Pyroelectric ceramic material for passive pyroelectric infrared sensor and preparation method thereof

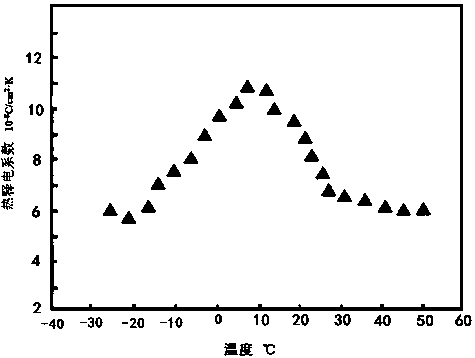

A technology of pyroelectric ceramics and pyroelectric infrared, applied in the field of piezoelectric ceramics, can solve the problems of pyroelectric performance attenuation, pyroelectric coefficient reduction, long-term short life, etc., and achieve small spontaneous polarization and low noise value , the effect of low phase transition temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

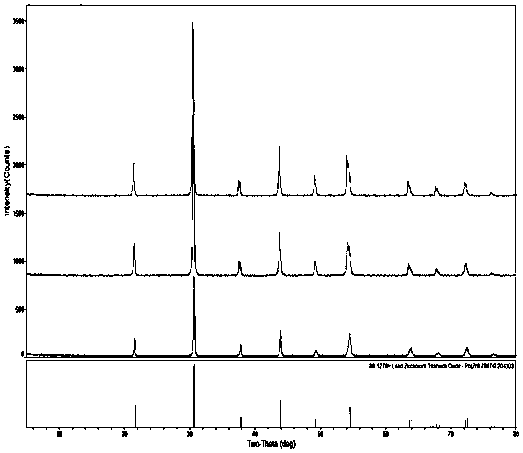

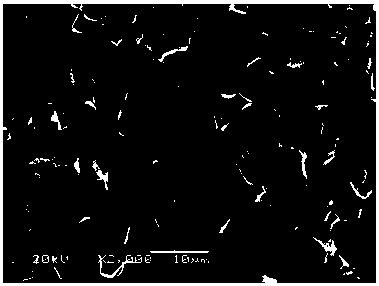

Embodiment 1

[0037] The pyroelectric ceramic material of the present embodiment consists of: (Pb 1-x-y La x Sr y ) (Mn 1 / 3 Nb 2 / 3 ) z (Zr 0.94 Ti 0.06 ) 1-z o 3 ; where: x=0.01, y=0.02, z=0.05. The pyroelectric ceramic material is prepared by the following method: (1) using PbO, ZrO 2 、TiO 2 , Nb 2 o 5 , MnO 2 , SrCO 3 and La 2 o 3 Prepare the above powder raw materials according to the elemental ratio, and mix them by wet ball milling; (2) The mixed raw materials are pre-fired at 800°C and the holding time is 2 hours to form ceramic calcined powder after pressure filtration and drying (3) Add the sintering aid ZnO into the ceramic calcined powder, grind and mix to form a ceramic slurry, and the mass of the sintering aid is 0.50wt% of the ceramic calcined powder; (4) use the ceramic slurry Based on the mass of the ceramic slurry, add 10wt% binder, 1.0wt% plasticizer and 0.1wt% release agent to the ceramic slurry for spray granulation to form ceramic particles; (5) pre-pres...

Embodiment 2

[0039] The pyroelectric ceramic material of the present embodiment consists of: (Pb 1-x-y La x Sr y ) (Mn 1 / 3 Nb 2 / 3 ) z (Zr 0.94 Ti 0.06 ) 1-z o 3 ; where: x=0.01, y=0.02, z=0.05. The pyroelectric ceramic material is prepared by the following method: (1) using PbO, ZrO 2 、TiO 2 , Nb 2 o 5 , MnO 2 , SrCO 3 and La 2 o 3 As raw materials, prepare the above powder raw materials according to the elemental ratio, and mix them by wet ball milling; (2) After the mixed raw materials are press-filtered and dried, they are pre-fired at 900°C and the holding time is 1h to form ceramic calcined powder. (3) Grind and mix the calcined ceramic powder to form a ceramic slurry; (4) Based on the quality of the ceramic slurry, add 10wt% binder and 1.0wt% plasticizer to the ceramic slurry Spray granulation with 0.1wt% mold release agent to form ceramic particles; (5) pre-press and isostatically press ceramic particles to form ceramic cylinders; ℃, the holding time is 2h; (7) The...

Embodiment 3

[0041] The pyroelectric ceramic material of the present embodiment consists of: (Pb 1-x-y La x Sr y ) (Mn 1 / 3 Nb 2 / 3 ) z (Zr 0.94 Ti 0.06 ) 1-z o 3 ; where: x=0.01, y=0.02, z=0.06. The pyroelectric ceramic material is prepared by the following method: (1) using PbO, ZrO 2 、TiO 2 , Nb 2 o 5 , MnO 2 , SrCO 3 and La 2 o 3 Prepare the above powder raw materials according to the elemental ratio, and mix them by wet ball milling; (2) The mixed raw materials are pre-fired at 800°C and the holding time is 2 hours to form ceramic calcined powder after pressure filtration and drying (3) Add the sintering aid ZnO into the ceramic calcined powder, grind and mix to form a ceramic slurry, and the mass of the sintering aid is 0.50wt% of the ceramic calcined powder; (4) use the ceramic slurry Based on the mass of the ceramic slurry, add 10wt% binder, 1.0wt% plasticizer and 0.1wt% release agent to the ceramic slurry for spray granulation to form ceramic particles; (5) pre-pres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com