Method for cleanly bleaching chemimechanical pulp

A chemical-mechanical and clean technology, applied in the field of pulp and paper making, to achieve the effect of reducing degradation, convenient transportation, and reducing the pollution load of waste water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

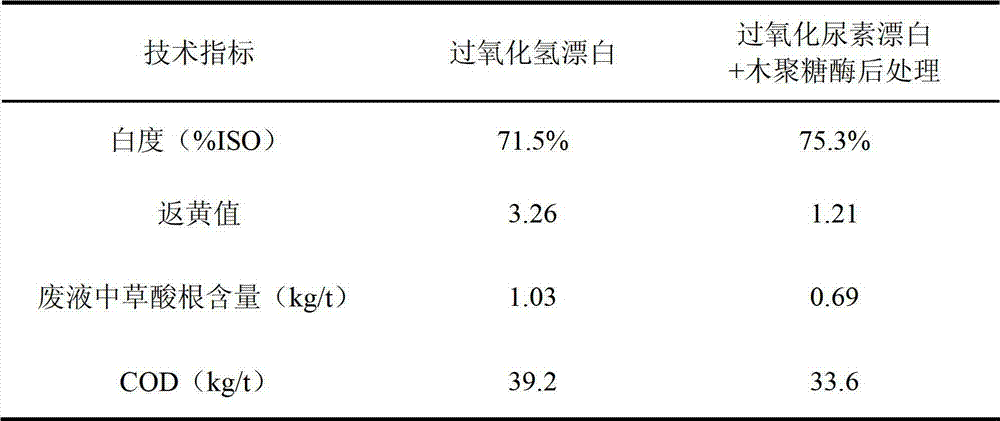

[0026] Cleaning and Bleaching Method of Poplar CTMP Pulp

[0027] (1) Bleaching with urea peroxide

[0028] A single tower was used to bleach poplar CTMP pulp with urea peroxide, and magnesium sulfate, sodium silicate, EDTA and urea peroxide were added to the pulp before entering the tower. The dosage of magnesium sulfate is 1.0kg / t dry pulp, the dosage of sodium silicate is 25kg / t dry pulp, the dosage of EDTA is 2.0kg / t dry pulp, and the dosage of urea peroxide is 100kg / t dry pulp (the peroxidized The hydrogen content is 31.5%); the pulp concentration is adjusted to 12% before entering the tower; the reaction time of the pulp in the tower is 90min; the reaction temperature is 85°C. After the reaction, the pulp is washed by a pulp washer and then enters the next section.

[0029] (2) Xylanase treatment

[0030] Use 1% dilute sulfuric acid to adjust the pH value of the washed pulp to 6.5, then add xylanase (solid) into the mixer, the enzyme dosage is 90g / t dry pulp, mix well...

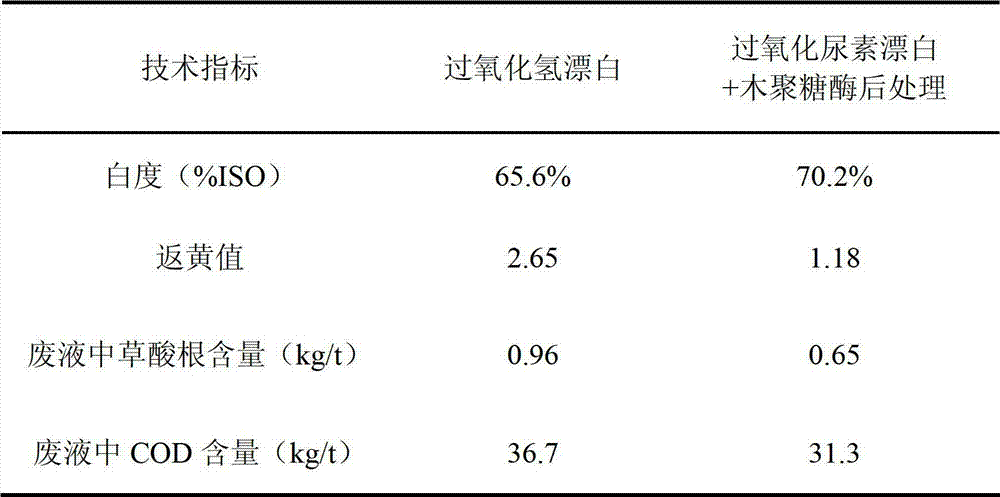

Embodiment 2

[0034] Clean Bleaching Method for Pine CTMP Pulp

[0035] (1) Bleaching with urea peroxide

[0036] The pine CTMP pulp was bleached with urea peroxide in a single tower, and magnesium sulfate, sodium silicate, EDTA and urea peroxide were added to the pulp before entering the tower. The dosage of magnesium sulfate is 1.0kg / t dry pulp, the dosage of sodium silicate is 30kg / t dry pulp, the dosage of EDTA is 2.5kg / t dry pulp, and the dosage of urea peroxide is 120kg / t dry pulp (the peroxidized The hydrogen content is 31.5%); the pulp concentration is adjusted to 12% before entering the tower; the reaction time of the pulp in the tower is 120min; the reaction temperature is 85°C. After the reaction, the pulp is washed by a pulp washer and then enters the next section.

[0037] (3) Xylanase treatment

[0038] Use 1% dilute sulfuric acid to adjust the pH value of the pulp to 6.5, then add xylanase (solid) into the mixer, the enzyme dosage is 80g / t dry pulp, mix well and send to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com