Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37results about How to "Improve alignment tolerance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

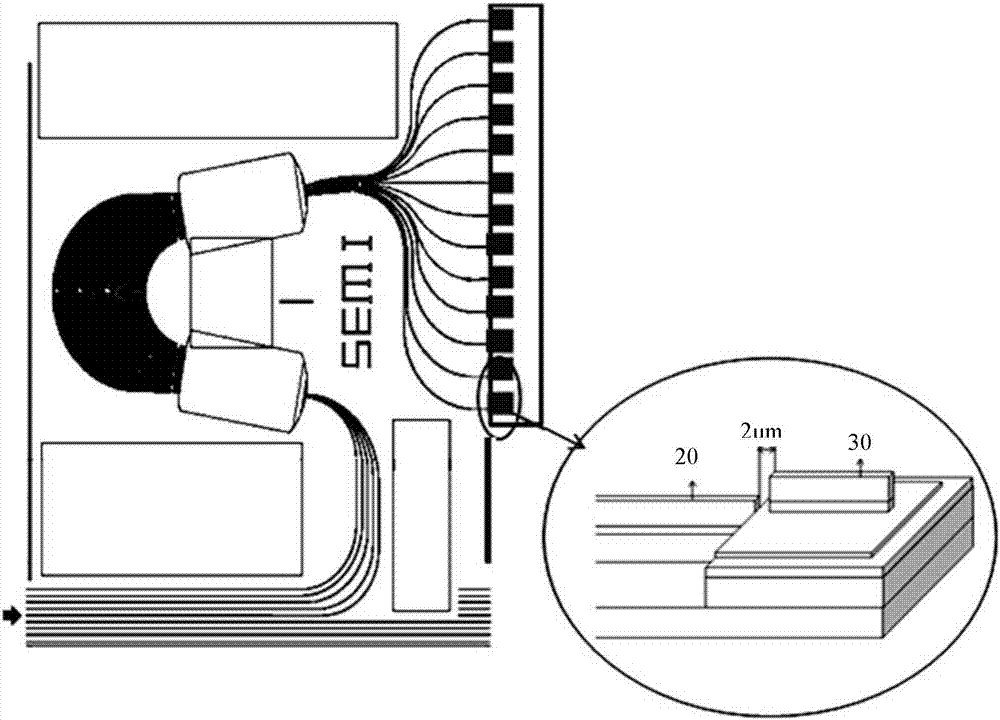

Optical apparatus and methods of manufacture thereof

ActiveUS20190265415A1Reliable and mechanical stableImprove manufacturabilityOptical waveguide light guideCouplingWaveguide

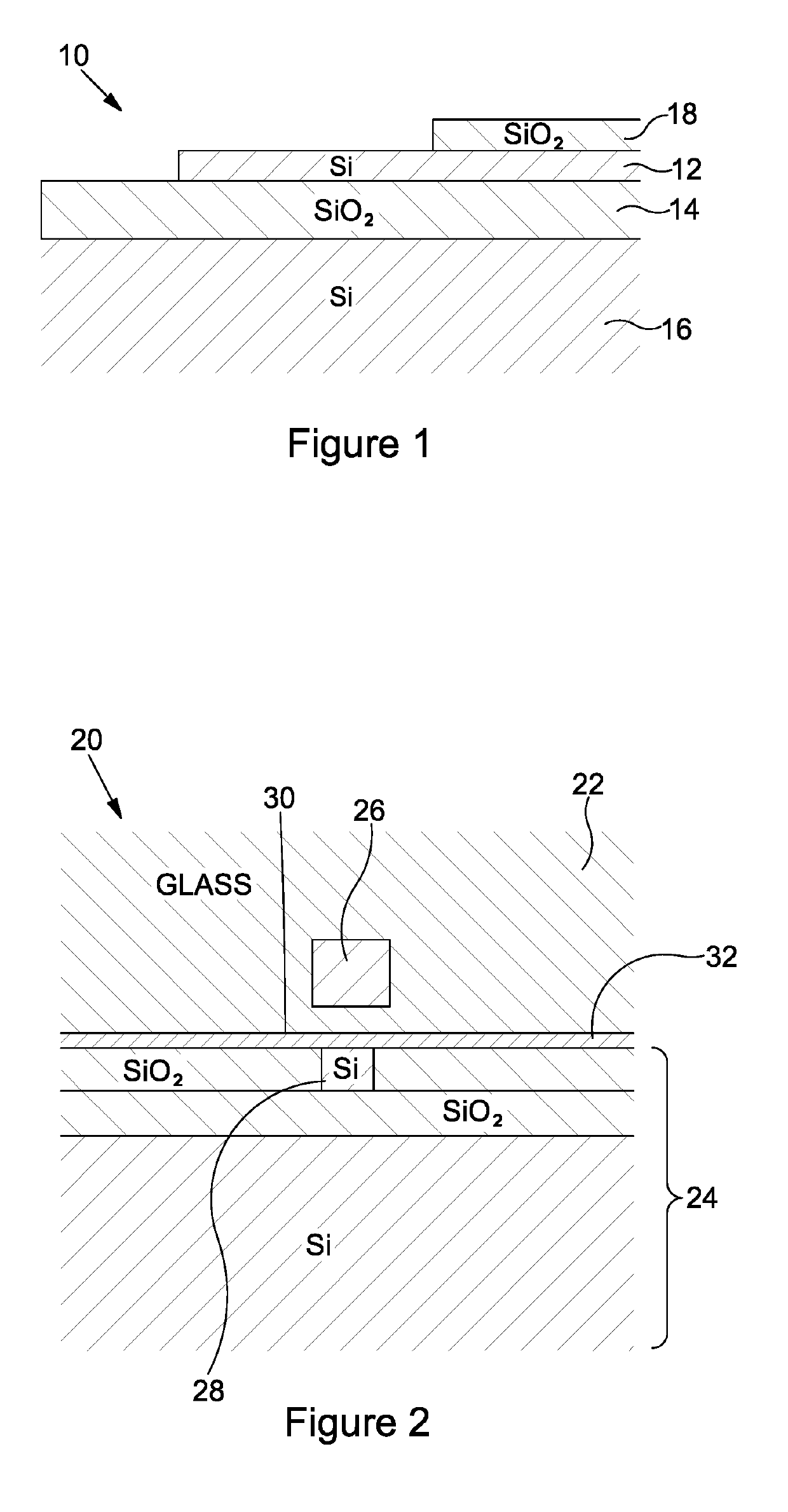

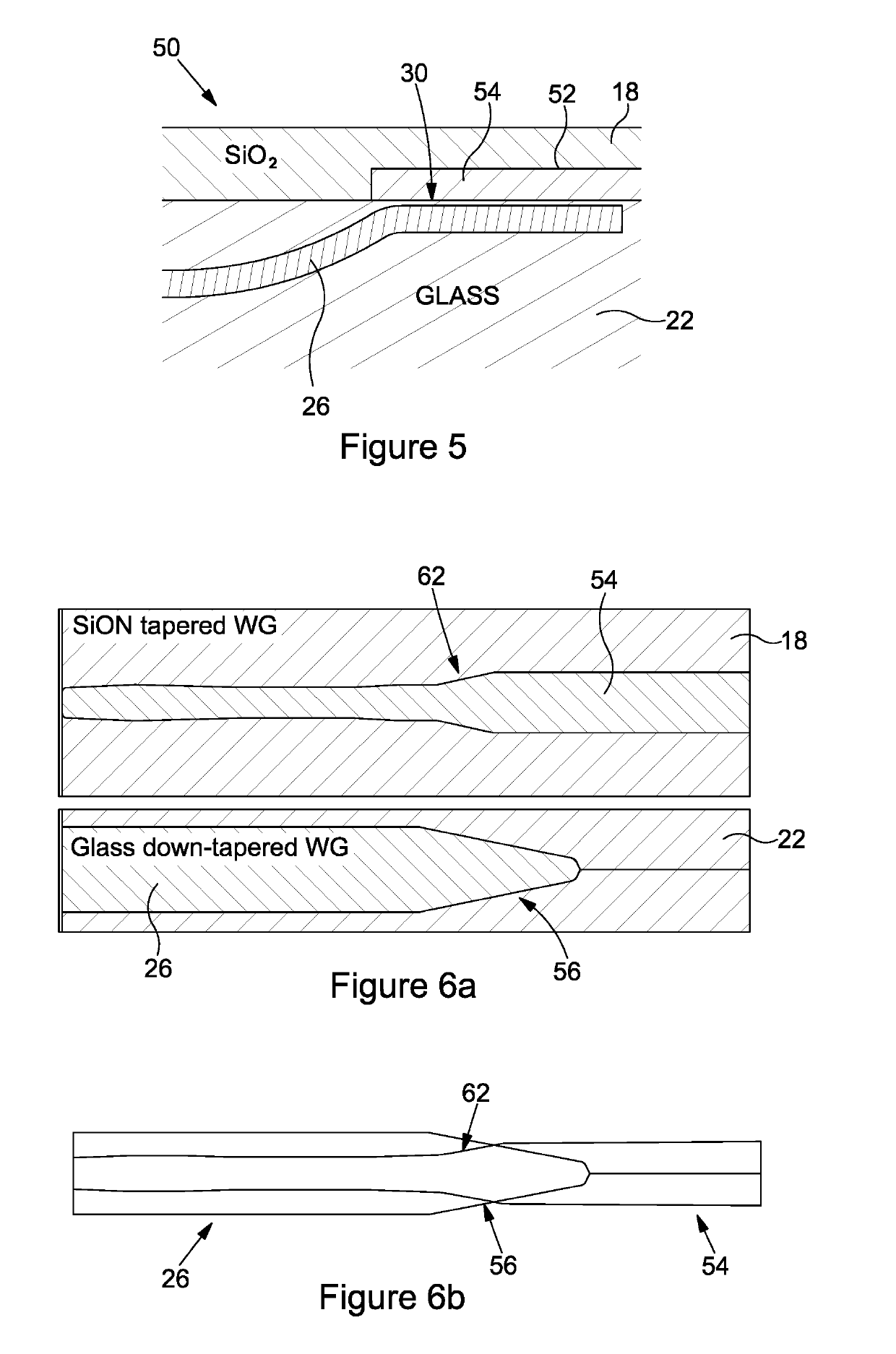

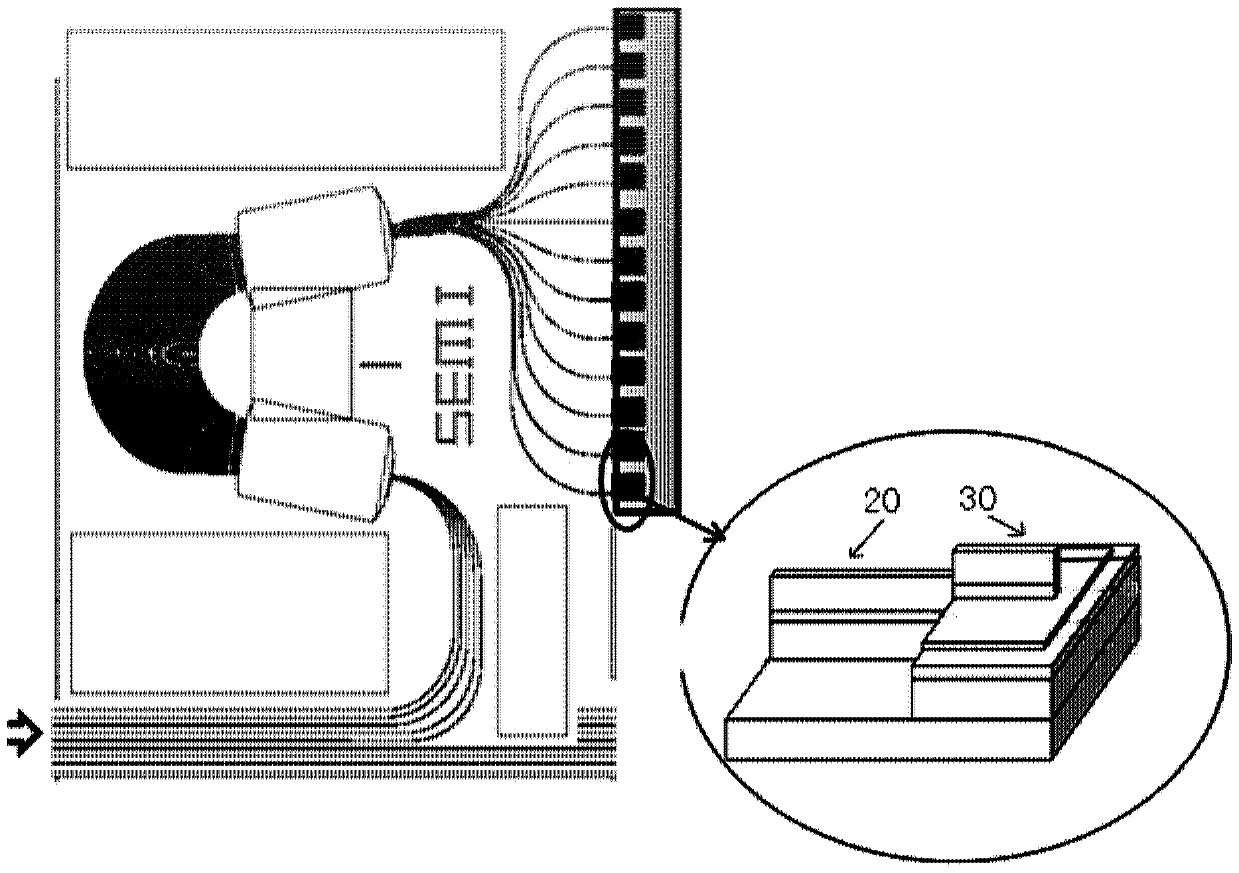

An optical apparatus 20 for evanescently coupling an optical signal across an interface 30 is described. The optical apparatus 20 comprises a first substrate 22 and a second substrate 24. The optical signal is evanescently coupled between a first waveguide 26 formed by laser inscription of the first substrate 22 and a second waveguide 28 of the second substrate 22. The first waveguide 26 comprises a curved section 34 configured to provide evanescent coupling of the optical signal between the first and second waveguides 26, 28 via the interface 30.

Owner:INTEL CORP

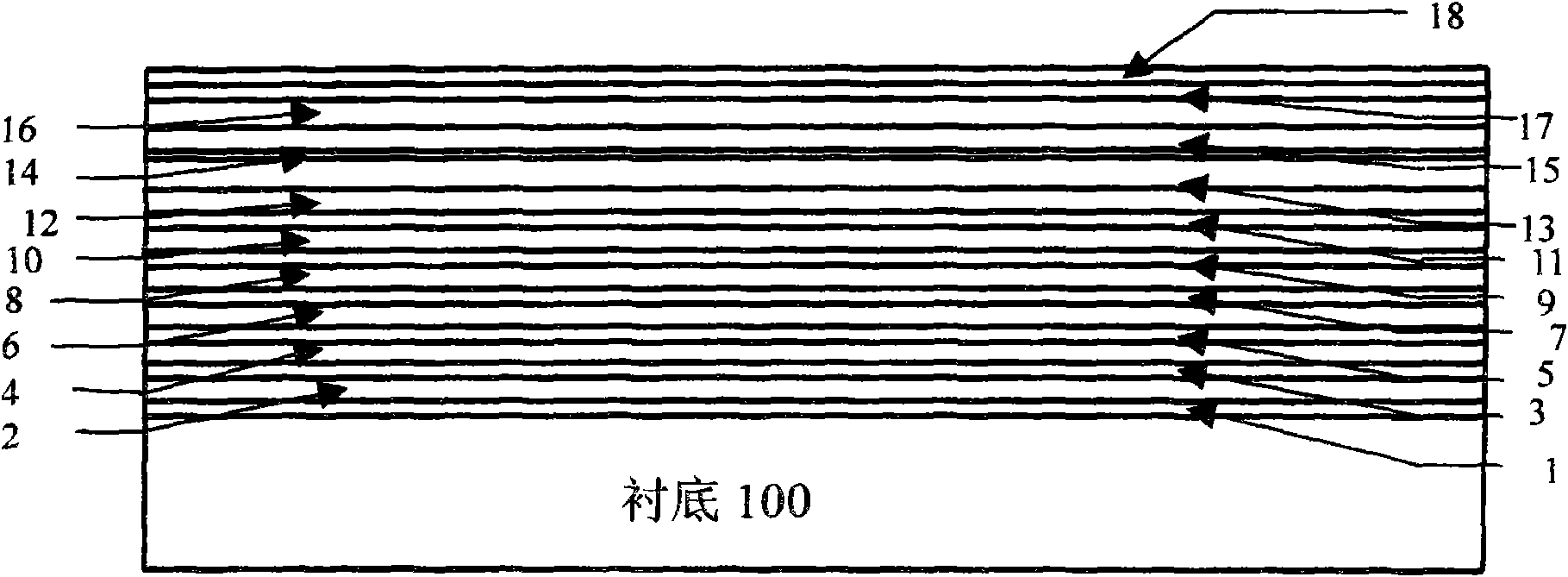

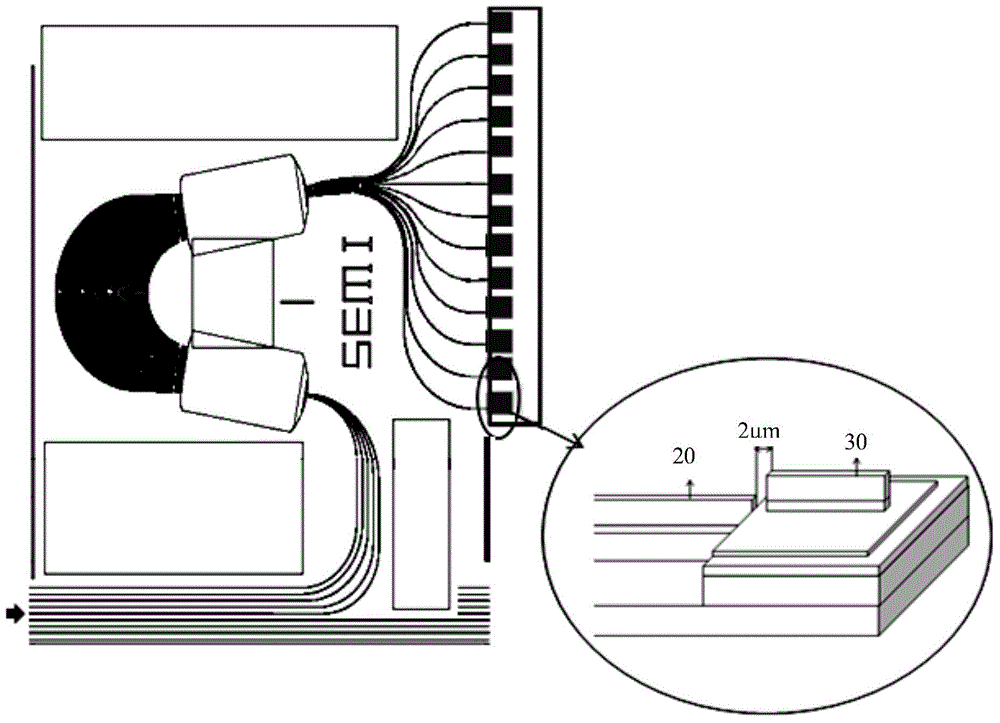

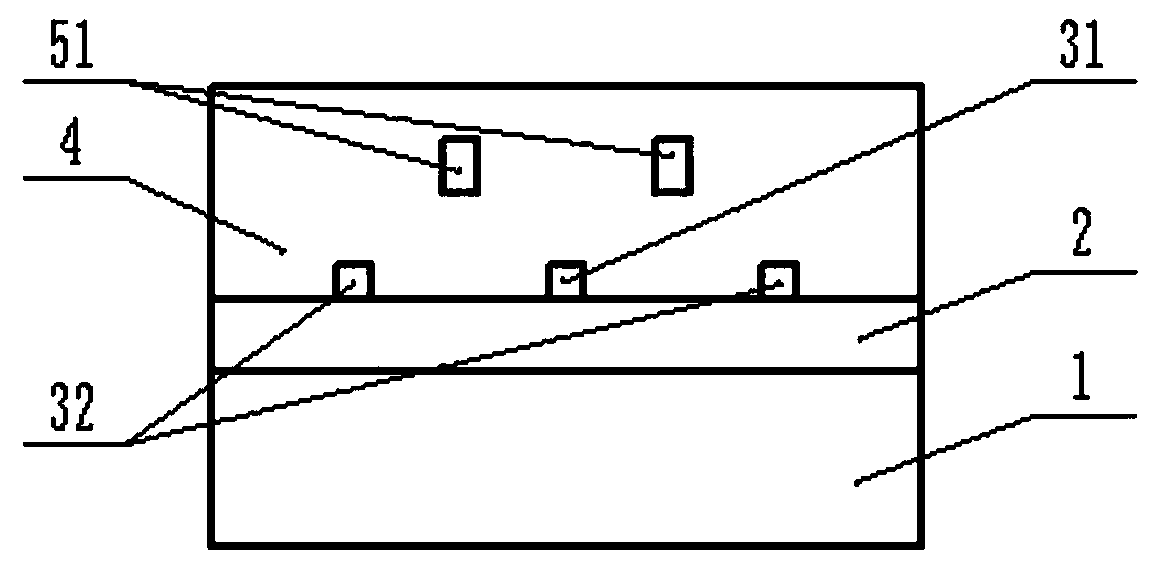

Hybrid integrated optical device with passively aligned laser chips having submicrometer alignment accuracy

ActiveUS9323011B1Improve alignment toleranceEasy alignmentCoupling light guidesOptical waveguide light guideWaveguideLaser

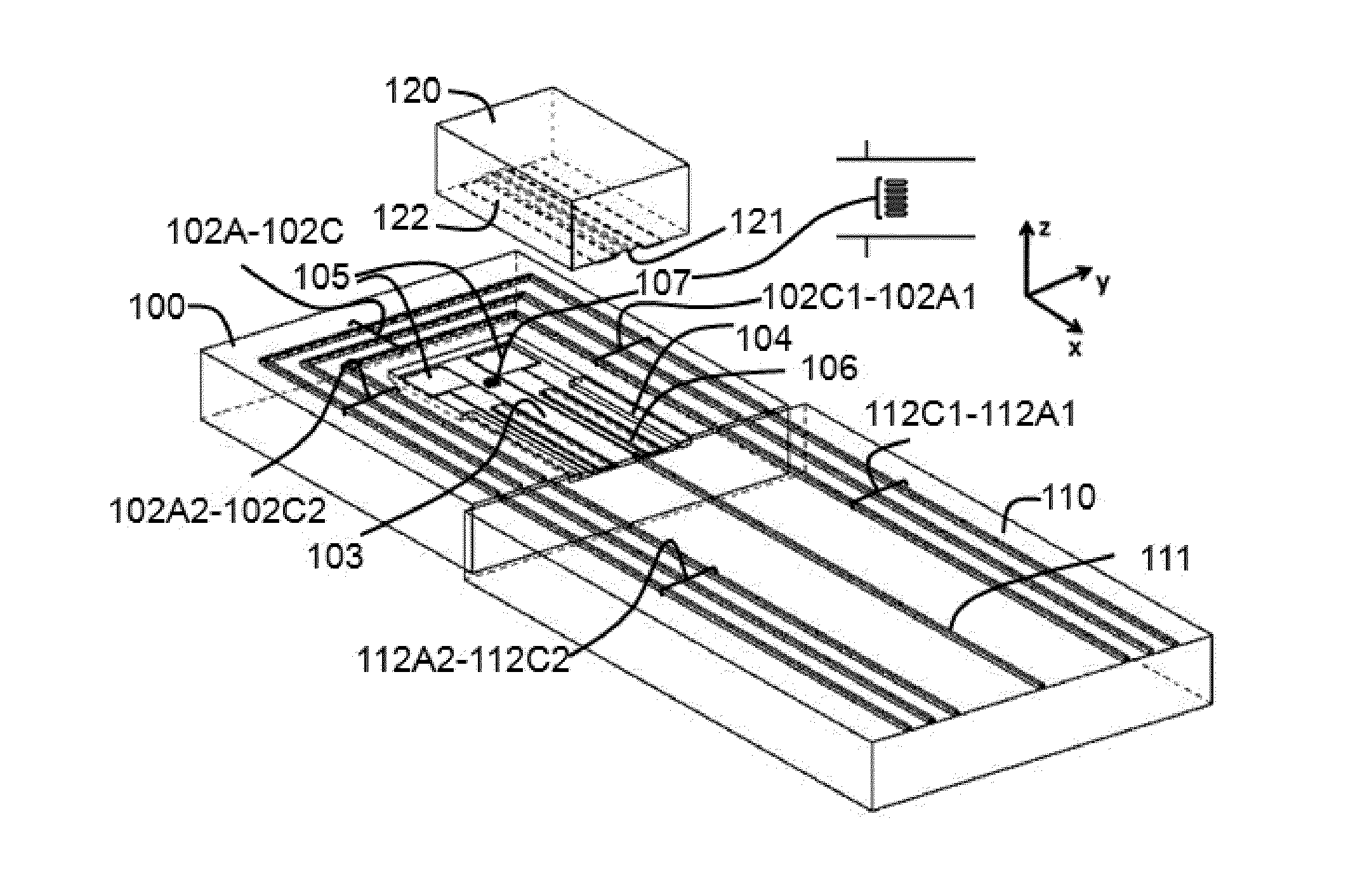

A hybrid optical device includes an optical bench chip, a laser chip with a laser waveguide flip-chip bonded onto the optical bench chip, and an optical waveguide chip with an optical device waveguide disposed adjacent the optical bench chip. The optical bench chip has multiple “U” shaped alignment optical waveguides and the optical waveguide chip has multiple alignment optical waveguides, and the pitches of the various sets of alignment waveguides are different. A misalignment between the laser waveguide and the optical bench chip is compensated for by aligning the optical waveguide chip to different positions of the optical bench chip using the multiple alignment optical waveguides on the optical bench chip and the optical waveguide chip, without turning on the laser, so that the laser waveguide of the laser chip is aligned with the optical device waveguide of the optical device chip.

Owner:LAXENSE

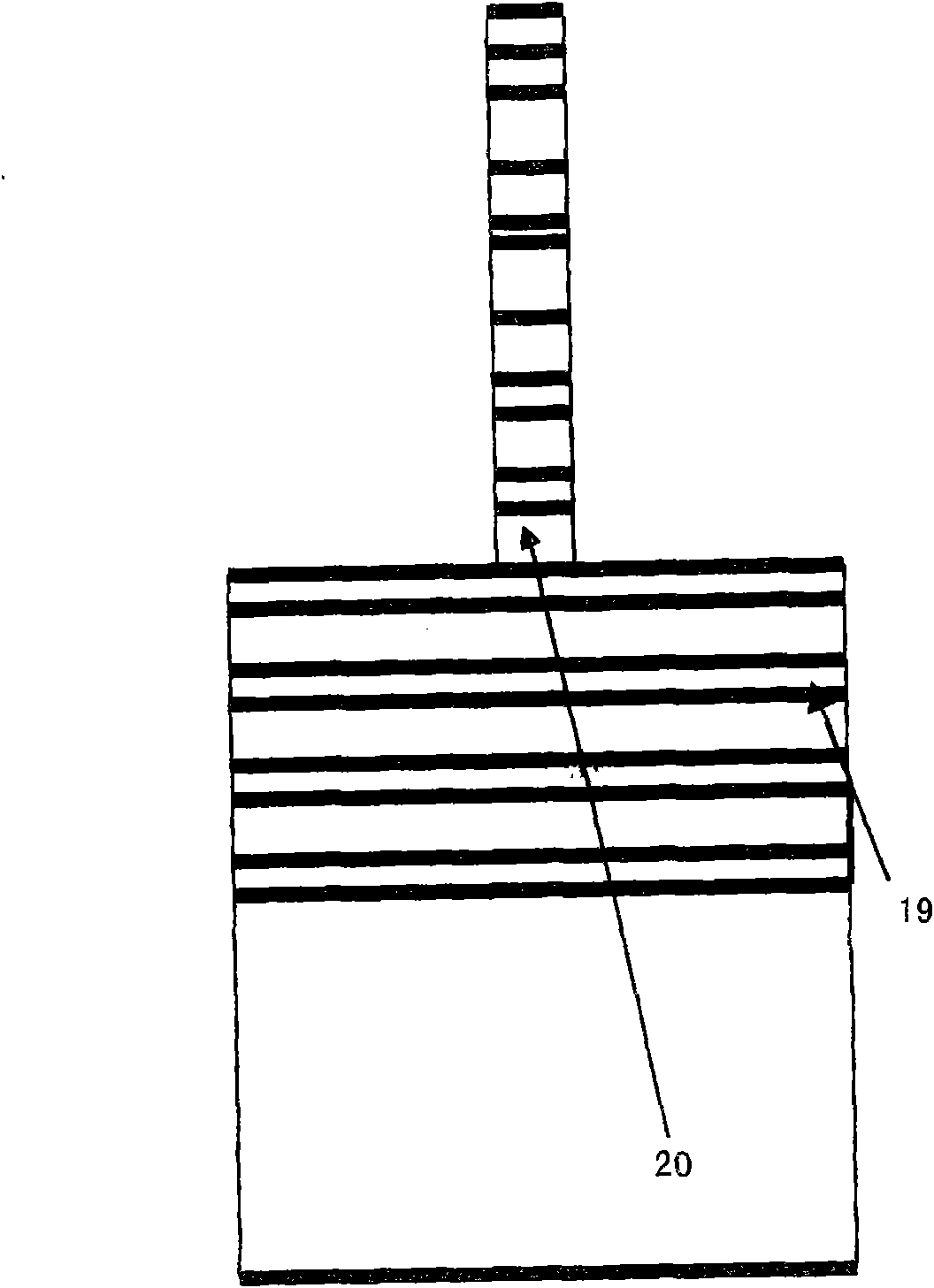

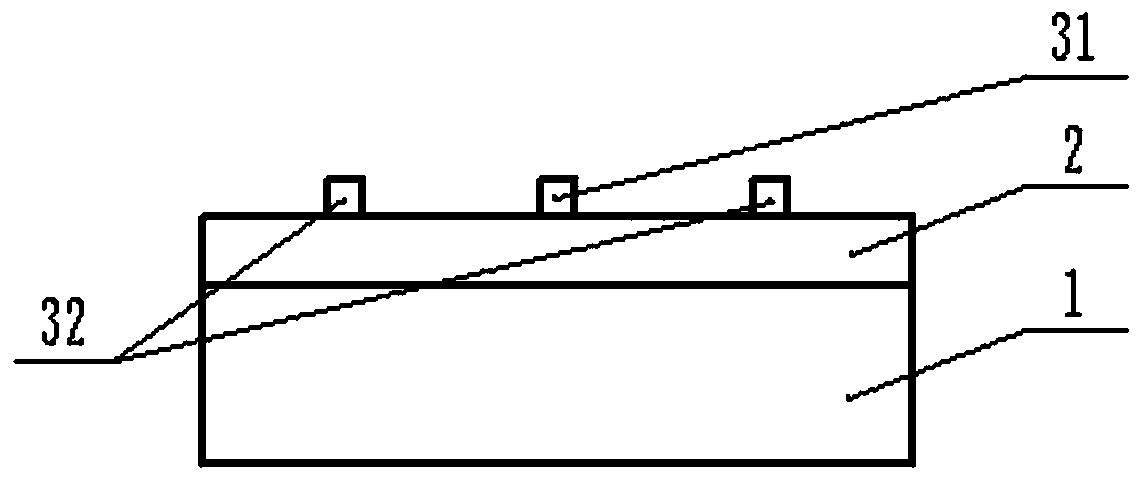

Method for preparing evanescent wave coupling type single carrier traveling wave photoelectrical detector

InactiveCN101614843AImprove coupling efficiencyImprove alignment toleranceCoupling light guidesOptical waveguide light guideIndiumEngineering

The invention provides a method for preparing an evanescent wave coupling type single carrier traveling wave photoelectrical detector. The method comprises the following steps of: orderly growing layers from an indium-phosphorus stress buffer layer to an InGaAs contact layer on a substrate; growing a layer of silicon oxide masking film on the InGaAs contact layer; etching both sides of the silicon oxide masking film, etching both sides of a silicon oxide masking strip, and obtaining a deep ridge structure; corroding partial deep ridge structure by a wet method, and forming an incident window region; forming N-shaped metal ohmic contacts on both sides of the deep ridge structure by a lift-off method; etching all layers outside the outer side edge of the N-shaped metal ohmic contact on the substrate; keeping all layers on the side of the incident window region, and forming a mesa structure on the substrate; preparing a signal electrodes of the titanium traveling wave electrode structure on the part extended from the upper surface of the deep ridge structure to the substrate by an inclined mesa; preparing a grounding electrode of the titanium traveling wave electrode structure on the part extended from the N-shaped metal ohmic contact on both sides of the deep ridge structure to the substrate by the inclined mesa; and reducing and splitting.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

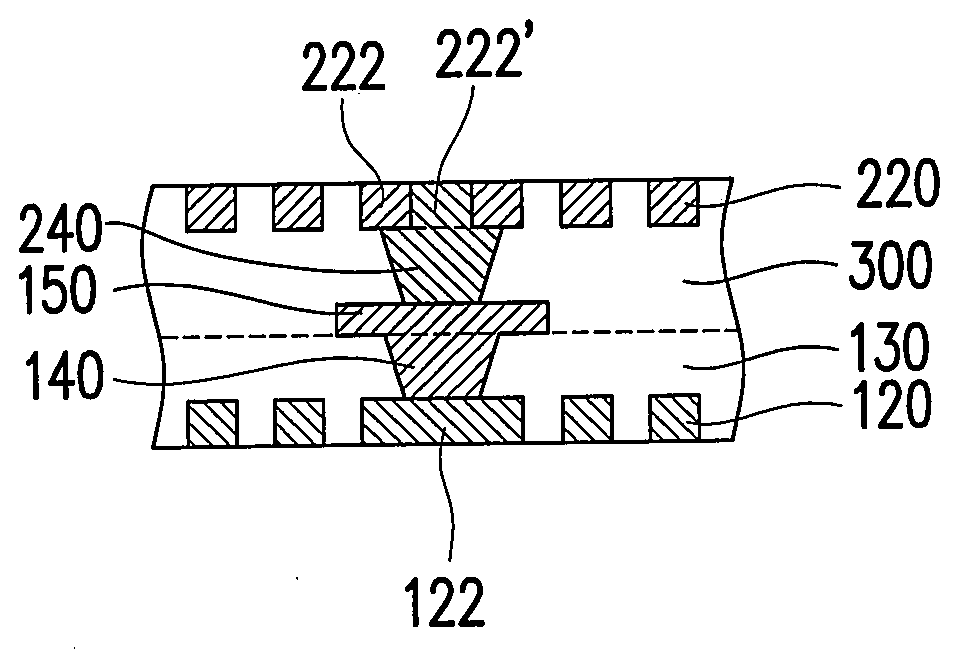

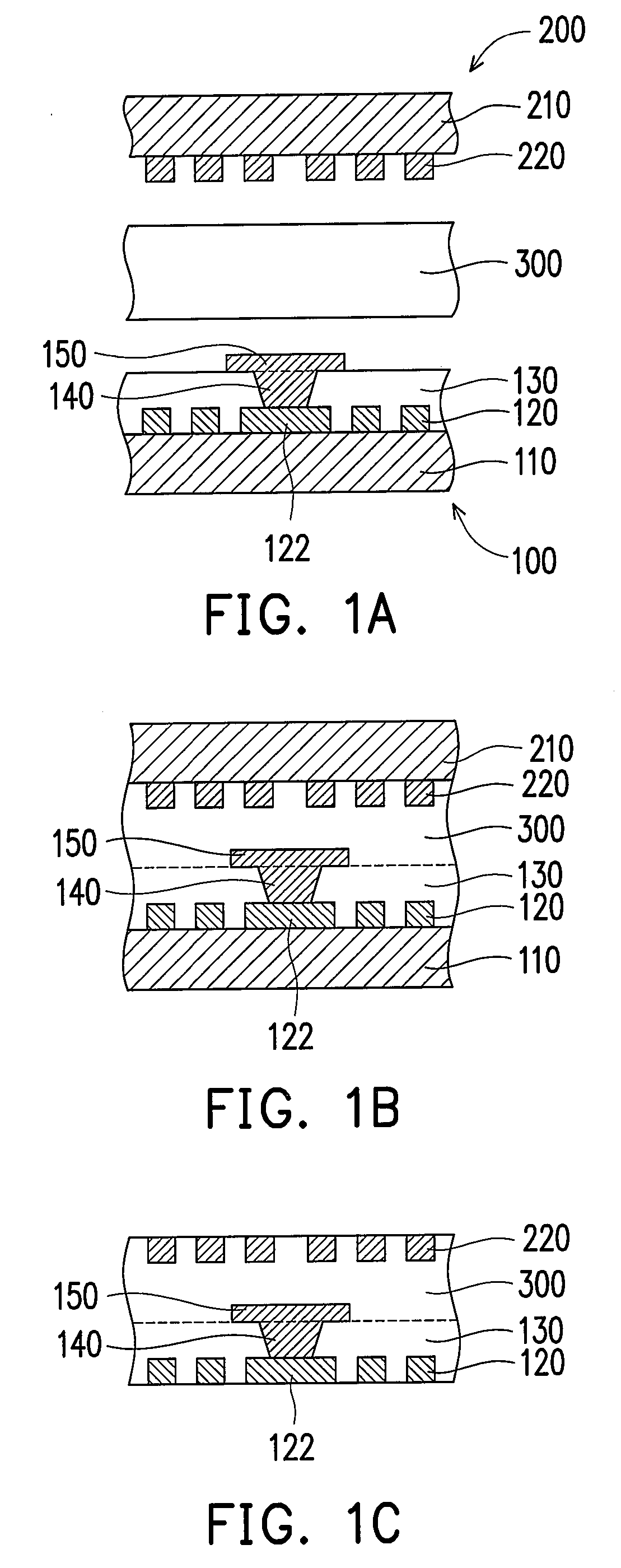

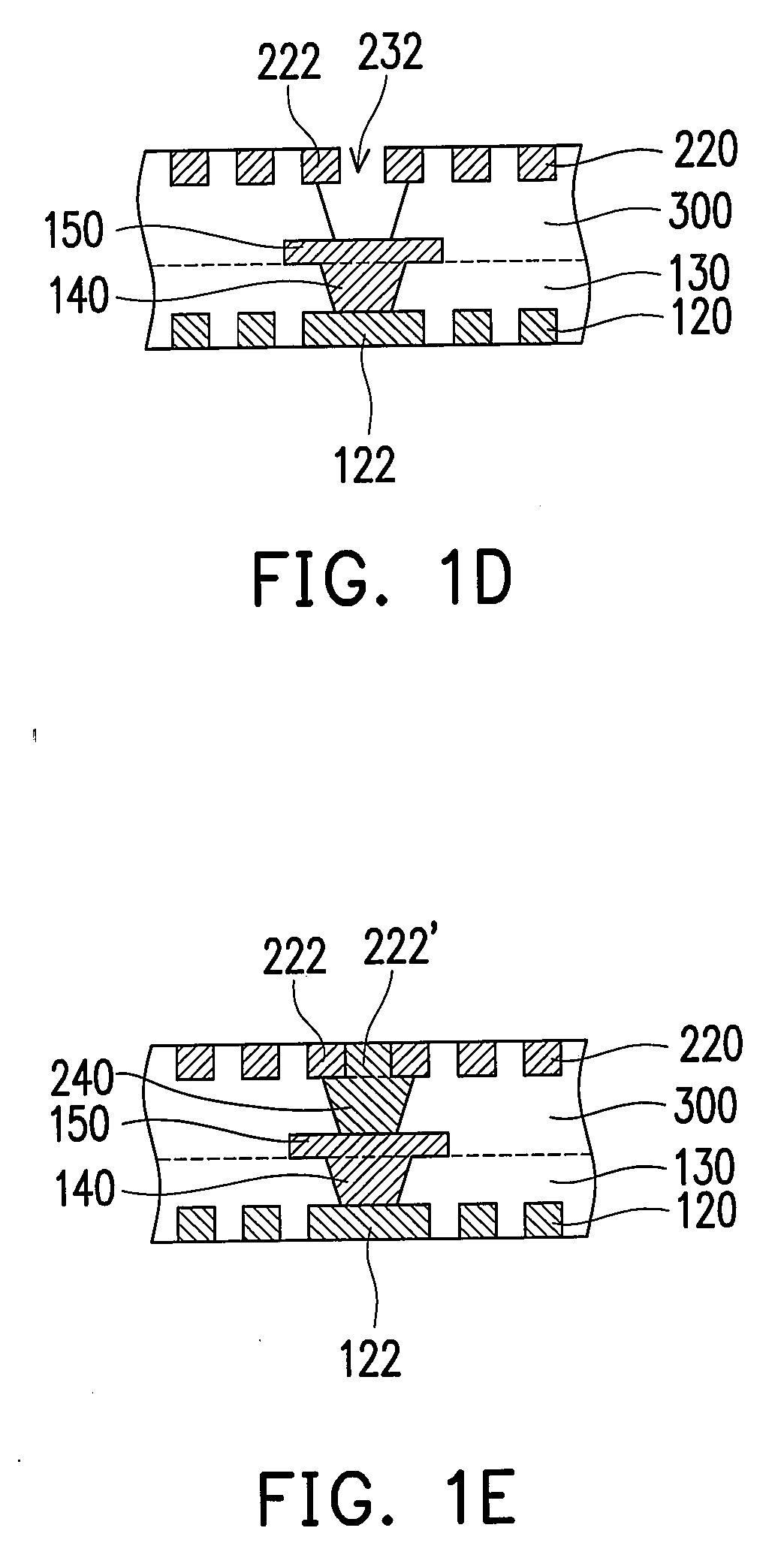

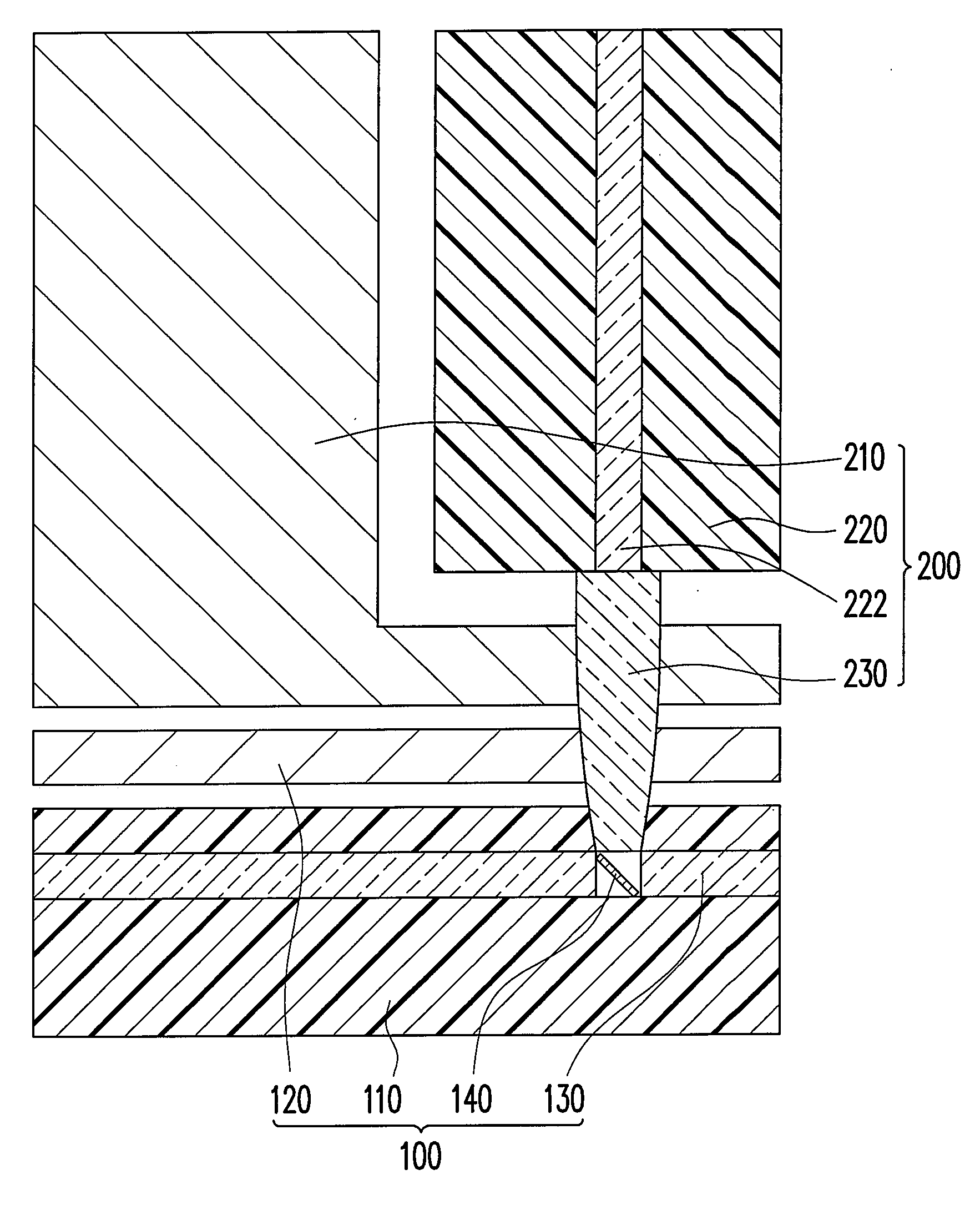

Circuit structure and process thereof

InactiveUS20080179744A1High aspect ratioIncreased circuit densitySemiconductor/solid-state device detailsPrinted circuit aspectsEngineeringDielectric layer

A circuit structure has a first dielectric layer, a first circuit pattern embedded in the first dielectric layer and having a first via pad, a first conductive via passing through the first dielectric layer and connecting to the first via pad, and an independent via pad disposed on a surface of the first dielectric layer away from the first via pad and connecting to one end of the first conductive via. The circuit structure further has a second dielectric layer disposed over the surface of the first dielectric layer where the independent via pad is disposed, a second conductive via passing through the second dielectric layer and connecting to the independent via pad, and a second circuit pattern embedded in the second dielectric layer, located at a surface thereof away from the independent via pad, and having a second via pad connected to the second conductive via.

Owner:UNIMICRON TECH CORP

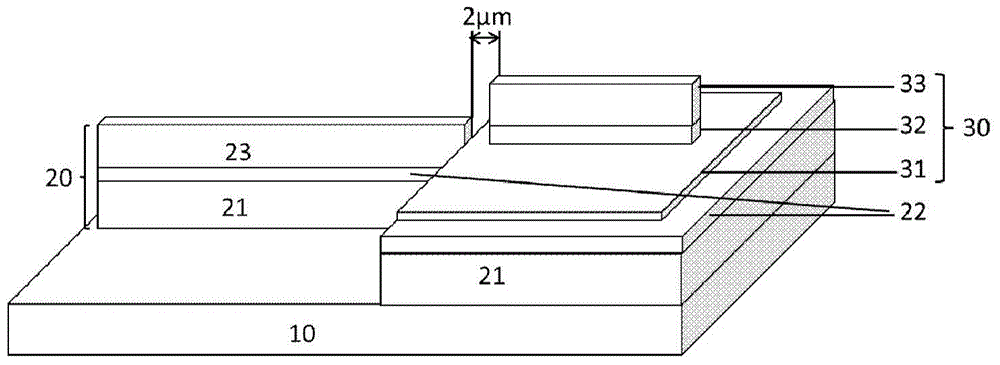

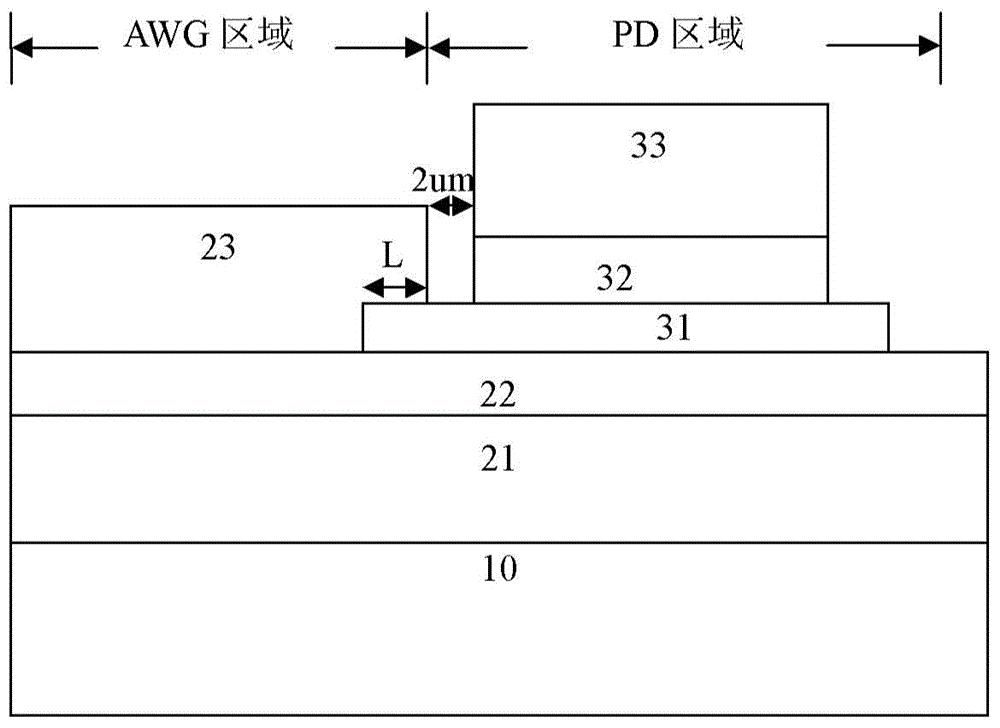

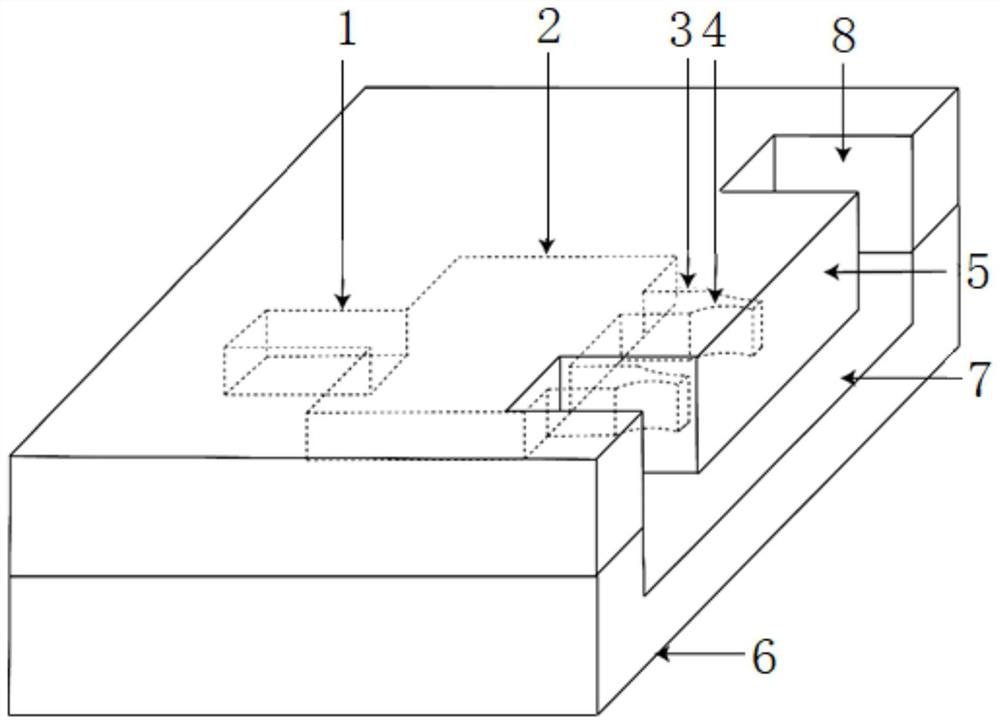

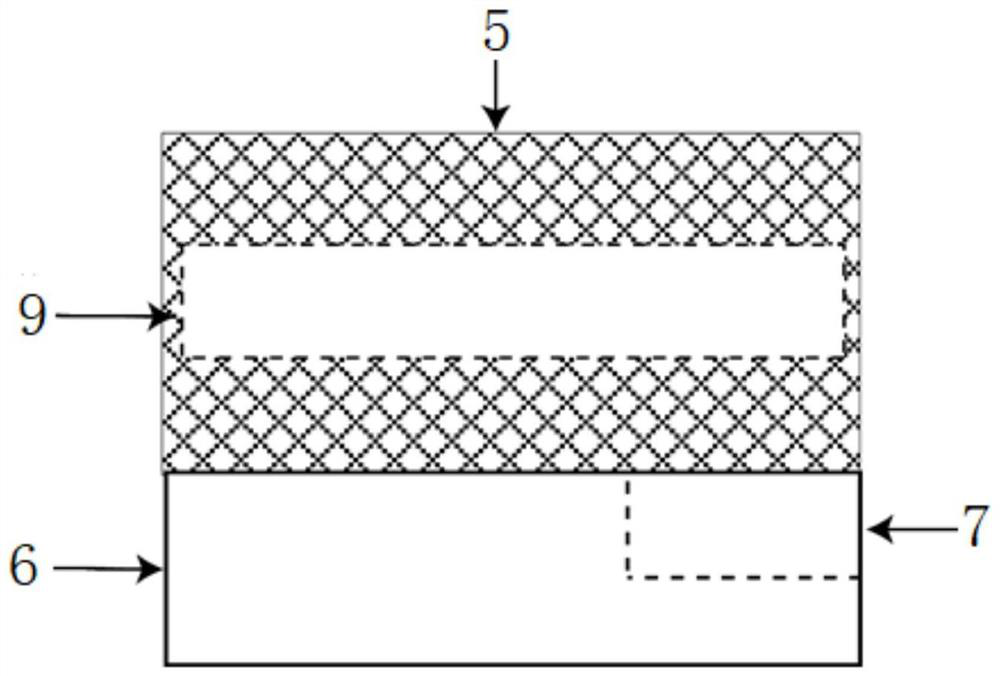

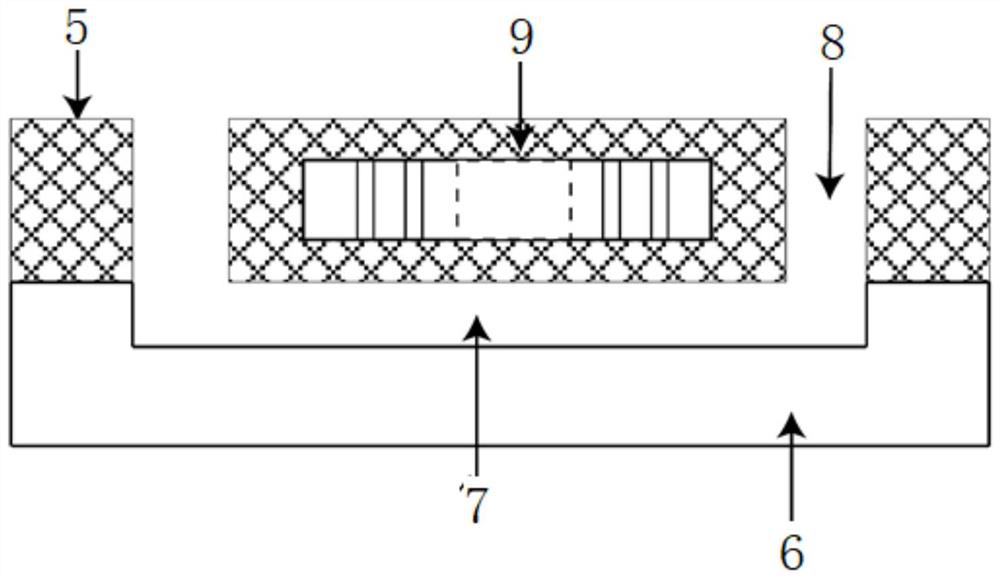

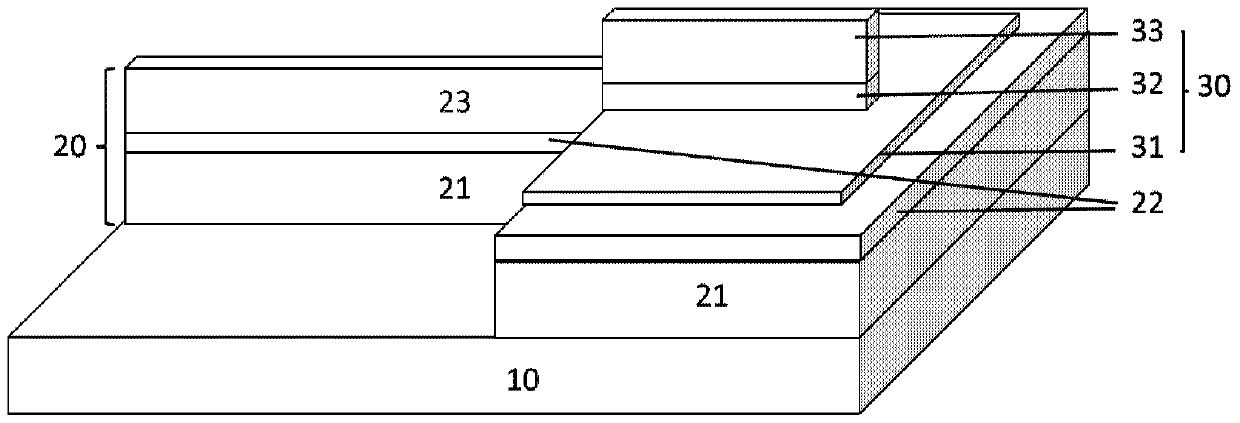

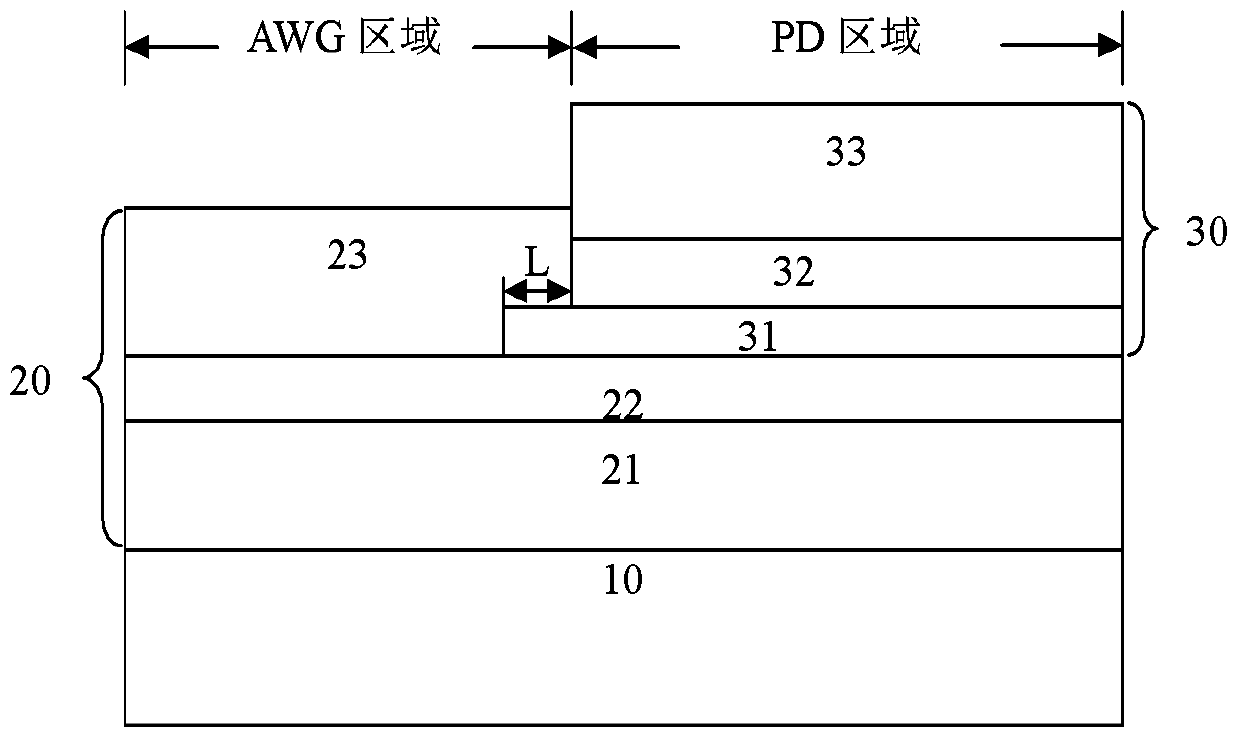

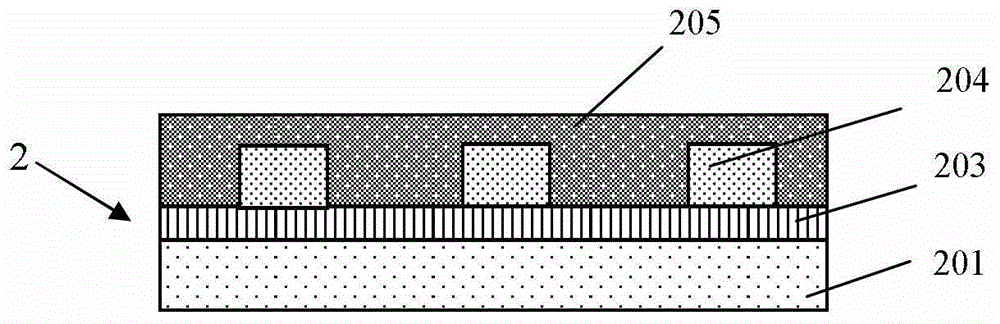

Integrated device for seamed butt joint of AWG (arrayed waveguide grating) output waveguide and detector and preparation method

ActiveCN104950382AAvoid coupling lossImprove coupling efficiencyOptical waveguide light guideCapacitanceCoupling loss

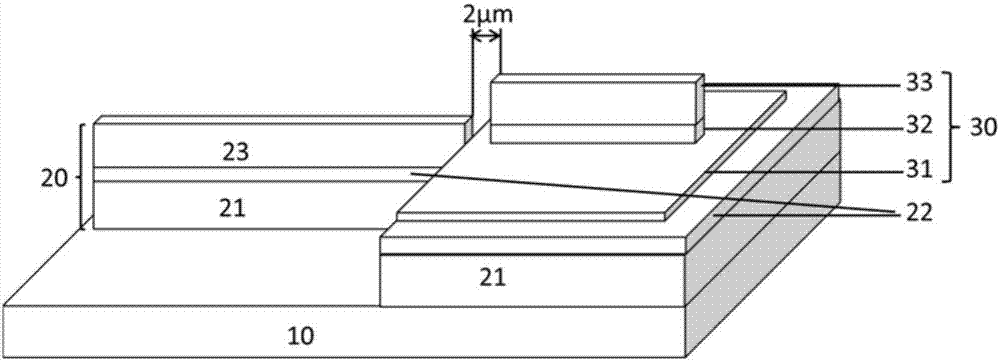

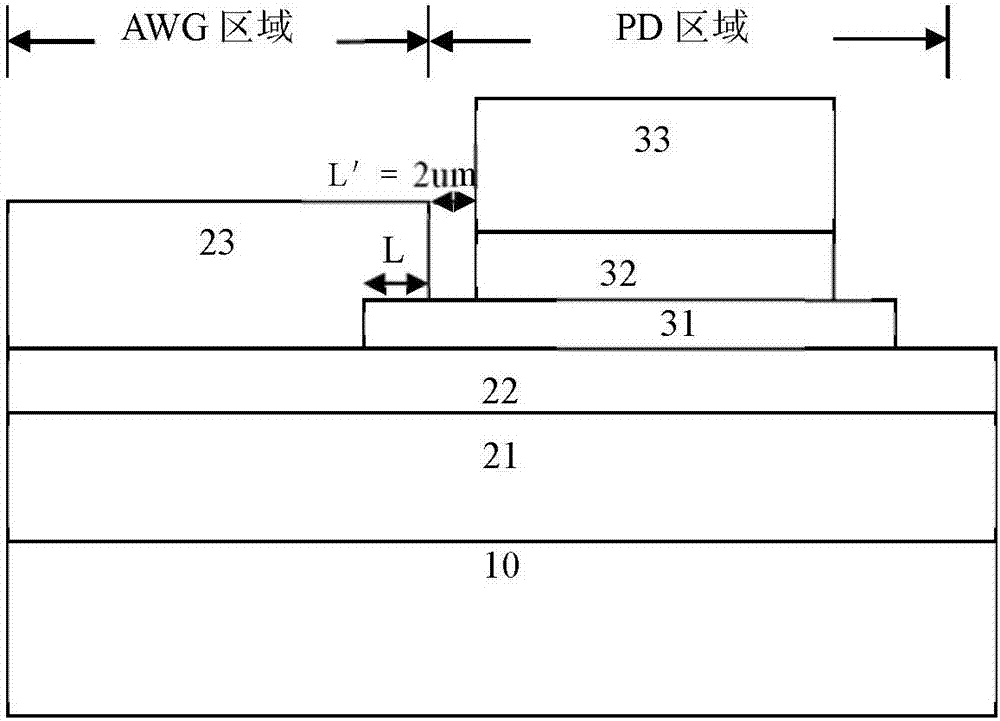

The invention provides an integrated device for seamed butt joint of an AWG (arrayed waveguide grating) output waveguide and a waveguide photodetector and a preparation method of the integrated device. The integrated device comprises a substrate, the AWG output waveguide and the waveguide photodetector, wherein the left area and the right area of the substrate are taken as an AWG area and a PD (photodetector) area respectively; the AWG output waveguide is located on the AWG area on the substrate, and an AWG lower coating layer and an AWG core layer extend to the PD area; the waveguide photodetector is formed above the AWG core layer in the PD area on the substrate, and a PD lower contact layer of the waveguide photodetector extends into an AWG upper coating layer of the AWG output waveguide and is located above the AWG core layer; a PD absorbing layer and a PD upper contact layer of the waveguide photodetector are spaced with the AWG upper coating layer of the AWG output waveguide by a narrow seam. According to the integrated device and the preparation method, excessive coupling loss generated during interconnection of discrete devices is avoided, and the energy efficiency of an optical link is improved through evanescent field coupling; meanwhile, by means of the seam between the AWG output waveguide and the waveguide photodetector, the capacitance of PD devices is reduced, and the device bandwidth is increased.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

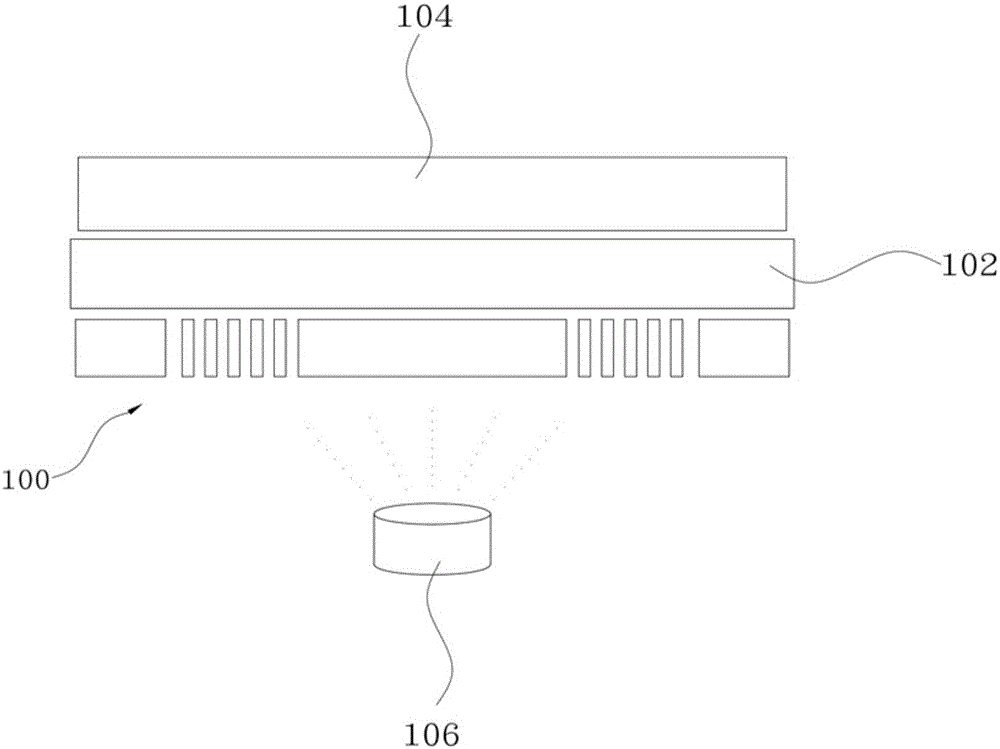

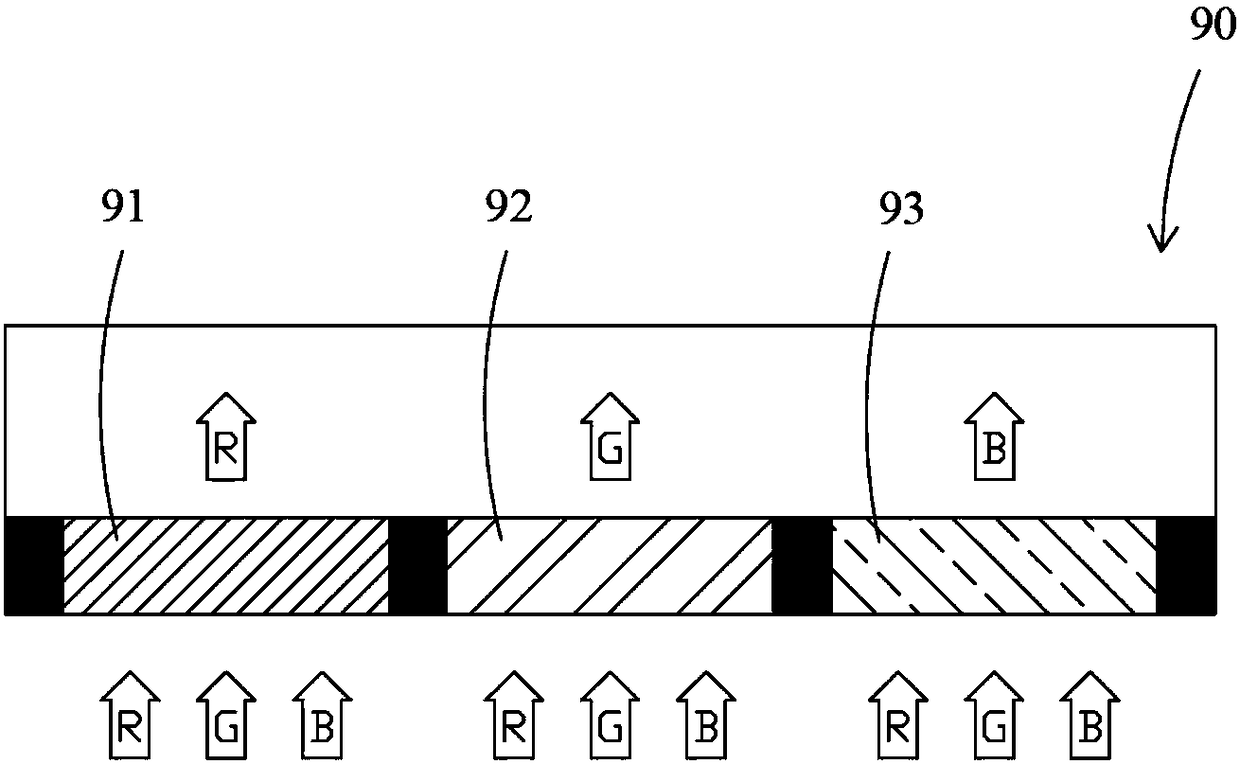

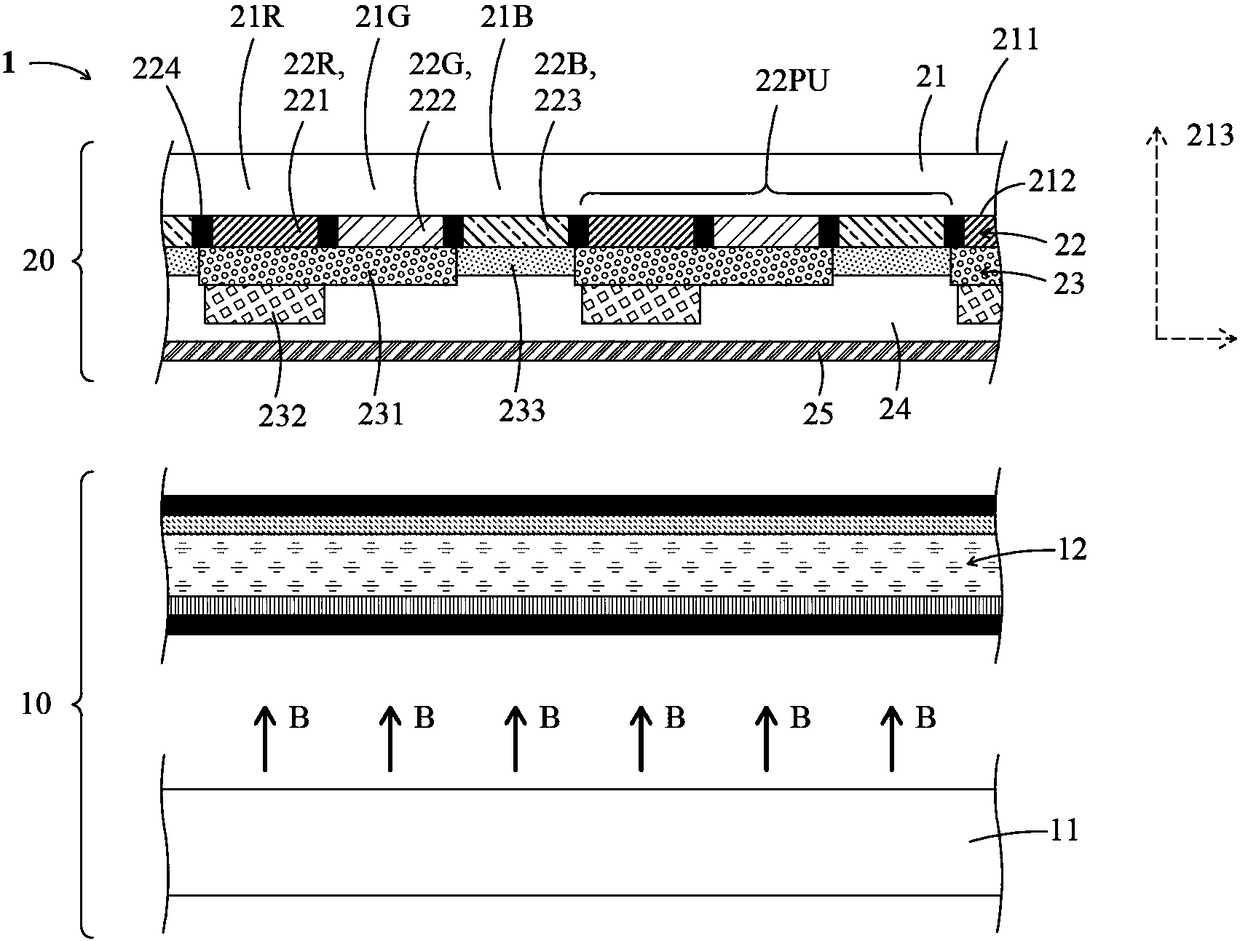

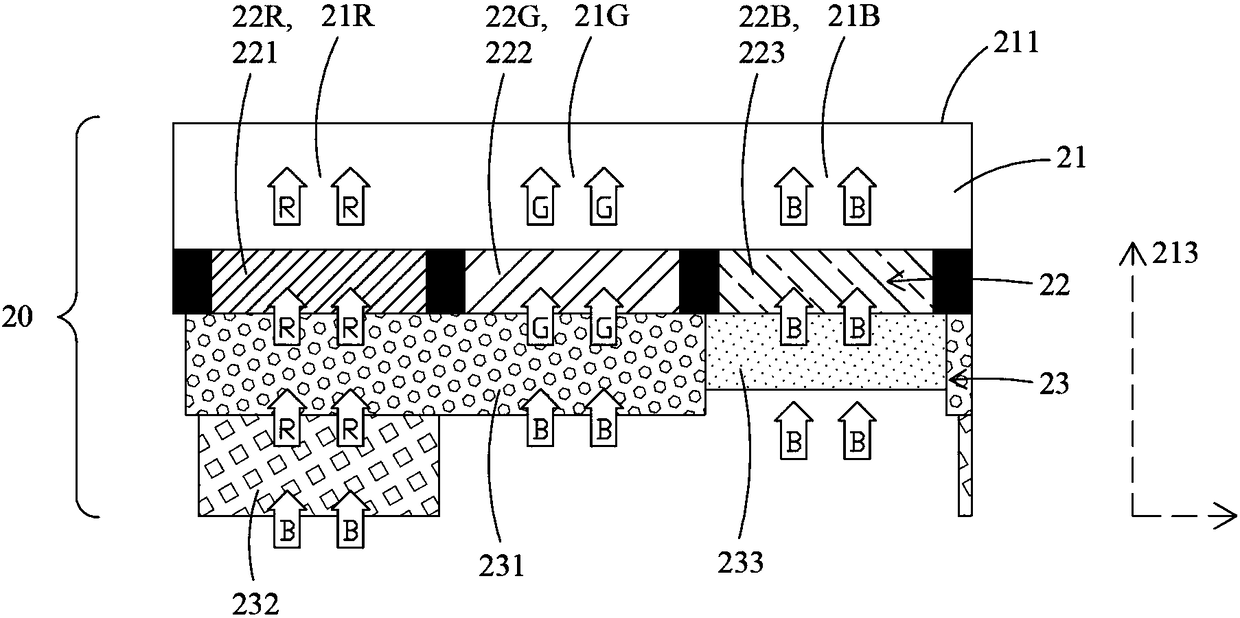

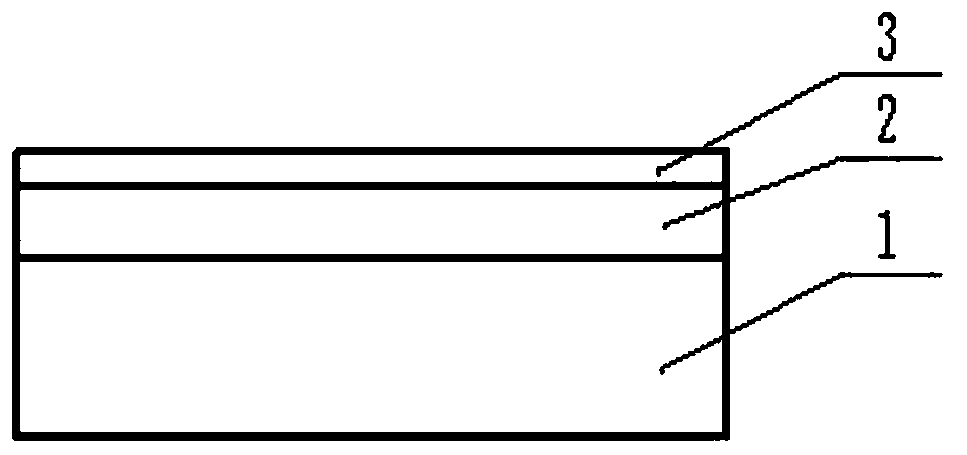

Photoluminescence display device and manufacturing method thereof

The invention provides a photoluminescence display device and a manufacturing method thereof. The photoluminescence display device includes a blue light source and a display panel arranged on one side of the blue light source; the display panel includes a light-transmitting substrate, a filtering layer structure, and a photoluminescence layer structure; the filtering layer structure is formed on the light-transmitting substrate, and includes a red region, a green region and a blue region which are adjacent to each other; and the photoluminescence layer structure is arranged on the filtering layer structure and faces the blue light source, and includes a red photoluminescence layer and a green photoluminescence layer, wherein the red photoluminescence layer is arranged on the green photoluminescence layer and faces the blue light source. Accordingly, the display device has good light energy utilization rate and a larger display visual angle; and the photoluminescence layer structure can avoid accurate positioning of pixels, and then the display device is easy to manufacture.

Owner:MAVEN OPTRONICS CO LTD

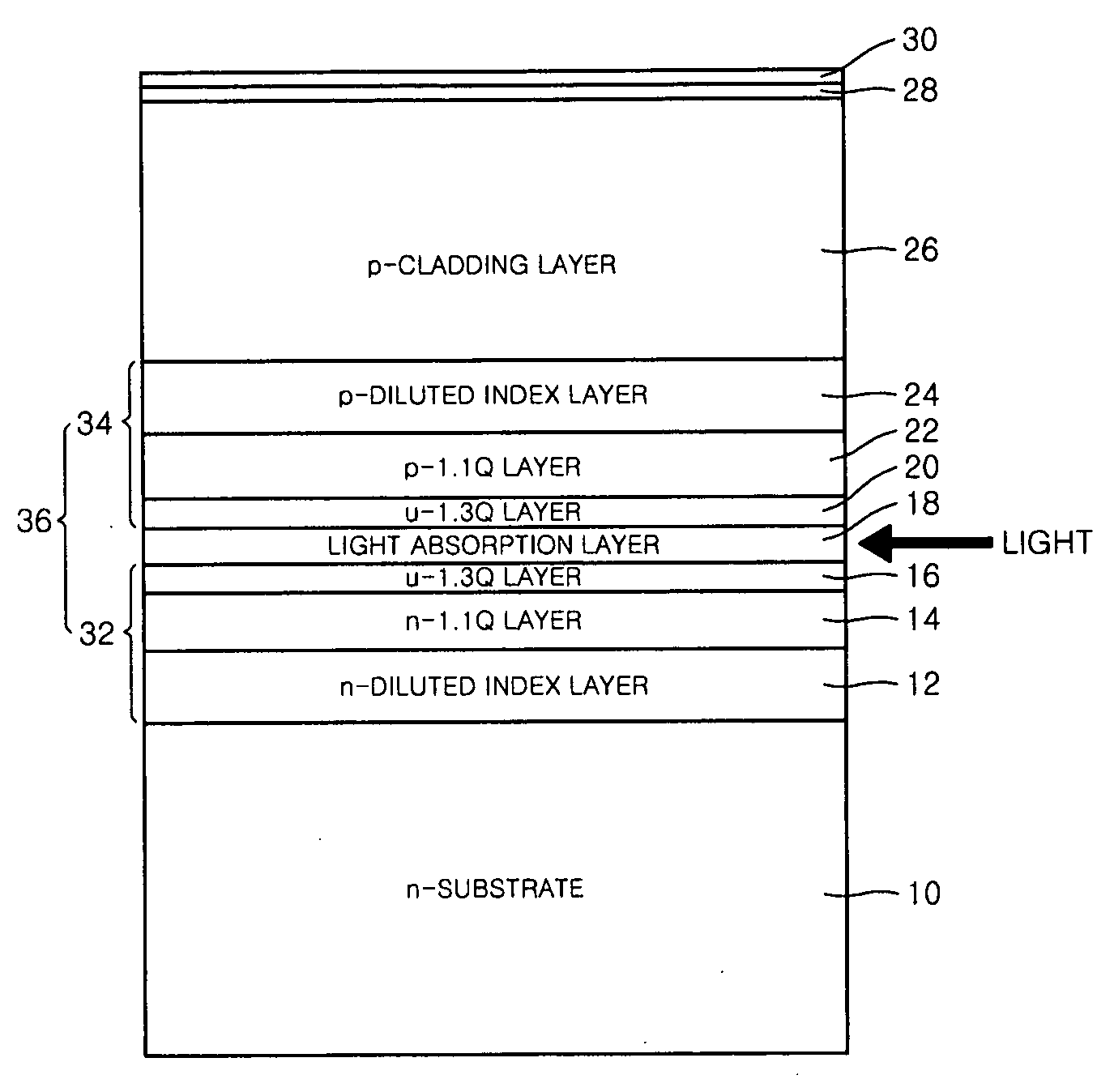

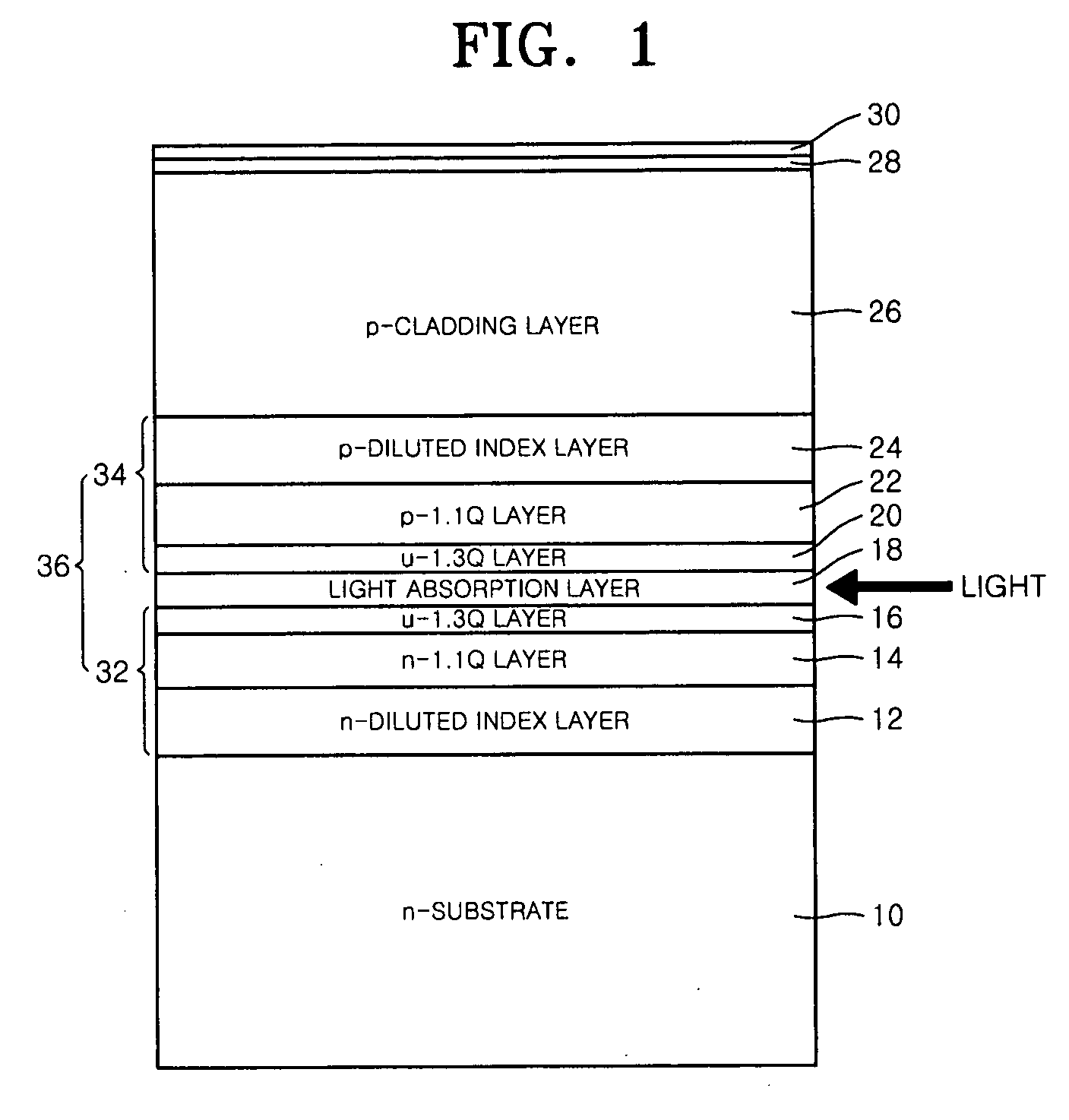

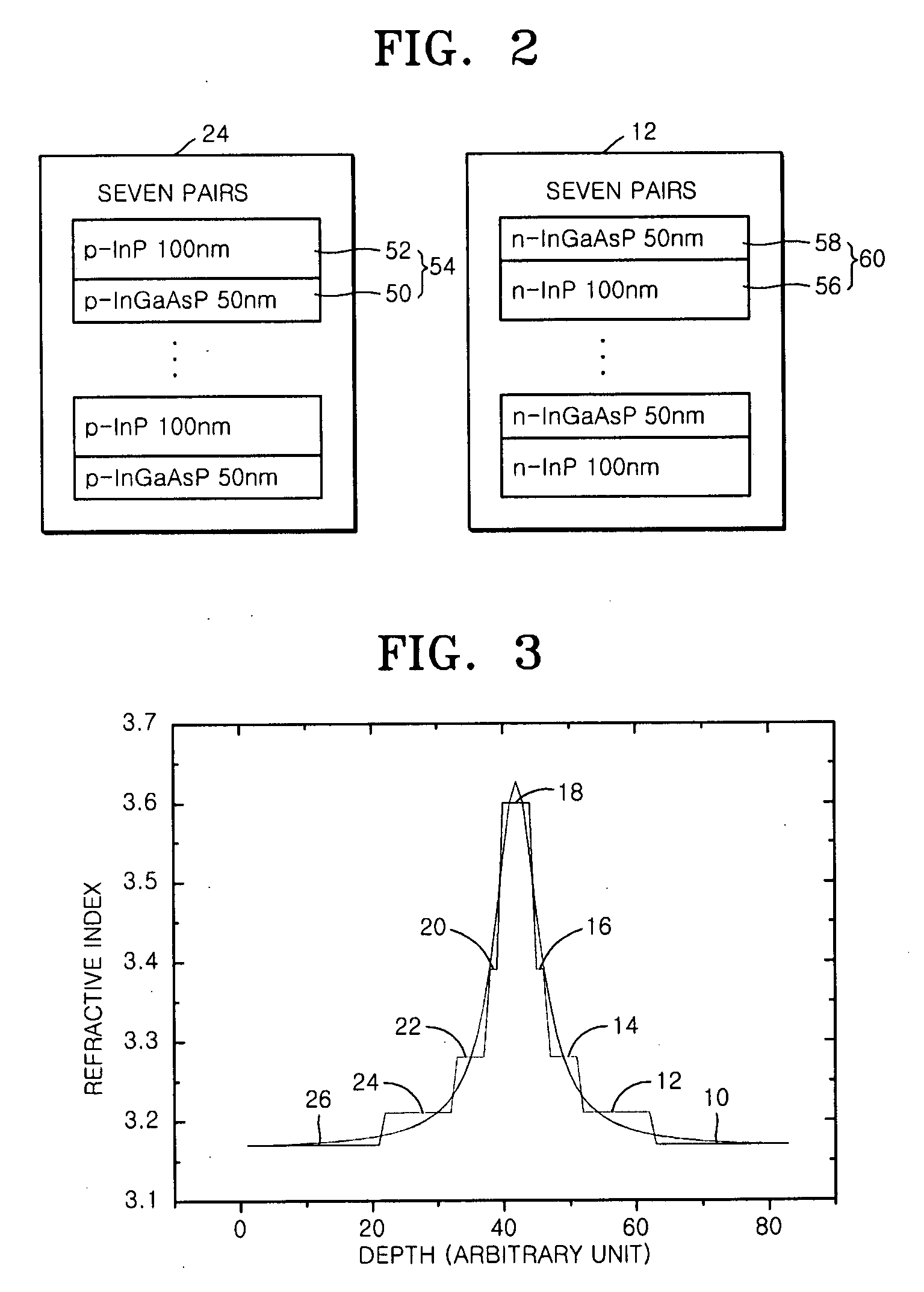

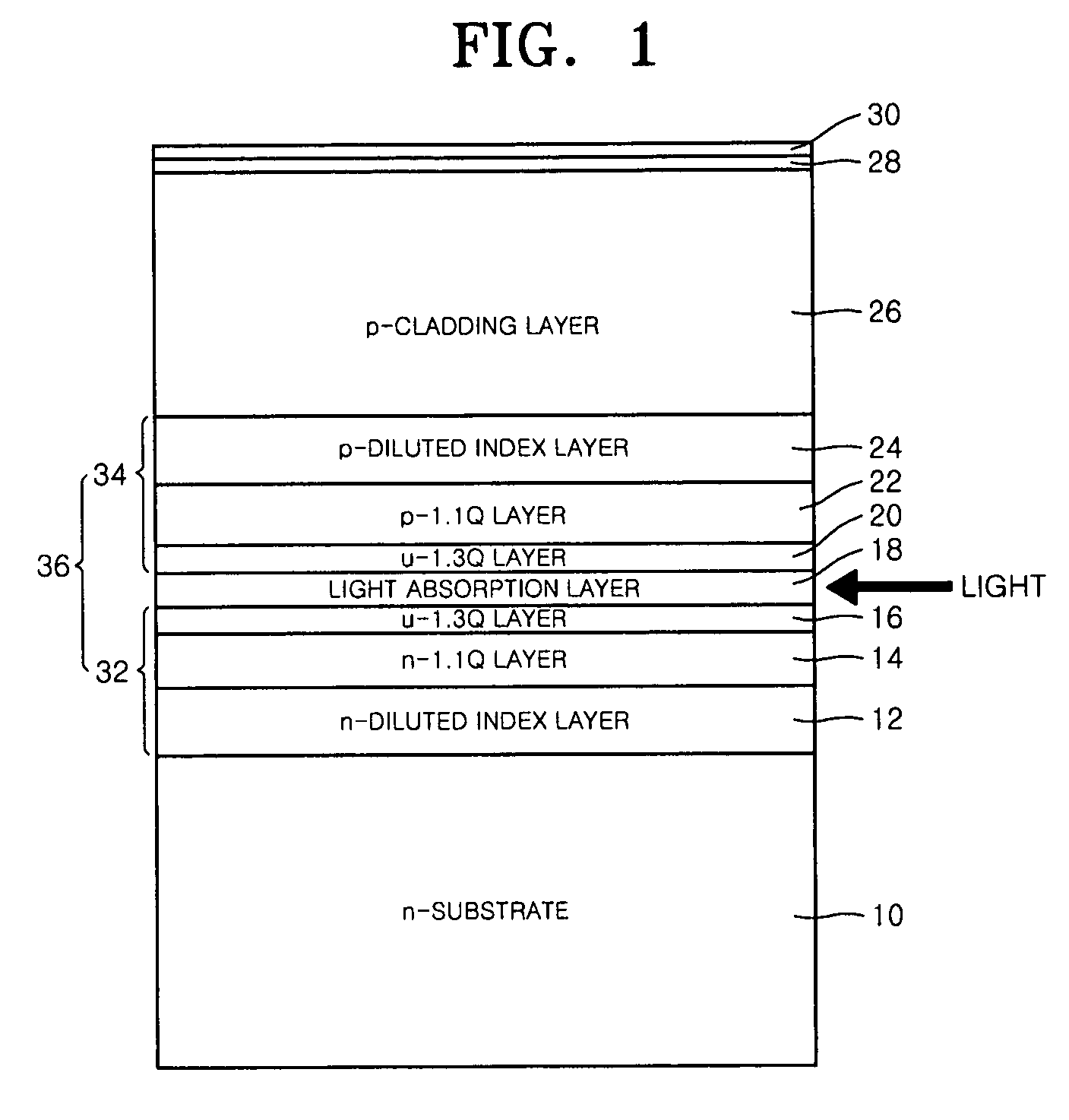

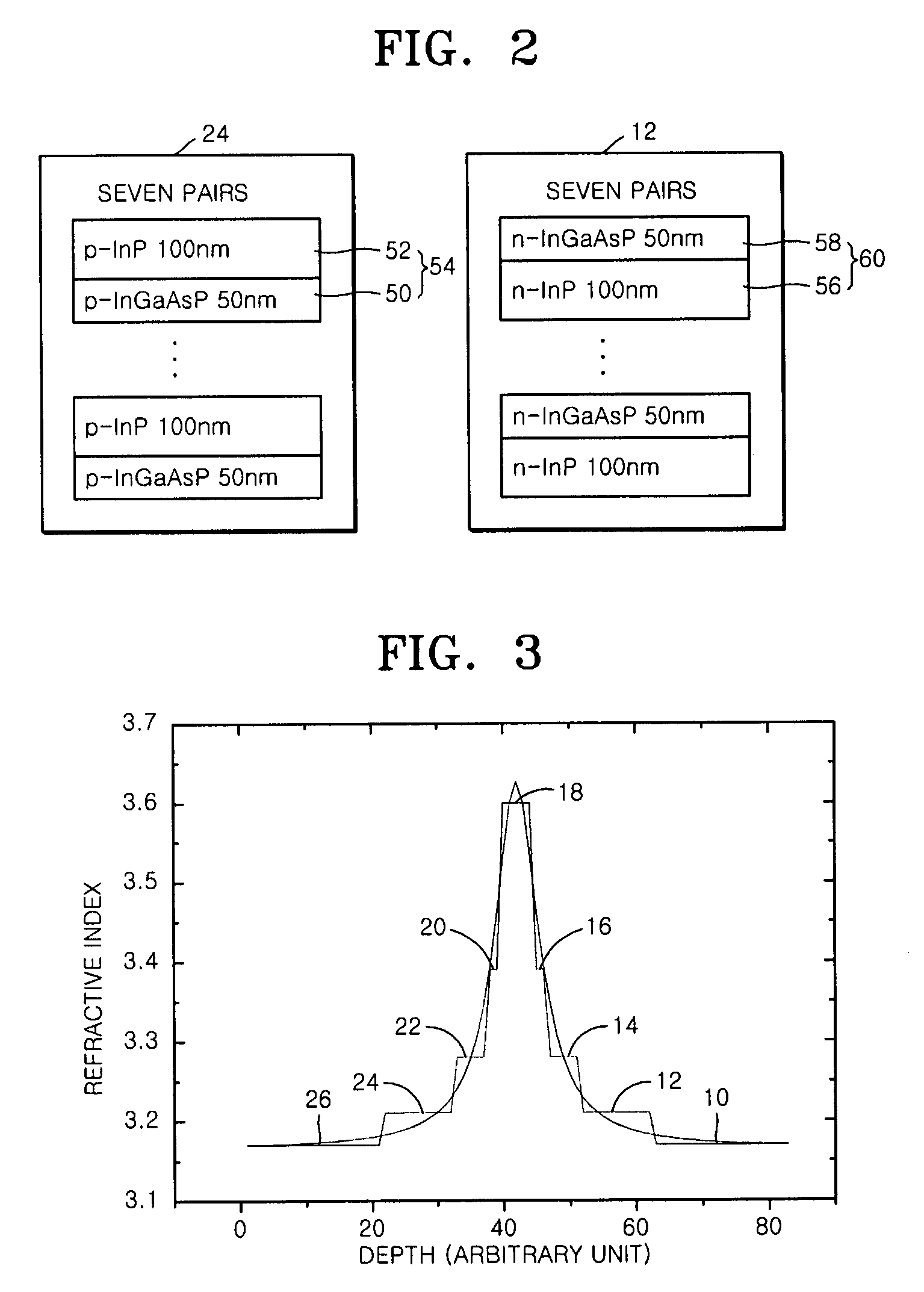

Waveguide pin photodiode having graded index distribution centering around optical absorption layer

InactiveUS20070133636A1Reduce speedImprove responsivenessLaser detailsCoupling light guidesLight guideDepth direction

A waveguide PIN photodiode is provided. The waveguide PIN photodiode includes a lower light guide layer, a light absorption layer, an upper light guide layer, and a cladding layer. The lower light guide is formed on a substrate, and the light absorption layer is formed on the lower light guide layer. The upper light guide layer is formed on the light absorption layer, and the cladding layer is formed on the upper light guide layer. The lower light guide layer, the light absorption layer, and the upper light guide layer constitute a core layer, which is an optical waveguide, and graded index distribution is symmetrically formed in a depth direction, centering around the light absorption layer having a highest refractive index.

Owner:ELECTRONICS & TELECOMM RES INST

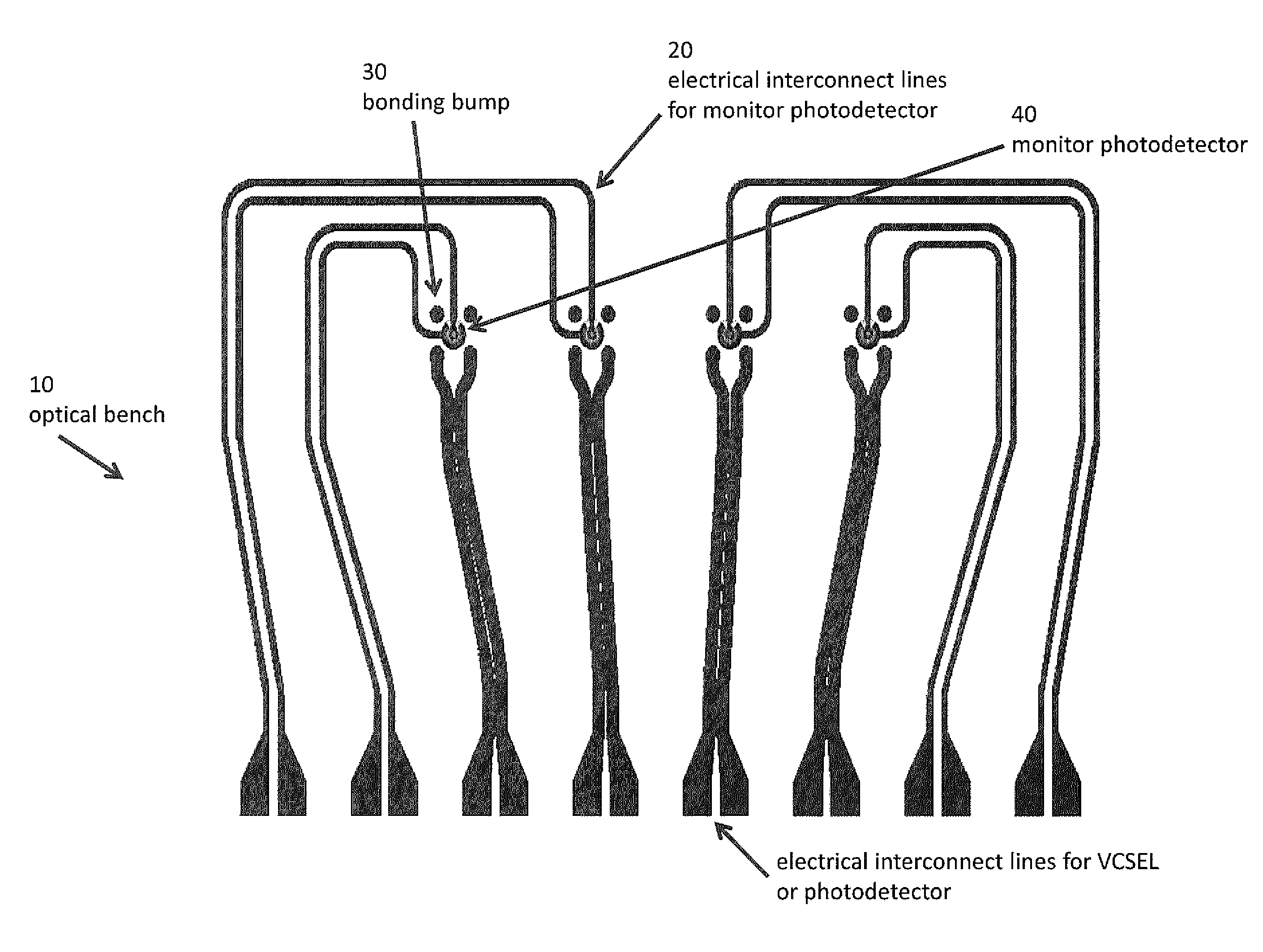

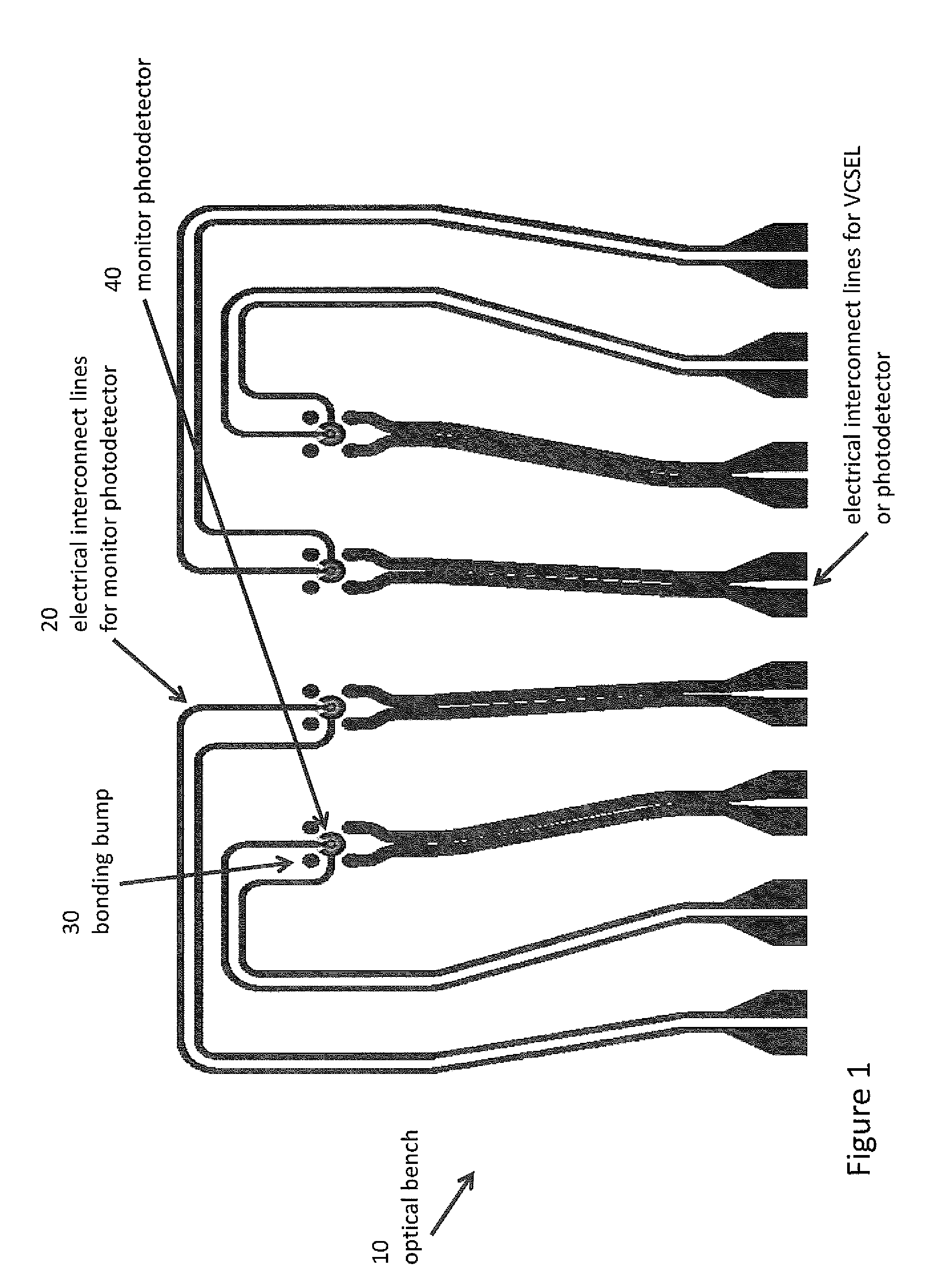

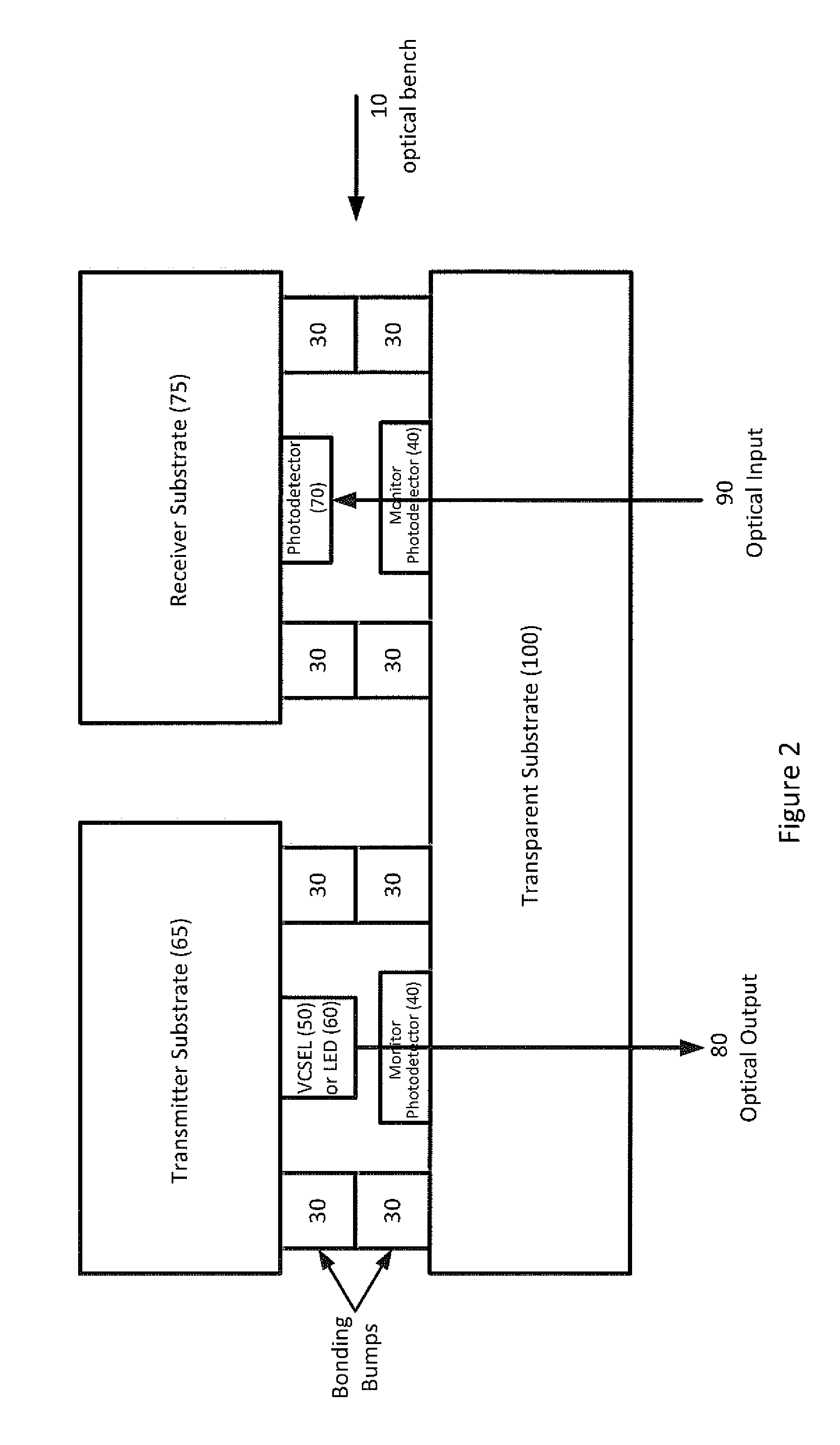

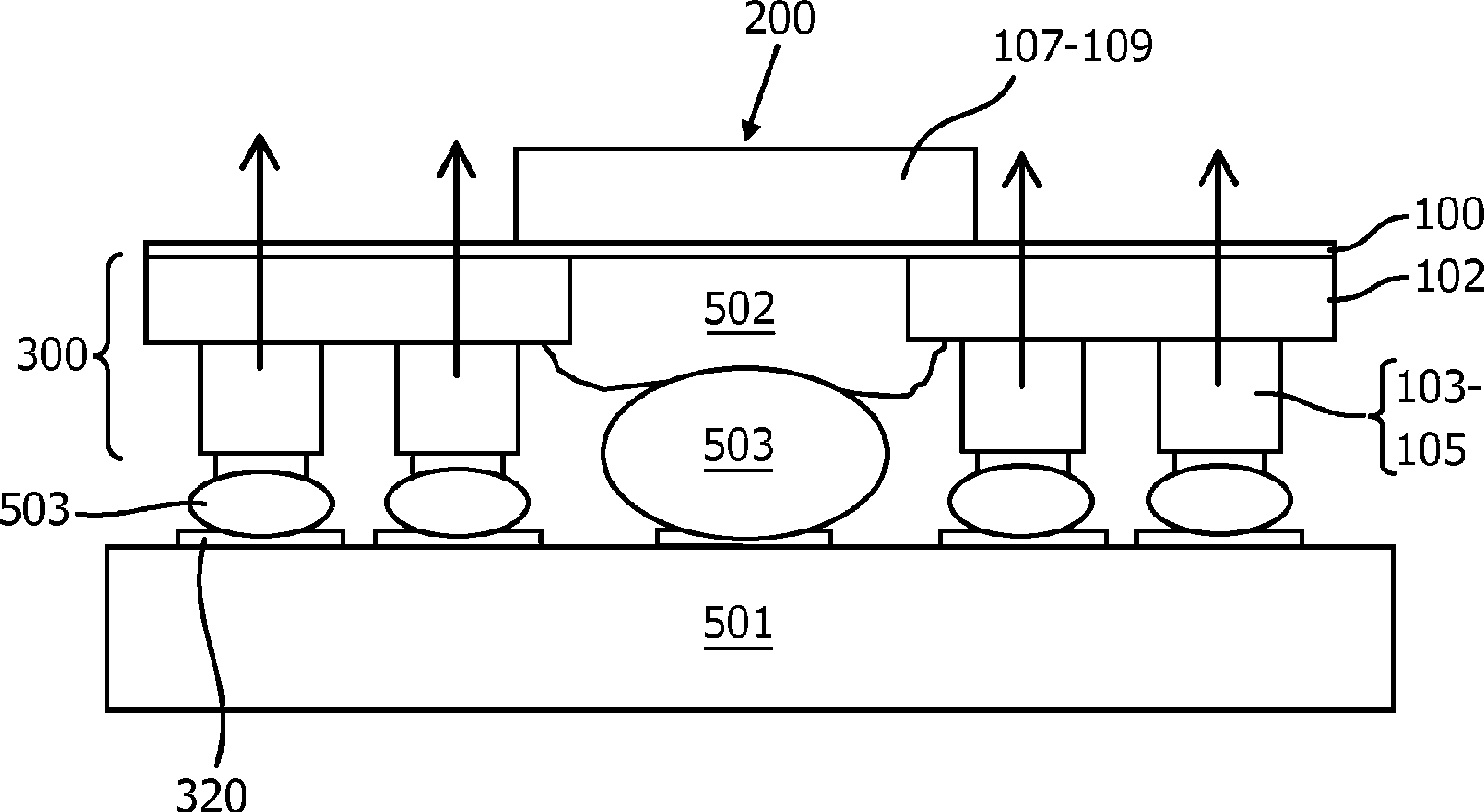

Optical bench apparatus having integrated monitor photodetectors and method for monitoring optical power using same

ActiveUS20140186032A1Small and fasterImprove alignment tolerancePhotometryTransmission monitoringVertical-cavity surface-emitting laserPhotodetector

Optical bench structure provides a platform for integrating optical transmitters, particularly Vertical-Cavity Surface-Emitting Lasers (VCSELs), with monitor photodetectors. A substrate with photodetectors on the front side is aligned with flip-chip bonding bumps so the emission of the transmitters is aligned with the monitor photodetectors and passes through the monitor photodetectors with a portion of the transmitted light absorbed by the monitor photodetectors. The photodetectors have a thin absorption region so the percentage of light absorbed may be relatively small, providing sufficient photocurrent to monitor the transmitted power having a minimal effect on the transmitted power. Microlenses are integrated on the backside of the substrate focus, steer and / or collimate the emitted optical beams from the transmitters. The structure enables photodetectors to be integrated on the optical bench allowing the received optical power to be monitored. The receiver photodetectors are integrated on the optical bench alone and / or in combination with the transmitters.

Owner:ZEPHYR PHOTONICS

Alignment method for metal masks

InactiveCN105132859AImprove yieldImprove alignment toleranceVacuum evaporation coatingSputtering coatingEvaporationColor mixing

The invention provides an alignment method for metal masks. According to the alignment method, a magnetic board is provided, a plurality of OLED substrates are formed above the magnetic board, and the fine metal masks are formed above the OLED substrates; each fine metal mask is at least partitioned into a first direct-row group and a second direct-row group according to the number and the size of the OLED substrates; and an evaporation source is provided to conduct evaporation on different direct-row groups in sequence so as to define sub pixel patterns of a single color. Compared with the prior art, the fine metal masks are aligned with the OLED substrates in a direct-row group manner, and evaporation is conducted on different direct-row groups of the metal masks in batches to define the sub pixel patterns of the single color; and due to the fact that the size of the direct-row groups of the metal masks is small, manufacturing is easier compared with a full mask, the alignment tolerance of the direct-row group masks and the OLED substrates can be increased, the risk of color mixing between adjacent pixels is lowered or eliminated, and the yield of products of overall substrates is increased.

Owner:AU OPTRONICS CORP

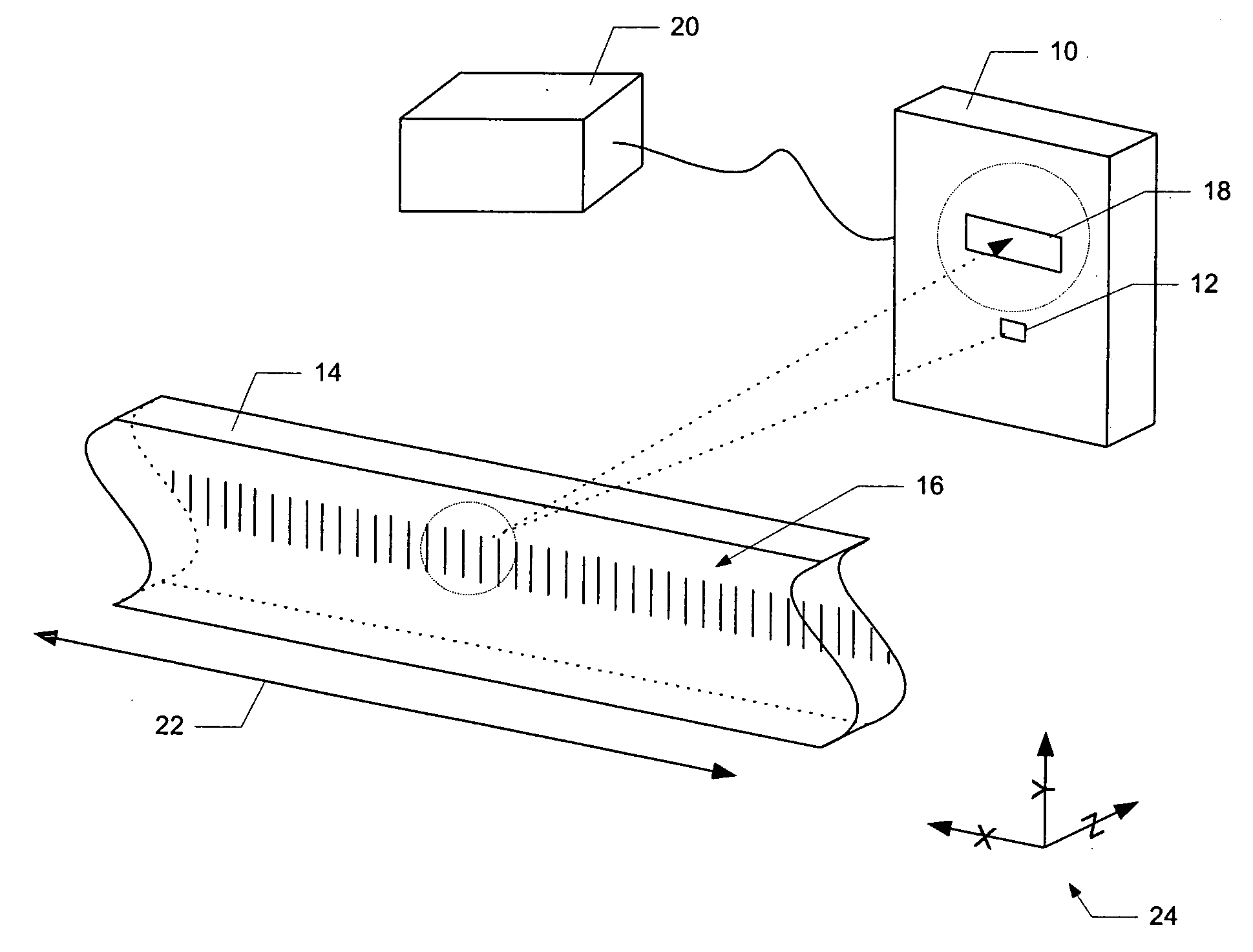

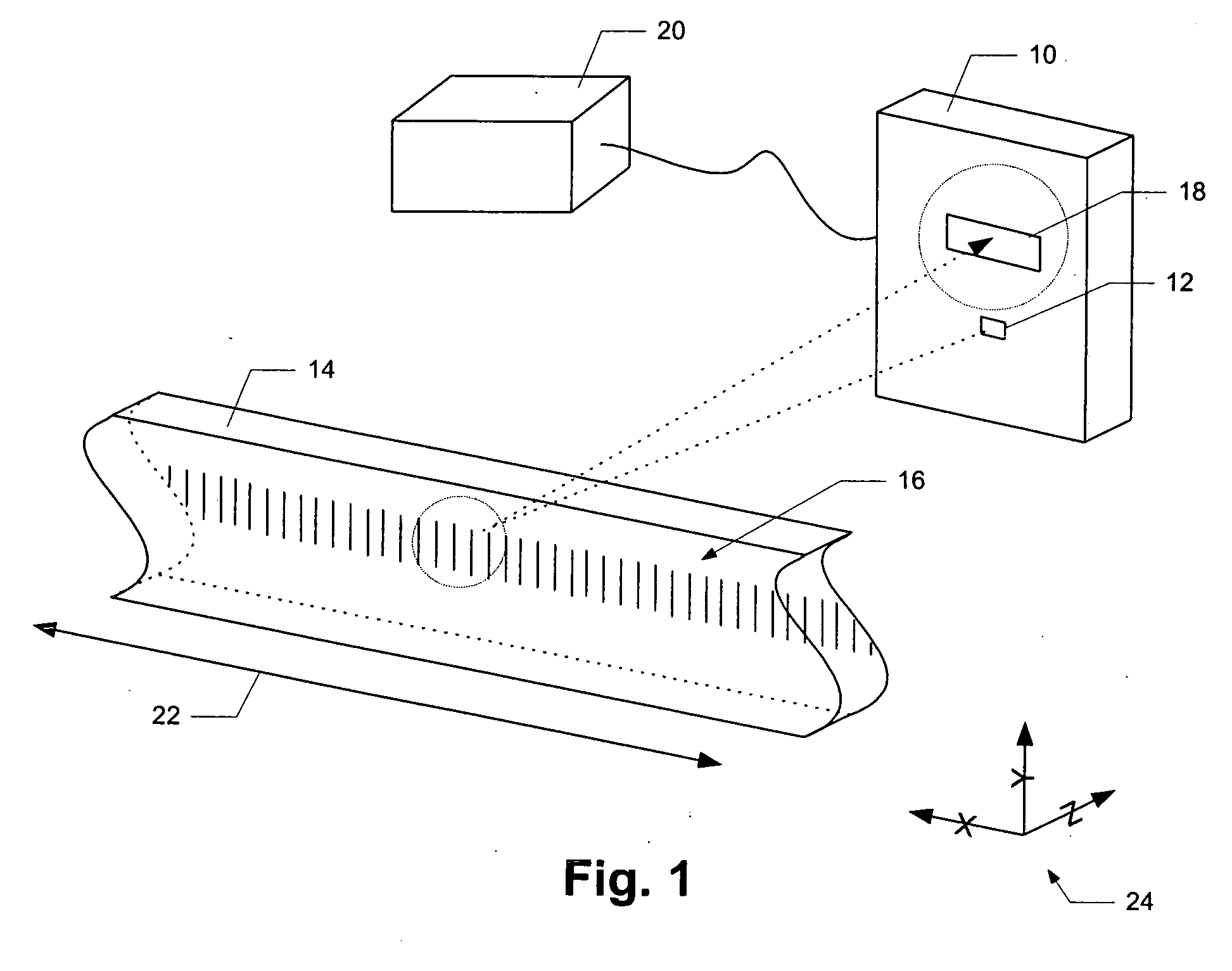

Optical encoder having slanted optical detector elements for harmonic suppression

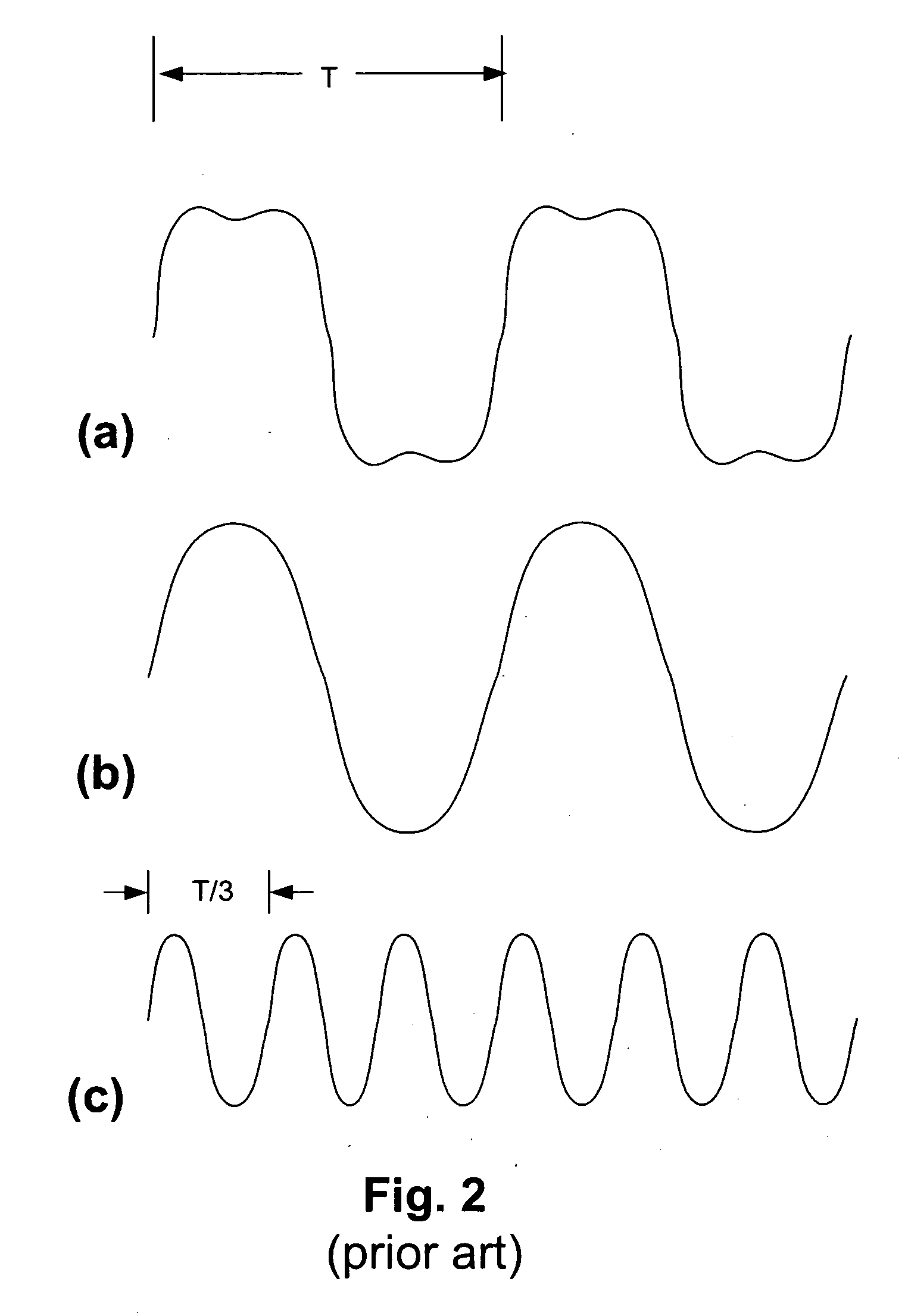

InactiveUS20070024865A1Improve alignment toleranceEasy to operateUsing optical meansConverting sensor output opticallyGratingHarmonic

An optical encoder includes a source of a light beam, an optical grating that generates a spatial pattern of interference fringes, and an optical detector which includes generally elongated detector elements that sample the interference fringe pattern at spatially separated locations along the direction of motion of the grating. Each detector element has one or more segments slanted along the direction of motion of the grating by an integer multiple of the period of an undesirable harmonic component of the fringe pattern, thereby spatially integrating the harmonic component and suppressing its contribution to an output of the detector. One specific detector type includes parallel elongated rectangular elements in a rectangular array that is rotated slightly about a Z axis; another type includes detector elements arranged to form a non-rectangular parallelogram. Another type of detector includes detector elements that each have multiple elongated rectangular segments which may be arranged into two non-parallel sets. The two sets can be further arranged in an alternating fashion so as to impart a zig-zag or chevron shape to each detector element.

Owner:THE GSI GRP LLC

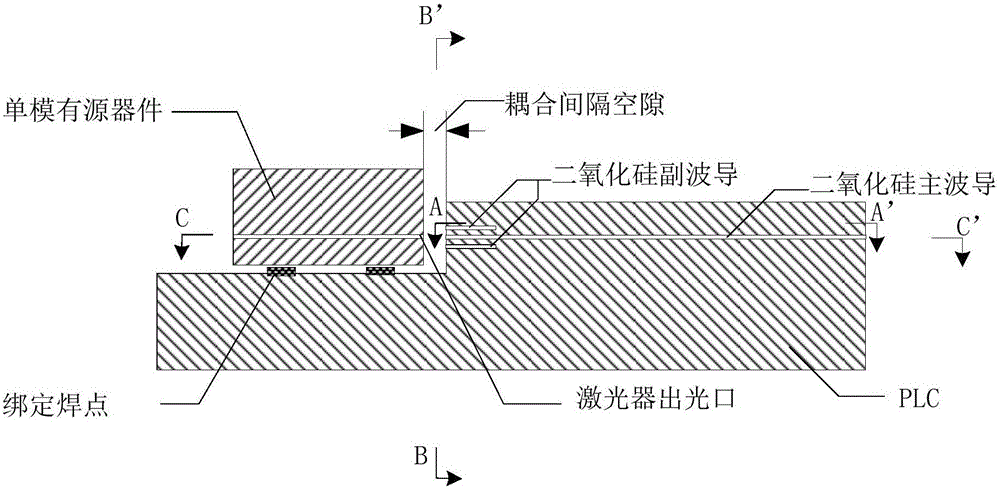

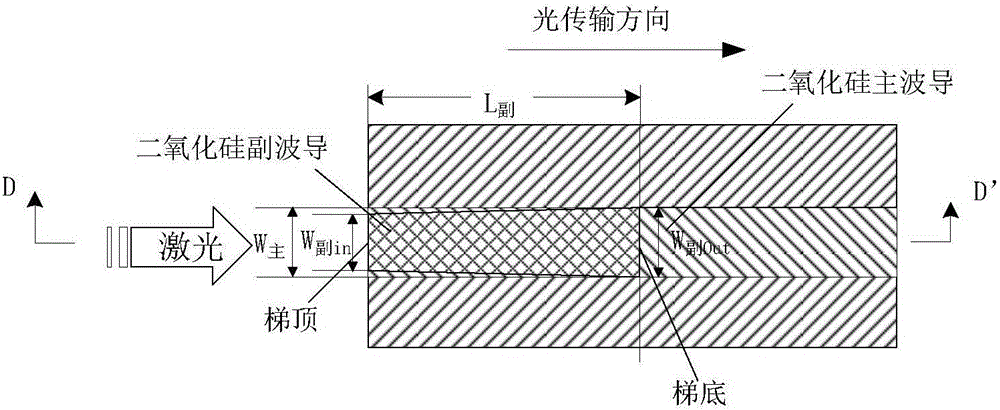

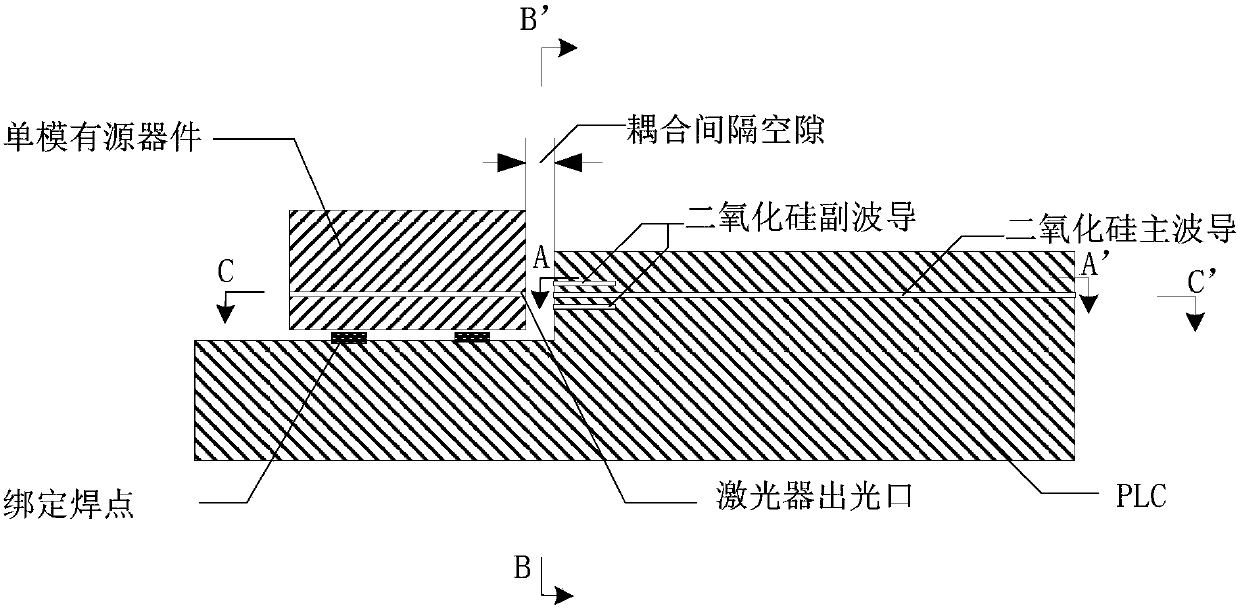

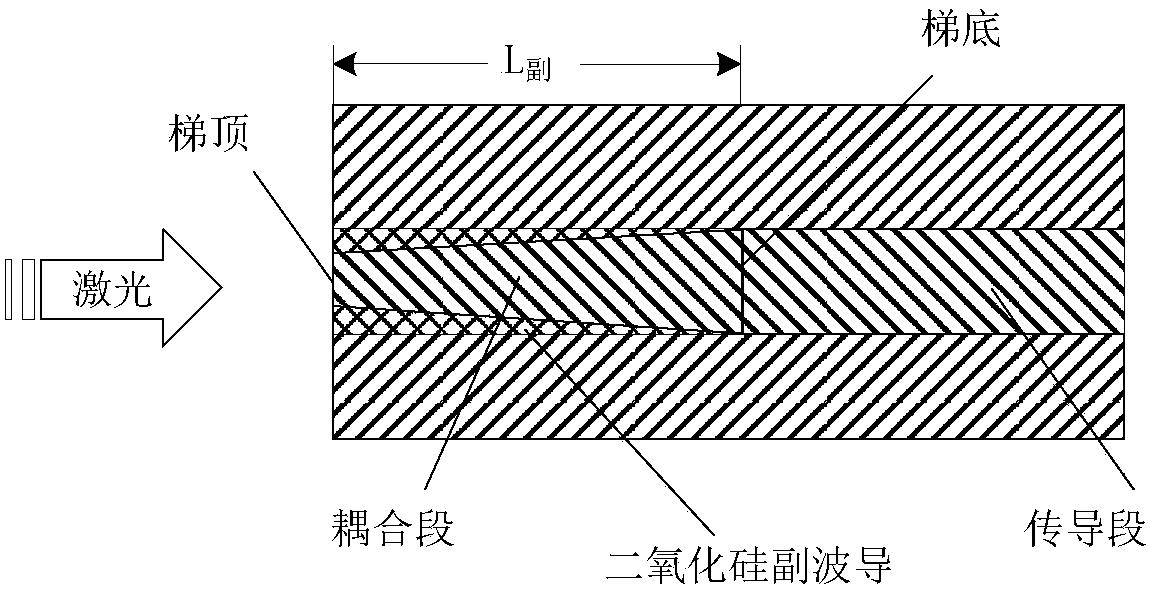

Multi-core planar optical waveguide structure and coupling structure thereof

ActiveCN105759373ALow process precision requirementsImprove alignment toleranceCoupling light guidesDirect couplingSilicon dioxide

The invention relates to the technical field of optical waveguide coupling and provides a multi-core planar optical waveguide structure and a coupling structure thereof. The multi-core planar optical waveguide structure comprises a main silicon dioxide waveguide for transmitting optical signals and an auxiliary waveguide for assisting light incidence, wherein the auxiliary waveguide comprises one or more auxiliary silicon dioxide waveguide bodies, and the auxiliary silicon dioxide waveguide bodies and the main silicon dioxide waveguide are arranged according to present central distances. The planar optical waveguide structure including one or more auxiliary silicon dioxide waveguide bodies can complete passive light alignment and direct coupling from a laser device to a PLC. Compared with the prior art, the alignment tolerance can be improved. Based on the improvement of the alignment tolerance, the requirement for process precision in an automatic device can be further reduced, the time for light alignment and welding can be shortened, the defective percentage is further reduced, and accordingly the purpose of reducing the costs is achieved.

Owner:WUHAN TELECOMM DEVICES

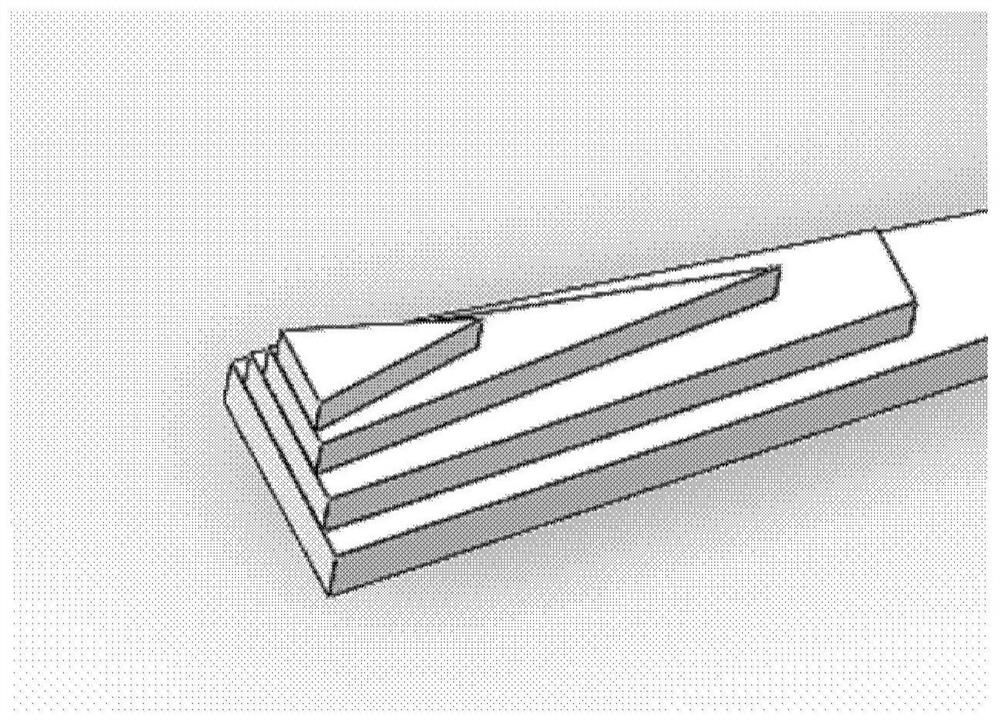

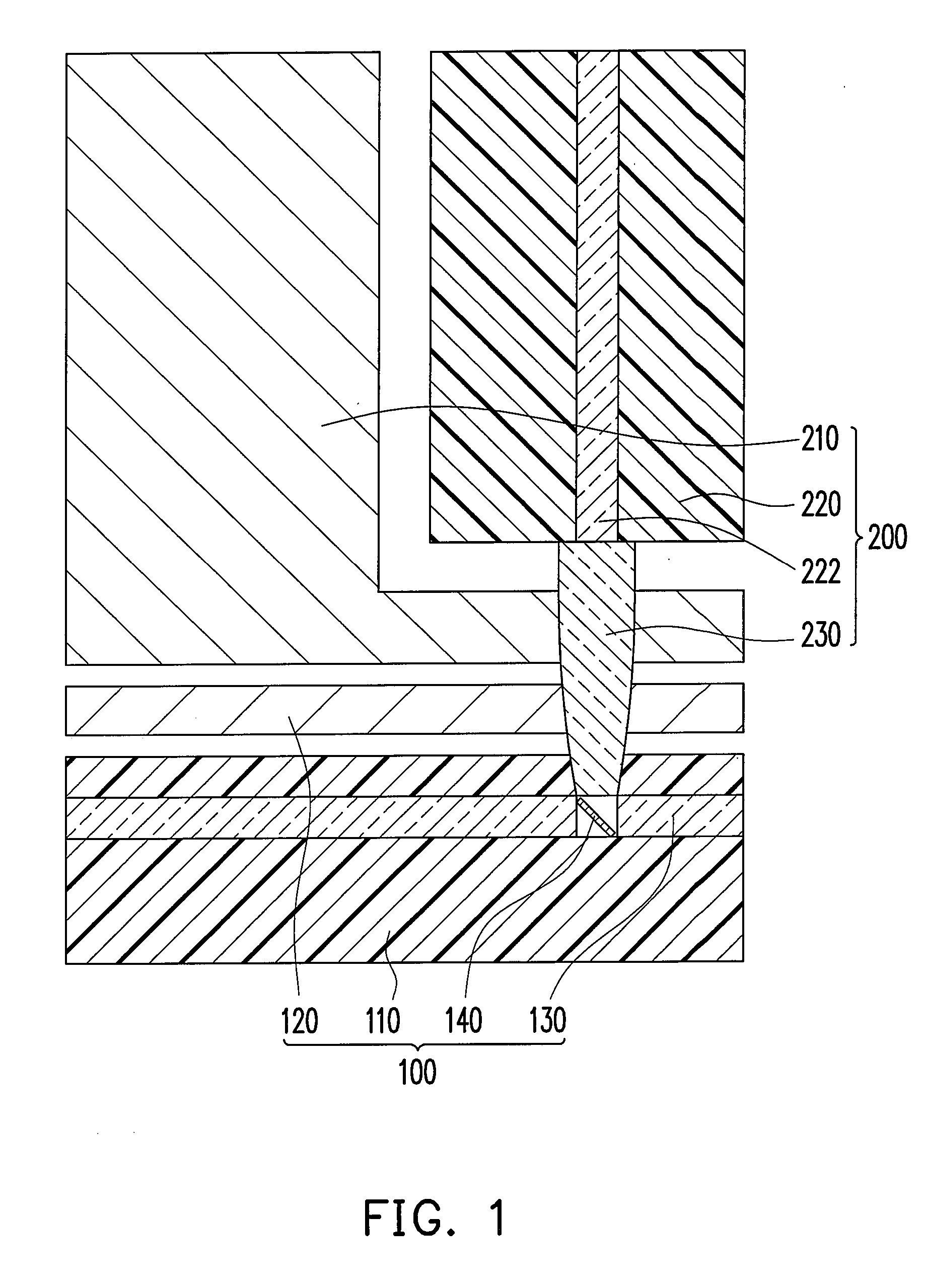

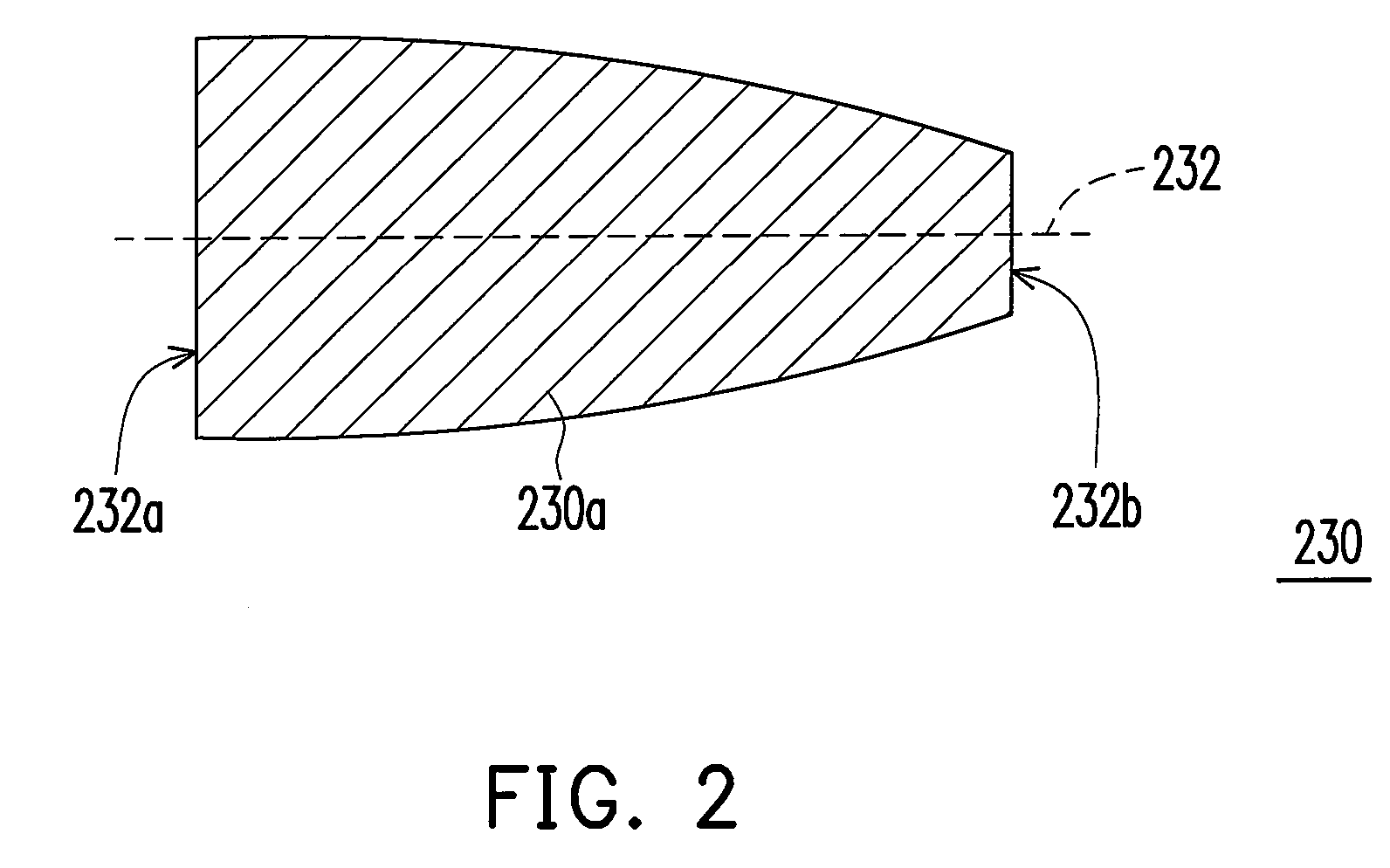

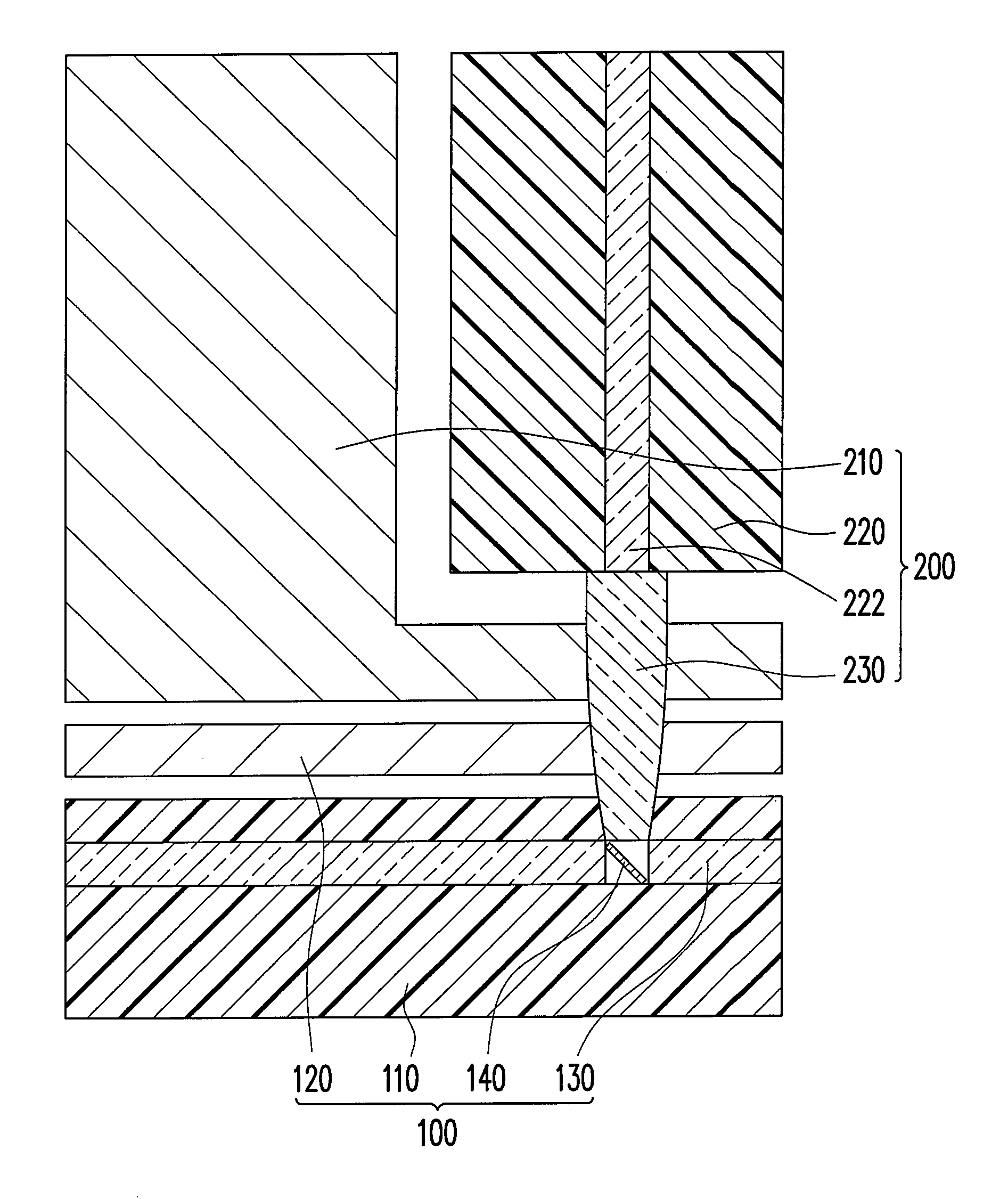

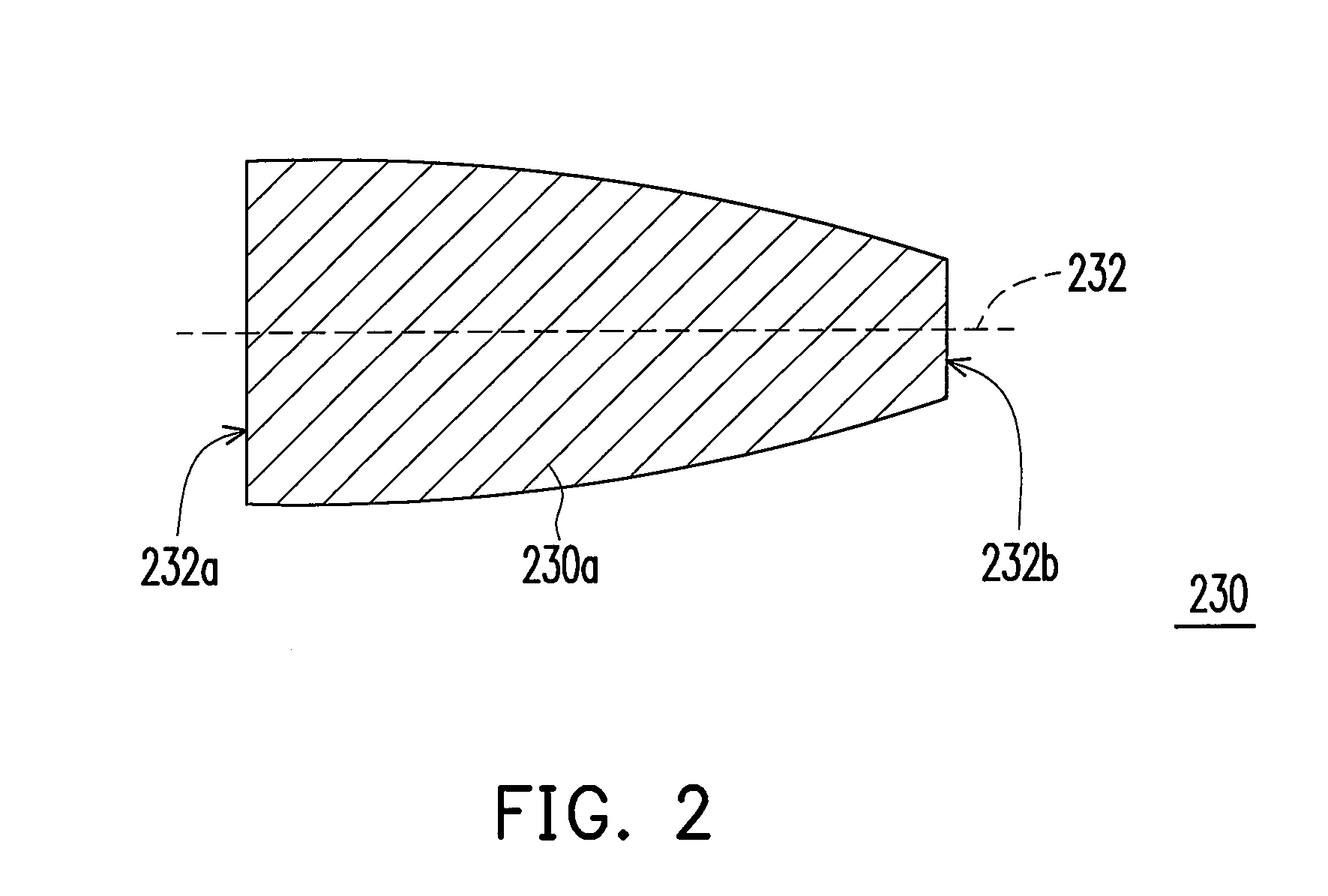

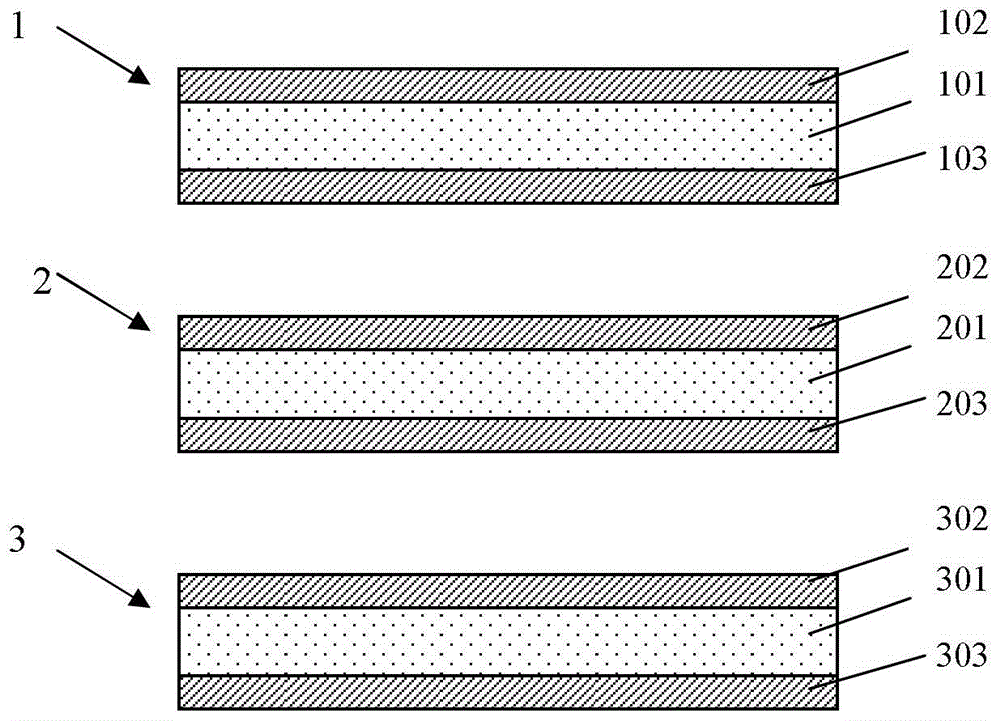

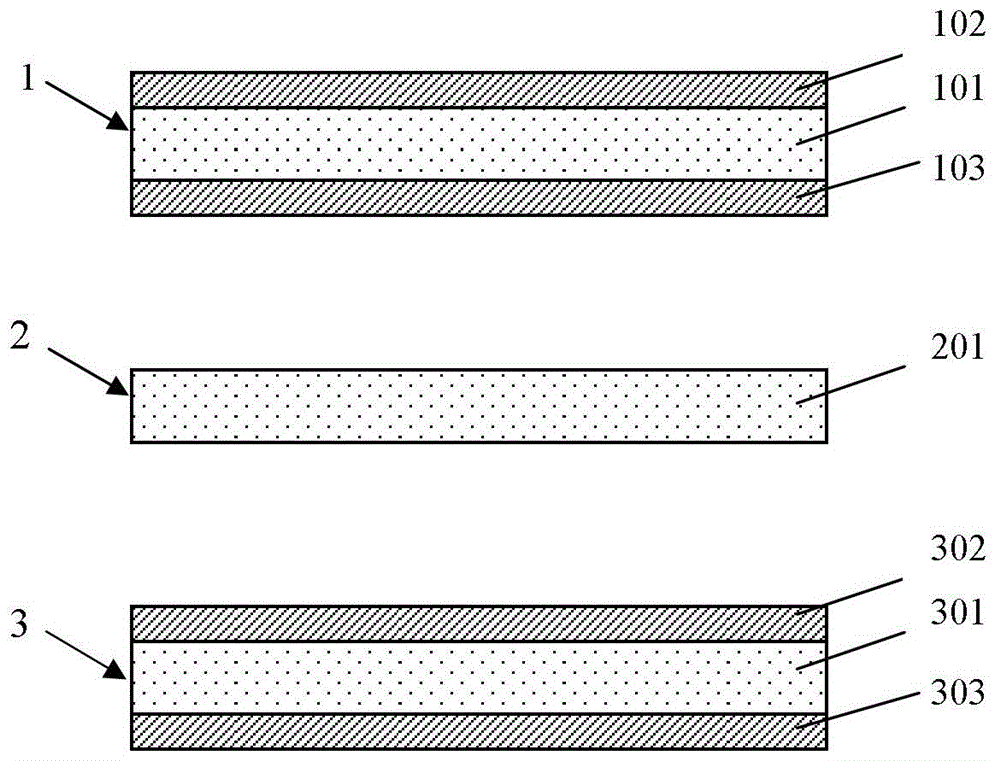

Method for manufacturing printed circuit board with conical optical waveguide

ActiveCN103926647ASimple preparation processImprove alignment toleranceOptical waveguide light guideCoupling lossEngineering

A method for manufacturing a printed circuit board with a conical optical waveguide includes the following steps that firstly, a substrate is manufactured, wherein the substrate is formed by a copper-clad plate, a medium layer is arranged in the middle of the copper-clad plate, and copper layers are arranged on the two sides of the copper-clad plate; secondly, an optical waveguide layer is manufactured, wherein an upper wrapper, a core layer and a lower wrapper are sequentially manufactured on the substrate, wherein the area of the cross section of the core layer of the optical waveguide gradually decreases in the optical signal propagation direction, the area of the cross section of the input end of the core layer of the optical waveguide is larger than the area of the cross section of the output end of the core layer, and then the conical optical waveguide is formed; thirdly, a matched printed circuit board is manufactured; fourthly, the printed circuit board and the substrate with the optical waveguide layer are laminated to form a mixed plate with the optical waveguide layer and the copper layers; fifthly, the mixed plate is subsequently machined through the drilling step, the electroplating step, the graph manufacturing step, the green oil coating step, the surface processing step, the cleaning step, the examining step, the cleaning step and the packaging step. According to the method, optical waveguide coupling loss of the circuit board can be effectively reduced, and the alignment tolerance of an optical fiber or the optical waveguide can be increased under the same coupling loss requirement.

Owner:SHANGHAI MEADVILLE SCI & TECH

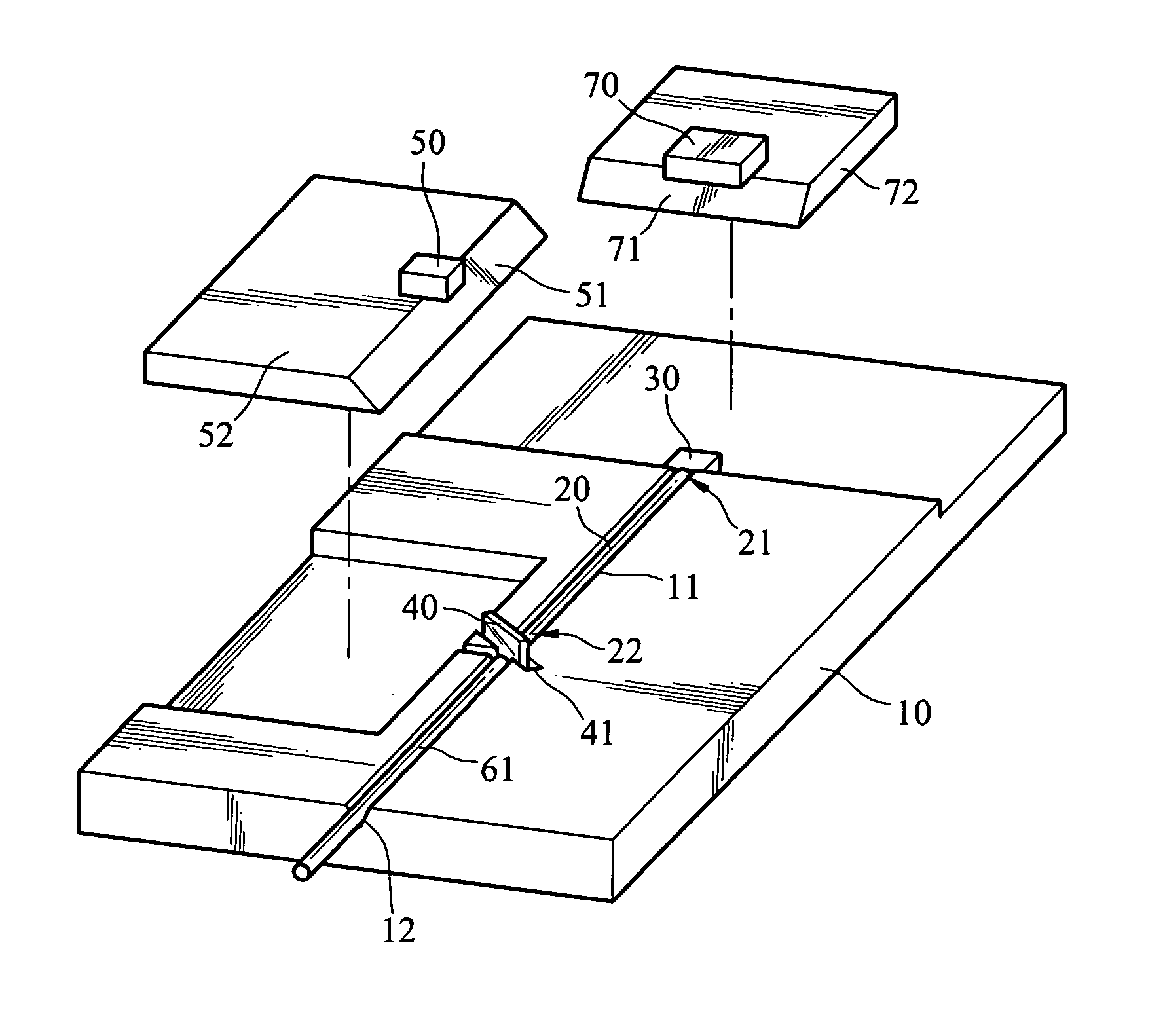

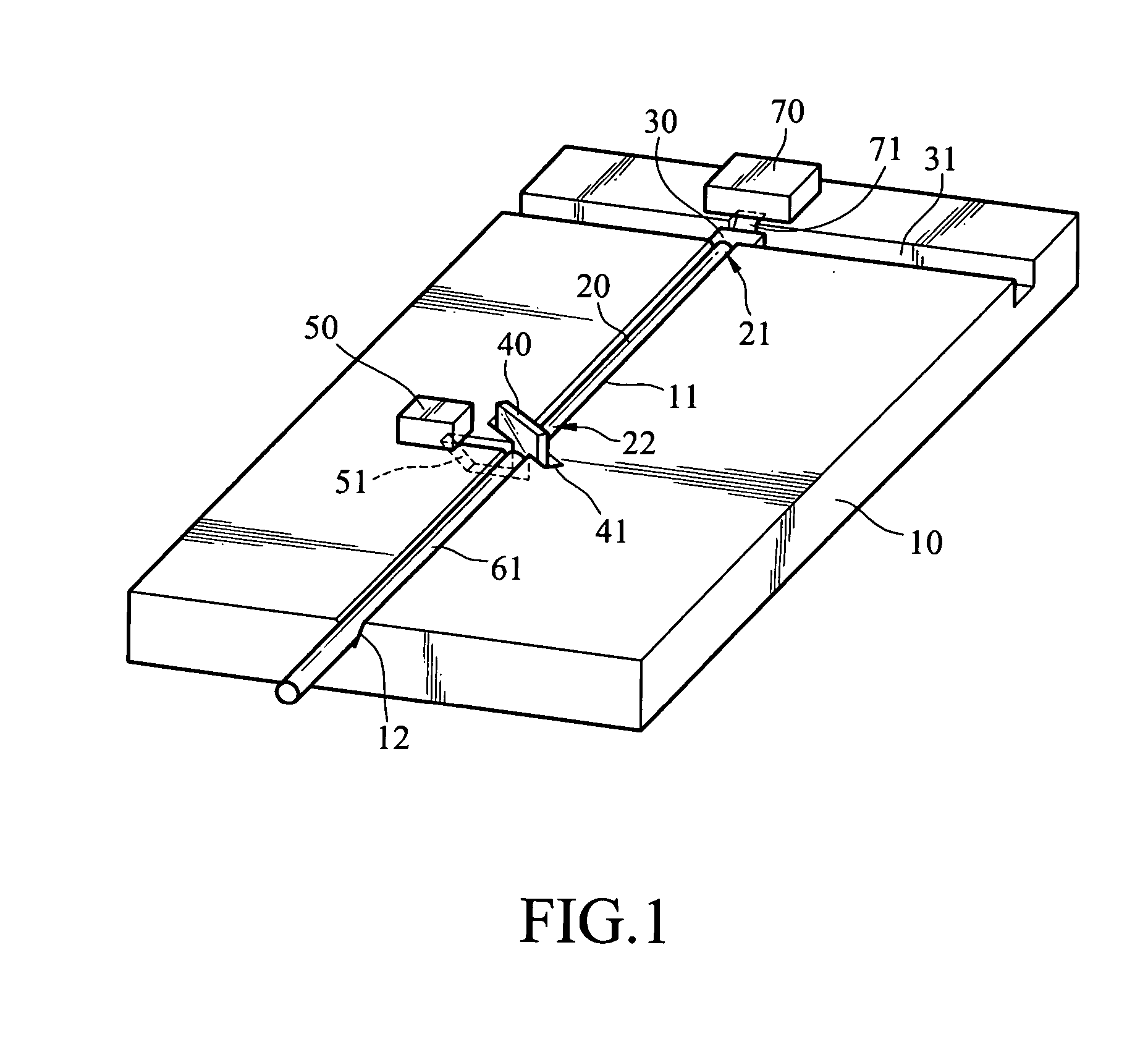

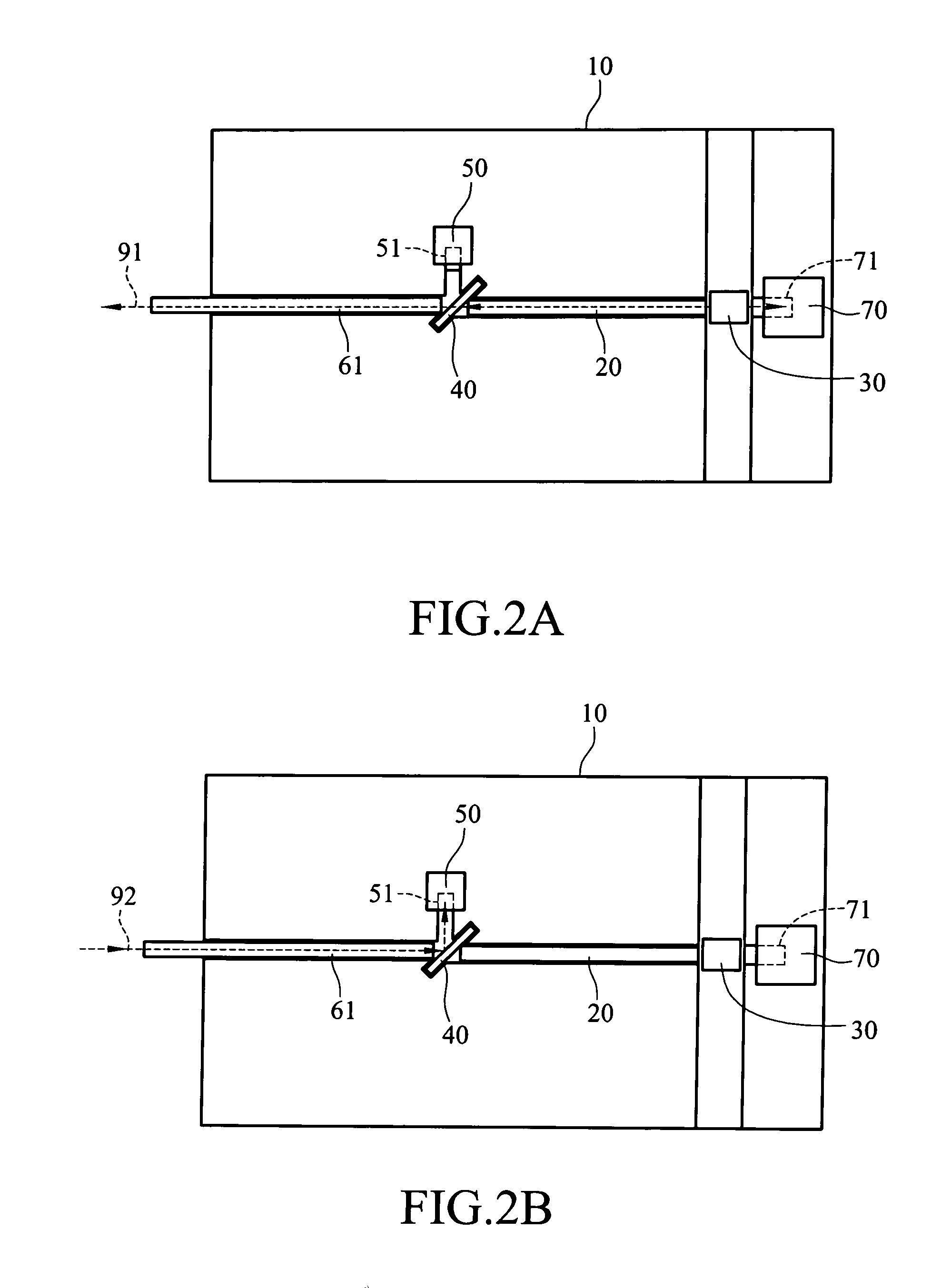

Fiber waveguide optical subassembly module

InactiveUS20060110106A1Improve alignment toleranceReduce dispersionCoupling light guidesFiberEngineering

A fiber waveguide optical subassembly uses the multi-mode fiber to increase the alignment tolerance between the active optical element and the waveguide. The filter is thinner to lower the dispersion due to the optical coupling gap. The subassembly further combines the optical bench to achieve passive positioning. Therefore it reduces the cost and enhances the transmission rate.

Owner:IND TECH RES INST

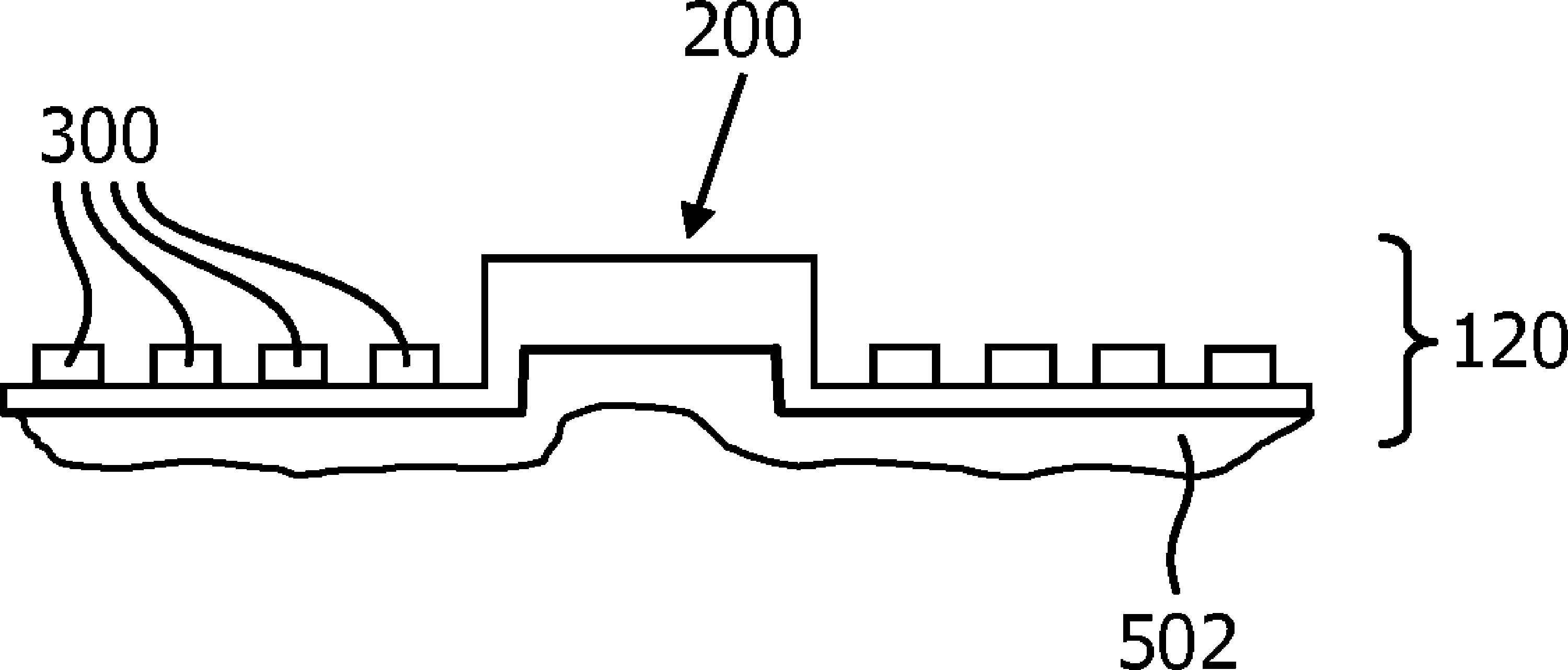

Optically pumped vertical external-cavity surface-emitting laser device

ActiveCN104247174AEasy alignmentReduce manufacturing costLaser optical resonator constructionExcitation process/apparatusOptical axisTime-Consuming

The present invention relates to an optically pumped vertical external-cavity surface-emitting laser device comprising at least one VECSEL (200) and several pump laser diodes (300). The pump laser diodes (300) are arranged to optically pump the active region (108) of the VECSEL (200) by reflection of pump radiation (310) at a mirror element (400). The mirror element (400) is arranged on the optical axis (210) of the VECSEL (200) and is designed to concentrate the pump radiation (310) in the active region (108) and to form at the same time the external mirror of the VECSEL (200). The proposed device avoids time consuming adjustment of the pump lasers relative to the active region of the VECSEL and allows a very compact design of the laser device.

Owner:KONINKLIJKE PHILIPS NV

Hybrid packaging device based on spot size transformation and grating coupling

PendingCN113484950AImprove optical coupling efficiencyImprove alignment toleranceOptical waveguide light guideGratingGrating coupling

The invention provides a hybrid packaging device based on spot size transformation and grating coupling. The hybrid packaging device comprises a silicon-based chip; a spot size converter which is integrated on the silicon-based chip and is used for realizing the optical mode conversion and coupling of optical signals; an optical modulator which is integrated on the silicon optical chip, is connected with the spot-size converter and a grating coupler, and is used for modulating the optical signals; the grating coupler which is integrated on the silicon-based chip and is used for realizing the coupling of optical signals and changing the optical direction, wherein the grating coupler comprises a waveguide structure and a grating structure, and the conical waveguide structure is connected with the spot size converter.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

Waveguide PIN photodiode having graded index distribution centering around optical absorption layer

InactiveUS7310469B2Reduce speedImprove responsivenessCoupling light guidesElectromagnetic receiversLight guideDepth direction

A waveguide PIN photodiode is provided. The waveguide PIN photodiode includes a lower light guide layer, a light absorption layer, an upper light guide layer, and a cladding layer. The lower light guide is formed on a substrate, and the light absorption layer is formed on the lower light guide layer. The upper light guide layer is formed on the light absorption layer, and the cladding layer is formed on the upper light guide layer. The lower light guide layer, the light absorption layer, and the upper light guide layer constitute a core layer, which is an optical waveguide, and graded index distribution is symmetrically formed in a depth direction, centering around the light absorption layer having a highest refractive index.

Owner:ELECTRONICS & TELECOMM RES INST

Double-cantilever inverted cone spot-size conversion structure for waveguide coupling

PendingCN114397730APrevent leakageImprove alignment toleranceOptical waveguide light guideBeam splittingEngineering

The invention discloses a double-cantilever inverted-cone spot-size conversion structure for waveguide coupling, and the structure consists of an input waveguide, a multimode waveguide interference region, two output waveguides, and parabolic inverted-cone structures at the rear ends of the output waveguides. The self-mapping effect is utilized to enable input light waves to generate a plurality of images on the cross section of the output waveguide, the light waves after beam splitting are spread in the output waveguide, and the cross section of the output waveguide passing through the parabola-shaped inverted cone structure is gradually reduced, so that the light waves of several output waveguides are diffused into the cladding so as to be conveniently coupled with a large-size waveguide. Compared with a traditional single inverted-cone-shaped coupler, the double-cantilever parabola-shaped inverted-cone-shaped structure is adopted, the alignment tolerance is improved, a small mode field of light transmitted by a small-size waveguide can be converted into a large mode field so that the light can be efficiently coupled into a large-size waveguide, meanwhile, a cladding layer where the parabola-shaped inverted-cone-shaped structure is located is suspended, substrate leakage is avoided, and the coupling efficiency is improved. And the loss during optical signal transmission is reduced.

Owner:BEIJING UNIV OF POSTS & TELECOMM

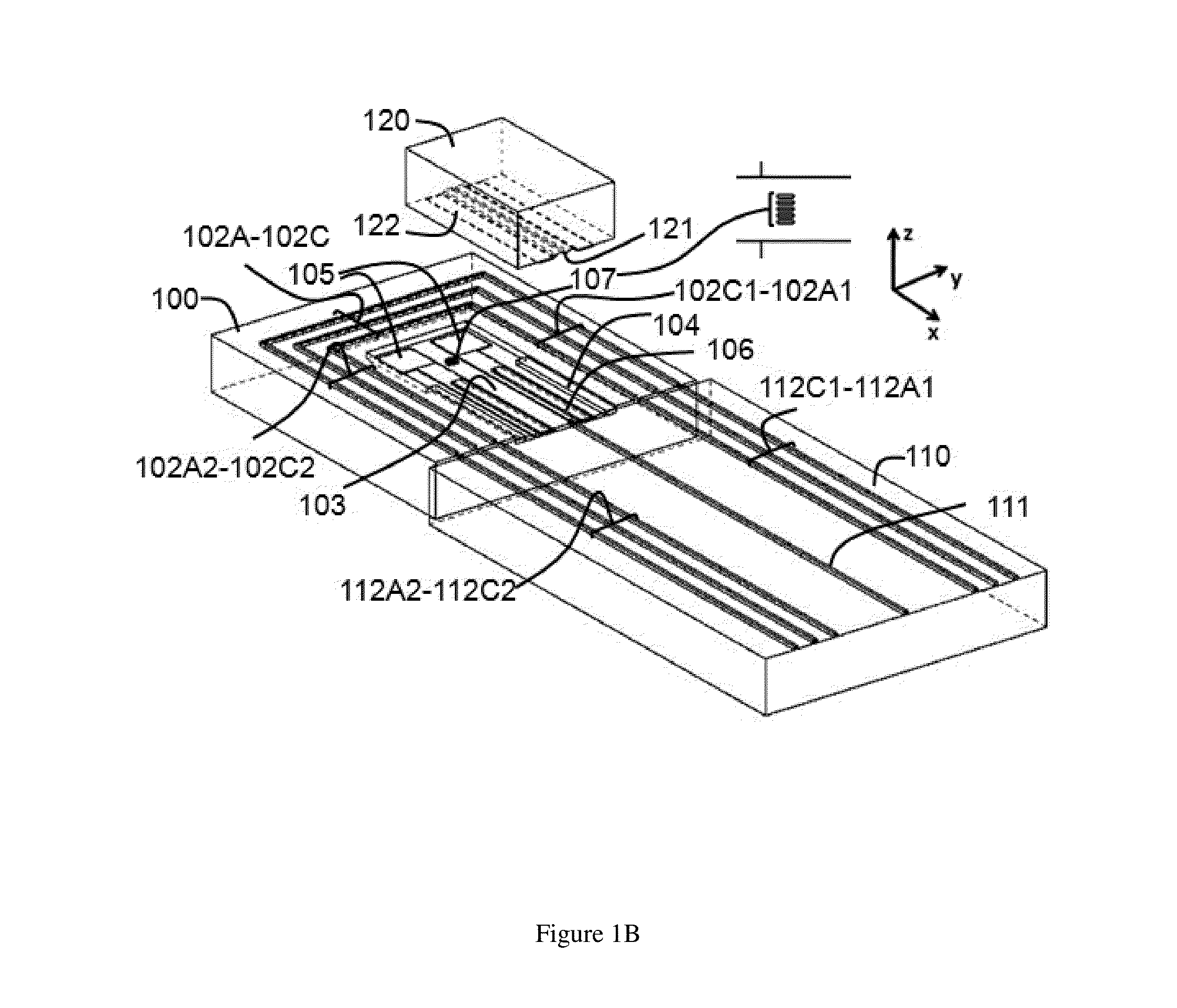

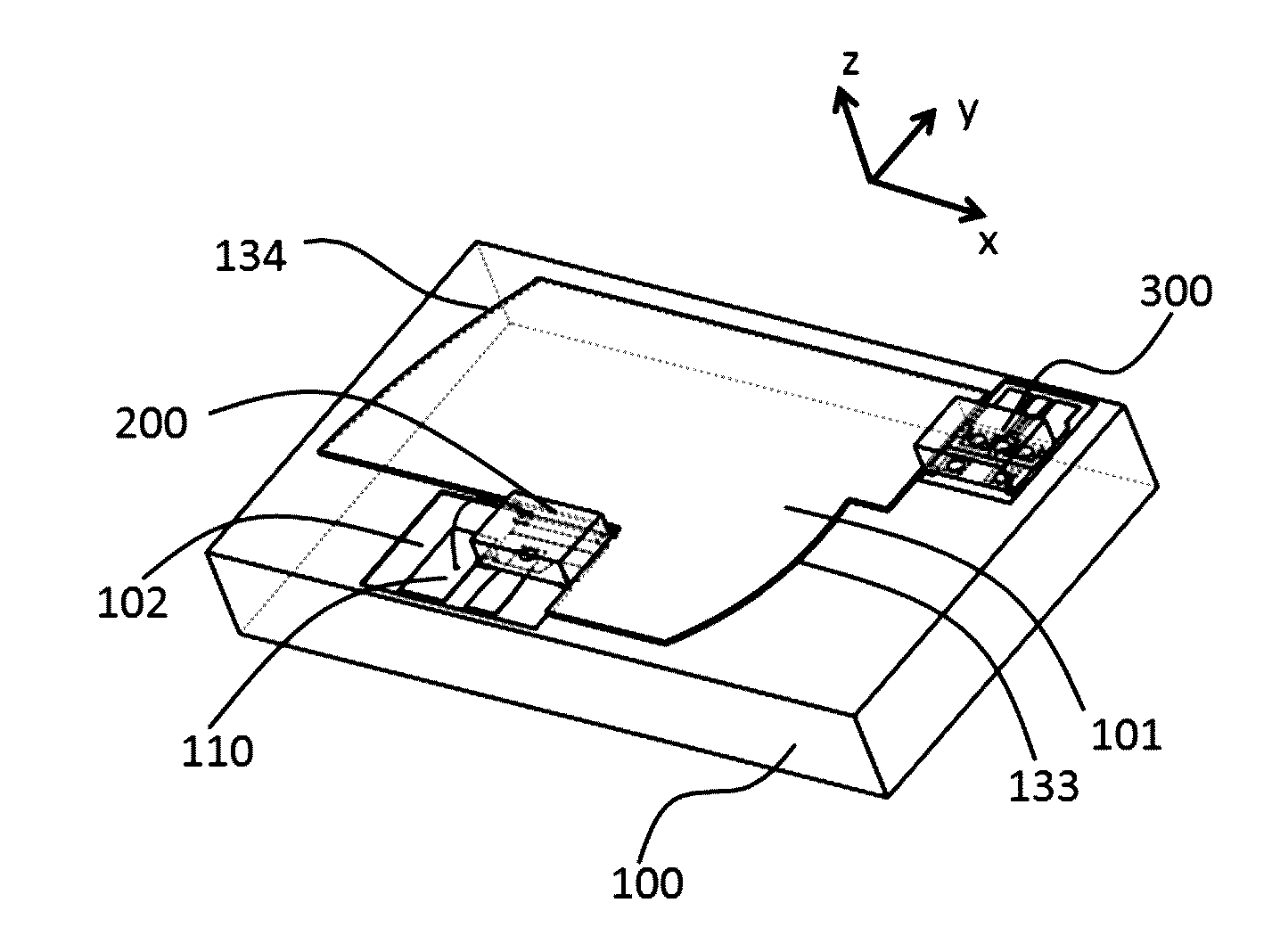

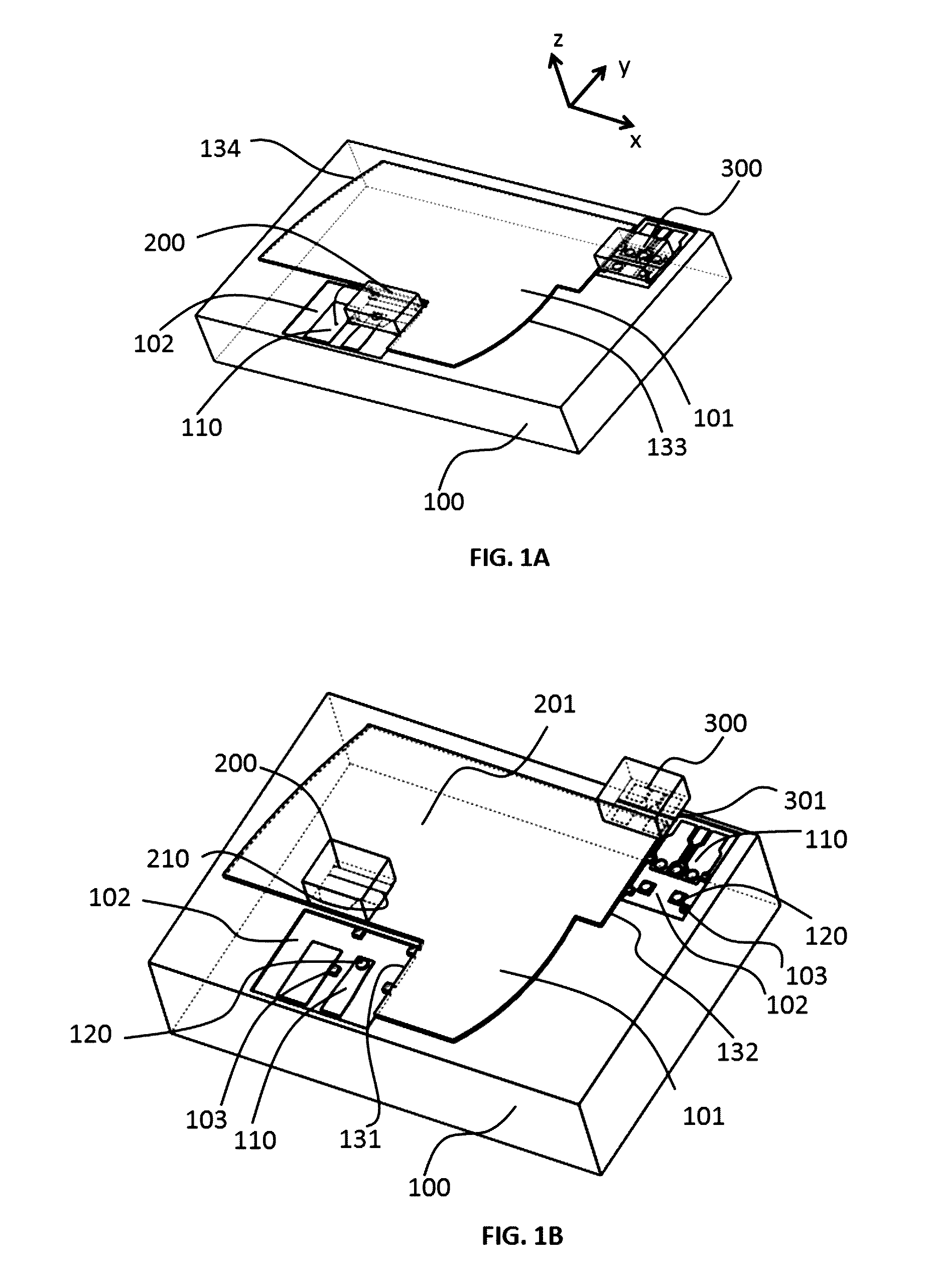

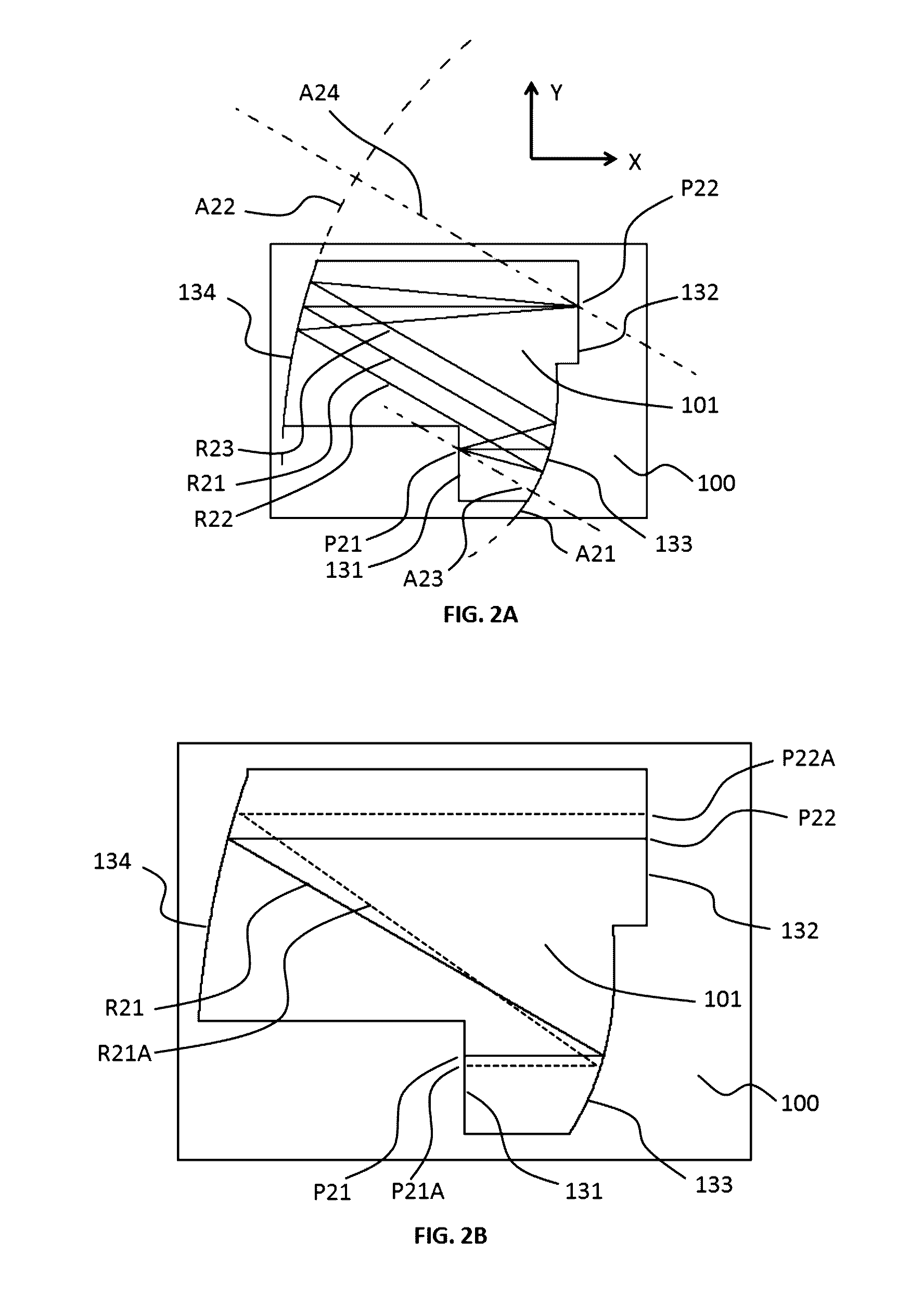

Hybrid integrated optical device enabling high tolerance optical chip bonding and the method to make the same

ActiveUS9513435B1Improve alignment toleranceEasy alignmentCoupling light guidesOptical waveguide light guideIn planeWaveguide

An optical device includes an optical bench and two flip-chip bonded optical chips. The optical bench includes a large area slab waveguide structure which has an input facet facing the first optical chip, an output facet facing the second optical chip, and one or more curved facet which reflects the slab mode light such that the input optical mode coupled through the input facet diverges in the slab waveguide plane as it propagates, reflects at the one or more curved facets, and focuses to an output optical mode at the output facet with mode size larger than the input optical mode in the in-plane direction. During fabrication, after the first optical chip is flip-chip bonded, the location of the focused output optical mode on the output facet is determined, and then the second optical chip is flip-chip bonded based on the determined location of the output optical mode.

Owner:LAXENSE

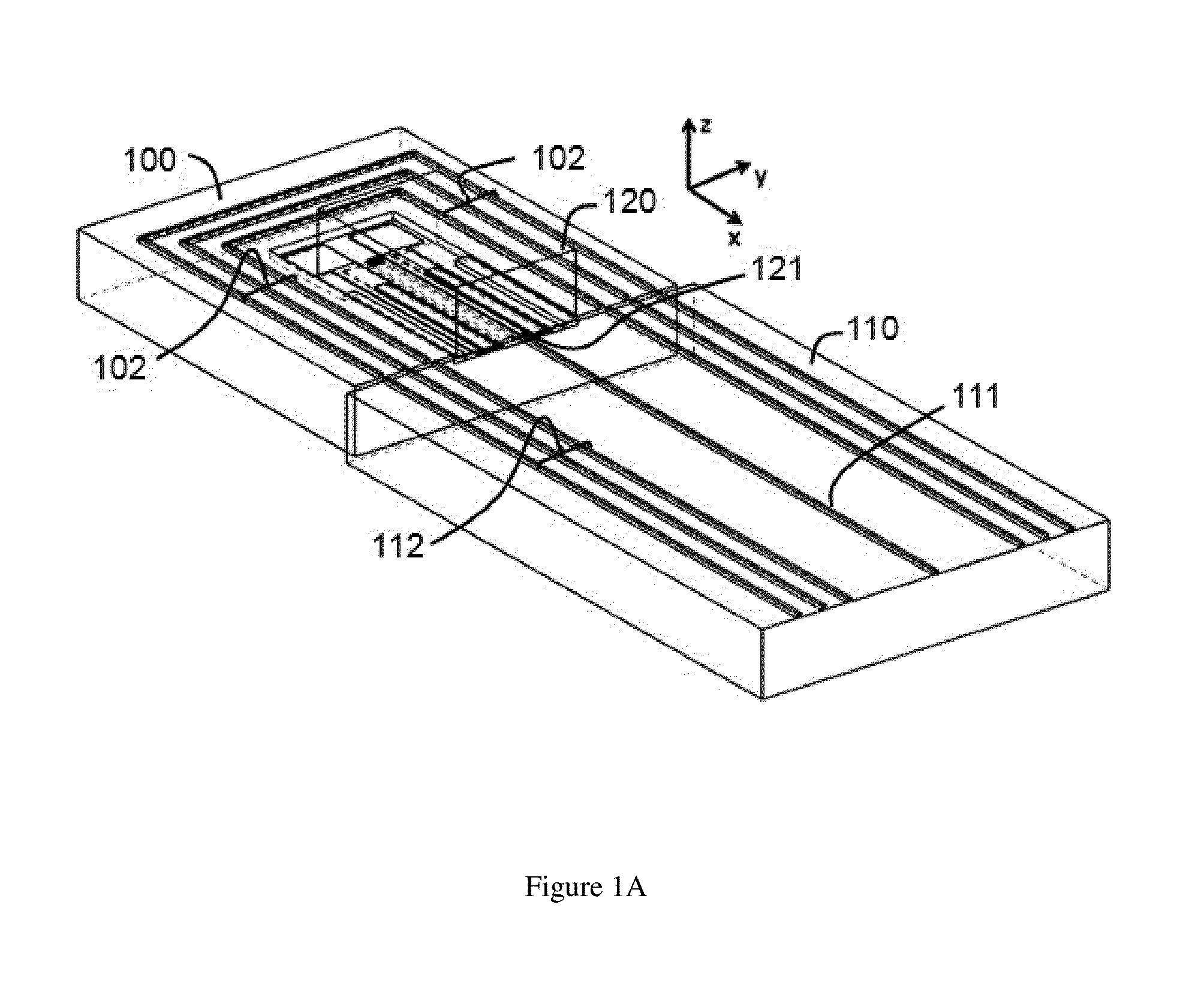

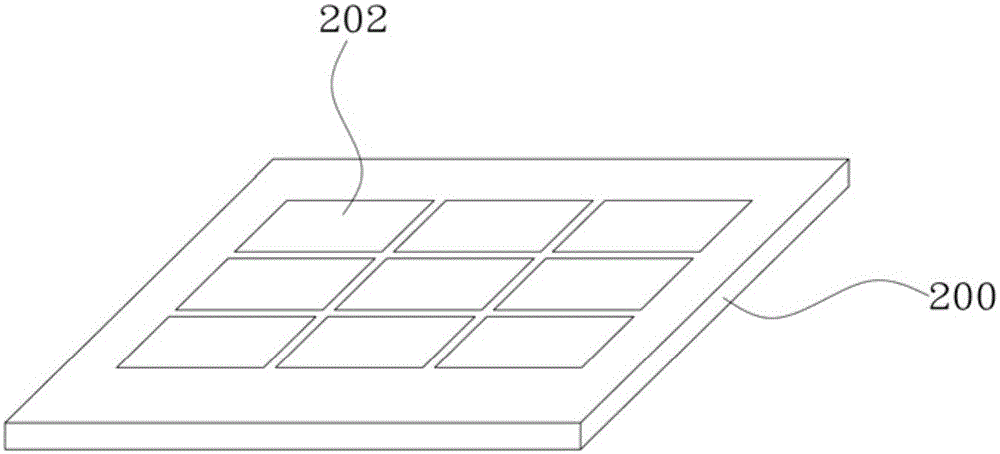

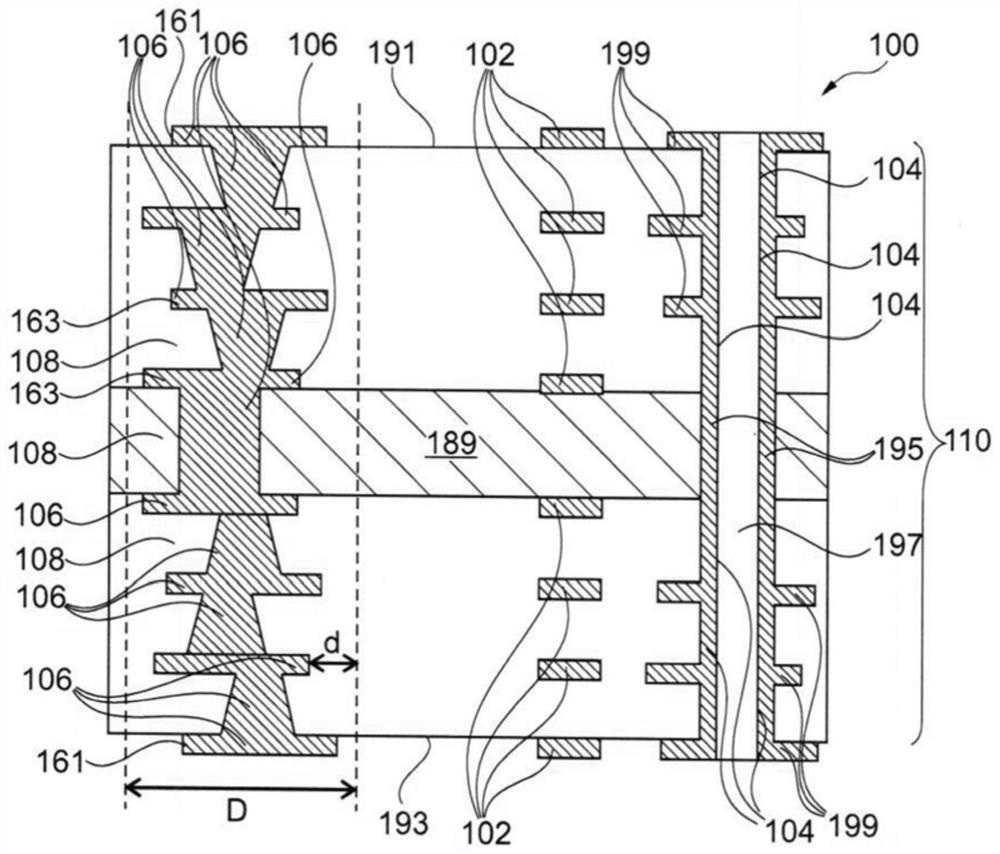

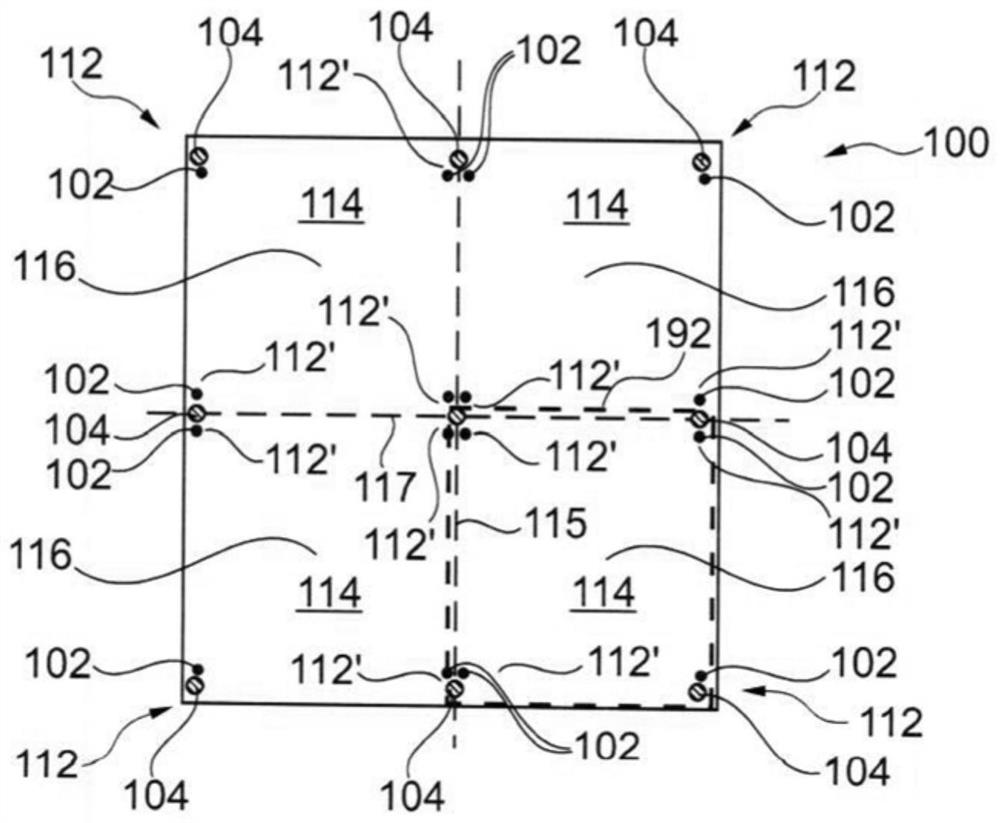

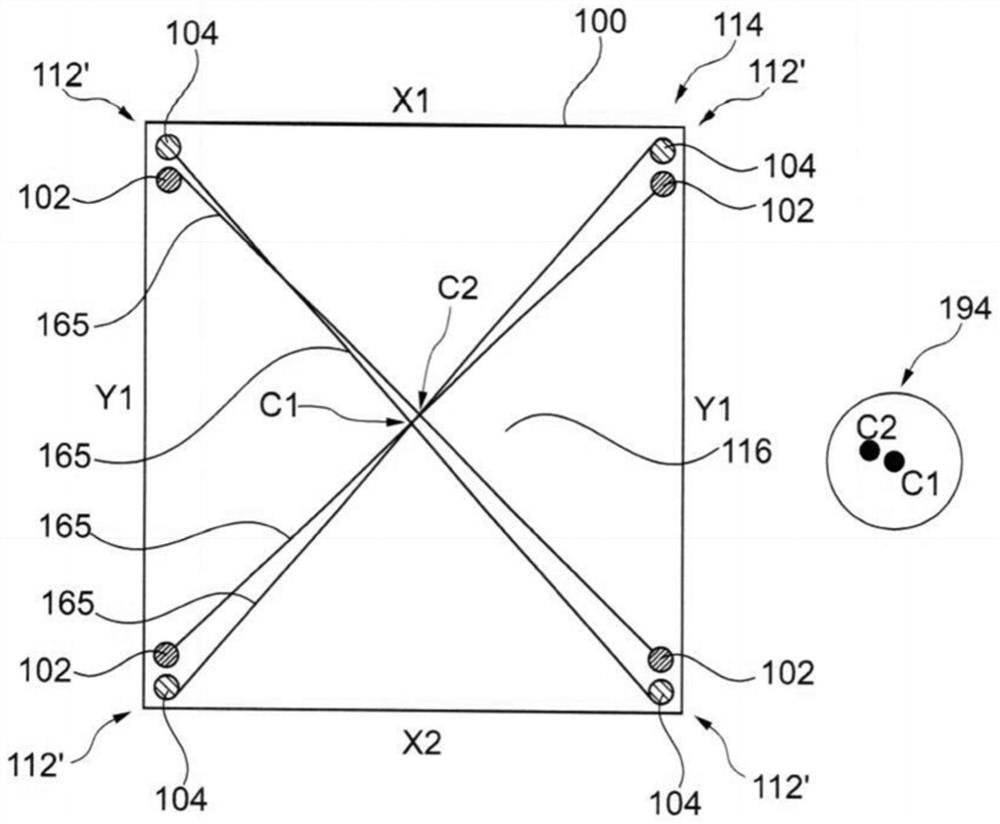

Component carrier structure aligned by combining evaluation pad pattern and hole pattern alignment marks

ActiveCN112087887AImprove alignment toleranceReduce the minimum footprintMultilayer circuit manufactureMechanical engineeringPhysics

The invention relates to a method of aligning a component carrier structure (100). The method comprises of forming one or more pad-type alignment marks (102) on and / or in the component carrier structure (100); forming one or more pass alignment marks (104) on the component carrier structure (100) and / or in the component carrier structure (100); and determining alignment information for aligning the component carrier structure (100) by combining alignment information derived based on the one or more pad-type alignment marks (102) and the one or more pass-type alignment marks (104). The invention also relates to a component carrier structure, a device for aligning the component carrier structure, a computer-readable medium, a program unit and a batch group consisting of component carriers.

Owner:AT&S (CHONGQING) CO LTD

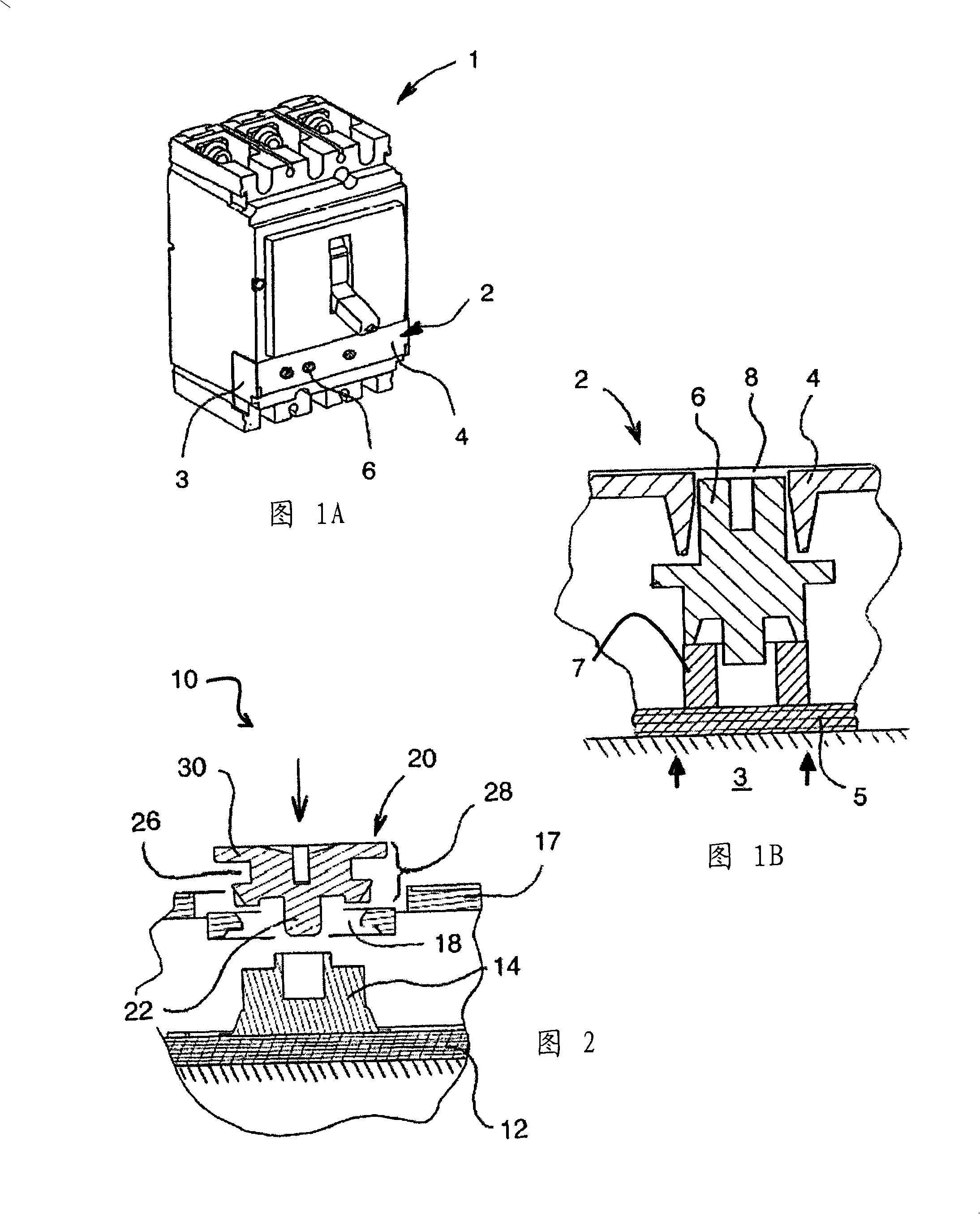

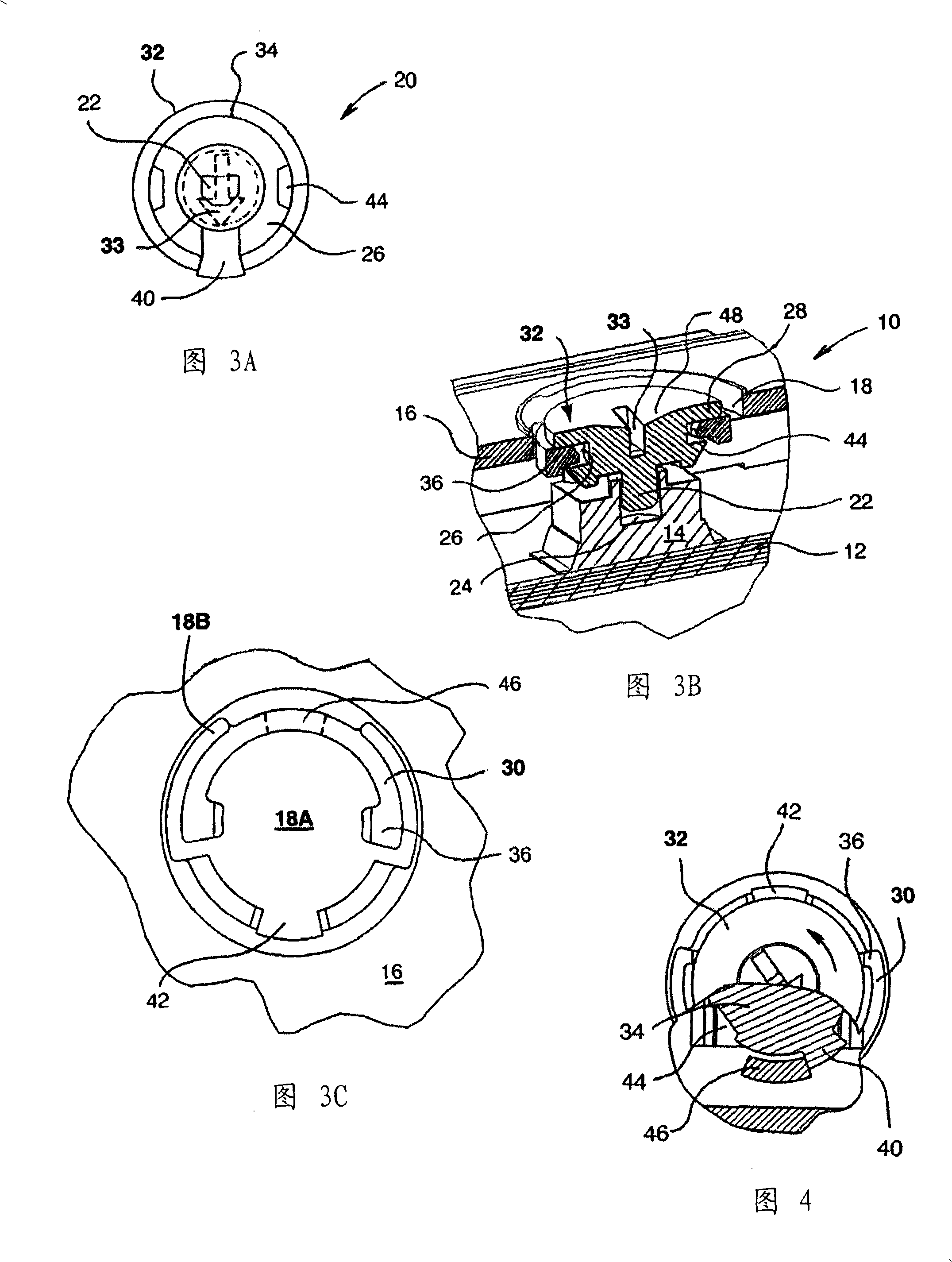

Device for controlling a component of an electronic board and activation system comprising same

ActiveCN101256920AAvoid stressEasy to processContact operating partsAdjustment of protective switch conditionsElectronic boardPrinted circuit board

The invention relates to a method for assembling the activation unit (20) of the adjustment part (14) of a printed circuit board (12), a component formed thereby and the control part of the component. The activation unit (20) includes a rod (22) and an upper part (28) provided with a groove (26), the groove is sandwiched in a proper opening (18) of a cover (16). Therefore, the cover counteracts the vertical stress of the activation unit (22, 28), and protects a panel (12). Furthermore, a gap may be left out between the upper part (28) and a hole (18), which is at the height of the groove (26).

Owner:SCHNEIDER ELECTRIC IND SAS

Optical intermediary component and optical daughter card module

ActiveUS20090169155A1Improve alignment toleranceEasy to assembleCoupling light guidesLight guideOptical axis

An optical intermediary component is suitable for guiding a light from an output optical path into an input optical path. The optical intermediary component includes a light guiding portion extending along a light axis. The light guiding portion has a light incident surface and a light emitting surface at two opposite ends thereof respectively. The light from the output optical path passes through the light incident surface and the light emitting surface of the light guiding portion in sequence, and is guided into the input optical path. The area of the light incident surface is greater than that of the light emitting surface. Therefore, a high assembly tolerance may reduce the manufacturing and assembly cost.

Owner:IND TECH RES INST

Optical intermediary component and optical daughter card module

ActiveUS7627215B2Improve alignment toleranceEasy to assembleCoupling light guidesOptical axisLight guide

An optical intermediary component is suitable for guiding a light from an output optical path into an input optical path. The optical intermediary component includes a light guiding portion extending along a light axis. The light guiding portion has a light incident surface and a light emitting surface at two opposite ends thereof respectively. The light from the output optical path passes through the light incident surface and the light emitting surface of the light guiding portion in sequence, and is guided into the input optical path. The area of the light incident surface is greater than that of the light emitting surface. Therefore, a high assembly tolerance may reduce the manufacturing and assembly cost.

Owner:IND TECH RES INST

Photoluminescence LED display device and manufacturing method thereof

The invention provides a photoluminescence LED display device and a manufacturing method thereof. The display device comprises a light emitting diode array and a display panel which is arranged at oneside of the light emitting diode array, and the display panel comprises a light-transmitting base plate and a photoluminescence layer structure. The photoluminescence layer structure is supported bythe light-transmitting base plate, and the light-transmitting base comprises comprises a red light penetrating area, a green light penetrating area and a blue light penetrating area; the photoluminescence layer structure comprises a red photoluminescence layer and a green photoluminescence layer, wherein the red photoluminescence layer is arranged on the green photoluminescence layer. Therefore, by arranging the photoluminescence layers in a vertical stacked mode, precise pixel positioning of the photoluminescence layer structure can be avoided, so that the display device can be manufactured more easily; and meanwhile, the display device is also relatively excellent in light energy utilization rate and relatively large in display view angle.

Owner:MAVEN OPTRONICS CO LTD

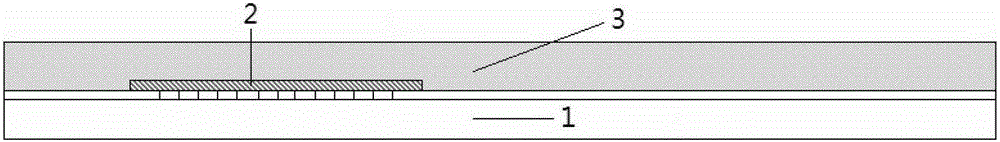

A kind of uncooled infrared detector tower pier and its making method

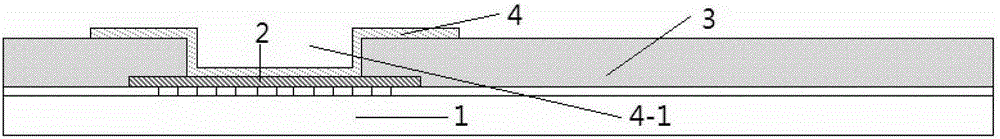

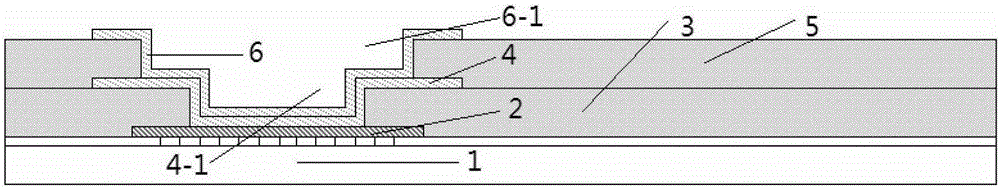

ActiveCN103112817BImprove performanceReduce areaDecorative surface effectsSolid-state devicesEngineeringTower

The invention relates to a tower-type pier of an uncooled infrared detector. The tower-type pier comprises an ASIC (Application Specific Integrated Circuit), wherein a polyimide sacrificial layer (3) and an electrode block (2) are arranged on the ASIC; an etch supporting hole (4-1) is formed in the polyimide sacrificial layer (3); a sputtering metal layer (4) is arranged on a wafer in which the etch supporting hole (4-1) is formed; a polyimide sacrificial layer (5) is arranged on the sacrificial layer (3), and an etch supporting hole (6-1) is formed in the polyimide sacrificial layer (5); a sputtering metal layer (6) is arranged on a wafer in which the etch supporting hole (6-1) is formed; a support layer (7) is arranged on the metal layer (6); a thermosensitive layer (8) is arranged on the support layer (7); a dielectric layer (9) is arranged on the thermosensitive layer (8); a through hole is formed in the metal layer (6) in the supporting hole; a contact hole (11) is formed in the dielectric layer (9); and electrode metal (12) is connected on the through hole (10) and the contact hole (11), and a passivation layer is deposited on the electrode metal (12) after the electrode metal (12) is connected on the through hole (10) and the contact hole (11).

Owner:YANTAI RAYTRON TECH

Integrated device and preparation method for jointing of AWG output waveguide and detector with seam

ActiveCN104950382BAvoid coupling lossImprove coupling efficiencyOptical waveguide light guideCoupling lossCapacitance

The invention provides an integrated device for seamed butt joint of an AWG (arrayed waveguide grating) output waveguide and a waveguide photodetector and a preparation method of the integrated device. The integrated device comprises a substrate, the AWG output waveguide and the waveguide photodetector, wherein the left area and the right area of the substrate are taken as an AWG area and a PD (photodetector) area respectively; the AWG output waveguide is located on the AWG area on the substrate, and an AWG lower coating layer and an AWG core layer extend to the PD area; the waveguide photodetector is formed above the AWG core layer in the PD area on the substrate, and a PD lower contact layer of the waveguide photodetector extends into an AWG upper coating layer of the AWG output waveguide and is located above the AWG core layer; a PD absorbing layer and a PD upper contact layer of the waveguide photodetector are spaced with the AWG upper coating layer of the AWG output waveguide by a narrow seam. According to the integrated device and the preparation method, excessive coupling loss generated during interconnection of discrete devices is avoided, and the energy efficiency of an optical link is improved through evanescent field coupling; meanwhile, by means of the seam between the AWG output waveguide and the waveguide photodetector, the capacitance of PD devices is reduced, and the device bandwidth is increased.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

A multi-core planar optical waveguide structure and its coupling structure

ActiveCN105759373BLow process precision requirementsImprove alignment toleranceCoupling light guidesDirect couplingOptoelectronics

The invention relates to the technical field of optical waveguide coupling and provides a multi-core planar optical waveguide structure and a coupling structure thereof. The multi-core planar optical waveguide structure comprises a main silicon dioxide waveguide for transmitting optical signals and an auxiliary waveguide for assisting light incidence, wherein the auxiliary waveguide comprises one or more auxiliary silicon dioxide waveguide bodies, and the auxiliary silicon dioxide waveguide bodies and the main silicon dioxide waveguide are arranged according to present central distances. The planar optical waveguide structure including one or more auxiliary silicon dioxide waveguide bodies can complete passive light alignment and direct coupling from a laser device to a PLC. Compared with the prior art, the alignment tolerance can be improved. Based on the improvement of the alignment tolerance, the requirement for process precision in an automatic device can be further reduced, the time for light alignment and welding can be shortened, the defective percentage is further reduced, and accordingly the purpose of reducing the costs is achieved.

Owner:WUHAN TELECOMM DEVICES

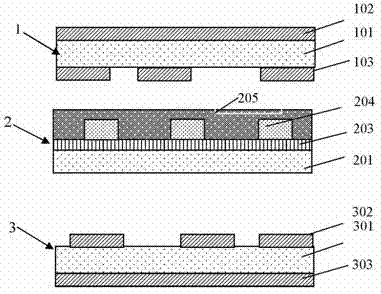

Spot size converter and preparation method thereof

ActiveCN111367016AIncrease Alignment ToleranceReduce absorption lossOptical waveguide light guideBuried oxideEngineering

The invention discloses a spot size converter and a preparation method thereof. The spot size converter comprises a silicon substrate, a buried oxide layer, a first waveguide located on the buried oxide layer, at least two second waveguides parallel to the first waveguide, an upper cladding and at least two low-refractive-index waveguides, wherein the second waveguides are arranged on the two sides of the first waveguide; the width of the first waveguide is gradually reduced from the incident surface to the emergent surface; the upper cladding is located on the buried oxide layer, the first waveguide and the second waveguides; the at least two low-refractive-index waveguides are located in the upper cladding, are higher than the first waveguide and are parallel to the first waveguide; thelow-refractive-index waveguides are arranged on the two sides of the first waveguide; the width of the low-refractive-index waveguide is gradually increased from the light incident surface to the light emergent surface, and the refractive index of the low-refractive-index waveguide is lower than that of the first waveguide. According to the invention, the alignment tolerance is large, and the substrate absorption loss is small.

Owner:UNITED MICROELECTRONICS CENT CO LTD

Integrated device of awg output waveguide and waveguide detector and its preparation method

ActiveCN105137537BAvoid coupling lossImprove energy efficiencyOptical waveguide light guideCoupling lossInterconnection

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

A method of manufacturing a printed circuit board with a tapered optical waveguide

ActiveCN103926647BSimple preparation processImprove alignment toleranceOptical waveguide light guideCoupling lossEngineering

A method for manufacturing a printed circuit board with a conical optical waveguide includes the following steps that firstly, a substrate is manufactured, wherein the substrate is formed by a copper-clad plate, a medium layer is arranged in the middle of the copper-clad plate, and copper layers are arranged on the two sides of the copper-clad plate; secondly, an optical waveguide layer is manufactured, wherein an upper wrapper, a core layer and a lower wrapper are sequentially manufactured on the substrate, wherein the area of the cross section of the core layer of the optical waveguide gradually decreases in the optical signal propagation direction, the area of the cross section of the input end of the core layer of the optical waveguide is larger than the area of the cross section of the output end of the core layer, and then the conical optical waveguide is formed; thirdly, a matched printed circuit board is manufactured; fourthly, the printed circuit board and the substrate with the optical waveguide layer are laminated to form a mixed plate with the optical waveguide layer and the copper layers; fifthly, the mixed plate is subsequently machined through the drilling step, the electroplating step, the graph manufacturing step, the green oil coating step, the surface processing step, the cleaning step, the examining step, the cleaning step and the packaging step. According to the method, optical waveguide coupling loss of the circuit board can be effectively reduced, and the alignment tolerance of an optical fiber or the optical waveguide can be increased under the same coupling loss requirement.

Owner:SHANGHAI MEADVILLE SCI & TECH

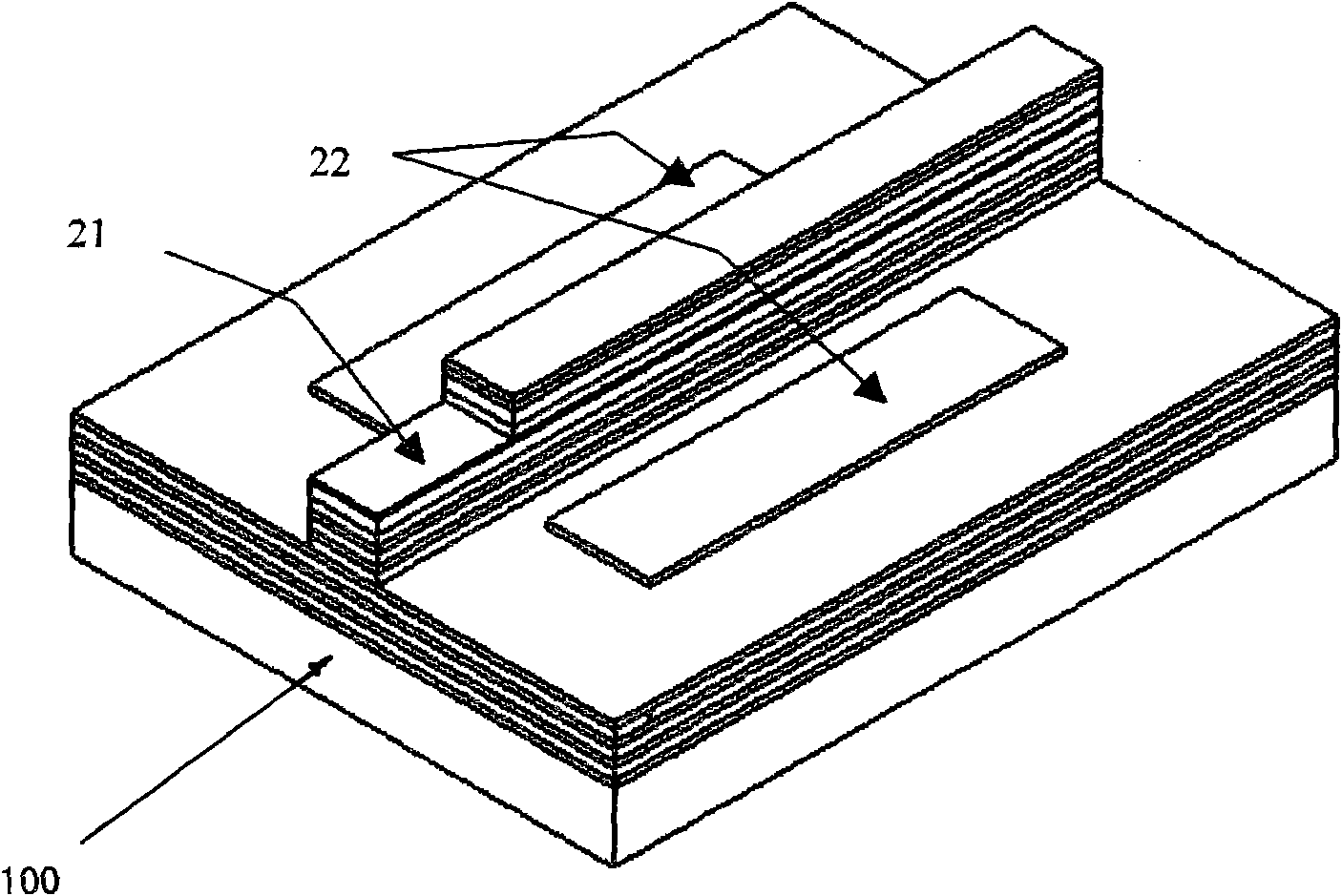

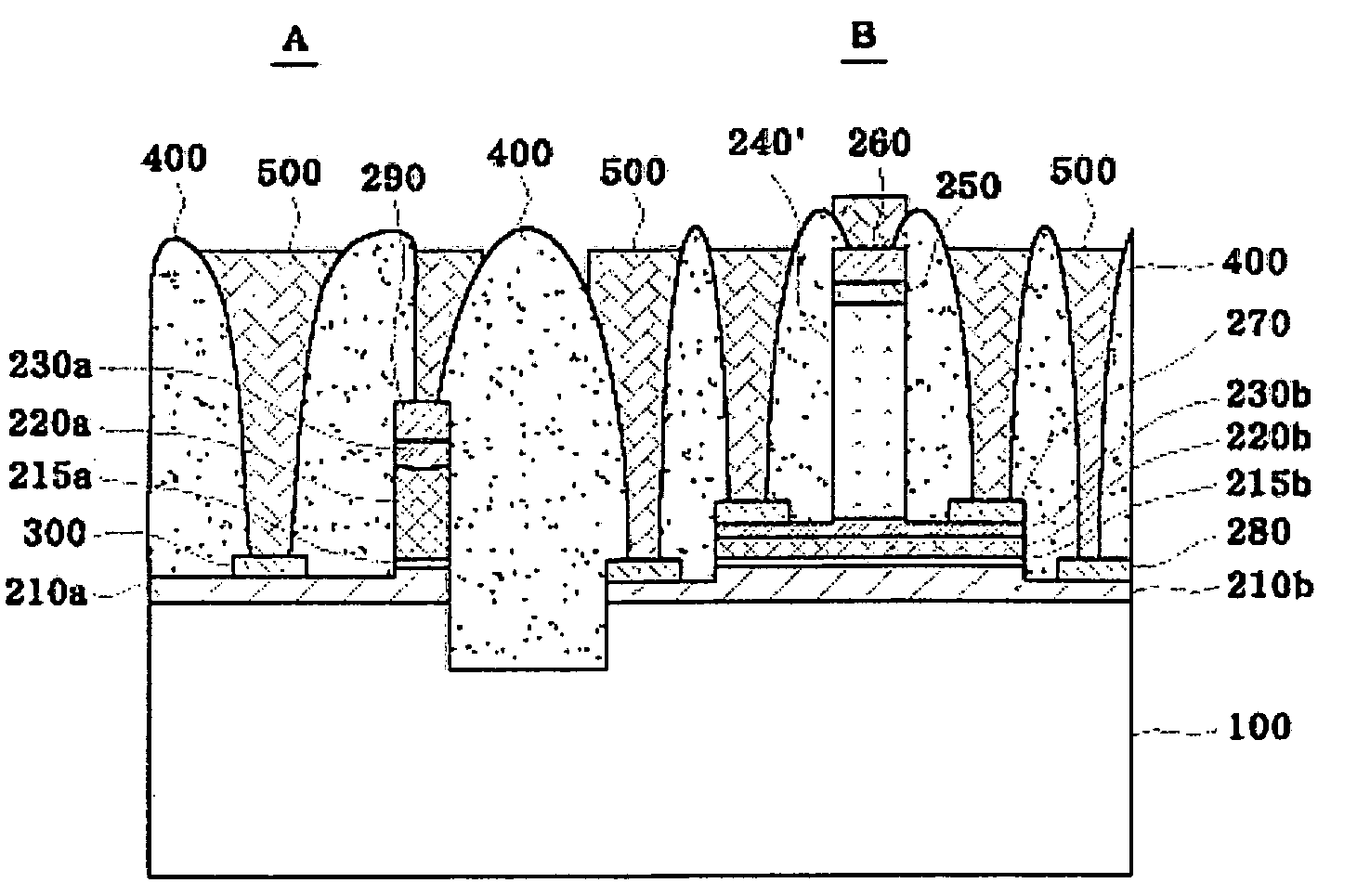

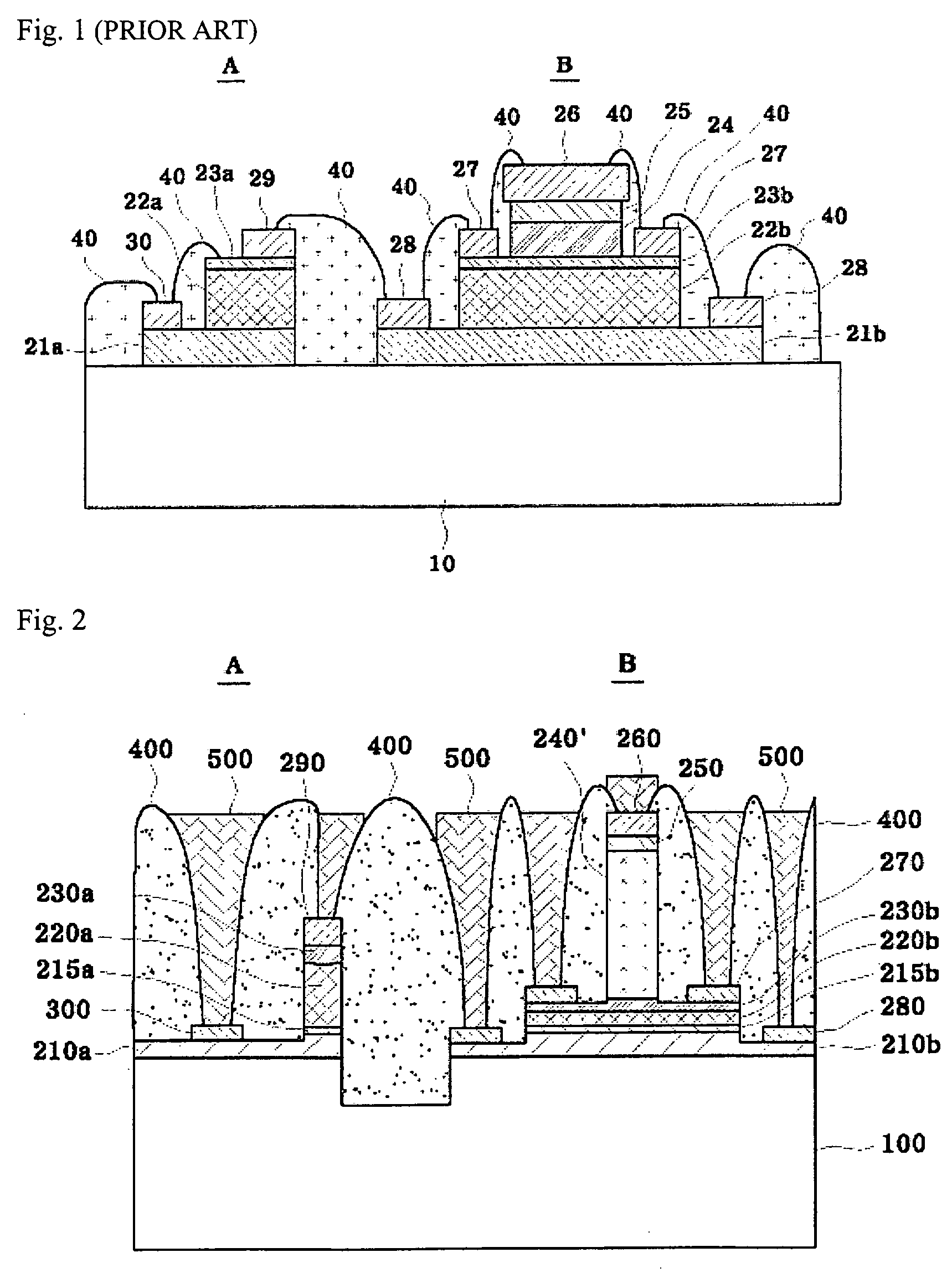

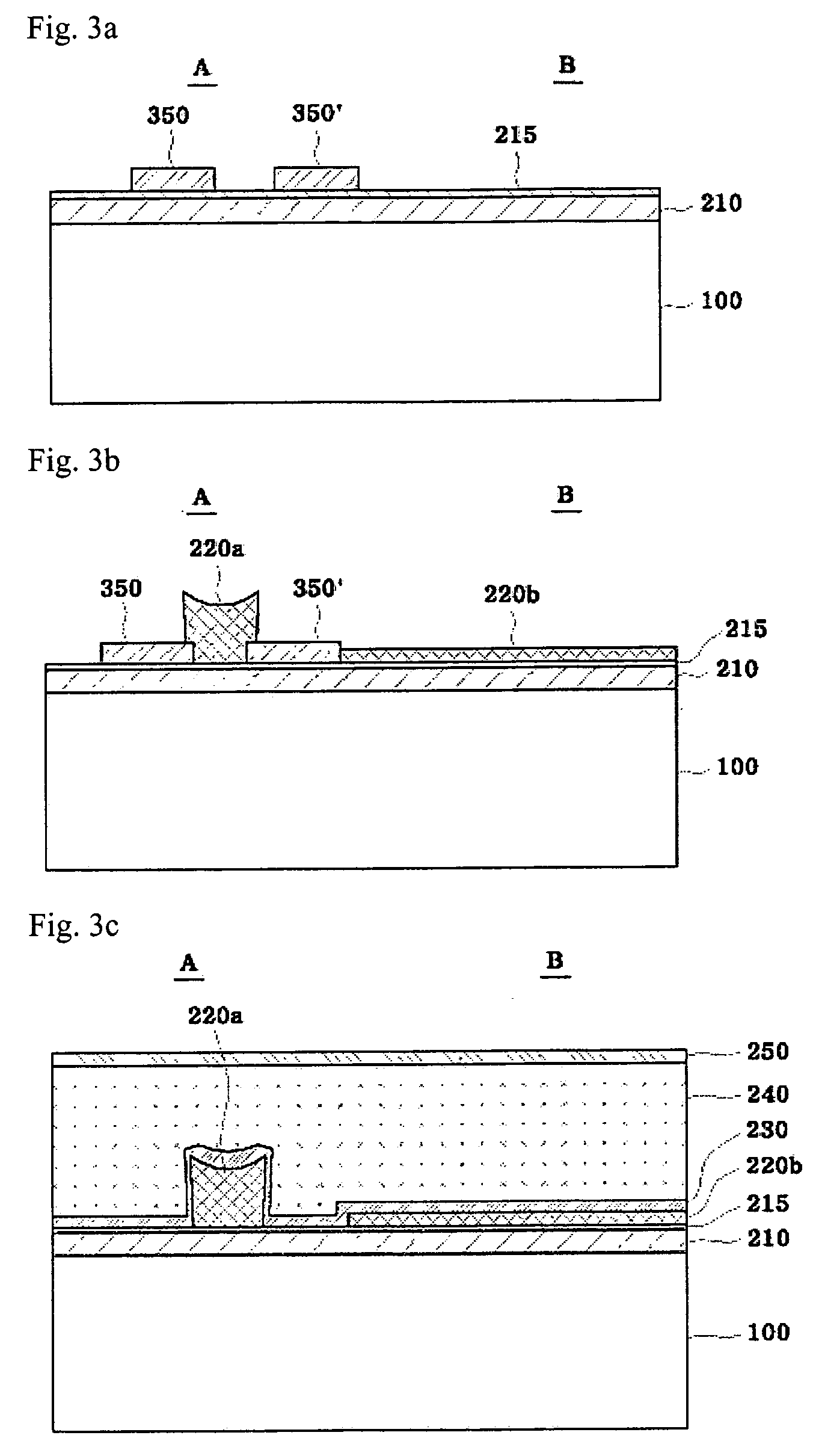

Method of fabricating optoelectronic integrated circuit chip

InactiveUS20050170549A1Improve quantum efficiencyImprove alignment toleranceSemiconductor/solid-state device manufacturingSemiconductor devicesHeterojunction bipolar transistorOrganic chemicals

Provided is a method of fabricating an optoelectronic integrated circuit chip. In particular, a method of fabricating an optoelectronic integrated circuit chip is provided, in which an optical absorption layer of a wave-guide type optical detector is grown to be thicker than a collector layer of a hetero-junction bipolar transistor by using a selective area growth by metal organic chemical vapor deposition (MOCVD) method, and the wave-guide type optical detector and the hetero-junction bipolar transistor are integrated as a single chip on a semi-insulated InP substrate, thereby readily realizing the wave-guide type optical detector improved in quantum efficiency and having the ultra-high speed characteristics.

Owner:ELECTRONICS & TELECOMM RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com