High-temperature electrolyte and lithium battery

An electrolyte and lithium battery technology, applied in secondary batteries, circuits, electrical components, etc., can solve problems such as low solubility, corrosion of aluminum foil prices, and corrosion of negative electrode SEI film decomposition electrode materials, to improve high temperature and cycle performance, The effect of high capacity recovery rate and improved high temperature cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0025] Embodiment: This embodiment relates to a high-temperature electrolyte, including: lithium salt, high-temperature additives, non-aqueous organic solvents and other additives;

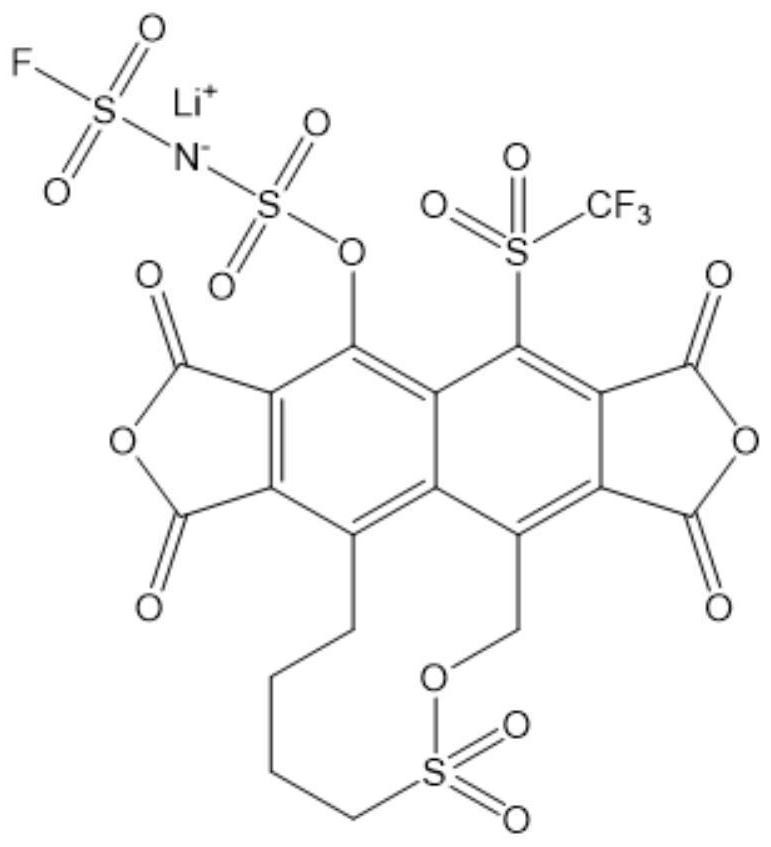

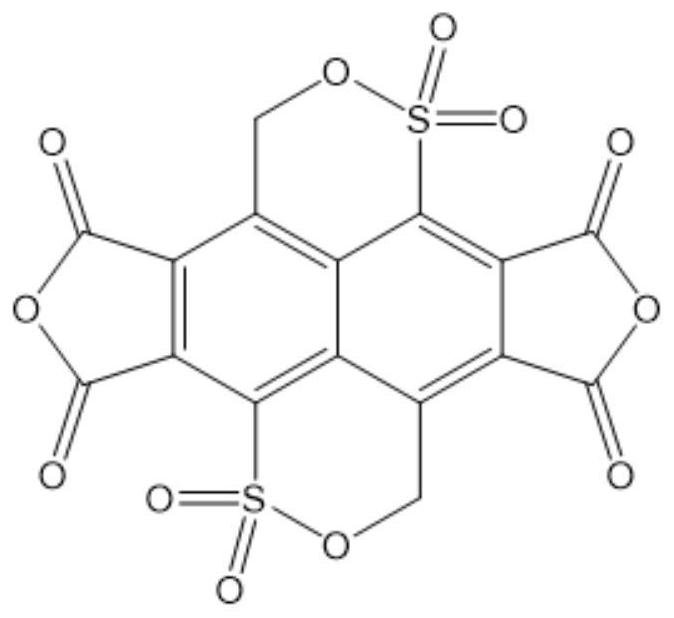

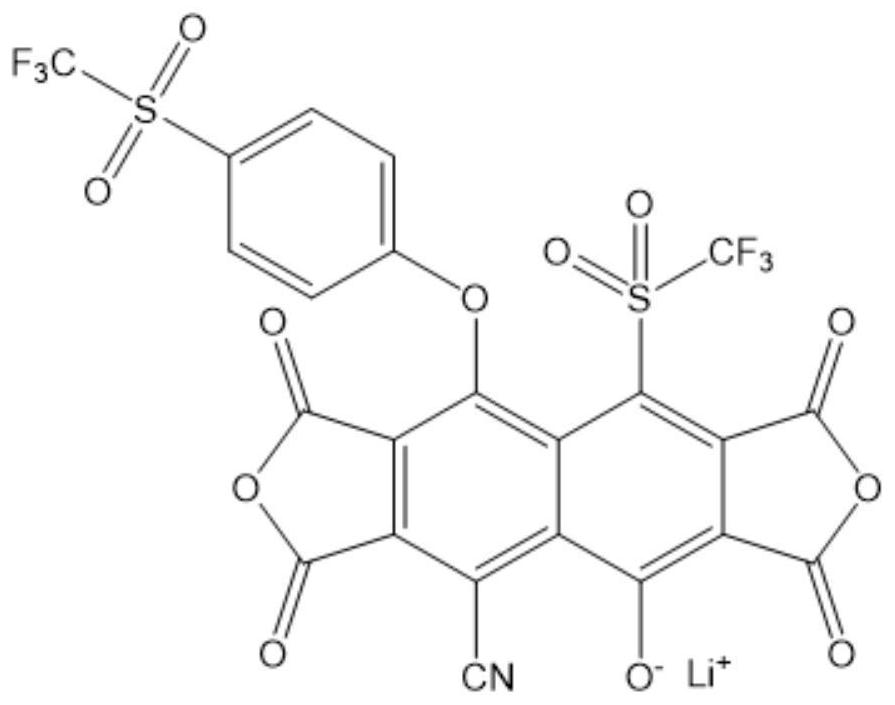

[0026] The general structural formula of the high temperature additive is as figure 1 As shown, wherein R1, R2, R3, R4 are fluorine, cyano, isocyanate, fluorosulfonyl, fluorosulfonylphenyl, fluorosulfonyl, fluorosulfonylphenyl, trifluoromethanesulfonyl, trifluoromethanesulfonyl, respectively Fluoromethanesulfonylphenyl, trifluoromethanesulfonate, trifluoromethanesulfonylphenyl, fluorosulfonimide lithiumsulfonyl, fluorosulfonyl imide lithiumsulfonylphenyl, fluorosulfonimide lithiumsulfonyl Acid group, fluorosulfonimide lithium sulfonate group, trifluoromethanesulfonyl imide lithium sulfonyl group, trifluoromethanesulfonyl imide lithium sulfonyl phenyl group, trifluoromethanesulfonyl imide lithium sulfonyl group, three Lithium fluoromethanesulfonyl sulfonate phenyl, lithium oxy, alkyl with 1-6 carb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com