Lead acid battery repair liquid and preparation method thereof

A technology of lead-acid battery and repair liquid, which is applied in the direction of lead-acid battery, secondary battery repair/maintenance, secondary battery, etc., and can solve the problems of incomplete repair function of battery repair liquid, incomplete battery repair, long preparation cycle, etc. , to achieve the effect of improving electrochemical performance, improving dry charge starting performance, and enhancing electrostatic repulsion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

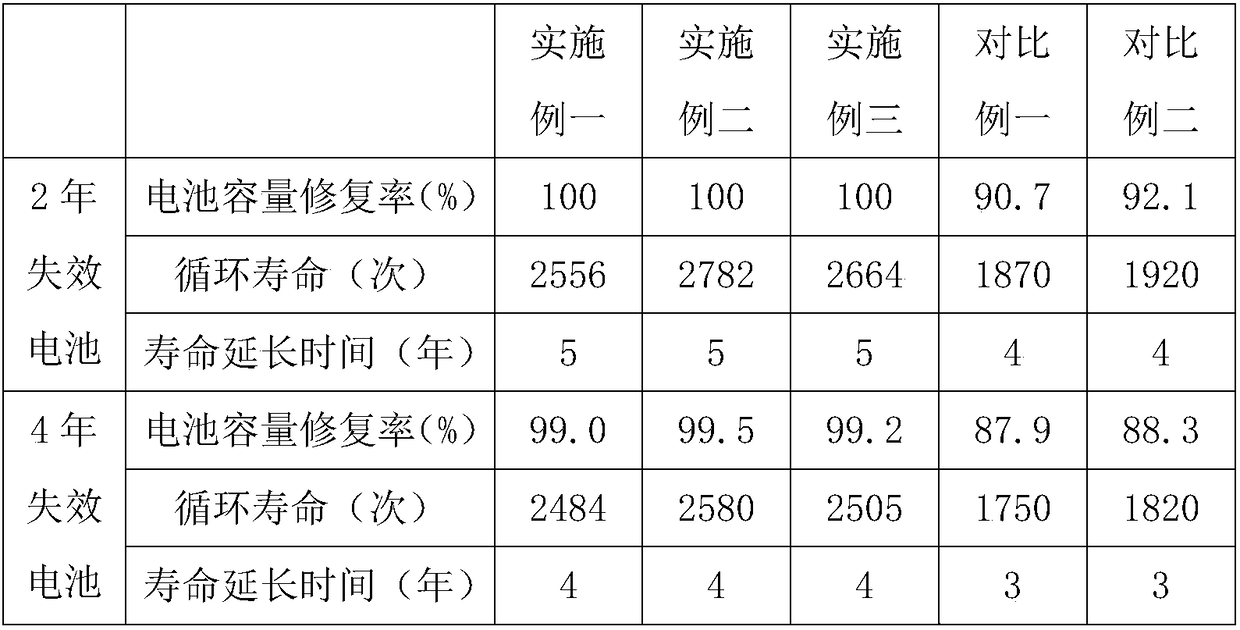

Embodiment 1

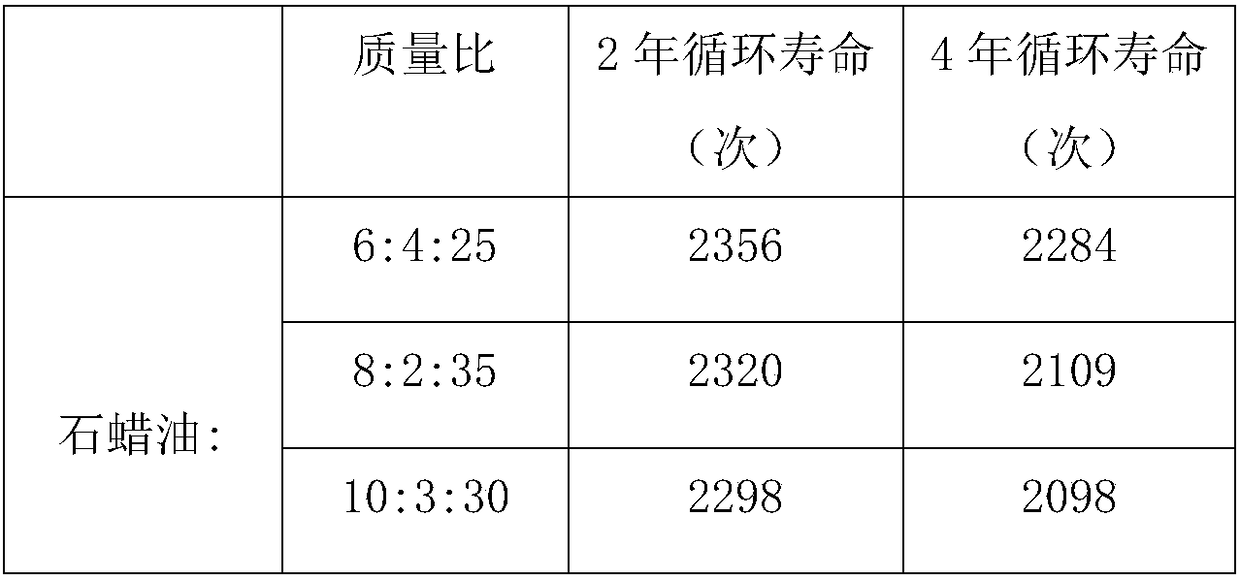

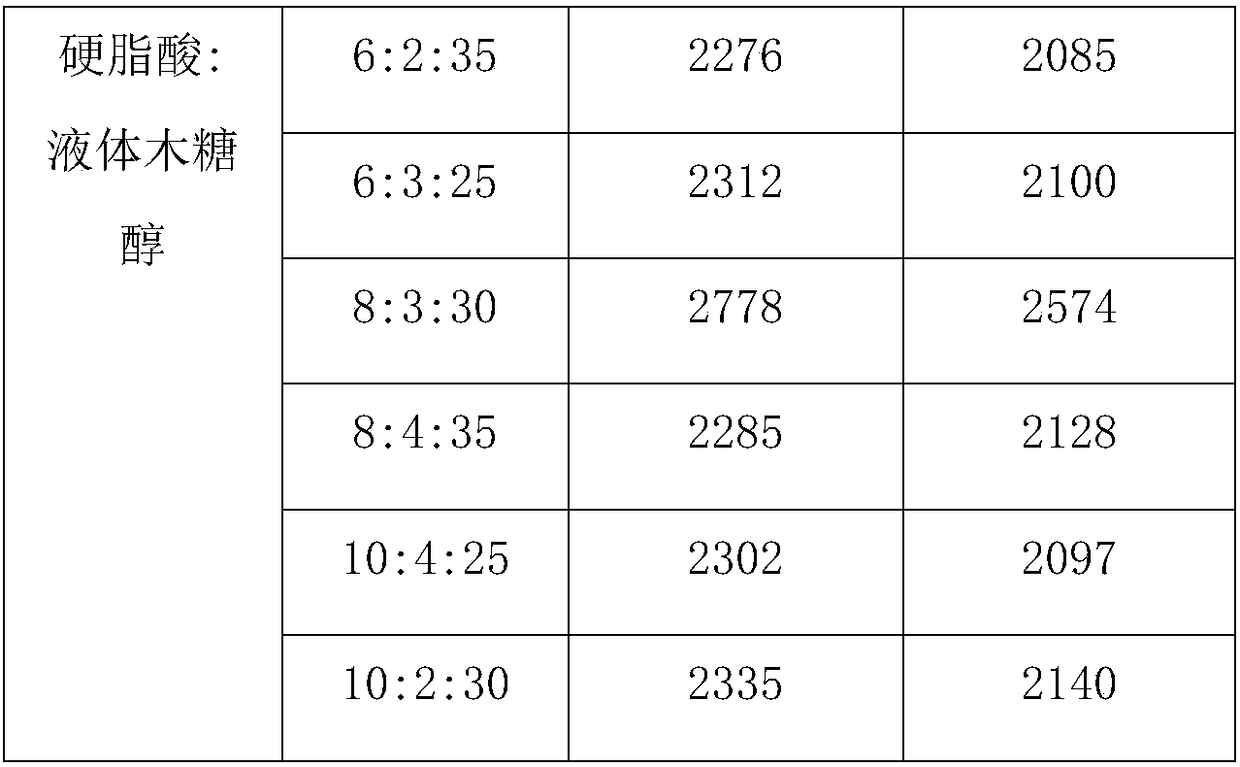

[0023] A kind of repair solution for lead-acid battery proposed by the present invention comprises the following raw materials in parts by weight: 0.5 part of nano carbon sol, 0.3 part of tin dioxide, 2 parts of potassium polyvinyl sulfate, 3 parts of sodium polystyrene sulfonate, mixed metal salt 1 part, 3 parts of sodium alginate, 0.8 parts of antioxidant, 35 parts of sulfuric acid solution, 60 parts of distilled water, wherein the concentration of polyvinyl potassium sulfate is 0.02mol / L, and the density of sulfuric acid solution is 1.12g / cm 3 , the mixed metal salt is a composition of copper chloride, zinc sulfate and barium sulfate, and the antioxidant is a compounding agent of paraffin oil, stearic acid and liquid xylitol in a mass ratio of 6:2:25.

[0024] Its preparation method comprises the following steps:

[0025] S1. According to the specific gravity, add sodium alginate into distilled water, stir and mix evenly, then raise the temperature to 48°C, add mixed metal ...

Embodiment 2

[0029] A kind of repair solution for lead-acid battery proposed by the present invention comprises the following raw materials in parts by weight: 0.7 part of nano carbon sol, 0.5 part of tin dioxide, 3 parts of polyvinyl potassium sulfate, 5 parts of sodium polystyrene sulfonate, mixed metal salt 1.3 parts, 3.9 parts of sodium alginate, 1.2 parts of antioxidant, 42 parts of sulfuric acid solution, 75 parts of distilled water, wherein the concentration of polyvinyl potassium sulfate is 0.028mol / L, and the density of sulfuric acid solution is 1.22g / cm 3 , the mixed metal salt is the composition of lead sulfate, calcium chloride, copper chloride, zinc sulfate and barium sulfate, and the antioxidant is a compound of paraffin oil, stearic acid and liquid xylitol in a mass ratio of 8:3:30. Dispensing.

[0030] Its preparation method comprises the following steps:

[0031] S1. According to the specific gravity, add sodium alginate into distilled water, stir and mix evenly, then rai...

Embodiment 3

[0035] A kind of lead-acid storage battery repair liquid that the present invention proposes, comprises the raw material of following weight part: 1 part of nano-carbon sol, 0.8 part of tin dioxide, 5 parts of polyvinyl potassium sulfate, 8 parts of sodium polystyrene sulfonate, mixed metal salt 1.5 parts, 4.5 parts of sodium alginate, 1.6 parts of antioxidant, 50 parts of sulfuric acid solution, 90 parts of distilled water, wherein the concentration of polyvinyl potassium sulfate is 0.035mol / L, and the density of sulfuric acid solution is 1.32g / cm 3 , the mixed metal salt is a composition of lead sulfate, calcium chloride and copper chloride, and the antioxidant is a compound of paraffin oil, stearic acid and liquid xylitol in a mass ratio of 10:4:35.

[0036] Its preparation method comprises the following steps:

[0037] S1. According to the specific gravity, add sodium alginate into distilled water, stir and mix evenly, then raise the temperature to 65°C, add mixed metal sa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com