Alignment method for metal masks

A metal mask, fine metal mask technology, applied in metal material coating process, ion implantation plating, coating and other directions, can solve the problems of color mixing, poor alignment accuracy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

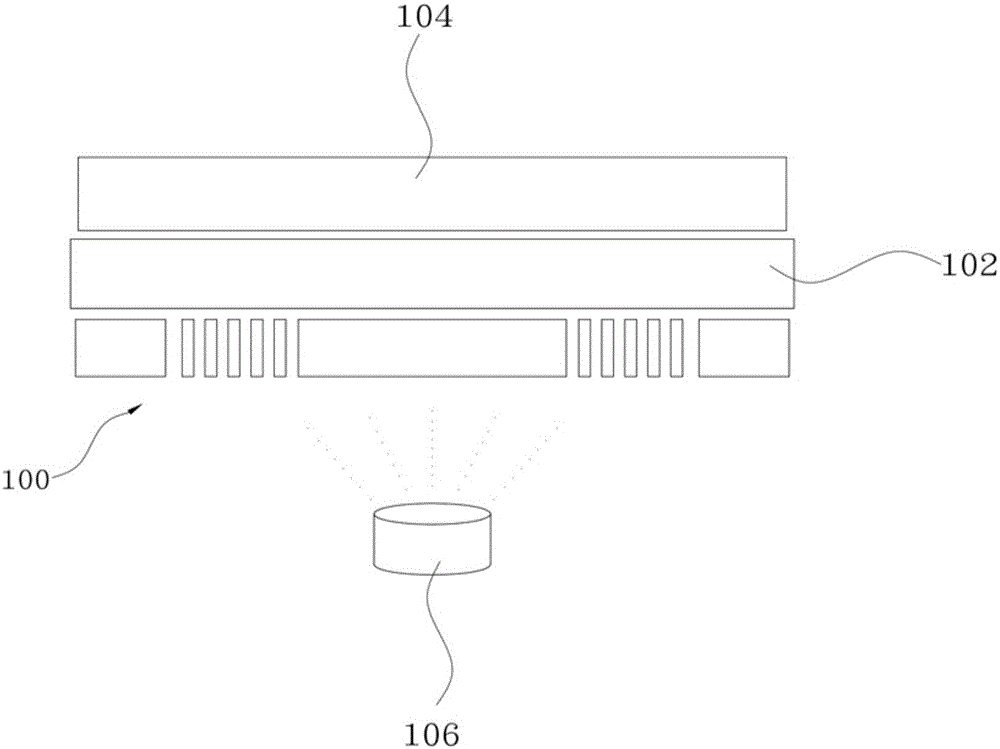

[0055] In a specific embodiment, the alignment method further includes: when the evaporation source S is evaporating different fine metal mask groups, providing a shielding layer to cover the non-evaporated area of the OLED substrate. For example, when the evaporation source S evaporates the first fine metal mask group 60, a shielding layer SH1 is provided to cover the current non-evaporated area of the OLED substrate; when the evaporation source S evaporates the second fine metal mask group When the group 70 performs evaporation, a shielding layer SH2 is provided on both sides of the second fine metal mask group 70 so as to cover the current non-evaporated area of the OLED substrate; when the evaporation source S is applied to the third fine metal mask group 80 When performing evaporation, a shielding layer SH3 is provided to cover the current non-evaporation area of the OLED substrate. Of course, the shielding layer here is not necessary, for example, in other embodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com