Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

41results about How to "High pyroelectric coefficient" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Anti-ferroelectric thin film used as thermoelectrical material and preparing method and use thereof

InactiveCN1990418AAdjust working temperatureHigh sensitivityPhotometry using electric radiation detectorsPyrometry using electric radation detectorsPyroelectric detectorsFerroelectric thin films

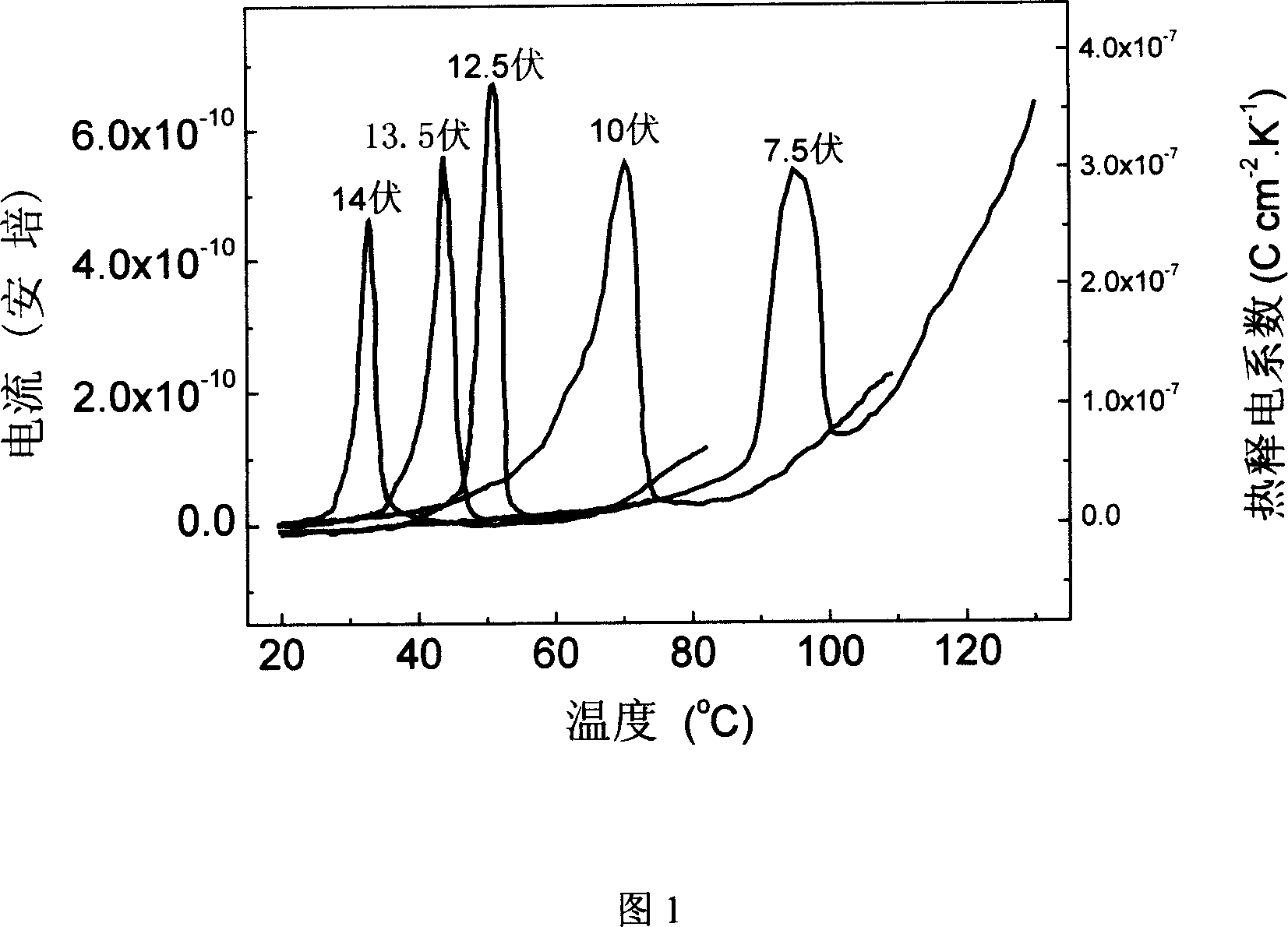

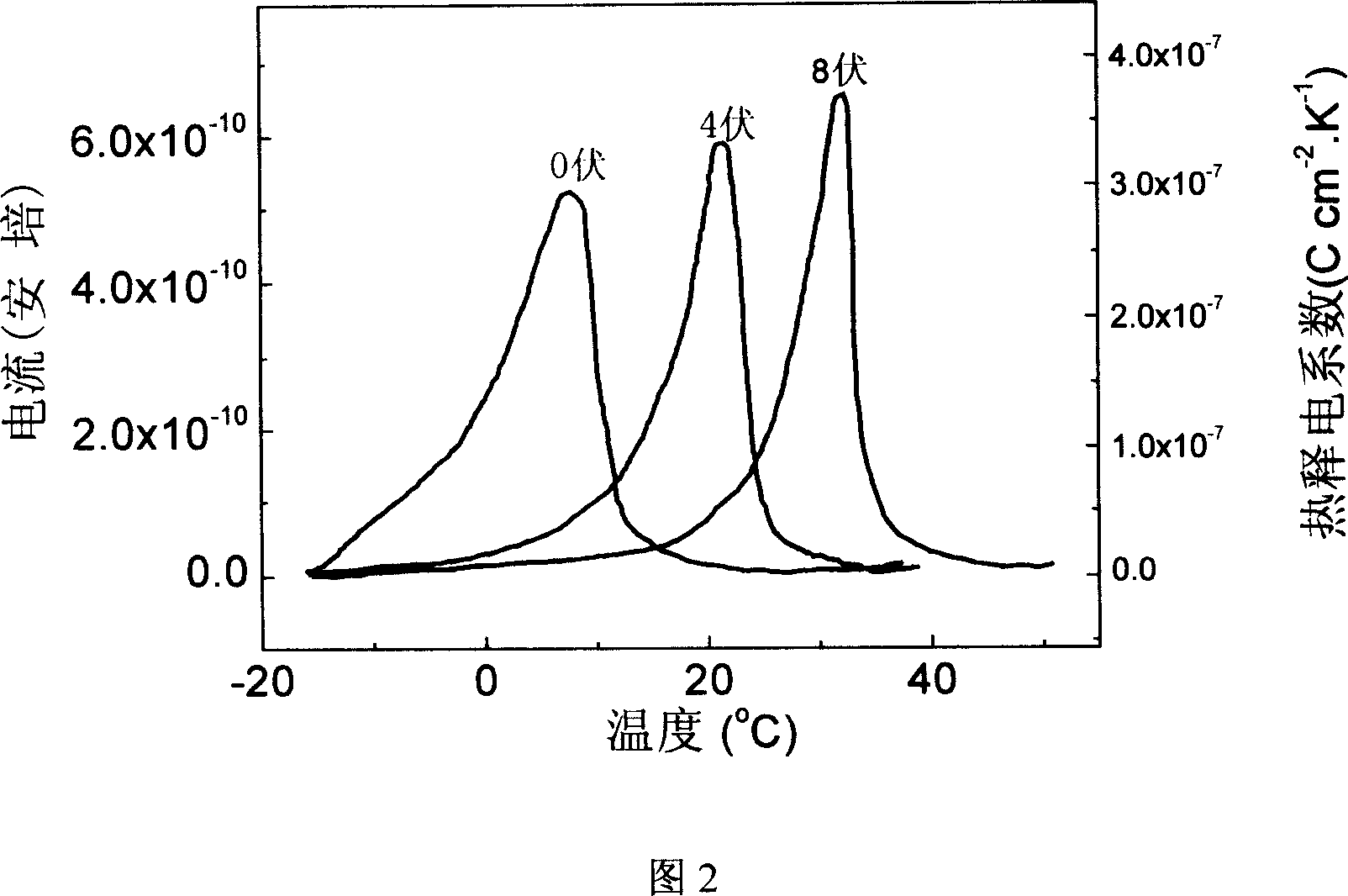

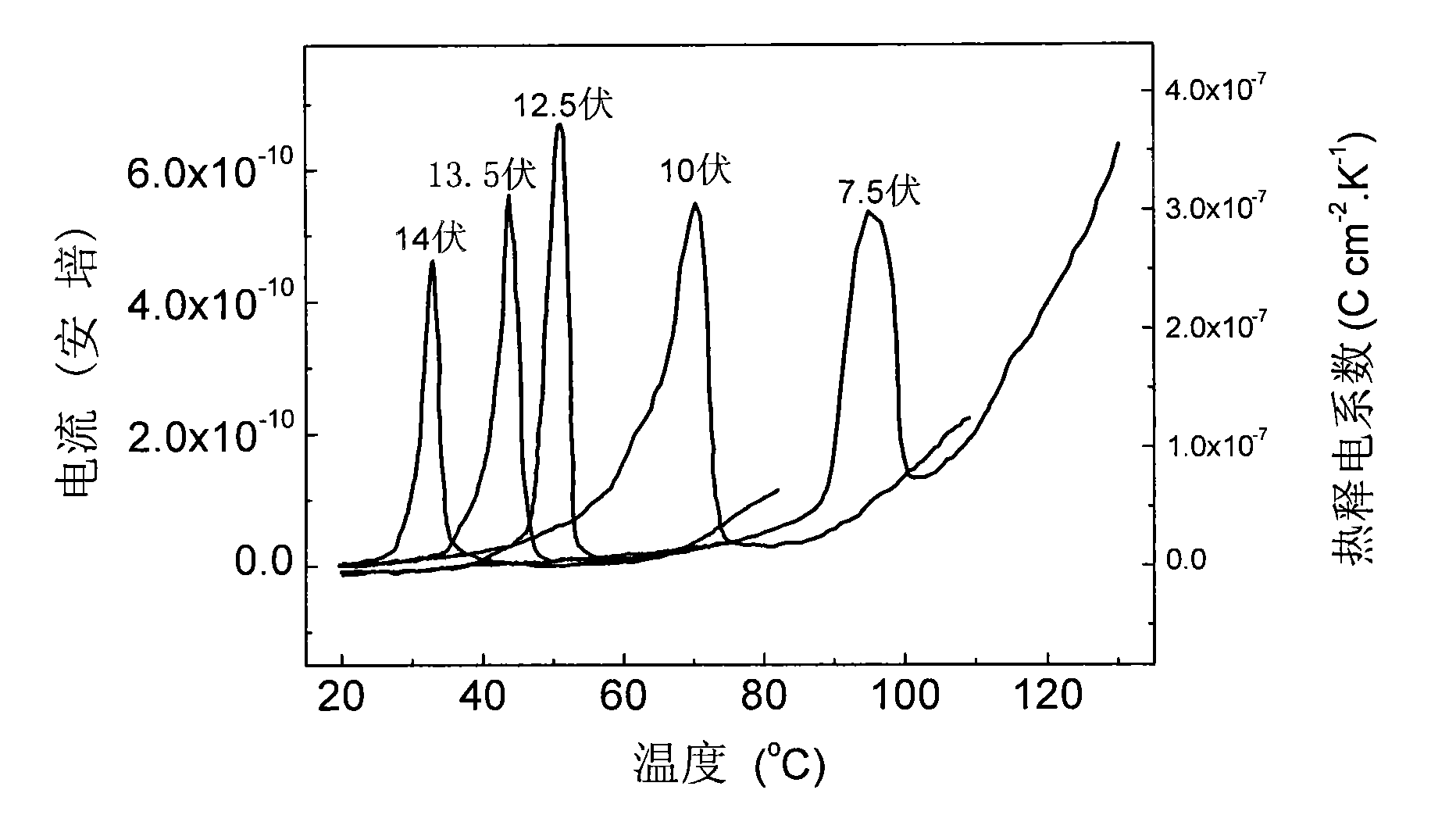

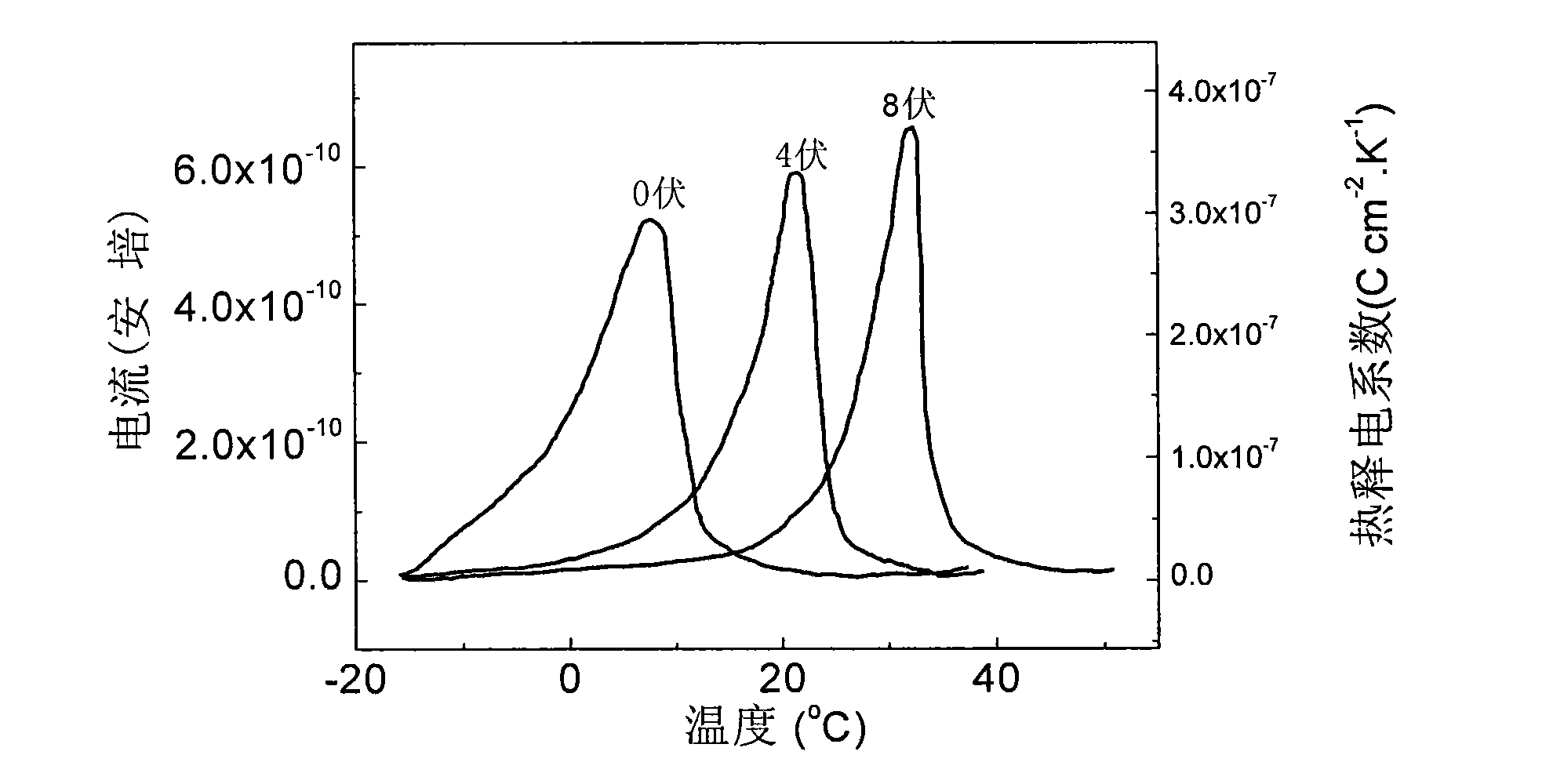

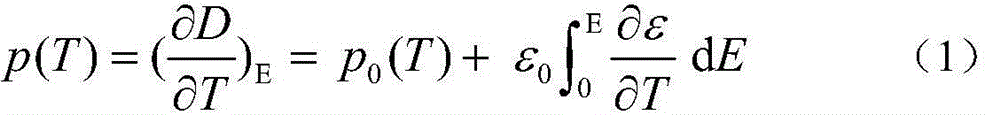

The invention discloses an anti-ferroelectric membrane with adjustable working temperature area and large heat-releasing rate, and the method for preparing the same and its application. It applies sol-gel method to prepare said anti-Ferroelectric membrane ((Pb, La or Nb) (Zr, Sn, Ti) O3, the solute of precursor comprises acetate lead, the acetate lanthanum or ethanol nb, acetate tin, zirconium iso-propoxide and titanium iso-propoxide; the solvent comprises acetic acid, glycol ethylene ether and water; the final concentration of precursor is controlled between 0.2-0.4 M. the bed piece is LaNiO3 / Pt / Ti / SiO2 / Si and Pt / Ti / SiO2 / Si. The product is mainly used for infrared heat-releasing electrical detector, smart device and system.

Owner:TONGJI UNIV

Preparation method of nano tourmaline modified dust removal filter material

ActiveCN107261641AHigh pyroelectric coefficientImprove charging capacityDispersed particle filtrationMembrane filtersEmulsionTest sample

The invention discloses a preparation method of a nano tourmaline modified dust removal filter material, which belongs to the technical field of high-temperature smoke dust removal. The preparation method comprises the following steps: carrying out heat treatment for nano tourmaline powder; weighing sodium hexametaphosphate and sodium polyacrylate, and mixing the sodium hexametaphosphate and sodium polyacrylate with water; weighing nano tourmaline powder, adding water, and mixing with PTFE emulsion; adding the sodium hexametaphosphate and sodium polyacrylate into a mixed solution of the nano tourmaline powder and PTFE emulsion, and obtaining a nano tourmaline treatment solution; soaking a filter material test sample in the nano tourmaline treatment solution, and obtaining a nano tourmaline filter material; and polarizing the nano tourmaline filter material by virtue of electrets, and obtaining the nano tourmaline modified dust removal filter material. By adopting the preparation method, not only is electrets performance high, small dust can be trapped, the dust filter efficiency can be improved, the dust removing rate can be increased, and the equipment resistance is reduced.

Owner:南京际华三五二一环保科技有限公司

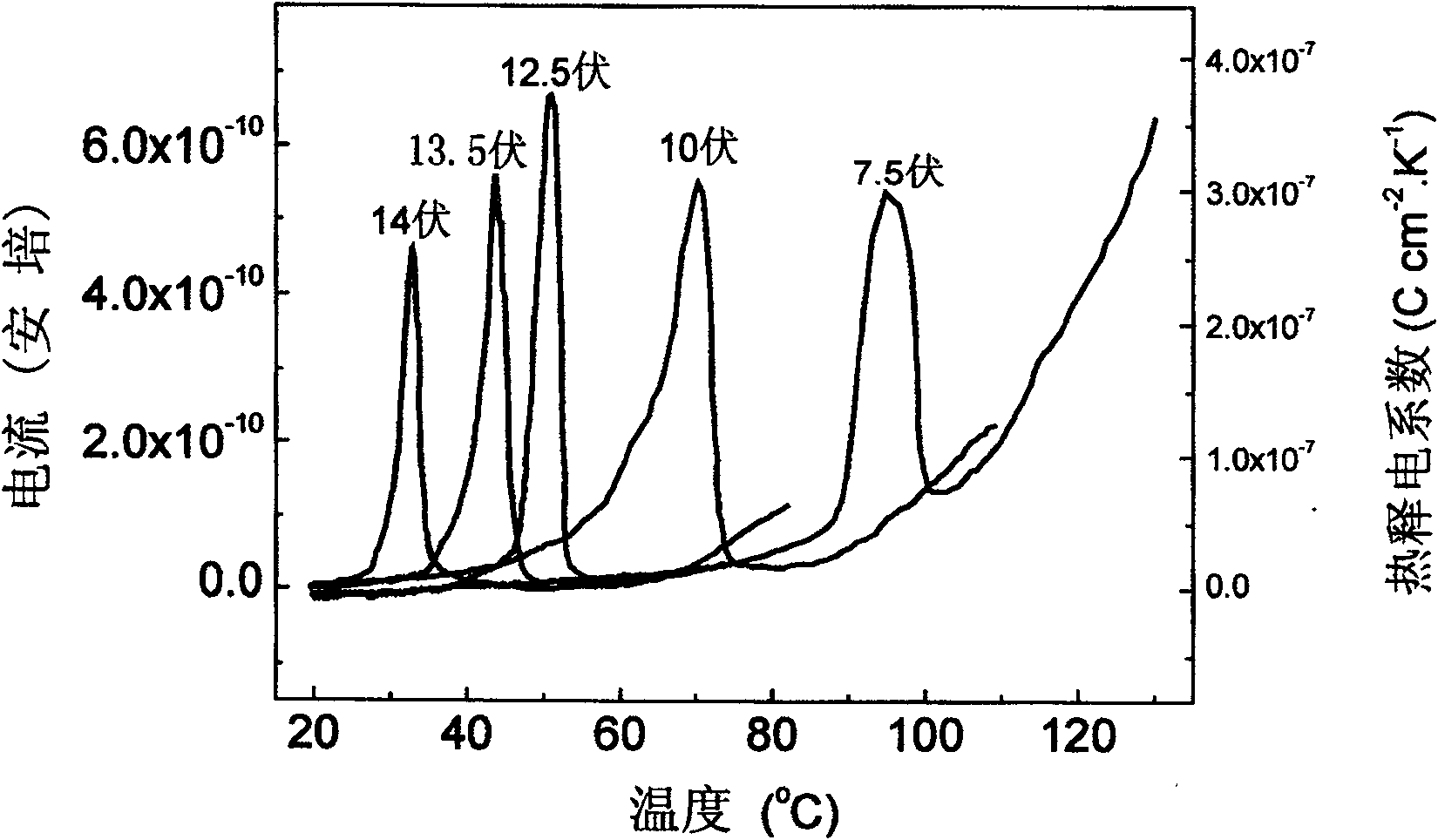

Antiferroelectric film with adjustable working temperature zone and higher pyroelectric coefficient and preparation method thereof

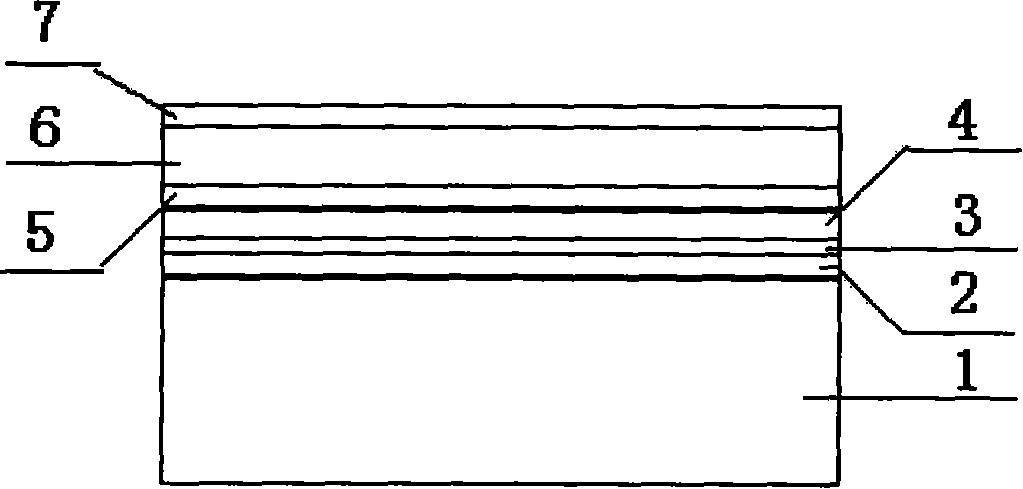

InactiveCN101670691AAdjust working temperatureHigh sensitivityLayered productsPyrometry using electric radation detectorsPyroelectric detectorsNiobium

The invention discloses an antiferroelectric film with adjustable working temperature zone and higher pyroelectric coefficient and a preparation method and application thereof. The antiferroelectric film (Pb,Nb)(Zr,Sn,Ti)O3 taken as the pyroelectric material is prepared by a sol gel method, the solute of precursor solution can be lead acetate, lanthanum acetate or niobium ethoxide, stannic acetate, zirconium isopropoxide and titanium isopropoxide, the solvent includes glacial acetic acid, ethylene glycol ethyl ether, acetylacetone and water, the final concentration of the precursor solution is controlled between 0.2-0.4 M, and the substrate comprises LaNiO3 / Pt / Ti / SiO2 / Si and Pt / Ti / SiO2 / Si. The antiferroelectric film is high in thermally stimulated current and adjustable in temperature andcan be used for a pyroelectric infrared detector, a smart device and a system.

Owner:TONGJI UNIV

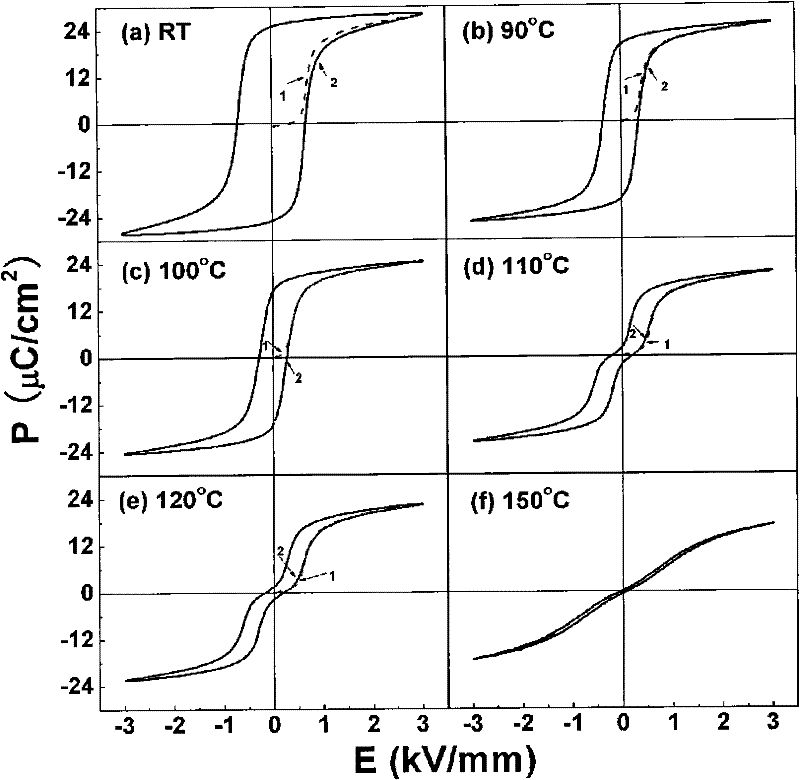

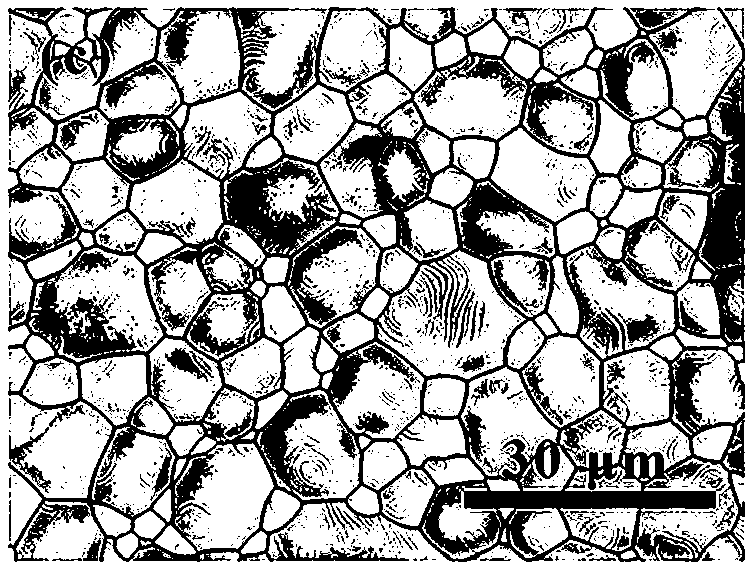

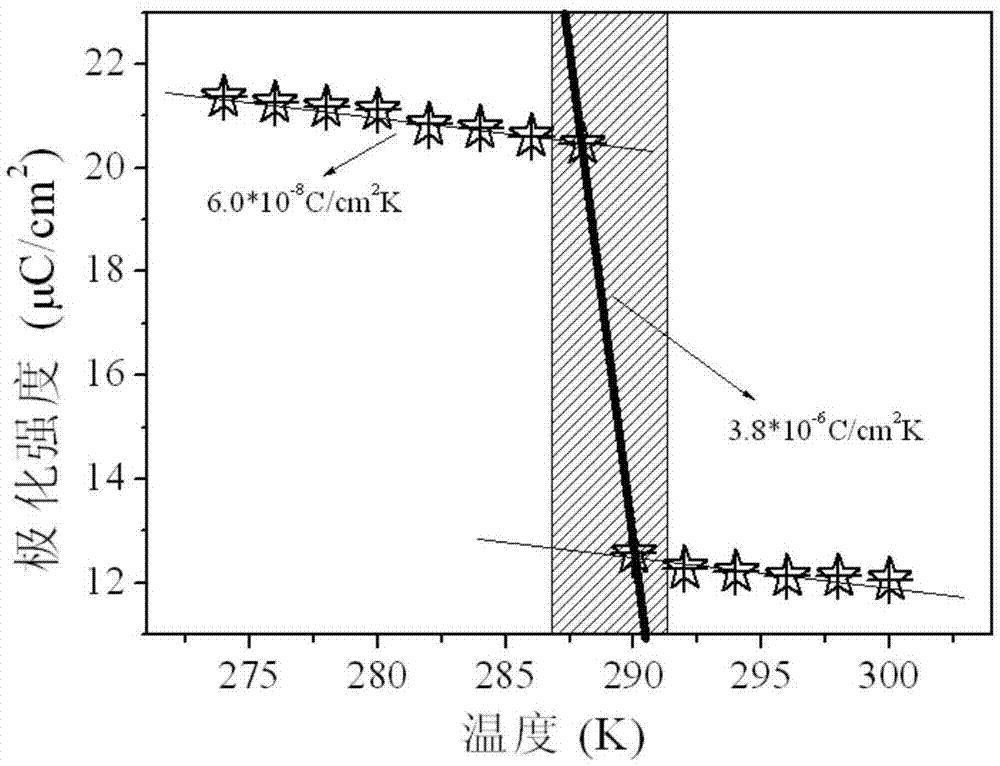

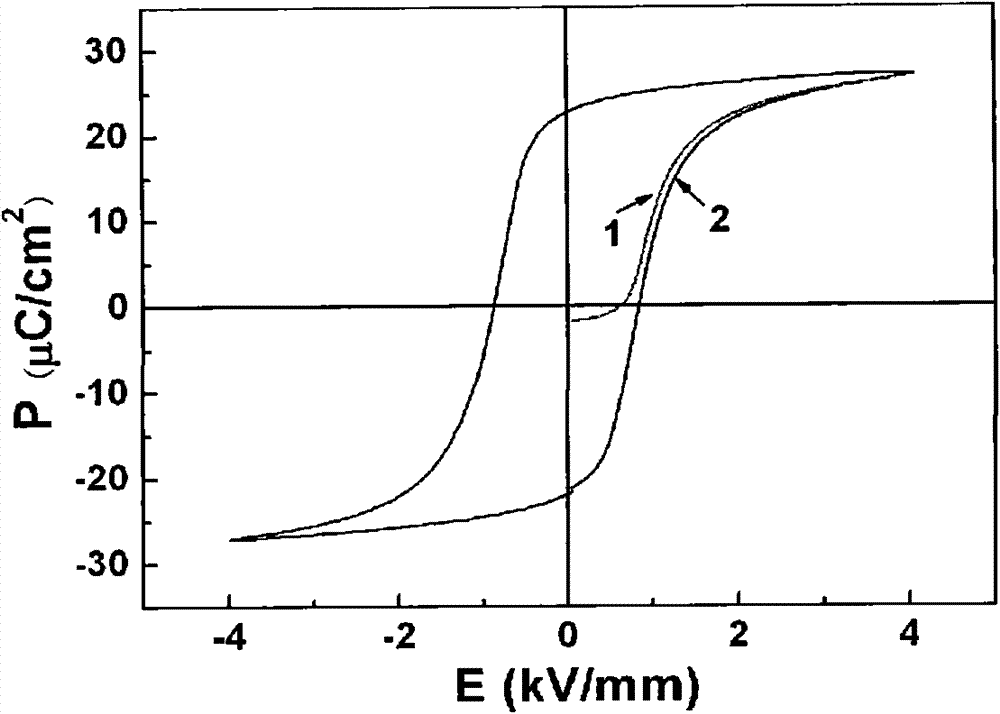

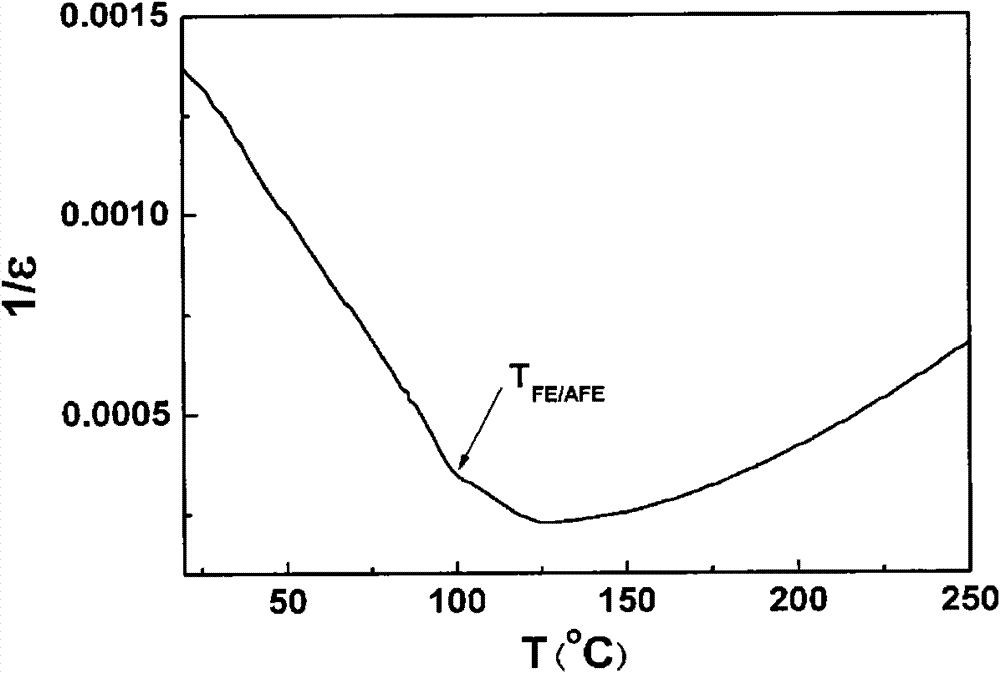

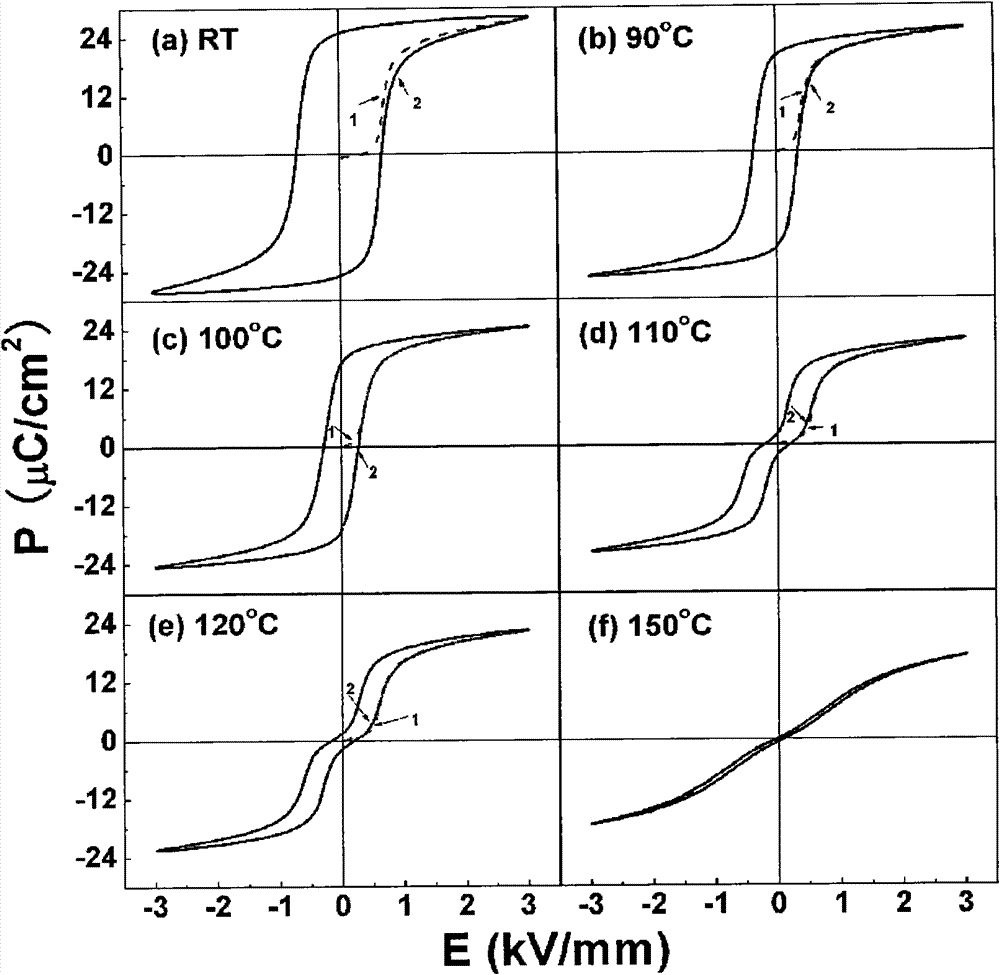

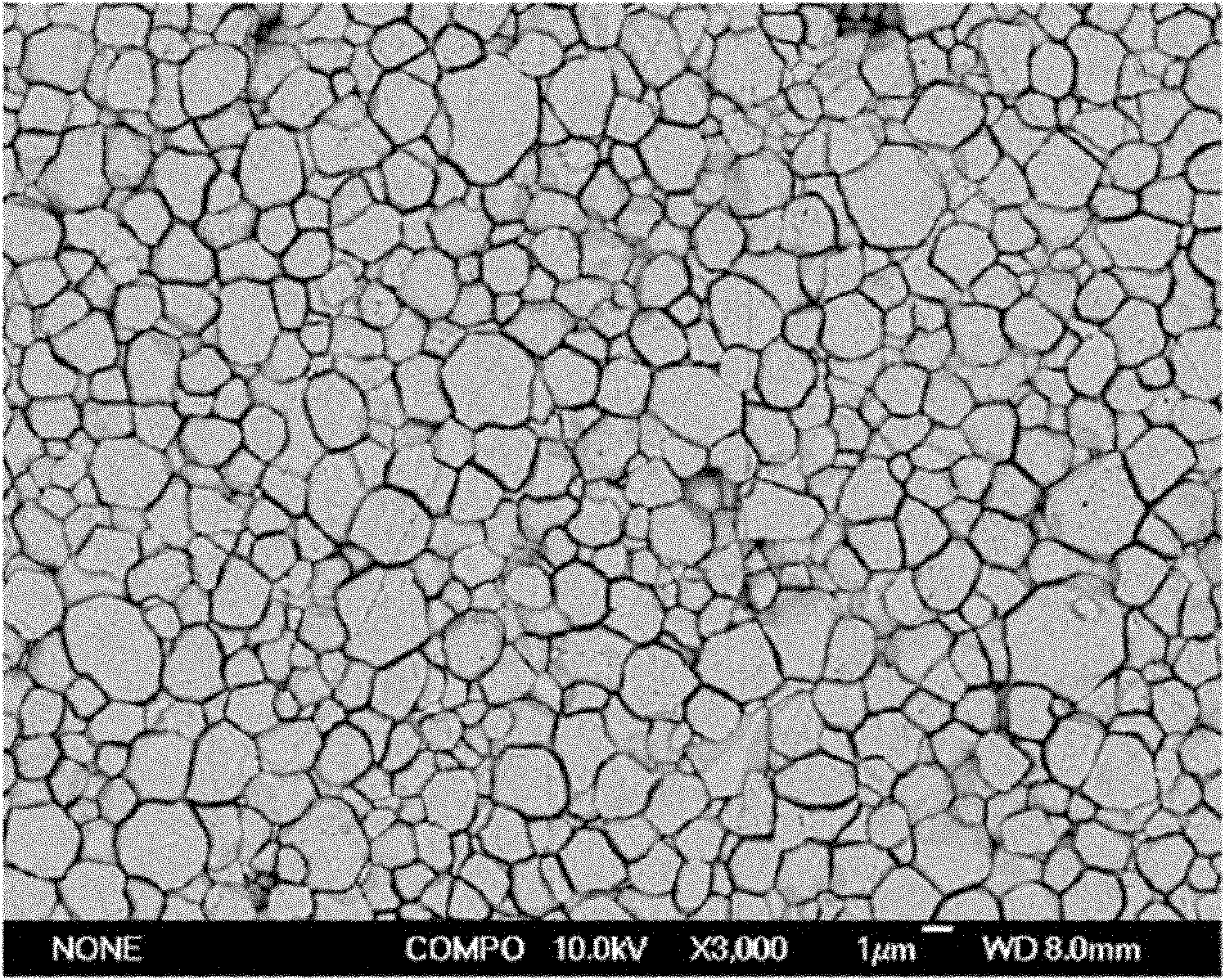

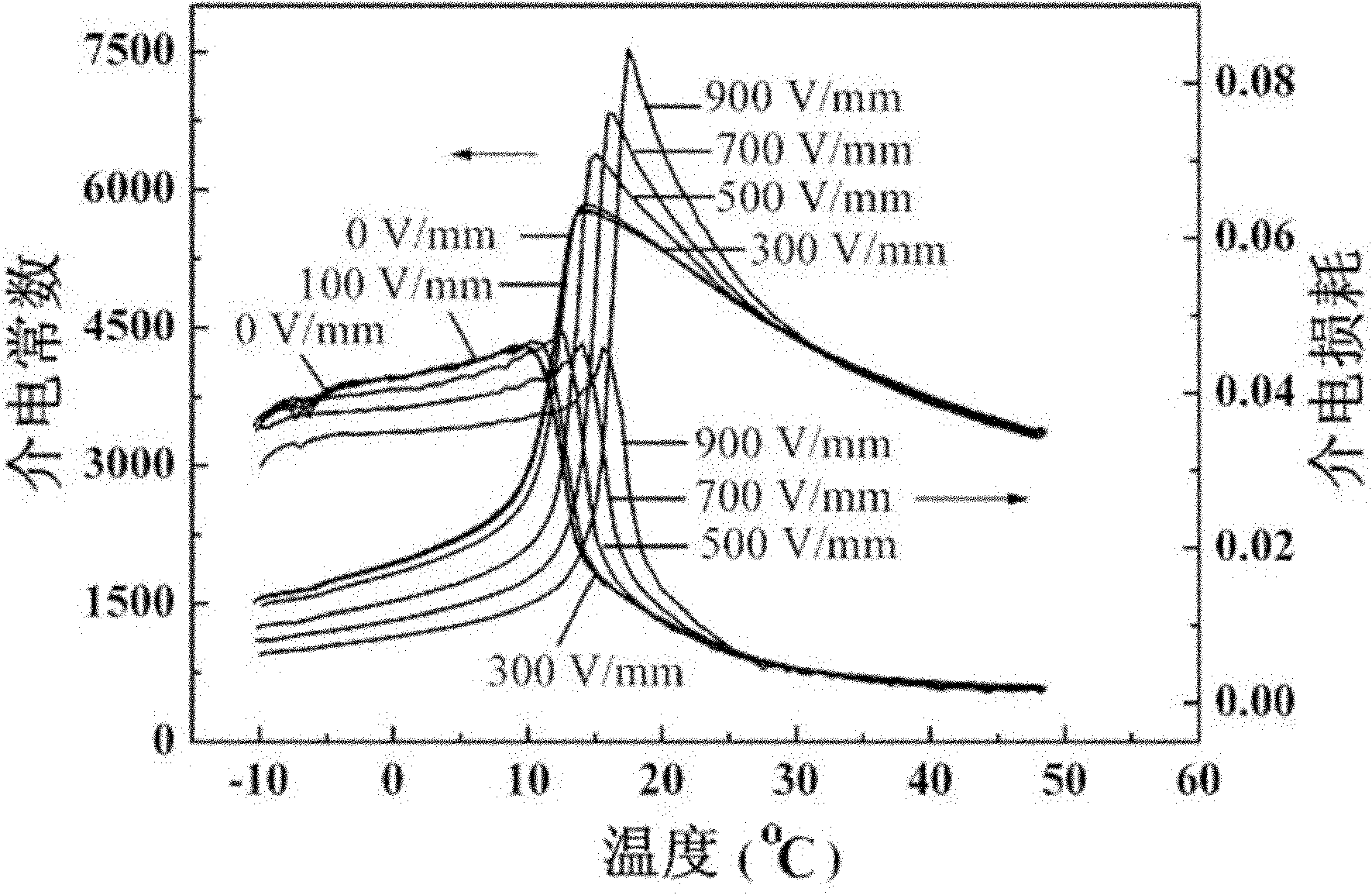

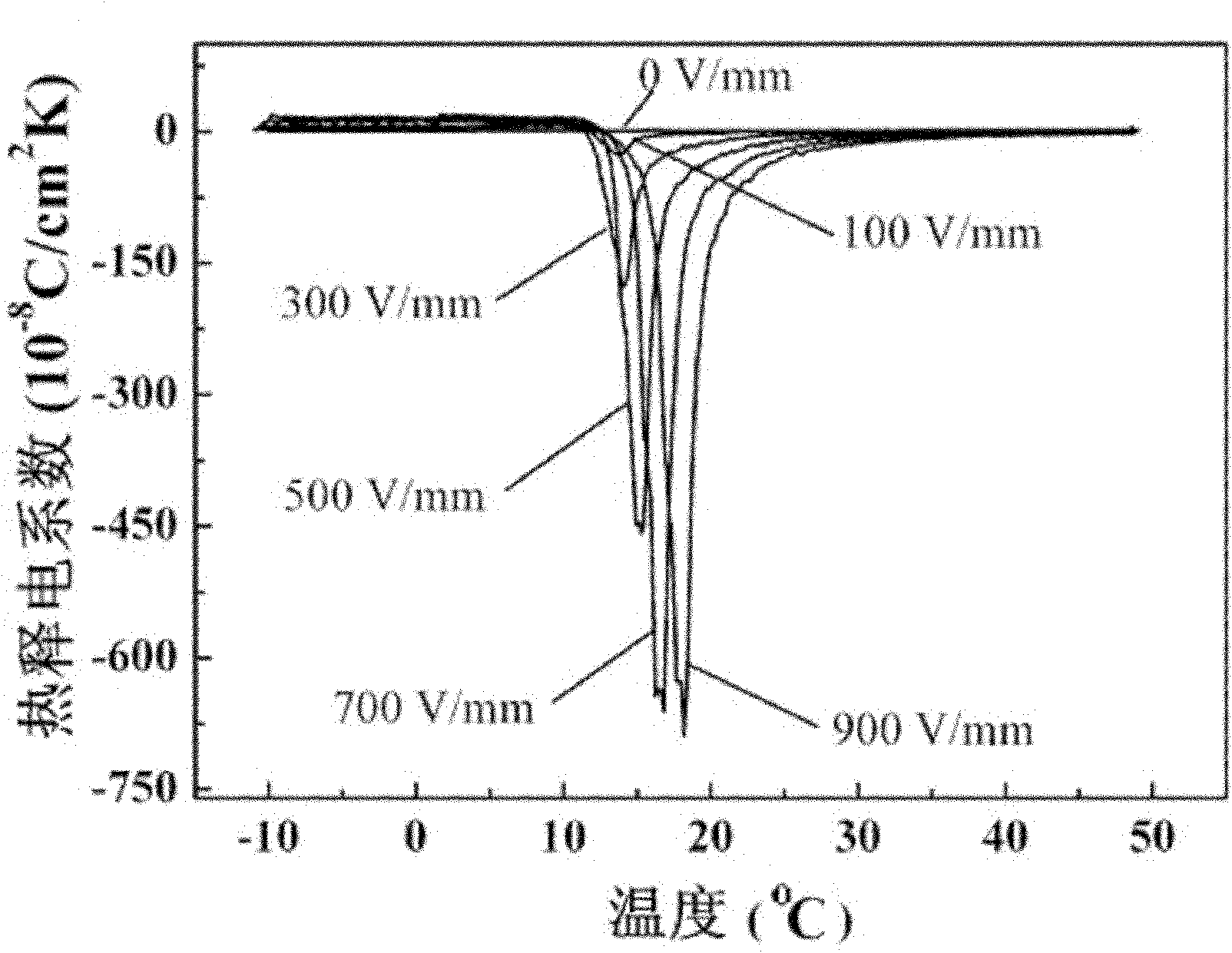

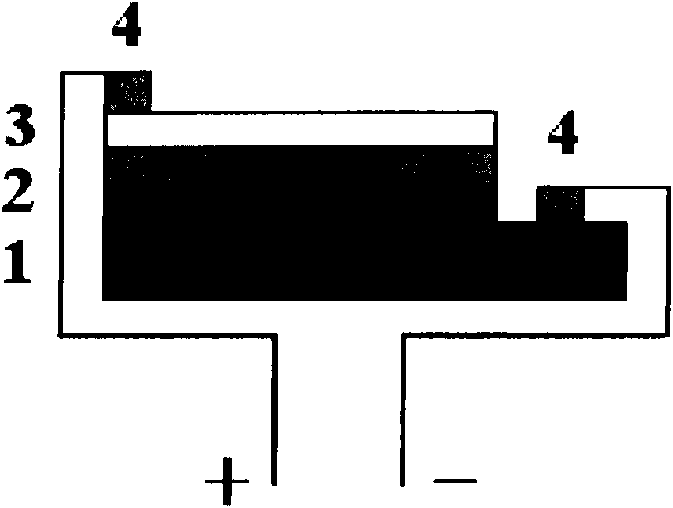

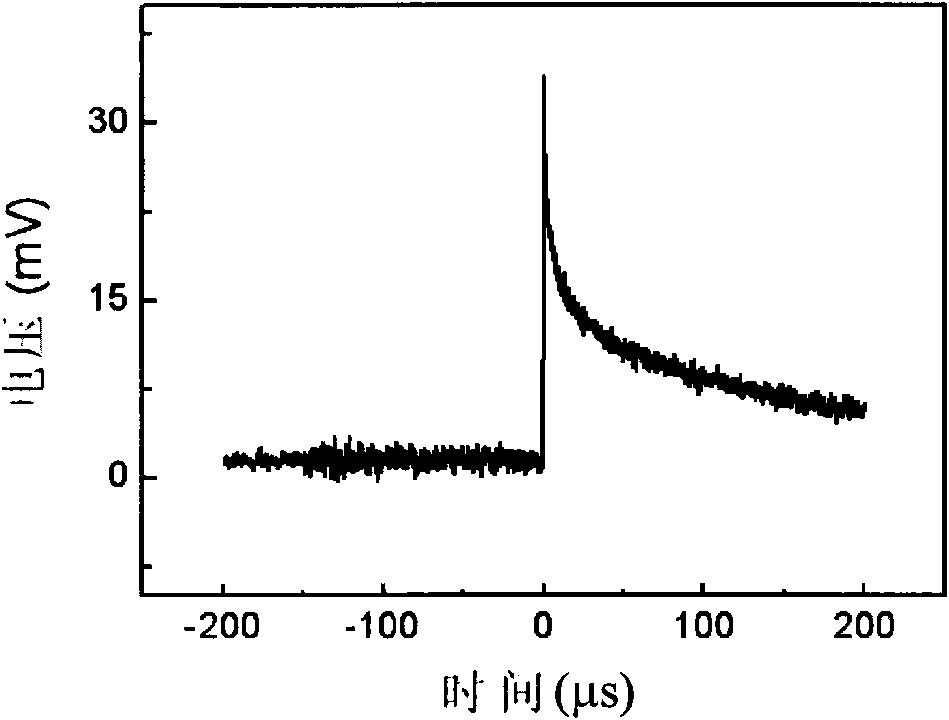

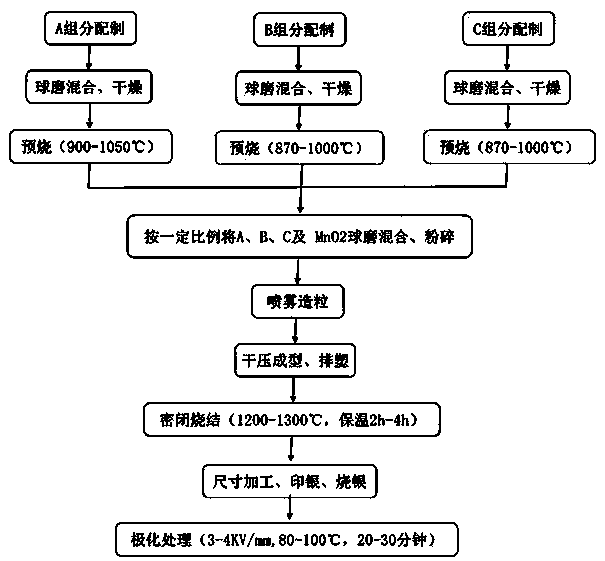

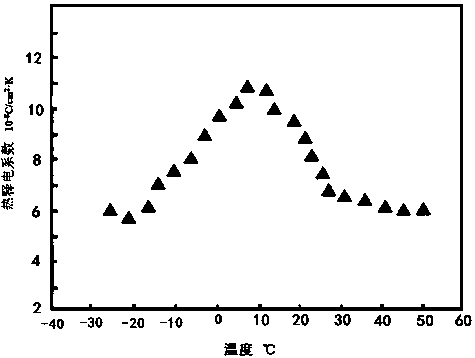

Ferroelectric-antiferroelectric (FE-AFE) phase change pyroelectric ceramic material, ceramic element thereof and preparation methods of material and element

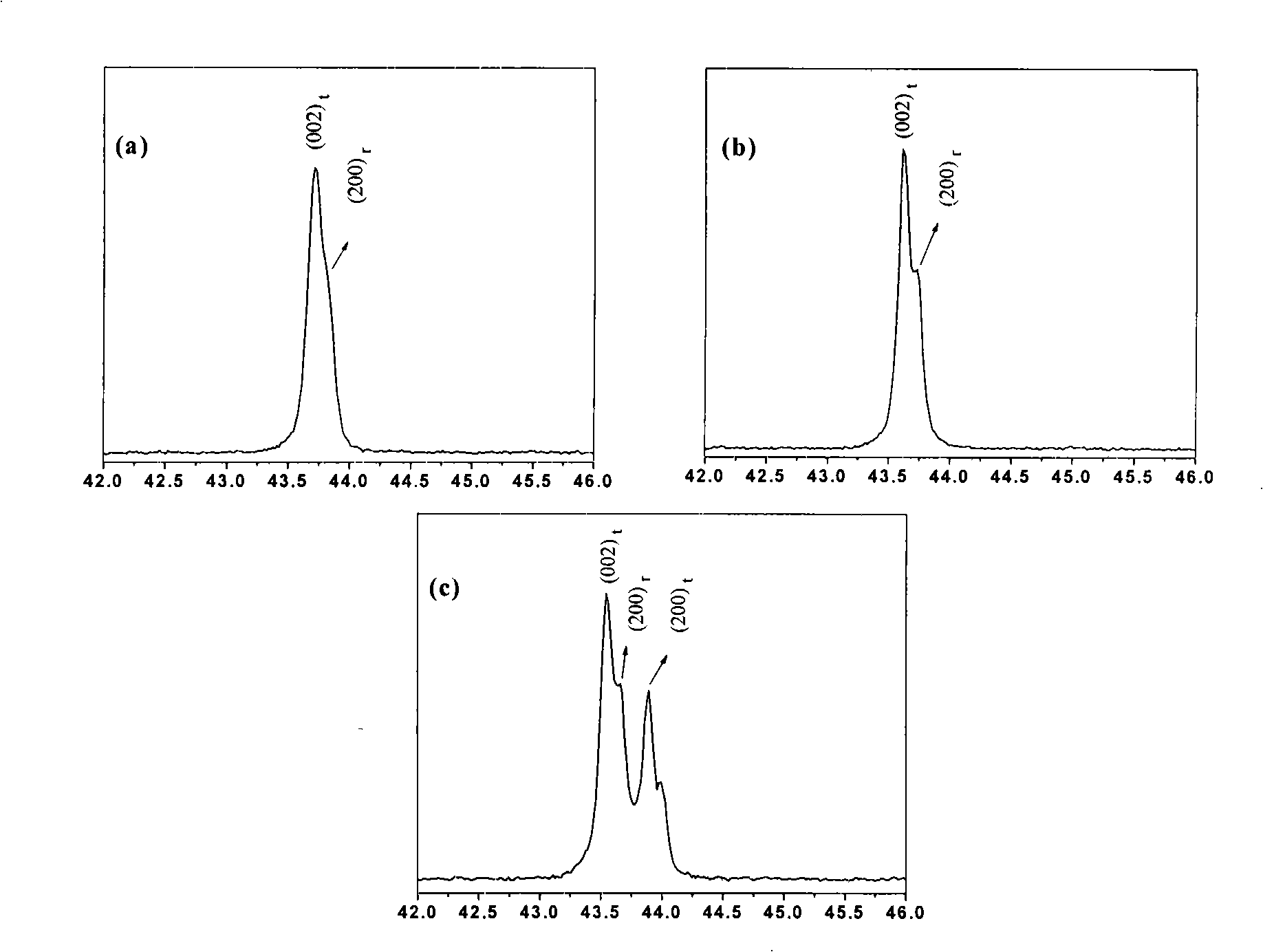

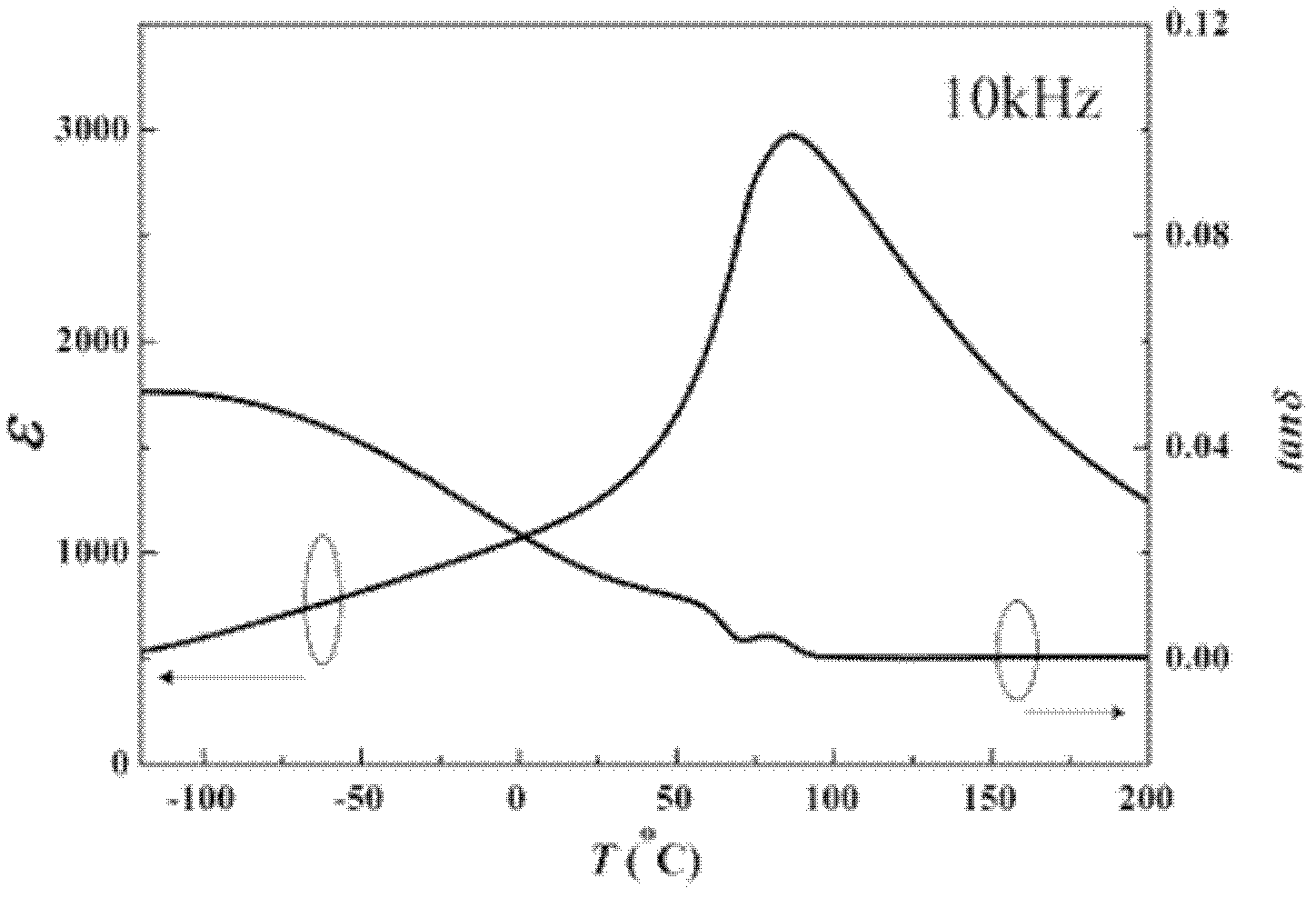

ActiveCN102241511ALarge pyroelectric responseHigh pyroelectric coefficientElectricityChemical composition

The invention which relates to an FE-AFE phase change pyroelectric ceramic material belongs to the field of pyroelectric ceramic. The invention discloses the FE-AFE phase change pyroelectric ceramic material, a pyroelectric ceramic element and preparation methods of the material and the element. Chemical components of the ceramic material accord with a general chemical formula of (Pb1-3x / 2Lax)(ZryTizSn1-y-z)O3, wherein x is more than 0 and equal to or less than 0.025, y is from 0.38 to 0.46, and z is from 0.14 to 0.18; and the ceramic material is in a ferroelectric phase at room temperature and can generate an FE-AFE phase change with the temperature change with or without an extra electric field. The pyroelectric ceramic element has a large polarized change with the FE-AFE phase change after being polarized or under the effect of a direct current bias, so a large pyroelectric response is obtained, a pyroelectric coefficient is 2-4 times more than traditional pyroelectric coefficients, and heat stagnation substantially does not exist, so the pyroelectric ceramic element can be used in the uncooled infrared detection technology and the fields of heat-electrical energy transformation and the like.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

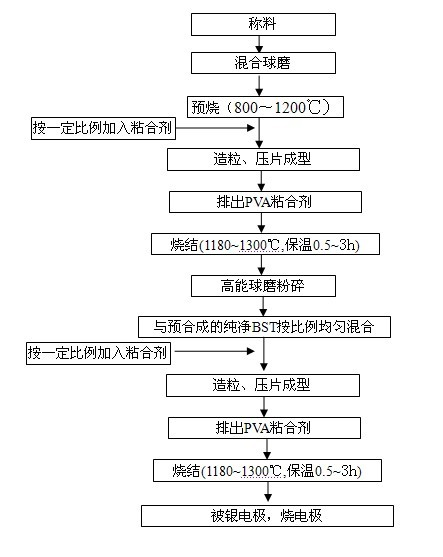

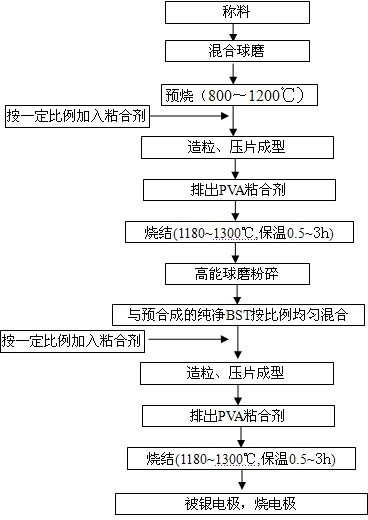

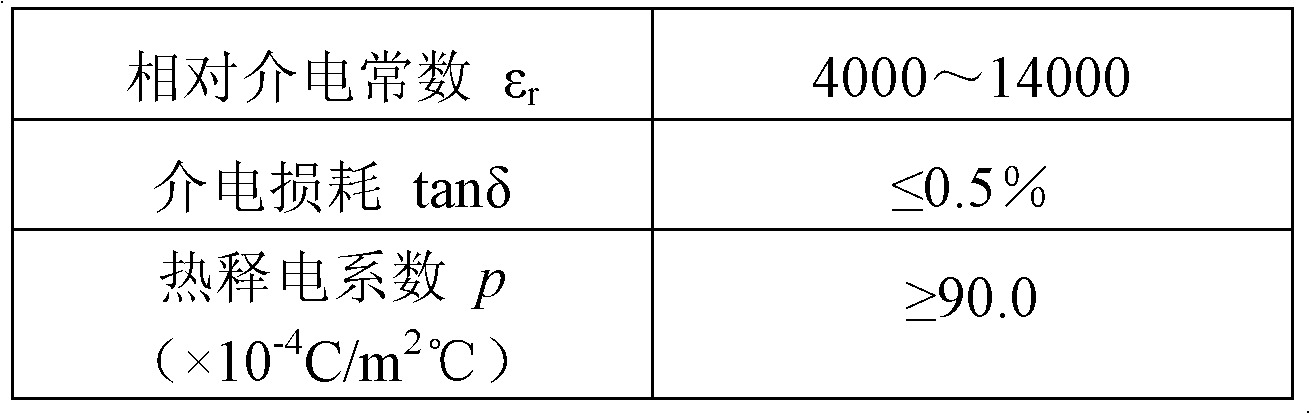

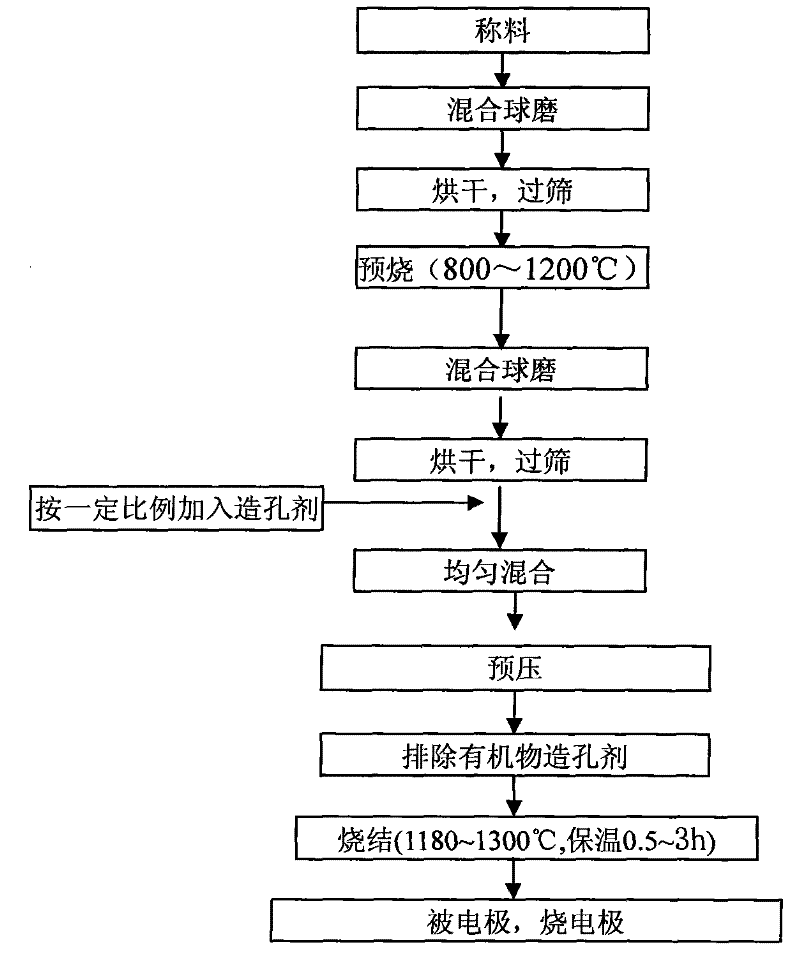

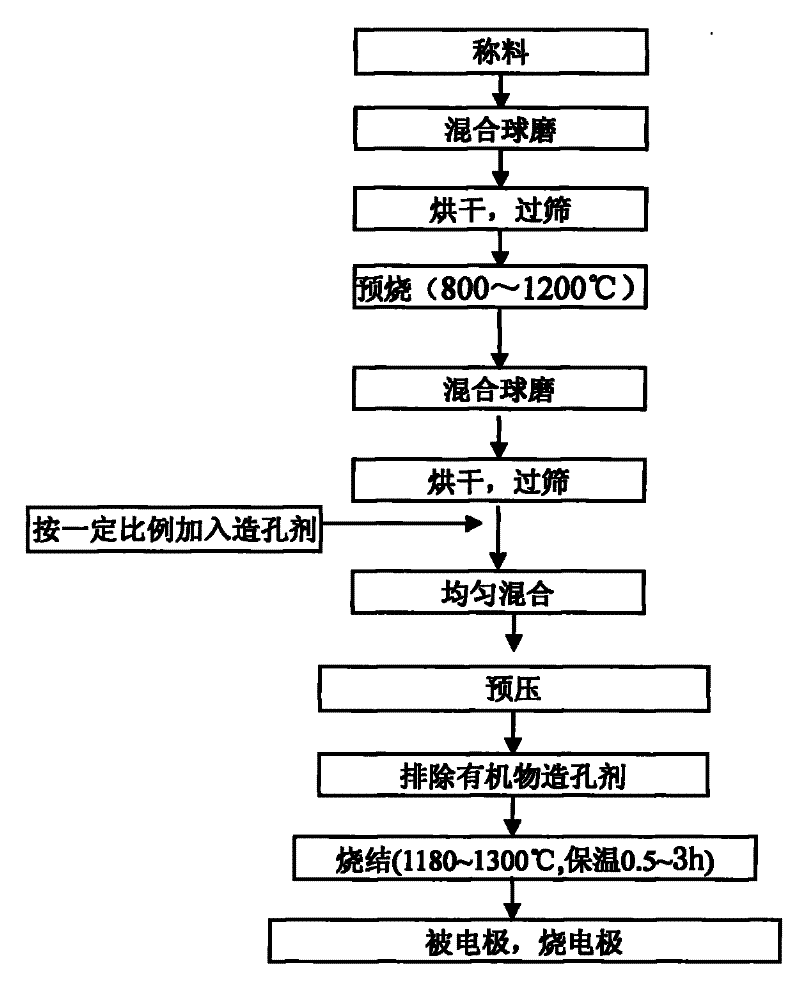

Preparation method of porous field pyroelectric ceramic material

InactiveCN101625268AHigh pyroelectric coefficientLow dielectric lossPyrometry using electric radation detectorsCeramicwareBarium strontium titanateDielectric loss

The invention discloses a method for preparing a porous barium strontium titanate field pyroelectric ceramic, comprising the following steps: firstly, mixing raw materials according to a stoichiometric ratio of respective chemical formula; pre-sintering the mixture at 800-1200 DEG C for 1-6 hours to obtain pre-sintered ceramic powder; then adding an organic substance pore-forming agent, mixing uniformly, tabletting and forming; heating again to remove organic substances; sintering, grinding, cleaning, adding an electrode and sintering the electrode. The porous BST field pyroelectric ceramic of the invention has the advantages of high pyroelectric coefficient, low dielectric loss, proper dielectric constant and excellent comprehensive pyroelectric property, and meets the requirements for manufacturing pyroelectric infrared detectors.

Owner:HUAZHONG UNIV OF SCI & TECH

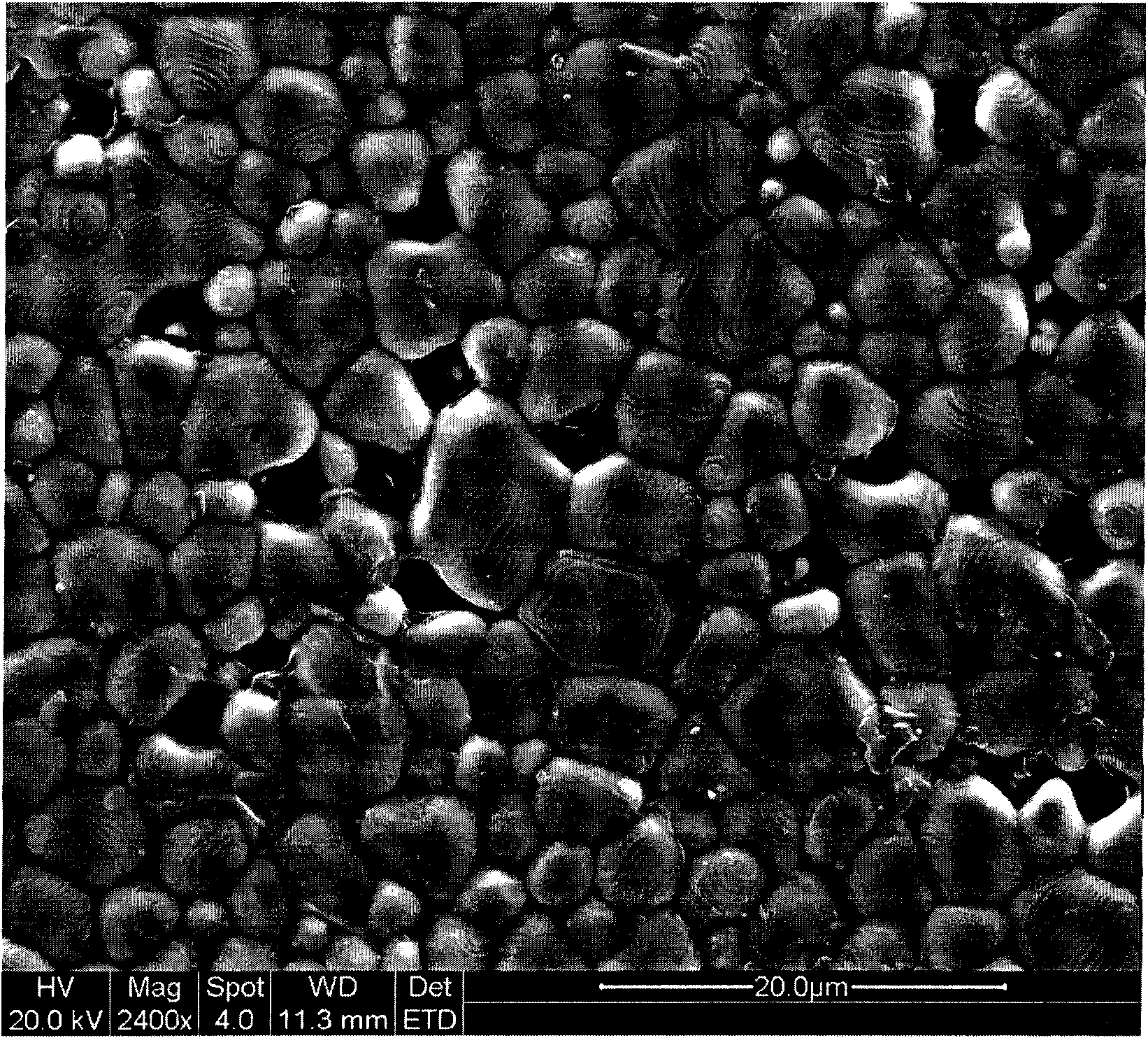

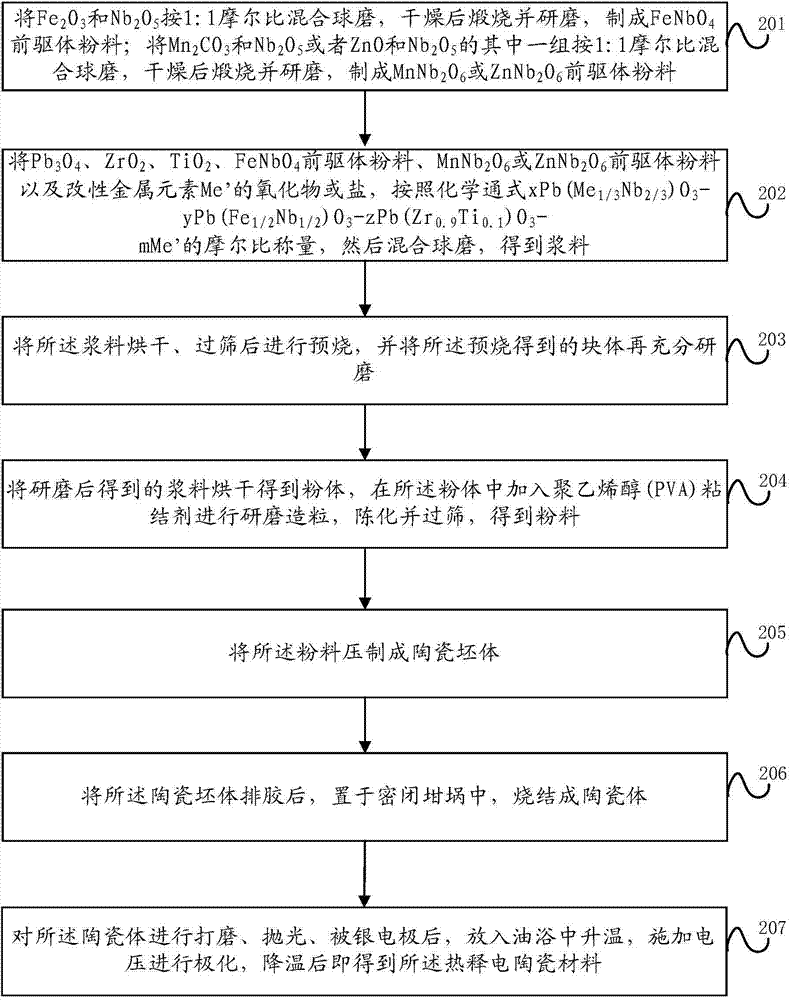

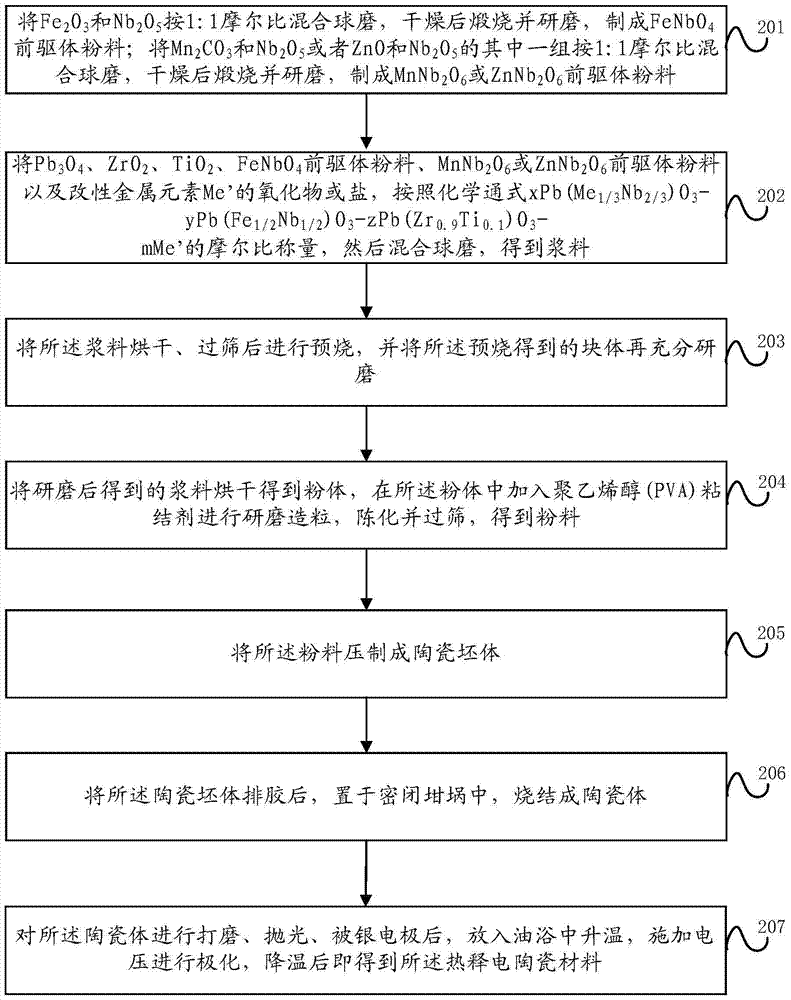

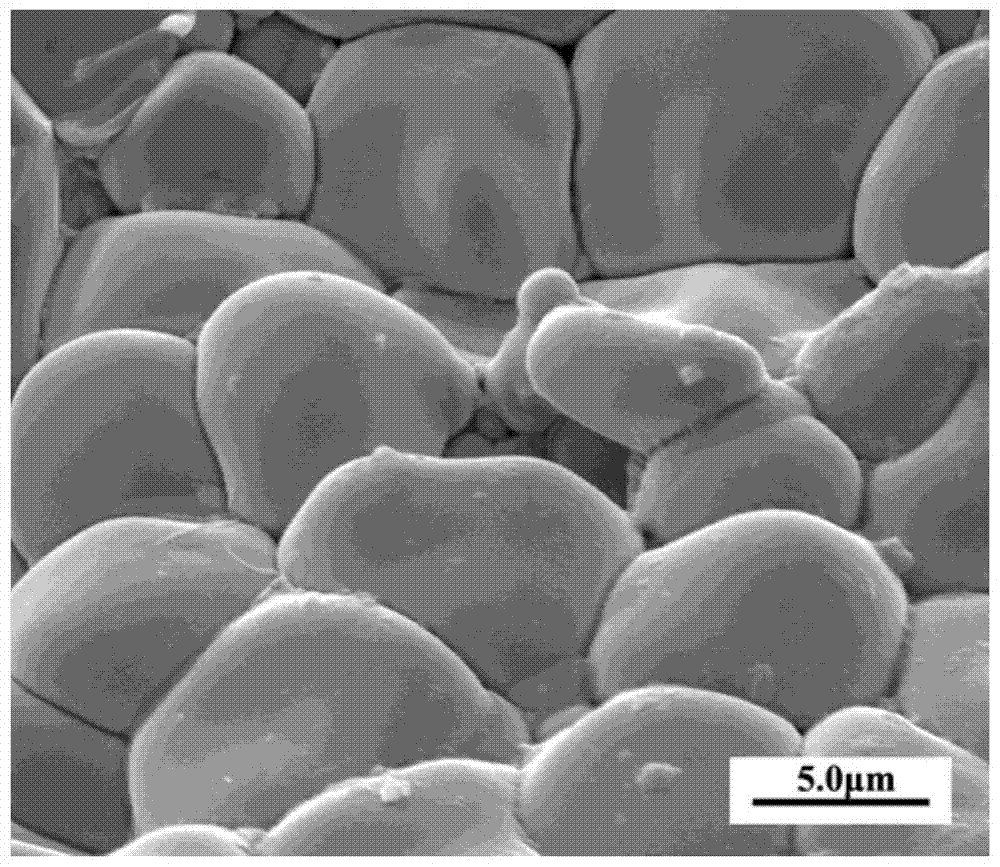

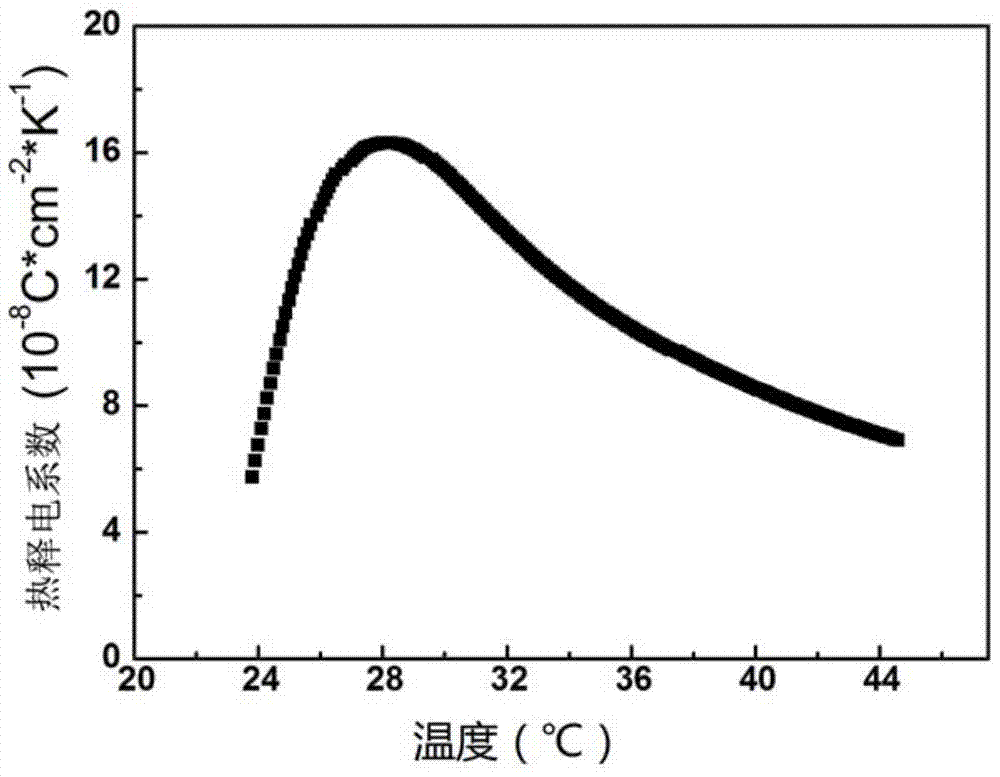

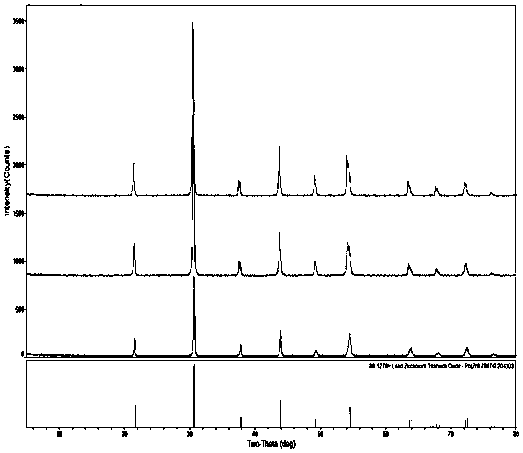

Multielement composite pyroelectric ceramic material and preparation method thereof

InactiveCN104725042AHigh pyroelectric coefficientModerate dielectric constantDielectric lossPyroelectric detectors

The invention discloses a multielement composite pyroelectric ceramic material and a preparation method thereof. The chemical general formula of the material is xPb(Me1 / 3Nb2 / 3)O3-yPb(Fe1 / 2Nb1 / 2)O3-zPb(Zr0.9Ti0.1)O3-mMe', wherein Me is one of Mn or Zn; x, y and z are respectively a mole coefficient, x is greater than or equal to 0.01 and less than or equal to 0.07, y is greater than or equal to 0.01 and less than or equal to 0.07, z is greater than or equal to 0.9 and less than or equal to 0.92, and x + y + z = 1; and Me' is a modifying metal element, m is a mole coefficient, and m is greater than or equal to 0 mol % and less than or equal to 5 mol %. The multielement composite pyroelectric ceramic material provided by the invention has a high pyroelectric coefficient, proper dielectric properties and a low dielectric loss, and the electrical properties can be adjusted, therefore, the multielement composite pyroelectric ceramic material has a good prospect in devices such as pyroelectric detectors and the like.

Owner:INST OF ACOUSTICS CHINESE ACAD OF SCI

Method for preparing wide-temperature zone phase change type pyroelectric ceramic material

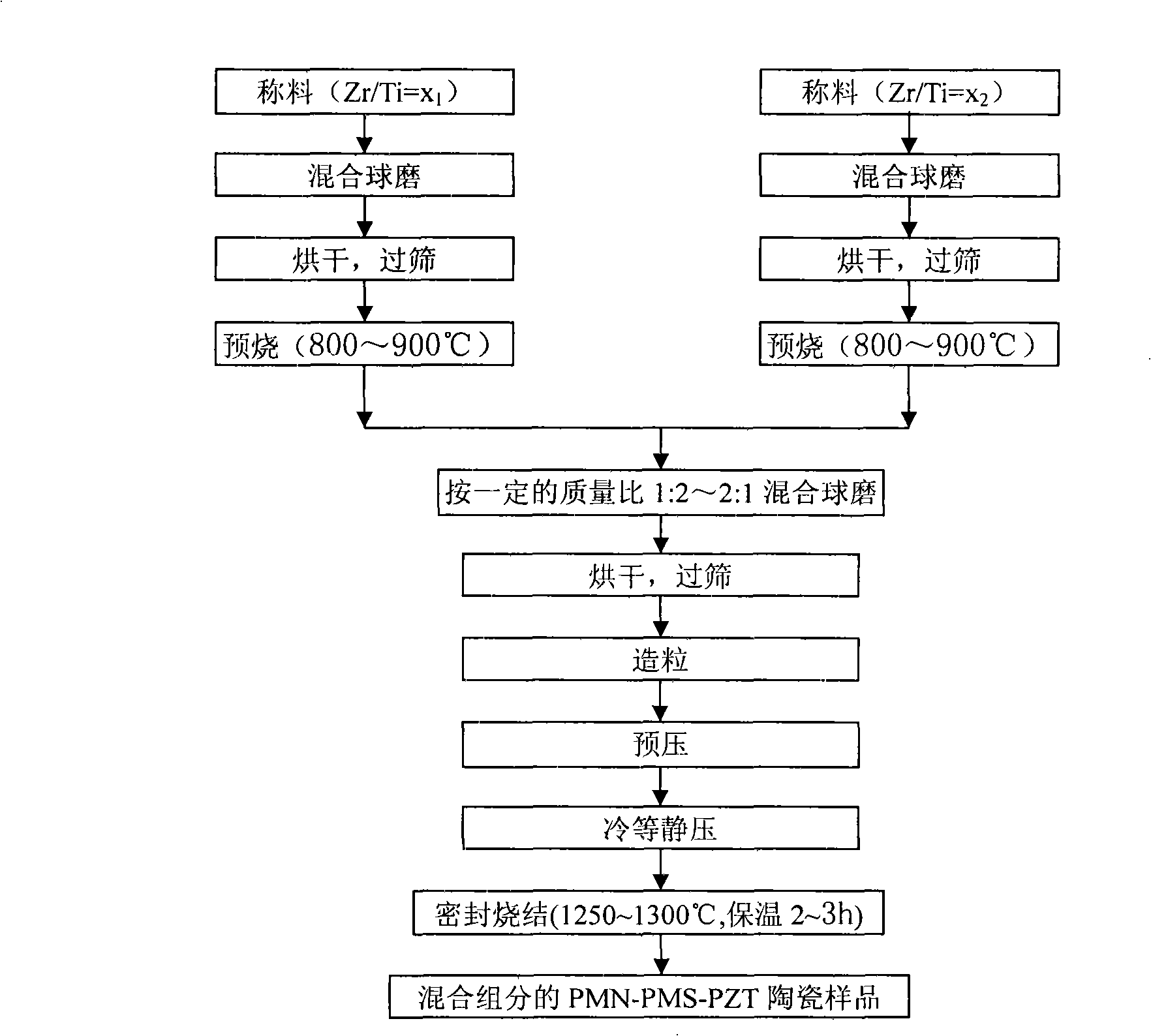

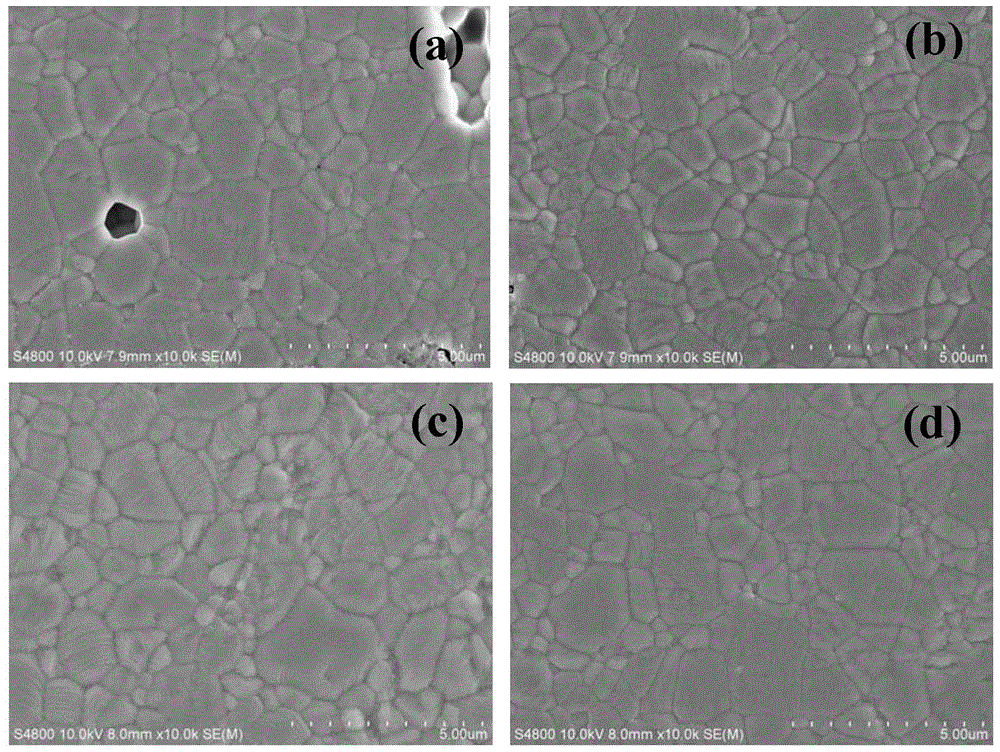

The invention discloses a preparation method for wide-temperature-range phase-transition pyroelectric ceramic materials, comprising the following steps: (1) based on the chemical formula Pb((Mn0.33Nb0.67) 0.5 (Mn0.33Sb0.67) 0.5)0.08 (ZrxTi1-x) 0.92O3, x stands for the molar fraction ratio between Zr and Ti and is greater than or equal to 0.80 but less than or equal to 0.98; selecting two different values in the value range of x; mixing PbO, ZrO2, TiO2, Nb2O5, Sb2O3 powder and Mn (NO3)2 based on the stoichiometric proportion in the respective chemical formula so as to get two mixtures; (2) insulating the two mixtures respectively for 4 to 6 hours at 800-900 DEG C to get pre-burning powder; (3) taking the pre-burning powder as base material and mixing the base material according to mass ratio of 1:2 to 2:1; molding the powder and insulating the powder for 2 to 3 hours at 1250-1300 DEG C for sintering; (4) grinding and washing the sintered material, then arranging and burning the electrodes; (5) after electrode burning, polarizing the material, and then retaining the voltage and cooling the material to room temperature. The mixed PMN-PMS-PZT pyroelectric ceramic prepared in the invention has high pyroelectric coefficient and good integrated pyroelectric performance in a wider temperature range, and is in line with the requirements of pyroelectric infrared detector production.

Owner:HUAZHONG UNIV OF SCI & TECH

High-Curie-temperature strontium-barium niobate pyroelectric ceramic material and preparation method thereof

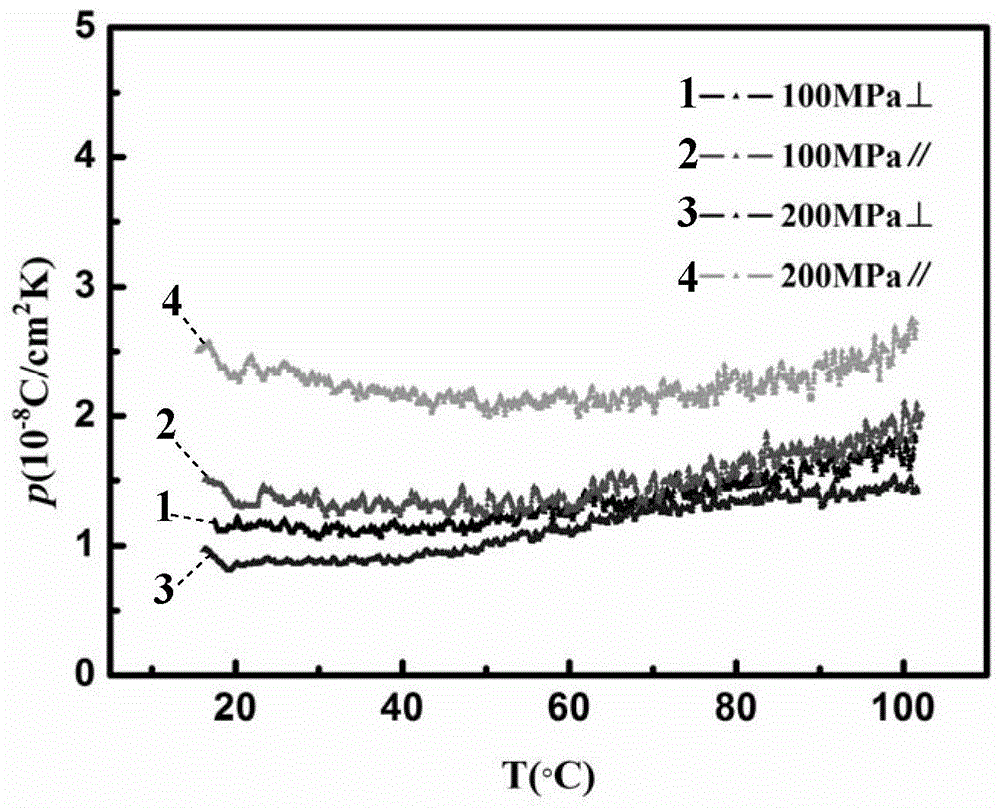

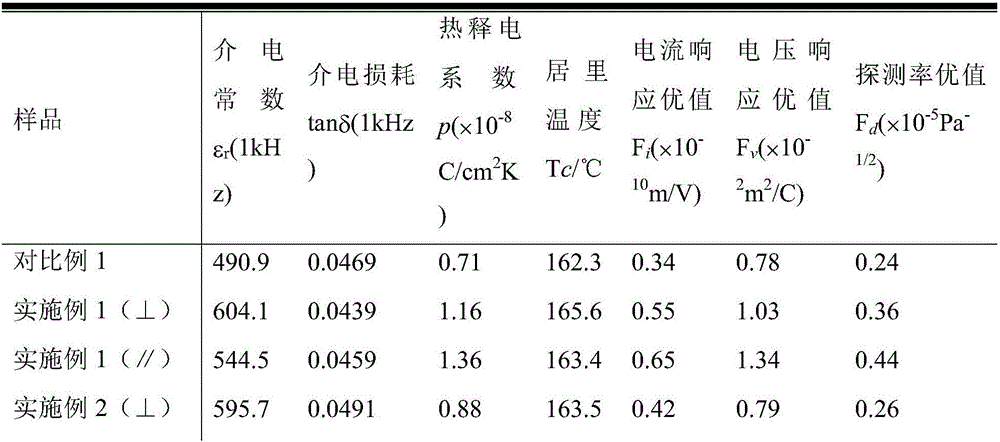

The invention relates to a high-Curie-temperature strontium-barium niobate pyroelectric ceramic material and a preparation method thereof. The material has the composition general formula of SrxBa1-xNb2O6, wherein x is larger than or equal to 0.25 and smaller than or equal to 0.35. The SBN ceramic material high in density and pyroelectric performance is obtained by preparing power through a solid phase method, preparing an SBN blank through cold isostatic pressing forming and other processes, putting the SBN blank in a mold, filling and covering the SBN blank with ZrO2 powder, raising the temperature to 1100-1150 DEG C, linearly and evenly pressurizing to 100-200 MPa with the axis of the mold as the hot-press axis, raising the temperature to 1200-1300 DEG C, keeping the temperature and the pressure for 2-4 h in the air atmosphere, and linearly depressurizing and cooling inside a furnace to the room temperature. The problem that high-Curie-temperature SBN components are poor in pyroelectric performance is solved.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

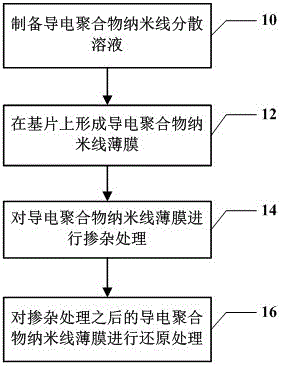

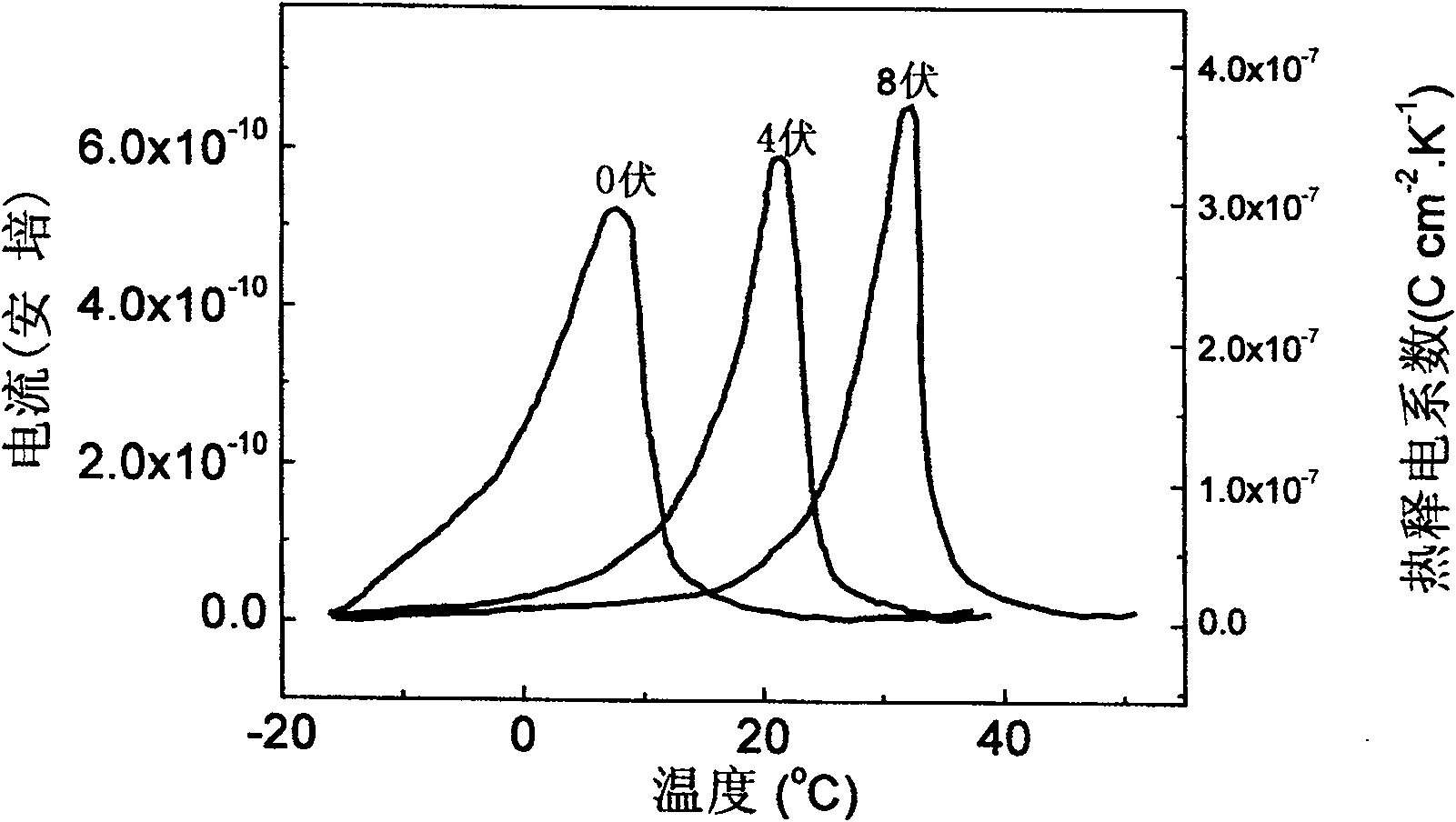

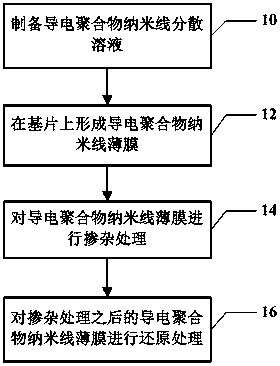

Method for preparing conducting polymer pyroelectric nano film

InactiveCN105085961AImprove conductivityHigh pyroelectric coefficientCoatingsPolymer scienceConductive polymer

The embodiment of the invention discloses a method for preparing a conducting polymer pyroelectric nano film. The method comprises the steps of preparing a conducting polymer nano wire by adopting a template process; then preparing a conducting polymer nano wire film by adopting an LB film process; and finally, doping and reducing the nano wire film by adopting a chemical process to obtain the conducting polymer pyroelectric nano film structure. The conducting polymer pyroelectric nano film prepared by adopting the method disclosed by the invention has the advantages of high pyroelectric coefficient, high thermal conductance and good stability, and has wide application in micro / nano energy collection and energy storage devices.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

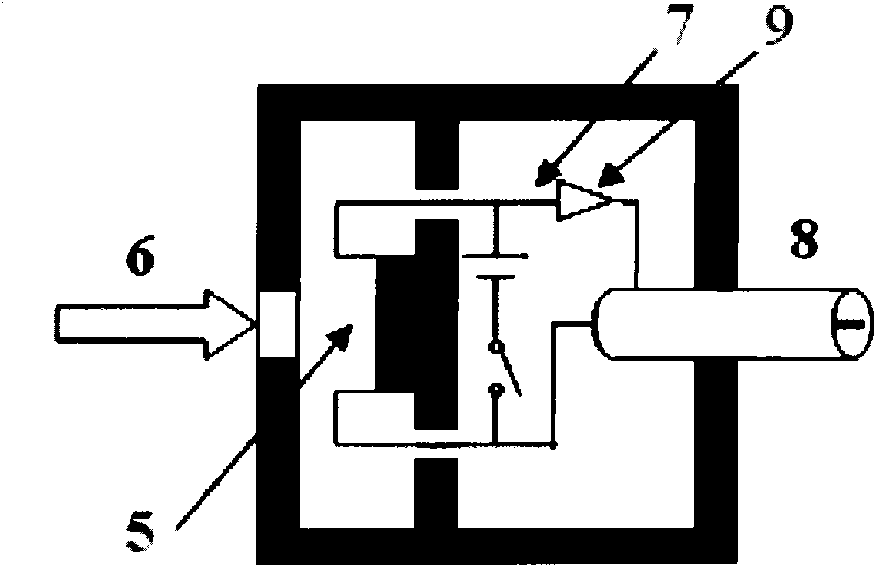

SMT intelligent pyroelectric infrared sensor

InactiveCN105698936AImprove anti-interference abilityStrong product weightSensing radiation from moving bodiesManufacturing cost reductionControl signal

The invention relates to a chip-type intelligent pyroelectric infrared sensor, which is a closed structure shell composed of a tube cap and a substrate. The upper surface of the tube cap has a window, and an infrared optical filter is embedded on the window; and the tube cap and the A receiving space is formed between the substrates, and the receiving space accommodates and encapsulates the infrared sensitive element, the supporting component and the signal processing module; the infrared sensitive element is fixed by the supporting component, and the supporting component and the signal processing module are directly fixed on the substrate. The pyroelectric infrared sensor of the present invention has the characteristics of miniaturization, intelligence, and the ability to output multiple control signals. This packaging structure is suitable for SMT automatic patch and reflow soldering processes, which is conducive to mass automatic production and improves manufacturing efficiency. Reduce manufacturing costs.

Owner:SENBA SENSING TECH CO LTD

BNT-based lead-free pyroelectric ceramic material with low dielectric loss and preparation method thereof

InactiveCN109456054AHigh pyroelectric performanceHigh depolarization temperatureChemical compositionDielectric loss

The invention relates to a BNT-based lead-free pyroelectric ceramic material with low dielectric loss and a preparation method thereof. The BNT-based lead-free pyroelectric ceramic material adopts a chemical composition of (1-x)(Bi0.5Na0.5)TiO3-xBa(Ni0.5Nb0.5)O3, and x is greater than 0 and is smaller than or equal to 0.04.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

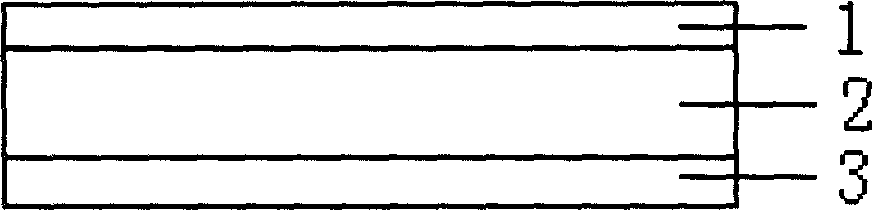

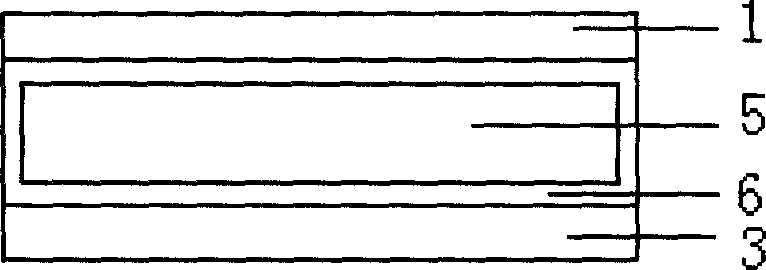

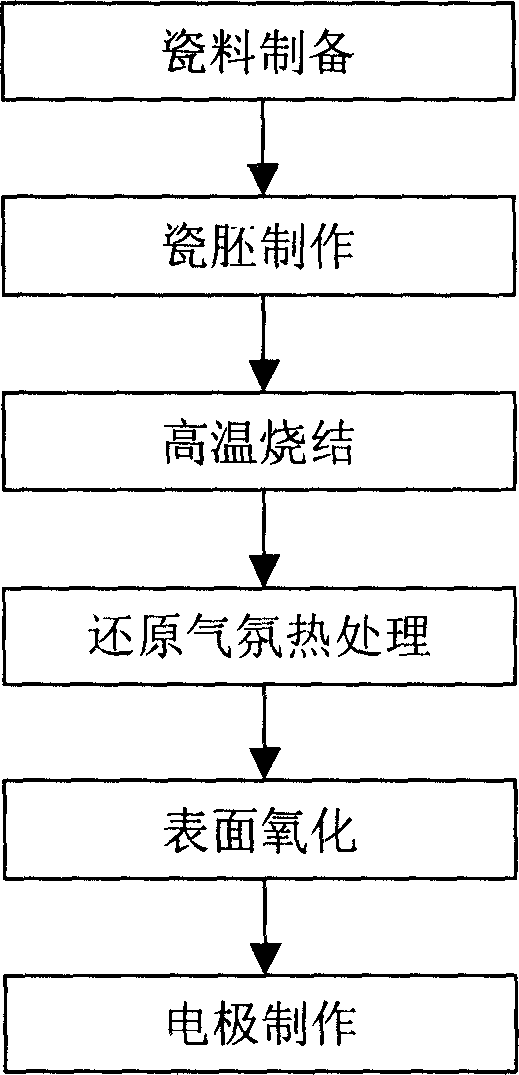

Pyroelectric unit infrared detector and production thereof

InactiveCN1746639AHigh pyroelectric coefficientHigh sensitivityThermoelectric device with dielectric constant thermal changePyrometry using electric radation detectorsSurface oxidationOxide

A unit pyroelectric infrared detector consists of top and bottom electrodes, BST ceramic semiconductor and BST ceramic oxide layer media wrapped outside of said semiconductor. It features that BST ceramic semiconductor is prepared by high temperature sintering and reduction heat treating ( Ba 0.7 Sr 0.3 ) TiO3 ceramic base material doped with 1 ¿C 5 wt % rare earth impurities with its thickness less than 0.20mn and resistance rate less than 10ª©.cm, BST ceramic oxide layer media is prepared by oxidizing surface of ceramic semiconductor with its thickness of 5 ¿C 10 micro m. The preparing method is also provided.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

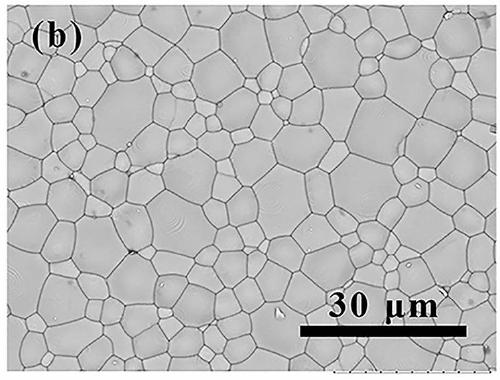

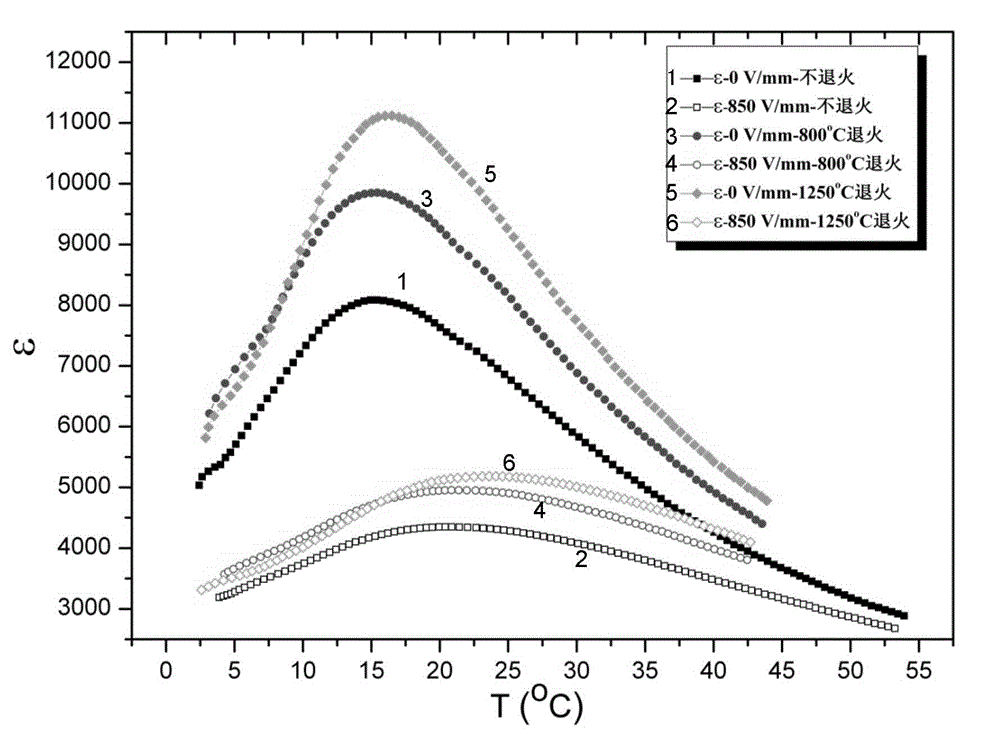

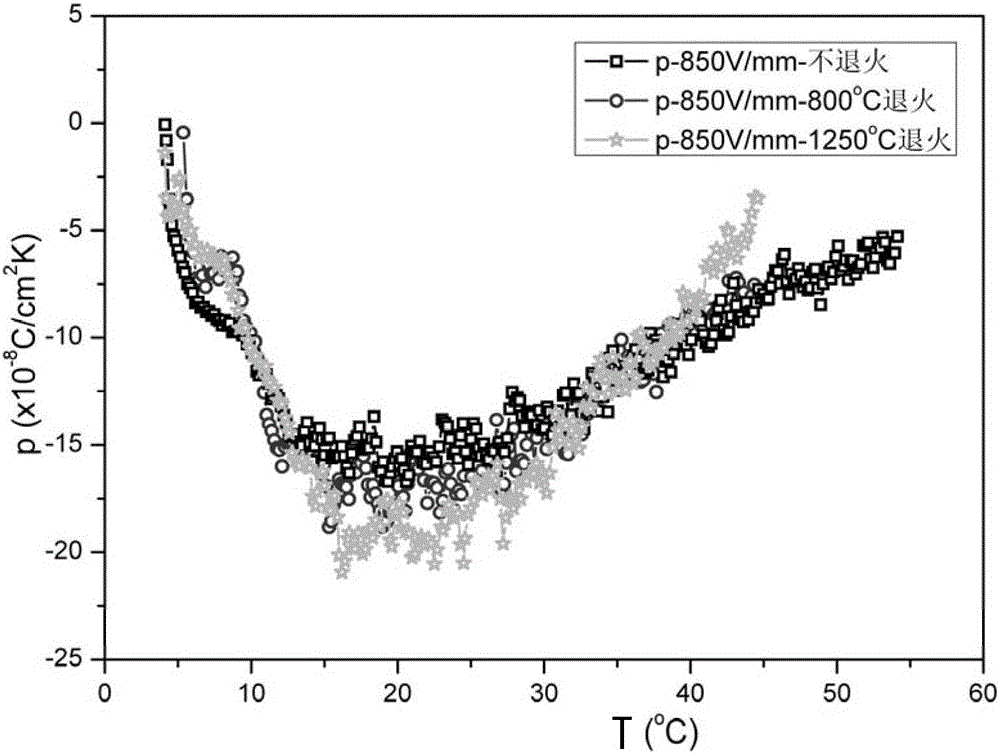

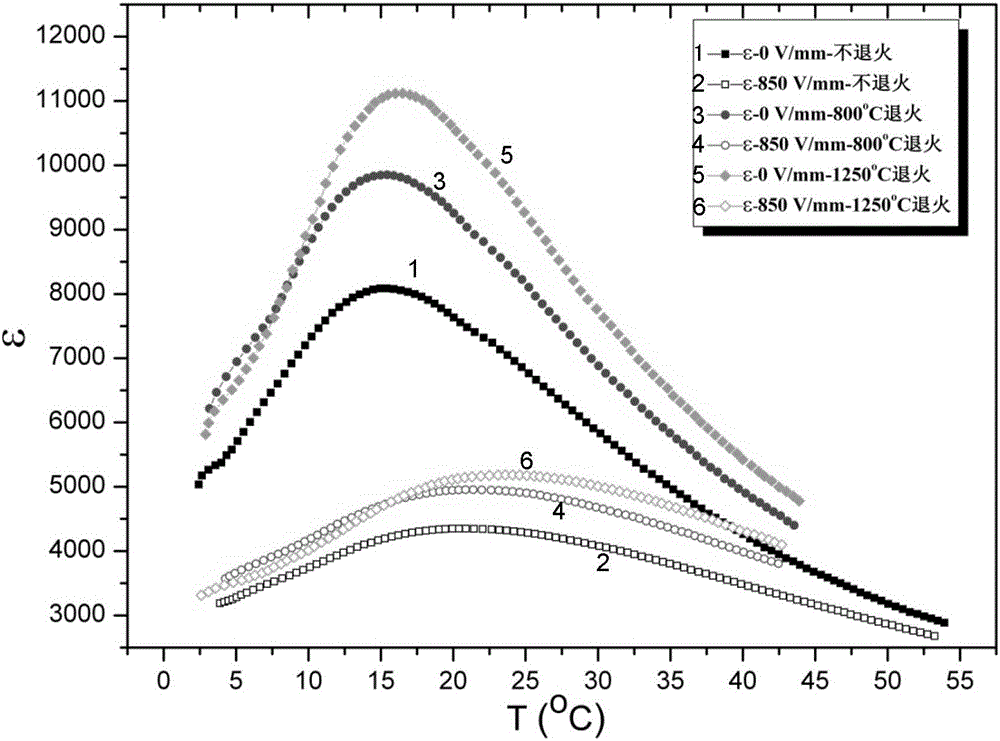

Method for preparing high-performance BST (barium strontium titanate) pyroelectric ceramics by adopting post-annealing process

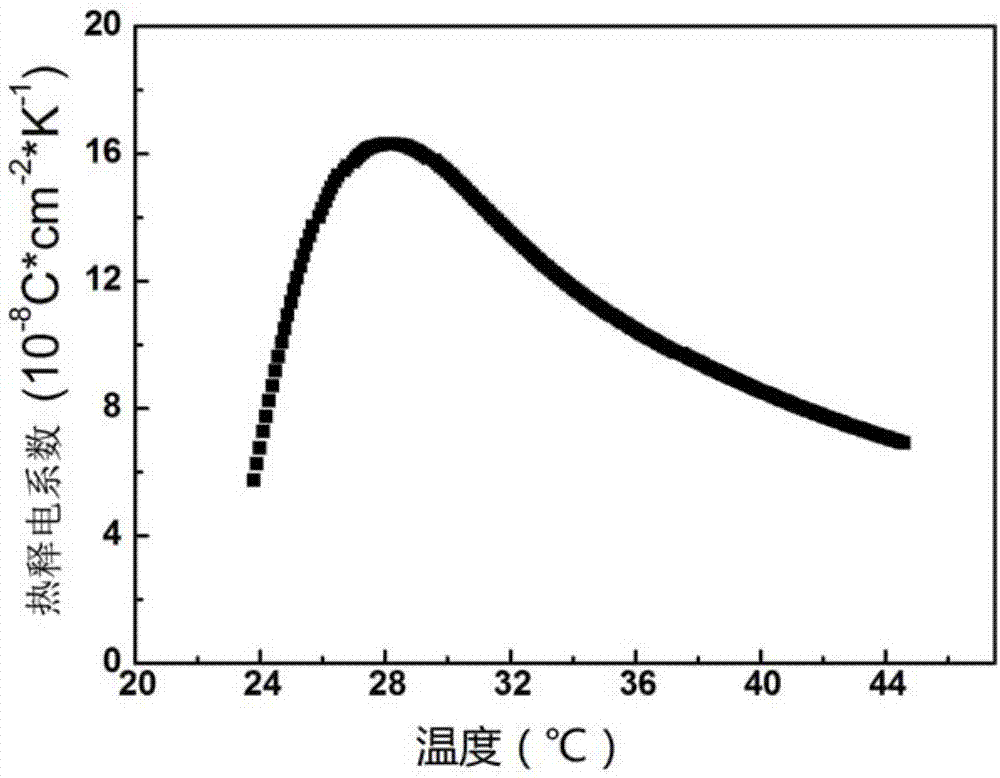

The invention relate to a method for preparing high-performance BST (barium strontium titanate) pyroelectric ceramics by adopting a post-annealing process. According to the method, BST ceramics obtained through sintering is subjected to annealing at the oxygen atmosphere, the annealing temperature ranges from 800 DEG C to 1,250 DEG C, the annealing time ranges from 2 hours to 5 hours, and then the high-performance BST pyroelectric ceramics can be prepared. According to the method for preparing the high-performance BST pyroelectric ceramics by adopting the post-annealing process, the annealing treatment is performed after the BST pyroelectric ceramics is obtained through sintering, and the high-performance BST pyroelectric ceramics can be prepared; the dielectric constant is high and can be higher than 9,500; the pyroelectric coefficient is high and can be higher than 18*10<-8>C / cm<2>K; and further, a sample is high in purity and performance and good in uniformity, manufacturing requirements of an uncooled infrared focal plane device can be met, and the problem that the BST ceramics cannot be sintered to high density is effectively solved.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Stress strain-assisted pyroelectric composite material and application thereof

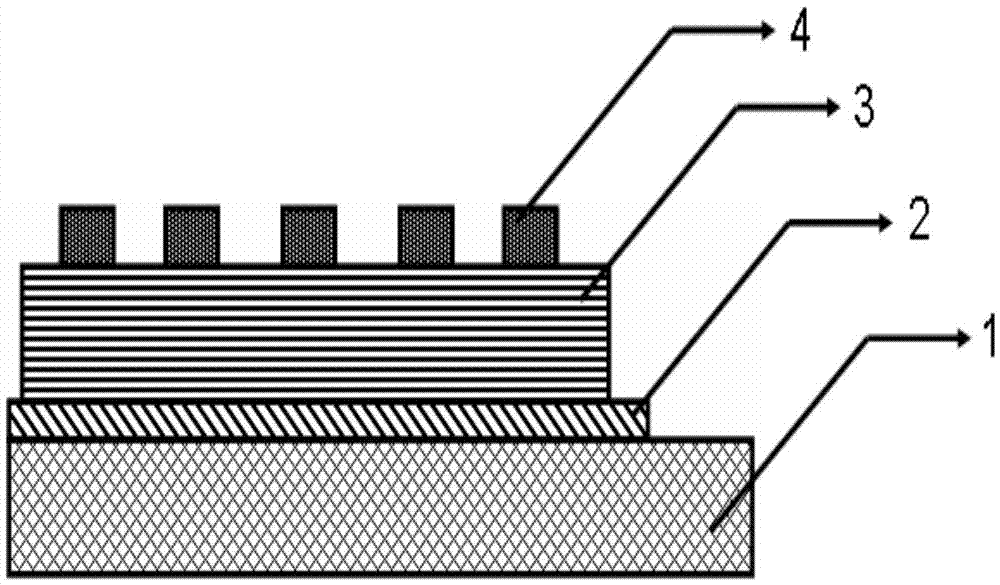

ActiveCN106898661AIncreased change in electric polarizationHigh pyroelectric coefficientSemiconductor devicesElectricityStress–strain curve

The invention provides a stress strain-assisted pyroelectric composite material. The composite material combines a pyroelectric material layer and a stress strain material layer; when the pyroelectric layer senses outside temperature changes caused by infrared light and changes of electric polarization happens, a stress strain applying layer generates stress strain under effects of outside conditions and the stress strain is transmitted to the pyroelectric layer, the changes of the electric polarization of the pyroelectric layer is thus enhanced, and a pyroelectric coefficient is improved. When the pyroelectric composite material is applied to the technical field of infrared detection, the detection sensitivity can be improved effectively, and the application prospect in the technical field of infrared detection is thus good.

Owner:NINGBO INNOVATION CENT FOR APPLIED MAGNETICS CO LTD

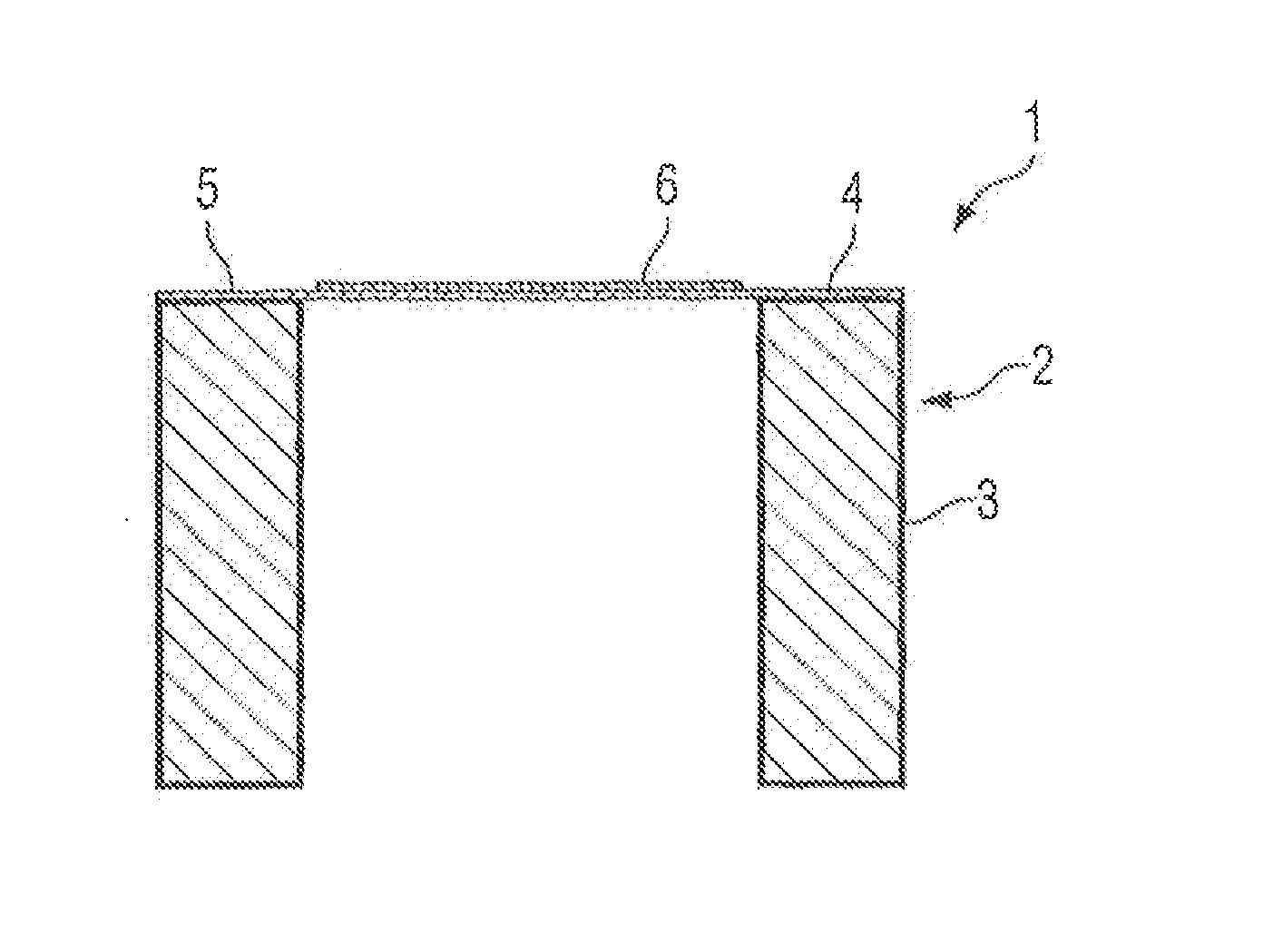

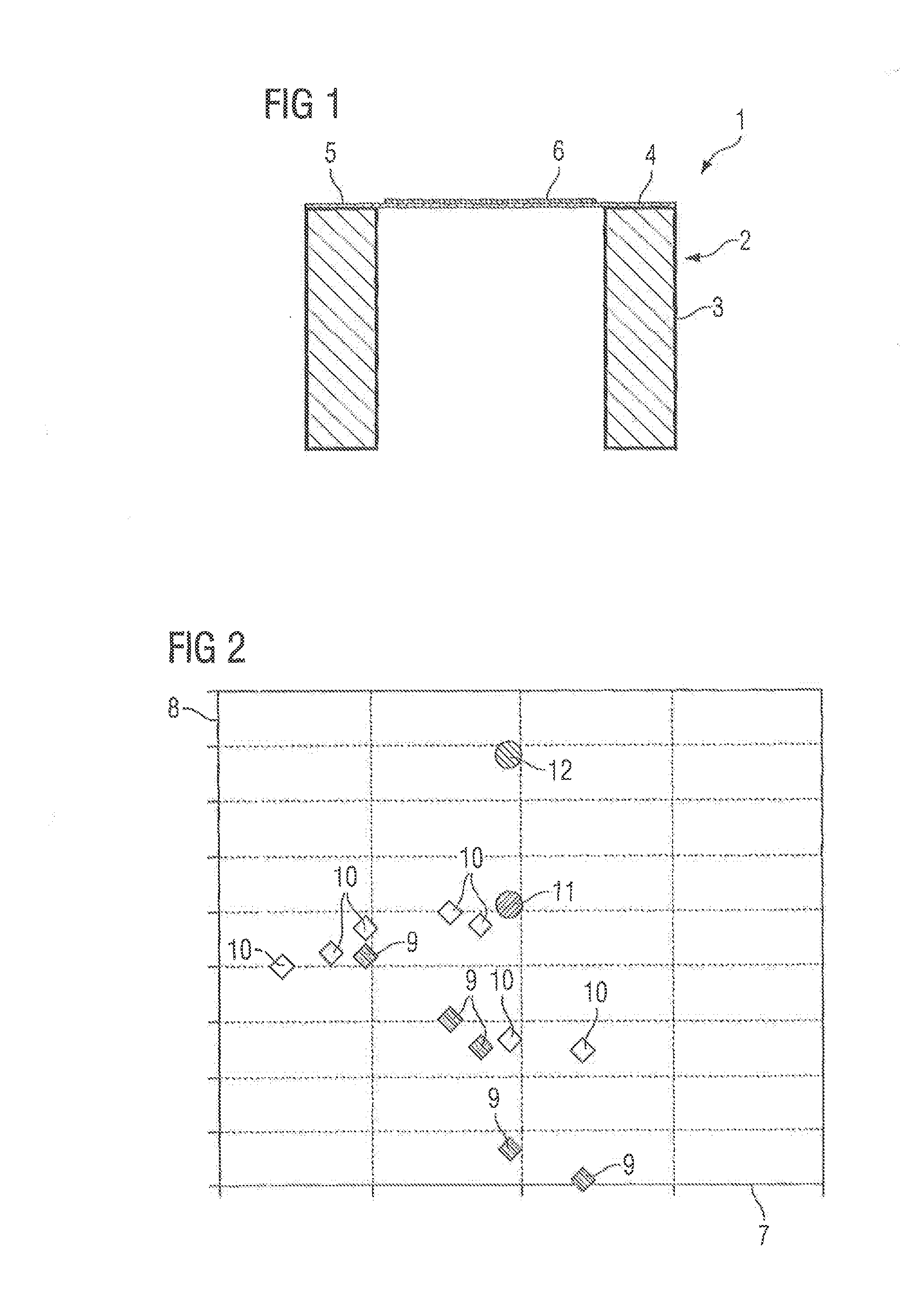

Method for producing a microsystem having a thin film made of lead zirconate titanate

ActiveUS20150091007A1High pyroelectric coefficientGood effectVacuum evaporation coatingSputtering coatingLead zirconate titanateThermal deposition

A method for producing a micro system, said method comprising: providing a substrate (2) made of aluminum oxide; producing a thin film (6) on the substrate (2) by depositing lead zirconate titanate onto the substrate (2) with a thermal deposition method such that the lead zirconate titanate in the thin film (6) is self-polarized and is present predominantly in the rhombohedral phase; and cooling down the substrate (2) together with the thin film (6).

Owner:AVAGO TECH INT SALES PTE LTD

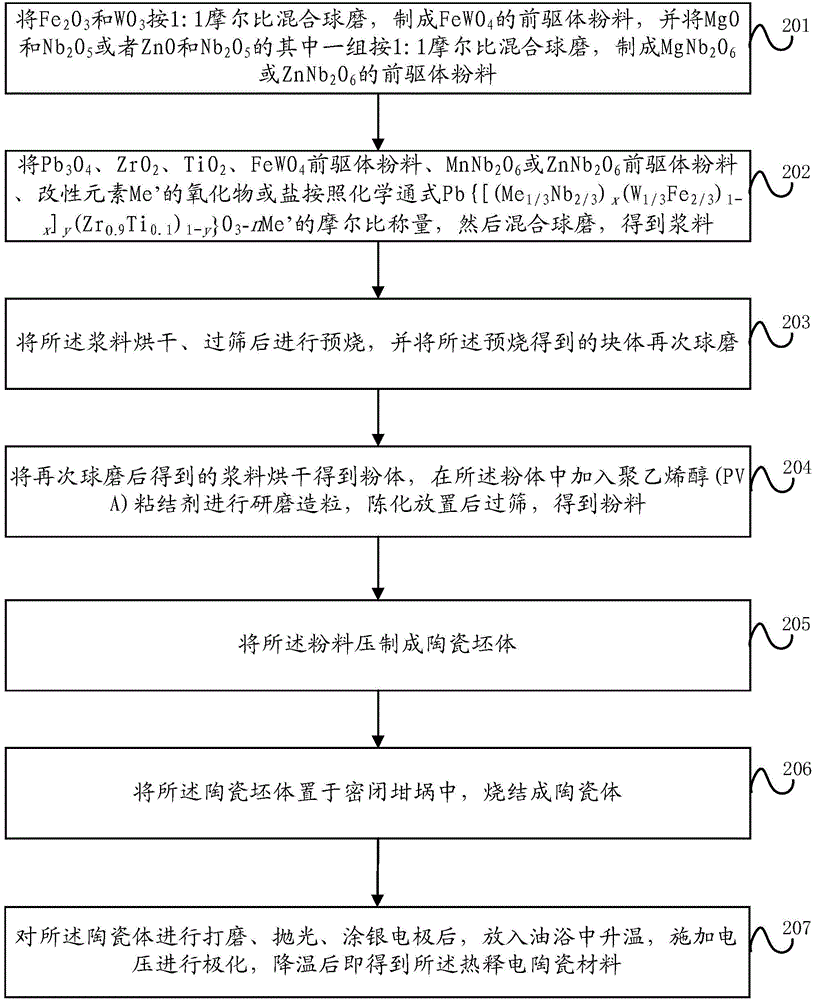

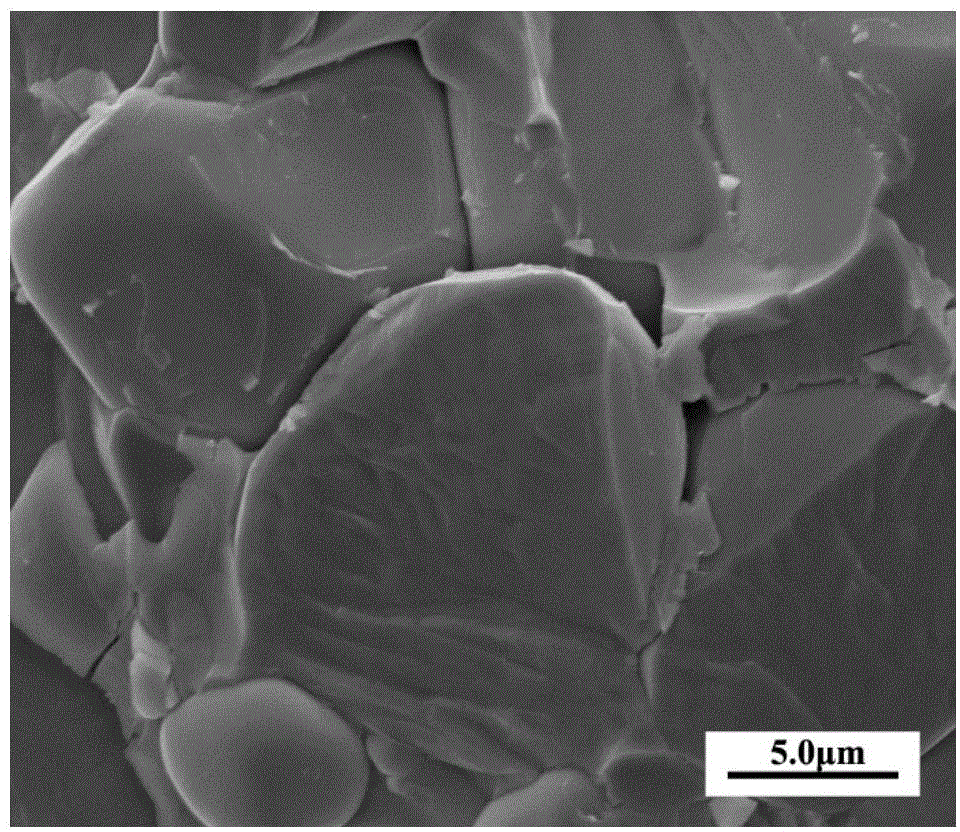

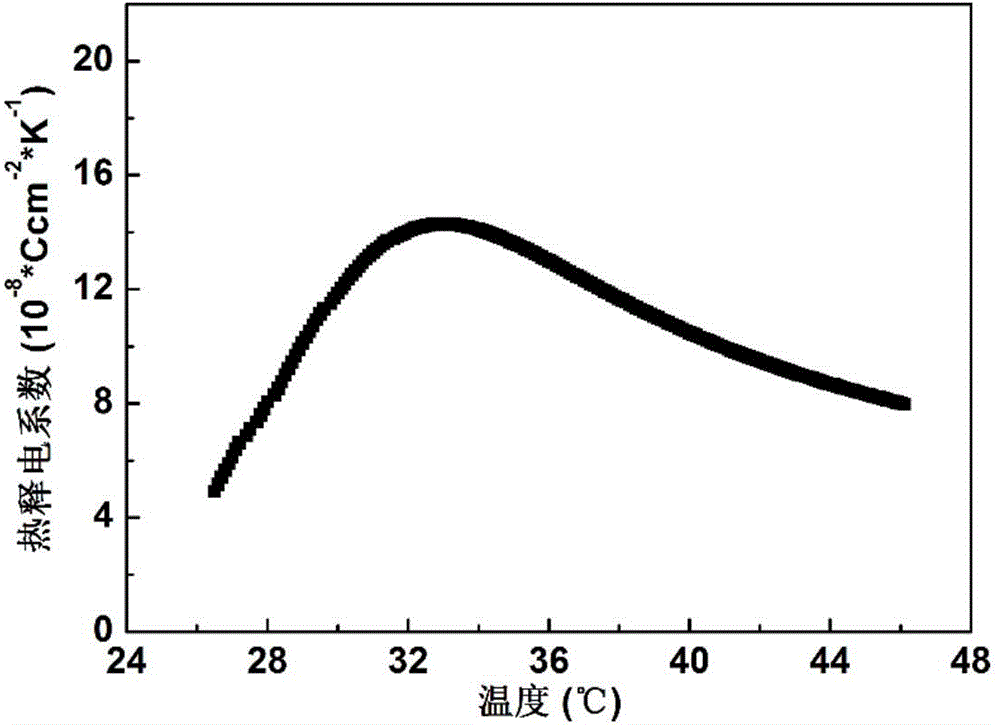

Composite pyroelectric ceramic material and preparation method thereof

InactiveCN104557038AHigh pyroelectric coefficientModerate dielectric constantMetallurgyPyroelectric detectors

The invention discloses a composite pyroelectric ceramic material and a preparation method thereof. The chemical general formula of the material is Pb {[(Me1 / 3Nb2 / 3)x(W1 / 3Fe2 / 3)1-x]y(Zr0.9Ti0.1) (1-y) }O3-nMe', wherein Me is Mg or Zn; x and y represent a mole fraction respectively, x is larger than or equal to 0.125 and smaller than or equal to 0.875, and y is larger than or equal to 0.08 and smaller than or equal to 0.11; Me' is a modified element and is one or more of Li, La and Sb, and the molar ratio range n is larger than or equal to 0 mol% and smaller than or equal to 5 mol%. The composite pyroelectric ceramic material has a higher pyroelectric coefficient and adjustable dielectric property, thereby having a better application prospect in various pyroelectric detectors.

Owner:INST OF ACOUSTICS CHINESE ACAD OF SCI

Ferroelectric-antiferroelectric (FE-AFE) phase change pyroelectric ceramic material, ceramic element thereof and preparation methods thereof

ActiveCN102241511BLarge pyroelectric responseHigh pyroelectric coefficientElectricityChemical composition

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

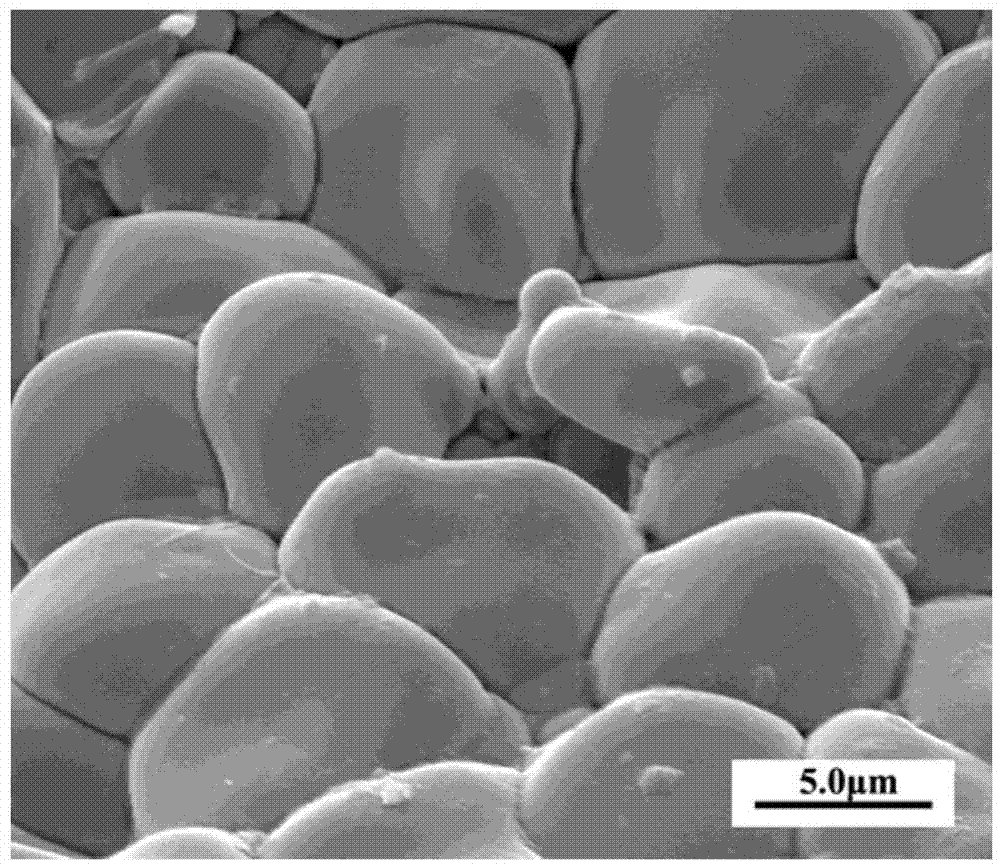

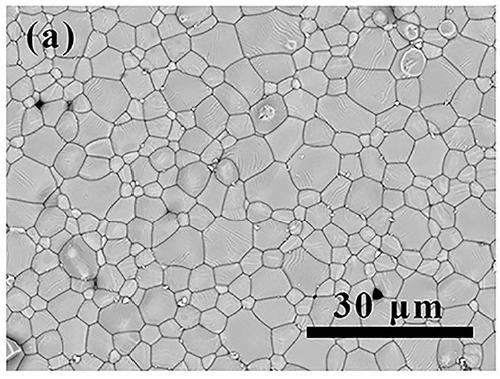

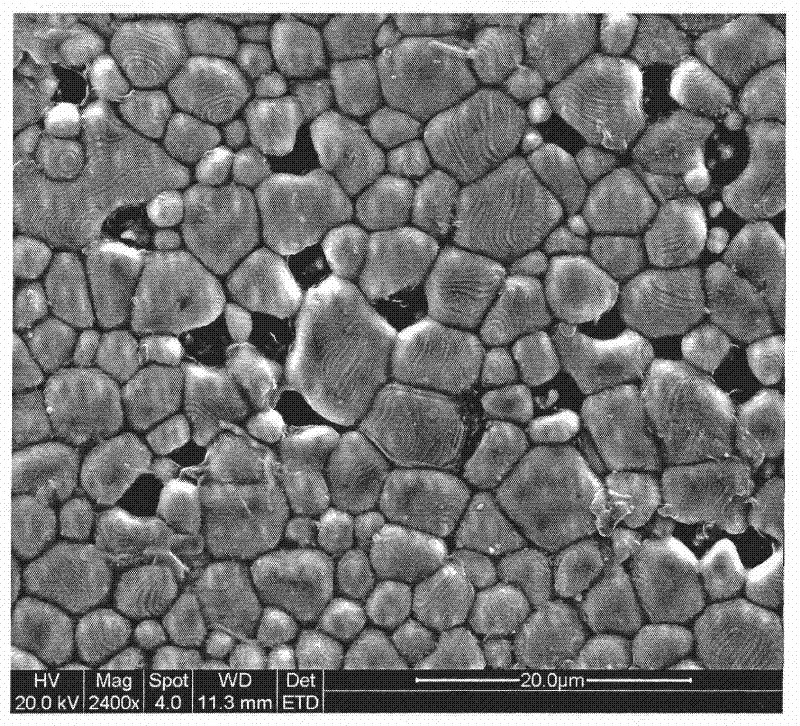

Method for preparing fine-grain lead scandium tantalate pyroelectric ceramic material

The invention discloses a method for preparing a fine-grain lead scandium tantalate pyroelectric ceramic material by a liquid-phase method for preparing powder and a two-step sintering process. The method comprises the following steps of: preparing Pb(Sc0.5Ta0.5)O3 powder by a liquid-phase method; ball-milling the powder and drying; adding an adhesive and then performing aging, sieving, forming and the like to prepare a blank; and finally sintering the blank by a two-step method. The method for preparing the material has the advantages of simple process, no need of special equipment, low costand the like, is suitable for mass production and can meet industrial requirements. The prepared lead scandium tantalate pyroelectric ceramic material has the advantages of high compactness, fine grains, moderate dielectric constant, high pyroelectric coefficient and the like; and a pyroelectric detectivity optimal value of a sample can reach 72.9*10<-5>Pa<-1 / 2> in an offset electric field of 700V / mm, so the performance requirement of applying the material to an uncooled infrared focal plane array detector can be met.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Pyroelectric detector

InactiveCN101922972AHigh sensitivityHigh pyroelectric coefficientPyrometry using electric radation detectorsElectricityPyroelectric detectors

The invention provides a pyroelectric detector which comprises a shell, a response element and a signal output interface, wherein the response element comprises a conductive substrate, a polarized CaCu3Ti4O12 film and a conductive transparent material film which are sequentially stacked; the response element is positioned in the shell; the shell is provided with a transparent window used for collecting outside electromagnetic radiation; the conductive substrate is used as a lower electrode, the conductive transparent material film is used as an upper electrode; the upper electrode and the lower electrode are electrically connected with the signal output interface; and the upper electrode faces to the transparent window. The response element has higher pyroelectric coefficient, thereby being capable of improving the sensitivity and the detectivity of the detector. Compared with other pyroelectric detectors, a power supply is connected in parallel with two electrodes of the response element, the invention ensures that the response speed of the detector is greatly improved, is beneficial to maintaining the polarization characteristic of a pyroelectric material, and prolongs the service life of elements.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

A method for preparing field pyroelectric ceramic material

The invention discloses a method for preparing strontium barium titanate field-induced pyroelectric ceramics. The heavily doped BST ceramic powder is mixed with the pure pre-synthesized BST powder according to a certain mass ratio; agent, mixed uniformly and granulated, then pressed into tablets; reheated to discharge the binder; sintered, ground, cleaned, applied and fired. The BST field-induced pyroelectric ceramic prepared by the invention has a high pyroelectric coefficient, low dielectric loss and a suitable dielectric constant, has good comprehensive pyroelectric performance, and meets the requirements for making pyroelectric infrared detectors .

Owner:HUAZHONG UNIV OF SCI & TECH

Composite pyroelectricity material, preparation method thereof, and method for preparing silicon-base thick film

InactiveCN101260217BHigh Voltage Response Figure of MeritHigh detection rateChemical industryThermoelectric devicesThermal insulationNanoceramic

Owner:HUAZHONG UNIV OF SCI & TECH

PZT (lead zirconate titanate)-based antiferroelectric ceramic material with low curie point and high bidirectional-adjustable dielectric electric field and preparation method thereof

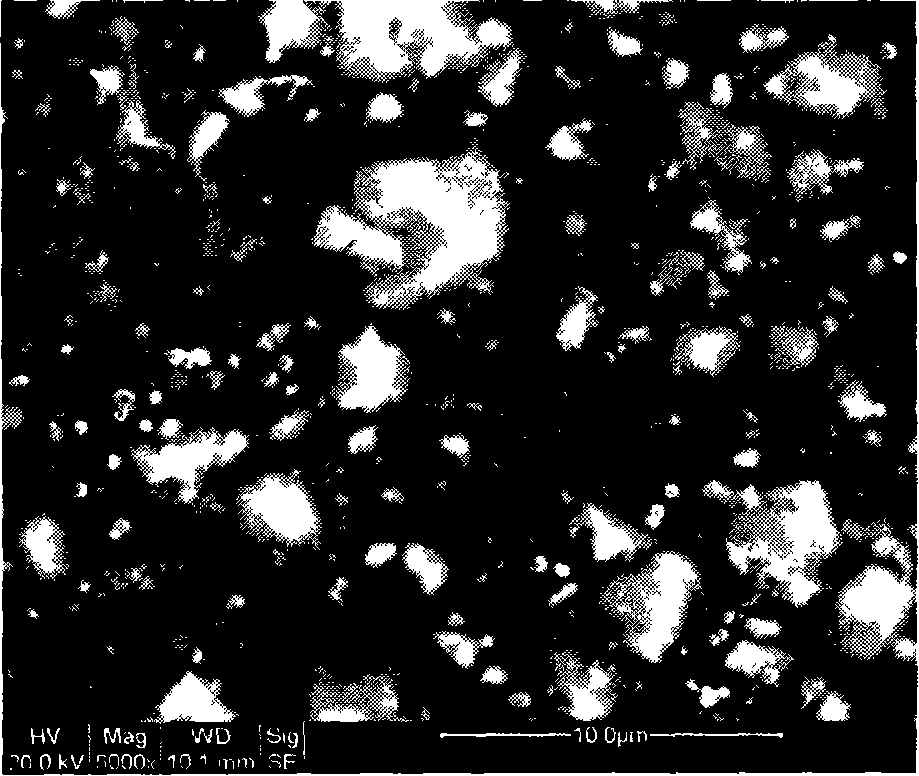

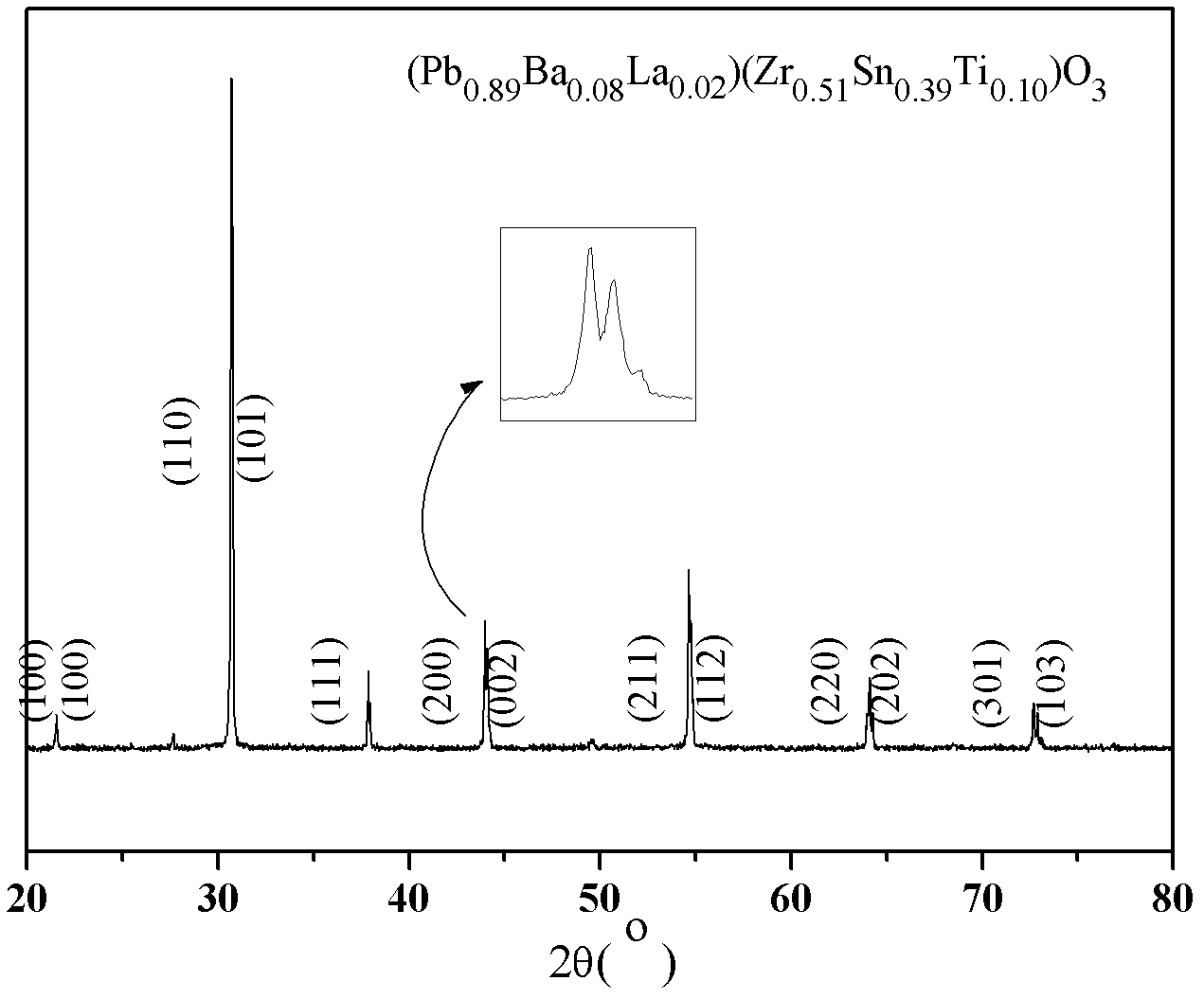

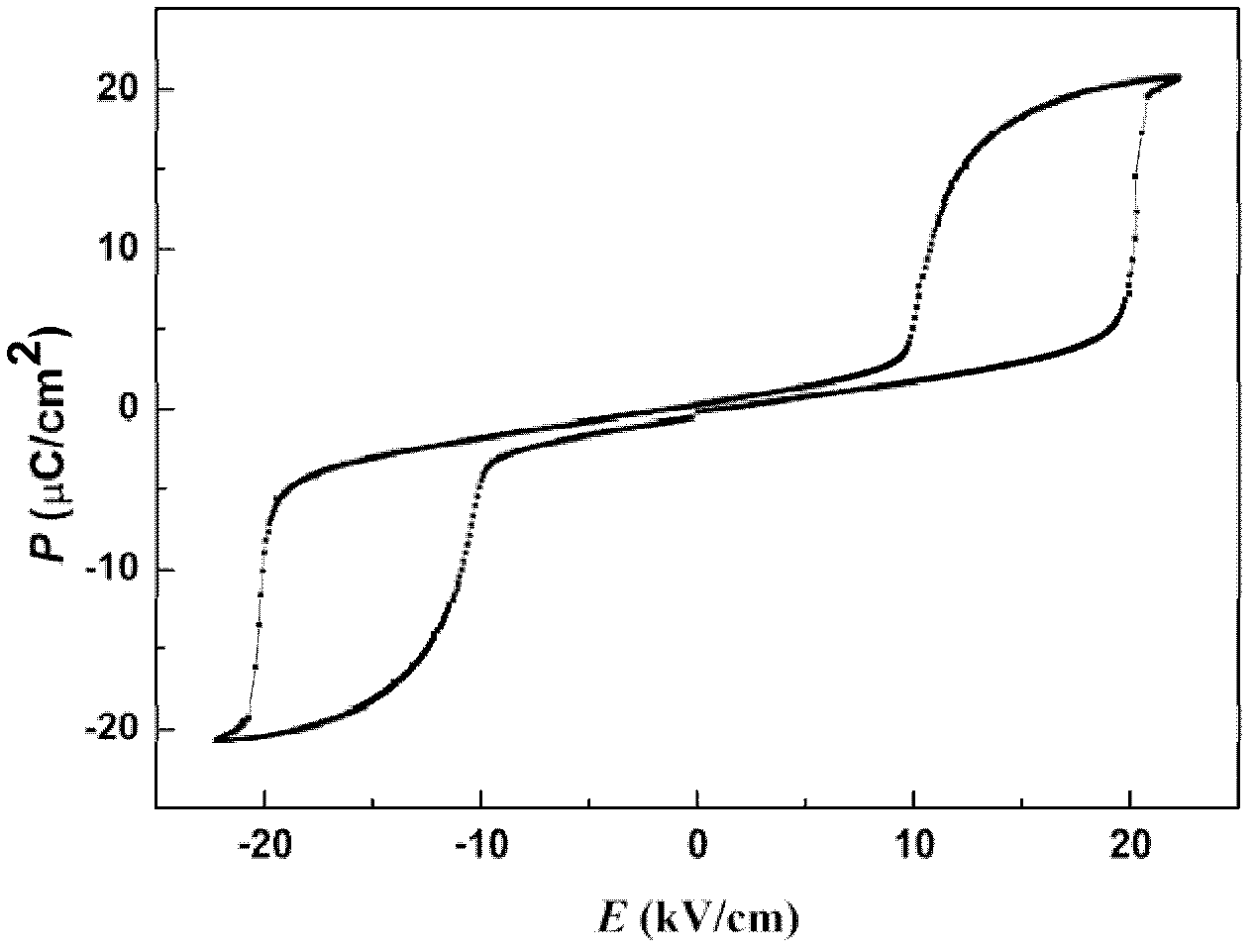

InactiveCN102643090BHigh dielectric constantHigh pyroelectric responseLead zirconate titanateDielectric loss

The invention relates to a PZT (lead zirconate titanate)-based antiferroelectric ceramic material with low curie point TC and a high bidirectional-adjustable dielectric electric field and a preparation method thereof and belongs to the technical fields of electronic materials and devices. The chemical general formula of the PZT-based antiferroelectric ceramic material with bidirectional adjustability of a dielectric electric field is (Pb[0.99-x-y]BaxLay)(Zr0.51Sn 0.39Ti0.10)O3, wherein x is larger than 0 and less than or equal to 0.20, and y is larger than 0 and less than or equal to 0.06. The PZT-based antiferroelectric ceramic material with dielectric bidirectional adjustability has high dielectric coefficient and low dielectric loss under a certain bias voltage in the vicinity of low curie point TC, and the dielectric coefficient is increased and then decreased along with the increase of the bias voltage; the PZT-based antiferroelectric ceramic material has bidirectional dielectric adjustability, simultaneously has high pyroelectric coefficient and pyroelectric current, and can be widely used in the fields of microelectronics, computers, capacitors, sensors, aerospace technologies and the like.

Owner:TONGJI UNIV

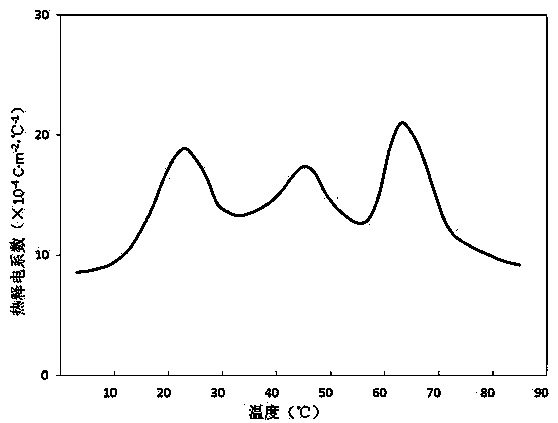

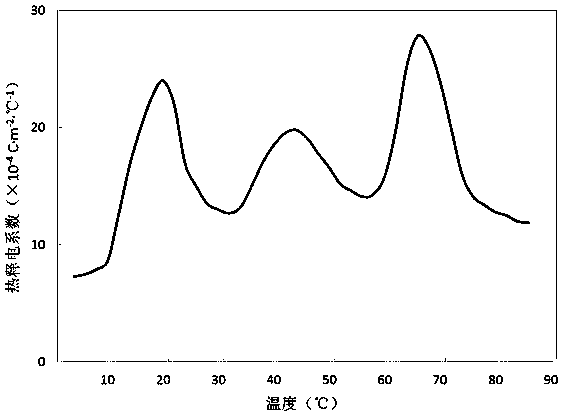

Pyroelectric ceramic material and preparation method thereof

The invention relates to a pyroelectric ceramic material and a preparation method thereof. The prepared zirconium-rich pyroelectric ceramic material has high pyroelectric coefficient in the temperature range of 10-80 DEG and high figure of merit of detectivity. A pyroelectric infrared sensor manufactured bu using the ceramic material has a high-level sensor sensitivity in the temperature range of10-80 DEG C in the case of thick ceramic, for example, ceramic of 0.15 mm thick, and the requirements of manufacture of high performance infrared pyroelectric sensors are met.

Owner:扬州江嘉科技有限公司

Anti-ferroelectric thin film used as thermoelectrical material and preparing method and use thereof

InactiveCN100545126CAdjust working temperatureHigh sensitivityPhotometry using electric radiation detectorsPyrometry using electric radation detectorsPyroelectric detectorsNiobium

The invention discloses an antiferroelectric thin film with adjustable working temperature range and large pyroelectric coefficient, its preparation method and application. The antiferroelectric thin film (Pb, La or Nb) (Zr, Sn, Ti) O of the present invention as pyroelectric material, it adopts sol-gel method to prepare, and the solute of precursor solution is lead acetate, lanthanum acetate La Or niobium ethoxide, tin acetate, zirconium isopropoxide and titanium isopropoxide, the solvent is glacial acetic acid, ethylene glycol ether, acetylacetone and water, the final concentration of the precursor solution is controlled between 0.2-0.4M, the substrate is LaNiO3 / Pt / Ti / SiO2 / Si and Pt / Ti / SiO2 / Si. The antiferroelectric thin film of the invention has high pyroelectric current and adjustable temperature, and can be used in infrared pyroelectric detectors, smart devices and systems.

Owner:TONGJI UNIV

A method for manufacturing conductive polymer pyroelectric nano film

InactiveCN105085961BImprove conductivityHigh pyroelectric coefficientCoatingsNanowireConductive polymer

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

A kind of multi-component composite pyroelectric ceramic material and its preparation method

InactiveCN104725042BHigh pyroelectric coefficientModerate dielectric constantThermoelectric device with dielectric constant thermal changePyroelectric detectorsDielectric loss

The invention discloses a multi-element composite pyroelectric ceramic material and a preparation method thereof. The general chemical formula of the material is: xPb(Me1 / 3Nb2 / 3)O3‑yPb(Fe1 / 2Nb1 / 2)O3‑zPb(Zr0 .9Ti0.1)O3‑mMe'; where Me is one of Mn or Zn; x, y, z are molar coefficients respectively, 0.01≤x≤0.07, 0.01≤y≤0.07, 0.9≤z≤0.92, And x+y+z=1; Me' is a modified metal element, m is the mole coefficient, 0≤m≤5mol%. The multi-element composite pyroelectric ceramic material provided by the present invention has a high pyroelectric coefficient, suitable dielectric properties and low dielectric loss, and its electrical properties are adjustable. Therefore, it is widely used in devices such as pyroelectric detectors. It has good application prospects.

Owner:INST OF ACOUSTICS CHINESE ACAD OF SCI

Pyroelectric ceramic material for passive pyroelectric infrared sensor and preparation method thereof

ActiveCN104609858BLower sintering temperatureWide sintering temperature rangeElemental compositionDielectric loss

The invention relates to a pyroelectric ceramic material for a passive pyroelectric infrared sensor, the chemical element composition of which is: (Pb1-x-yLaxSry) (Mn1 / 3Nb2 / 3)z(Zr0.94Ti0.06)1-zO3+ φat%A; where: 0.002≤x≤0.1, 0.01≤y≤0.1, 0.01≤z≤0.1; where, φ=0 or 2.8≤φ≤5.5, said A is a mixture of B2O3 and Cr2O3, the two The molar ratio is 1:1. The pyroelectric ceramic material of the present invention has a low sintering temperature and a wide sintering temperature range, and because of the low phase transition temperature, small spontaneous polarization, low dielectric constant and dielectric loss, the passive infrared pyroelectric sensor produced has noise Low value, high sensitivity, long detection distance; suitable for making sensors such as pyroelectric passive infrared sensors and uncooled focal plane infrared sensors.

Owner:SENBA SENSING TECH CO LTD

A kind of preparation method of nano tourmaline modified dust removal filter material

ActiveCN107261641BHigh pyroelectric coefficientImprove charging capacityDispersed particle filtrationMembrane filtersEmulsionTest sample

The invention discloses a preparation method of a nano tourmaline modified dust removal filter material, which belongs to the technical field of high-temperature smoke dust removal. The preparation method comprises the following steps: carrying out heat treatment for nano tourmaline powder; weighing sodium hexametaphosphate and sodium polyacrylate, and mixing the sodium hexametaphosphate and sodium polyacrylate with water; weighing nano tourmaline powder, adding water, and mixing with PTFE emulsion; adding the sodium hexametaphosphate and sodium polyacrylate into a mixed solution of the nano tourmaline powder and PTFE emulsion, and obtaining a nano tourmaline treatment solution; soaking a filter material test sample in the nano tourmaline treatment solution, and obtaining a nano tourmaline filter material; and polarizing the nano tourmaline filter material by virtue of electrets, and obtaining the nano tourmaline modified dust removal filter material. By adopting the preparation method, not only is electrets performance high, small dust can be trapped, the dust filter efficiency can be improved, the dust removing rate can be increased, and the equipment resistance is reduced.

Owner:南京际华三五二一环保科技有限公司

Preparation method of porous field pyroelectric ceramic material

InactiveCN101625268BHigh pyroelectric coefficientLow dielectric lossPyrometry using electric radation detectorsCeramicwareBarium strontium titanateDielectric loss

The invention discloses a method for preparing a porous barium strontium titanate field pyroelectric ceramic, comprising the following steps: firstly, mixing raw materials according to a stoichiometric ratio of respective chemical formula; pre-sintering the mixture at 800-1200 DEG C for 1-6 hours to obtain pre-sintered ceramic powder; then adding an organic substance pore-forming agent, mixing uniformly, tabletting and forming; heating again to remove organic substances; sintering, grinding, cleaning, adding an electrode and sintering the electrode. The porous BST field pyroelectric ceramic of the invention has the advantages of high pyroelectric coefficient, low dielectric loss, proper dielectric constant and excellent comprehensive pyroelectric property, and meets the requirements for manufacturing pyroelectric infrared detectors.

Owner:HUAZHONG UNIV OF SCI & TECH

Method for preparing high-performance barium strontium titanate pyroelectric ceramics by post-annealing process

ActiveCN104098330BHigh dielectric constantHigh pyroelectric coefficientThermoelectric device with dielectric constant thermal changeTime rangeHigh density

The invention relates to a method for preparing high-performance barium strontium titanate pyroelectric ceramics using a post-annealing process. The sintered barium strontium titanate ceramics are annealed in an oxygen atmosphere. The annealing temperature is 800-1250°C and the annealing time is 2- In 5 hours, high-performance barium strontium titanate pyroelectric ceramics can be produced. The present invention can obtain high-performance barium strontium titanate pyroelectric ceramics by performing post-annealing treatment after sintering the barium strontium titanate ceramics. Its dielectric constant can reach more than 9500 and its pyroelectric coefficient High, it can reach more than 18×10-8C / cm2K, and the sample has high purity, high performance and good uniformity, which can meet the requirements for making uncooled infrared focal plane devices, and effectively solves the problem of BST ceramics being difficult to sinter to high density. .

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com