Paper pulp high density bleaching method

A technology of pulp and bleaching chambers, applied in pulp bleaching, pulp dehydration, etc., can solve the problems of high-concentration pulp bleaching that is difficult to apply in engineering, difficult to exceed 25%, and low transmission efficiency, so as to reduce the consumption of bleaching chemicals and electricity consumption. Consumption, reduce the effect of heat energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

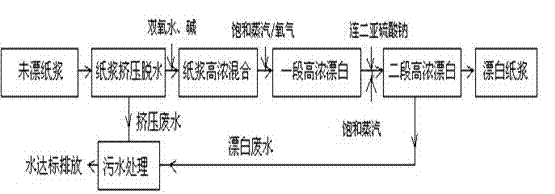

Image

Examples

Embodiment 1

[0027] (1) Concentrate the unbleached masson pine chemical pulp with a concentration of 17% after washing to obtain a concentrated pulp with a concentration of 26.2%;

[0028] (2) Extruding and dehydrating the concentrated pulp with a parallel twin-screw extruder at a compression ratio of >3.0 to obtain a high-consistency pulp with a concentration of more than 30%;

[0029] (3) Pump hydrogen peroxide and bleaching auxiliaries into the high-concentration slurry at a pressure of 0.5 MPa at the extrusion exit of the parallel twin-screw press to obtain a mixture of ingredients and chemicals; bleaching auxiliaries include hydrogen Sodium oxide, chelating agent, stabilizer; relative to the dry pulp quality, the amount of hydrogen peroxide is 3.5%, the amount of sodium hydroxide is 2.5%, the amount of DTPA is 0.3%, and the amount of sodium silicate is 0.5%;

[0030] (4) Convey the material and drug mixture to the high-concentration bleaching chamber with a feeding screw, add saturate...

Embodiment 2

[0034] (1) Concentrate the unbleached eucalyptus chemical pulp with a concentration of 20% after washing to obtain a concentrated pulp with a concentration of 28%;

[0035] (2) Extruding and dehydrating the concentrated pulp with a parallel twin-screw extruder at a compression ratio of >3.0 to obtain a high-consistency pulp with a concentration of more than 30%;

[0036] (3) Pump hydrogen peroxide and bleaching auxiliaries into the high-concentration slurry at a pressure of 1.0 MPa at the extrusion exit of the parallel twin-screw press to obtain a mixture of ingredients and chemicals; the bleaching auxiliaries include hydrogen Sodium oxide, chelating agent, stabilizer; relative to the dry pulp quality, the amount of hydrogen peroxide is 4.0%, the amount of sodium hydroxide is 3.0%, the amount of DTPA is 0.1%, and the amount of sodium silicate is 0.5%;

[0037] (4) One-stage high-consistency bleaching of pulp: transport the mixture of material and drug into the high-consistency...

Embodiment 3

[0041] (1) Concentrate unbleached eucalyptus chemical pulp and bamboo pulp with a concentration of 20% (the mass ratio of unbleached eucalyptus chemical pulp and bamboo pulp is 2:1) after washing to obtain concentrated pulp with a concentration of 28%. pulp;

[0042] (2) Extruding and dehydrating the concentrated pulp with a parallel twin-screw extruder at a compression ratio of >3.0 to obtain a high-consistency pulp with a concentration of more than 30%;

[0043] (3) Pump hydrogen peroxide and bleaching aid into the high-concentration slurry at a pressure of 1.5 MPa at the extruding part of the parallel twin-screw press to obtain a mixture of ingredients and chemicals; the bleaching solution It is a solution of hydrogen peroxide; bleaching aids include sodium hydroxide, chelating agent, and stabilizer; relative to the dry pulp quality, the amount of hydrogen peroxide is 4.0%, the amount of sodium hydroxide is 3.0%, the amount of DTPA is 0.1%, silicon Sodium acid consumption is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com