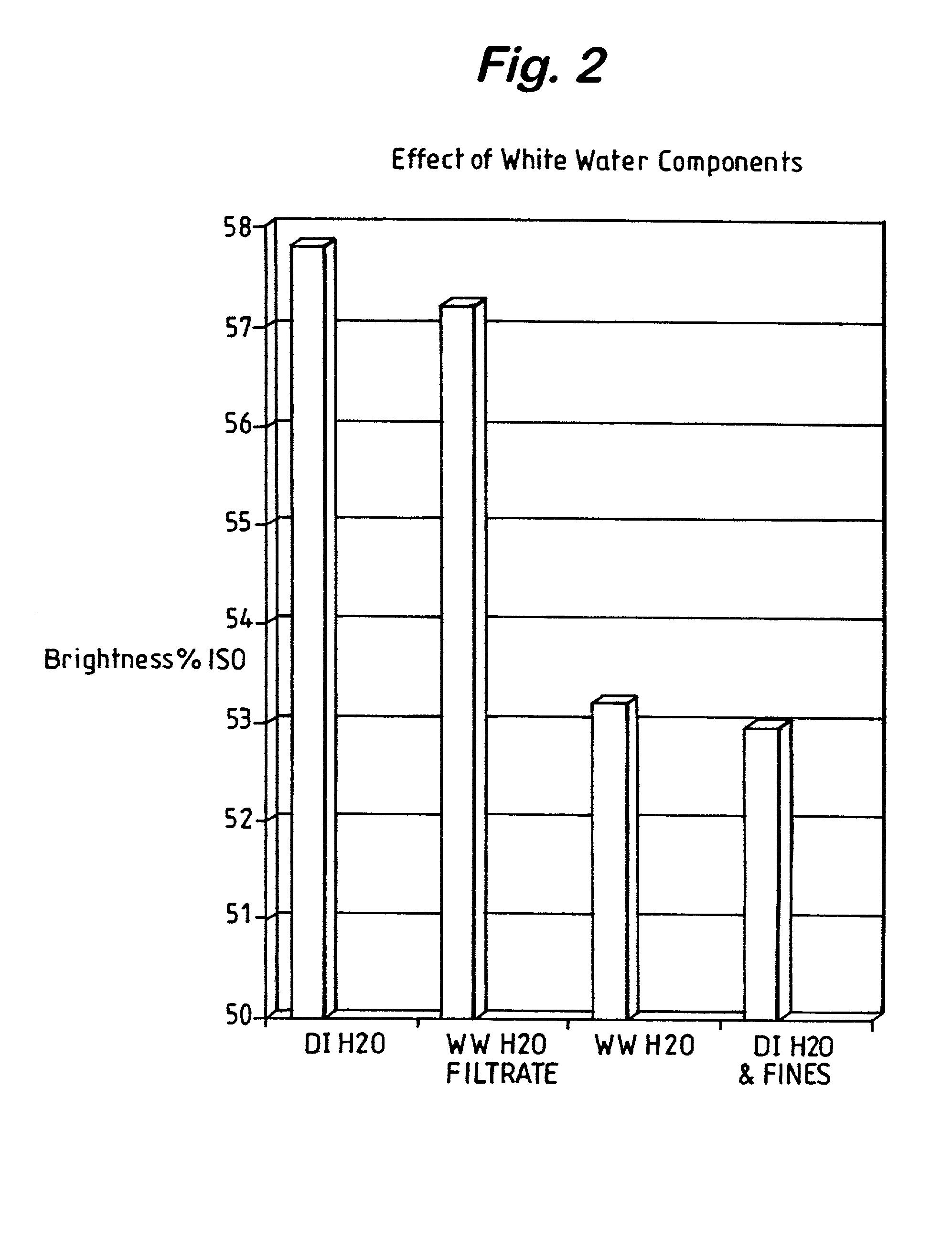

Method for brightening mechanical pulps

InactiveUS20030062138A1Reduce brightnessLow efficiencyPulp bleachingPulping with acid salts/anhydridesChemistryPulp (paper)

The present invention is directed to an improved method for brightening mechanical pulp under neutral or alkaline papermaking conditions. The improvement comprises the steps of: (a) separating neutral or alkaline pulp dilution water into a high-solids stream and a neutral or alkaline low-solids stream; and (b) reusing the neutral or alkaline low-solids stream for pulp dilution purposes prior to a bleaching process.

Owner:HACHE MAURICE JOSEPH ALBERT +1

Paper pulp high density bleaching method

InactiveCN102242514AReduce power consumptionIncrease frictionPulp de-wateringPulp bleachingFiberSodium sulfite

The invention provides a paper pulp high density bleaching method which comprises the following steps: condensing unleached paper pulp after washing and carrying out extruding dehydration on the condensed paper pulp with a double-screw extruder so as to obtain a high density slurry; pumping mixed liquor of hydrogen peroxide and a bleaching auxiliary agent into the high density slurry to obtain a mixture of materials and reagents; inputting the mixture into a high density bleaching warehouse with feeding spirals and carrying out bleaching at elevated temperature and pressure so as to obtain a bleached slurry; directly inputting the bleached slurry into a high density pulping machine with feeding spirals without washing, and adding sodium hydrosulphite into the high density pulping machine with metering screws during the process of feeding so as to obtain a mixture of materials and reagents; inputting the mixture into the high density bleaching warehouse with feeding spirals after the mixture comes out from the high density pulping machine, discharging the mixture after bleaching at elevated temperature and carrying out fiber dispersion and washing to obtain high beating degree bleaching paper pulp. According to the invention, slurries are delivered by spirals and concentration of the delivered slurries is high, which enables energy consumption in delivery to be reduced, heat energy consumption in the chemical reaction of bleaching to be effectively reduced and economic benefits to be increased.

Owner:SOUTH CHINA UNIV OF TECH

Bleaching device for producing textiles

InactiveCN108457024AControl liftEasy to take outLiquid/gas/vapor treatment machines driving mechanismsArchitectural engineeringTextile production

The invention discloses a bleaching device for producing textiles. The bleaching device comprises a base, wherein support pillars are fixed on four sides of the top end of the base; a top plate is fixed at the top ends of the support pillars; a servo motor is mounted at the bottom end of the top plate; a transmission rod is fixed on an output shaft of the servo motor; vertical plates are fixed ontwo sides of the bottom end of the top plate; two groups of guide rods are fixed between the vertical plates and are in sliding connection with movable blocks; a connection rod is fixed between the movable blocks and is in sliding connection with a sliding block; a fixed plate is fixed at the bottom ends of the two groups of movable blocks; sleeve rods are fixed on two sides of the bottom end of the fixed plate; stop blocks are arranged in the sleeve rods; movable rods are fixed at the bottom ends of the stop blocks; the bottom ends of the movable rods extend to the outside of the sleeve rodsand are fixed with storage baskets. The bleaching device is ingenious in design, reasonable in structure, simple to operate and high in flexibility; the labor is reduced; the storage baskets can be conveniently controlled to rise and fall; the bleaching efficiency of the device can be improved; the textiles can be more uniformly bleached; the popularization of the bleaching device is facilitated.

Owner:南陵百绿汇农业科技有限公司

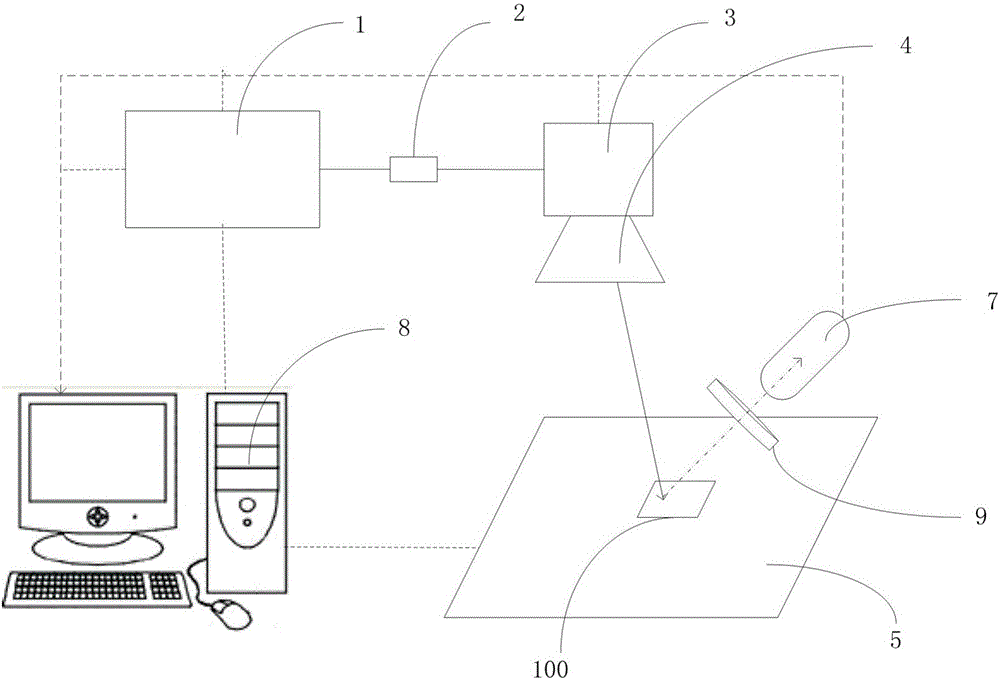

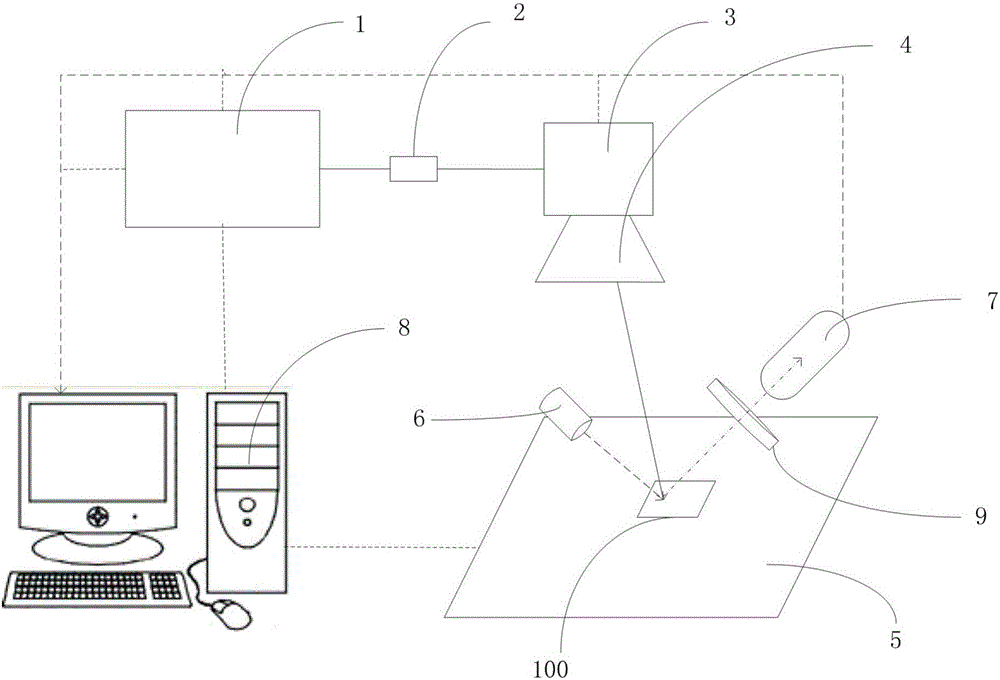

Laser marking and bleaching device and machining method thereof

InactiveCN106064279AMarking improvementImprove bleaching efficiencyLaser beam welding apparatusGalvanometerPersonal computer

The invention discloses a laser marking and bleaching device and a machining method thereof. The device comprises a laser, a beam expanding device, a galvanometer, a lens, a moving platform, a power detection device and an industrial personal computer, wherein the beam expanding device is arranged behind the laser; the galvanometer is arranged behind the beam expanding device; the lens is arranged behind the galvanometer; a workpiece is placed on the moving platform; the power detection device is used for detecting power of emitted light and feeds back measured data to the industrial personal computer; and the industrial personal computer is used for controlling marking and bleaching. Compared with the prior art, the laser marking and bleaching device and the machining method thereof have the beneficial effects as follows: marking and bleaching results are detected in real time and the difference and the trend relation between the marking and bleaching results and target results are analyzed in the marking process through power feedback, then the laser, the galvanometer and the moving platform are adjusted, and the marking and bleaching efficiency is greatly improved through the manner.

Owner:INNO LASER TECH CORP LTD

Method for manufacturing papermaking pulp

InactiveCN102197174AEffective bleaching processHigh yieldPulp bleachingFibrous raw materialsChemistryOzone

The present invention relates to a method for manufacturing papermaking pulp, including: a step of refining wood, including an ozone treatment, so as to obtain a mechanical pulp; a deacidification step including placing the mechanical pulp in contact with a deacidification composition including at least one alkaline agent for more than an hour; and a bleaching step including placing the deacidified pulp in contact with a bleaching composition; wherein the pH varies by less than 0.2 points during the last 30 minutes of the deacidification step, and the pH is 6 to 10 at the end of the deacidification step.

Owner:ARKEMA FRANCE SA +1

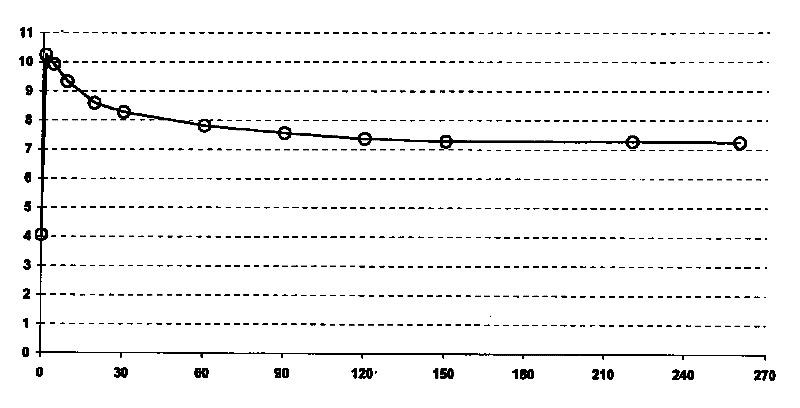

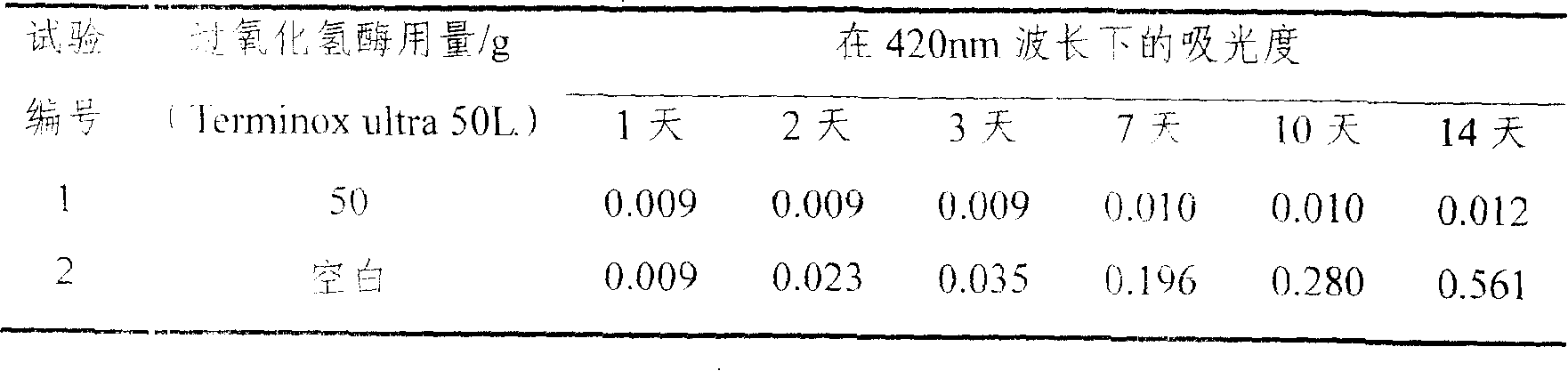

Method for preparing alkyl glycoside

InactiveCN100390187CLight colorMild reaction conditionsSugar derivativesOrganic-compounds/hydrides/coordination-complexes catalystsReaction temperaturePotassium

The invention discloses a new method for preparing alkyl indicant, technically characterized in making ultramicro pulverization processing on anhydrous glucose or crystal water containing glucose, then reacting with C8-C20 high grade alcohol under the existence of organic sulphonic acid catalyst, vacuum dehydrating and obtaining alcohol solution of alkyl indicant, then neutralizing acdic catalyst with organic acid sodium or potassium salt, vacuum distilling to eliminate excessive high grade alcohol, using chelating agent or sodium silicate to screen Fe ions, Mn ions and other ions, using tetraacetyl ethylene diamine as oxydol activating agent, bleaching alkyl indicant solution, and finally using hydrogen peroxide enzyme to eliminate the residual hydrogen peroxide from the products. The advantages of the invention: the reaction temperature is low and the reacting time is short, the process is simple and convenient, the production cost is low, and the prepared alkyl indicant is colorless or approximately colorless, transparent, peculiar smell-free, and stable to store.

Owner:NORTHWEST UNIV

Bleaching method for bleaching deinked waste pulp

ActiveCN101560740AAvoid pollutionImprove the shortcomings of the yellowish color of the bleaching systemPaper recyclingPulp bleachingSodium borohydrideSodium bisulphite

The invention discloses a bleaching method for bleaching deinked waste pulp. The bleaching method has the advantage of avoiding the environment pollution caused by the conventional bleaching using sodium hydrosulfite and thiourea dioxide. The method is an environment friendly reducibility bleaching method which has great improvement on the whiteness of the waste pulp and low cost. The method can overcome the defect of a yellow color system lying in the conventional bleaching through the sodium hydrosulfite. In addition, sulphate used in the method can selectively be sodium bisulphite or sodium pyrosulfite so as to further improve the whiteness after the waste pulp is bleached and reduce the dosage of sodium borohydride. A chelating agent is at least one of sodium silicate, disodium edta or tetrasodium salt, and diethylene triamine pentacetic acid or sodium tripolyphosphate. Additives and the dosage of the additives can be adjusted according to the actual metallic ion content in the waste pulp so as to improve the bleaching efficiency and reduce the cost of the bleaching medicine for unit whiteness improvement.

Owner:NINGBO ASIA PULP & PAPER +1

Preparation method of high-strength corrugated board

InactiveCN107700275APlay a role in penetrationAct as surface activePulping with inorganic basesPulping with organic solventsPapermakingEconomic benefits

The invention discloses a preparation method of a high-strength corrugated board and belongs to the technical field of papermaking; the high-strength corrugated board is made via the steps of secondary pretreating, grinding, beating, forming and the like. The yield, breaking length and ring crush index of crude pulp made by using the preparation method of crude pulp and high-strength corrugated boards are all significantly higher than those of the pulp made by using the prior art; the preparation method meets the national industrial policies of resource conservation, environmental friendliness, circular economy, and energy conservation and emission reduction, the redundant abandoned resources such as bagasse are developed and utilized, contamination can be decreased, and economic benefit can be increased.

Owner:广西金荣纸业有限公司

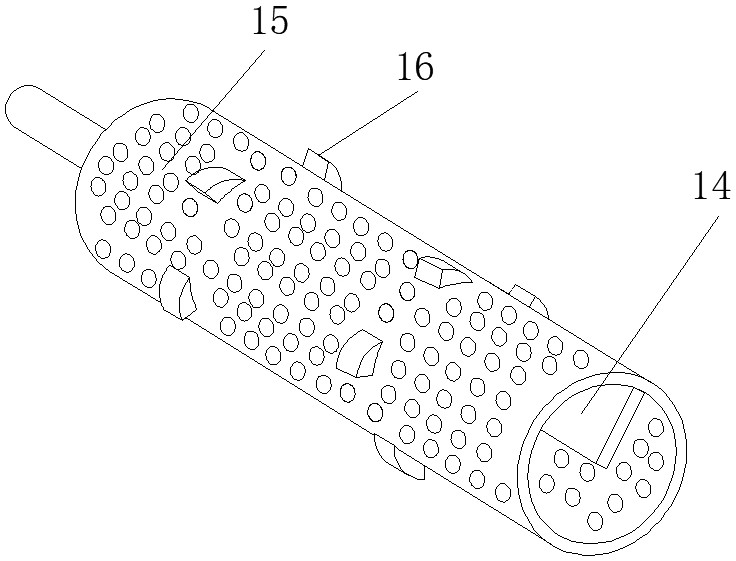

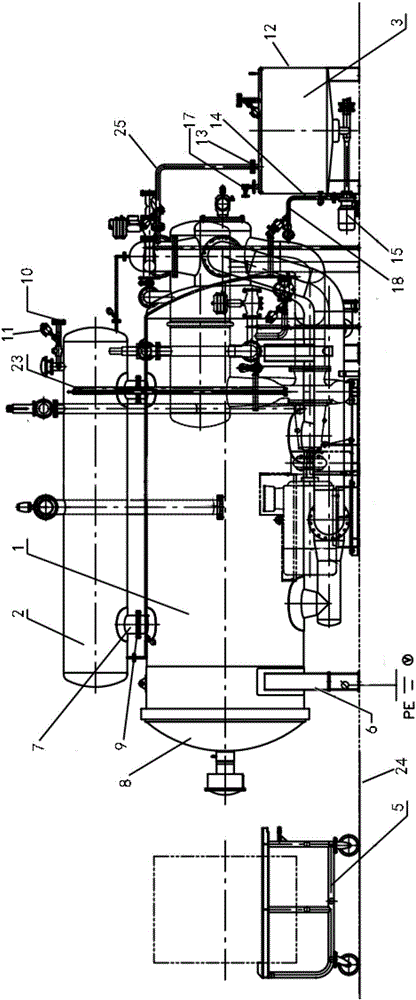

Horizontal kiering tank for kiering gauze

ActiveCN106381621AImprove bleaching efficiencyImprove pass rateTextile treatment containersTextile treatment machine arrangementsEngineeringWater level

The invention discloses a horizontal kiering tank for kiering gauze. The horizontal kiering tank comprises a main cylinder body, an expanding cylinder, a preparation cylinder, a heat exchanger, a control panel and a water gauge device, wherein the main cylinder body is cylindrical, is horizontally arranged on a cylinder body bracket, is used for accommodating fabrics and rinsing solution, and is a place for carrying out a rinsing process; the expanding cylinder is arranged above the main cylinder body, and is used for reducing the pressure inside the main cylinder body; the preparation cylinder comprises a barrel, a water inlet, a water outlet, a stirring motor, a charging pump motor and a pressurizing opening, and is used for preparing a bleaching agent; the heat exchanger is used for heating tap water and introducing the tap water into the preparation cylinder; the control panel is used for setting programs and controlling operation of the kiering tank; and the water gauge device is used for monitoring the water level in the main cylinder body. According to the horizontal kiering tank, the kiering process and bleaching agent preparation are mechanized, the gauze bleaching efficiency is improved, and only one person is required for operation, so that the production time and labor cost can be reduced; and the main cylinder body is horizontally arranged, so that the height of a workshop can be reduced, and an operation platform is not required.

Owner:MEDWELL MEDICAL PROD

Pulping method with zero discharge of sewage

InactiveCN105178083AHigh extraction rateLess investmentCellulose material pulpingBlack liquorSteam cooking

A pulping method with zero discharge of sewage comprises the steps: 1) mixing evenly a pulping raw material with a steam cooking agent and a catalyst, then adding into a spherical digester, then introducing steam, and carrying out steam cooking; 2) allowing the steam-cooked raw materials to pass through a plurality of series-connection twin-screw extruders successively, extruding and extracting black liquids, to obtain a pulp, allowing the black liquid obtained from the final twin-screw extruder to return to the former twin-screw extruder, stirring and mixing, then continuing to extrude, directly merging the black liquids obtained from the first twin-screw extruder and the second twin-screw extruder, concentrating and drying the merged black liquid to obtain alkali lignin or lignosulfonate, wherein the pulp concentration of pulp washing and pulp bleaching is 25-40%; 3) then sending the pulp into a twin-screw rubbing and kneading pulping machine, carrying out multi-section series washing while rubbing kneading and grinding, or carrying out multi-section series washing and multi-section series bleaching, allowing the washing water to return to the former-section washing process, finally obtaining washing water namely residuary washing water containing the black liquid coming from the first-section washing process, and allowing the washing water to return to the pulping raw material or the spherical digester; and 4) finally, allowing the pulp to enter a dual-disk pulp grinding machine, adding water and carrying out fine grinding.

Owner:蒋寿悟

Antibacterial paper towel and preparation method thereof

InactiveCN109914138AHigh whitenessEfficient degradationAntibacterial agentsCosmetic preparationsFiberMicrowave radiometry

The invention relates to an antibacterial paper towel and a preparation method thereof, and discloses a process for papermaking by using Qianjinfang medicine residue, wherein the process comprises: microwave pretreatment, fermentation, washing, paper making, extracting of medicinal ingredients from waste liquid, paper modification and the like. According to the present invention, the short fiber is prepared by using the Qianjinfang medicine residue, and the long fiber property of the cotton fiber is combined, such that the prepared antibacterial paper towel has good tensile property; the prepared antibacterial paper towel has remarkable wet strength through internal sizing and surface application; by using the microwave radiation method and the biological method, harmful chemicals are notintroduced during the whole process, such that the hygienic characteristics of the paper are ensured; and the medicinal ingredients are extracted from the pulping waste liquid, and are mixed with thebase medicine liquid component comprising Cortex Ailanthi, Sophora flavescens Ait, Cortex Moutan, frankincense and borneol, and the obtained mixture is applied on the paper, such that the obtained antibacterial paper towel has good anti-inflammatory and antibacterial effects, can prevent microbial infection, does not have irritation and side effects on the skin and vaginal mucosa, and is suitablefor women.

Owner:ZHUZHOU QIANJIN PHARMA

Pearl bleaching process

InactiveCN100566622CSustained uniform releaseOvercome or weaken surface tensionJewellerySolventMethanol

The invention discloses a pearl bleaching technology, which comprises the following steps that: in the sufficient sunshine, pearls after being polished are put into prepared bleaching liquid and soaked at the temperature ranging from 14 to 17 DEG C for 48 to 50 hours for bleaching treatment, and then rinsed and dried; the step is repeated for at least one time; classification: unqualified pearls are screened out and the bleaching treatment for unqualified pearls continues to be repeated for at least one time. In the invention, the format of the bleaching liquid, consisting of a hydrogen peroxide bleaching agent, a composite interface agent, a composite catalyst and a methanol solvent, is adopted for bleaching at the low temperature of 14 to 17 DEG C so as to realize the good bleaching effect under low concentrations of the hydrogen peroxide bleaching agent within a short time, thus effectively reducing the damage to the skin of the pearl and improving the glossiness of the pearl. By adopting the method of the invention, the pearls bleached have better gloss, smooth surface, higher whiteness and good stability.

Owner:浙江梵沛珍珠股份有限公司

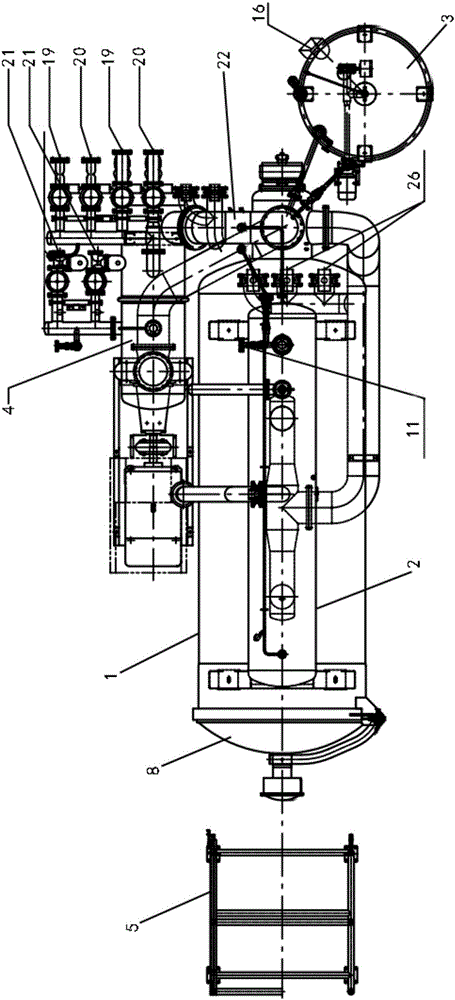

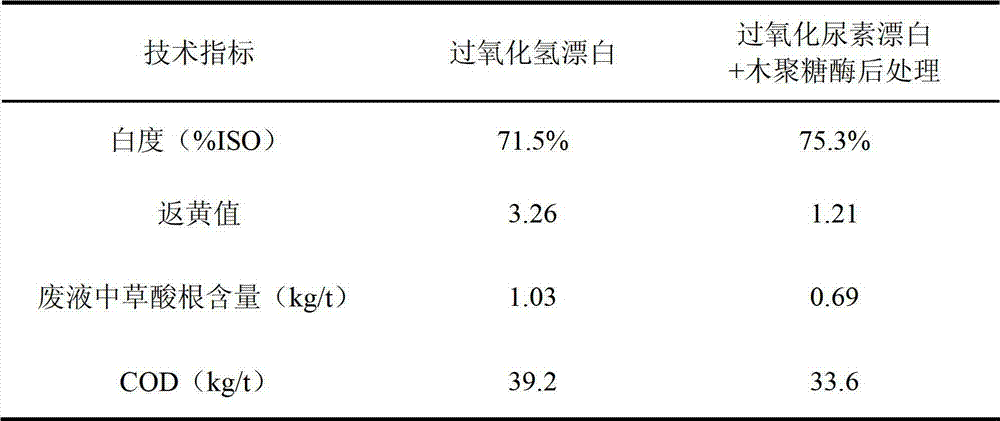

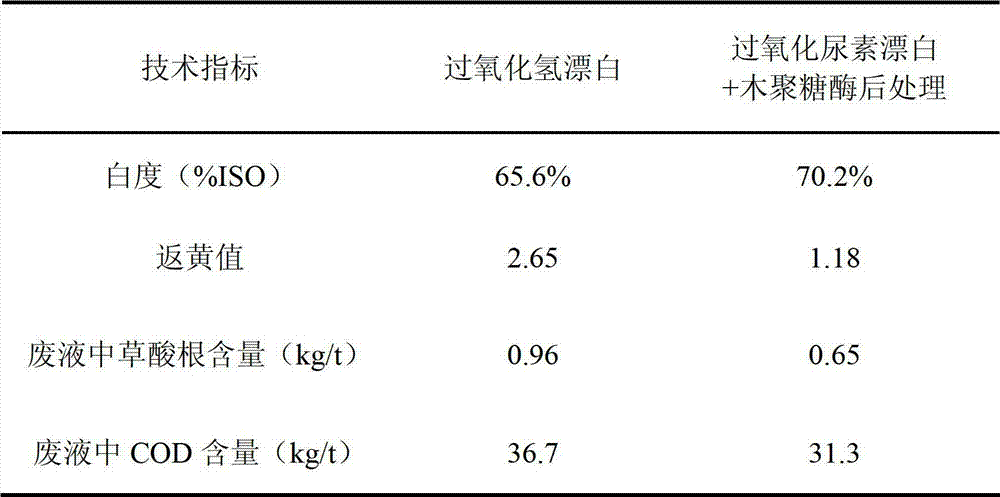

Method for cleanly bleaching chemimechanical pulp

The invention discloses a method for cleanly bleaching chemimechanical pulp. The method comprises the following steps of: firstly, bleaching with carbamide peroxide: adding magnesium sulfate, sodium silicate, EDTA (Ethylene Diamine Tetraacetic Acid) and carbamide peroxide in chemimechanical pulp, adjusting the concentration of paper pulp to 10-15 percent, feeding the paper pulp into a bleaching tower for bleaching and washing after the reaction is ended; and secondly, treating with xylanase: adjusting the pH value of the washed paper pulp to 6.0-7.0, then adding the xylanase, controlling the concentration of paper pulp to 8-12 percent, uniformly mixing, carrying out enzyme treatment and then washing. The carbamide peroxide adopted by the method disclosed by the invention is a novel paper pump bleaching agent and has the advantages of convenience in package and transportation, favorable stability, no addition of alkaline for bleaching, high whiteness of the bleached paper pulp and the like. When the method disclosed by the invention is used for cleanly bleaching the chemimechanical pulp, the whiteness and the whiteness stability of the paper pulp can be improved; meanwhile, the formation of oxalate in the bleaching process is reduced; and the pollution load of wastewater generated by bleaching is reduced.

Owner:SOUTH CHINA UNIV OF TECH

Reducing and bleaching composition for pulp from decoloured waste paper and its bleaching method

InactiveCN1351211AReduce invalid decompositionImprove bleaching efficiencyPulp bleachingSodium carbonateSolvent

A reducing and bleaching composition for decoloured waste pulp is prepared from sodium dithionite (5-15 wt.%), chelating agent (1.25-15), sodium carbonate or sodium hydroxide or their mixture (0.25-3) and water (79.5-93.5) through uniform mixing. Its bleaching method features that the stabilizer and said composition are cooperated, and the oil or solvent not dissolved in water is added to isolate air, so improving the stability of bleaching liquid, reducing consumption of sodium dithionite and improving bleaching effect. Its advantages include less damage to strength and opaqueness of paper fibres, less corrosion to pipeline, less pollution and low cost.

Owner:SOUTH CHINA UNIV OF TECH

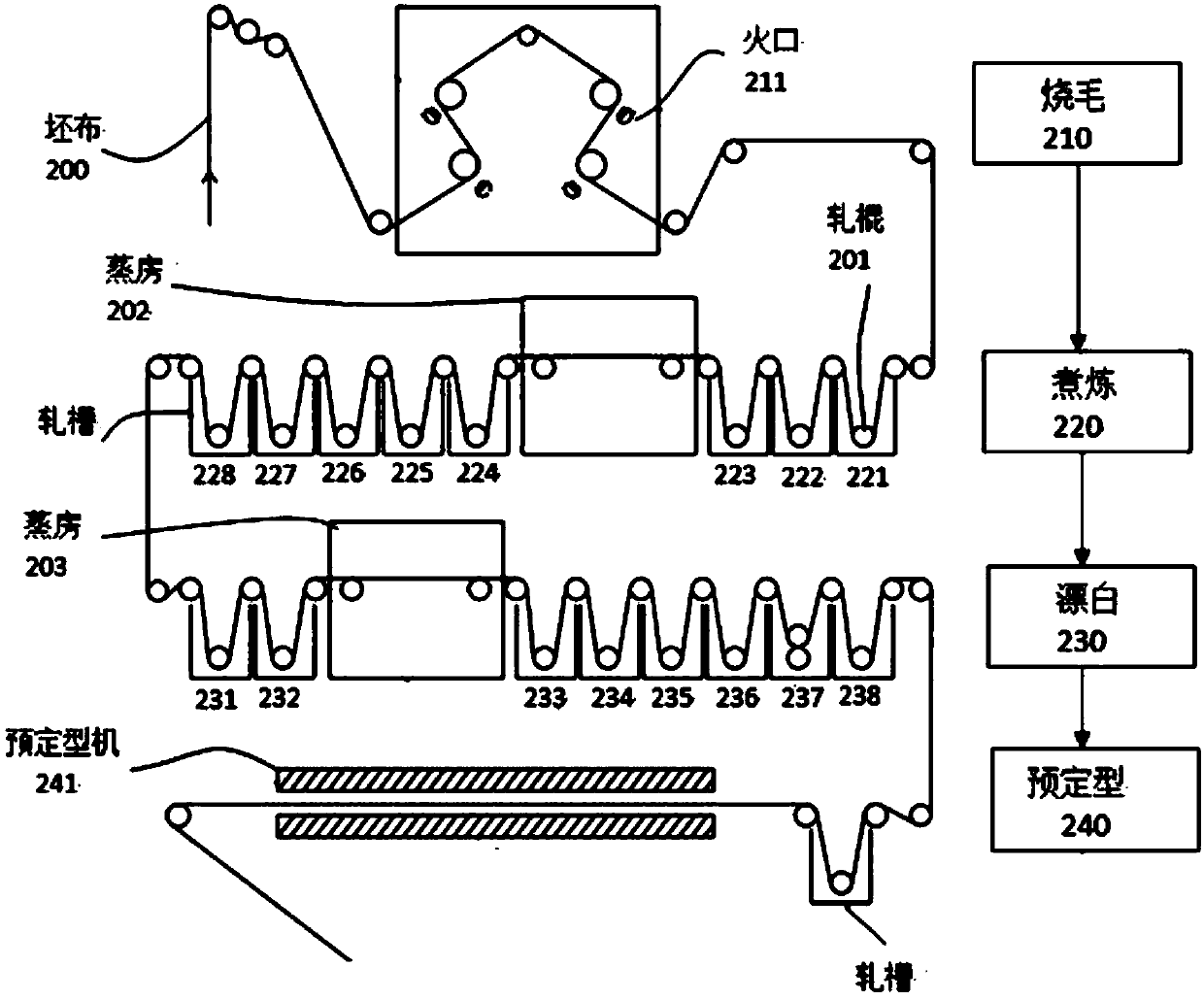

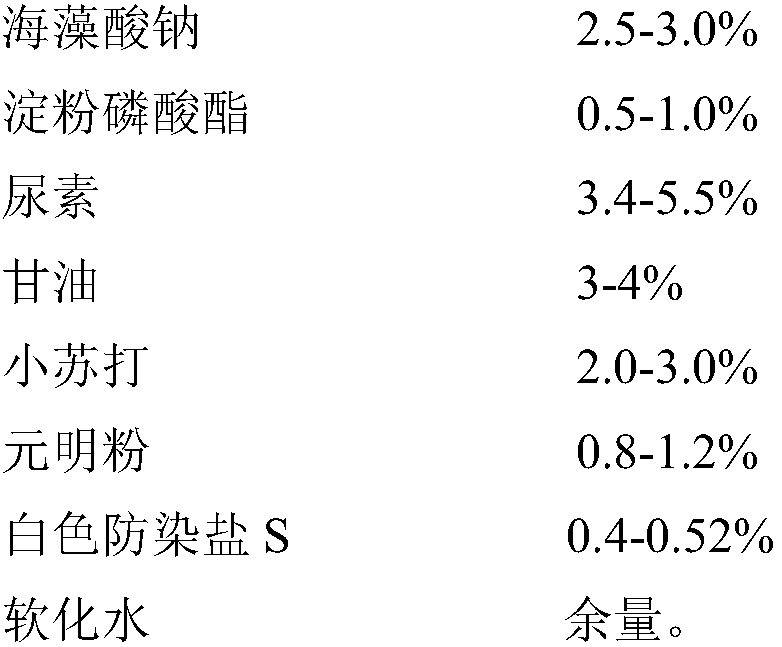

Pretreatment technology before digital printing of high-count cotton fabric

InactiveCN107761411AGood alkali resistanceAdapt to alkaline treatmentMercerising of indefinite length fabricsPhysical treatmentSlurryEngineering

The invention relates to a pretreatment technology before digital printing of high-count cotton fabric. Before digital printing, processes of singeing, ultrasonic boiling and bleaching, mercerizing, process of padding a slurry and preshaping are sequentially performed on gray fabric, and through formula optimization and technological optimization during boiling and bleaching as well as slurry padding, the fabric has a relatively good printing state before digital printing; the high-count cotton fabric treated by the pretreatment technology provided by the invention not only keeps smooth and soft surface properties of the high-count cotton and the like, but also is endowed with relatively high cleanliness, whiteness, dye affinity and the like, so that a guarantee is provided for high-precision digital printing, and the printed fabric is exquisite in pattern and high in color and luster.

Owner:JIANGSU HONGLIU BEDSHEET LIMITED

Reducing and bleaching composition for pulp from decoloured waste paper and its bleaching method

Owner:SOUTH CHINA UNIV OF TECH

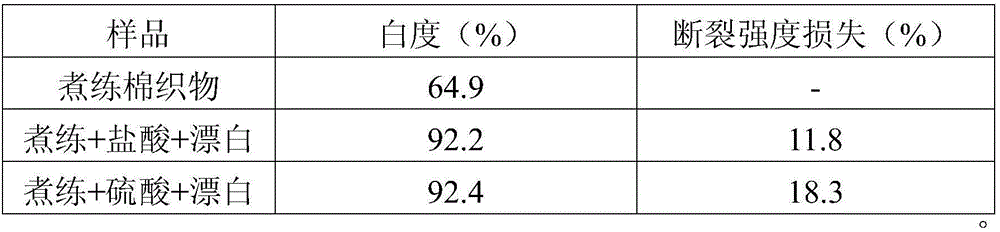

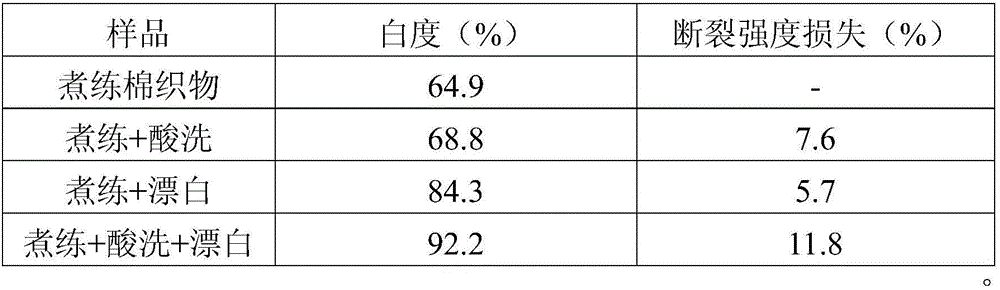

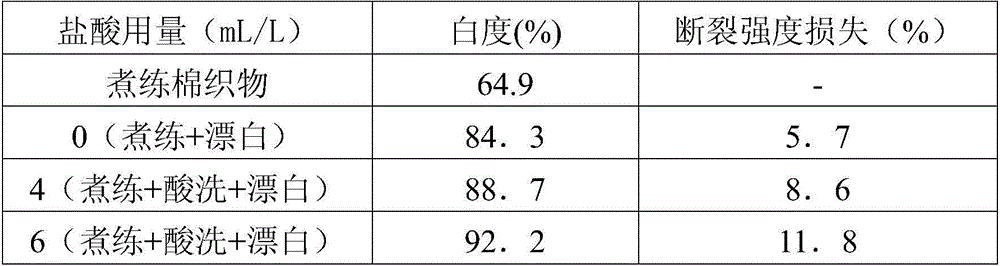

Method for bleaching cotton fabrics with high whiteness effects

InactiveCN106223006AAvoid damageHigh whitenessBleaching apparatusGrip property fibresInorganic saltsDecomposition

The invention discloses a method for bleaching cotton fabrics with high whiteness effects. The method is characterized in that inorganic acid is used for treating cotton fabrics; inorganic salts and mineral matters which cause ineffective decomposition of hydrogen peroxide are removed; hydrogen peroxide is used for carrying out bleaching treatment; natural pigments in cotton fibers are removed, so that the cotton fabrics have high-whiteness bleaching effects and good strength.

Owner:SHAOXING UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com