Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "High capacity recovery rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

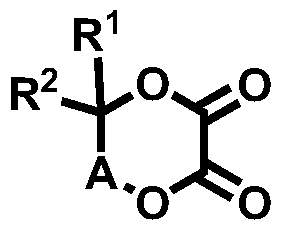

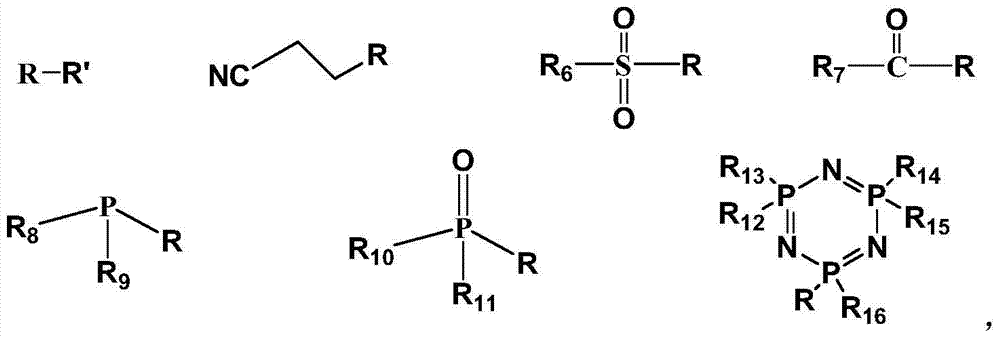

Lithium-ion battery electrolyte for high-voltage ternary positive electrode material system

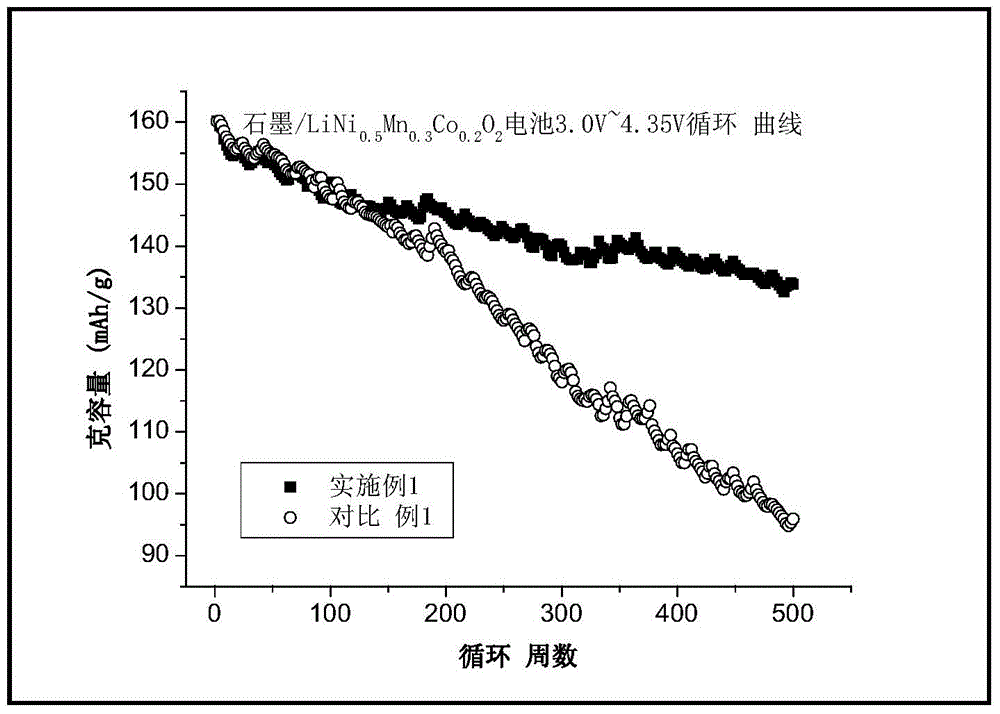

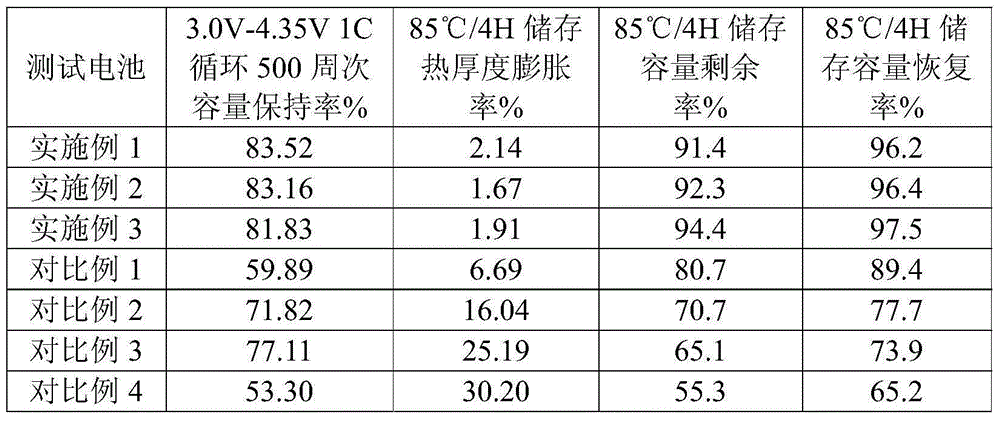

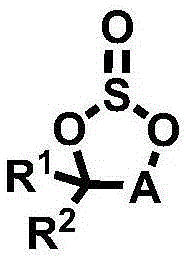

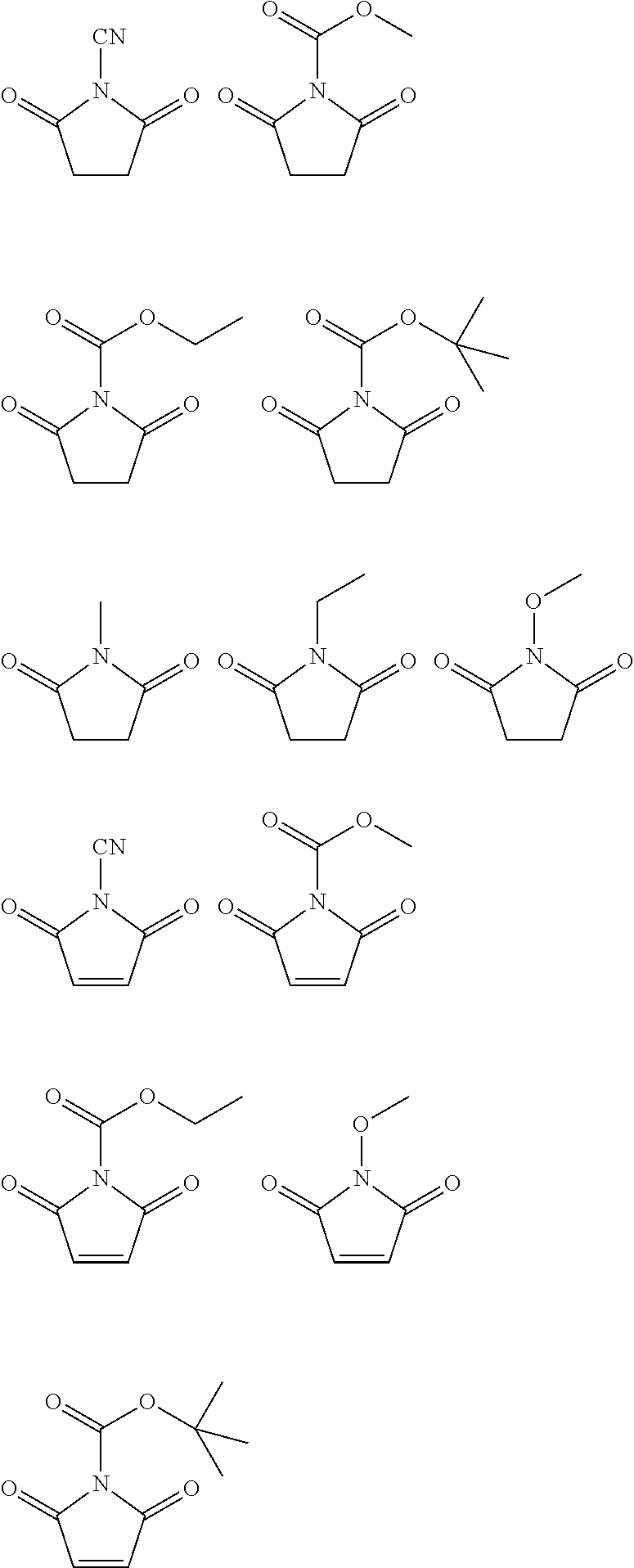

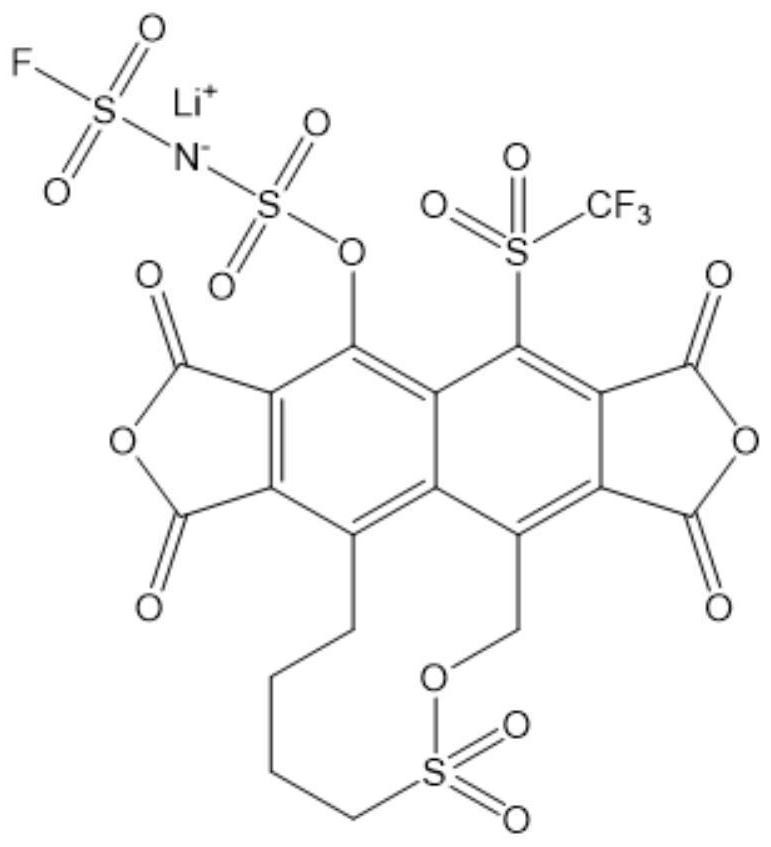

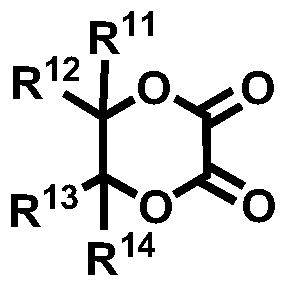

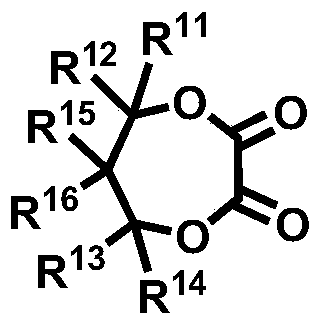

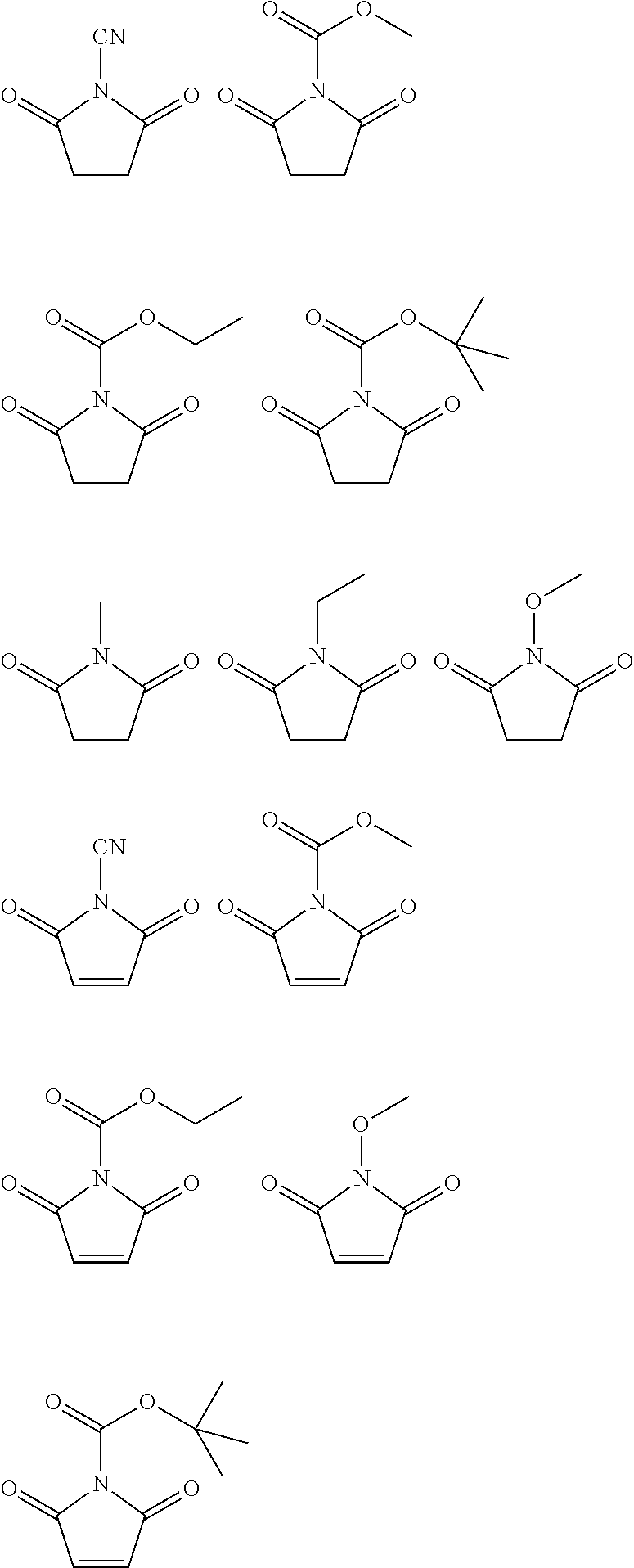

ActiveCN105140564AImprove cycle performanceImprove high temperature performanceSecondary cellsOrganic electrolytesSolventStructural formula

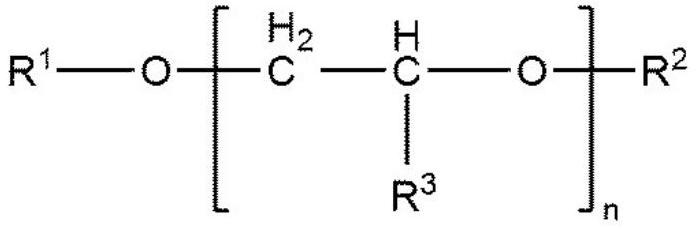

The invention provides a lithium-ion battery electrolyte for a high-voltage ternary positive electrode material system. The lithium-ion battery electrolyte comprises a non-aqueous solvent, lithium hexafluorophate and a functional additive; the functional additive comprises a cyclic anhydride compound, a lithium salt type additive and methylene methanedisulfonate; the general structural formula of the cyclic anhydride compound is as shown in the description, wherein R1, R2, R3 and R4 are independently selected from any one of hydrogen atom, fluorine atom, or straight chain or branched chain alkyl with the number of carbon atoms of 1-4. The cyclic anhydride compound used in the lithium-ion battery electrolyte is higher in reduction potential (the reduction potential of succinic anhydride is 1.50 V vs Li+ / Li) on the negative electrode surface, so that other components in the electrolyte can be preferably reduced into films in the first charging process of the battery, the formed SEI film is high in stability. The cyclic anhydride compound used in the lithium-ion battery electrolyte is capable of effectively improving the cycle performance and high-temperature performance of the battery; and compared with fluoroethylene carbonate, the cyclic anhydride compound has excellent high-temperature performance as well as capability of improving the cycle performance.

Owner:GUANGZHOU TINCI MATERIALS TECH

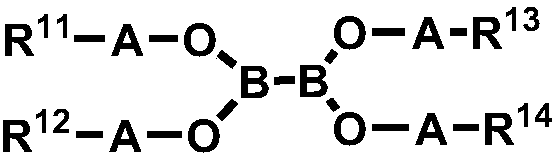

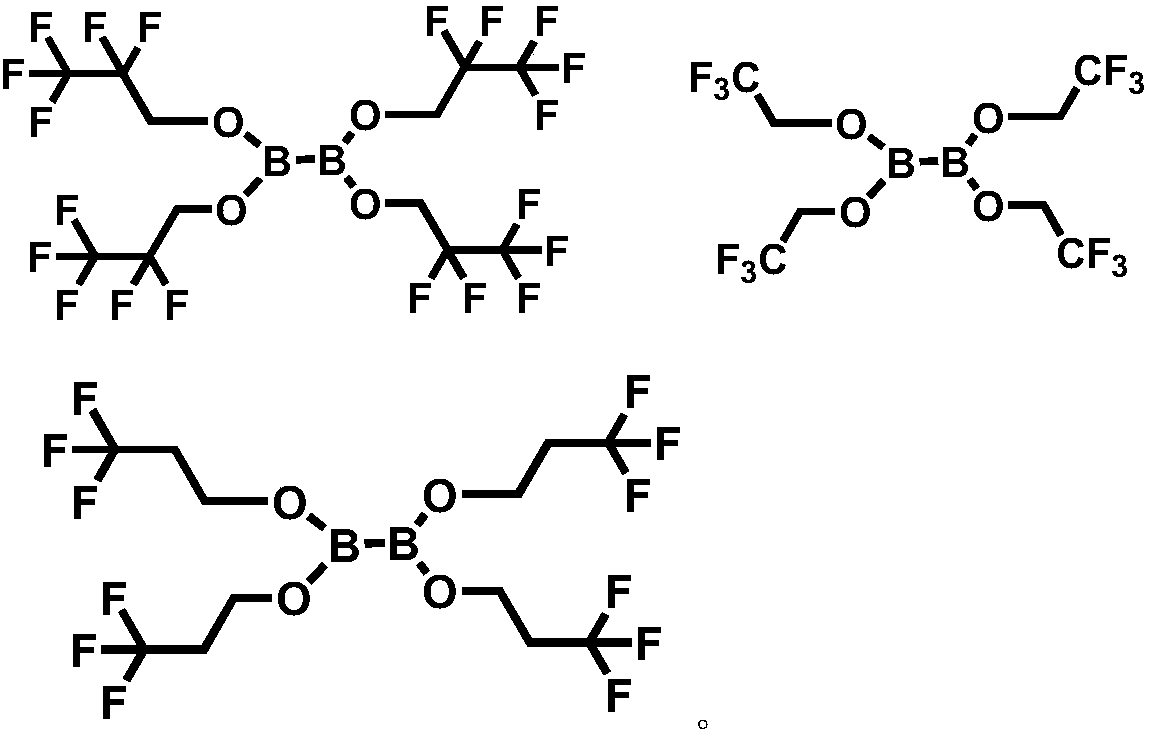

Electrolyte for lithium secondary battery and lithium secondary battery containing the same

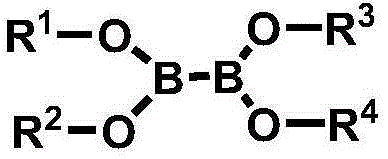

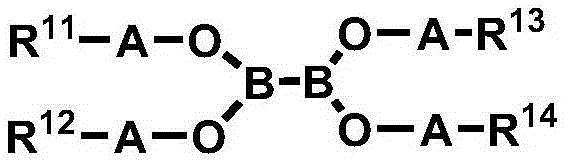

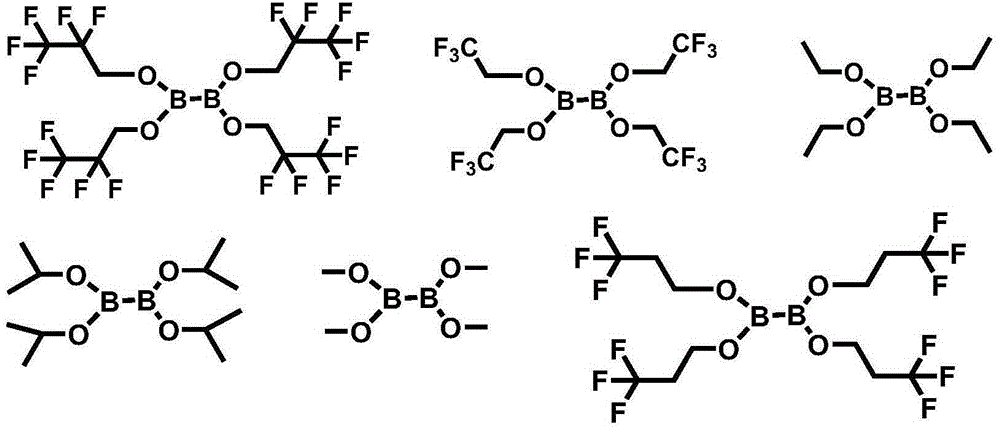

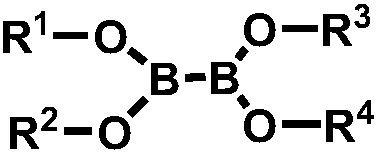

ActiveCN105428714AImprove swelling (swelling) phenomenonExcellent high temperature storage characteristicsGroup 3/13 element organic compoundsElectrolytesArylHalogen

Provided are an electrolyte for a lithium secondary battery, and a lithium secondary battery containing the same, wherein the electrolyte for a secondary battery has significantly excellent high-temperature stability, low-temperature discharge capacity, and life cycle characteristics. The electrolyte for the lithium secondary battery comprises a lithium salt; a non-aqueous organic solvent; and a boron derivative represented by the following chemical formula 1. In the chemical formula 1, R1 to R4 are each independently (C1-C10)alkyl, (C6-C12)aryl or (C6-C12)ar(C1-C10)alkyl, and alkyl, aryl, and aralkyl of R1 and R2 may be further substituted with at least one substituent selected from the group consisting of cyano, hydroxyl, halogen, (C1-C10)alkyl and (C6-C12)aryl.

Owner:SK ON CO LTD

Electrolyte for Lithium Secondary Battery and Lithium Secondary Battery Containing the Same

InactiveCN105428713AImprovement of swellingExcellent high temperature storage characteristicsElectrolytesLi-accumulatorsLithiumEngineering

Provided are an electrolyte for a lithium secondary battery and a lithium secondary battery containing the same. The lithium secondary battery using the electrolyte for a lithium secondary battery according to the present invention has excellent high-temperature stability, high-temperature capacity recovery rate, low-temperature discharge capacity, and life cycle characteristics.

Owner:SK INNOVATION CO LTD

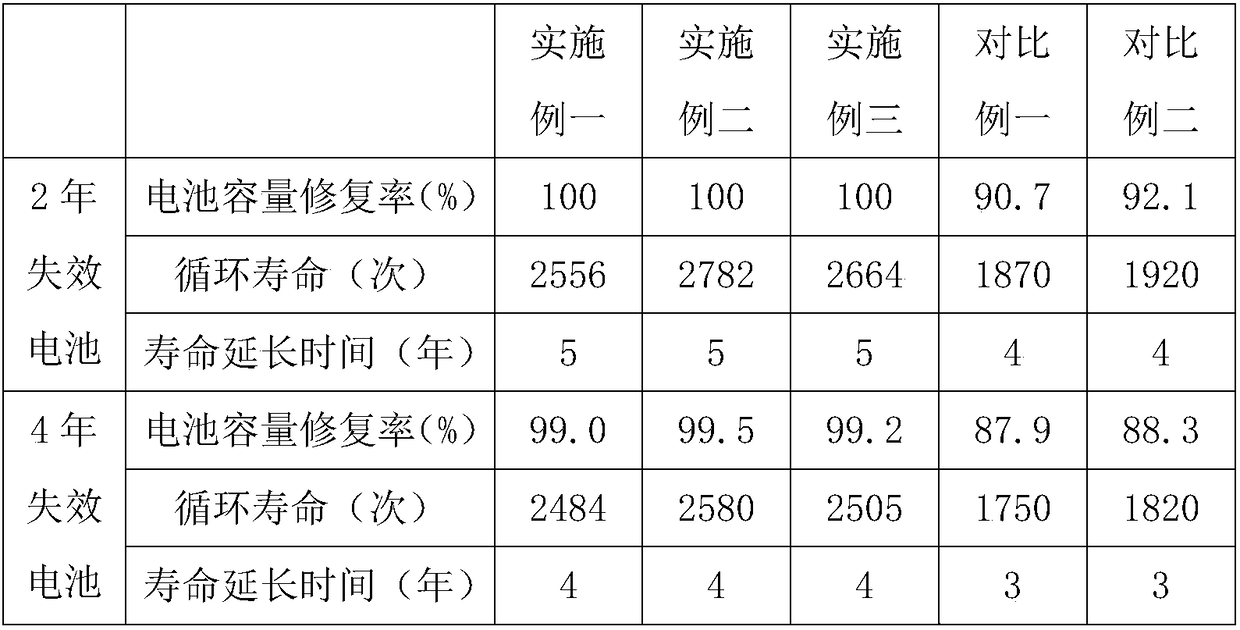

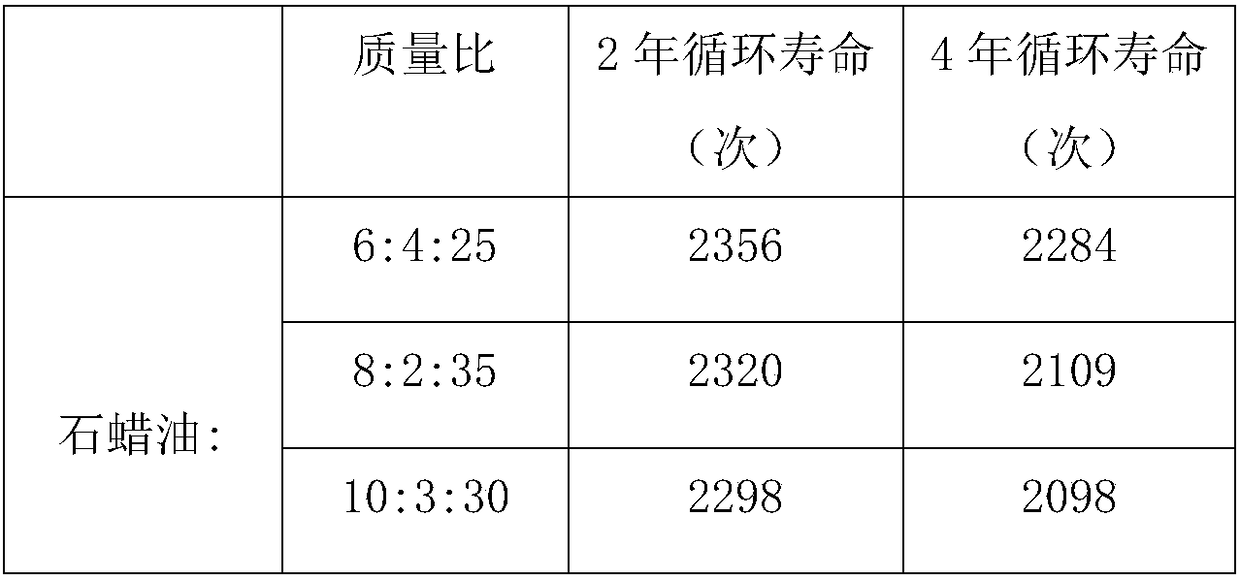

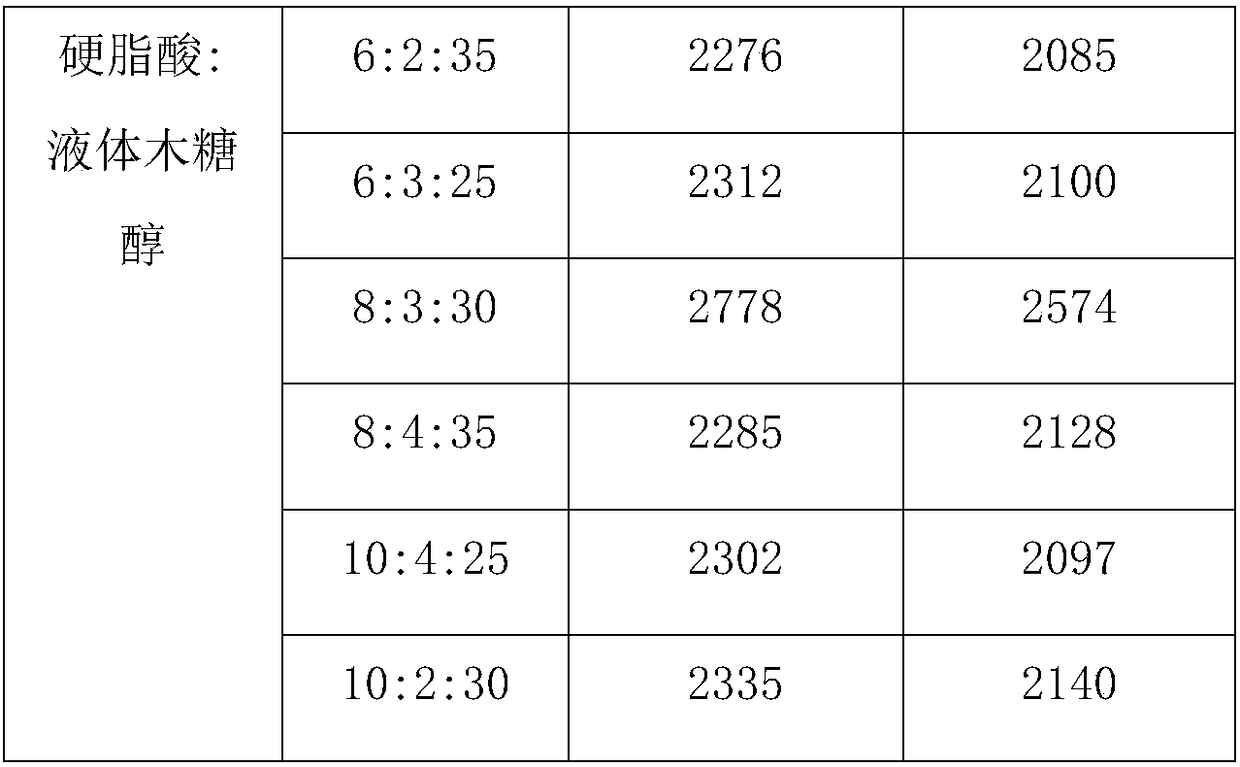

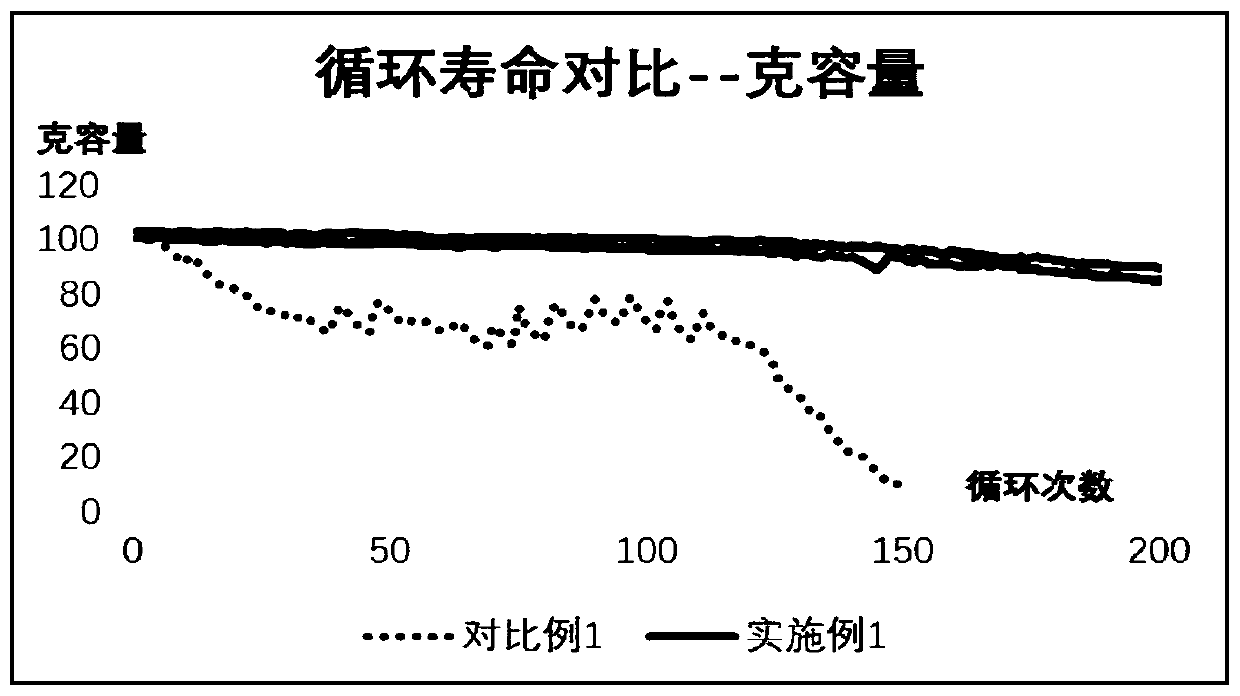

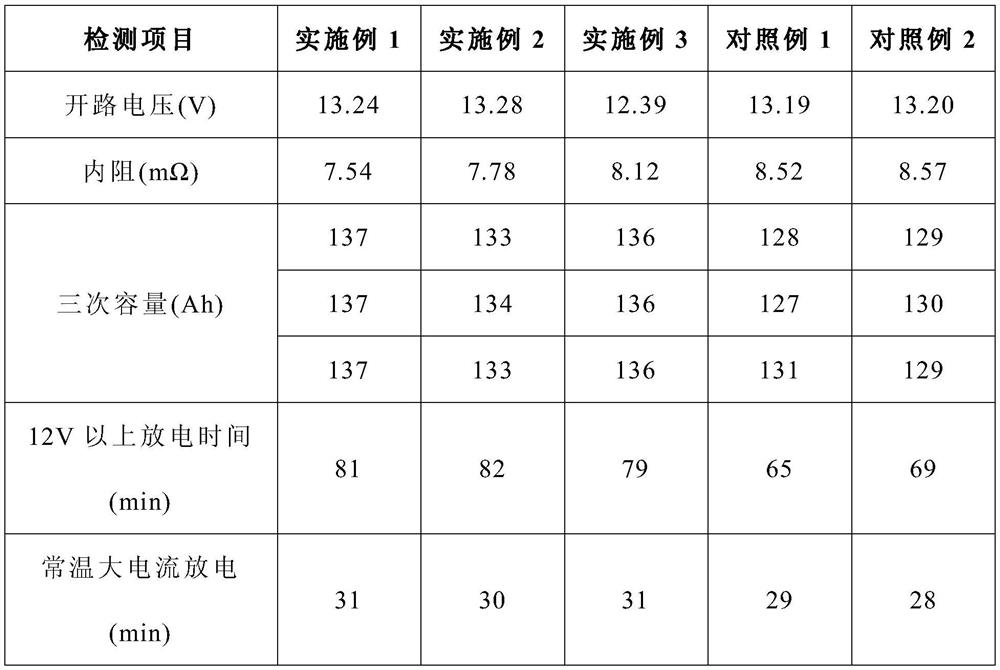

Lead acid battery repair liquid and preparation method thereof

ActiveCN108493503AImprove electrochemical performanceIncrease profitLead-acid accumulatorsSecondary cells servicing/maintenanceTin dioxideAntioxidant

Belonging to the technical field of lead acid batteries, the invention in particular relates to a lead acid battery repair liquid and a preparation method thereof, and solves the problems of incomplete battery repair, troublesome operation, poor effect, easy secondary pollution, long preparation period of battery repair liquid, low preparation efficiency and poor stability in the prior art. The lead acid battery repair liquid comprises the following raw materials by weight: 0.5-1 part of nano-carbon sol, 0.3-0.8 part of tin dioxide, 2-5 parts of potassium polyvinyl sulfate, 3-8 parts of sodiumpolystyrene sulfonate, 1-1.5 parts of a mixed metal salt, 3-4.5 parts of sodium alginate, 0.8-1.6 parts of an antioxidant, 35-50 parts of a sulfuric acid solution, and 60-90 parts of distilled water.The lead acid battery repair liquid obtained by the invention has the advantages of good stability, comprehensive repair, convenient use, quick effect and long service life, and the lead acid batterycapacity repair rate is up to 100%. Also the preparation method is simple, has the characteristics of simple and easily available raw materials, low preparation cost, and is worth popularizing.

Owner:天能集团(濮阳)再生资源有限公司

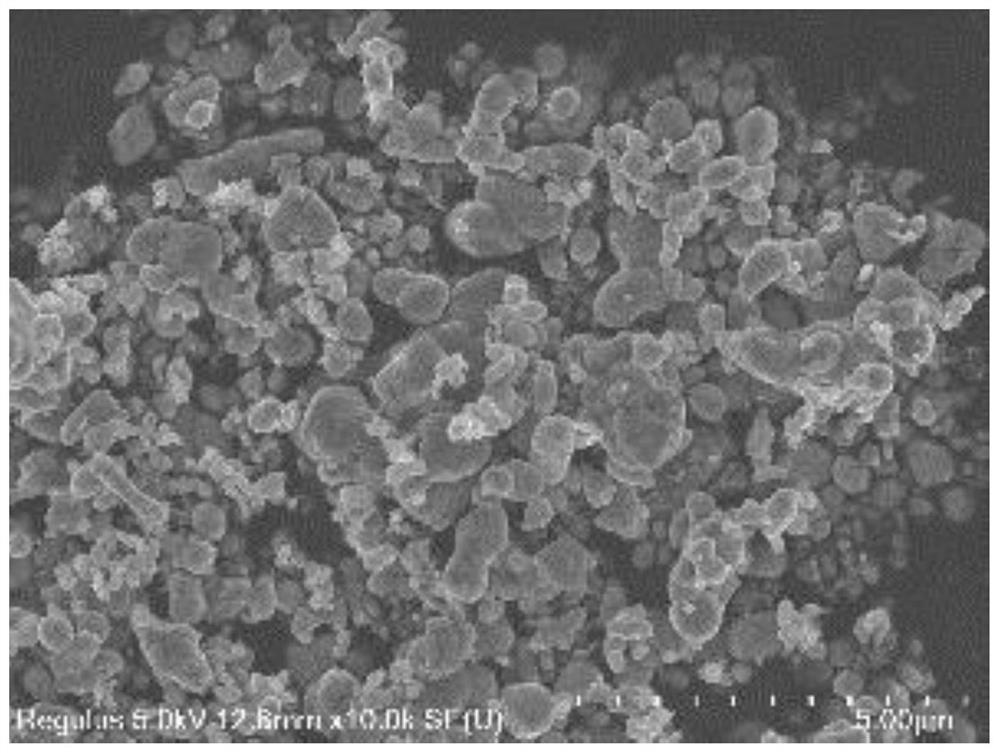

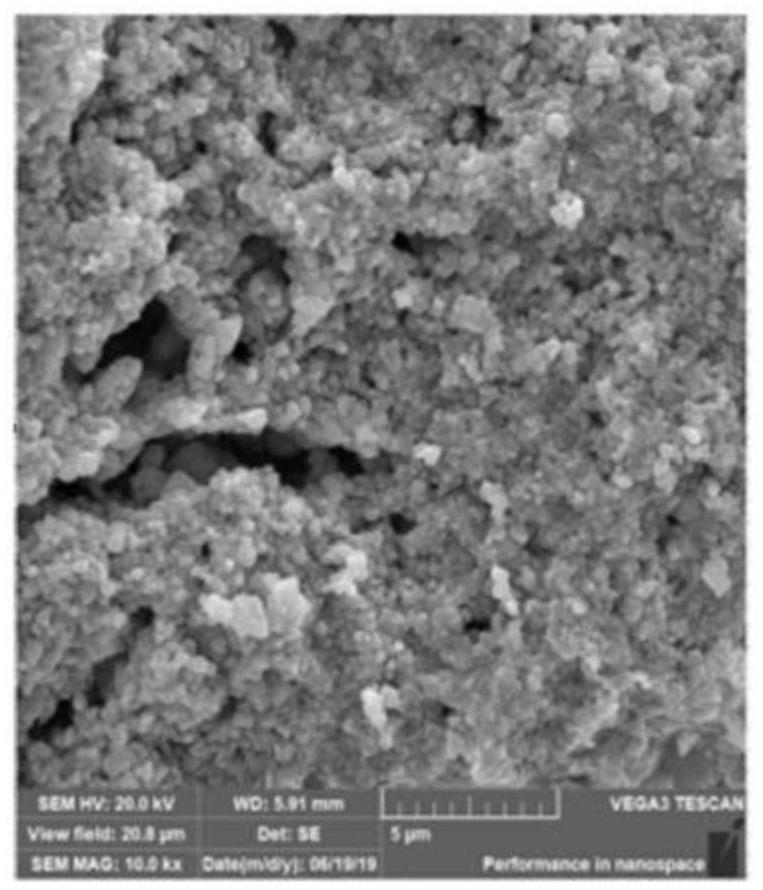

Aqueous ion battery and preparation method thereof

ActiveCN111430819AInhibit corrosionLow self-discharge rateFinal product manufactureNegative electrodesChemical activityCharge and discharge

The invention provides an aqueous ion battery and a preparation method thereof, and relates to the technical field of batteries. The metal modified zinc powder is prepared by adopting a coating or doping mode, AND is used as a main negative electrode material to prepare the aqueous ion battery. The microstructure of the metal modified zinc powder is designed to be needle-shaped, so that the chemical activity of the metal modified zinc powder is improved, the corrosion of the negative electrode in the standing process after the battery is charged is effectively delayed, the hydrogen evolution reaction of the battery in the charging and discharging process is inhibited, the cycle life of the battery is prolonged, and the self-discharge rate of the battery is reduced.

Owner:北京恩力动力科技有限公司 +2

Battery

InactiveCN105336956AImprove self-dischargeHigh capacity recovery rateCell electrodesSolventElectrochemistry

The invention provides a battery. The battery comprises a cathode, an anode, and an electrolyte solution. According to the battery, the cathode comprises a cathode active material capable of realizing reversible deintercalation-intercalation of first metal ions; the electrolyte solution comprises a solvent capable of dissolving and ionizing electrolytes; the electrolyte solution comprises the first metal ions and second metal ions; in charging and discharging processes, the second metal ions can be transformed into a second metal via reduction and be deposited on the anode, and the second metal can be reversibly transformed into the second metal ions via oxidation dissolving; wherein, the cathode also comprises a silicon dioxide additive. The battery is capable of improving a problem of battery self-discharging, and improving battery electrochemical performance.

Owner:POSITEC POWER TOOLS (SUZHOU) CO LTD +1

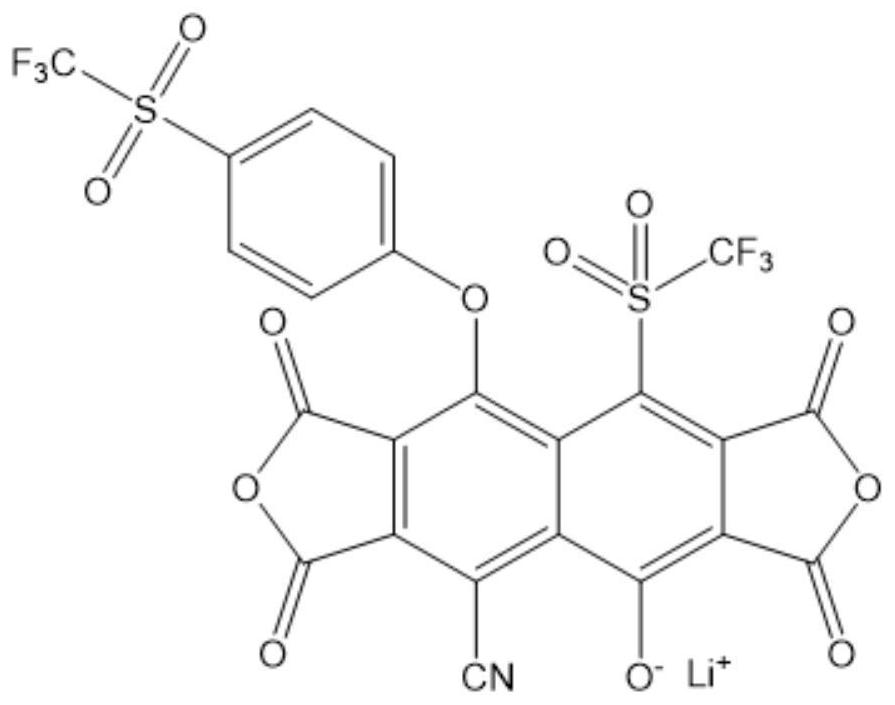

Lithium Secondary Battery Electrolyte and Lithium Secondary Battery Including Same

ActiveUS20160322665A1Excellent high-temperature storage characteristicHigh capacity recovery rateCell electrodesLi-accumulatorsOrganic solventPhysical chemistry

Provided are a lithium secondary battery electrolyte and a lithium secondary battery. The lithium secondary battery electrolyte includes a lithium salt, a non-aqueous organic solvent, and a pyrrole derivative. The lithium secondary battery includes a cathode, an anode, a separator, and the lithium secondary battery electrolyte. The secondary battery electrolyte according to the present invention has advantages of excellent stability at a high temperature and high discharge capacity at a low temperature.

Owner:SK ON CO LTD

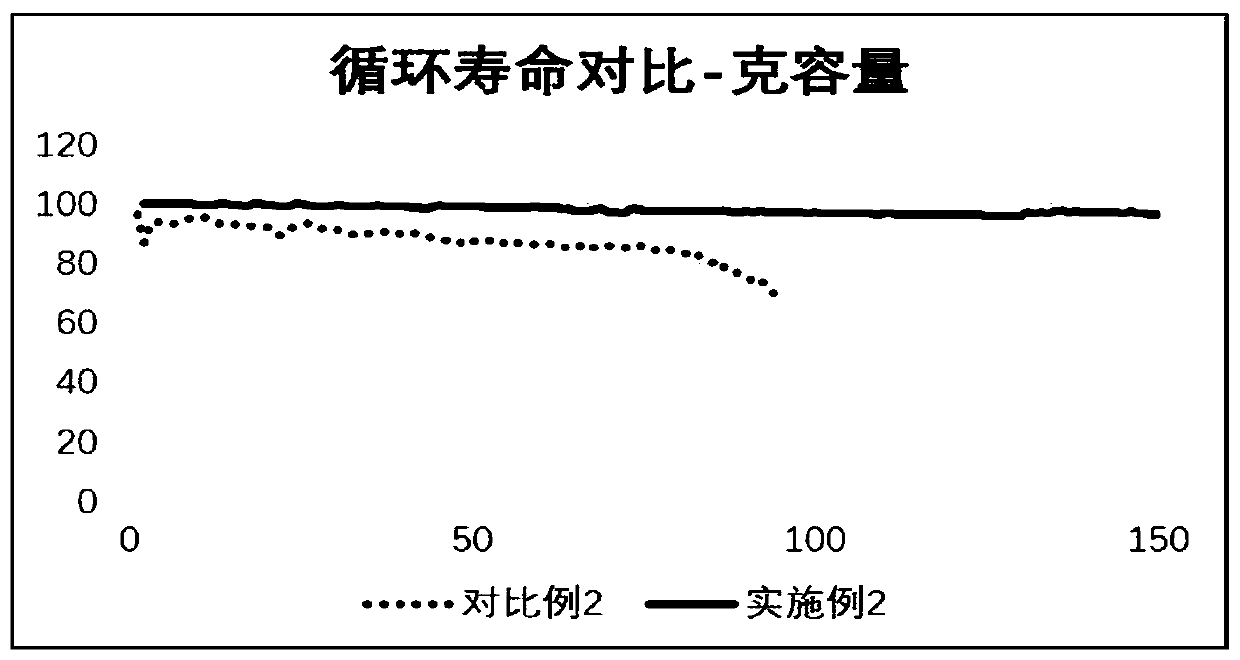

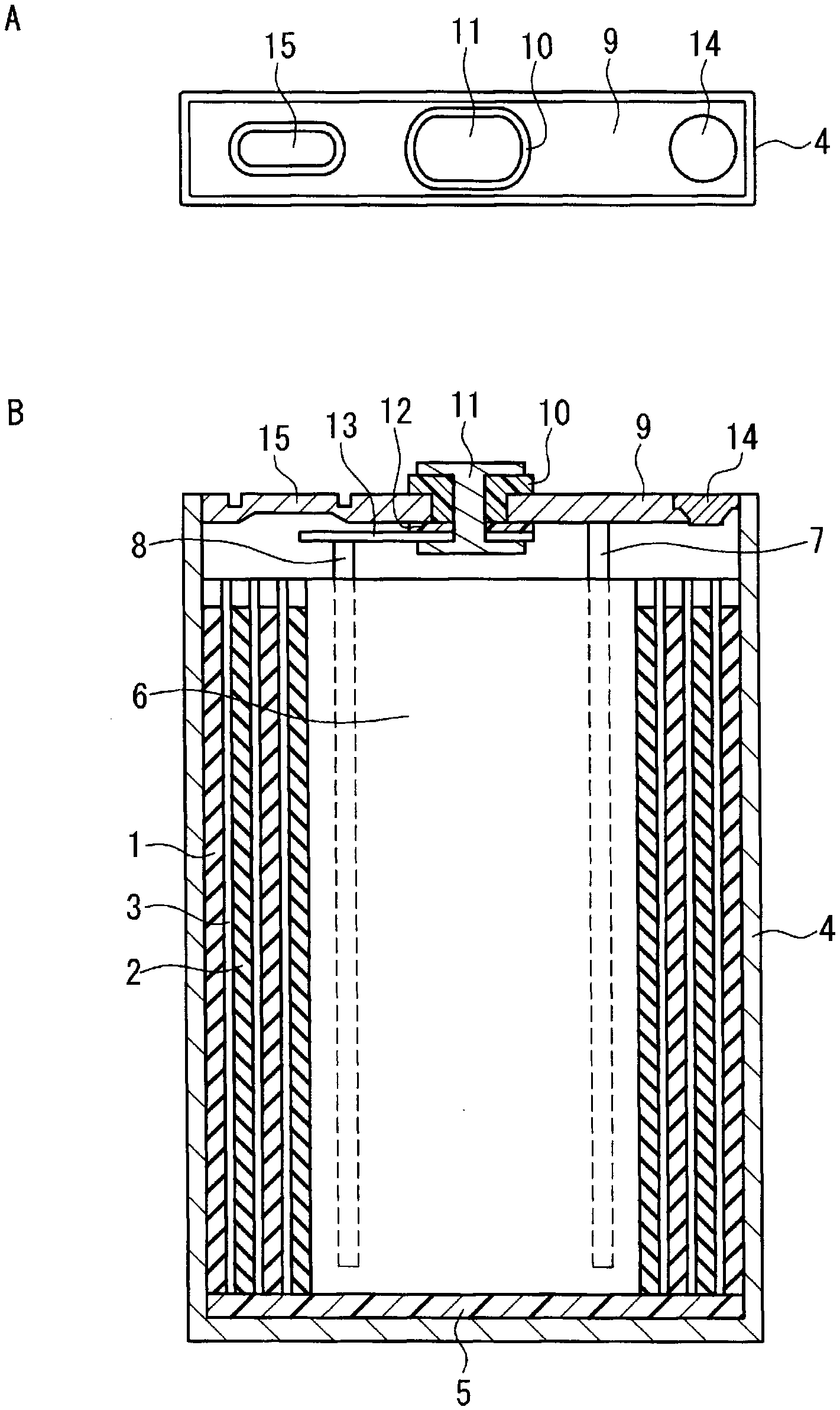

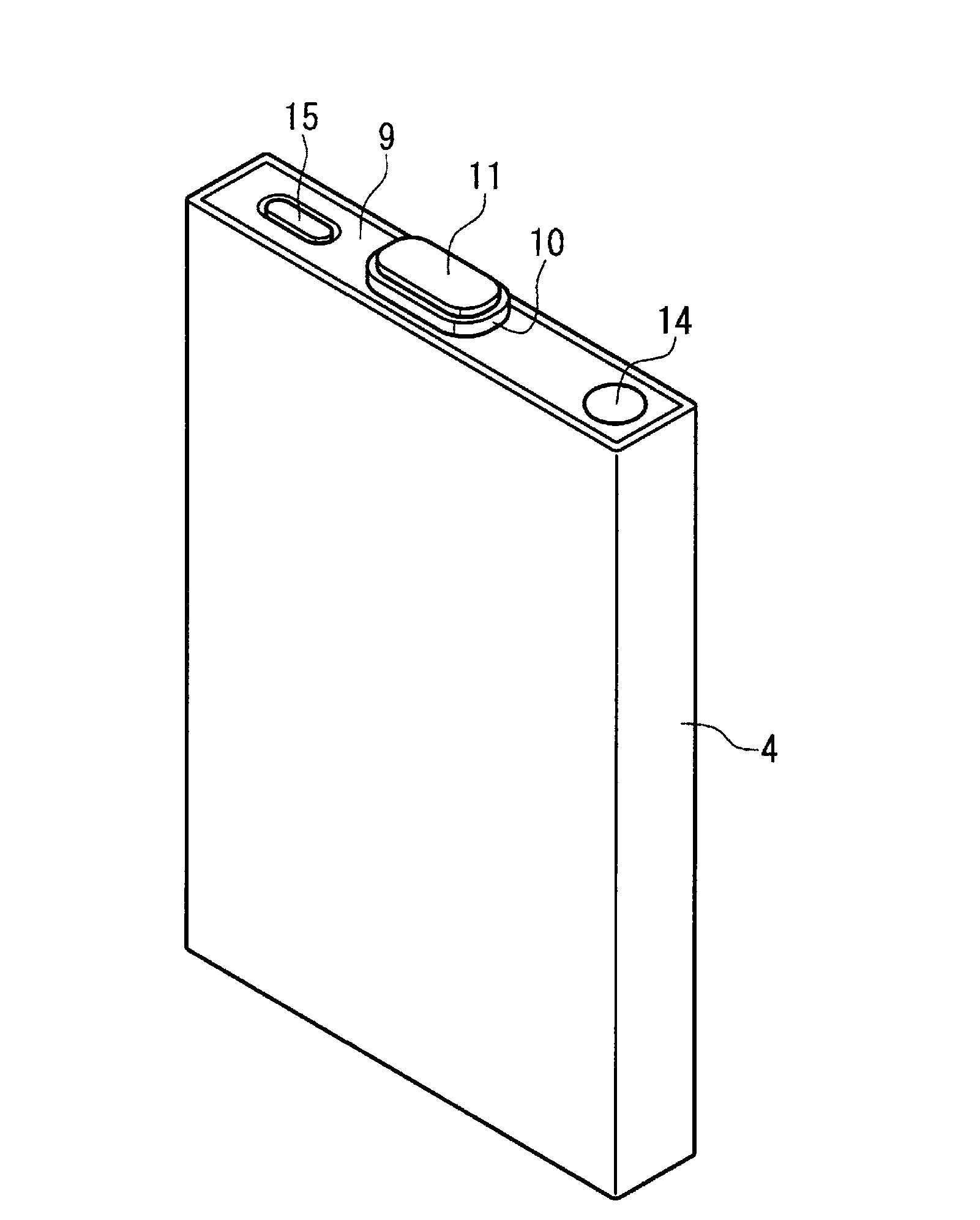

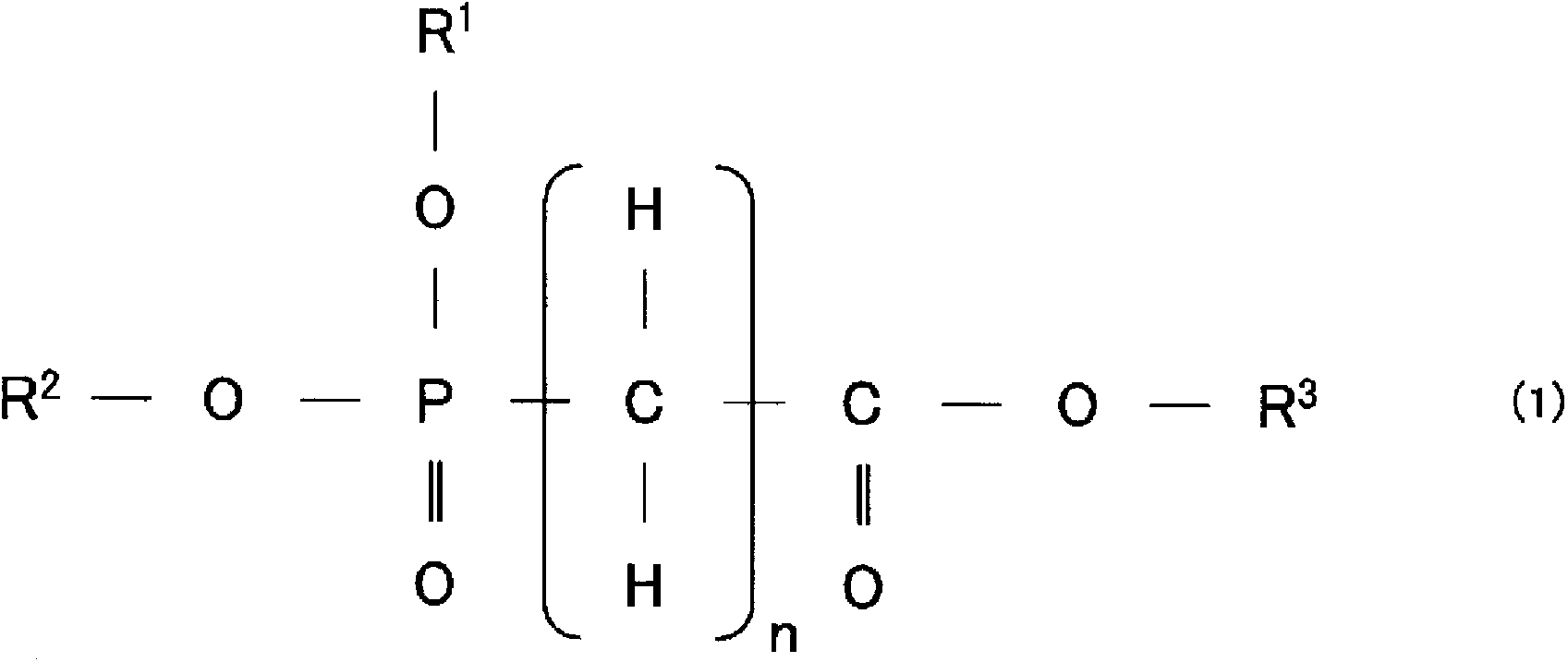

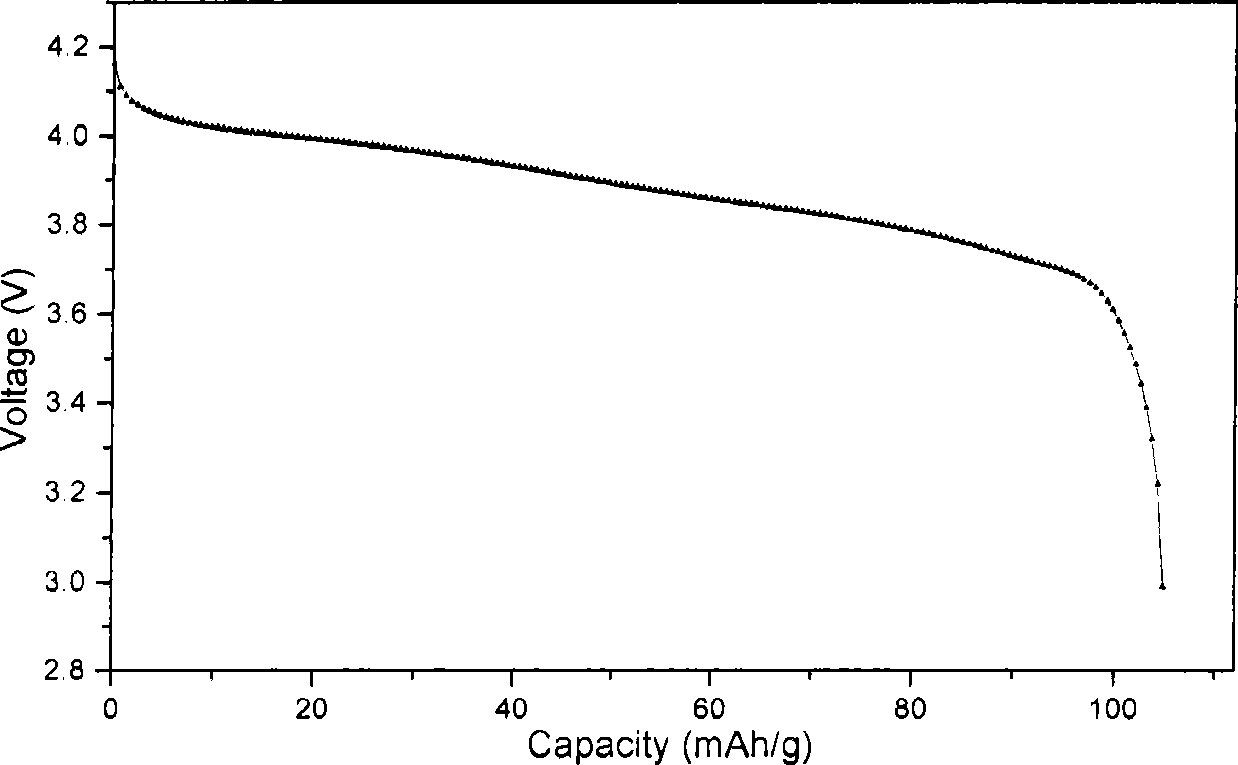

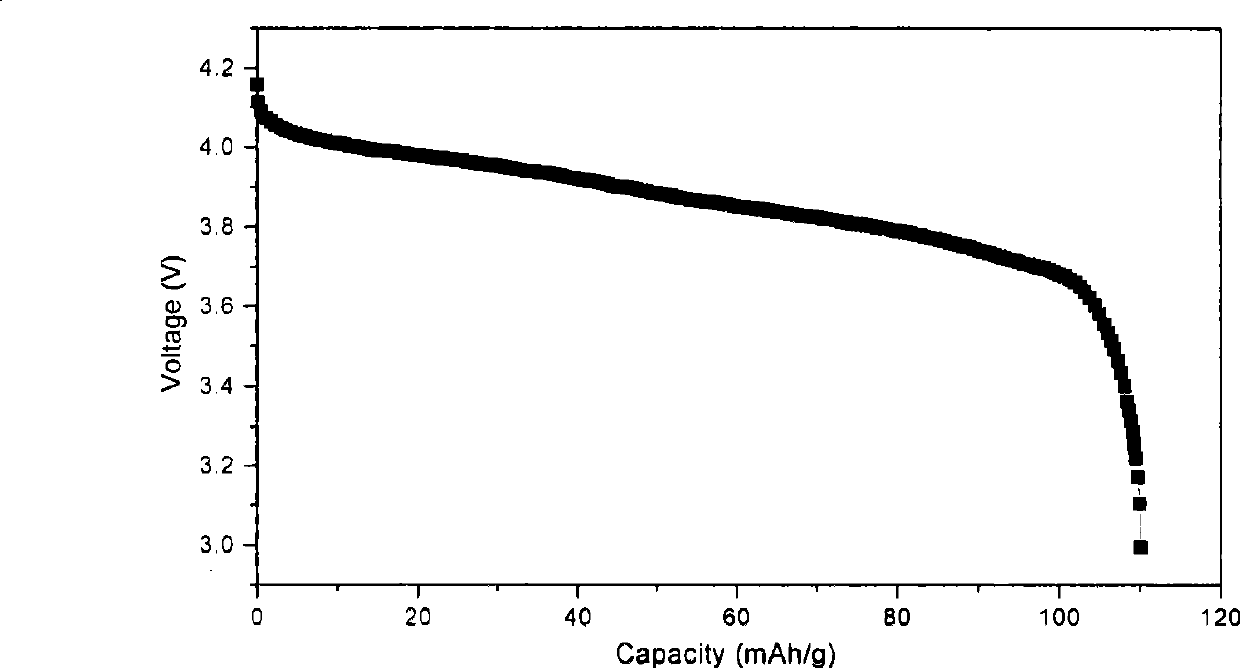

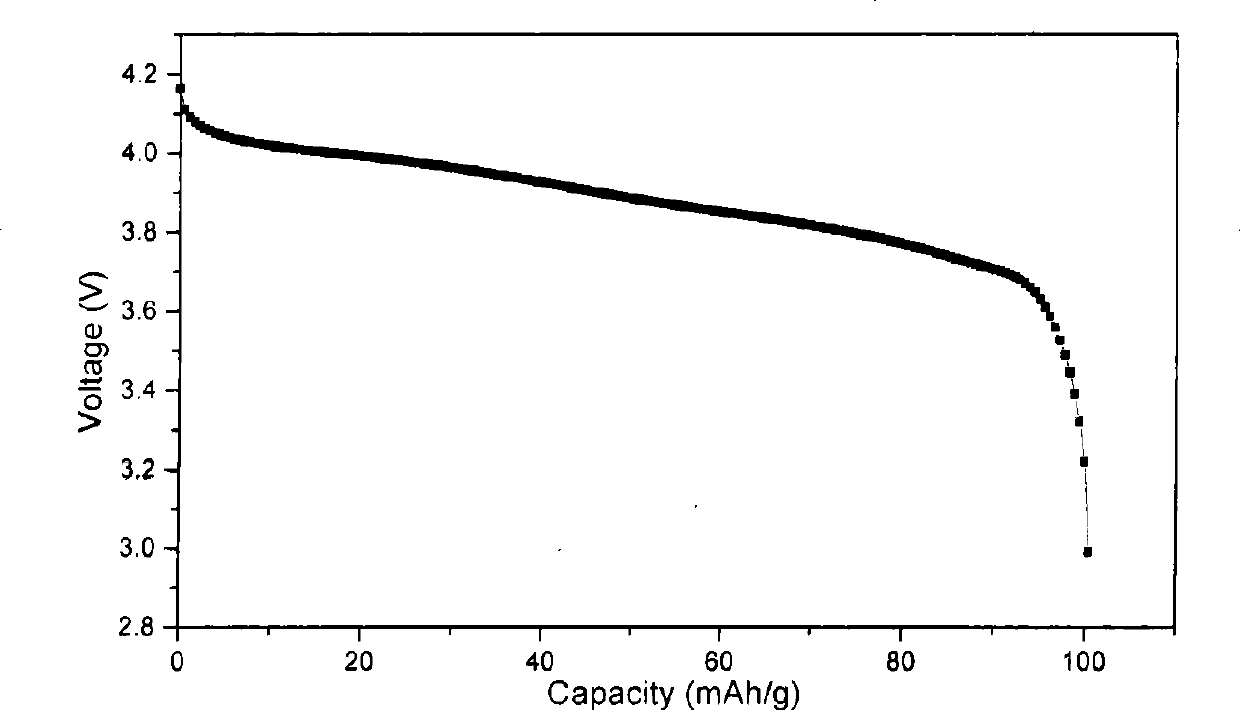

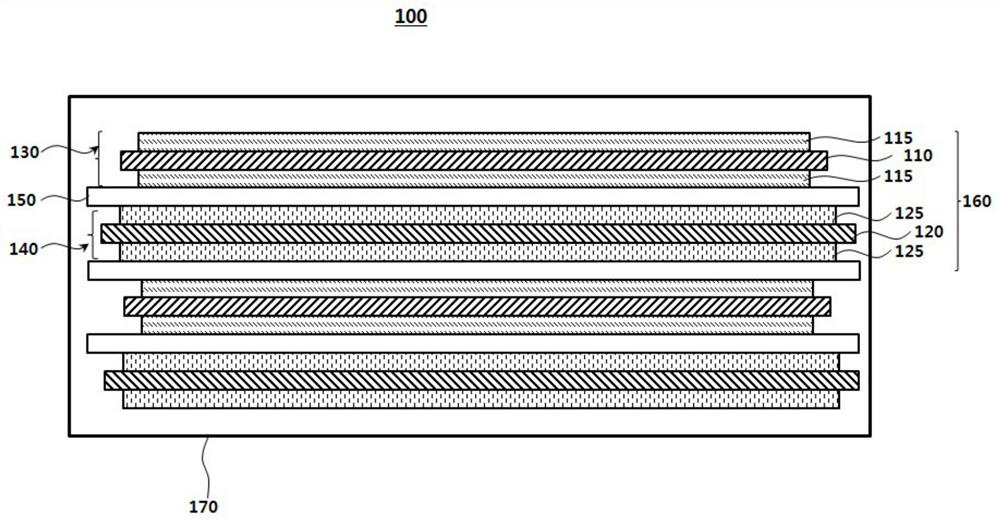

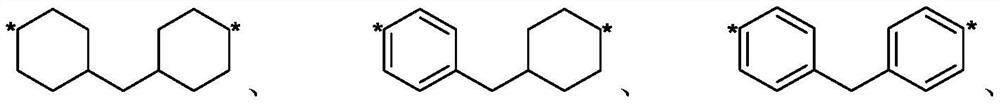

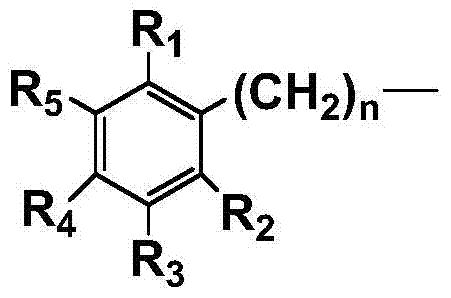

Lithium secondary battery

InactiveCN103038928AIncrease capacityHigh capacity recovery rateLi-accumulatorsNon-aqueous electrolyte accumulator electrodesHalogenLithium-ion battery

The lithium secondary battery of the present invention is provided with a positive electrode, a negative electrode, a nonaqueous electrolyte, and a separator, and is characterized by: the positive electrode including a current collector and a positive electrode mixture layer formed on top of the current collector; the positive electrode mixture layer including a positive electrode active material; the positive electrode active material including a lithium-containing complex oxide containing lithium and nickel; the molar ratio of lithium to nickel in the total volume of the lithium-containing complex oxide being 0.5-1.05%; and the nonaqueous electrolyte including 0.5-20% by weight of a phosphonoacetate compound represented in Formula (1). In Formula (1), R1, R2 and R3 all independently represent C1-12 alkyl groups that can be substituted with halogen atoms, and n represents an integer of 0 to 6.

Owner:HITACHI MAXELL ENERGY LTD

Anode material capable of reducing capacity attenuation after storing lithium manganate battery

The invention relates to an anode material, the capacity of which is attenuated after the storage of a lithium manganate battery is reduced. The anode material is composed of the following components: lithium manganate, Li2CO3, LiF or LiOH and carbon nanofibers; the anode material has the advantages that the components are simple and reasonable, the production cost is low, the circulation performance of the lithium manganate battery can be effectively enhanced, the capacity recovery rate after the storage of the lithium manganate battery is improved, and the energy density and the gram specific capacity of the lithium manganate battery are improved; the industrialized mass production can be realized, the anode material can be matched with lithium batteries of various types, and can replace the anode of the prior lithium manganate battery.

Owner:CENT SOUTH UNIV

A high-voltage ternary cathode material system lithium-ion battery electrolyte

ActiveCN105140564BImprove cycle performanceImprove high temperature performanceSecondary cellsOrganic electrolytesStructural formulaSolvent

The invention provides a lithium-ion battery electrolyte for a high-voltage ternary positive electrode material system. The lithium-ion battery electrolyte comprises a non-aqueous solvent, lithium hexafluorophate and a functional additive; the functional additive comprises a cyclic anhydride compound, a lithium salt type additive and methylene methanedisulfonate; the general structural formula of the cyclic anhydride compound is as shown in the description, wherein R1, R2, R3 and R4 are independently selected from any one of hydrogen atom, fluorine atom, or straight chain or branched chain alkyl with the number of carbon atoms of 1-4. The cyclic anhydride compound used in the lithium-ion battery electrolyte is higher in reduction potential (the reduction potential of succinic anhydride is 1.50 V vs Li+ / Li) on the negative electrode surface, so that other components in the electrolyte can be preferably reduced into films in the first charging process of the battery, the formed SEI film is high in stability. The cyclic anhydride compound used in the lithium-ion battery electrolyte is capable of effectively improving the cycle performance and high-temperature performance of the battery; and compared with fluoroethylene carbonate, the cyclic anhydride compound has excellent high-temperature performance as well as capability of improving the cycle performance.

Owner:GUANGZHOU TINCI MATERIALS TECH

Neutral repair liquid for lead-acid battery and preparation technology of neutral repair liquid

InactiveCN108232341AHigh capacity recovery rateFast capacityLead-acid accumulatorsSecondary cells servicing/maintenanceBattery capacityPolymer

The invention provides a neutral repair liquid for a lead-acid battery and a preparation technology of the neutral repair liquid. The preparation technology comprises specific steps as follows: a heating kettle is heated to 85-95 DEG C, haloid acid, a polymer and magnesium oxide are added to deionized water and stirred uniformly, and a primary combined liquid is generated; heat preservation is performed for 70-90 min, other raw materials are added with stirring, and a secondary combined liquid is generated; heat preservation is performed for 70-90 min, then tartaric acid and calcium chloride are added and heated with stirring, and a semitransparent viscous solution, namely, the repair liquid for the lead-acid battery is obtained. Capacity restoration rate of the battery repaired by the repair liquid is high; battery capacity restores quickly, and capacity of the battery even with slight physical damage can be also increased greatly; the repair liquid has a prevention function, the effective reaction period can be as long as 1 year or longer after being added to the battery for repair, and accordingly, sulfate formation can be delayed in a long term; the repair liquid is neutral inchemical property, has no adverse effects on a human body and the environment and is safe and reliable.

Owner:天津华庆百胜能源有限公司

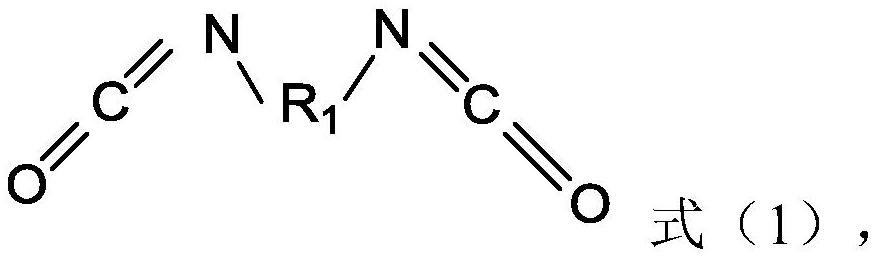

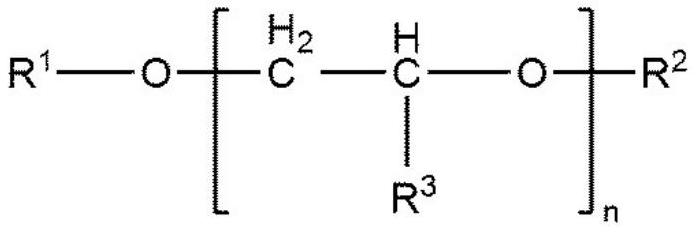

Lithium ion battery

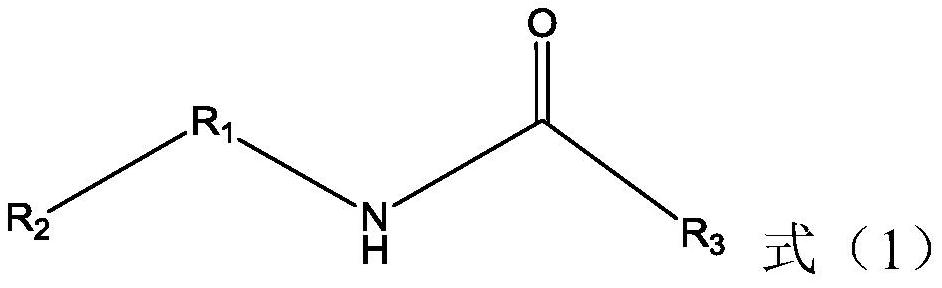

PendingCN114583242APromote circulationEasy to storeCell electrodesSecondary cells servicing/maintenanceElectrolytic agentOrganosolv

The invention relates to the technical field of lithium ion batteries, and discloses a lithium ion battery. The lithium ion battery comprises a positive electrode, a negative electrode, a diaphragm arranged between the positive electrode and the negative electrode, and a non-aqueous electrolyte, wherein an active material of the positive electrode contains LiFePO4; the non-aqueous electrolyte contains an organic solvent, a lithium salt, vinylene carbonate and a compound represented by a formula (1), in the formula (1), R1 is one or more of chain-shaped, cyclic and aromatic groups with 2-20 carbon atoms, and the compaction density of the positive electrode material is more than 2g / cm < 3 >. According to the lithium ion battery provided by the invention, the circulation and storage performance at high temperature can be remarkably improved, the capacity retention rate and the capacity recovery rate of the battery are greatly improved, the thickness swelling rate after high-temperature storage is obviously reduced, and meanwhile, dissolution of iron ions can be greatly reduced.

Owner:SHENZHEN CAPCHEM TECH

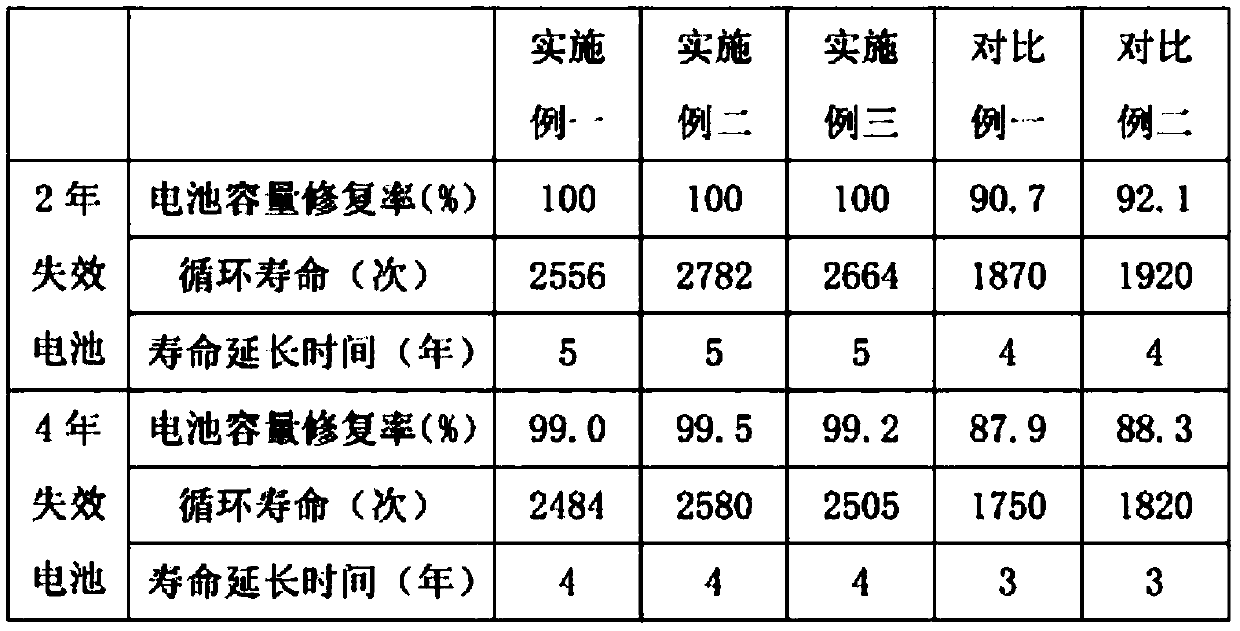

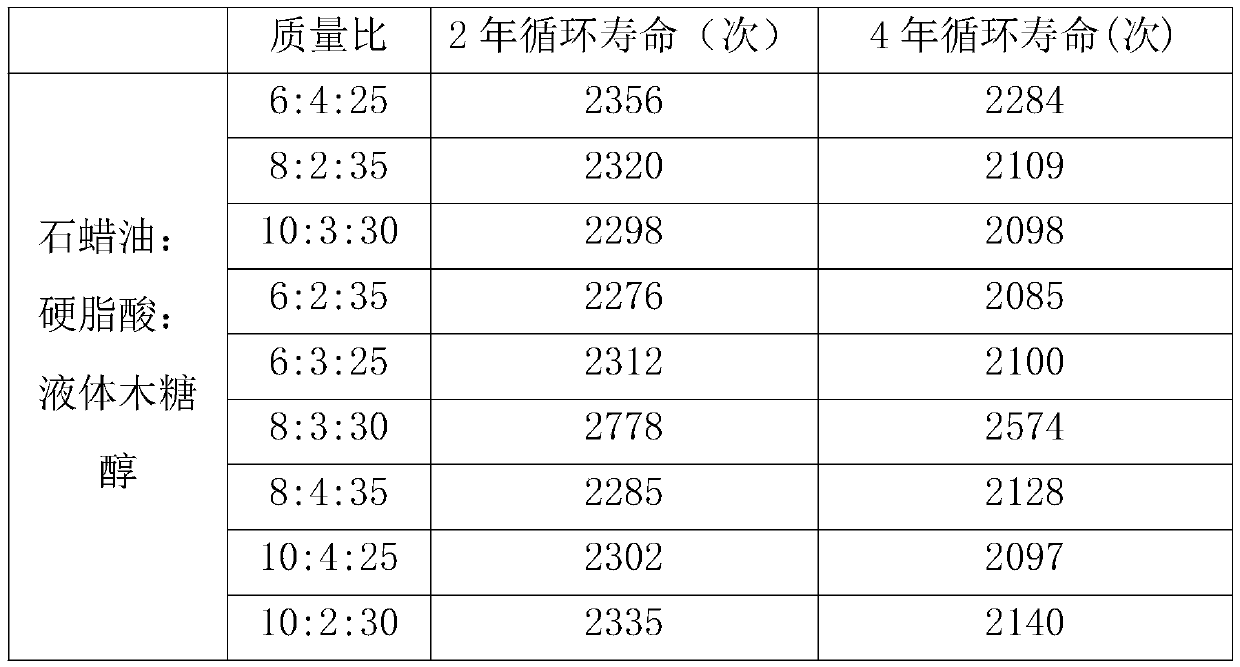

Biomacromolecular repairing agent for lead-acid storage battery and preparation method of biomacromolecular repairing agent

ActiveCN113078376ARestore capacityFormulation ScienceLead-acid accumulatorsElectrolyte/reactants regenerationHydroxybutyric acidGluconic acid

The invention discloses a biomacromolecule repairing agent for a lead-acid storage battery. The biomacromolecule repairing agent is prepared from the following raw materials in parts by weight: 1-15 parts of gamma-hydroxybutyric acid, 1-20 parts of acetic acid, 1-30 parts of gamma-PGA, 1-8 parts of N-acetyl gluconic acid, 1-15 parts of Lunasin peptide, 10-50 parts of ST peptide, 1-20 parts of beta-hydroxy-alpha-aminobutyric acid, 1-40 parts of L-2-amino-3-hydracrylic acid, 20-60 parts of distilled water and 15-40 parts of sulfuric acid. According to the invention, in the charge-discharge cycle process of the lead-acid storage battery, the biomacromolecule repairing agent is adopted to continuously melt lead sulfate crystals and prevent the lead sulfate crystals from being attached to an electrode plate again, so that ecological restoration of the aged lead-acid storage battery is realized, and secondary pollution to the environment is avoided.

Owner:WUHAN NARI LIABILITY OF STATE GRID ELECTRIC POWER RES INST

High-temperature lithium ion battery electrolyte and lithium ion battery

ActiveCN102082292BEasy to manufactureEasy to operateCell electrodesSecondary cellsElectrolytic agentElectrical battery

The invention discloses a high-temperature lithium ion battery electrolyte and a lithium ion battery. The electrolyte is prepared by uniformly mixing electrolyte salts, a nonaqueous organic solvent, a high-temperature film-forming additive and high-temperature gas generation inhibiting additives, wherein the high-temperature film-forming additive is lithium bis(oxalate) borate (LiBOB); the LiBOB accounts for 0.2-3% by mass of the mixed lithium salt solution formed by the electrolyte salts and the nonaqueous organic solvent; the high-temperature gas generation inhibiting additive is one or twoof ionic liquid and phthalic anhydride, and accounts for 0.8-9% by mass of the mixed lithium salt solution; and the total content of the added high-temperature film-forming additive and high-temperature gas generation inhibiting additives accounts for 1-11% by mass of the mixed lithium salt solution. The lithium ion battery comprises a cathode, an anode, a diaphragm and the high-temperature lithium ion battery electrolyte. The invention has the advantage of reasonable design, the steps in the preparation processes are simple and convenient to implement, and the prepared electrolyte and the lithium ion battery have excellent comprehensive performance.

Owner:XIAN SAFTY ENERGY TECH

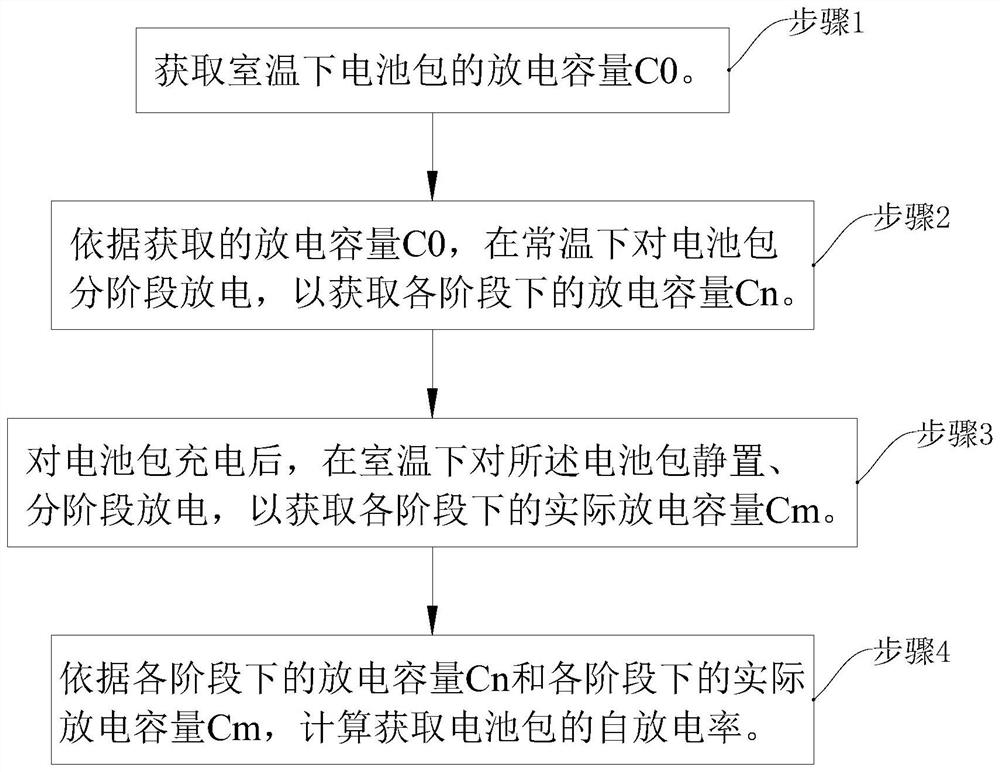

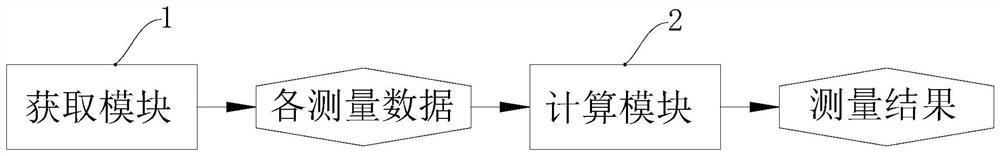

Method and device for determining self-discharge of battery pack

PendingCN114545258AAccurate self-discharge rateMitigate the Effect of Capacitance Measurement ErrorsElectrical testingThermodynamicsProcess engineering

The invention provides a method and a device for determining self-discharge of a battery pack. The method for determining the self-discharge of the battery pack comprises the following steps: firstly, obtaining the discharge capacity C0 of the battery pack at room temperature; according to the obtained discharge capacity C0, the battery pack is discharged in stages so as to obtain the discharge capacity Cn in each stage, and the discharge operation of each stage of the battery pack is carried out at normal temperature; after the battery pack is charged, at room temperature, the battery pack is subjected to standing and staged discharging, so that the actual discharging capacity Cm in each stage is obtained; and finally, obtaining the self-discharge rate of the battery pack according to the discharge capacity Cn in each stage and the actual discharge capacity Cm in each stage. According to the determination method, two groups of discharge capacitance measurement values are detected, and one group of measurement values is carried out after the battery pack stands and the environment adapts to the temperature, so that the influence of the temperature rise factor of the battery pack caused by discharge on the capacitance measurement error can be reduced; by means of correction calculation of two groups of data, more accurate self-discharge rate of the battery pack can be measured.

Owner:SVOLT ENERGY TECHNOLOGY CO LTD

Lithium secondary battery electrolyte and lithium secondary battery containing same

ActiveCN105428714BImprove swelling (swelling) phenomenonExcellent high temperature storage characteristicsGroup 3/13 element organic compoundsElectrolytesArylOrganic solvent

The present invention provides a lithium secondary battery electrolyte and a lithium secondary battery containing the same, and specifically, provides a secondary battery electrolyte with excellent high temperature stability, low temperature discharge capacity and life characteristics, the secondary battery The electrolyte contains a lithium salt; a non-aqueous organic solvent; and a boron derivative shown in the following chemical formula 1: in the chemical formula 1, R1 to R4 are independently (C1-C10) alkyl, (C6-C12) aryl or (C6-C12) aryl (C1-C10) alkyl, the alkyl, aryl and aralkyl groups of R1 to R2 can be further selected from cyano, hydroxyl, halogen, (C1-C10) alkyl and (C6-C12) One or more substituents in the aryl group are substituted.

Owner:SK ON CO LTD

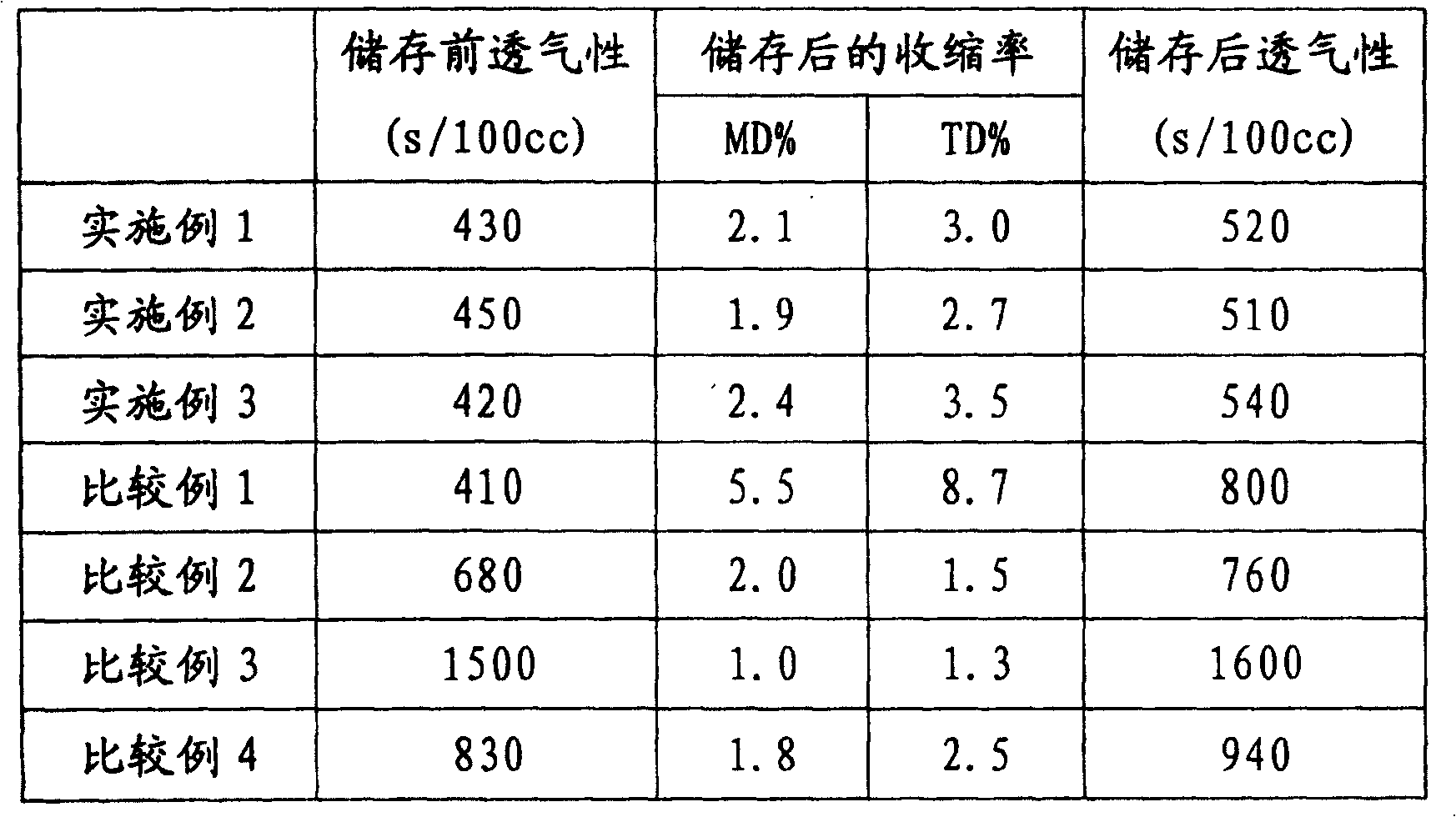

Method for making high-temperature-resistance polyolefin microporous membrane

ActiveCN100418741CImprove high temperature performanceLow heat shrinkageFlat articlesPolyolefinPolymer science

This invention relates to a manufacturing method for high temperature-proof polyolefin micro-porous films including: a, melting the polyolefin resin and a solvent to a uniform solution, b, extruding said solution out by the mold head of an extrusion machine to be cooled and cast on a roller to become a thick plate, c, stretching the thick plate in dual way to a thin film, d, washing off the solvent on the film, e, stereotyping the film laterally the second time to get the polyolefin porous film characterizing that said film is fixed in two ways vertically and horizontally in short time high temperature process and its high temperature performance is improved greatly.

Owner:康辉南通新材料科技有限公司

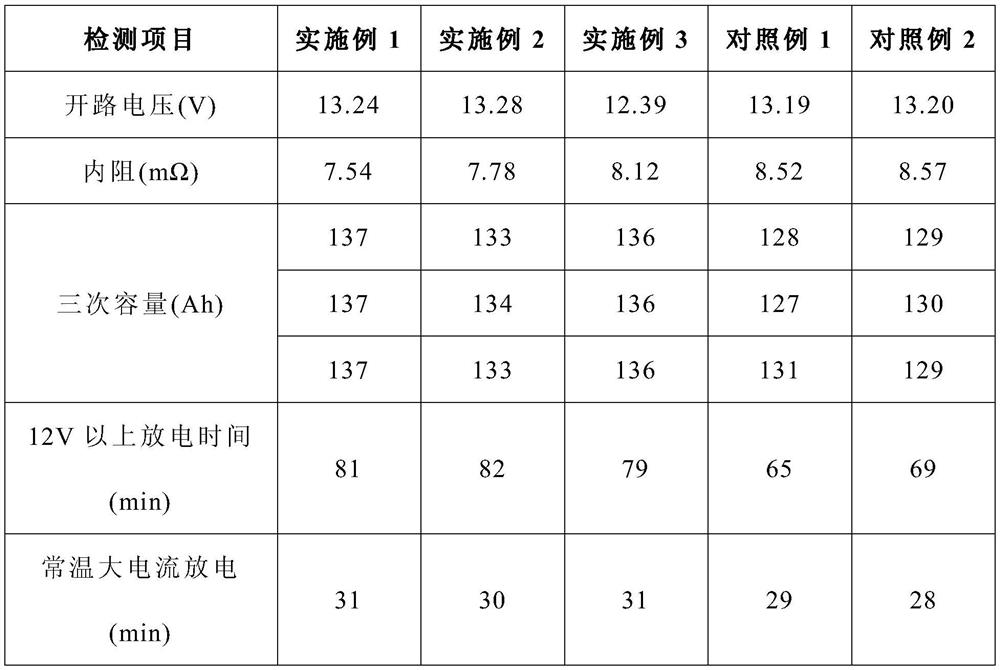

Motorcycle battery and preparation method thereof

InactiveCN106654183AHigh capacity recovery rateAvoid decompositionCell electrodesSecondary cellsLithiumNitrate

The present invention relates to a motorcycle battery, which comprises a positive electrode, an electrolytic solution and a negative electrode, wherein the positive electrode material comprises, by mass, lithium cobaltate, compound cyclic ether, a lithium iron nitrate solution, flake graphite, lithium manganate, a binder, an electric conduction agent and an additive, the electrolytic salt of the electrolytic solution comprises, by mass, ethylene glycol dimethyl ether, an emulsifier, LiCFSO and LiBF, and the negative electrode comprises, by mass, an acrylic emulsion, a filler, amorphous carbon, an electric conduction agent, a thickener, a binder, and an oily agent. With the positive electrode material of the present invention, the decomposition of the electrolytic solution and the generation of HF can be effectively inhibited, and the capacity recovery rate after the storage of the motorcycle battery can be improved.

Owner:重庆市巴南区王富机械厂

Electrolyte solution for lithium secondary battery and lithium secondary battery including the same

PendingCN114079085AImprove stabilityInhibit side effectsPositive electrodesLi-accumulatorsElectrolytic agentPhysical chemistry

Owner:SK ON CO LTD

Lithium ion battery

PendingCN114447430AEasy to storeImprove cycle performanceSecondary cells servicing/maintenanceOrganic electrolytesElectrolytic agentOrganic solvent

The invention relates to the technical field of lithium ion batteries, and discloses a lithium ion battery. The lithium ion battery comprises a positive electrode, a negative electrode, a diaphragm arranged between the positive electrode and the negative electrode and a non-aqueous electrolyte, a positive electrode material of the positive electrode contains a positive electrode active material LiNixCoyMzO2, M is selected from Mn and / or Al, 0.5 < = x < = 1, 0 < = y < = 0.5, 0 < = z < = 0.5, and x + y + z < = 1; the nonaqueous electrolyte solution contains an organic solvent, a lithium salt, and a compound represented by formula (1). According to the lithium ion battery, the chemical performance during circulation and storage at high temperature can be remarkably improved.

Owner:SHENZHEN CAPCHEM TECH

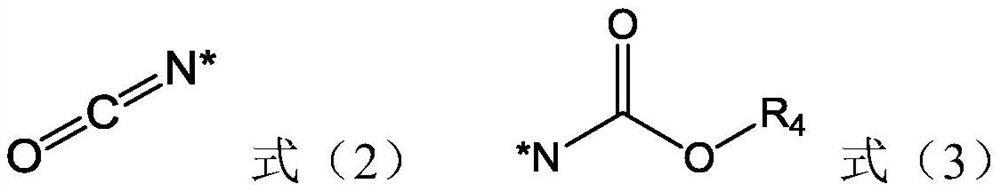

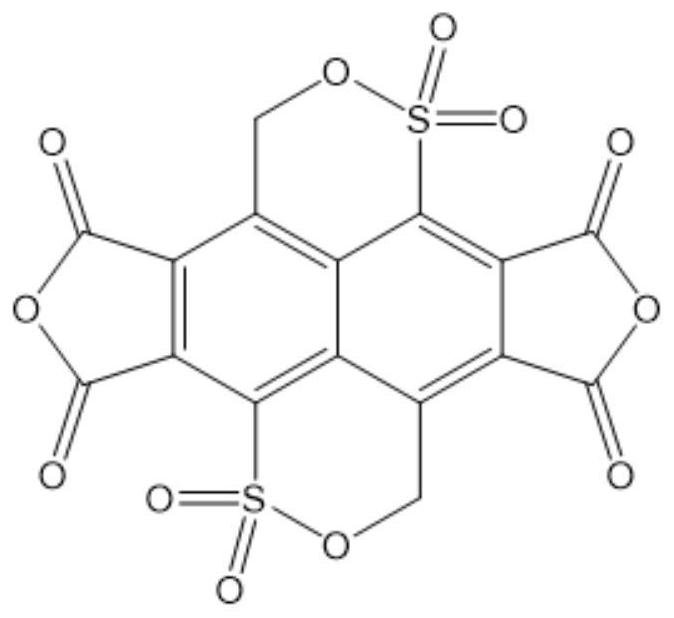

High-temperature electrolyte and lithium battery

PendingCN114497703AImprove high temperature and cycle performanceHigh capacity recovery rateSecondary cellsLithium electrodeOrganic solvent

The invention belongs to the field of lithium ion batteries, and particularly discloses a high-temperature electrolyte which comprises the following components in percentage by weight: 2-20% of lithium salt; 0.01%-20% of a high-temperature additive; 70%-90% of a non-aqueous organic solvent; and 0.1%-10% of other additives. The invention also provides a lithium battery which comprises a positive electrode, a negative electrode, a diaphragm and the electrolyte. The high-temperature additive added into the electrolyte contains a large number of anhydride groups, can form an interface film with good and stable performance on the surface of an electrode in battery circulation, inhibits dissolution of positive electrode metal ions at high temperature, participates in formation of a passive film on the surface of a negative electrode, modifies the structure and components of an SEI film, and improves the high-temperature and circulation performance of the battery; the introduced sulfonate group can form a stable SEI film on the surface of the negative electrode, the impedance of the SEI film is not increased after high-temperature storage, the capacity recovery rate is relatively high, and the high-temperature cycling stability of the battery is improved.

Owner:SHANGHAI YUYUAN POWER TECH CO LTD

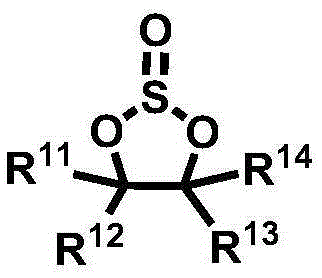

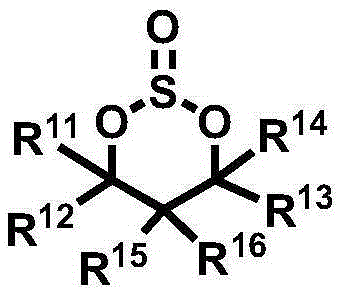

Novel compound and lithium secondary battery electrolyte containing it

ActiveCN105440010BImprove featuresImprove swelling (swelling) phenomenonOrganic chemistryLi-accumulatorsElectrical batteryPhysical chemistry

The present invention provides a novel compound, a lithium secondary battery electrolyte containing it and a lithium secondary battery containing the lithium secondary battery electrolyte of the present invention, the high temperature stability and low temperature discharge capacity of the secondary battery electrolyte of the present invention And life characteristics are very excellent.

Owner:SK ON CO LTD

Biomacromolecular repair agent for lead-acid battery and preparation method thereof

ActiveCN113078376BRestore capacityFormulation ScienceLead-acid accumulatorsElectrolyte/reactants regenerationHydroxybutyric acidEngineering

Owner:WUHAN NARI LIABILITY OF STATE GRID ELECTRIC POWER RES INST

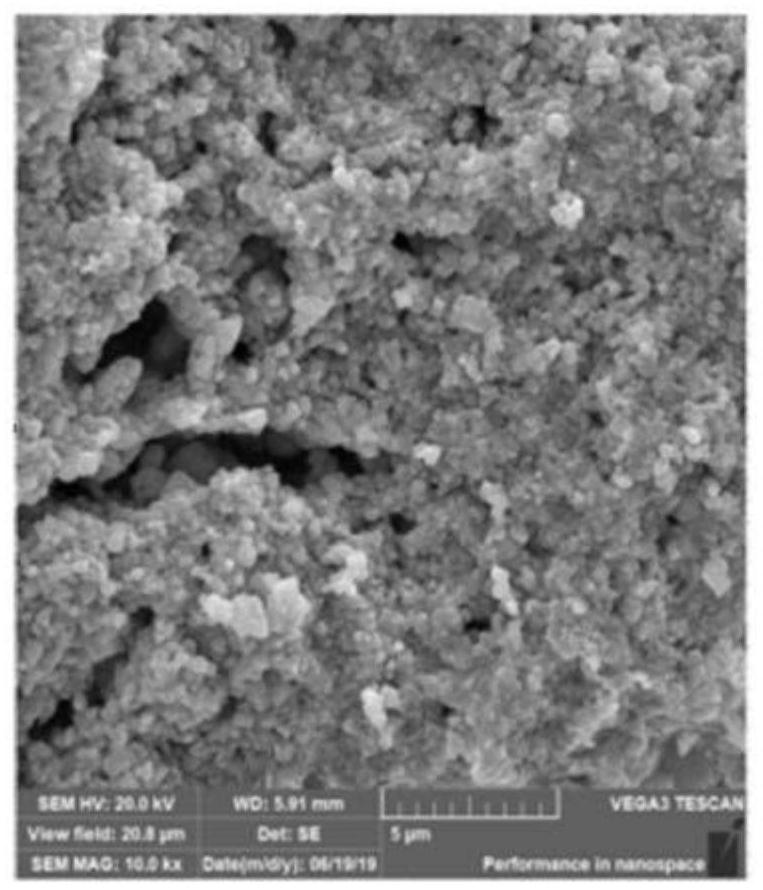

Nano activator of lead-acid storage battery and preparation method of nano activator

InactiveCN111952589ADepolarizationImprove deep discharge capabilityMaterial nanotechnologyElectrode manufacturing processesElectrolytic agentActive agent

The invention belongs to the technical field of lead-acid storage batteries, and particularly relates to a nano activator of a lead-acid storage battery and a preparation method of the nano activator.The nanometer activating agent of the lead-acid storage battery is prepared from the following raw materials in percentage by weight: 6-12 parts of a soluble metal salt, 0.5-1 part of stannous sulfate, 3-8 parts of polyethylene sodium sulfate, 5-9 parts of a water-absorbing amine polymer, 0.6-1.2 parts of polyvinylpyrrolidone, 0.3-0.8 part of nanometer graphene oxide, 20-40 parts of a sulfuric acid solution, 0.5-1 part of a reducing agent, 4-10 parts of ammonium acetate, and 45-75 parts of distilled water. The raw materials are safe and friendly to the environment, and conditions for preparation are mild. The obtained lead-acid storage battery nanometer active agent is convenient to use, the nanometer active agent is directly added into lead-acid storage battery electrolyte, the capacityrepairing rate of a lead-acid storage battery can reach 100%, and the lead-acid storage battery nanometer active agent is small in dosage, rapid in activation, comprehensive in repairing function, easy for industrial production and worthy of popularization.

Owner:黄俊雄

Lithium secondary battery electrolyte and lithium secondary battery including same

ActiveUS10177410B2Excellent high-temperature storage characteristicDischarge capacityCell electrodesLi-accumulatorsOrganic solventLithium-ion battery

Owner:SK ON CO LTD

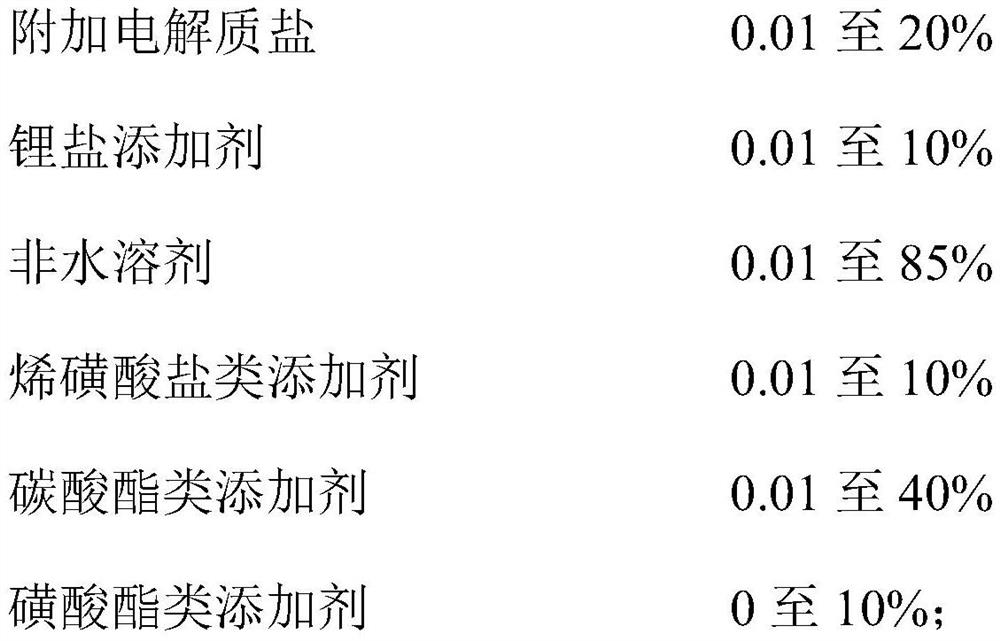

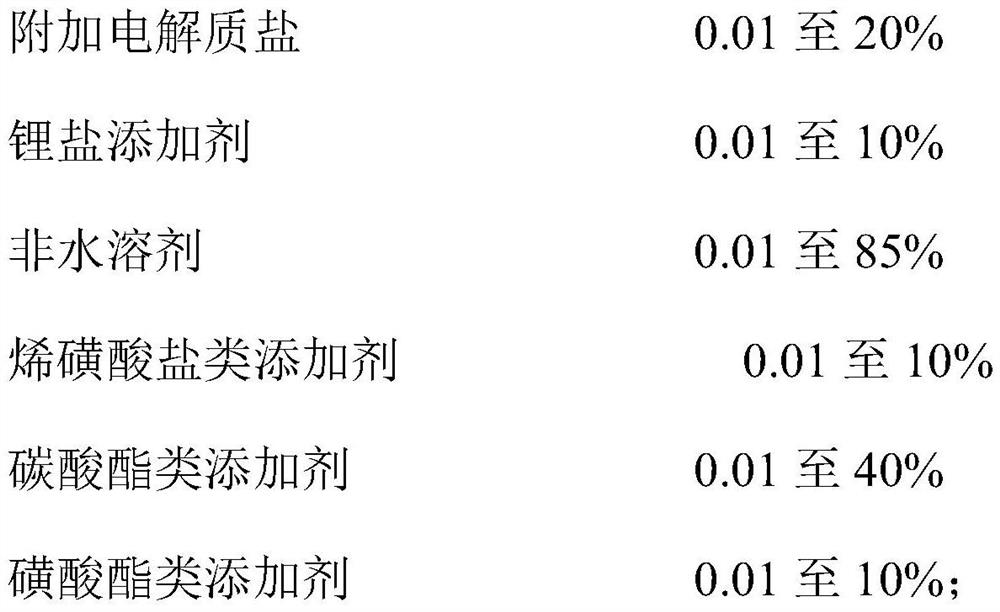

Non-aqueous electrolyte for lithium battery and lithium ion battery

PendingCN114361594AGood lithium conduction performanceLower impedanceSecondary cellsElectrolytic agentPhysical chemistry

The invention discloses a non-aqueous electrolyte for a lithium battery and the lithium ion battery. The non-aqueous electrolyte for the lithium battery comprises an electrolyte salt, a non-aqueous solvent and an additive, and the additive comprises an olefin sulfonate additive. According to the non-aqueous electrolyte for the lithium battery, a small amount of the olefin sulfonate additive is added, DTD, PS and PST are not used at the same time, gas production is reduced, the non-aqueous electrolyte has high film-forming sensitivity, the lithium conductivity of the battery is improved, the impedance of the battery is reduced, and meanwhile the high-temperature cycle and capacity recovery rate are improved.

Owner:ENVISION DYNAMICS TECH (JIANGSU) CO LTD +1

A kind of lead-acid battery repair liquid and preparation method thereof

ActiveCN108493503BImprove electrochemical performanceIncrease profitLead-acid accumulatorsSecondary cells servicing/maintenanceTin dioxideAntioxidant

Belonging to the technical field of lead acid batteries, the invention in particular relates to a lead acid battery repair liquid and a preparation method thereof, and solves the problems of incomplete battery repair, troublesome operation, poor effect, easy secondary pollution, long preparation period of battery repair liquid, low preparation efficiency and poor stability in the prior art. The lead acid battery repair liquid comprises the following raw materials by weight: 0.5-1 part of nano-carbon sol, 0.3-0.8 part of tin dioxide, 2-5 parts of potassium polyvinyl sulfate, 3-8 parts of sodiumpolystyrene sulfonate, 1-1.5 parts of a mixed metal salt, 3-4.5 parts of sodium alginate, 0.8-1.6 parts of an antioxidant, 35-50 parts of a sulfuric acid solution, and 60-90 parts of distilled water.The lead acid battery repair liquid obtained by the invention has the advantages of good stability, comprehensive repair, convenient use, quick effect and long service life, and the lead acid batterycapacity repair rate is up to 100%. Also the preparation method is simple, has the characteristics of simple and easily available raw materials, low preparation cost, and is worth popularizing.

Owner:天能集团(濮阳)再生资源有限公司

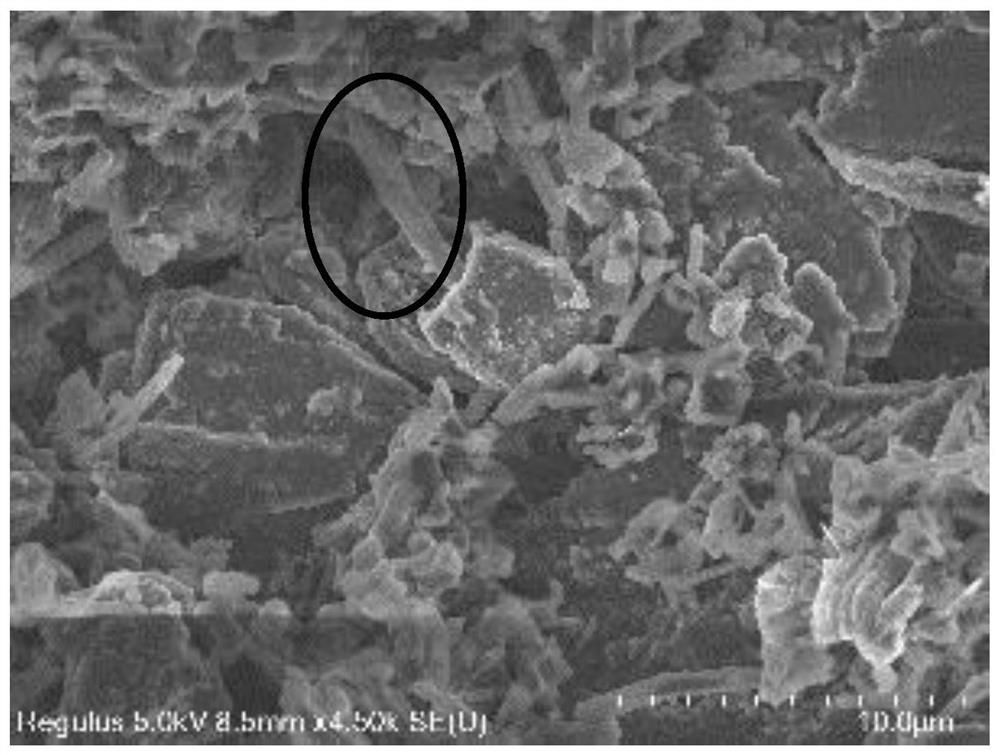

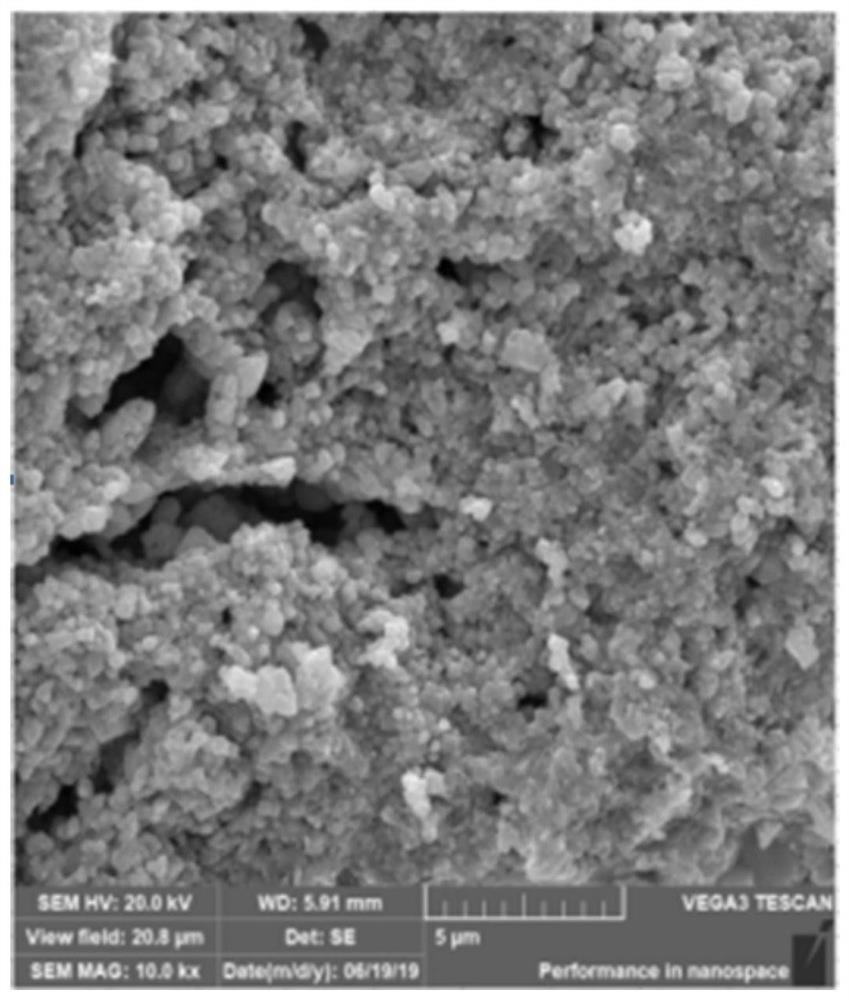

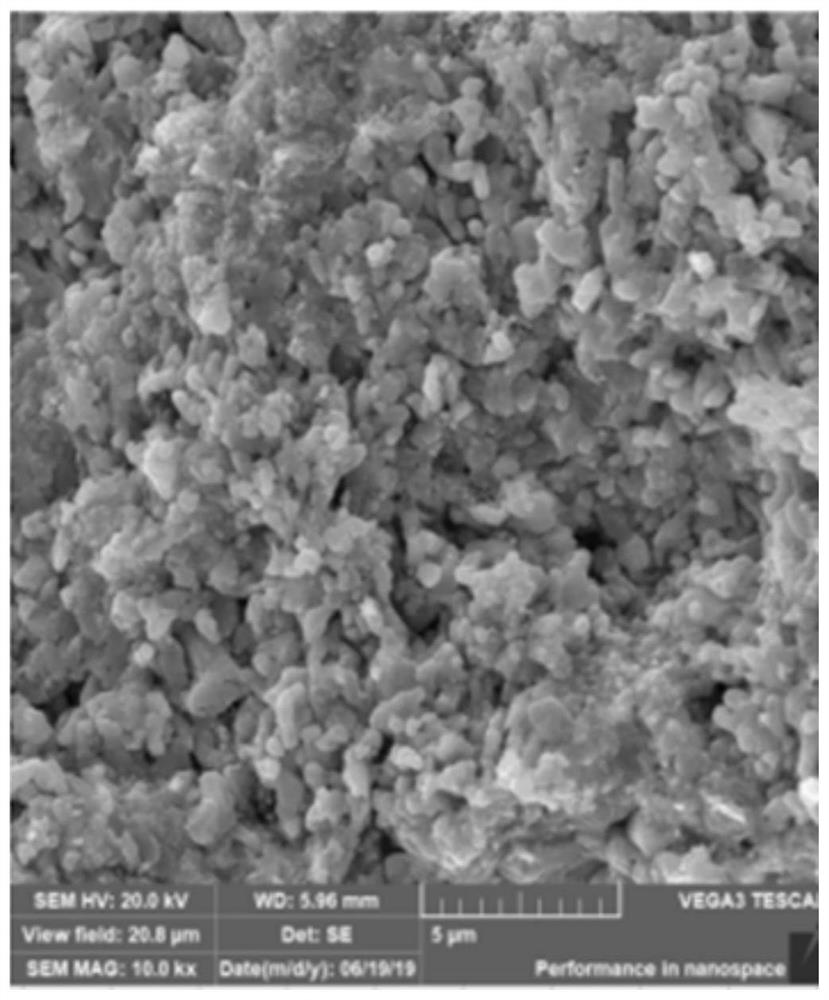

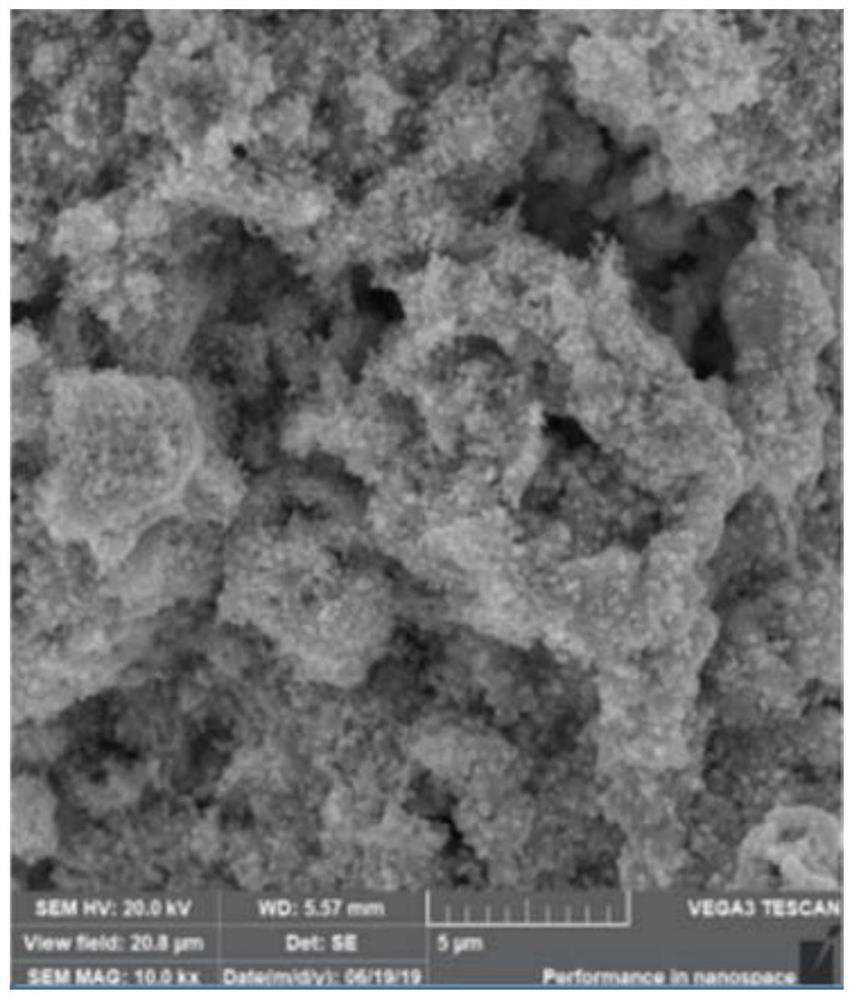

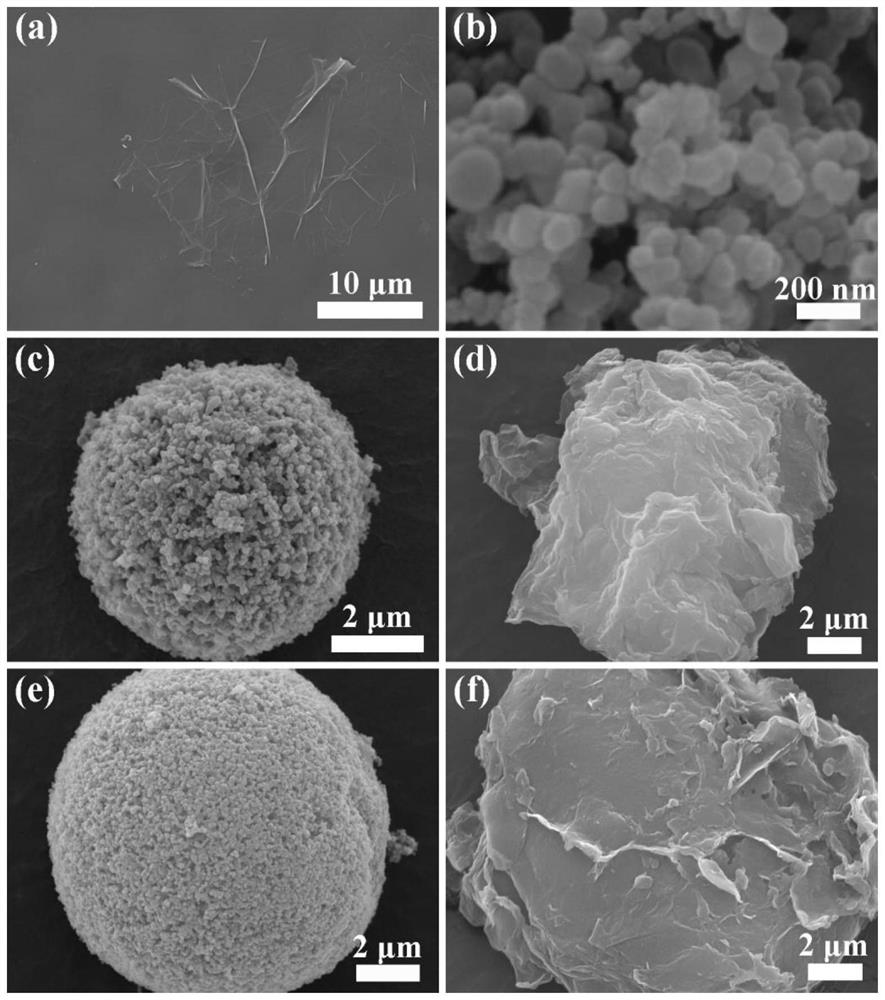

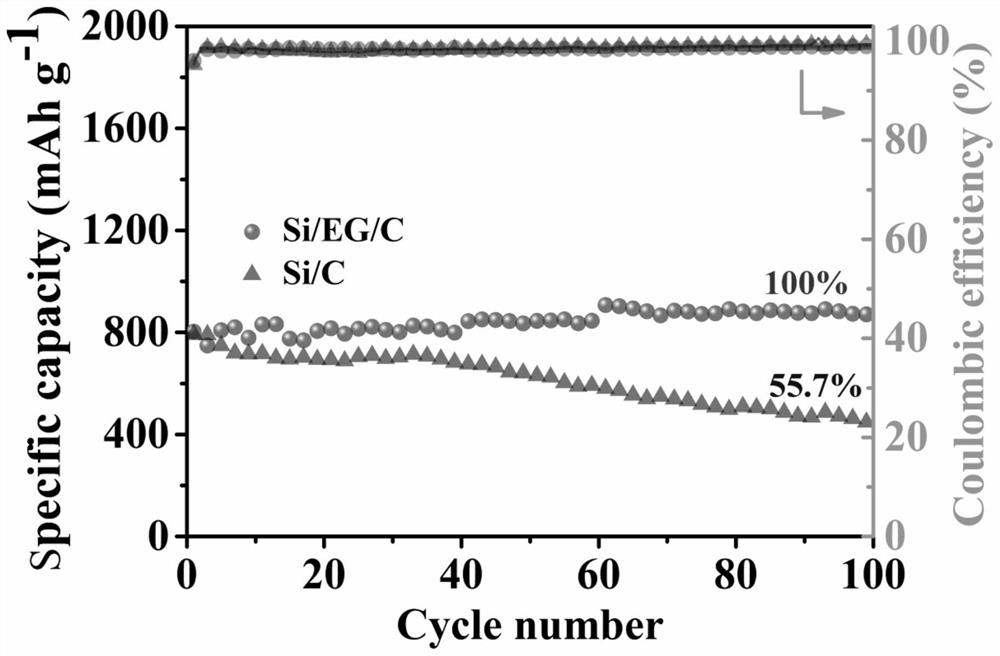

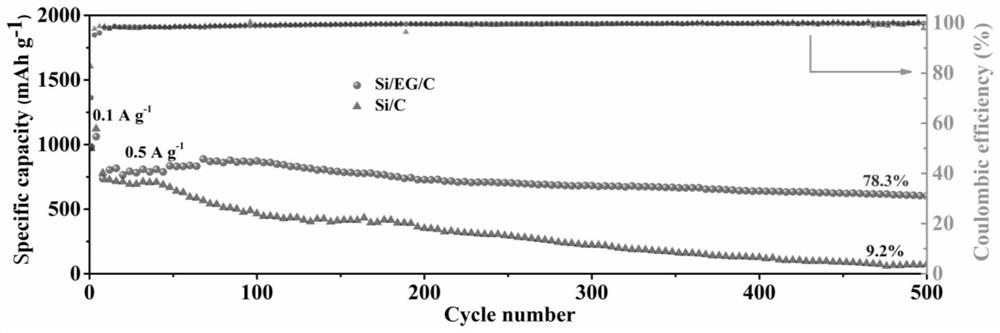

Electrically exfoliated graphene silicon carbon composite material as well as preparation method and application thereof

PendingCN114497493AMove quicklyReduce contact areaCell electrodesSecondary cellsCarbon compositesSpray dried

The invention relates to an electrically exfoliated graphene silicon carbon composite material. A preparation method comprises the following steps: mixing electrically exfoliated graphene, a silicon-based material and a saccharide material according to a certain ratio, and then carrying out ball milling; carrying out spray drying granulation on the ball-milled product; and carrying out high-temperature calcination on the spray-dried product in an inert atmosphere to obtain a final product. The electrically exfoliated graphene silicon carbon composite material is prepared by the preparation method. The invention also discloses an application of the electrically exfoliated graphene silicon carbon composite material in a lithium ion battery. The electrically exfoliated graphene silicon-carbon composite material has the beneficial effects that the electrically exfoliated graphene is compounded with the silicon-based material and the saccharide material to synthesize the electrically exfoliated graphene silicon-carbon composite material with excellent cycle performance, that is, the electrically exfoliated graphene silicon-carbon composite material contains the electrically exfoliated graphene, and the content of the electrically exfoliated graphene can reach 20%; and the adopted method is high in efficiency, the production process is simple and easy to control, and large-scale production is easy.

Owner:HUAZHONG UNIV OF SCI & TECH

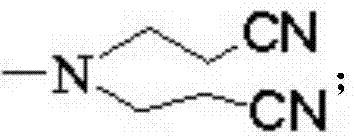

A kind of electrolytic solution containing nitrile ethylamine and a kind of lithium secondary battery

ActiveCN104681868BInhibition of irreversible oxidation reactionsImprove oxidation resistanceSecondary cellsHigh temperature storageOrganic solvent

The invention discloses electrolyte-containing nitrile ethyl amine and a lithium secondary battery. The electrolyte comprises electrolyte lithium salt, nitrile ethyl amine, a non-water organic solvent and an additive, wherein the concentration of the electrolyte lithium salt in electrolyte is 0.5-2mol / L; the nitrile ethyl amine is 0.1%-20% (in percentage by weight) of the electrolyte; the used amount of the additive is 0.1-10.0% of the weight of the organic solvent. The nitrile ethyl molecular structure comprises more than one pair of bisnitrile functional groups and can be complexed with transitional metal ions, is added by a small amount to effectively inhibit irreversible oxidation reaction of the organic solvent on a positive surface, so that the oxidization resistance of the electrolyte is improved; the nitrile ethyl molecular structure contains a Louis alkaline amine radical, and can be used for effectively stabilizing physical and chemical properties of the electrolyte through the complexing between the amine and free trace HF and PF5 in the electrolyte. With the technical characteristics, the nitrile ethyl amine is beneficial to improving the circulating performances of the battery under high voltage, so that a gas inflation rate of the battery under a high-temperature storage environment is reduced, and a capacity recovery rate is increased.

Owner:GUANGZHOU TINCI MATERIALS TECH

A kind of electrolyte of lithium ion battery and application thereof

ActiveCN103779606BAppropriate viscosityImprove high temperature resistanceSecondary cellsTemperature resistanceRetention ratio

The invention relates to electrolyte of a lithium ion battery and application of the electrolyte. The electrolyte consists of electrolytes, an organic solvent and additives, wherein the additives consist of the following components by taking the total weight of the electrolyte as standard: 5-6.5% of 4,5-diethyl vinylene carbonate, 0.5-3.5% of 4-methyl-5-propyl vinylene carbonate, 3-5.2% of trimethylene sulfite, and 0.01-0.45% of methyl tertiary butyl ether. The electrolyte adopts a four-solvent system, so that the electrolyte has proper dielectric constant and viscosity; the four functional additives are added to form an SEI film with compactness and stability, meanwhile, the stability of the high-temperature SEI film at high temperature can be improved, and the high-temperature resistance of the electrolyte can be improved; the conductivity of the electrolyte is high, and the rate and the power characteristic of a lithium iron phosphate power battery can be improved effectively; the lithium ion power battery can be stored at high-temperature state, the capacity retention ratio and the capacity recovery rate are high, and the cycle performance is good.

Owner:NINGBO VEKEN BATTERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com