A novel low-temperature oxygen bleaching catalyst and its preparation method and application

A catalyst and oxygen bleaching technology, applied in textiles and papermaking, etc., can solve the problems of complex synthesis process, fiber damage, insufficient catalytic efficiency, etc., and achieve the effect of shortening the process flow and stable structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] In a preferred embodiment, the preparation method of the low-temperature oxygen bleaching catalyst of the present invention includes, for example, the following steps:

[0027] 1) Take 10-100g of clay material, under normal temperature conditions, immerse in 1mol / L NaCl solution and stir for 8-12h, then suction filter, and rinse with deionized water;

[0028] 2) Add the product in 1) to the ethanol solution of zinc salt, immerse and stir for 8-12h, filter and dry for later use;

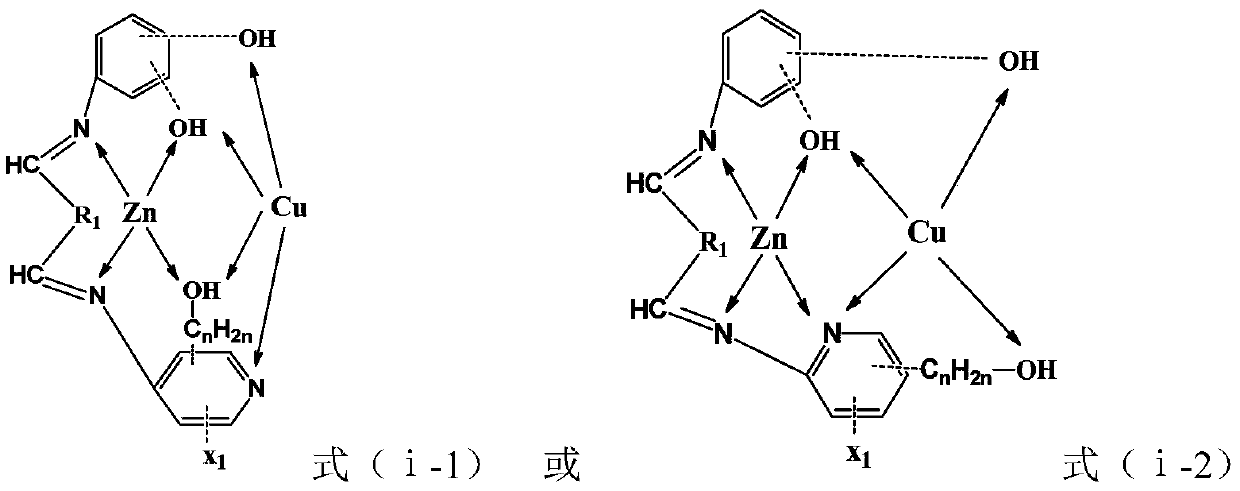

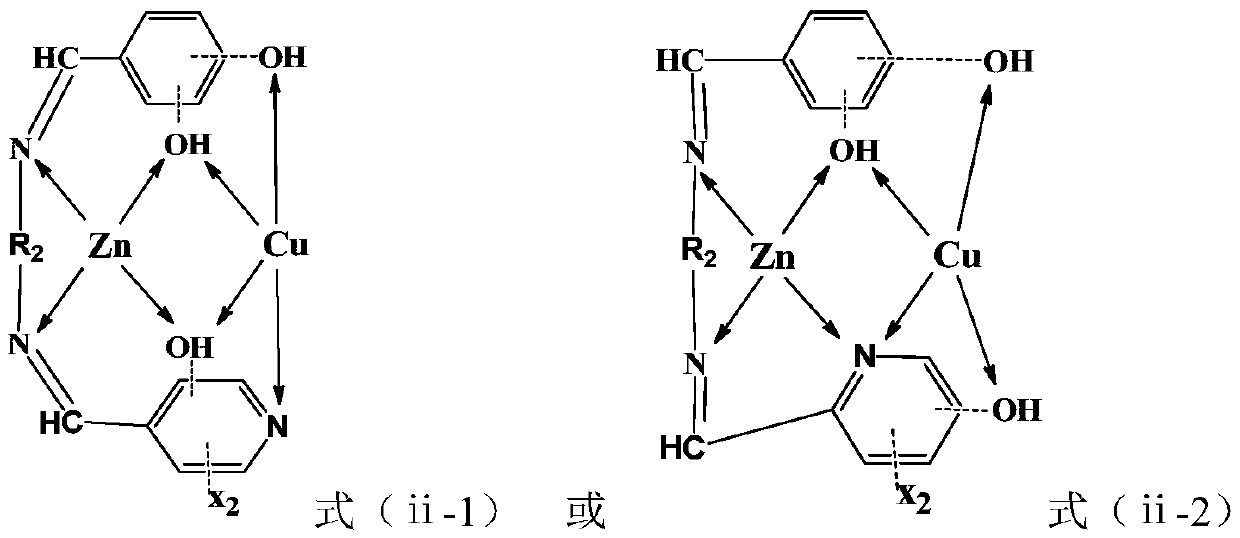

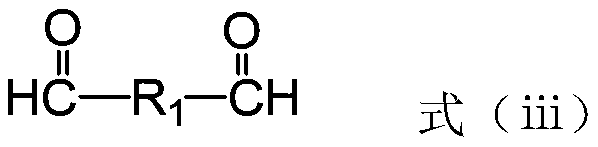

[0029] 3) Take another ethanol solution of the following substance A, stir, slowly add a certain proportion of the ethanol solution of the following substances B and C dropwise, reflux and stir for 2-5h to obtain a double Schiff base ligand;

[0030] 4) Take a certain amount of double Schiff base ligand and add it to 2) to prepare zinc salt-loaded clay. After refluxing for 1-3h, add copper salt ethanol solution, continue refluxing for 1-3h, and cool to room temperature , The solvent is removed to obtai...

Embodiment 1

[0066] 1. Preparation of low-temperature oxygen bleaching catalyst: Take 20g of bentonite, immerse it in 100ml, 1mol / L NaCl solution and stir for 8h, then suction filter and clean with deionized water; add 200ml, 10g / L zinc chloride ethanol solution, immerse and stir for 10h , Filter drying. Take 10mmol of m-phthalaldehyde and 15ml of absolute ethanol, stir at room temperature, add dropwise 15ml of ethanol solution containing 8.5mmol of 2,4-dihydroxybenzylamine, reflux and stir for 2.5h, and then dropwise add 20ml of 10mmol of 3- The ethanol solution of hydroxy-4-aminopyridine was refluxed and reacted for 3 hours to obtain a double Schiff base ligand; 15g of Zn loaded 2+ Ionic bentonite, reflux for 1.5h, then add 10mmol copper acetate, reflux for 2h, cool to room temperature, remove the solvent.

[0067] 2. Application of the above low-temperature oxygen bleaching catalyst:

[0068] 1) Preparation of oxygen bleaching working fluid: the same as traditional technology;

[0069] 2) Ad...

Embodiment 2

[0072] 1. Preparation of low-temperature oxygen bleaching catalyst: Take 40g of attapulgite, immerse it in 100ml, 1mol / L NaCl solution and stir for 10h, then suction filter, clean with deionized water; add 200ml, 10g / L zinc acetate ethanol solution, soak and stir for 10h After that, suction filter and dry. Take 10mmol of terephthalaldehyde and 15ml of absolute ethanol, stir at room temperature, add dropwise 15ml of ethanol solution containing 9.0mmol of 3,4-dihydroxybenzylamine, reflux and stir for 4h, then add dropwise 20ml of 10mmol of 2-amino -5-hydroxymethylpyridine in ethanol, reflux for 4h to obtain double Schiff base ligand; add 30g of Zn 2+ Ionic attapulgite, reflux for 2h, then add 10mmol copper nitrate, reflux for 1.5h, cool to room temperature, remove solvent.

[0073] 2. Application of the above low-temperature oxygen bleaching catalyst:

[0074] 1) Preparation of oxygen bleaching working fluid: the same as traditional technology;

[0075] 2) Add 10μmol / L catalyst and 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com