Method for manufacturing printed circuit board with conical optical waveguide

A technology of printed circuit board and tapered optical waveguide, which is applied in the direction of optical waveguide light guide, light guide, optics, etc., to achieve the effect of improving coupling efficiency, reducing coupling loss, and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

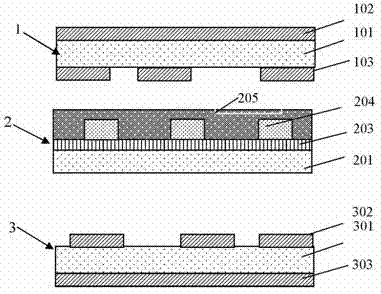

[0030] see Figure 1 to Figure 8 , taking a four-layer copper layer + one optical waveguide layer as an example (two copper layers + one optical waveguide layer + two copper layers), the process flow is as follows:

[0031] 1) Substrate production, 1, 2, and 3 are cut copper clad laminates, copper clad laminates 1 and 3 are used for the production of four copper layers, and the copper clad laminate 2 in the middle is used for the production of the optical waveguide layer. Among them, 101 is a dielectric layer, 102 and 103 are copper layers, see figure 1 ; The optical waveguide substrate 201 is a copper clad laminate with copper etched away, see figure 2 .

[0032] 2) Fabrication of the optical waveguide layer, including the lower cladding layer 203, the core layer 204, and the upper cladding layer 205, see image 3 , the specific production steps include film application, exposure, development, and baking. Wherein, the optical waveguide material used in the core layer and...

Embodiment 2

[0041] This embodiment is the manufacture of a six-layer PCB board with a tapered optical waveguide. Firstly, the manufacture of the inner substrate is completed through material cutting and pattern transfer of the core board, and then the manufacture of the optical waveguide is performed on the inner substrate. The optical waveguide is produced by coating, exposing, developing, and baking the optical waveguide wet film material. The cross-section of the input end of the tapered optical waveguide core layer is 70×70 μm, the cross-section of the output end is 30×30 μm, and the length of the optical waveguide is It is 50cm. Follow-up is completed through lamination, drilling, electroplating, graphic production, green oil, characters, chemical immersion silver, testing, milling shape, packaging, etc.

[0042] Table 1

[0043] Axial offset (μm)

[0044] -15

[0045] Table 2

[0046] Longitudinal offset (μm)

[0047] In summary, the printed circuit b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com