Wood surface bleaching technology and its special-purpose apparatus

A veneer and process technology, applied in the field of wood bleaching, can solve problems such as unseen, low production efficiency, large investment, etc., and achieve the effects of stabilizing quality, improving efficiency, and improving efficiency and effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

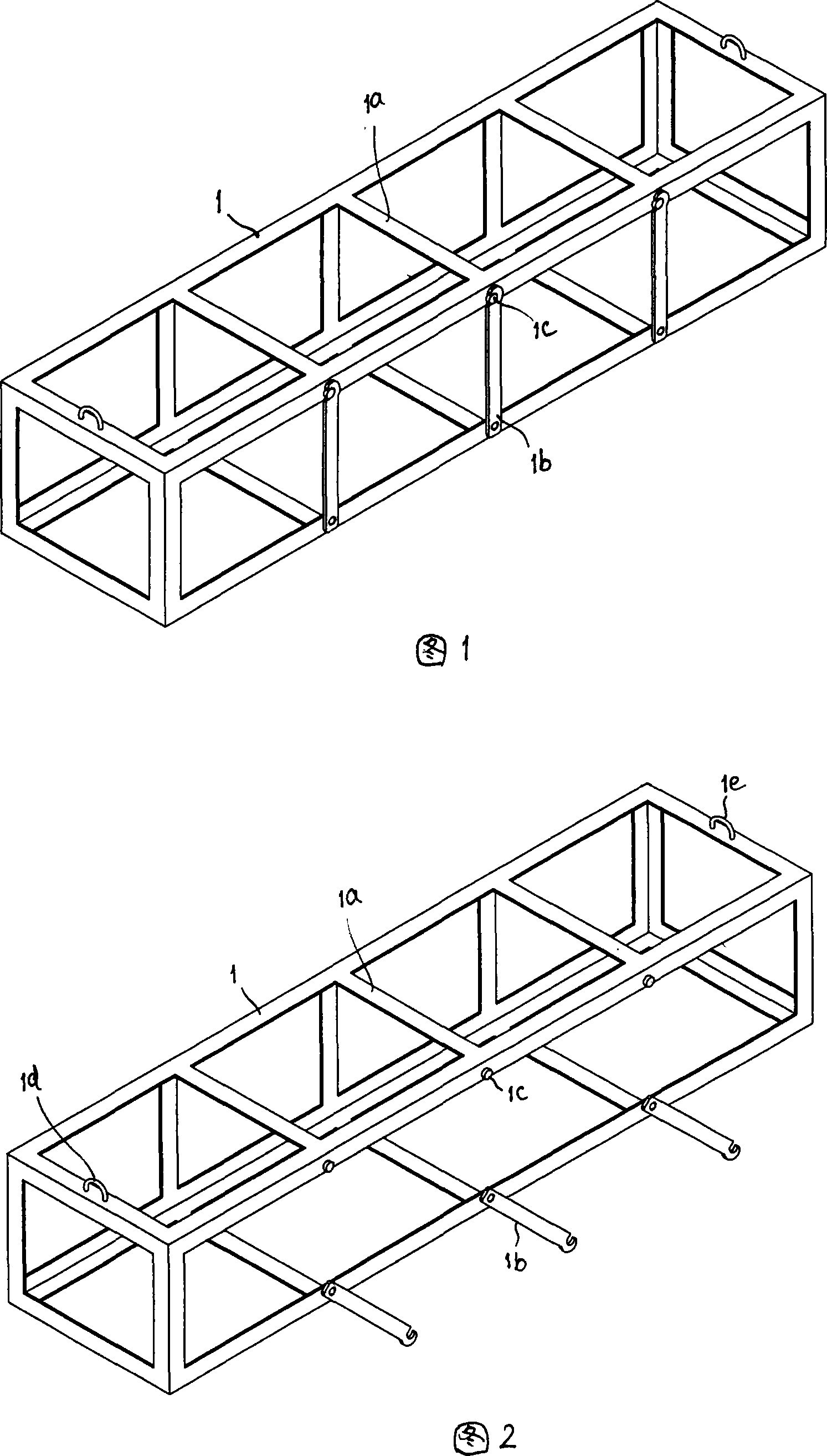

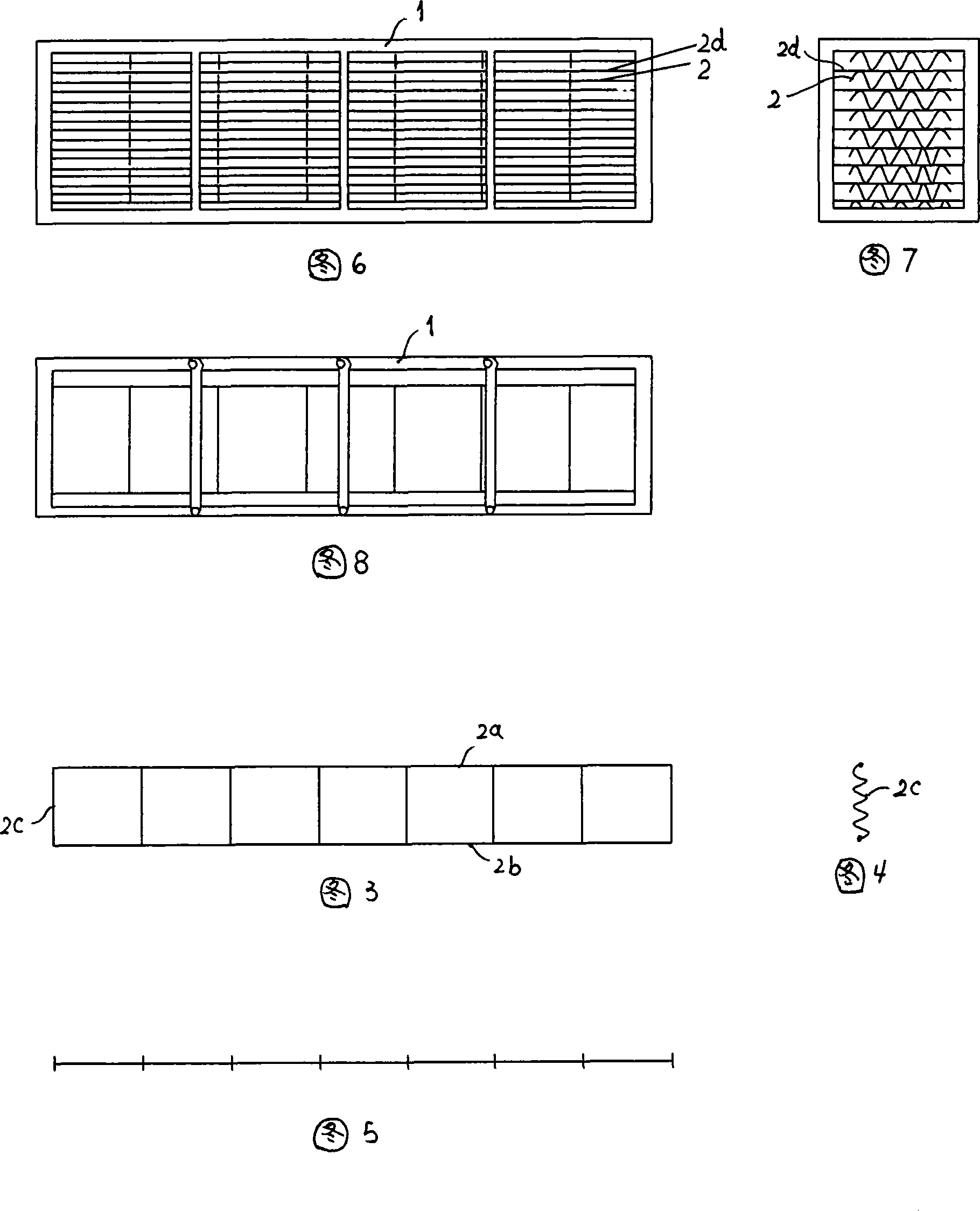

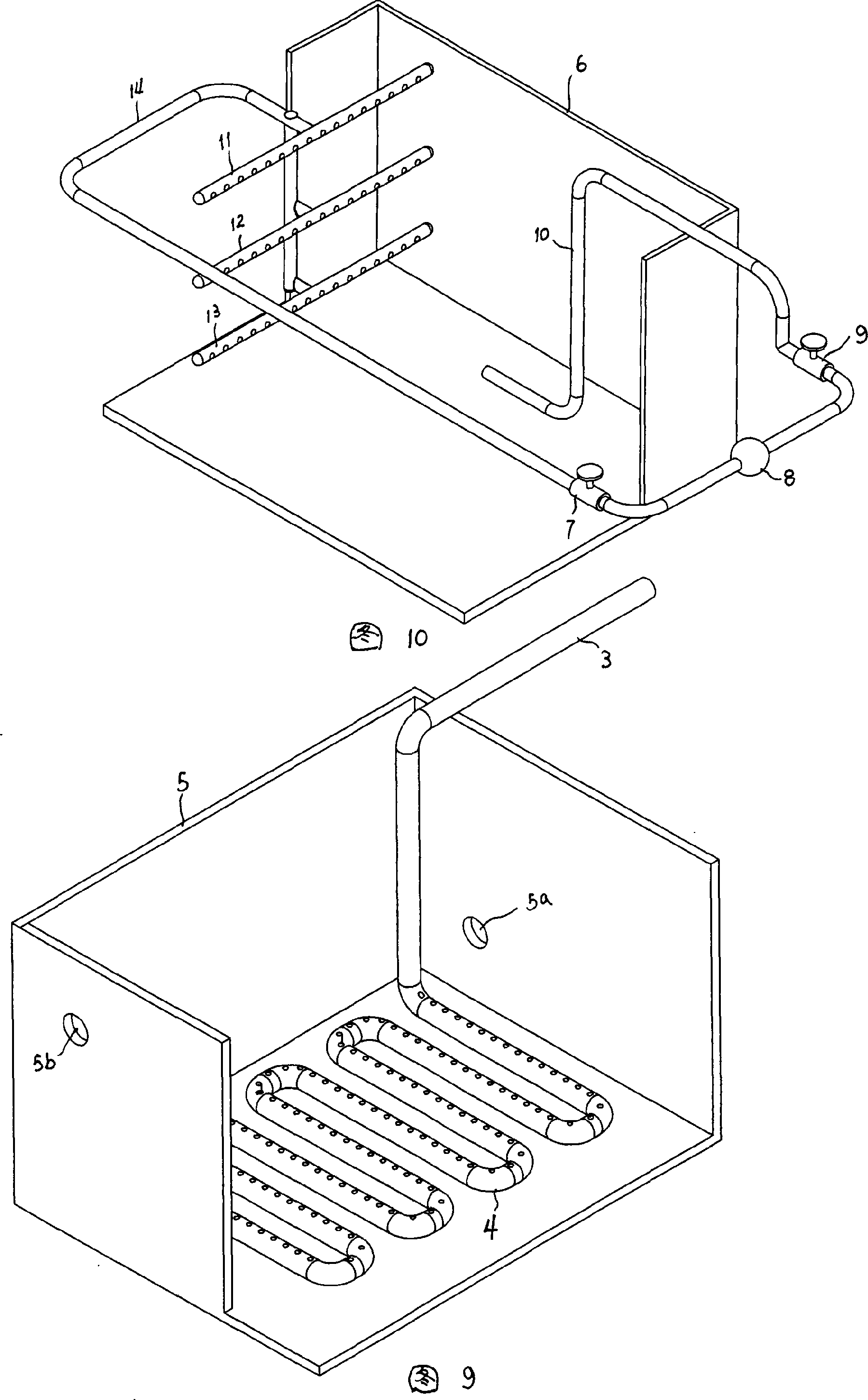

[0024] Wood veneer bleaching process of the present invention, carry out according to the following steps: a) by 1000ml water dissolving 2-5 gram hydrogen peroxide, 3 gram sodium hydroxide, 1 gram sodium silicate, 0.05 gram magnesium chloride, prepare bleaching solution in No. 1 bleaching pool 5 : When preparing, first dissolve sodium hydroxide, sodium silicate, and magnesium chloride in water to obtain a solution, then add the sodium hydroxide solution to the magnesium chloride solution, then add the sodium silicate solution, and finally add hydrogen peroxide; b) add the veneer Put into veneer bleaching frame, put into bleaching tank, make bleaching solution submerge veneer completely; c) adopt pump to make the bleaching solution in the pool be in continuous circulation through circulation pipeline (referring to Fig. 9, No. 1 bleaching tank 5 is provided with inlet Liquid port 5a and liquid outlet port 5b, adopt pump to do forced circulation through pipeline); d) At the same t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com