Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "High hardware requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

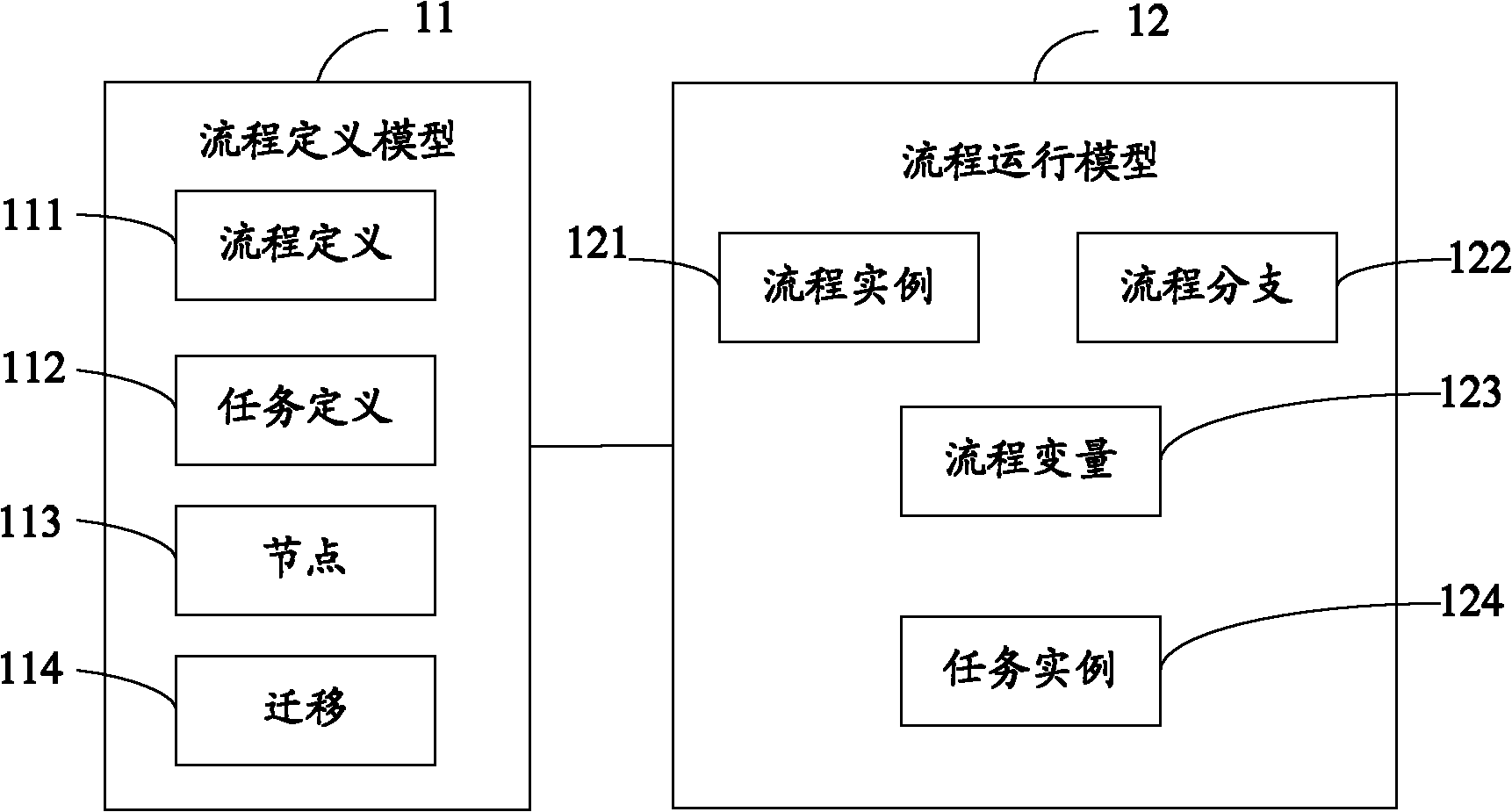

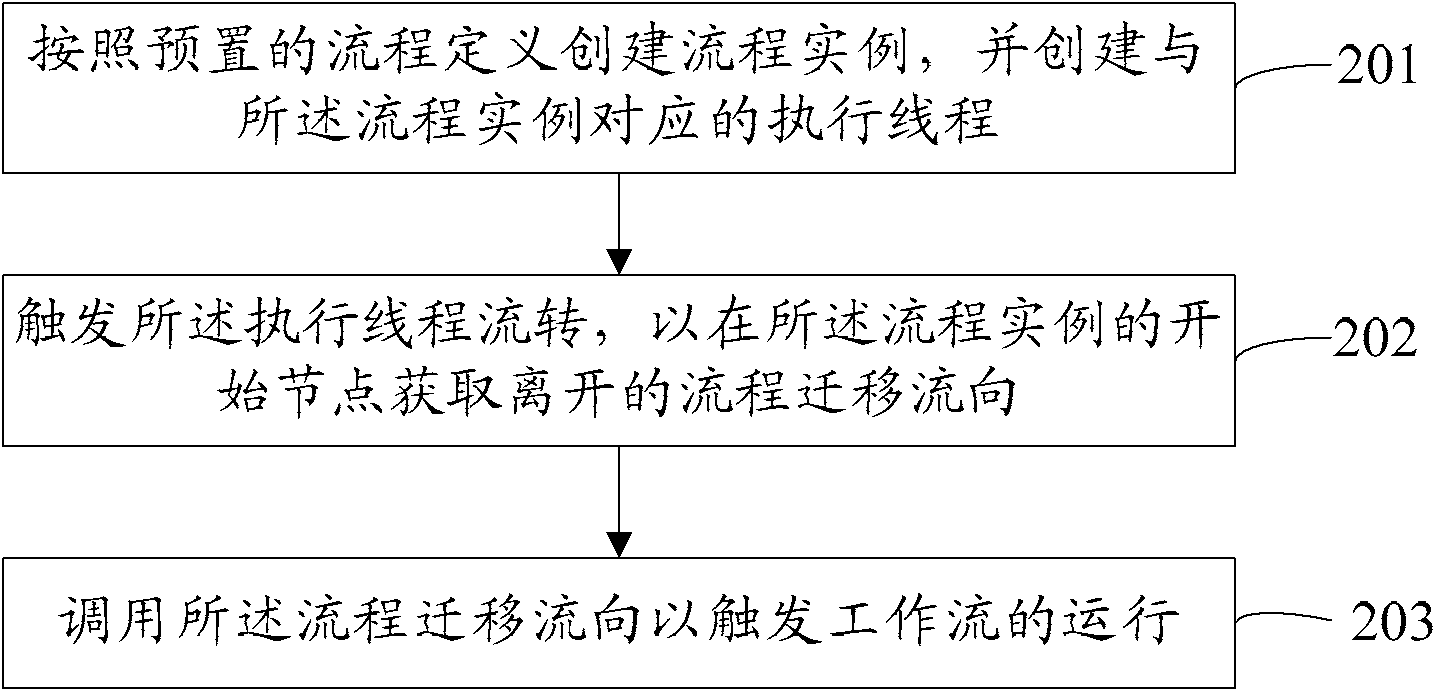

Workflow operation method and system

InactiveCN102043625ASatisfy low-cost intensificationMeet the requirements of low-cost intensificationResourcesSpecific program execution arrangementsOperation modelPerformance requirement

The invention provides a workflow operation method and a system thereof. The method comprises the steps: presetting a flow definition model and a flow operation model, wherein the flow definition model comprises preset task definition, flow definition, node and migration objects, the flow operation model comprises preset flow instance, flow branch, task instance and flow variable objects; creating a flow instance according to the preset flow definition, and creating an execution thread corresponding to the flow instance; triggering the execution thread to flow, so as to acquire migration flow direction of a left flow at an initial node of the flow instance; and calling the migration flow direction of the flow to trigger workflow to operate. The method and the system provided by the invention can firstly meet workflow operation requirements of high data quantity and high concurrent load, secondly reduces application difficulty of development, testing and management, and finally has simple technical architecture and low hardware requirement while meeting performance requirement and also meets the low cost intensification requirement.

Owner:AGRICULTURAL BANK OF CHINA

Thunder and lightning locator with sound sensors and locating method thereof

InactiveCN101799560AImprove stabilityQuick responseUsing reradiationData processing systemHyperboloid

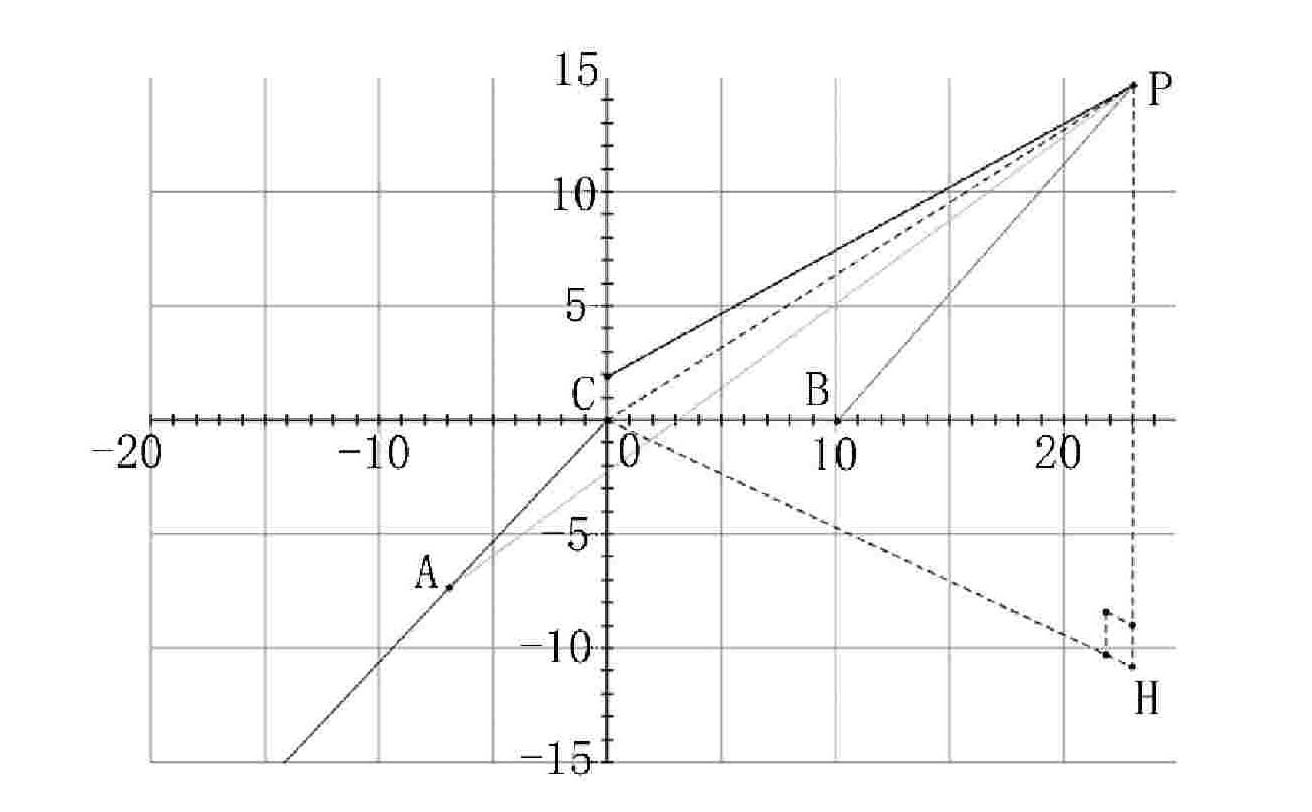

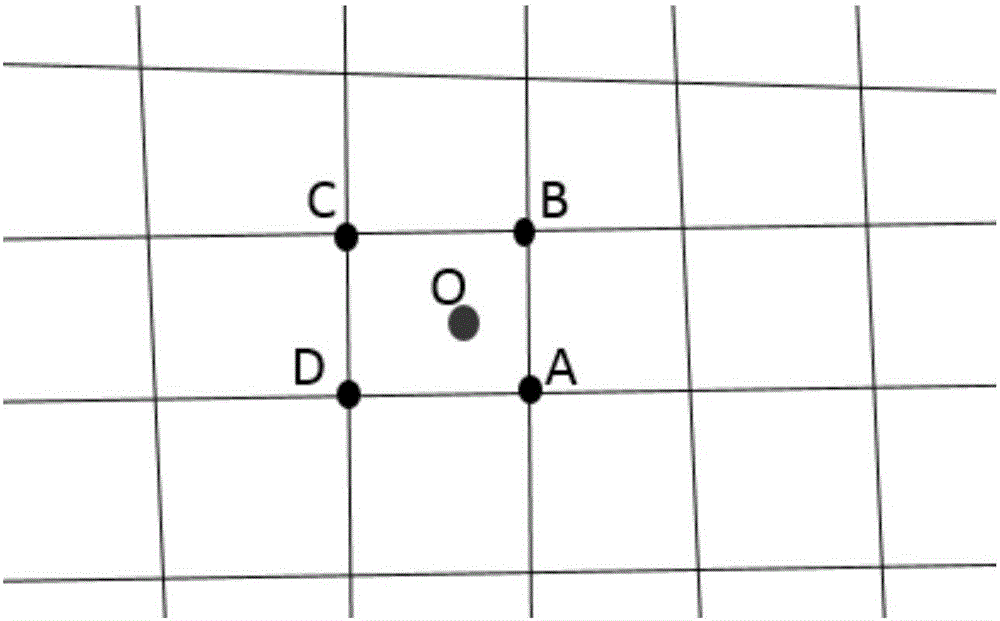

The invention relates to a thunder and lightning locator with sound sensors and a locating method thereof. The thunder and lightning locator comprises four sound sensors, a four-passage data acquisition card and a data processing system, wherein the four sound sensors are distributed on four observing points; when thunder and lightning occur, the sound sensors positioned on the four space observing points respectively record the thunder reaching time of the observing points; four groups of time data are converted from A / D (analog to digital) by the four-passage data acquisition card and then transmitted to the data processing system; the data processing system solves the difference of the thunder reaching time of three space observing points through logical operation and computes the difference of the distances of the three space observing points according to the propagation speed of sound in the air; and a coordinate of a thunder and lightning generation position is determined according to an equation set and a principle that a point can be determined by intersecting three hyperboloids in space. The invention ensures high measurement precision, also simplifies a locating measurement method, reduces the hardware requirements and the equipment cost, realizes the accurate automatic locating of the thunder and lightning and can be widely used in the field of meteorological sounding.

Owner:CMA METEOROLOGICAL OBSERVATION CENT

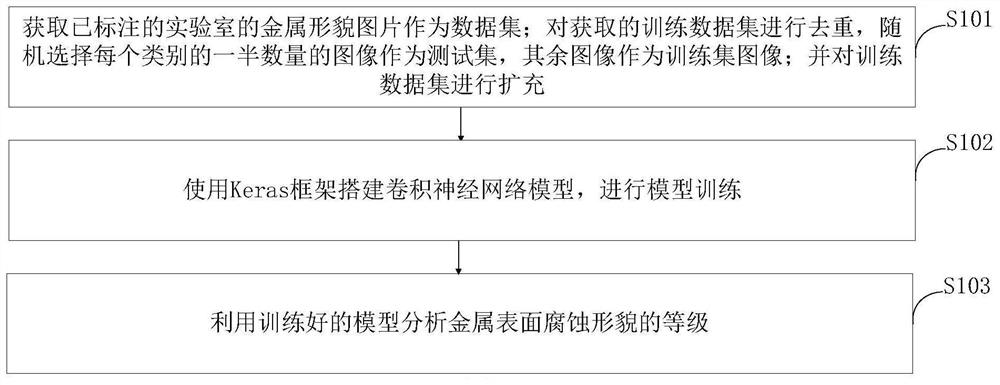

Corrosion level information processing method and system based on image recognition

PendingCN111862093AReduce overfittingAvoid difficultiesImage enhancementImage analysisInformation processingData set

The invention belongs to the technical field of metal corrosion morphology grade judgment, and discloses a corrosion grade information processing method and system based on image recognition, and themethod comprises the steps: obtaining a labeled laboratory metal morphology picture as a data set; carrying out the de-duplication on the obtained training data set, randomly selecting a half of images of each category as a test set, and taking other images as training set images; expanding the training data set, namely carrying out the data enhancement; building a convolutional neural network model by using a Keras framework, carrying out model training, and storing optimal model parameters; and analyzing the grade of the corrosion morphology of the metal surface by utilizing the trained optimal model. According to the method, the judgment of the metal corrosion morphology grade is realized by using a computer vision technology, so the judgment efficiency is greatly improved and the judgment uniformity and objectivity are ensured under the condition of ensuring the judgment accuracy. The method can assist engineers engaged in material research in judging the metal corrosion grade, andvarious difficulties of a previous judgment method are solved.

Owner:HUAZHONG UNIV OF SCI & TECH

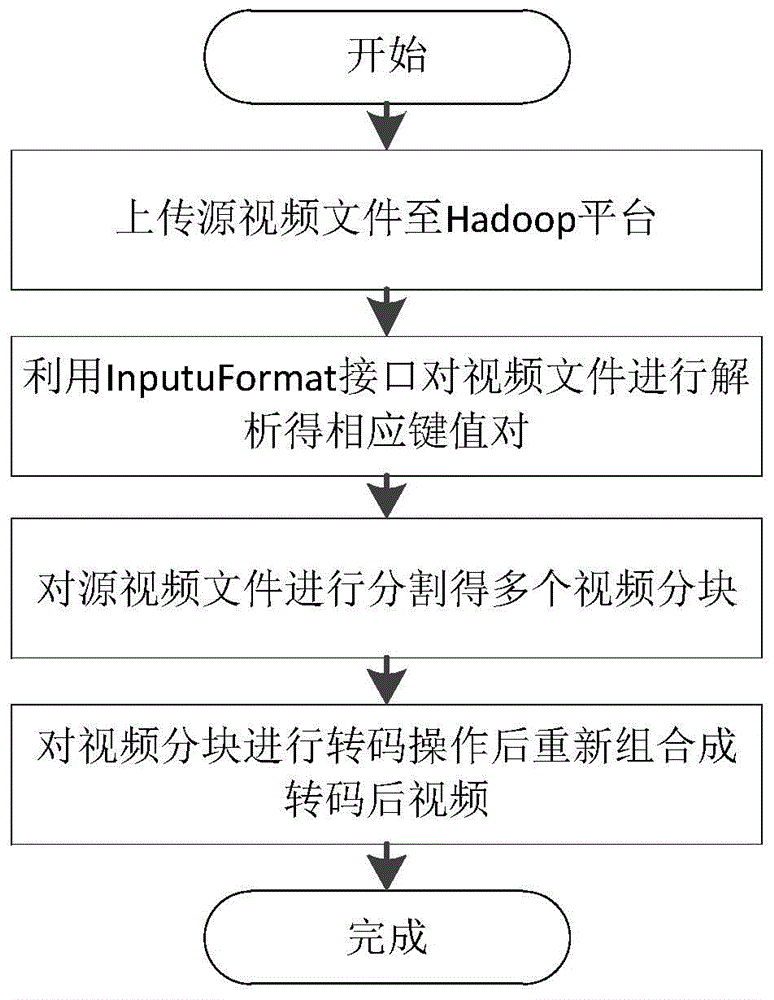

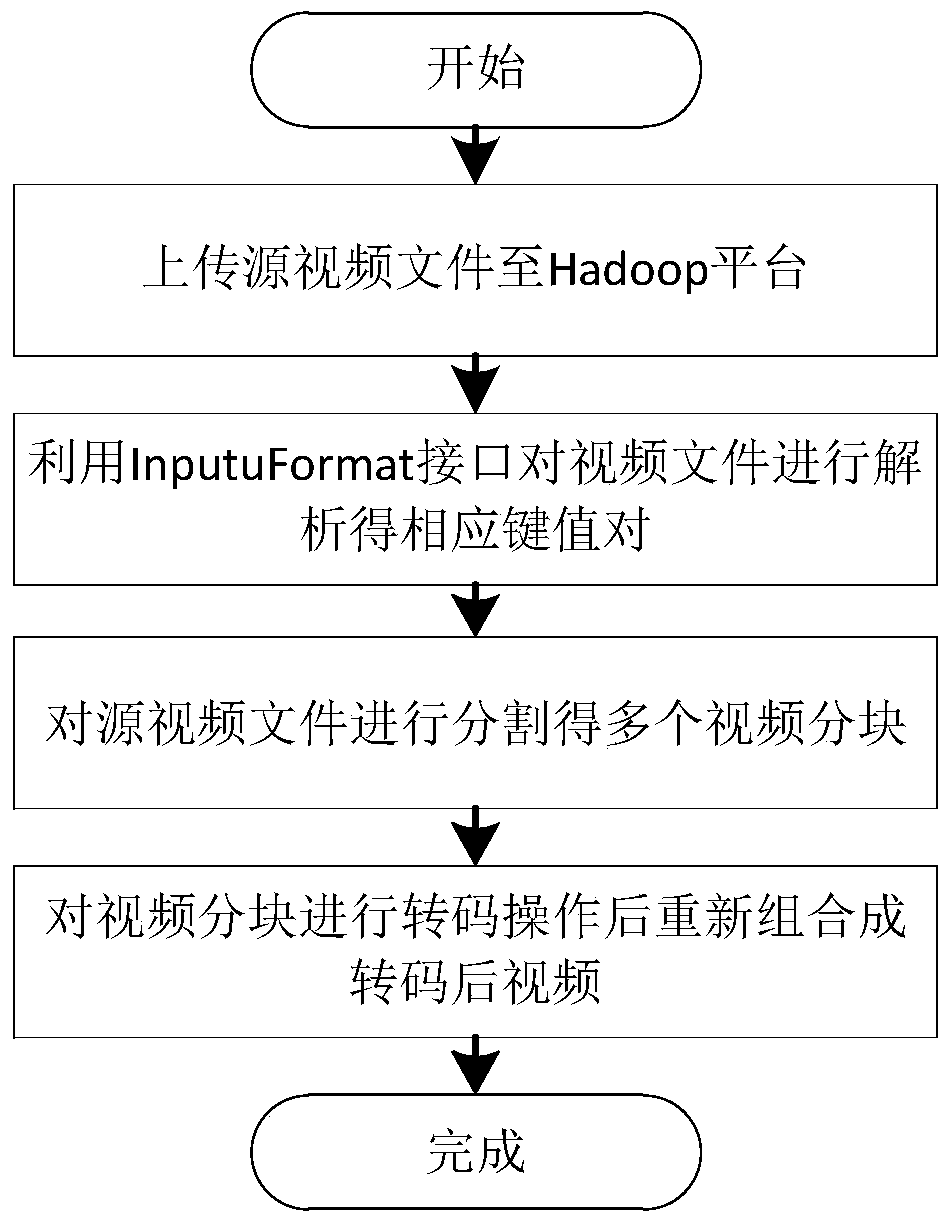

Distributed video transcoding method

ActiveCN104935951AAdapt to storage needsHigh hardware requirementsDigital video signal modificationSelective content distributionComputer architectureDistributed File System

The invention provides a distributed large-scale video transcoding system, and belongs to the technical field of big data and video processing. According to the method, large-scale video transcoding is implemented through adoption of a distributed method on a big data processing platform Hadoop. In the method, large-scale video data is stored with an HDFS file system, distributed processing is performed with a MapReduce programming module, and processing of videos is implemented by means of a multimedia library Xuggler. The storage and transcoding of the large-scale video data are implemented with the expandability and stability characteristics of the distributed file system; the defects of high hardware requirement, difficulty in maintenance, difficulty in expansion and the like in the conventional centralized storage are overcome; and the ever-increasing storage and transcoding demands of the large-scale video data are met dynamically.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

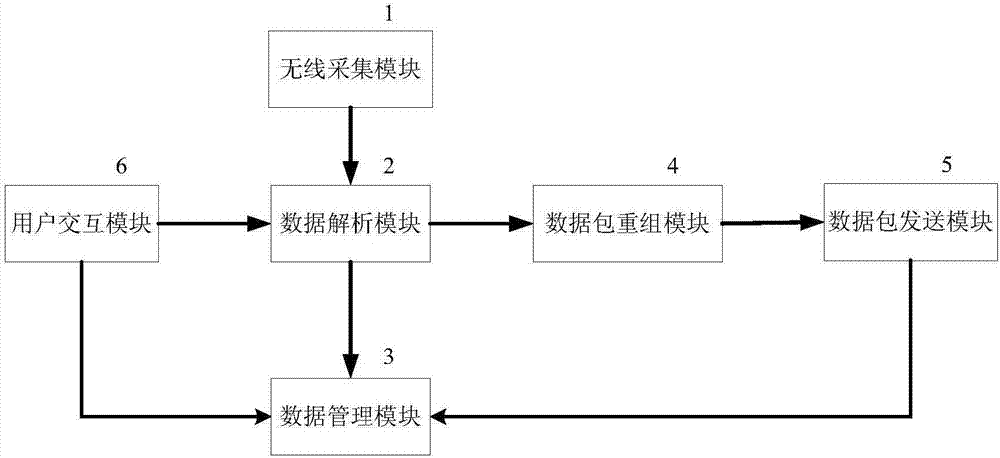

Signal shielding system based on wireless network and method thereof

InactiveCN106921460AImprove real-time performanceImprove scalabilityConnection managementCommunication jammingWireless mesh networkAnalysis data

The invention discloses a signal shielding system based on a wireless network and a method thereof, and relates to a wireless data frame recombination technology. The system is as follows: a wireless collection module (1), a data analysis module (2) and a data management module (3) are interacted in sequence, thereby implementing data capture, analysis and storage operations; a user interaction module (6), the data analysis module (2), a data packet recombination module (4) and a data packet sending module (5) are interacted in sequence, thereby implementing data extraction, recombination and sending operations of a user designated AP; and the data management module (3) is respectively interacted with the user interaction module (6), the data analysis module (2) and the data packet sending module (5), thereby implementing user information, analysis data and log saving and storage. The signal shielding system based on the wireless network and the method thereof disclosed by the invention have the following advantages and positive effects: (1) the pertinence is strong; (2) the real-time performance is high; (3) the expansibility is good; and (4) the imperceptibility is strong.

Owner:WUHAN HONGXU INFORMATION TECH

Faster RCNN convolutional neural network single-target recognition method based on LeakyRelu activation function

ActiveCN110569971AResolve identifiabilityResolve detectionNeural architecturesNeural learning methodsActivation functionImaging processing

The invention belongs to the field of image processing in computer vision, and particularly relates to a Faster RCNN convolutional neural network single-target recognition method based on a LeakyReluactivation function. The invention provides an improved relu activation function, namely a LeakyRelu activation function, and the function better reserves image data information and is more beneficialto extraction of image features. The function is applied to the field of detection and extraction of a target object in an image in a convolutional neural network, so that the detection accuracy is improved. The detection accuracy of an existing neural network image processing algorithm is improved, and the problems caused by image recognition and detection of a convolutional neural network adopting relu as an activation function at present are solved.

Owner:JILIN UNIV

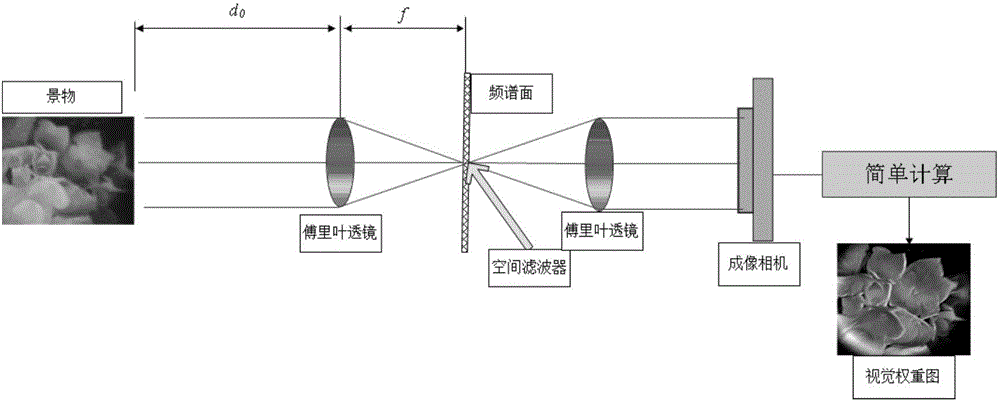

Imaging-based visual weight graph extraction method

InactiveCN105809159AAcquisition stableHigh resolutionImage enhancementImage analysisFrequency spectrumVisual perception

The invention discloses an imaging-based visual weight graph extraction method. A system brought forward by the invention is based on a single-optical-path double Fourier lens imaging, can directly carry out imaging analysis of a visual weight on a scene, and can effectively and rapidly obtain a high-precision visual weight graph. The method comprises the following steps: 1, constructing a single-optical-path double Fourier lens imaging system; and 2, generating a visual weight image. According to the method, the single-optical-path double Fourier lens imaging system is constructed, different filtering of two times is realized at a frequency spectrum surface, different low-pass filtering effects are realized, a filtering result is obtained by use of an industrial camera, finally, the visual weight graph is obtained through an absolute value of a gray-scale difference between images, and the processing result is close to that of human eye visual system. The corresponding visual weight graph can be rapidly obtained as long as the system aims at the scene (it should be satisfied that an object distance is greater than a lens focal length by more than ten times).

Owner:HANGZHOU DIANZI UNIV

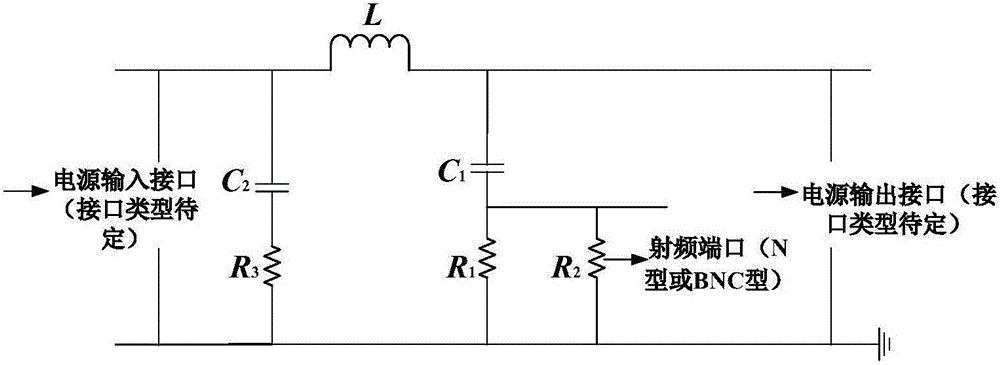

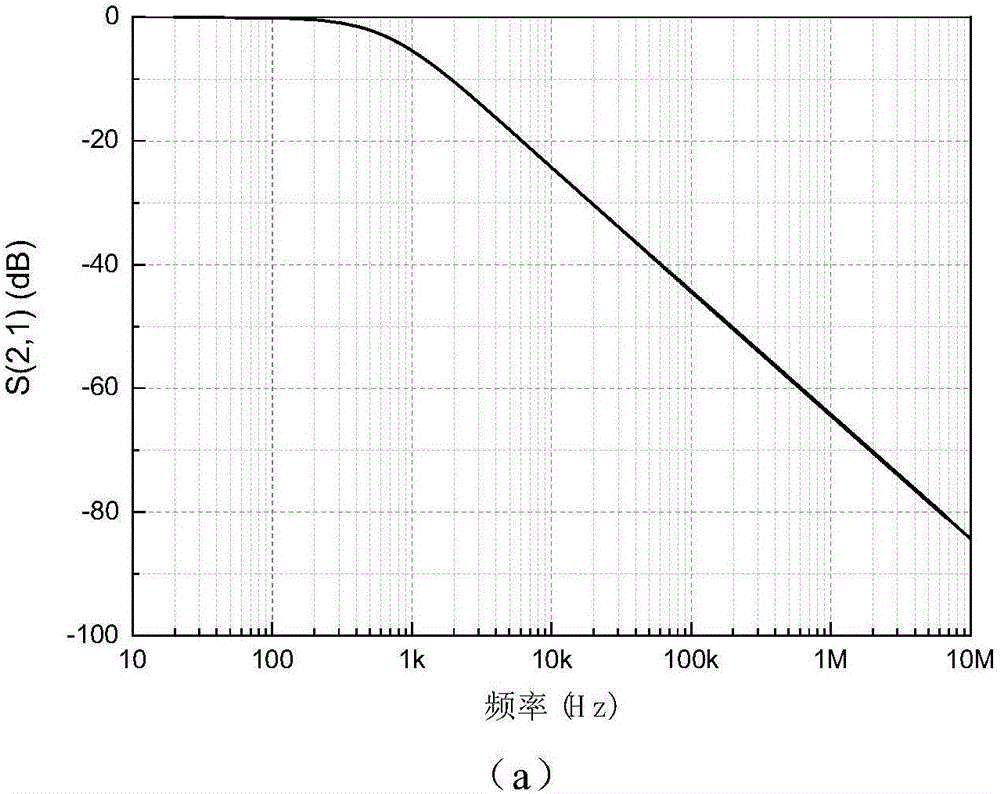

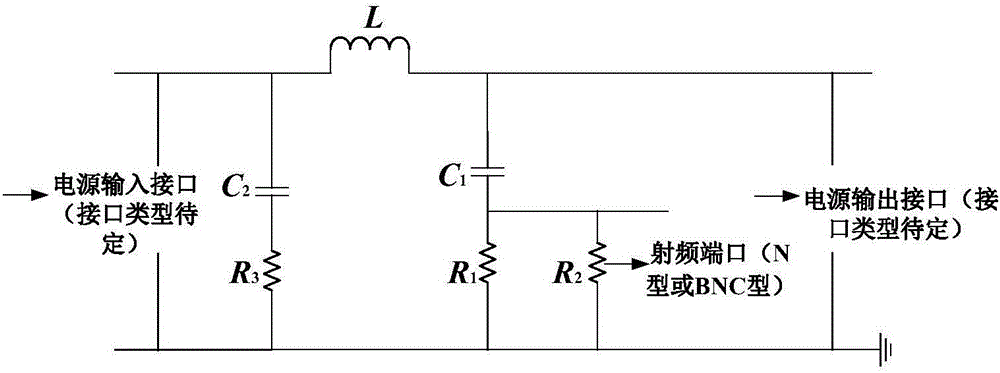

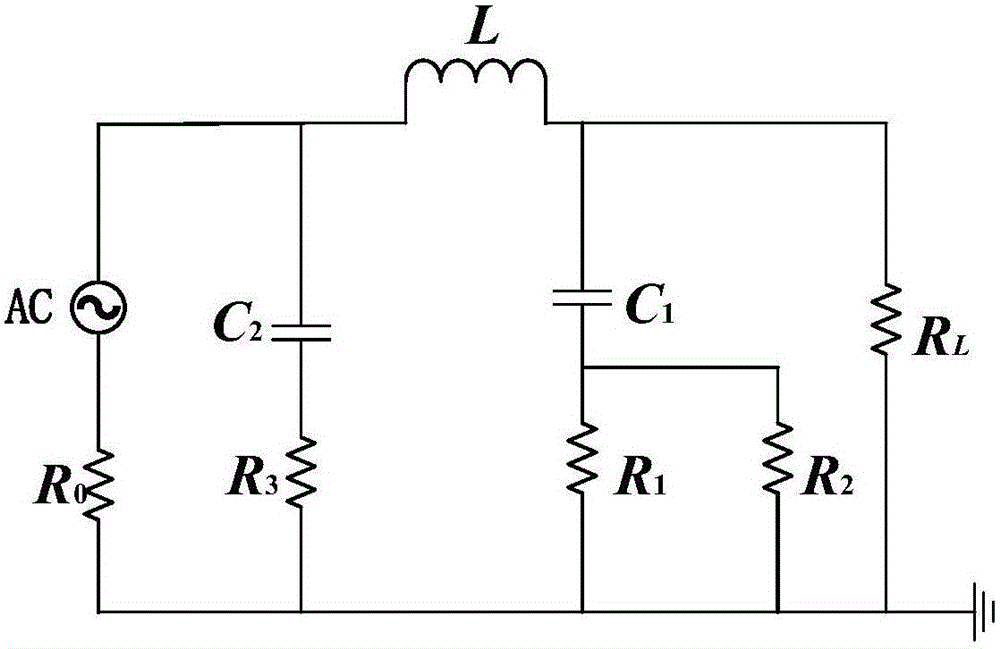

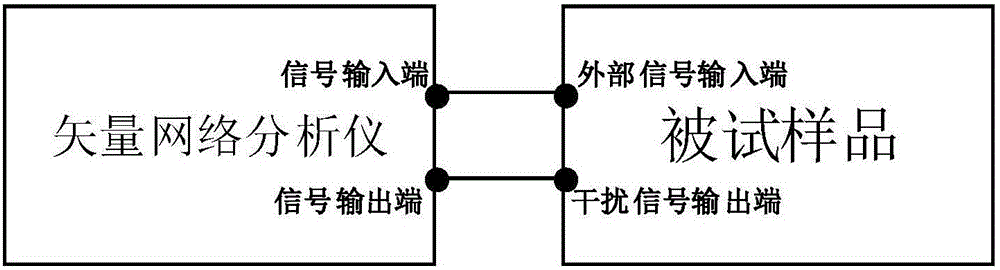

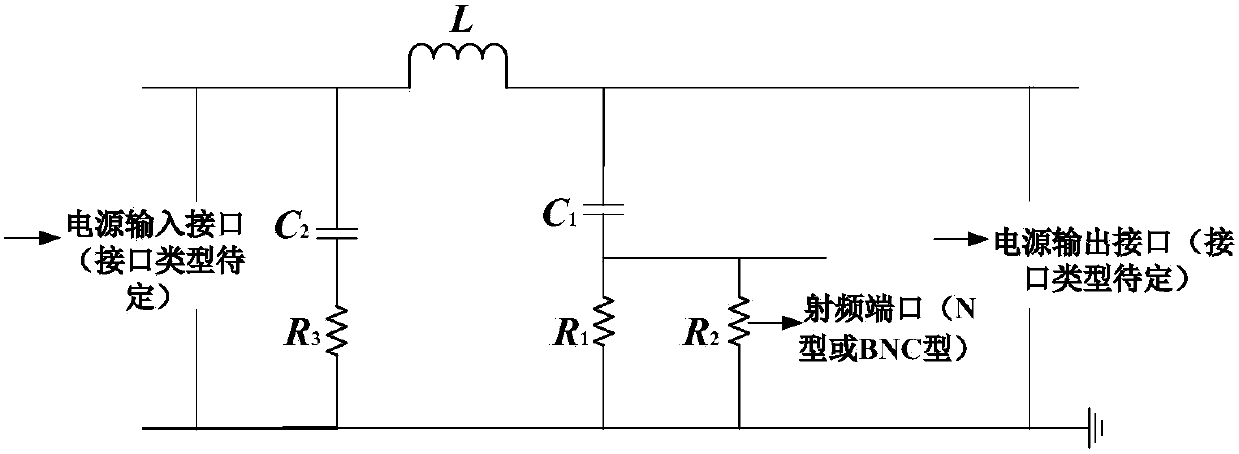

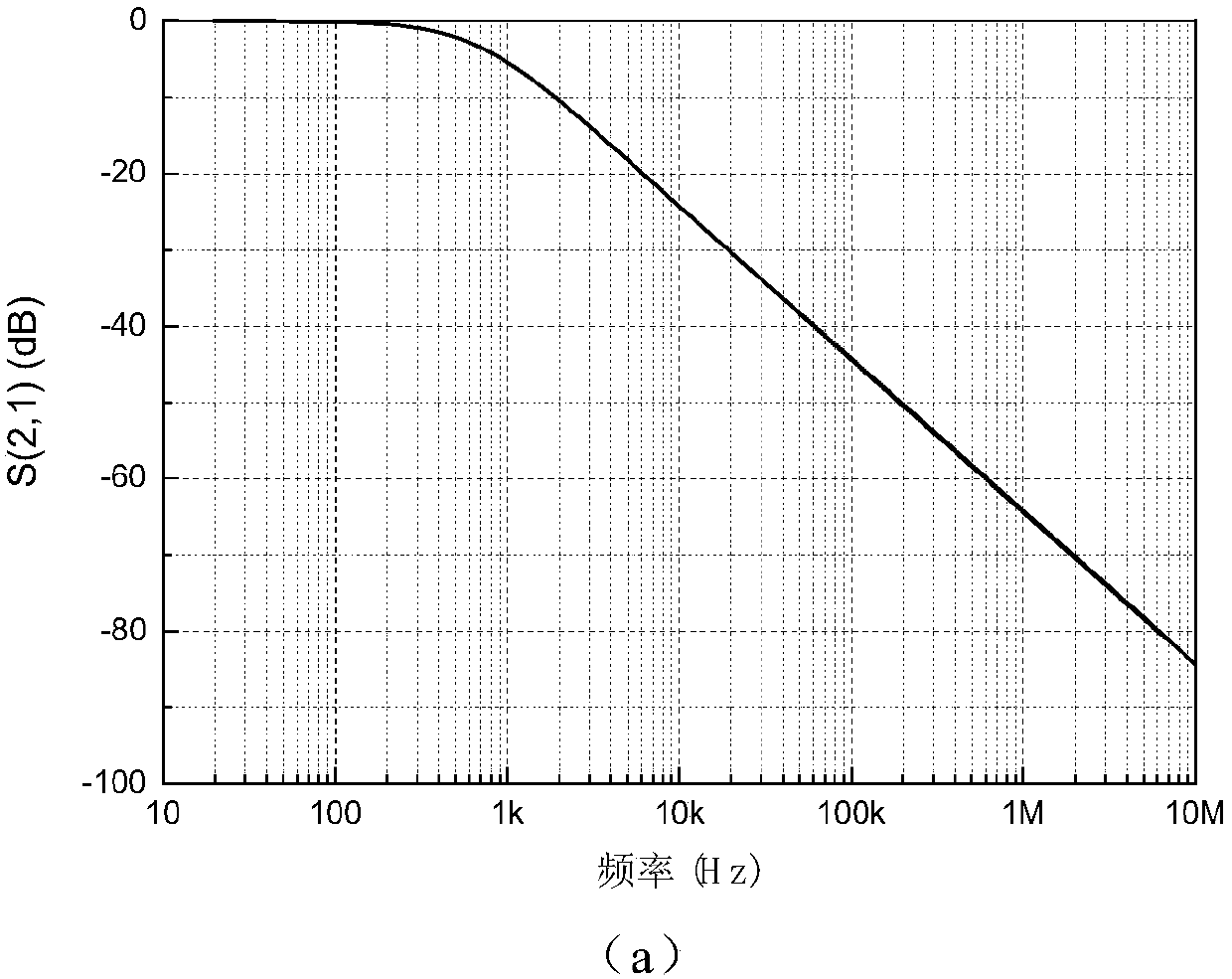

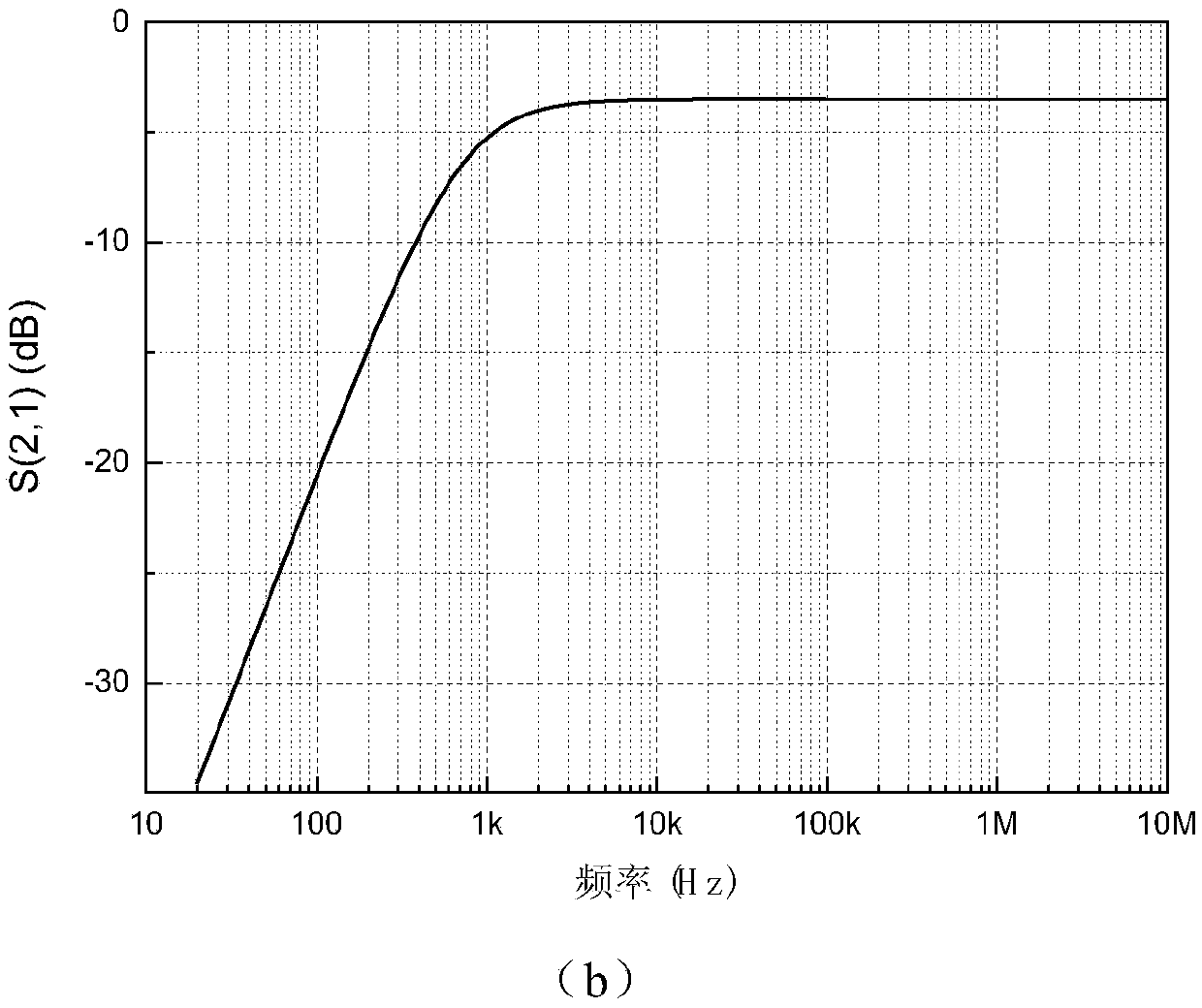

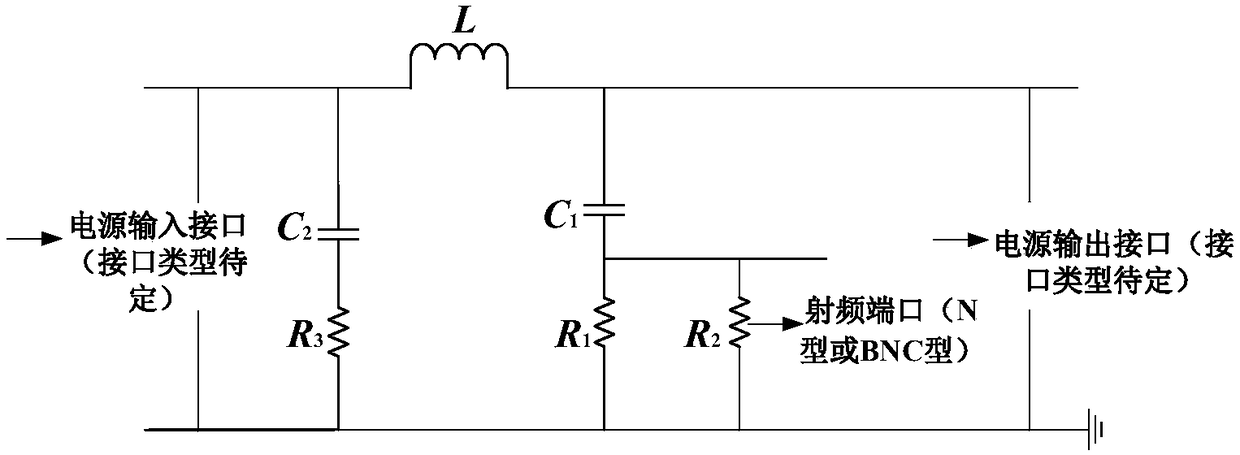

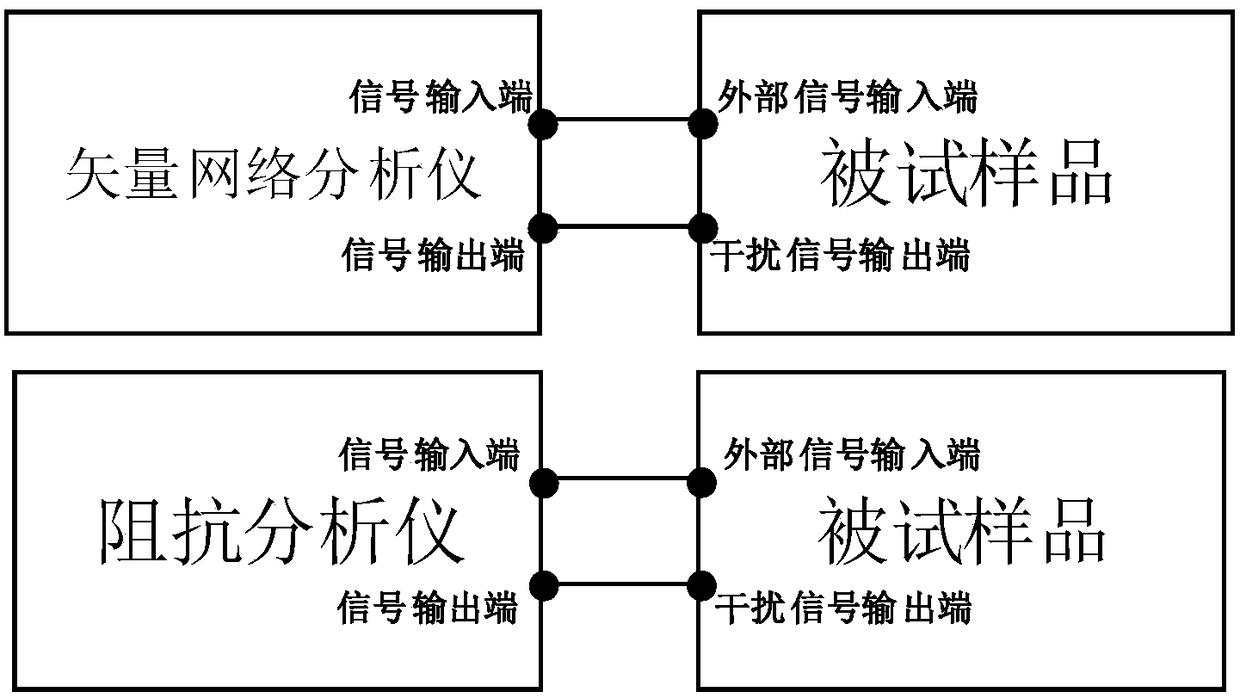

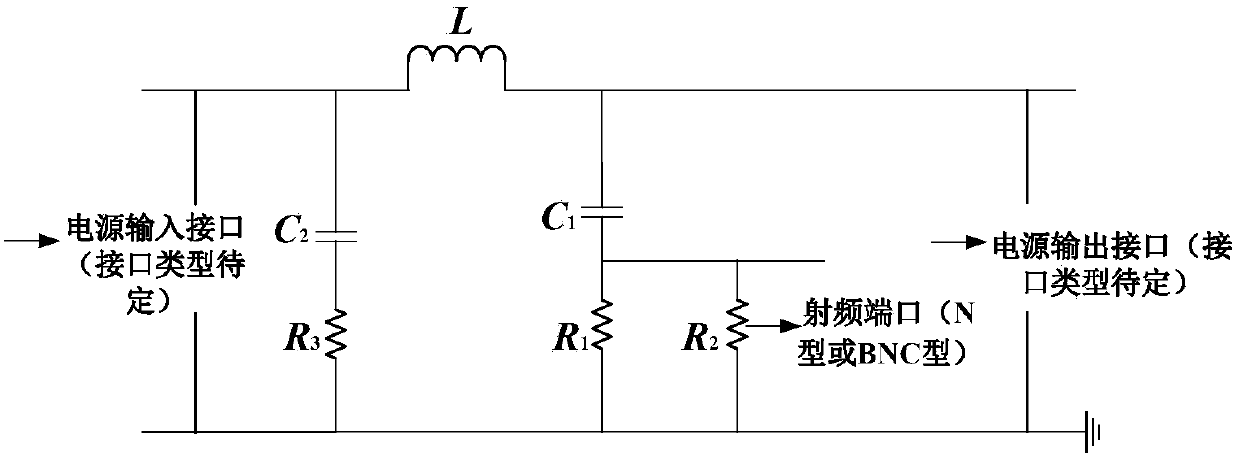

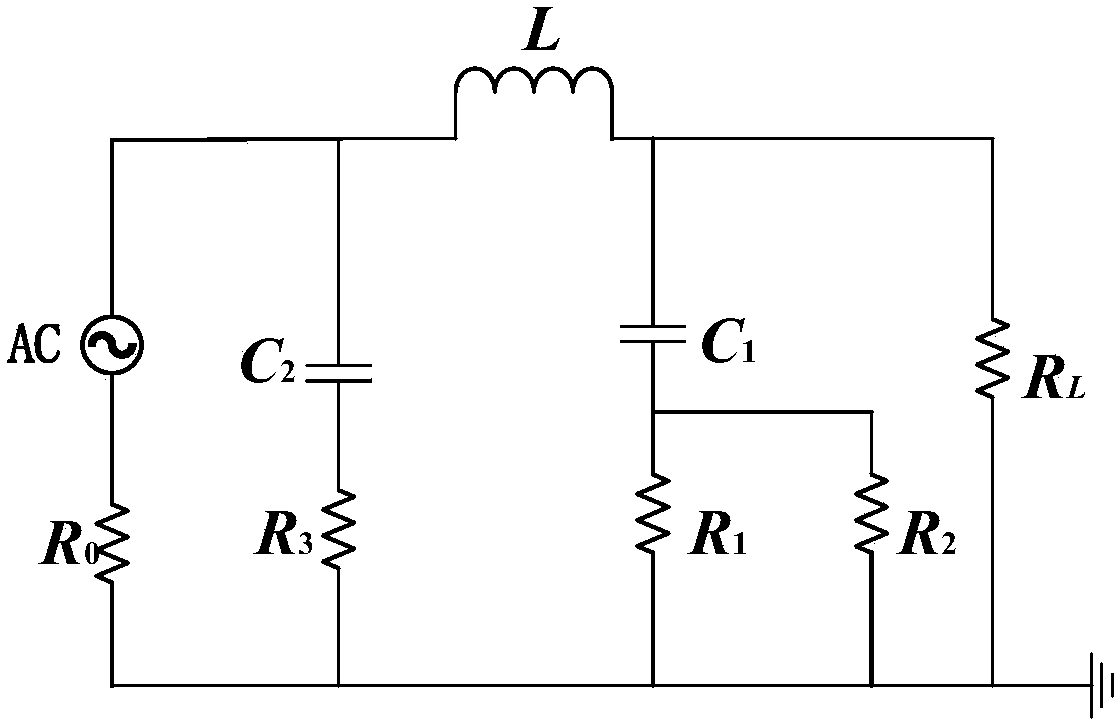

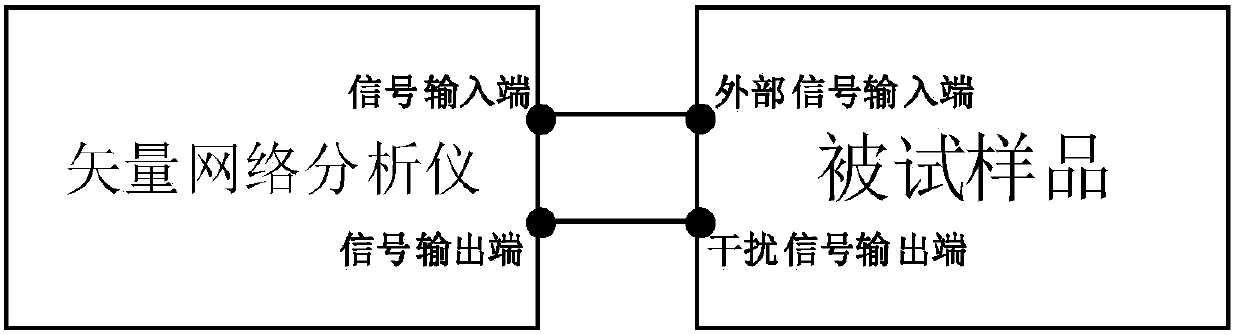

Coupling and decoupling characteristic determining method of V-type line impedance stabilization network

ActiveCN106199476AHigh hardware requirementsLow costResistance/reactance/impedenceThird partyCoupling

The invention discloses a coupling and decoupling characteristic determining method of a V-type line impedance stabilization network and belongs to the electromagnetic compatibility conducted emission testing technical field. According to the method, the coupling and decoupling characteristics of the V-type line impedance stabilization network can be calculated and analyzed; and as for a line impedance stabilization network (LISN) of which the component parameters are known, whether the coupling and decoupling characteristics of the LISN satisfy work requirements can be predicted in the aspect of trend. The method can predict and judge the coupling and decoupling characteristics of the LISN according to which a third party metering check unit does not carry out metering, and plays a role of guiding the design and development of novel LISN which can better satisfy requirements.

Owner:BEIHANG UNIV

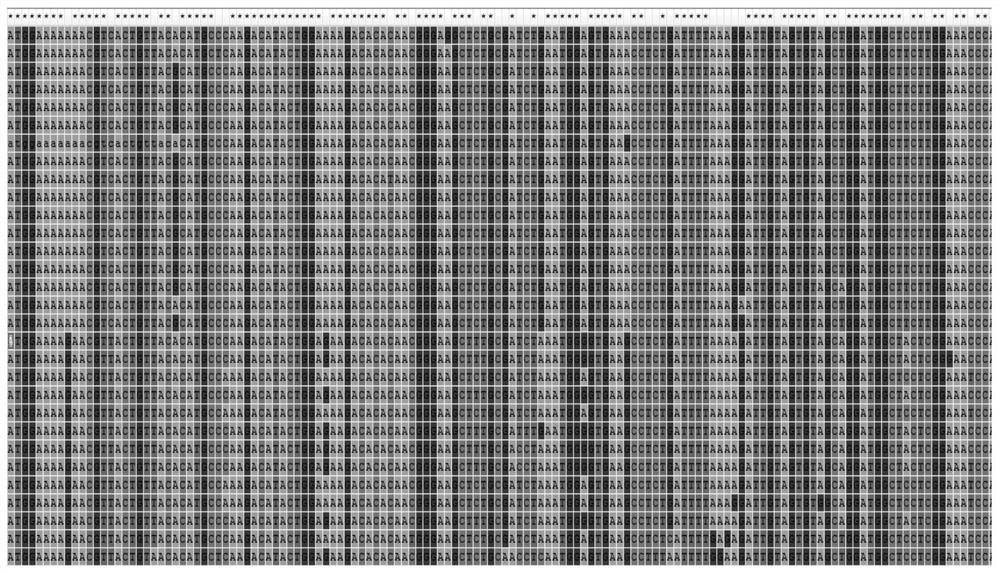

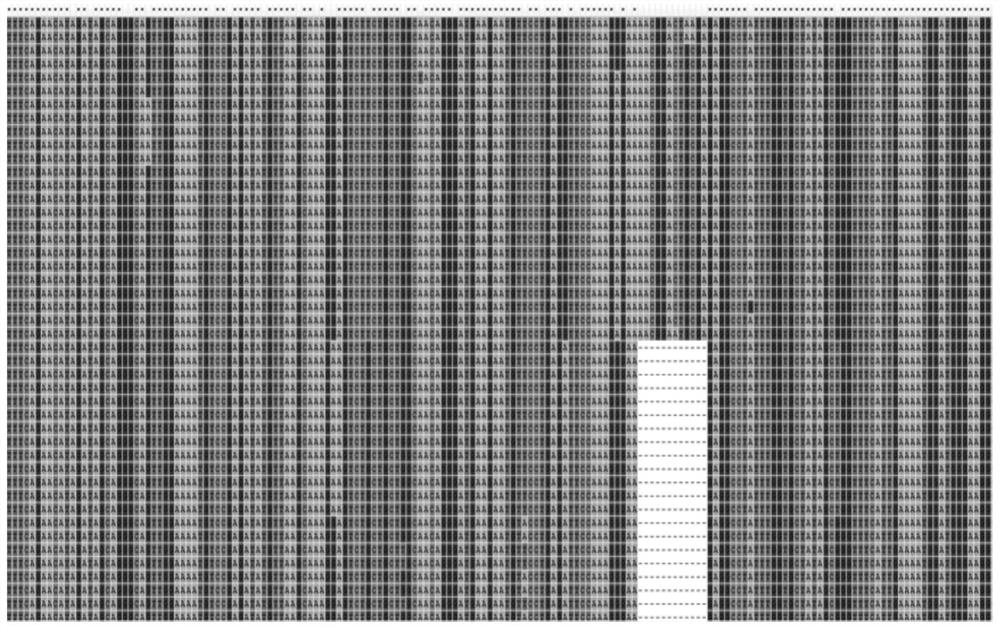

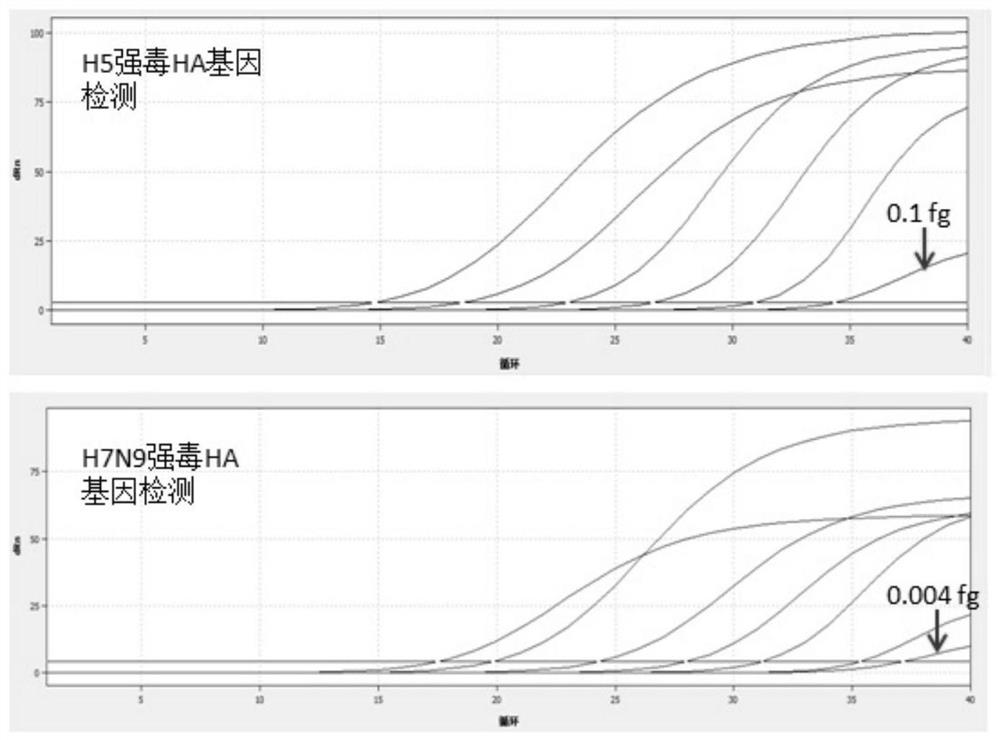

Detection method for H5 and H7N9 subtype high-pathogenicity avian influenza viruses

ActiveCN109554507AHigh sensitivityShort detection timeMicrobiological testing/measurementMicroorganism based processesNucleotideVirus influenza

The invention provides a fast detection method for detecting and distinguishing H5 and H7N9 subtype high-pathogenicity avian influenza viruses at the same time. The nucleotide sequences of HA genes ofan H5 subtype high-pathogenicity avian influenza virus and an H7N9 subtype high-pathogenicity avian influenza virus separated in recent years are respectively compared, a primer and a probe are designed at a conserved region, and a fast detection method for nucleic acid in accordance with the H5 and H7N9 subtype high-pathogenicity avian influenza viruses in a real-time fluorescent quantitative RT-PCR method is established. A real-time fluorescent RT-PCR method for the H5 and H7N9 subtype high-pathogenicity avian influenza viruses provided by the invention is high in sensitivity and short in detection time, open loops of electrophoresis and the like are not needed, only one fluorescent PCR apparatus is needed, and detection of two subtype avian influenza viruses can be completed in an airtight reaction tube; and besides, in the detection course, a reaction curve can be examined in a real-time manner, and results can be quickly judged.

Owner:CHINA ANIMAL HEALTH & EPIDEMIOLOGY CENT

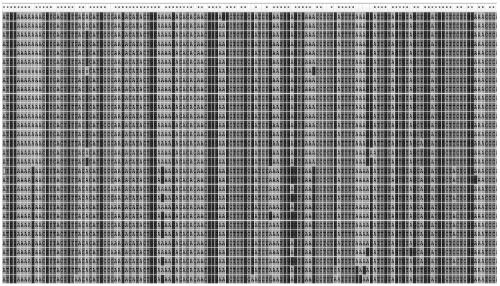

High-speed bullet train side window model boundary displacement calculation method and bonding strength calculation method based on RS mapping

InactiveCN106777592AReduce the impactImprove analysis accuracyGeometric CADDesign optimisation/simulationBoundary displacementAdhesive

Provided is a high-speed bullet train side window model boundary displacement calculation method based on RS mapping. The method comprises the steps that an overall model of a high-speed bullet train body and a side window structure is built, a local model of a side window is built, displacement and coordinates of all nodes in the overall model under various working conditions are obtained, and displacement interpolation parameter calculation is conducted on all nodes on the boundary of the local model; displacement of all the nodes on the boundary of the local model is obtained according to the displacement interpolation parameters and displacement of a specified node, displacement of the node is loaded to the local model of the side window, the bonding strength of the side window is analyzed, and stress and deformation of a side window adhesive are obtained. The invention provides a high-speed bullet train side window bonding strength calculation method.

Owner:JILIN UNIV

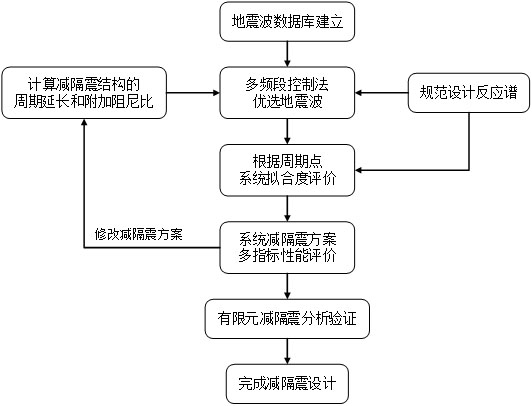

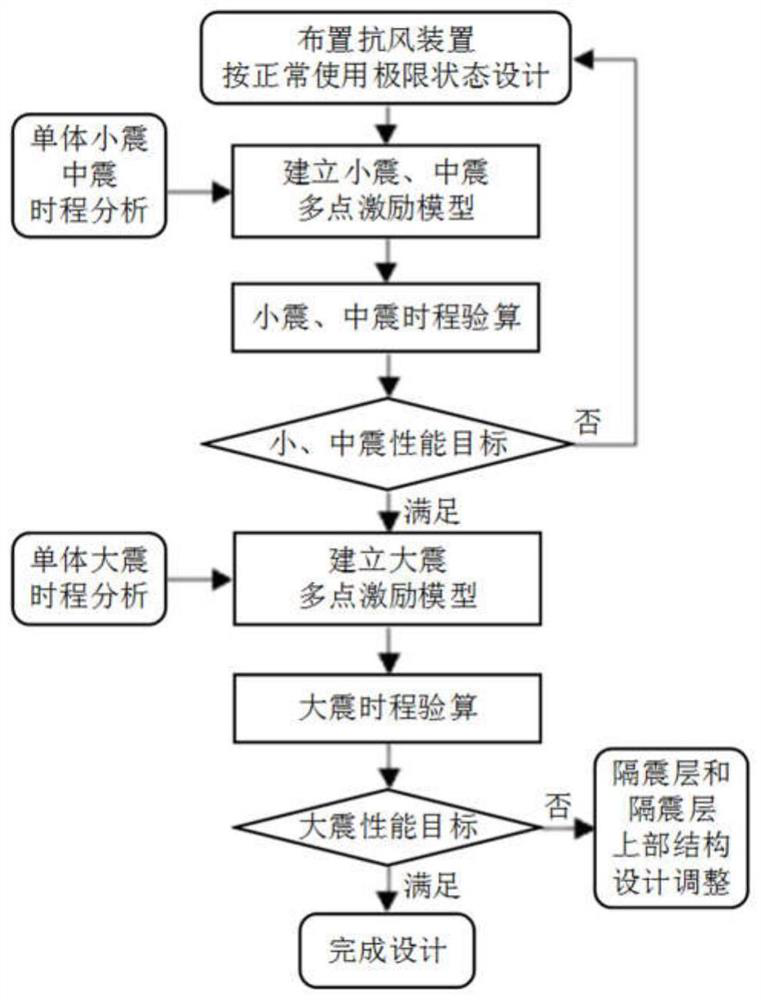

Wave selection and efficient design method and system for seismic mitigation and isolation structure

ActiveCN113094793AEfficient and accurate wave selectionResolve accuracyGeometric CADDesign optimisation/simulationMulti bandEvaluation result

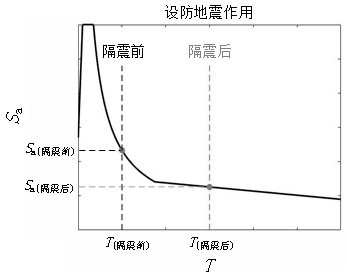

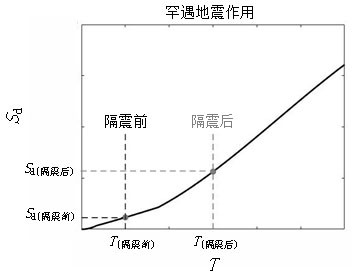

The invention discloses a seismic mitigation and isolation structure wave selection and efficient design system. The method comprises the following steps: establishing a seismic wave database; preliminarily arranging a seismic mitigation and isolation scheme, and calculating the period extension or additional damping ratio of the seismic mitigation and isolation structure; determining a standard design spectrum of a certain site; preferably selecting seismic waves in the seismic wave database according to a multi-band control method; performing systematic calculation of the fitting degree of the standard design spectrum and the seismic wave response spectrum; designing a response spectrum in combination with fortification and rare occurrence earthquakes, and performing systematic multi-index evaluation on the seismic mitigation and isolation scheme effect; modifying the scheme according to the evaluation result until the system evaluation requirement is met; carrying out finite element software seismic mitigation and isolation analysis verification; and completing the shock absorption and isolation design. The high-efficiency seismic mitigation and isolation design method is realized, an analysis and evaluation system is comprehensively designed, an integrated operation process is realized, the calculation and analysis efficiency is greatly improved, the number of repeated iterations in the seismic mitigation and isolation design process is reduced, and the method is suitable for popularization and application of high-efficiency seismic mitigation and isolation design in various regions.

Owner:云南省设计院集团有限公司

Text image direction correction method and device

PendingCN111353493AImprove efficiency and accuracyImprove accuracyCharacter and pattern recognitionMachine learningDimensionality reductionAlgorithm

The invention provides a text image direction correction method and device, and the method comprises the steps: intercepting a pixel block of a target printed single character from a target text imageaccording to a preset interception rule, and generating a printed character matrix corresponding to the pixel block; respectively obtaining a first dimension reduction vector corresponding to the printing word matrix and a second dimension reduction vector corresponding to the rotated printing word matrix by applying a preset principal component analysis model, wherein the principal component analysis model is an unsupervised machine learning model which is obtained by pre-training and is used for determining the characteristics of the printing word matrix; obtaining a target row vector corresponding to the first dimension reduction vector from a pre-obtained feature vector library, and obtaining an inclination angle and an inclination direction of a target text image according to the first dimension reduction vector, the second dimension reduction vector and the target row vector so as to correct the direction of the target text image. The accuracy and efficiency of recognizing the inclination angle of the text image can be improved, and then the accuracy and efficiency of text image direction correction are improved.

Owner:INDUSTRIAL AND COMMERCIAL BANK OF CHINA

V-type line impedance stabilization network isolation determination method

ActiveCN106018976AHigh hardware requirementsLow costResistance/reactance/impedenceMeasurement and VerificationNetwork isolation

The invention discloses a V-type line impedance stabilization network isolation determination method, and belongs to the technical field of electromagnetic compatibility conduction emission test. According to the method, isolation of a V-type line impedance stabilization network can be analyzed through calculation. As for the LISN of which the component parameters are known, whether the isolation performance of the LISN meets the working requirements can be predicted and judged by the method. The method has a reference function for measurement and verification of the isolation index of the V-type line impedance stabilization network and has directive significance for design and development and production of the novel LISN of which the performance further meets the requirements.

Owner:BEIHANG UNIV

Rapid detection method for distinguishing strong and weak toxicities of H7N9 subtype bird flu virus

ActiveCN109680101AQuick judgmentHigh sensitivityMicrobiological testing/measurementDNA/RNA fragmentationFluorescenceNucleotide

The invention provides a rapid detection method for distinguishing strong and weak toxicities of H7N9 subtype bird flu virus. A real-time fluorescent quantitation RT-PCR nucleic acid rapid detection method for distinguishing strong and weak toxicities of H7N9 subtype bird flu virus is established by comparing nucleotide sequences of HA and NA genes of H7N9 subtype bird flu virus separated in recent years and respectively designing a primer and a probe in a conservation zone thereof. According to the real-time fluorescent quantitation RT-PCR nucleic acid rapid detection method for distinguishing strong and weak toxicities of H7N9 subtype bird flu virus provided by the invention, strong and weak toxicities of H7N9 subtype bird flu virus can be detected and distinguished in a same reaction tube and the H7N9 subtype bird flu virus can be detected; the rapid detection method has high sensitivity and short detection time; open links, such as electrophoresis, are not required; only a fluorescent PCR instrument is required for finishing the detection in an airtight reaction tube; during the detection process, a reaction curve can be checked in real time and a result can be quickly judged.

Owner:CHINA ANIMAL HEALTH & EPIDEMIOLOGY CENT

Aerostat main cable surface defect detection method and system based on small sample learning

The invention provides an aerostat main cable surface defect detection method and system based on small sample learning. The method comprises the following steps: setting a system software and hardware environment; aerostat main cable surface images are collected and processed through preset adversarial network expansion, cable surface enhanced image data are obtained and marked, and a defect sample library is constructed according to the cable surface enhanced image data; designing a network model according to a DenseNet network and main cable defect characteristics, constructing the network model by using small sample learning, and training the network model according to a defect sample library; processing the query set in the defect sample library by using the trained network model and using a yolov4 single-stage detection algorithm so as to obtain shallow texture features and high-level semantic features; the structure of a DenseNet network of a network model is utilized, shallow texture features are transmitted to high-level semantic features through jump connection, and the high-level semantic features are processed through metric logic; and selecting and acquiring surface defect detection data of the main cable of the aerostat in different modes at the terminal. The technical problems of high defect omission ratio, high false detection rate and low detection efficiency are solved.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 38 RES INST

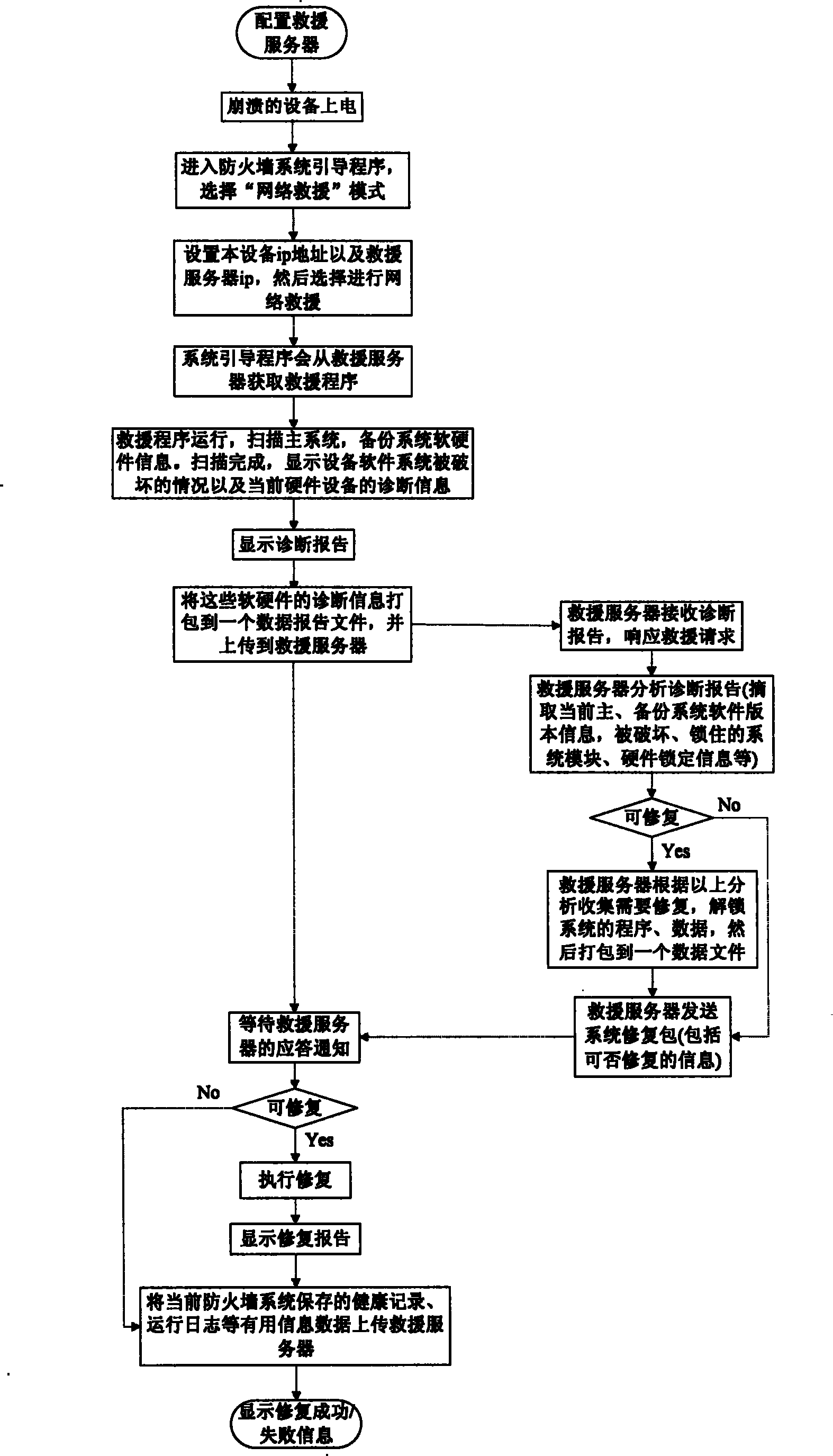

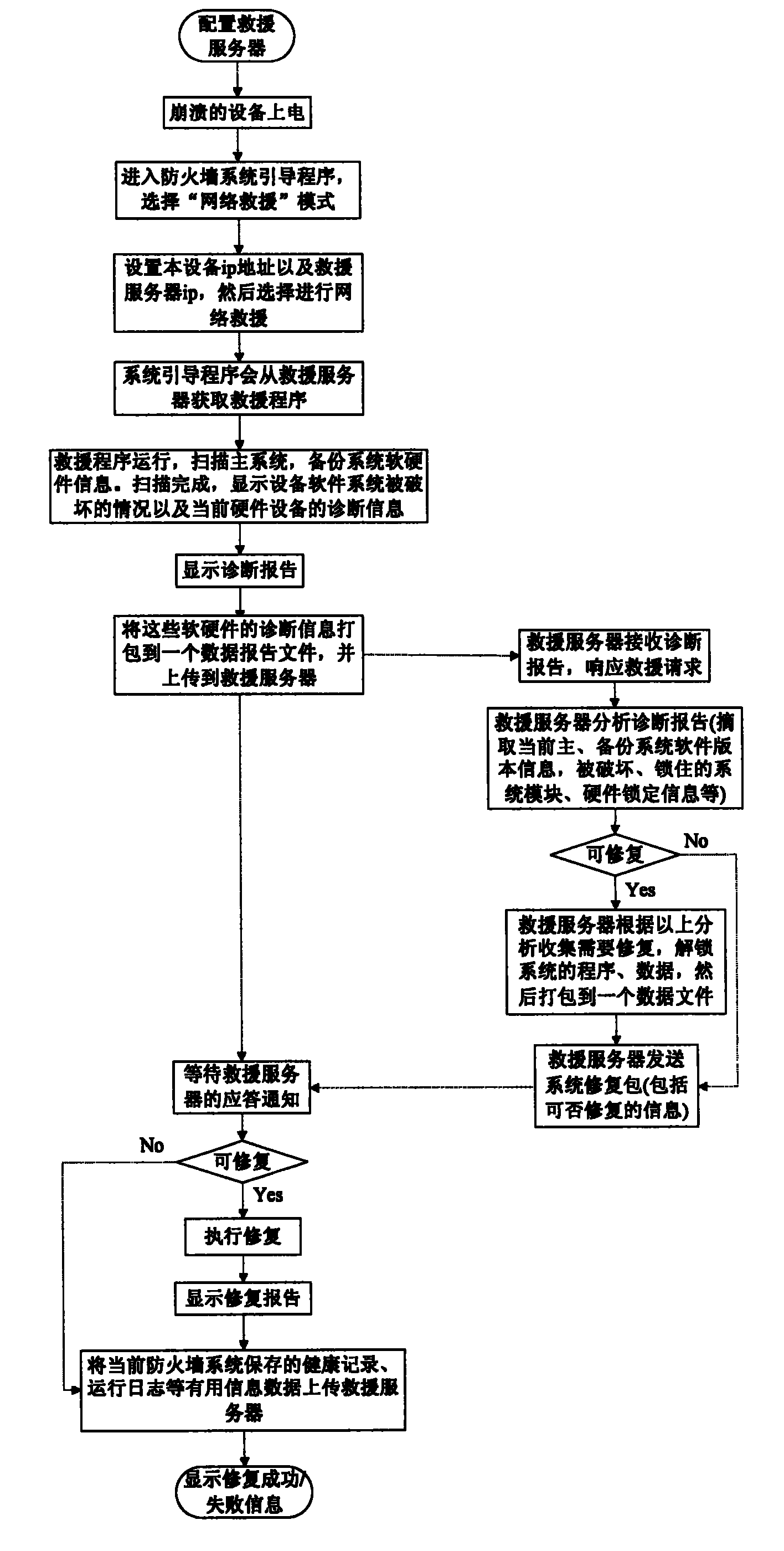

Automatic repair method for firewall system

ActiveCN101242260BAvoid development workloadAvoid development complexitySoftware testing/debuggingSecuring communicationSoftware systemData file

The invention discloses an automatic repair method for a firewall system, comprising: configuring an emergency server; after powering on a crashed equipment, entering a firewall system bootstrap program, connecting to the emergency server, and downloading an emergency repair program; the emergency repair program enters a crashed system to perform a scan to obtain a broken condition of the equipment software system and a diagnostic message of the hardware; packing the diagnostic message to a data report file, and uploading the data report file to the emergency server; the emergency server receives and analyzes the diagnostic report; if the firewall system can be repaired, the emergency server collects programs and data required for repairing and unlocking the system based on the analysis, and packing the programs and data to a data file; the emergency server sends the data file and information whether being repaired to the crashed equipment as a system repair pack; and if the firewall system can be repaired, an emergency repair program in the crashed equipment carries out a repair. The invention increases the reliability of the firewall system.

Owner:BEIJING TOPSEC NETWORK SECURITY TECH

A rapid detection method for distinguishing between strong and weak viruses of h7n9 subtype avian influenza virus

ActiveCN109680101BQuick judgmentHigh sensitivityMicrobiological testing/measurementDNA/RNA fragmentationNucleotideBird flu (avian influenza)

The invention provides a rapid detection method for distinguishing the strong and weak viruses of H7N9 subtype avian influenza virus. By comparing the nucleotide sequences of the HA and NA genes of the H7N9 subtype avian influenza virus isolated in recent years, they are respectively designed in their conserved regions. Primers and probes were identified, and a real-time fluorescence quantitative RT-PCR nucleic acid rapid detection method that can distinguish between strong and weak H7N9 subtype avian influenza virus was established. The real-time fluorescent RT-PCR method for distinguishing the strong and weak viruses of the H7N9 subtype avian influenza virus provided by the present invention can detect and distinguish the strong and weak viruses of the H7 subtype avian influenza virus in the same reaction tube, and can also detect the N9 subtype bird flu virus. It has high sensitivity, short detection time, and does not require open links such as electrophoresis. It can be completed in a closed reaction tube with only one fluorescent PCR instrument, and the reaction curve can be viewed in real time during the detection process to make a quick judgment on the result.

Owner:CHINA ANIMAL HEALTH & EPIDEMIOLOGY CENT

An intelligent management system and intelligent management method

InactiveCN103632122BMiniaturizationVarious shapesLogisticsSensing by electromagnetic radiationNetwork managementNetwork communication

Owner:AUQMA YINAN NEW ENERGY ELECTRIC CARS

A Design Method for Shockproof and Isolated Overhead Corridor Structure in High Intensity and High Wind Pressure Area

ActiveCN113175070BAvoid Assembly WorkloadHigh hardware requirementsProtective buildings/sheltersShock proofingClassical mechanicsHigh intensity

The invention discloses a design method for an overhead corridor structure for shock absorption and isolation in areas with high intensity and high wind pressure, and relates to the design field of overhead corridor structures for shock absorption and isolation. The structural design of the overhead corridor located in a high-intensity and high-wind pressure area must ensure the limit state of the bearing capacity and the limit state of normal use at the same time. Because the single buildings on both sides of the connection usually have different natural vibration periods, the use of seismic isolation bearings in the corridor The shock-isolation layer is formed between the monomer and the horizontal force of interaction, which can greatly reduce the horizontal force of interaction, and the deformation can be suppressed through the vibration-damping device, so as to achieve a better structural design. Based on the principle of standard design spectrum, the invention proposes a design method for seismic-isolation overhead corridors suitable for high-intensity and high-wind pressure areas in view of the situation that the lower part of the seismic-isolation layer is a building structure and the quality of the upper structure of the seismic-isolation layer is smaller than that of the lower structure . The invention obtains the excitation at the support of the corridor through the single seismic response, and obtains the horizontal seismic design spectrum used in the design of the upper structure of the seismic isolation layer of the corridor through envelope regression.

Owner:ZHEJIANG UNIV

Boundary Displacement Calculation Method and Adhesive Strength Calculation Method of Side Window Model of High Speed Train Based on rs Mapping

InactiveCN106777592BImprove analysis accuracyImprove interpolation accuracyGeometric CADDesign optimisation/simulationBoundary displacementEngineering

Provided is a high-speed bullet train side window model boundary displacement calculation method based on RS mapping. The method comprises the steps that an overall model of a high-speed bullet train body and a side window structure is built, a local model of a side window is built, displacement and coordinates of all nodes in the overall model under various working conditions are obtained, and displacement interpolation parameter calculation is conducted on all nodes on the boundary of the local model; displacement of all the nodes on the boundary of the local model is obtained according to the displacement interpolation parameters and displacement of a specified node, displacement of the node is loaded to the local model of the side window, the bonding strength of the side window is analyzed, and stress and deformation of a side window adhesive are obtained. The invention provides a high-speed bullet train side window bonding strength calculation method.

Owner:JILIN UNIV

A Method for Determining Coupling and Decoupling Characteristics of V-type Linear Impedance Stabilized Network

ActiveCN106199476BHigh hardware requirementsLow costResistance/reactance/impedenceThird partyCoupling

Owner:BEIHANG UNIV

Design method of seismic mitigation and isolation overhead corridor structure in high-intensity and high-wind-pressure area

ActiveCN113175070AAvoid Assembly WorkloadHigh hardware requirementsProtective buildings/sheltersShock proofingEngineeringSeismic isolation

The invention discloses a design method of a seismic mitigation and isolation overhead corridor structure in a high-intensity and high-wind-pressure area, and relates to the field of design of seismic mitigation and isolation overhead corridor structures. According to the design of the overhead corridor structure located in the high-intensity and high-wind-pressure area, the bearing capacity limit state and the normal use limit state need to be guaranteed at the same time, a seismic isolation layer is formed between a corridor and the single buildings through a seismic isolation support due to the fact that the natural vibration periods of connected single buildings on the two sides are usually different, and the horizontal force of interaction can be greatly reduced; the deformation is inhibited through a damping device, so that a better structural design scheme is achieved. Based on a standard design spectrum principle, the invention provides the design method for the seismic mitigation and isolation overhead corridor suitable for the high-intensity and high-wind-pressure area aiming at the conditions that the lower part of the seismic isolation layer is a building structure and the mass of an upper structure of the seismic isolation layer is smaller than that of a lower structure. According to the design method of the seismic mitigation and isolation overhead corridor structure in the high-intensity and high-wind-pressure area, excitation at a corridor support is obtained through single earthquake response, and a horizontal earthquake design spectrum for designing the upper structure of the corridor seismic isolation layer is obtained through envelope regression.

Owner:ZHEJIANG UNIV

Artificial intelligence service system with high safety

The invention discloses an artificial intelligence service system with high security. The artificial intelligence service system comprises a cloud computing platform, a bait platform and a user terminal, wherein the cloud computing platform is used for storing and processing data and training an artificial intelligence model; the bait platform is used for receiving data sent by a user terminal, a database used for storing data is arranged in the bait platform, a converter used for reading the data and generating new data is arranged in the bait platform, and the new data generated by the converter and original data are the same in content and different in format at the same time. The cloud computing platform only receives data in a format to which new data belongs, and the new data is transmitted to the cloud computing platform; and the user terminal sends a deployment request corresponding to the artificial intelligence model to the bait platform under the triggering of a user, and receives a processing result output after processing of the cloud computing platform. By means of cooperation of the bait platform and the cloud computing platform, isolation between data uploaded by the user and the cloud computing platform is achieved, and safety is improved.

Owner:江苏欣业大数据科技有限公司

A distributed video transcoding method

ActiveCN104935951BAdapt to storage needsHigh hardware requirementsDigital video signal modificationSelective content distributionComputer architectureDistributed File System

The invention provides a distributed-based large-scale video transcoding system, which belongs to the technical field of big data and video processing. The method of the present invention adopts a distributed method on the big data processing platform Hadoop to finally realize large-scale video transcoding, the method utilizes the HDFS file system to store large-scale video data, utilizes the MapReduce programming model to carry out distributed processing, and uses the multimedia library Xuggler implements video processing. The invention utilizes the scalability and stability characteristics of the distributed file system to realize the storage and transcoding of large-scale video data, solves the shortcomings of traditional centralized storage such as high hardware requirements, difficult maintenance, and difficult expansion, and dynamically adapts to the growing Large-scale video data storage and transcoding requirements.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

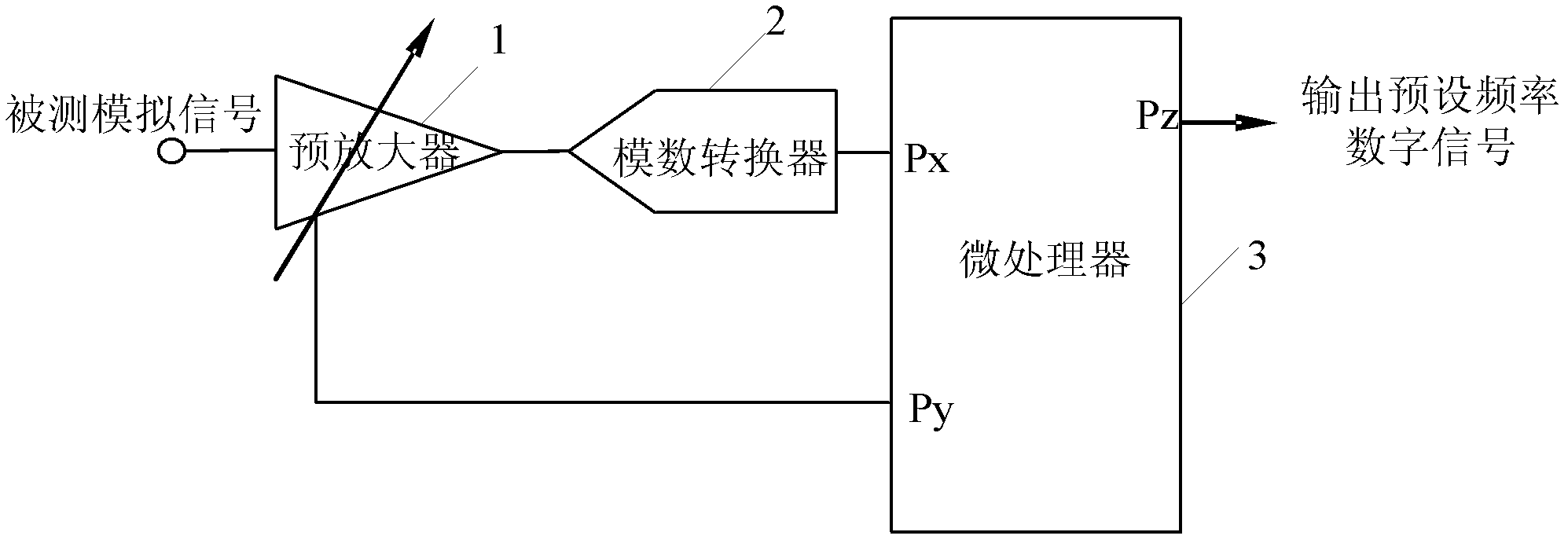

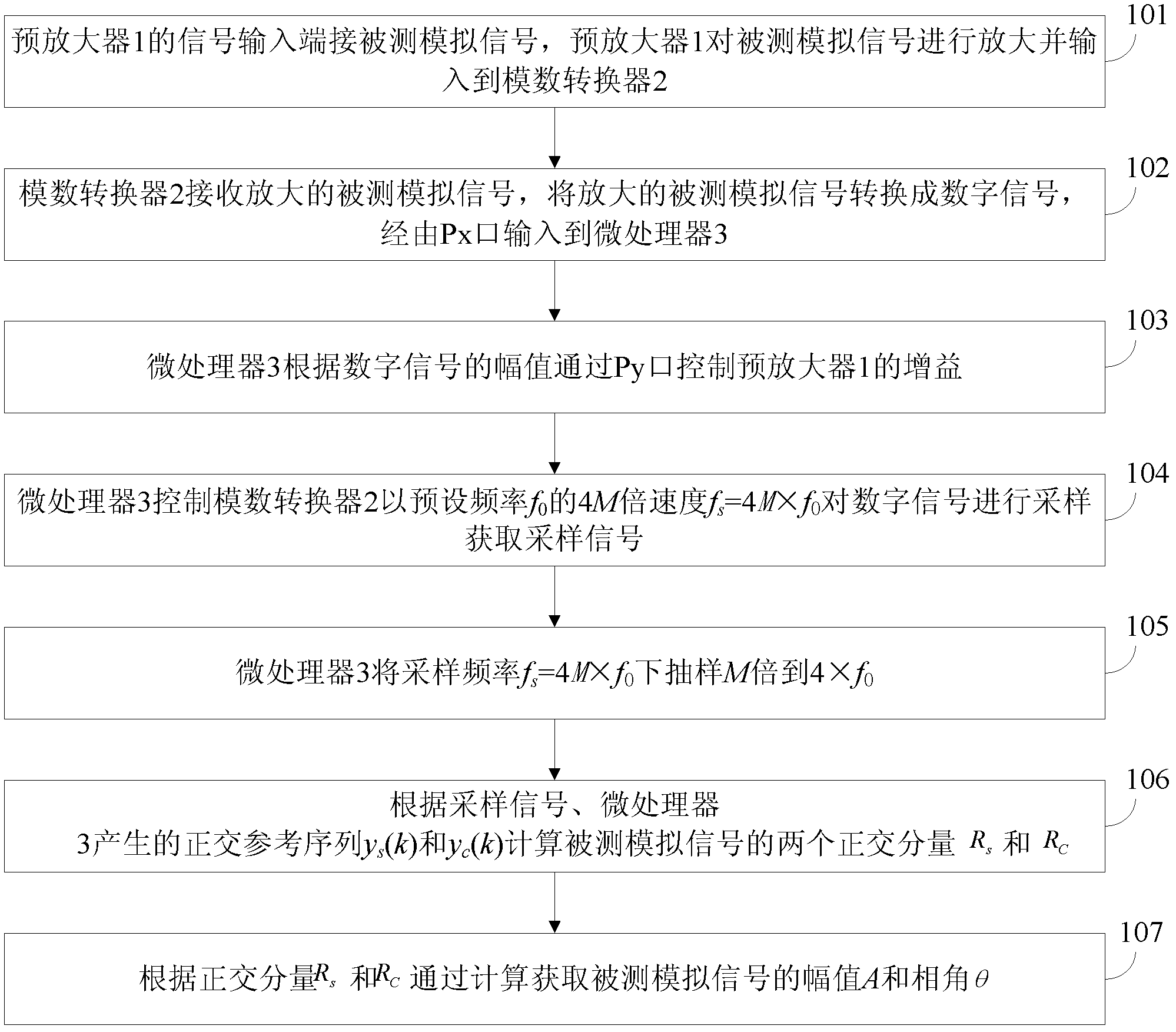

Digital phase locking amplifier and digital phase locking control method

ActiveCN102332878BImprove reliabilityHigh hardware requirementsPulse automatic controlParametric amplifiersAnalog signalEngineering

The invention discloses a digital phase locking amplifier and a digital phase locking control method. The digital phase locking amplifier comprises a pre-amplifier and a micro-processor. The pre-amplifier is used for amplifying a tested analogue signal, inputting the tested analogue signal into an analogue-digital converter, converting the amplified tested analogue signal into a digital signal, and inputting the digital signal into the micro-processor through a Px interface. The micro-processor is used for controlling the gain of the pre-amplifier through a Py interface according to the amplitude of the digital signal, processing the digital signal, detecting the digital signal with the pre-set frequency in the digital signal, and outputting the digital signal with the pre-set frequency through a Pz interface. The control method comprises the following steps: the micro-processor controls the analogue-digital converter to sample the tested analogue signal according to the speed which is 4M times of that of the pre-set frequency F0, represented in the equation of fs=4M*f0, so as to obtain a sampling signal; the micro-processor downwardly samples the sampling frequency fs=4M*f0 to 4*f0; two orthogonal components RS and RC of the tested analogue signal are calculated according to the sampling signal; and the amplitude A and the phase angle of the tested analogue signal can be obtained by calculation.

Owner:TIANJIN UNIV

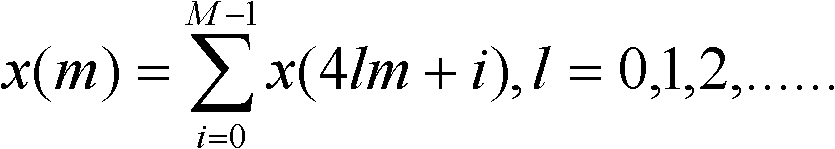

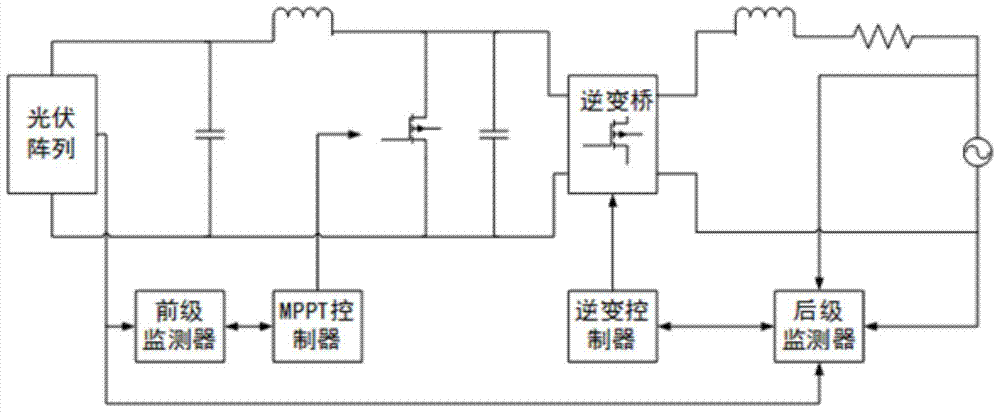

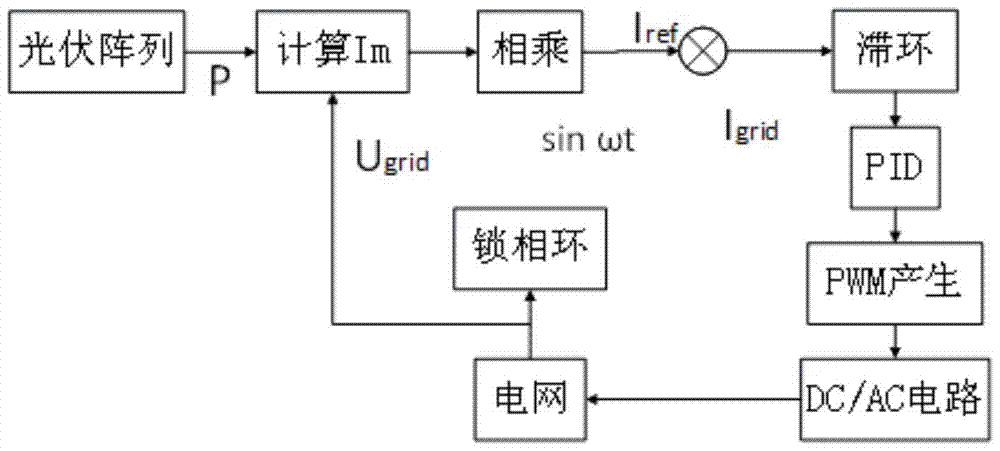

Control method of single-phase two-stage photovoltaic grid-connected system

InactiveCN104682426BStable waveformSimple calculationSingle network parallel feeding arrangementsPhotovoltaic energy generationHysteresisReference current

The invention provides a control method for a single-phase two-stage photovoltaic grid-connected system. The control method comprises the following steps: when the system operates normally, a pre-monitor monitors the output voltage and the output power of a photovoltaic array to select a proper sampling frequency for sampling to obtain a voltage value and a power value of each sampling moment and transmits the values to an MPPT (maximum power point tracking) controller for calculation; under the control of an inversion circuit, a post-monitor transmits acquired data of the output power and the power grid voltage of the photovoltaic array to an inversion controller, and a phase signal, generated by the power grid voltage data, of reference current through a phase-locked loop is also input into the inversion controller, and the data are multiplied with the phase signal to obtain a reference current signal, and actual grid-connected current and the reference current generate corresponding PWM (pulse width modulation) through a comparator, a hysteresis process and a PID (proportion-integral-differential) process to control on and off of a switch tube of the inversion circuit. According to the control method, a good control effect on the single-phase two-stage photovoltaic grid-connected system is achieved, so that the maximum output power of the photovoltaic array is guaranteed, and the unit factor control of the inversion circuit can be also guaranteed.

Owner:SHANGHAI JIAO TONG UNIV

A detection method for h5 and h7n9 subtype highly pathogenic avian influenza virus

ActiveCN109554507BHigh sensitivityShort detection timeMicrobiological testing/measurementMicroorganism based processesNucleotideAvian virus

Owner:CHINA ANIMAL HEALTH & EPIDEMIOLOGY CENT

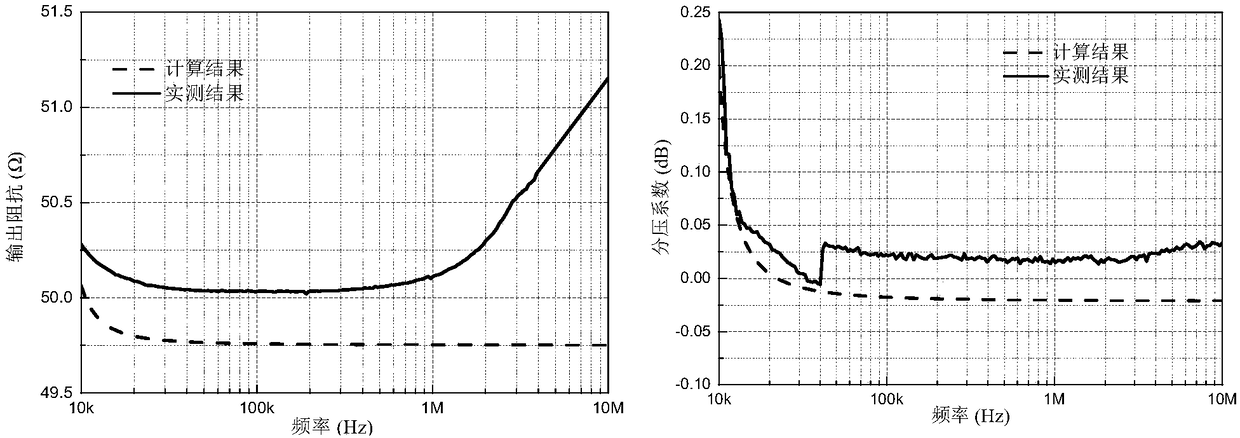

A method for determining the output impedance and voltage division coefficient of a v-type linear impedance stabilization network

ActiveCN106053959BHigh precisionImprove efficiencyResistance/reactance/impedenceDisturbance voltageEngineering

The invention, which belongs to the technical field of the electromagnetic-compatibility conducted emission testing, discloses a method for determining an output impedance and a voltage division coefficient of a V type line impedance stabilization network (LISN). According to the method, for an LISN with known element parameters in a description, the output impedance and voltage division coefficient of the LISN can be obtained based on calculation and analysis; and a tested piece interference voltage value that is measured practically by a receiver during a testing process can be corrected. According to the invention, the method plays an important role in correcting a conducted emission testing result and has guiding significance in improving the conducted emission testing precision.

Owner:BEIHANG UNIV

A Method for Determining the Isolation Degree of a V-Type Linear Impedance Stabilized Network

ActiveCN106018976BHigh hardware requirementsLow costResistance/reactance/impedenceNetwork isolationMeasurement and Verification

Owner:BEIHANG UNIV

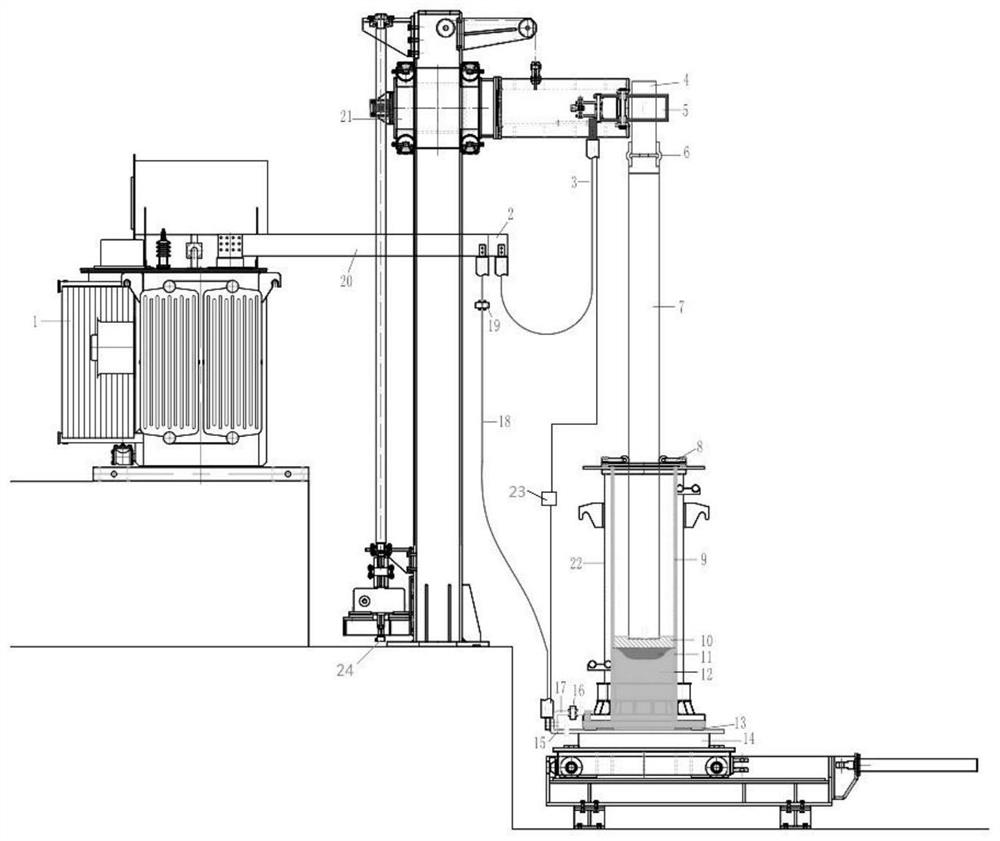

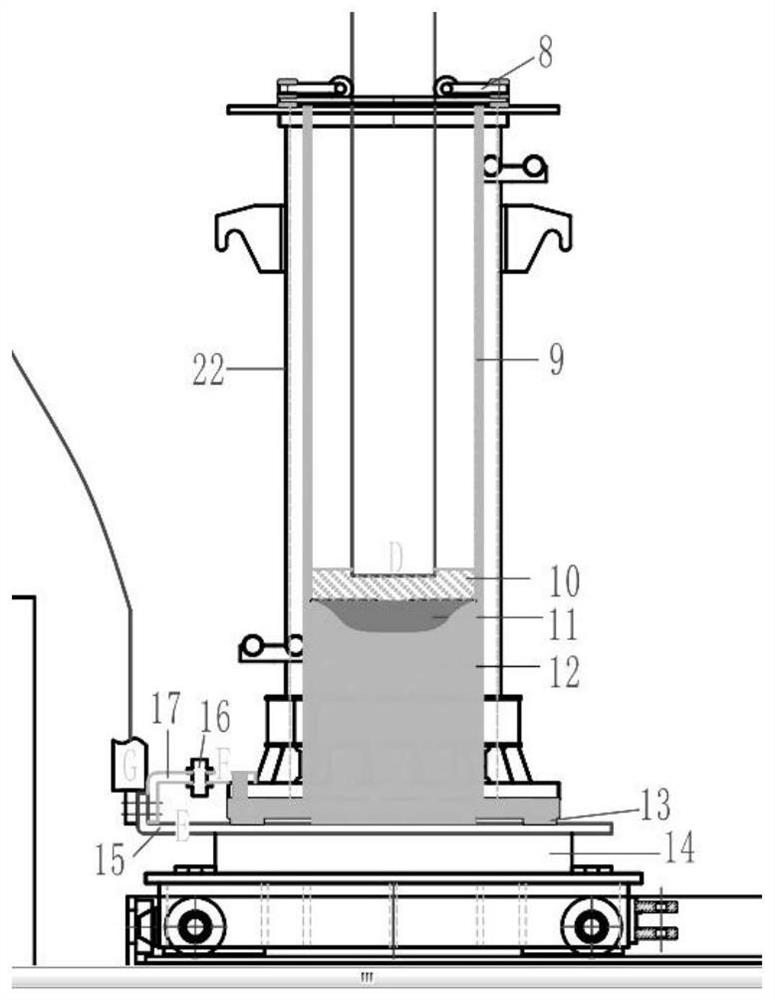

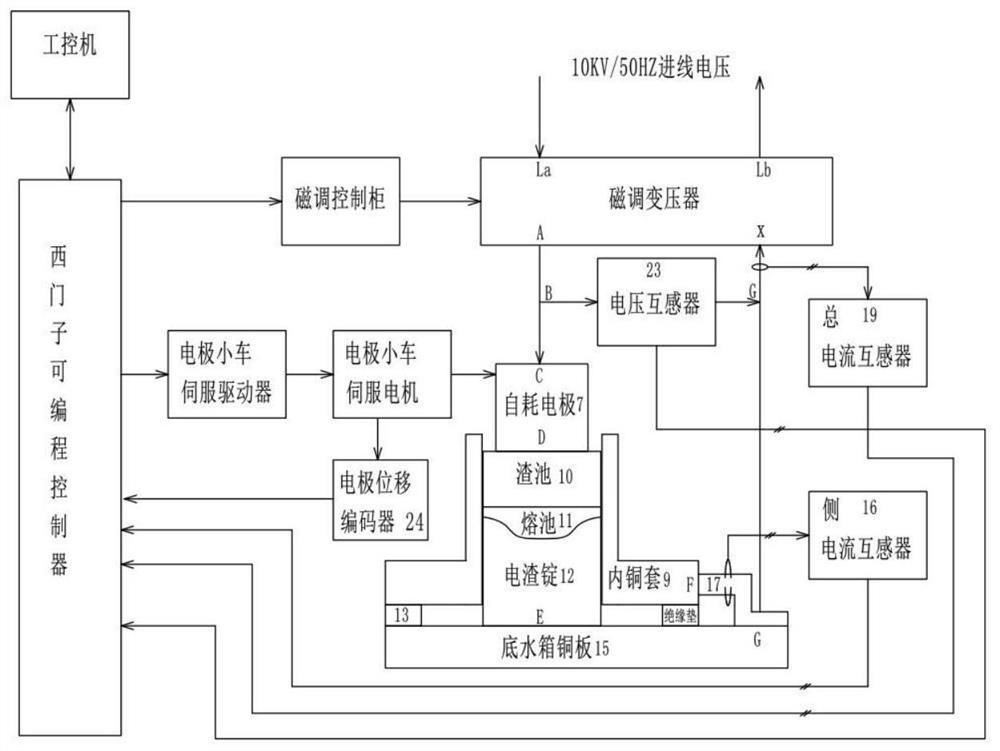

Conductive type fixed crystallizer constant melting speed side flow control electroslag furnace and constant melting speed control method

InactiveCN112760491AAdd current detectionOvercome the difficulty of not being able to effectively measure the slag surface voltageSlagCopper electrode

The invention discloses a conductive type fixed crystallizer constant melting speed side flow control electroslag furnace and a constant melting speed control method. The furnace comprises a smelting transformer, a secondary side a-phase output copper bar, an a-phase water-cooled cable, an electrode false head, a copper electrode chuck, an electrode flexible connector, an electrode, an insulation type electrode centering frame, a conductive type fixed crystallizer, a high-temperature-resistant insulation cushion layer, a bottom water tank, a bottom water tank copper plate, a side current transformer, a side current flexible connector, an x-phase water-cooled cable, a total current transformer, a secondary side x-phase output copper bar, an electrode lifting trolley, a furnace mouth voltage transformer and an electrode displacement encoder. The method comprises the following steps: presetting an electrode voltage drop rate table of a furnace mouth voltage and an electrode length, automatically searching the table by a program, calculating a voltage drop on the length of an unmelted electrode, calculating a slag surface voltage of the electrode between a slag bath end and a crystallizer, dividing the slag surface voltage by a side current by the program to obtain a slag surface resistance value, taking the slag surface resistance value as a correction parameter of a melting speed control ring, and finely adjusting the descending speed of the electrode, so that large fluctuation of the insertion depth caused by unsatisfactory actual working conditions is compensated for.

Owner:ZHONGXING ENERGY EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com