Photoluminescence LED display device and manufacturing method thereof

A technology of photoluminescence and display devices, applied in identification devices, instruments, etc., can solve the problems of increasing mass production of red and green fluorescent materials arranged side by side, poor alignment, difficult control of the manufacturing process, etc., and achieve improved light energy The effect of using efficiency, increasing the tolerance error of alignment, and avoiding uneven thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

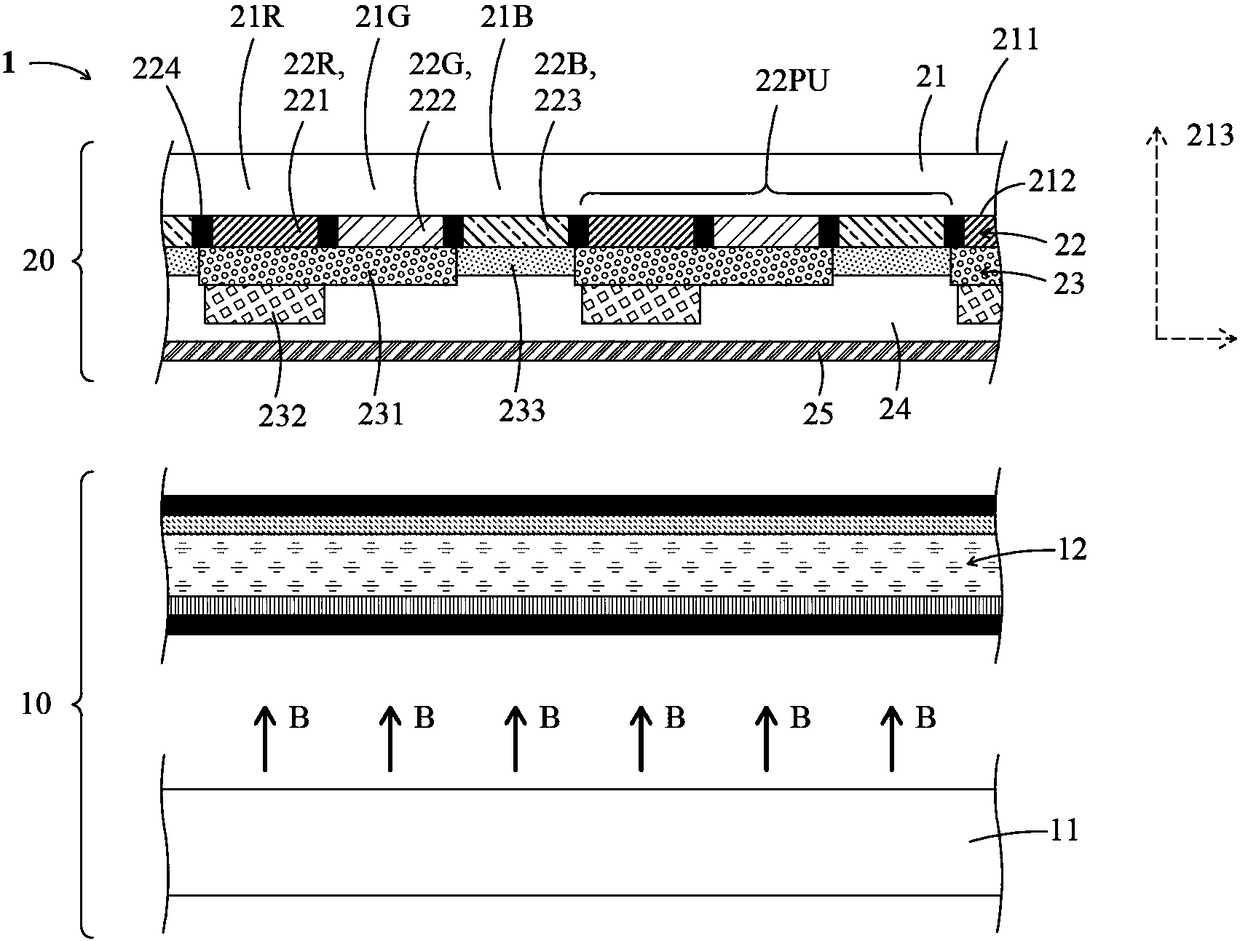

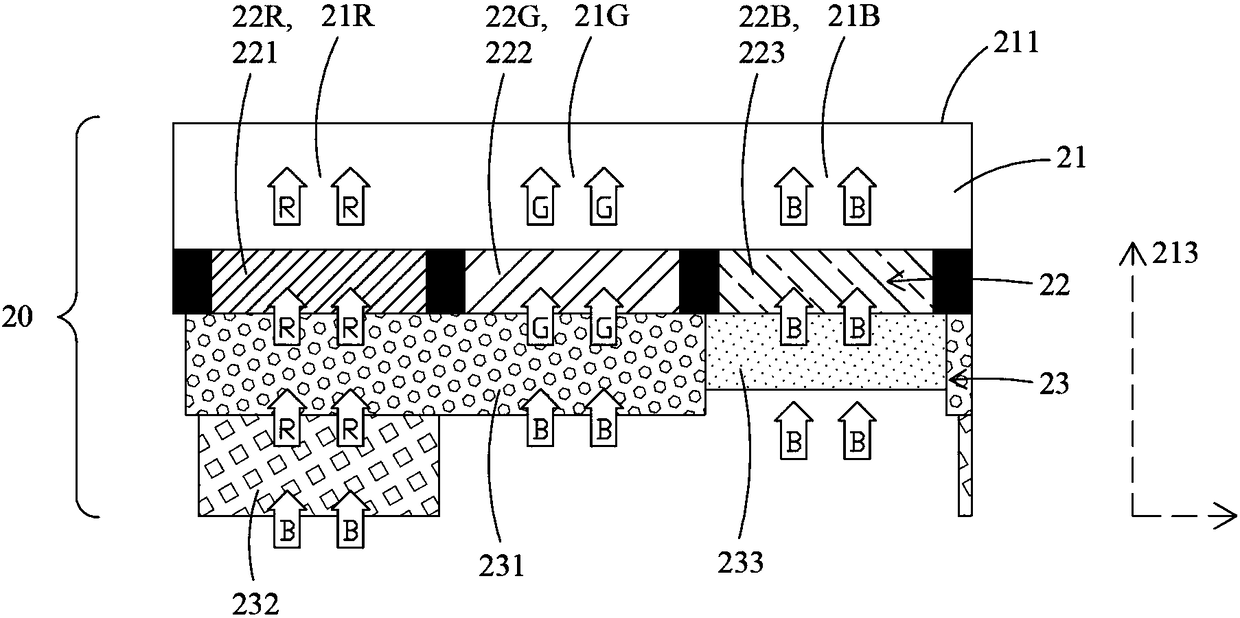

[0075] see Figure 2A FIG. 1 is a schematic diagram of a photoluminescent (PL) display device 1 according to a first preferred embodiment of the present invention. The photoluminescent LED display device 1 (hereinafter referred to as PL display device 1) can provide red pixels formed by red light, green pixels formed by green light and blue pixels formed by blue light, and on the display device A color image is formed. The PL display device 1 can include a blue light source 10 and a display panel 20, the display panel 20 is arranged on one side of the blue light source 10 (for example, the light output side), and the display panel 20 and the blue light source 10 can be separated, or touch. The technical content of the blue light source 10 and the display panel 20 will be further described as follows.

[0076] The blue light source 10 can generate a blue light B, and can make the blue light B evenly illuminate a specific area of the display panel 20, that is, when the disp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com