Pyroelectric detector

A pyroelectric detector and electrode technology, applied in the field of pyroelectric detection, can solve the problems of limited detector response rate and detection rate, low sensitivity and signal-to-noise ratio, and low pyroelectric coefficient, so as to improve sensitivity and detection rate , maintain polarization characteristics, increase the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

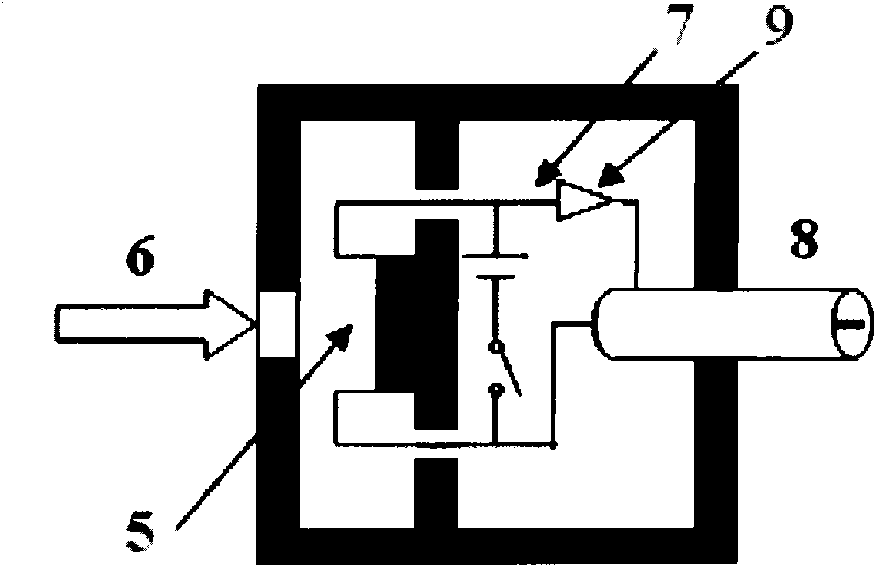

[0030] The pyroelectric detector provided by the present invention includes an opaque sealed casing, a response element located in the casing and a signal output interface, and the casing has a transparent window for receiving external electromagnetic radiation. The response element has an upper electrode and a lower electrode, and the upper electrode and the lower electrode of the response element are electrically connected to the signal output interface; the response element is placed at a distance of 1 mm to 5 mm from the transparent window, and the upper electrode faces the The above transparent window. The transparent window can adopt the structure of a wide-angle lens so as to receive external electromagnetic radiation at a large angle.

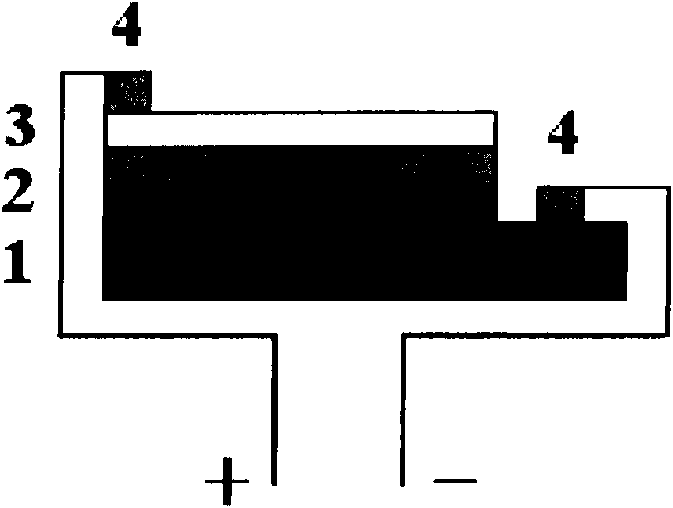

[0031] Such as figure 1 As shown, the response element of this embodiment includes sequentially stacked Nb:SrTiO 3 Substrate 1, CCTO thin film 2 and ITO thin film 3 after polarization; The Nb:SrTiO 3 The substrate forms the lower ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com