Multielement composite pyroelectric ceramic material and preparation method thereof

A technology of pyroelectric ceramics and multi-element compounding, which is applied in the field of materials, can solve the problems that new quaternary composite pyroelectric ceramic systems are rarely reported.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1 of the present invention provides a novel quaternary multi-component composite pyroelectric ceramic material, whose general chemical formula is: xPb(Me1 / 3 Nb 2 / 3 )O 3 -yPb(Fe 1 / 2 Nb 1 / 2 )O 3 -zPb(Zr 0.9 Ti 0.1 )O 3 -mMe';

[0030] Among them, Me is one of Mn or Zn; x, y, z are molar coefficients respectively, 0.01≤x≤0.07, 0.01≤y≤0.07, 0.9≤z≤0.92, and x+y+z=1; Me ' is a modified metal element, m is a molar coefficient, and 0≤m≤5mol%.

[0031] Me' may include, but is not limited to, one or more of Cr, Ce, Li or La.

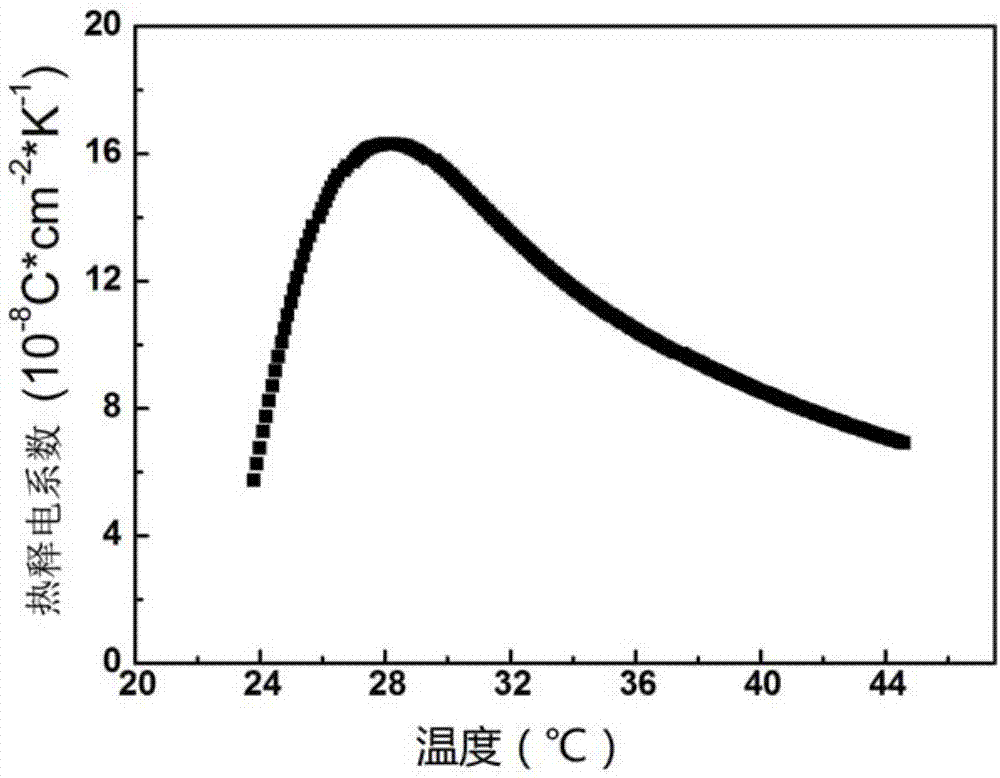

[0032] The novel quaternary multi-component composite pyroelectric ceramic material xPb(Me 1 / 3 Nb 2 / 3 )O 3 -yPb(Fe 1 / 2 Nb 1 / 2 )O 3 -zPb(Zr 0.9 Ti 0.1 )O 3 -mMe' (can be abbreviated as PMnN-PFN-PZT or PZN-PFN-PZT) has a higher pyroelectric coefficient (λ=5×10 -8 C·cm -2 ·K -1 ~20×10 -8 C·cm -2 ·K -1 ), the appropriate dielectric constant ε r (100-500) and lower dielectric loss tanδ (0.005-0.030), and these properties are ad...

Embodiment 2

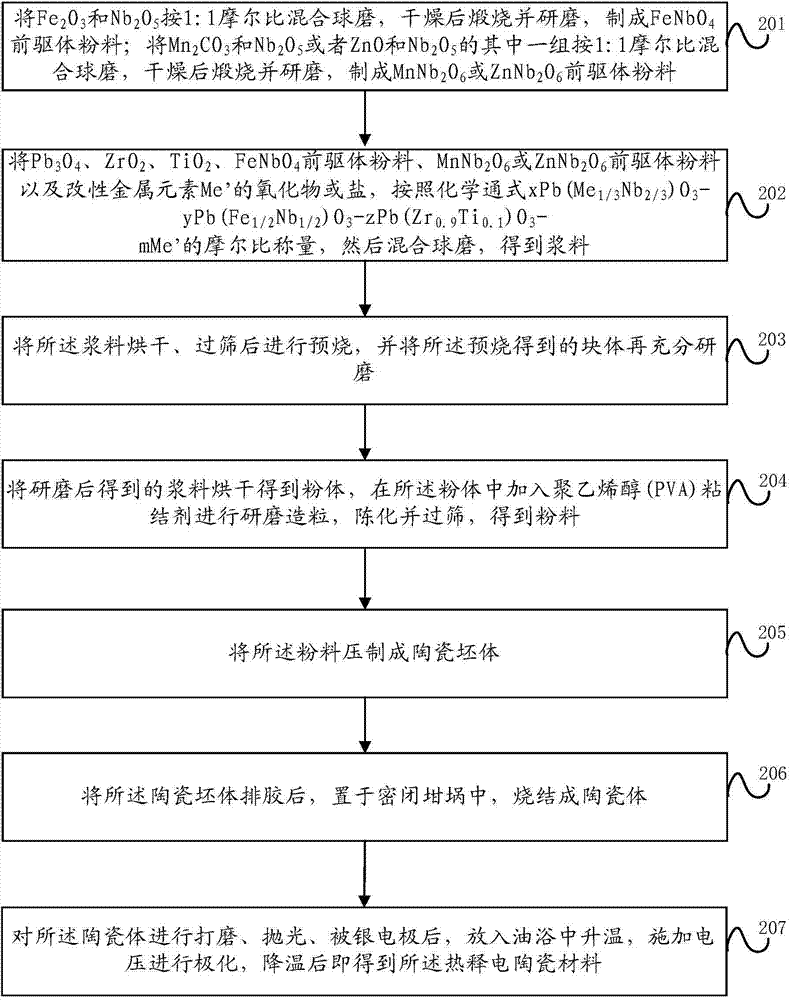

[0034] This embodiment provides the preparation method of the pyroelectric ceramic material in the above-mentioned embodiment 1, such as figure 1 shown, including:

[0035] Step 201, the Fe 2 o 3 and Nb 2 o 5 Mix ball milling at 1:1 molar ratio, dry and then calcinate and grind to make FeNbO 4 Precursor powder; the Mn 2 CO 3 and Nb 2 o 5 or ZnO and Nb 2 o 5 One group of them was ball-milled at a molar ratio of 1:1, dried and then calcined and ground to make MnNb 2 o 6 or ZnNb 2 o 6 Precursor powder;

[0036] Step 202, Pb 3 o 4 , ZrO 2 、TiO 2 , FeNbO 4 Precursor powder, MnNb 2 o 6 or ZnNb 2 o 6 Precursor powder and the oxide or salt of the modified metal element Me', according to the general chemical formula xPb(Me 1 / 3 Nb 2 / 3 )O 3 -yPb(Fe 1 / 2 Nb 1 / 2 )O 3 -zPb(Zr 0.9 Ti 0.1 )O 3 The mol ratio of -mMe' is weighed, then mixed and ball milled to obtain the slurry;

[0037] Wherein, the Me' includes one or more of Cr, Ce, Li or La.

[0038] Step 203...

Embodiment 3

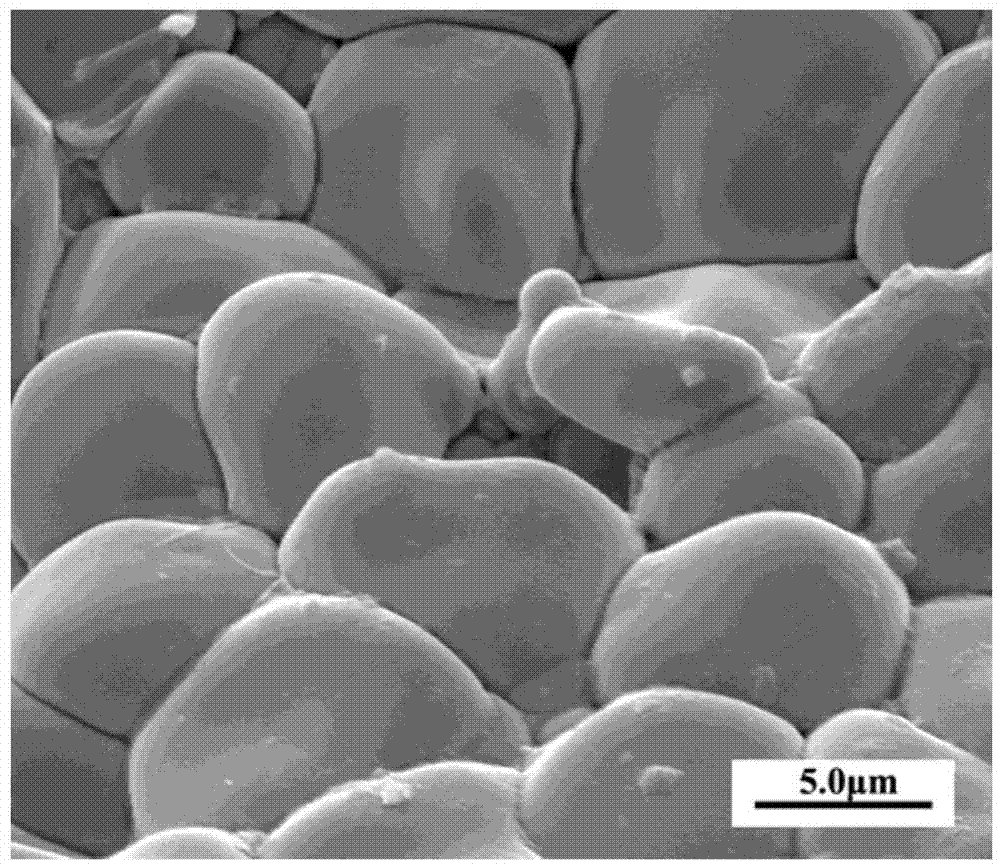

[0051] Will Mn 2 CO 3 and Nb 2 o 5 Mix and ball mill at a molar ratio of 1:1, dry and then calcinate and grind to make MnNb 2 o 6 Precursor powder; the Fe 2 o 3 and Nb 2 o 5 Mix and ball mill at 1:1 molar ratio, dry and then calcinate and grind to make FeNbO 4 Precursor powder. will Pb 3 o 4 , ZrO 2 、TiO 2 , MnNb 2 o 6 Precursor powder and FeNbO 4 Precursor powder according to 0.05Pb(Mn 1 / 3 Nb 2 / 3 )O 3 -0.03Pb(Fe 1 / 2 Nb 1 / 2 )O 3 -0.92Pb(Zr 0.9 Ti 0.1 )O 3 Weigh the molar ratio, add anhydrous ethanol medium to mix and ball mill, dry and sieve, and pre-calcine at 750°C for 2 hours. Ball mill and dry the block obtained after pre-calcination, add 5% PVA to granulate, age for 6 hours, and press it into a green body with a diameter of 15mm and a thickness of about 1.5mm after sieving. Sintering at 1120° C. for 2.5 hours to obtain a ceramic body. After grinding, polishing, and silvering the obtained ceramic body, it was polarized in 140°C silicone oil with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pyroelectric coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com