A method for preparing field pyroelectric ceramic material

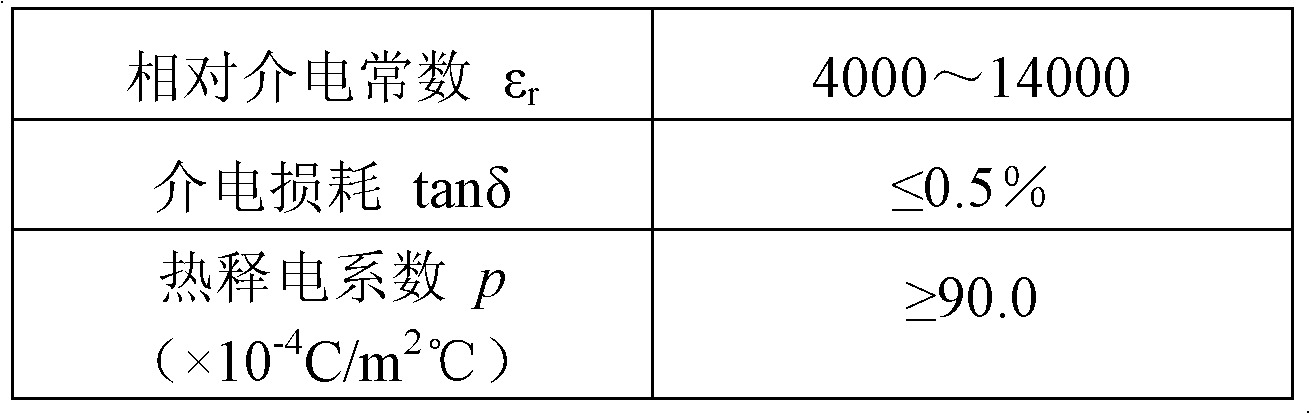

A pyroelectric ceramic and field induced technology, which is applied in the field of preparing field pyroelectric ceramic materials and preparing low-loss and high-performance barium strontium titanate field pyroelectric ceramic materials, and can solve the problem of weakening infrared detection ability and pyroelectricity. Problems such as decrease in electrical coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

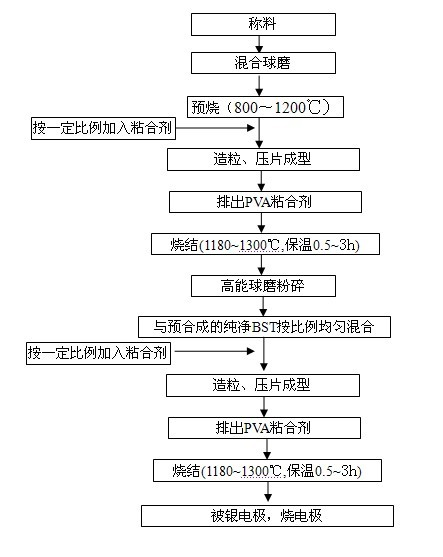

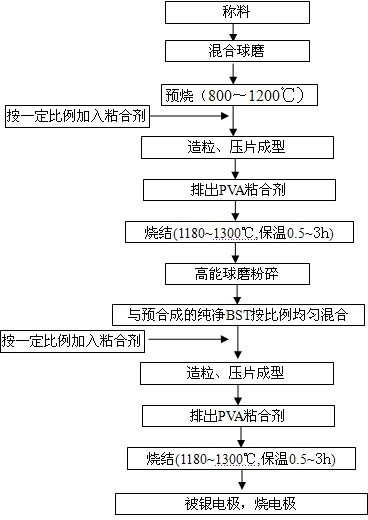

Method used

Image

Examples

example 1

[0039] According to the chemical formula Ba 0.68 Sr 0.32 TiO 3 +10mol% Mn, will be analytically pure BaTiO 3 , SrTiO 3 powder and Mn(NO 3 ) 2 The solution is configured with BST ceramic powder according to the stoichiometric ratio in the respective chemical formulas. After being ball milled, crushed and sieved, it is pre-fired at 1100°C for 2 hours, and the pre-fired powder is uniformly mixed with the binder polyvinyl alcohol. Mixing, granulation, molding (the molding process includes two steps of preforming and cold isostatic pressing). Then keep it at 600°C for 2 hours to discharge the binder, and keep it at 1400°C for 0.5 hour for sintering to obtain heavily doped BST ceramics. Thereafter, after the ceramics are pulverized by high-energy ball milling, they are evenly mixed with pure pre-synthesized BST powder (mixing ratio is 1:20, mass ratio), and then paraffin wax binder is added, granulated and formed (wherein the forming process includes pre-synthesized Forming a...

example 2

[0043] The heavily doped BST ceramic powder was mixed with the pre-synthesized pure BST powder at a mass ratio of 1:100. The final sintering temperature of ceramics is 1350°C, and the holding time is 2h. All the other are the same as Example 1, and the process parameters are shown in Table 2. Its performance is shown in Table 3.

[0044] Example 3-4:

[0045] The chemical formula of heavily doped BST is Ba 0.68 Sr 0.32 TiO 3 +20mol%Mn+60mol%Y, the pre-calcination temperature is 1000°C, and the temperature is kept for 6 hours, and the analytically pure BaCO 3 , SrCO 3 、TiO 2 powder and Mn(NO 3 ) 2 , Y(NO 3 ) 3 Mix according to the stoichiometric ratio in the chemical formula. The sintering temperature of medium-doped BST is 1300℃, and the holding time is 2h.

[0046] The heavily doped BST ceramic powder and the pre-synthesized pure BST powder were mixed at a mass ratio of 1:40 and 1:70. The binder used for the two granulations was paraffin wax, and the binder disch...

example 5

[0048] With the heavily doped element Mn (NO in the example 3-4 3 ) 2 and Y(NO 3 ) 3 The solution was changed to MgO and Nb respectively 2 o 5For powder, the doping amount is the same as in Example 3-4, the calcining temperature is 1200°C, and the holding time is 1h. The adhesive is deionized water, and the adhesive discharge process is: 100°C, heat preservation for 1h. The final sintering temperature of the ceramics is 1300°C and the temperature is kept for 2.5h. All the other are the same as Example 1, and the process parameters are shown in Table 2. Its performance is shown in Table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com