Zero discharge process of pulping waste liquid of all-cotton straw pulp

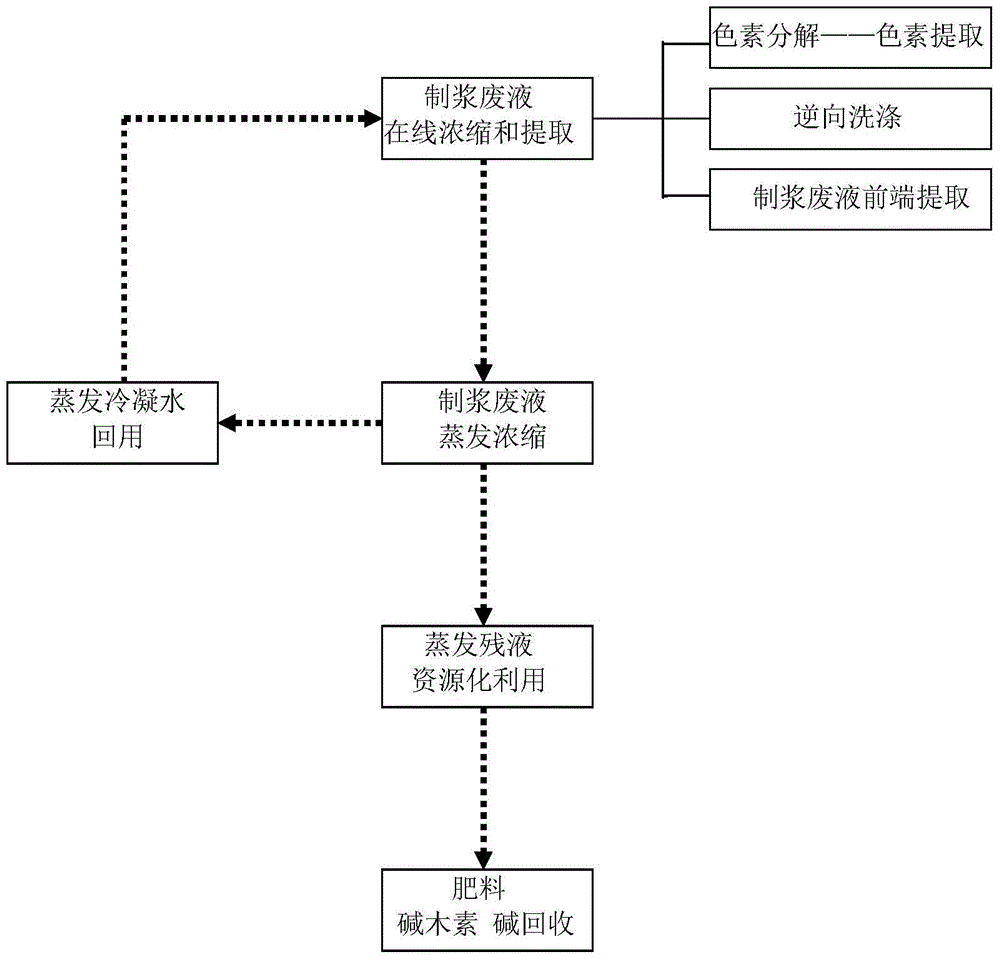

A technology for pulping waste liquid and zero discharge is applied in the field of pulping and papermaking, which can solve the problems of low concentration, difficult treatment, and large water volume, and achieve zero discharge, reduce pollution load, and improve bleaching efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

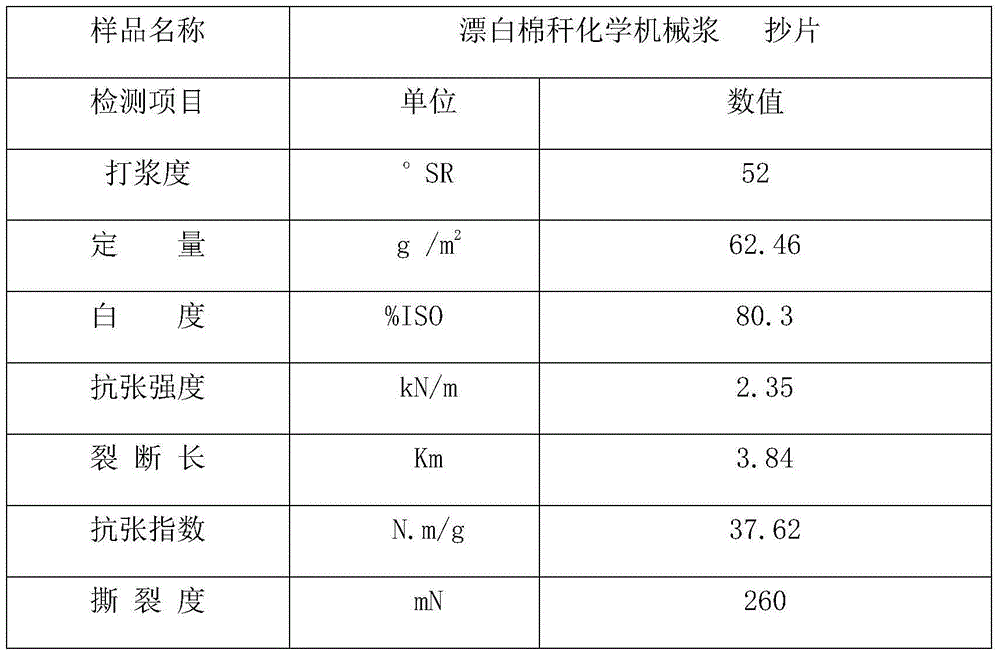

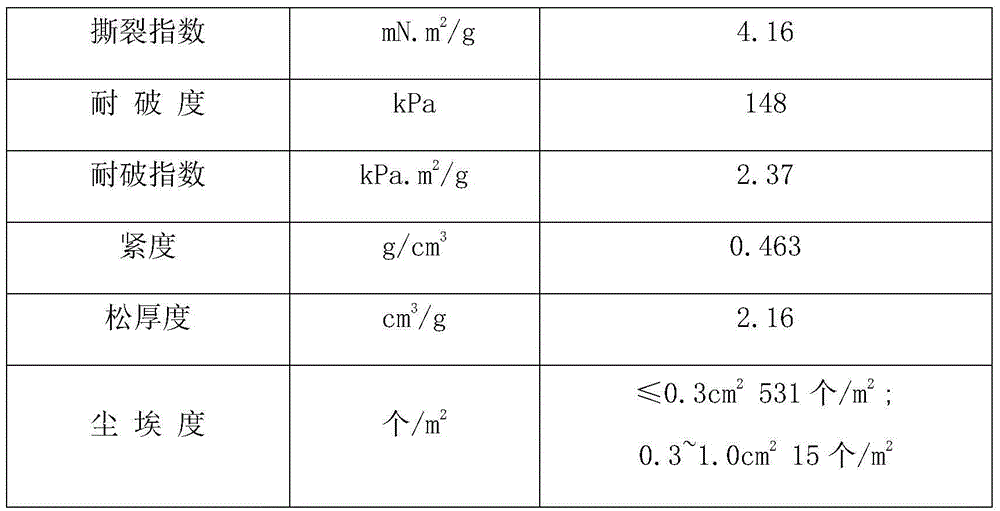

Examples

Embodiment 1

[0047] Raw material: cotton straw, place of origin: Liaocheng, Shandong Province

[0048] Raw material preparation: air-dry the whole stalk raw material, with a moisture content of 14%, cut and crush to 20-50mm

[0049] Pilot test platform: Shandong Kailong Paper Technology Co., Ltd. 10,000 tons / year high brightness non-wood fiber bleached mechanical pulp pilot line

[0050] Implementation steps:

[0051] The technological process adopted is: raw material washing (a)——raw material cooking (b)—extrusion washing, pulp washing, silk rubbing and dosing (cdef4)—dipping (g4)—extrusion washing, pulp washing, silk rubbing and dosing (h4) - Dipping (i4) - Washing (j4) - High consistency refining (k4) - Dosing (l4) - Dipping (bleaching) (m4) - Washing (n4) - High consistency grinding Pulp (o4) - pulp washing (p4).

[0052] 1. Raw material washing (a). It is carried out in a drum-type raw material scrubber with an output of 10,000 tons / year, the raw material concentration is 5%, and ...

Embodiment 2

[0080] The technological conditions of raw material cooking (b) are: temperature is 40 DEG C, time is 120min, NaOH 2%.

Embodiment 3

[0082] The technological conditions of the raw material cooking (b) are: the temperature is 99° C., the time is 120 min, and NaOH is 1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com