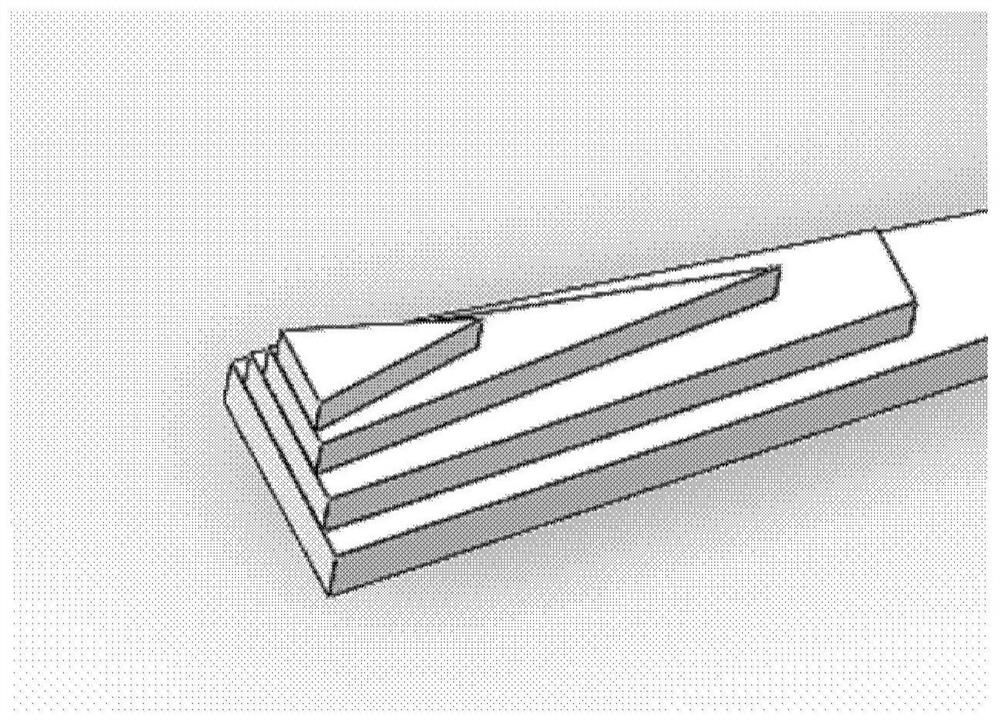

Hybrid packaging device based on spot size transformation and grating coupling

A grating coupling and hybrid packaging technology, applied in the directions of light guides, optics, optical components, etc., can solve the problems of small alignment tolerance, large package size, low coupling efficiency, etc., to achieve small overall size and improve alignment tolerance. , the effect of improving the optical coupling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Hereinafter, an embodiment of the present disclosure will be described with reference to the accompanying drawings. It should be understood, however, that these descriptions are merely exemplary, and not to limit the scope of the disclosure. In the following detailed description, many of the specific details are set forth to provide a comprehensive understanding of the embodiments of the present disclosure. However, it is apparent that one or more embodiments may be implemented without these specific details. Further, in the following description, a description of the well-known structure and techniques is omitted to avoid unnecessarily obscuring the concepts of the present disclosure.

[0023] Light coupling is generally divided into two types, which are direct coupling and indirect coupling, and indirect coupling is not conducive to large scale integration. The use of direct coupling is a more mature is to use a mold converter and a grating coupler. Although the mutant co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com