Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "Has a yield strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-strength hot rolled steel plate for counter enameling and manufacturing method thereof

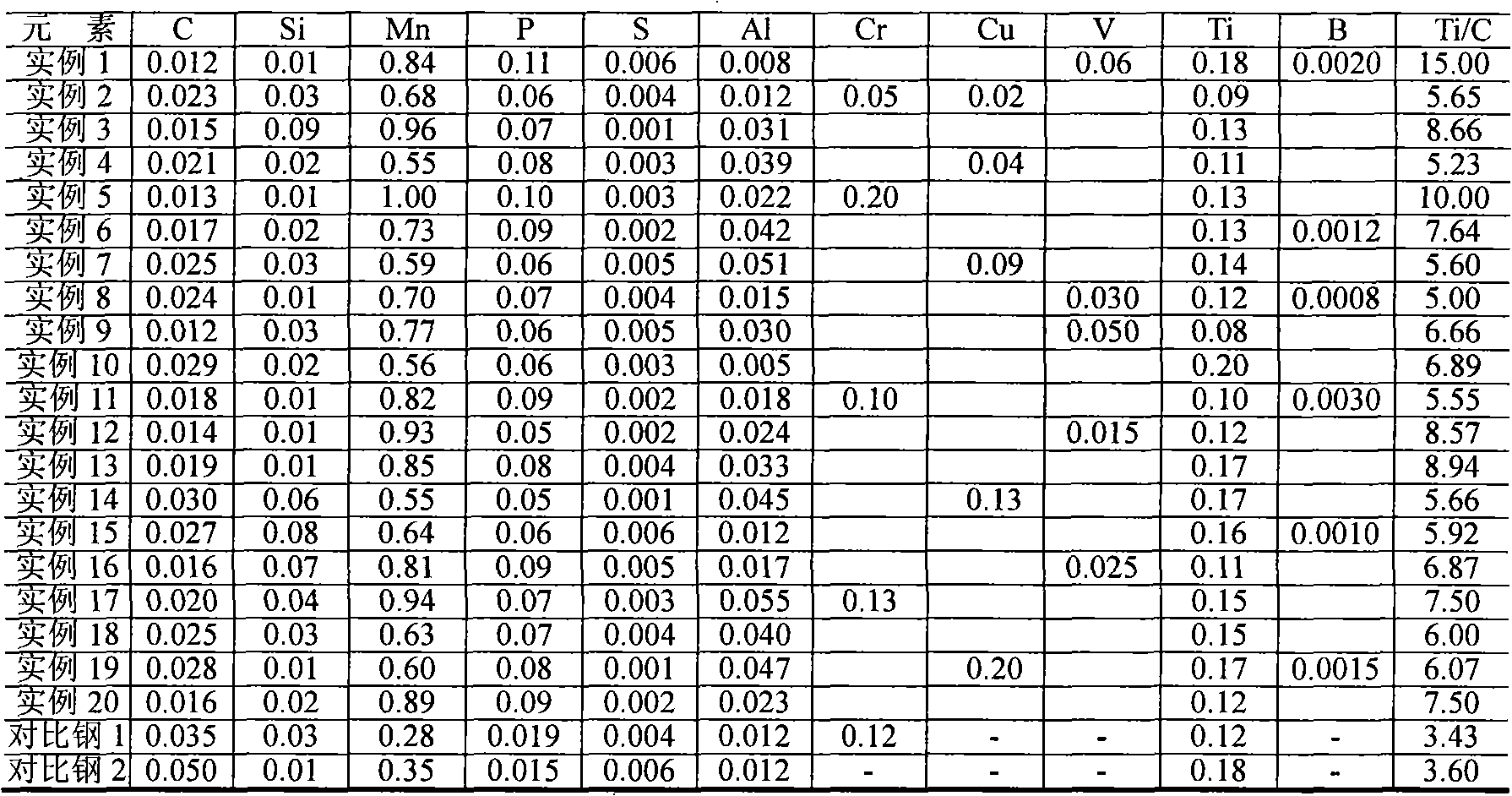

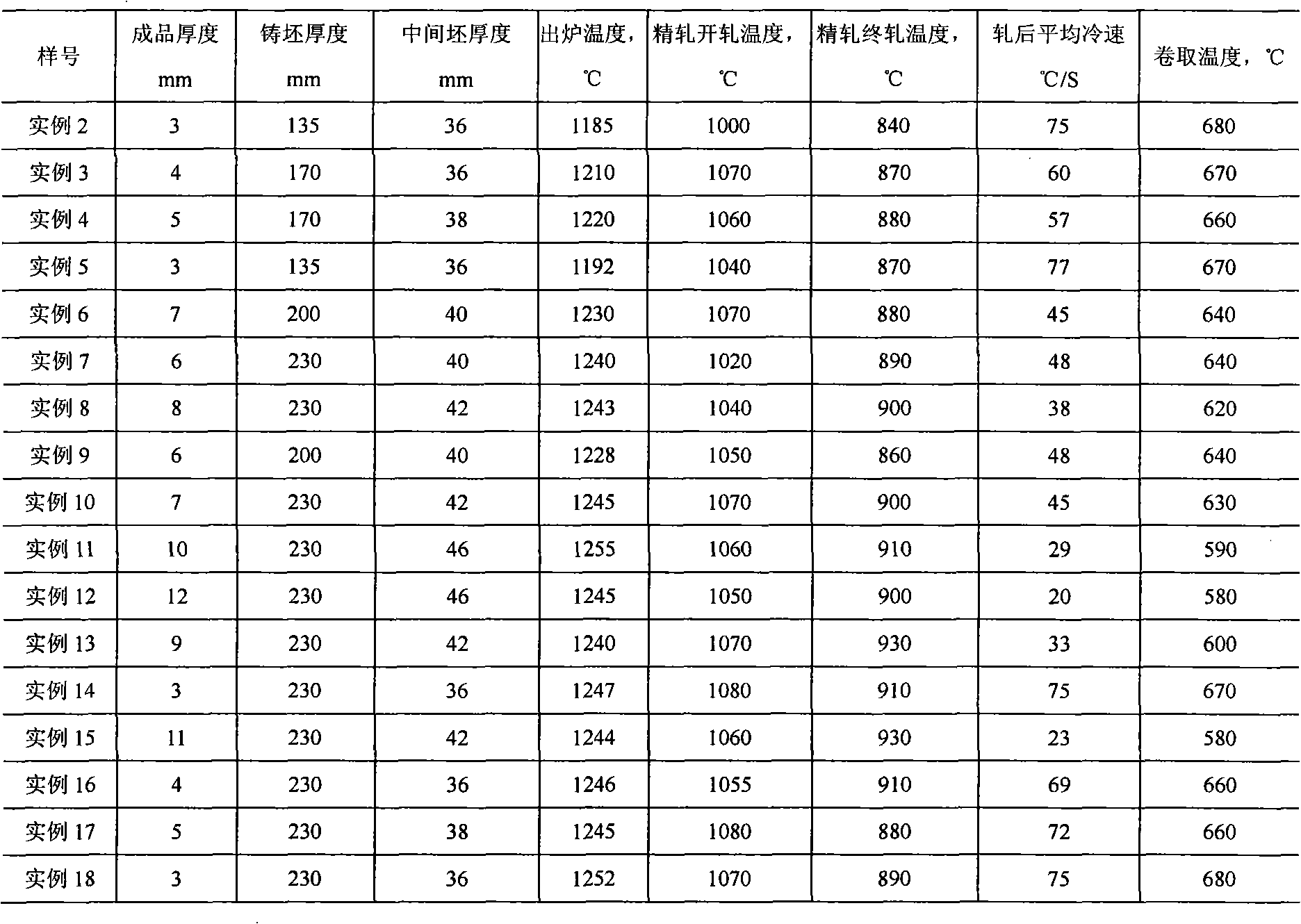

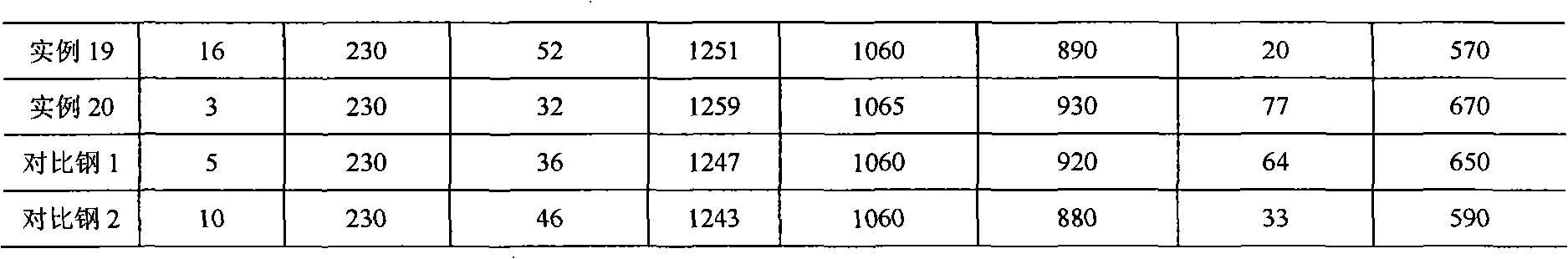

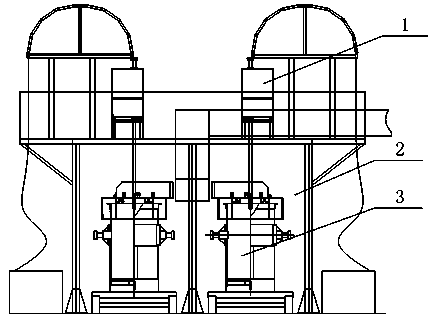

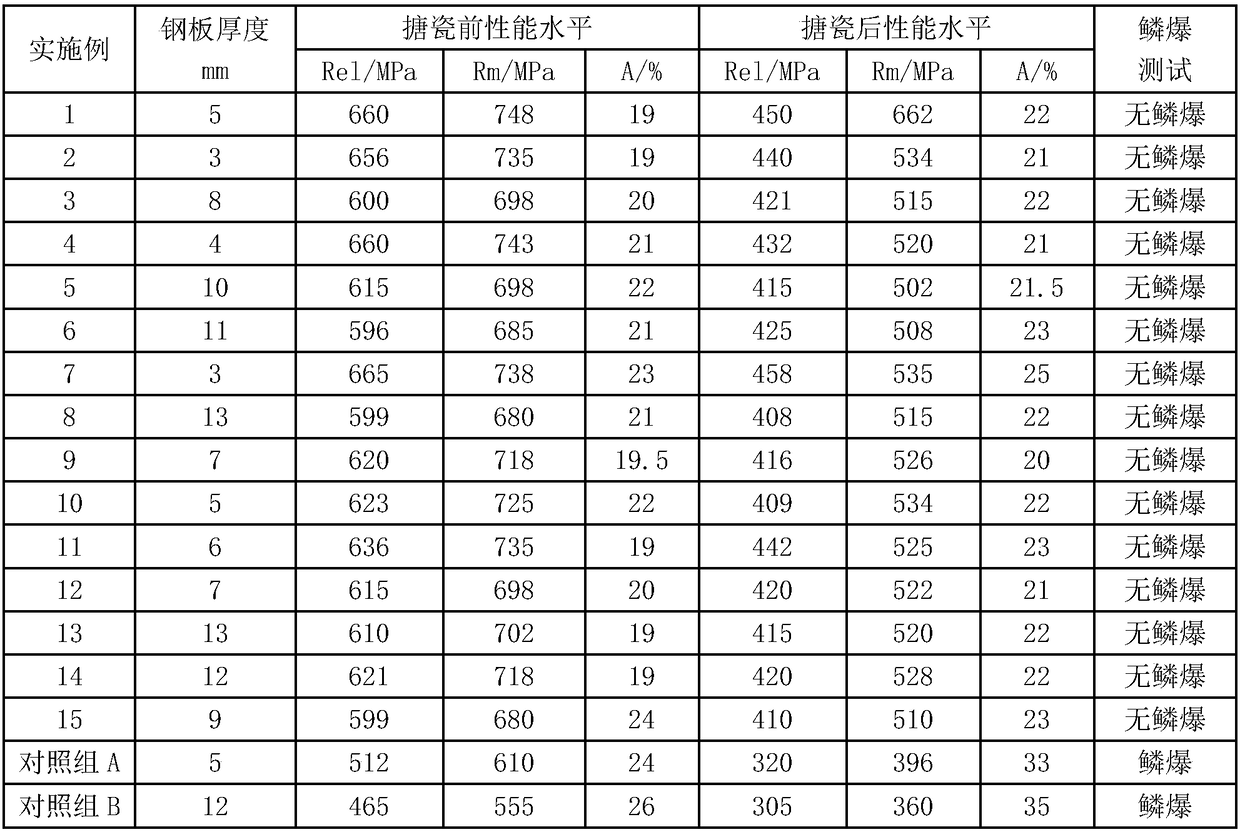

The invention relates to a high-strength hot rolled steel plate for counter enameling and a manufacturing method thereof. The high-strength hot rolled steel plate for counter enameling comprises the following smelting components in weight percent: 0.012-0.03 percent of carbon (C), not greater than 0.10 percent of silicon (Si), 0.55-1.0 percent of manganese (Mn), 0.05-0.11 percent of phosphorus (P), not greater than 0.006 percent of sulfur (S), not greater than 0.005 percent of nitrogen (N), 0.08-0.20 percent of titanium (Ti), 0.005-0.055 percent of aluminum sulfide (Als), 5-15 percent of Ti / C and the balance of ferrum and inevitable impurities, wherein more than one or two of vanadium, boron (B), copper (Cu) and chromium (Cr) is selectively added. The manufacturing method comprises the following steps: producing a plate blank through continuous casting; evenly heating the plate blank to 1180-1260 DEG C; then, removing phosphorous with high-pressure water and carrying out rough rolling to prepare an intermediate blank; carrying out 5-7-pass finish rolling to target thickness; carrying out laminar flow cooling to 570-680 DEG C and coiling. The high-strength hot rolled steel plate for the counter enameling has no phosphorus explosion; the yield strength is higher than 280MPa after the high-strength hot rolled steel plate for the counter enameling is enameled under the conditions that the temperature is 800-920 DEG C and the thickness is greater than 8mm. The high-strength hot rolled steel plate for the counter enameling is suitable for roll forming, bend forming and simple punch forming and is a reliable special steel plate material for a counter enameling assembly structure.

Owner:ANGANG STEEL CO LTD

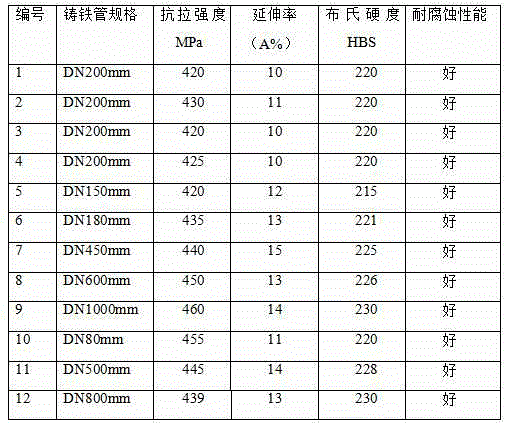

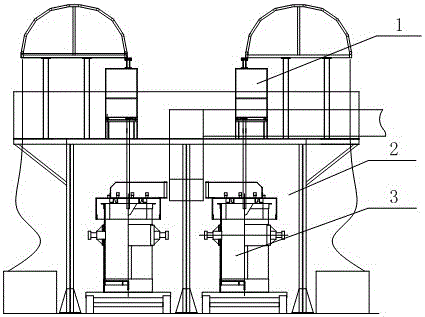

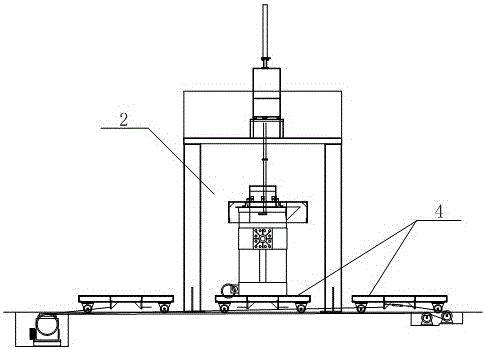

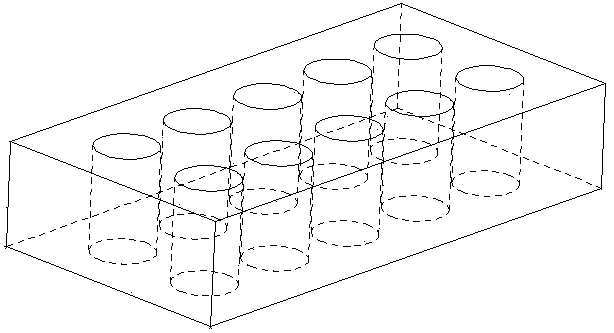

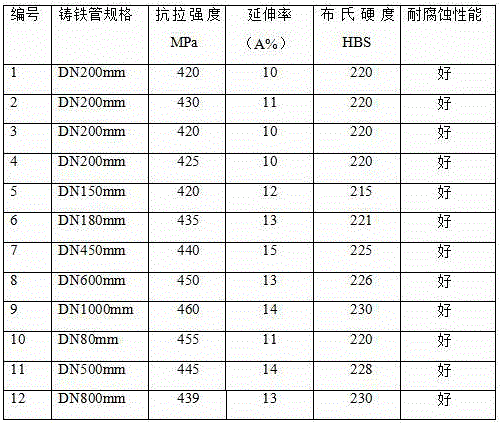

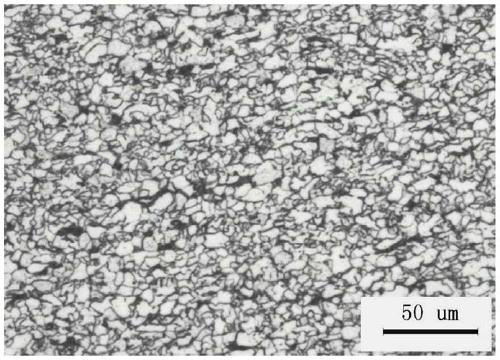

Method for preparing centrifugal nodular cast iron pipe

ActiveCN104480382AImprove appearance qualityRefining material organizationLiquid surface applicatorsCoatingsIRON PREPARATIONSCast iron pipe

The invention discloses a method for preparing a centrifugal nodular cast iron pipe. The method discloses the preparation process of the centrifugal nodular cast iron pipe of high quality, the preparation process comprises a series of operation processes of molten iron preparation, nodulizing of molten iron, centrifugal casting, annealing treatment, pipe body shaping and coating protection and the like. The method is suitable for preparation of cast iron pipes of the specification of DN 80-1000 mm, the application range is wide, and the preparation process is simple. The cast iron pipe prepared through the method has the characteristics of being high in appearance quality, fine in material structure, high in production efficiency, long in service life and the like, and compared with existing steel pipes and gray iron pipes, the cast iron pipe prepared through the method has better decay resistance and tensile property.

Owner:SICHUAN CHUANJIAN PIPES

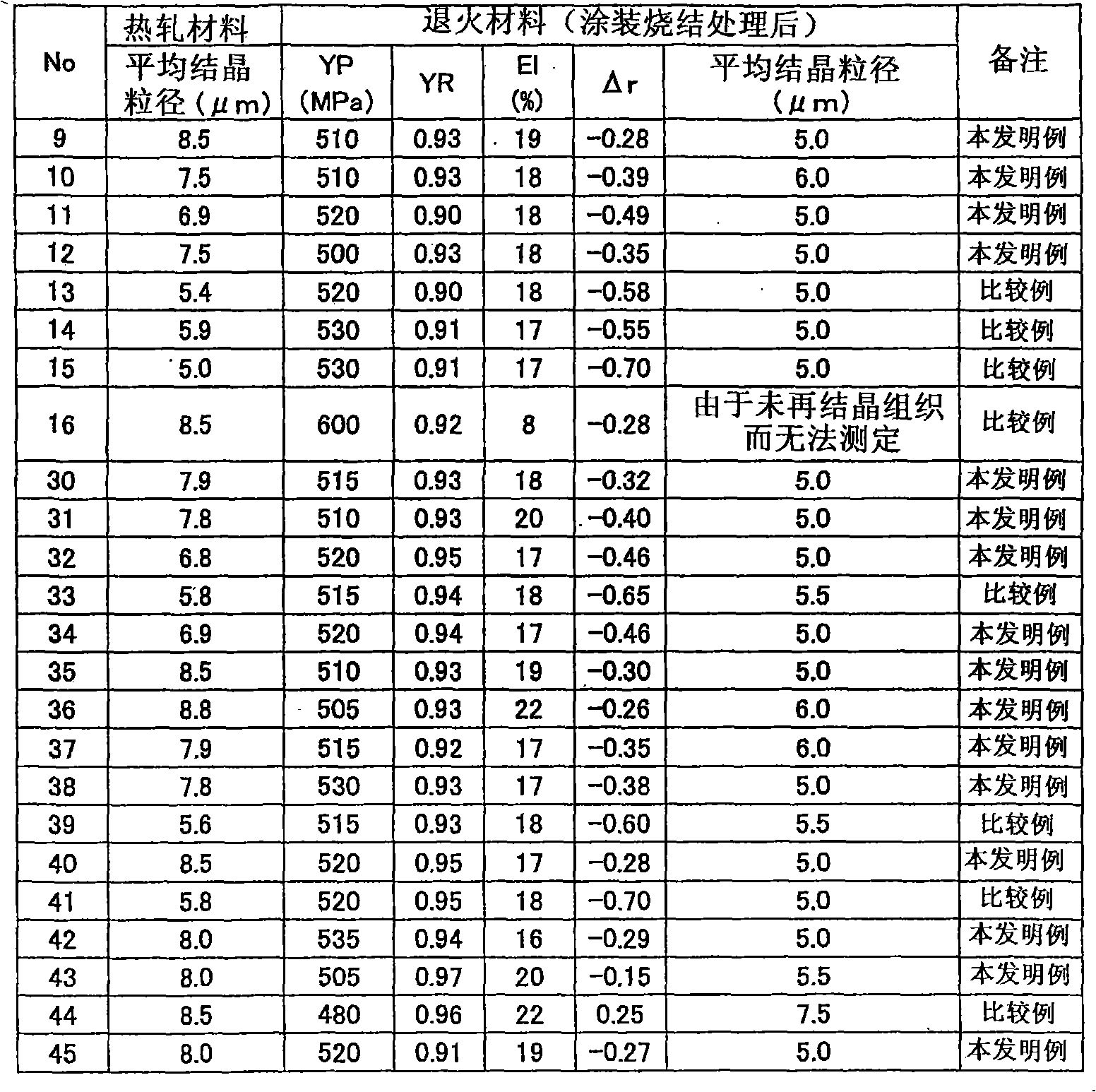

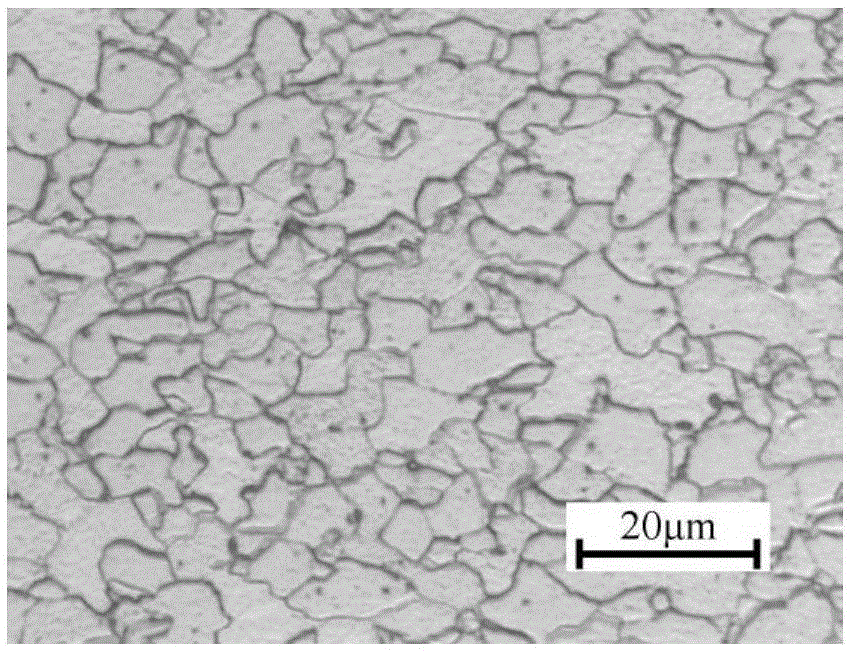

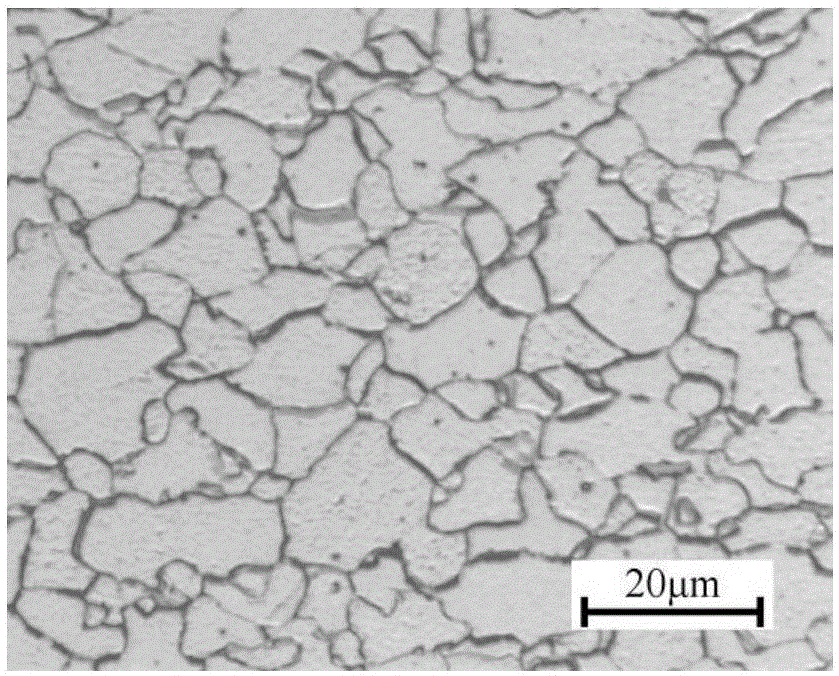

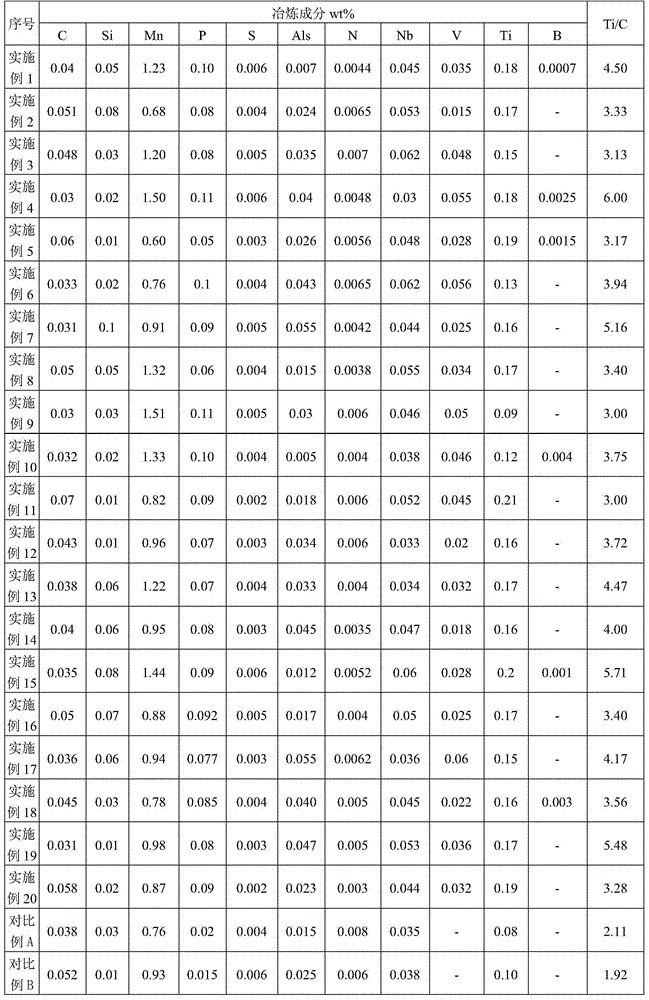

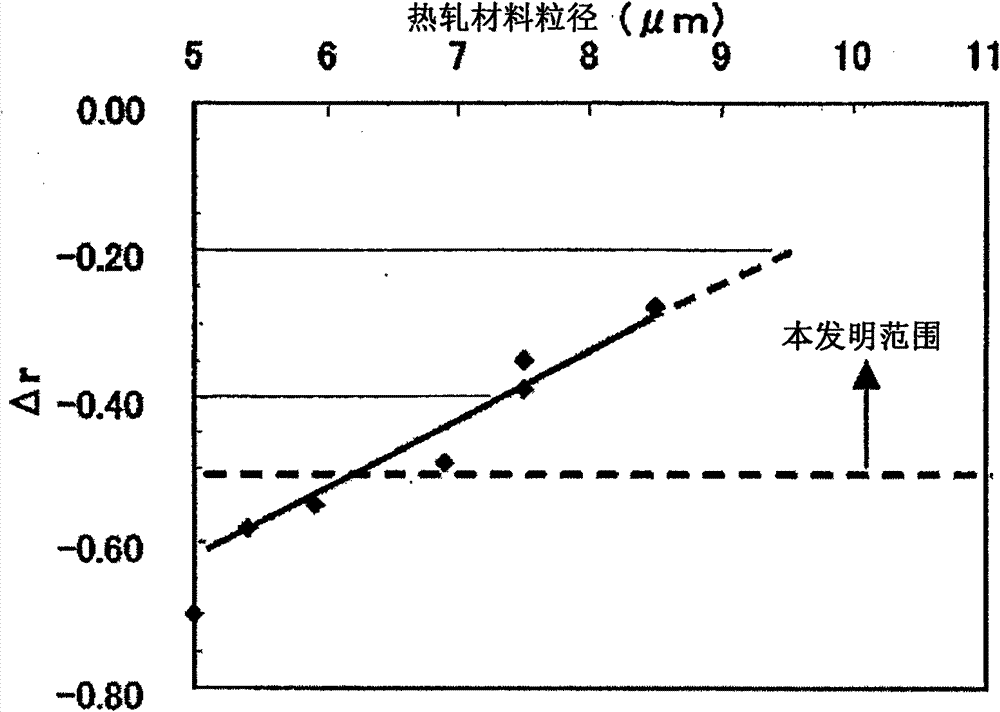

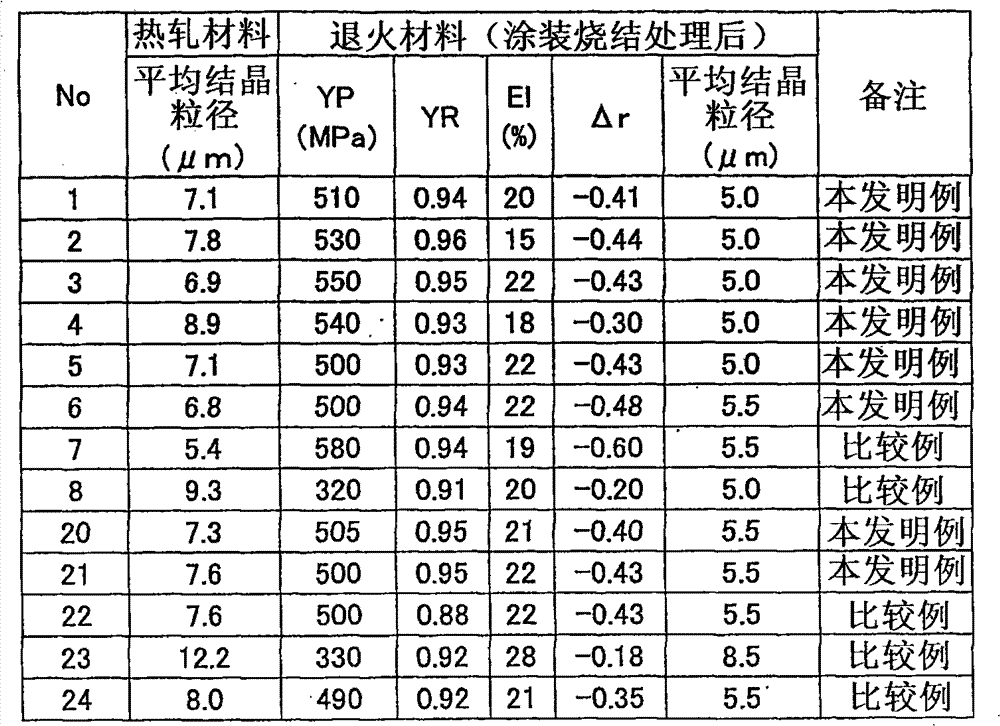

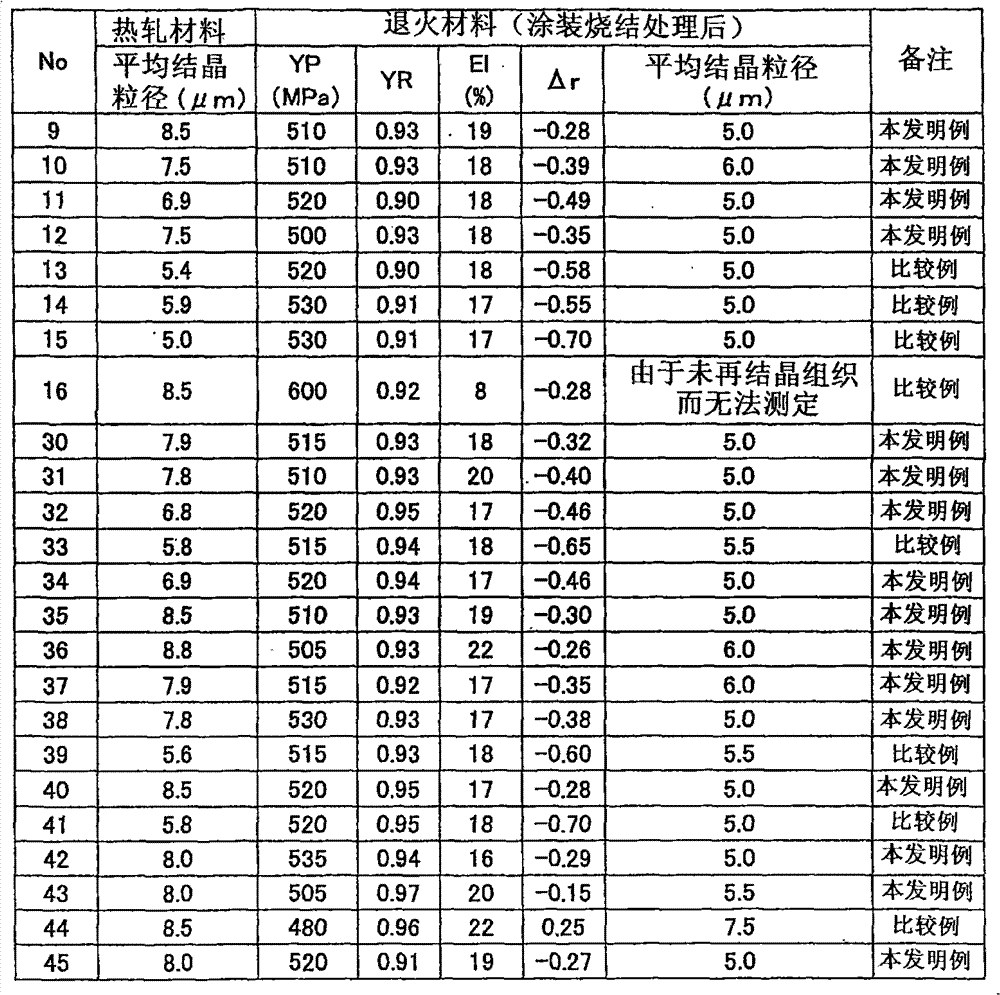

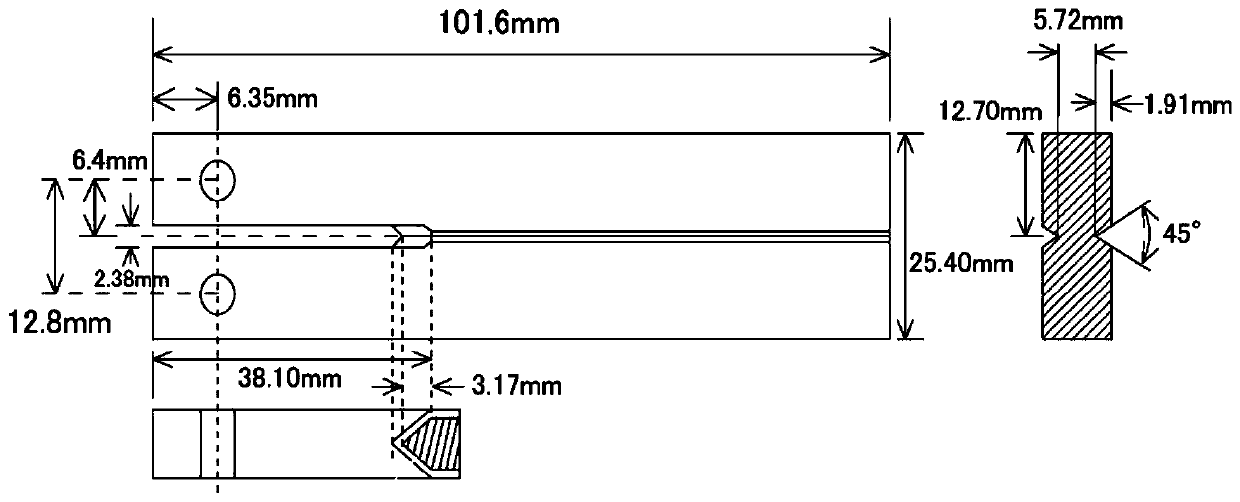

Steel sheet for cans, hot-rolled steel sheet to be used as the base metal and processes for production of both

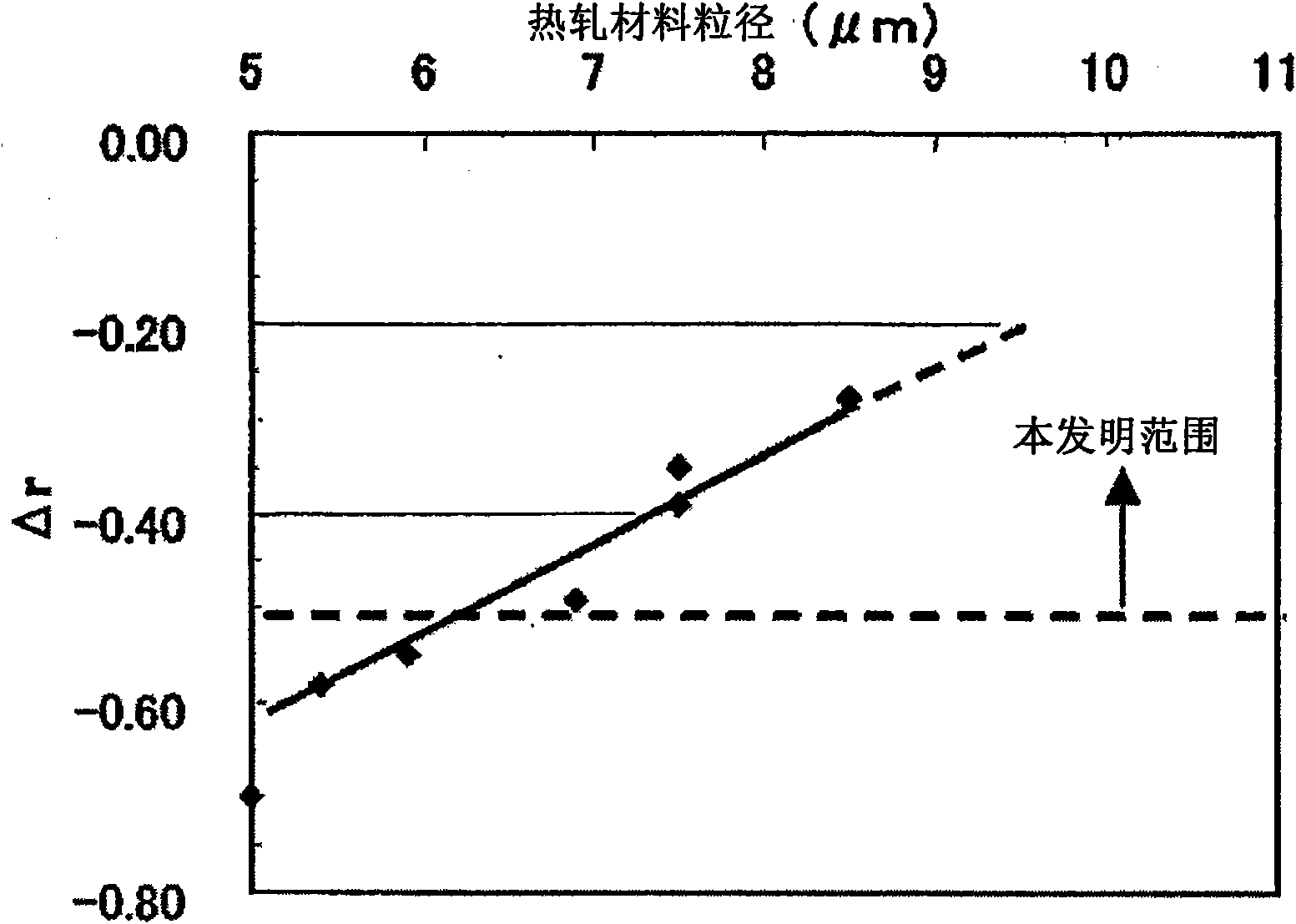

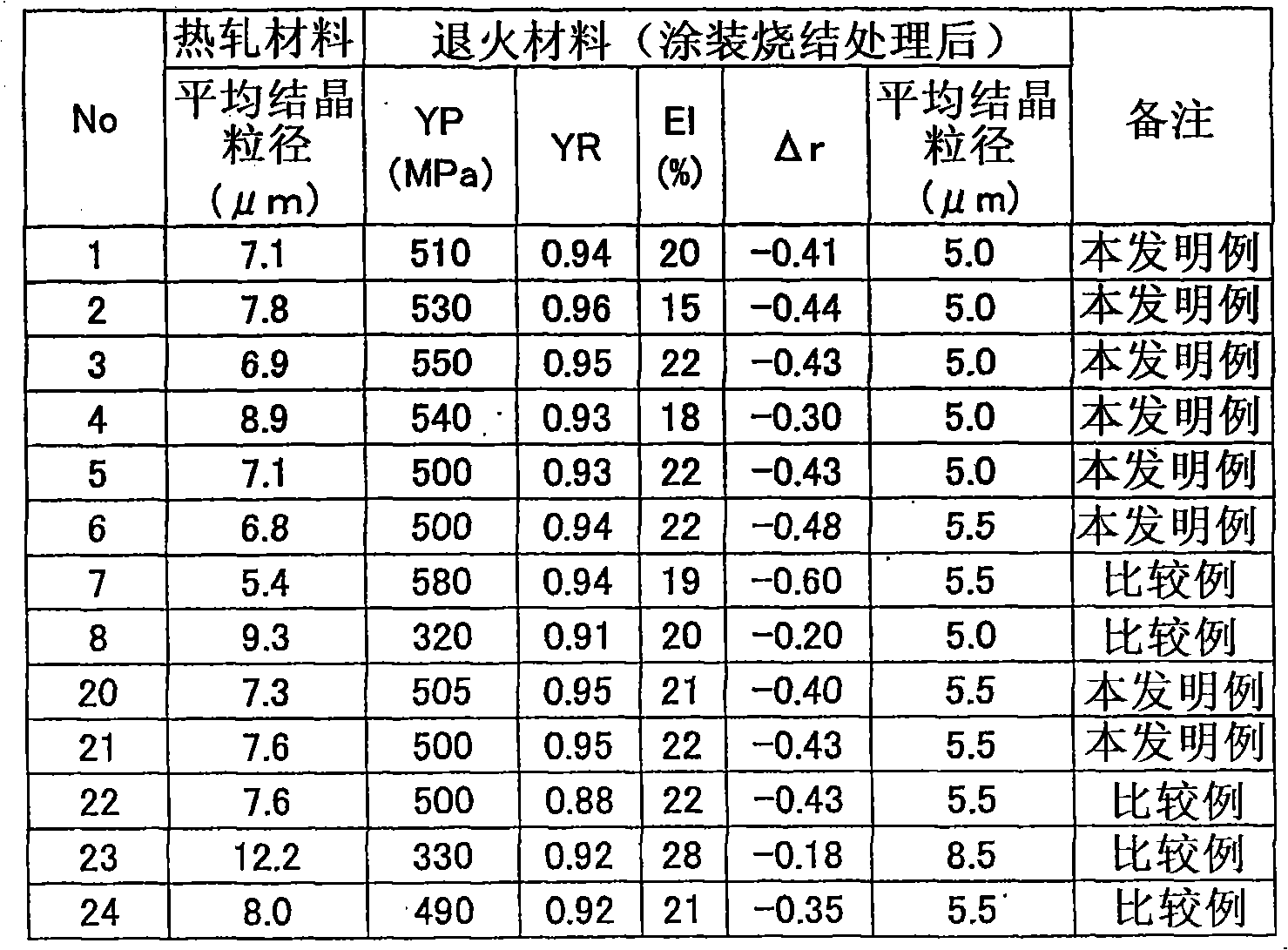

In producing a steel sheet for cans, a steel sheet which consists substantially of ferrite single-phase structure and has a mean grain diameter of 7[mu]m or below and which exhibits a yield strength of 500MPa or above, a yield ratio of 0.9 or above, a total elongation of 10% or above, and deltar of -0.50 to 0 after coating and baking is produced by incorporating C: 0.01 to 0.12%, Si: 0.005 to 0.5%, Mn: 0.3 to 1.5%, P: 0.005 to 0.2%, Al: 0.10% or below, N: 0.012% or below, and Nb: 0.005 to 0.10% and combining solid solution hardening, precipitation hardening, and grain refinement hardening. The hot rolling is conducted principally under the conditions of FT of 870 DEG C or above, cooling rate after hot rolling of 40 DEG C / s or below, and CT of 620 DEG C or above to adjust the mean grain size of a hot-rolled sheet serving as material for the steel sheet for cans to 6[mu]m or above.

Owner:JFE STEEL CORP

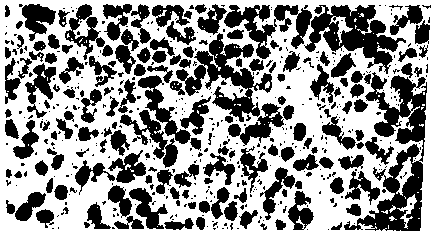

Hot-rolled steel plate for enameled high-strength double-face enamel and manufacturing method of steel plate

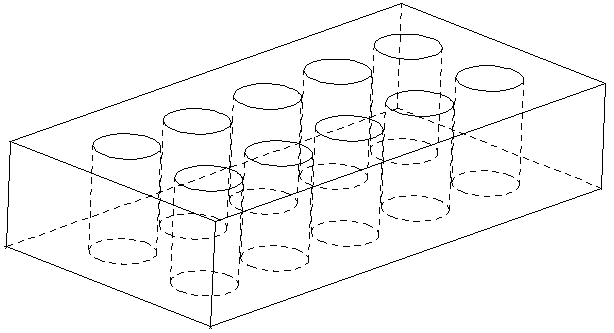

InactiveCN106480368AExcellent anti-scale explosion performanceGuaranteed Yield StrengthHigh pressure waterHigh pressure

The invention discloses a hot-rolled steel plate for enameled high-strength double-face enamel and a manufacturing method of the steel plate. When the thickness of the steel plate is smaller than or equal to 8 mm, the chemical components in the steel comprise, by weight percent, 0.030% to 0.070% of C, not larger than 0.10% of Si, 0.60% to 1.5% of Mn, 0.05% to 0.11% of P, not larger than 0.006% of S, not larger than 0.008% of N, 0.09% to 0.21% of Ti, 0.03% to 0.07% of Nb, 0.015% to 0.060% of V, 0.005% to 0.055% of Als, 3.0% to 6.0% of Ti / C and the balance is Fe and inevitable impurities, when the thickness of the steel plate is larger than 8 mm, B is added, the content of the B ranges from 0.0005% to 0.005%,. The casting blank with the above component is heated to 1180 DEG C to 1250 DEG C, after soaking, high-pressure water descaling and rough rolling cogging are carried out, the finish rolling cogging temperature ranges from 880 DEG C to 1100 DEG C, the finish rolling temperature ranges from 880 DEG C to 930 DEG C, rapid cooling to the reeling temperature is achieved with the cooling speed larger than or equal to 30 DEG C / S after rolling, and the reeling temperature ranges from 630 DEG C to 700 DEG C.

Owner:ANGANG STEEL CO LTD

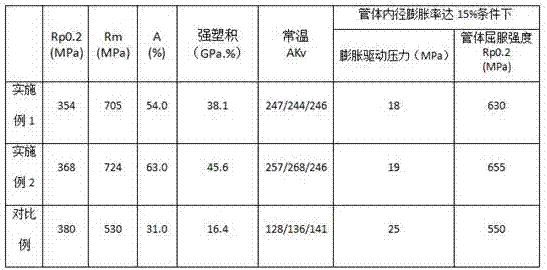

Manufacturing method for high manganese steel seamless pipe

The invention relates to a manufacturing method for a seamless pipe, and in particular to a manufacturing method for a high manganese steel seamless pipe with high strength and corrosion resistance. The manufacturing method for the high manganese steel seamless pipe comprises the following steps that a high manganese steel ingot comprising, by weight percentage (%), 0.08-0.60% of C, 0.10-3.60% of Si, 15.00-28.00% of Mn, 0.02-4.50% of Al, no more than 0.045% of P, no more than 0.045% of S, 0.01-0.30% of Nb, 0.001-0.040% of N, 0.01-0.20% of Ti, 0.01-0.20% of V, and the balance Fe and inevitable impurities is kept warm for 6-8 hours at the temperature of 1150-1250 DEG C, the steel ingot is hot-forged into a cylindrical blank at the temperature of 850-1150 DEG C, then the cylindrical blank is covered with a heat preservation cover quickly for slow cooling, and the cylindrical blank is air-cooled to the room temperature 48 hours later by hoisting the cover away.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Industrial preparing method of water-cooling metal mold centrifugal nodular cast iron pipe

The invention discloses an industrial preparing method of a water-cooling metal mold centrifugal nodular cast iron pipe. According to the method, pig iron is used, the technologies of molten iron preparing, molten iron nodulizing, centrifugal casting, annealing, shaping and coating are carried out, and then the finished cast iron pipe is obtained. The preparing method is suitable for preparing the high-quality metal mold centrifugal nodular cast iron pipe of DN80-1000 mm. The preparing process comprises a series of operation procedures such as molten iron preparing, molten iron nodulizing, centrifugal casting, annealing, shaping and coating, the preparing technology is simple, the prepared cast iron pipe has the advantages of being high in appearance quality, fine in material structure, high in production efficiency, long in service life and the like, and compared with an existing steel pipe and an existing gray iron pipe, the water-cooling metal mold centrifugal nodular cast iron pipe has better corrosion-resisting performance and tensile performance.

Owner:SICHUAN CHUANJIAN PIPES

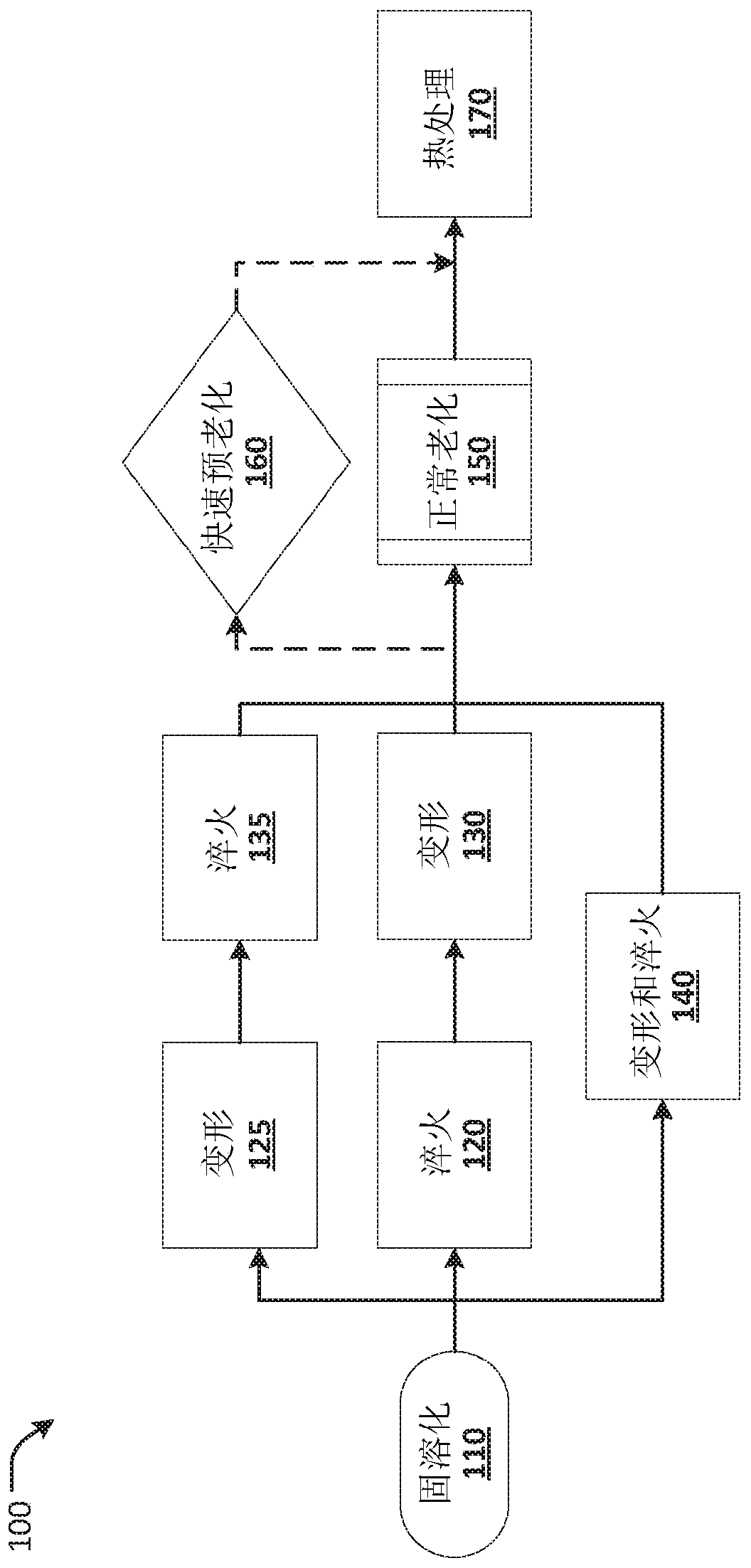

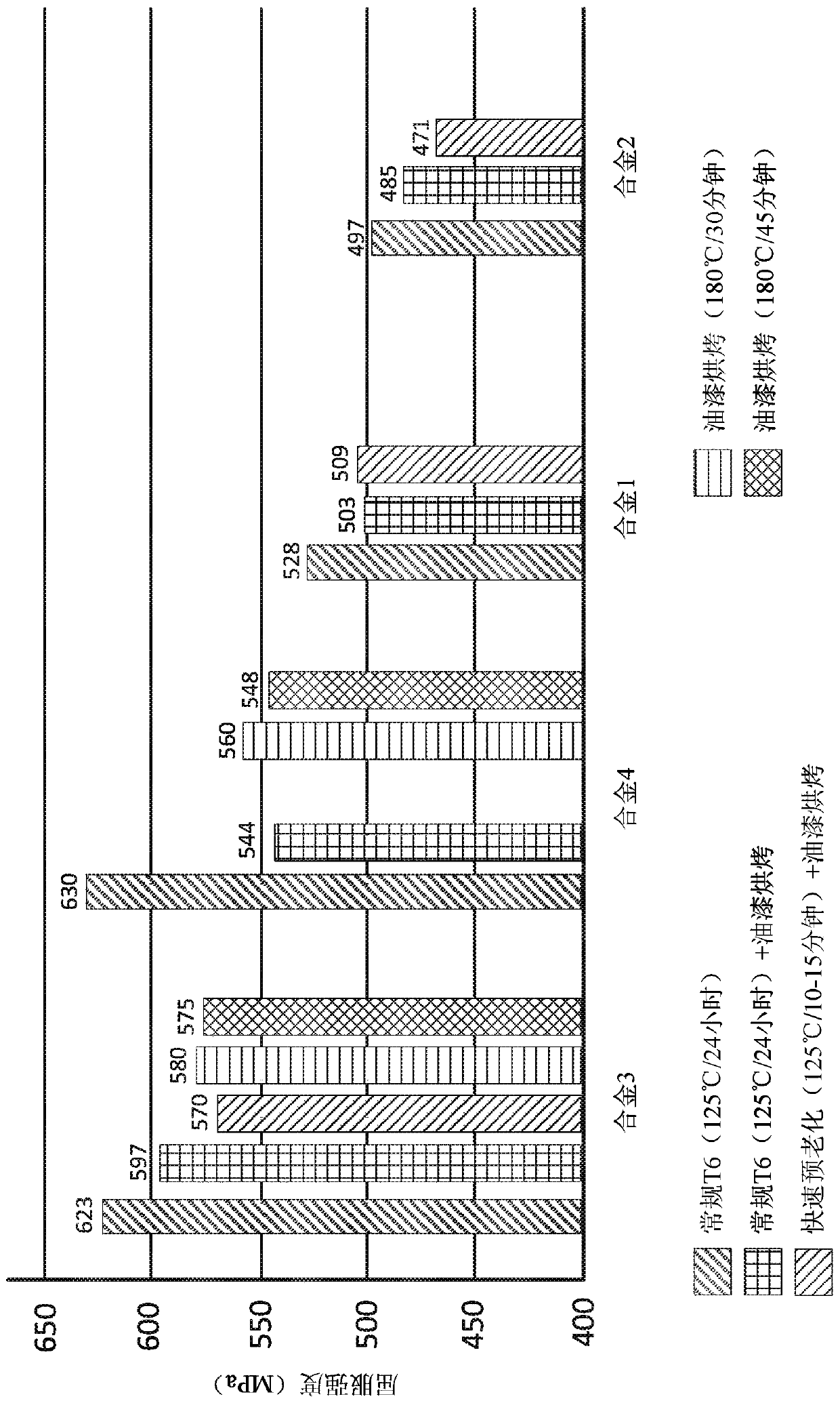

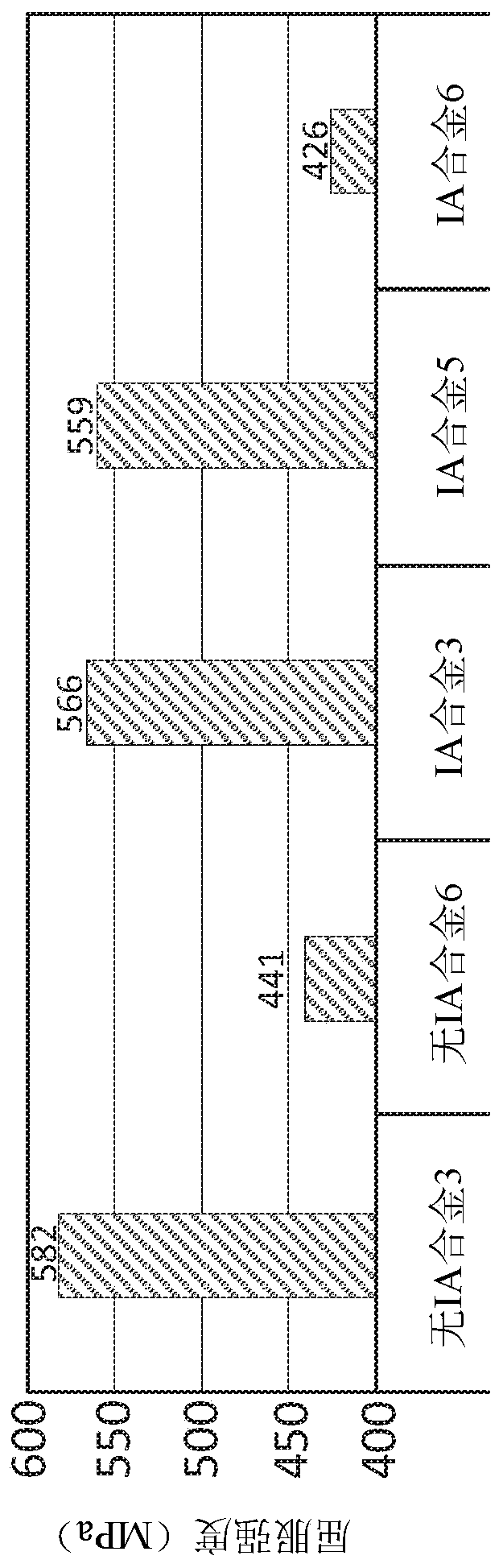

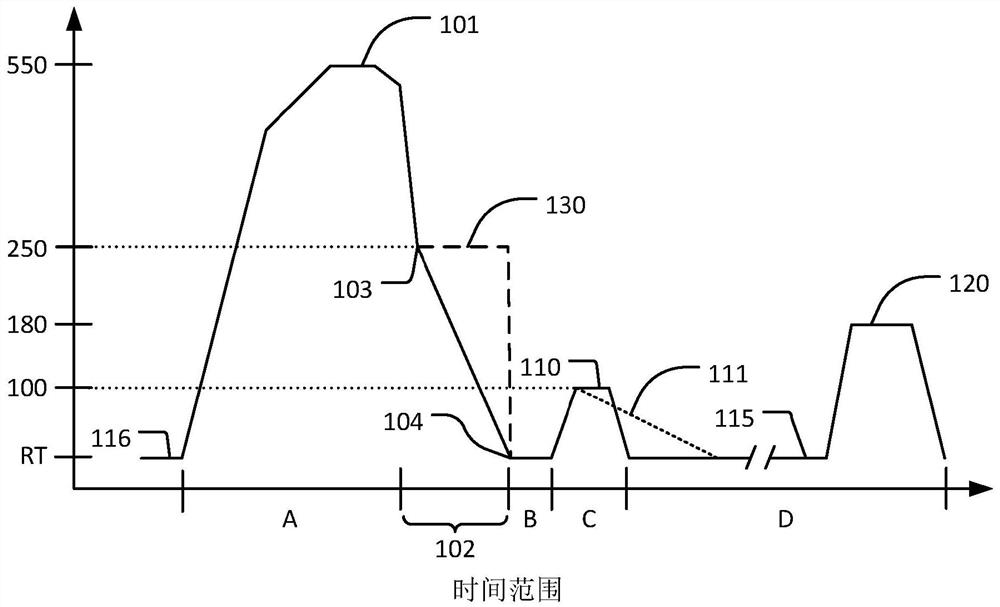

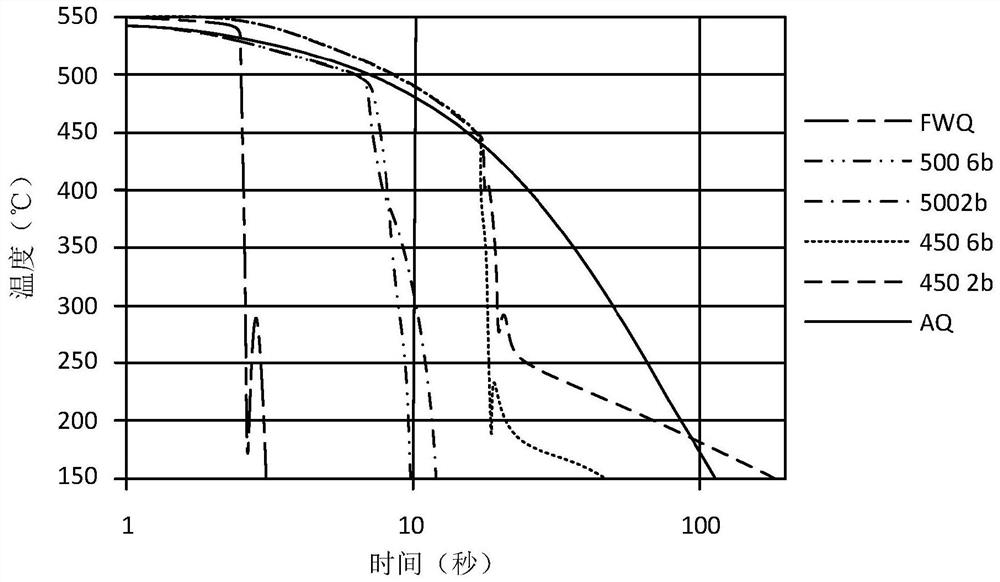

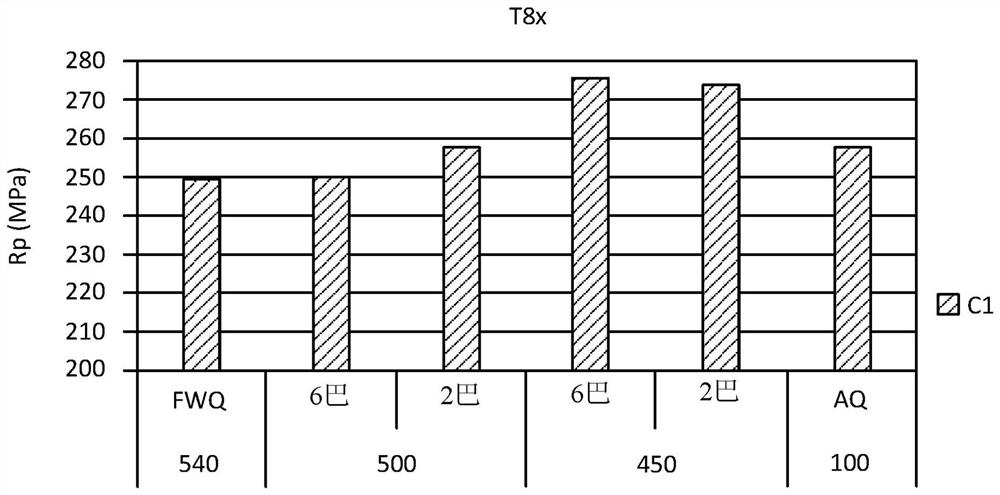

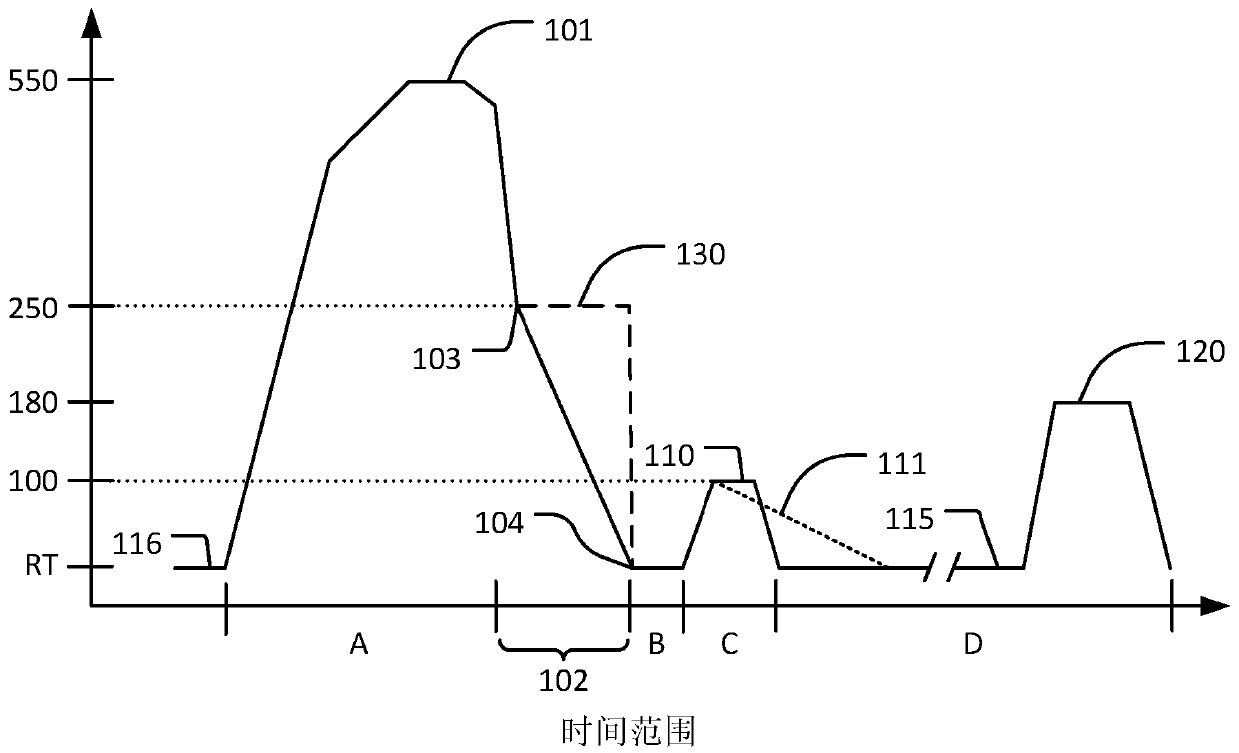

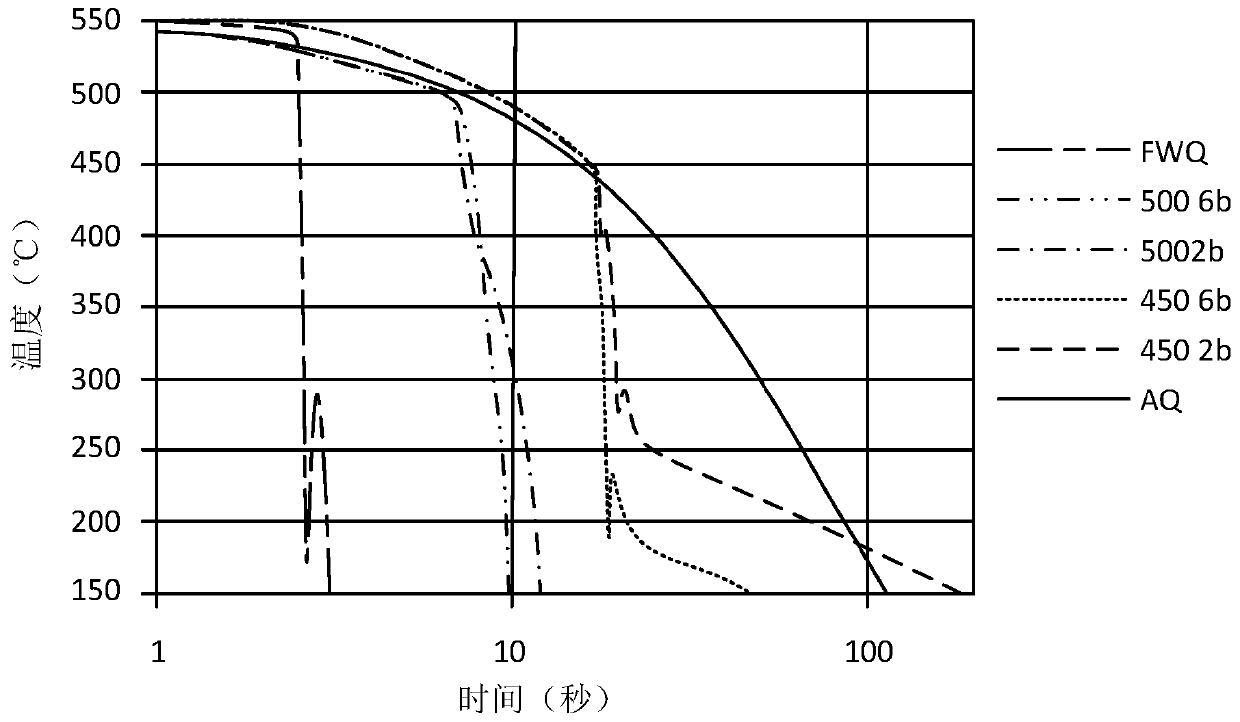

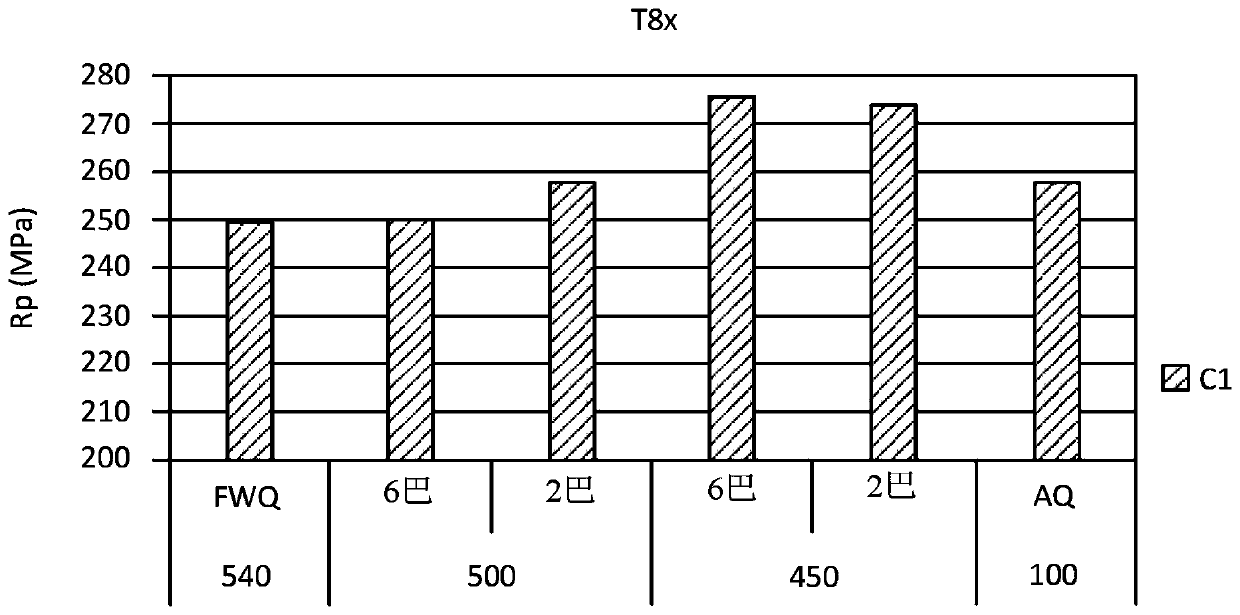

Rapid aging of high strength 7xxx aluminum alloys and methods of making the same

Disclosed herein are methods of processing 7xxx aluminum alloys using a rapid pre-aging step, along with alloys prepared according to the methods. The aluminum alloy products described herein have high strength when subjected to a rapid pre-aging step, as described above, and subsequent thermal treatment, such as paint baking or coating. The alloys prepared and processed according to the methods described herein can be used, for example, in automotive, transportation, electronics, and industrial applications.

Owner:NOVELIS INC

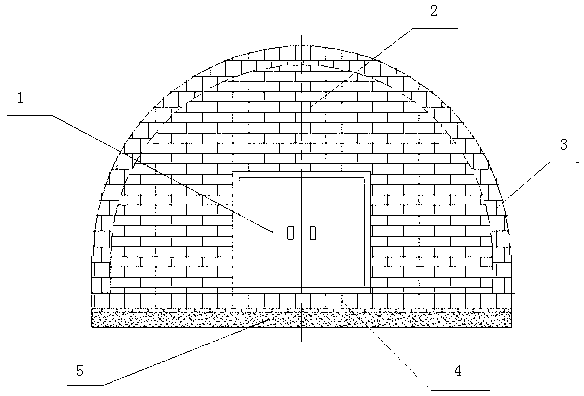

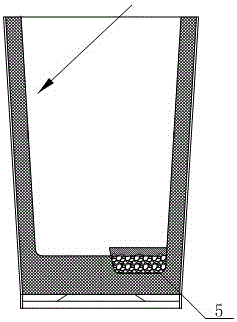

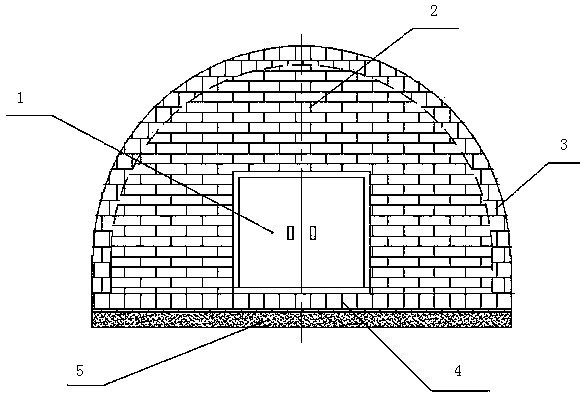

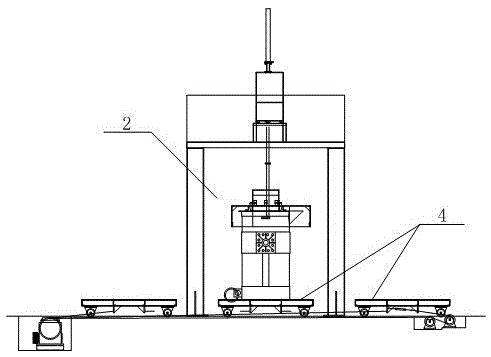

Pressure resistance and pressure relief bricks for coal mine underground seal wall and construction method of seal wall

InactiveCN103244145AExtended service lifeReduce maintenance timesUnderground chambersTunnel liningPolyesterPolyol

The invention discloses pressure resistance and pressure relief bricks for a coal mine underground seal wall and a construction method of the seal wall. The pressure resistance and pressure relief bricks are formed by ceramsite and bounding agent; the bounding agent is formed by multi-iso-cyanogens phenol resin and polyester polyol; a weight ratio of the iso-cyanogens phenol resin and the polyester polyol is 1: 0.8 to 1: 1.2; and a weight ratio of the ceramsite and the bounding agent is 1: 1 to 1: 1.5. The construction method of the seal wall comprises adding a sand and rock bedding layer to a catching groove of the bottom face of a tunnel which is under the seal wall and performing construction above the sand and rock bedding layer with one or two layers of pressure resistance and pressure relief bricks; constructing a main wall body of the seal wall with red bricks; and constructing the connecting positions of the lateral side and the top face of the tunnel and the seal wall with one or two layers of pressure resistance and pressure relief bricks. When pressure is performed on the tunnel, the pressure resistance and pressure relief bricks well absorb the pressure due to the capability of contracting and deforming to be a half; accordingly the service life of the seal wall is prolonged; maintaining times of the seal wall are reduced; and the pressure resistance and pressure relief bricks can be reused to reduce the construction cost and maintenance cost of the seal wall.

Owner:TANGSHAN KAILUAN GUANGHUI EQUIP MFGCO +1

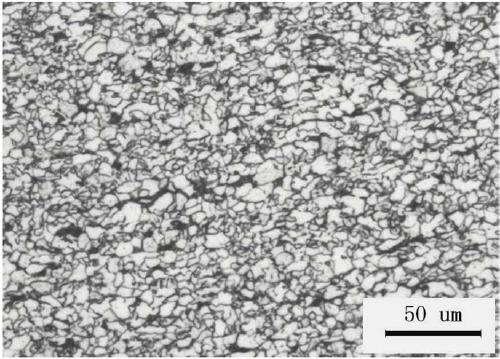

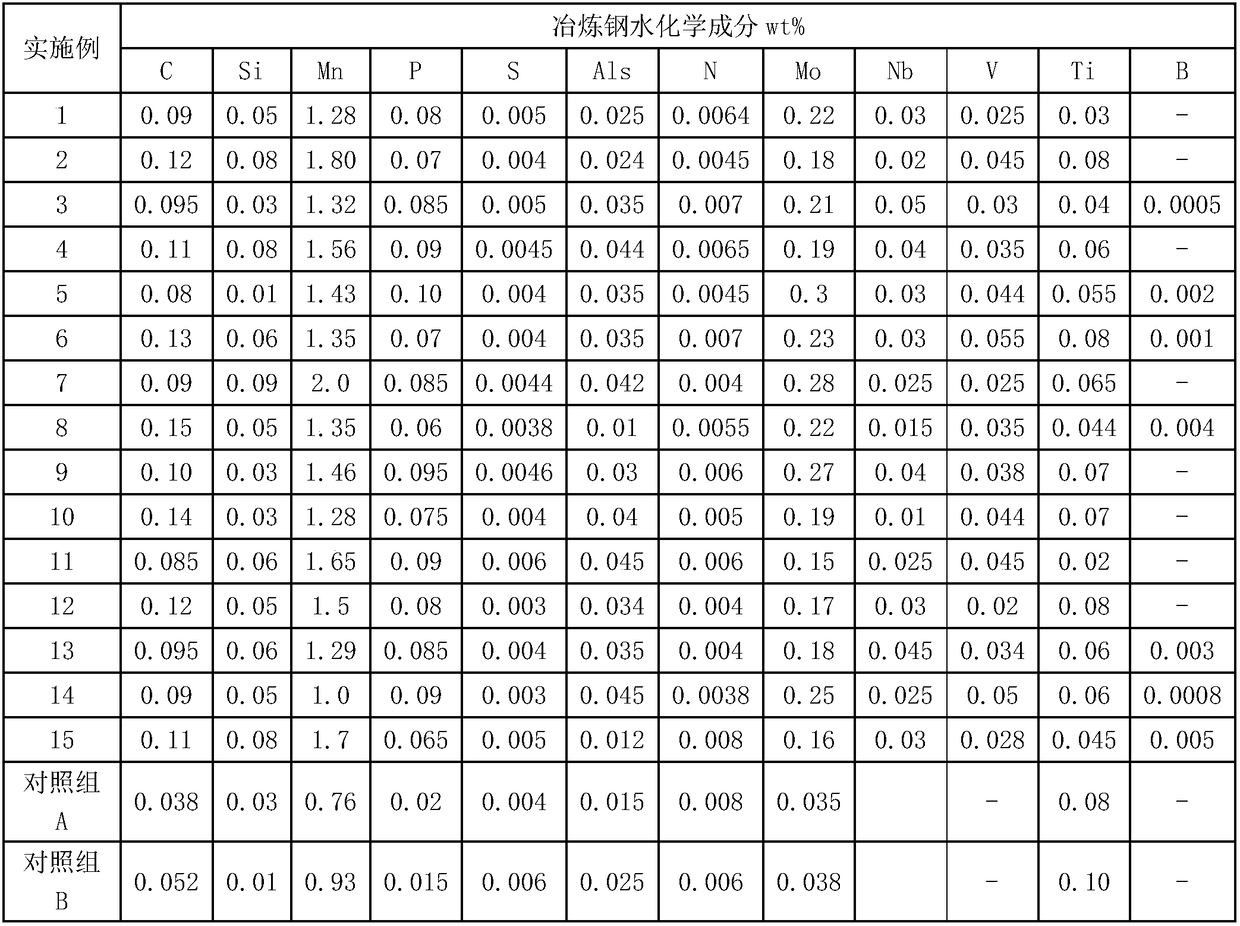

Hot rolled steel plate with the honed yield strength of 400 MPa for counterenamel and manufacturing method of hot rolled steel plate

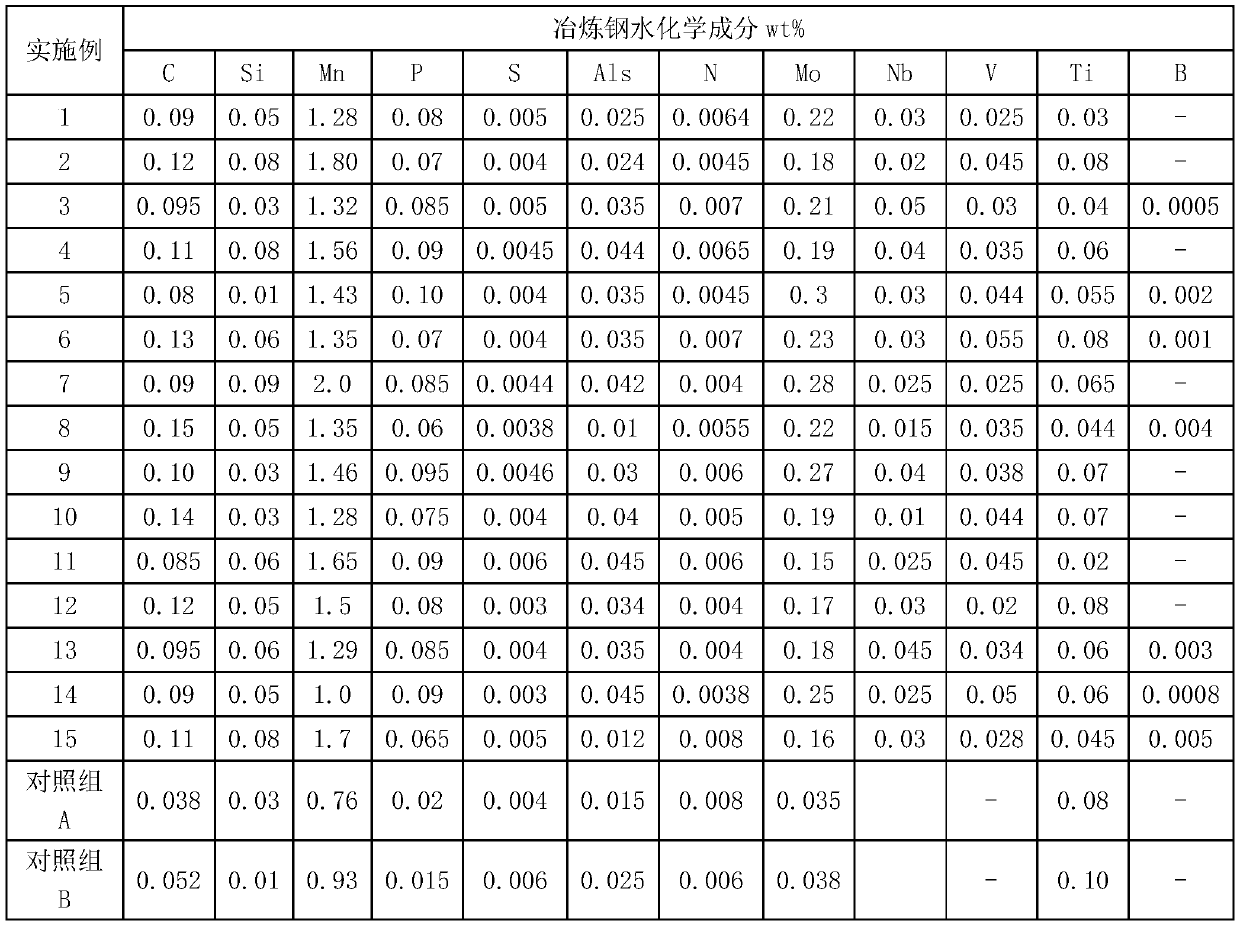

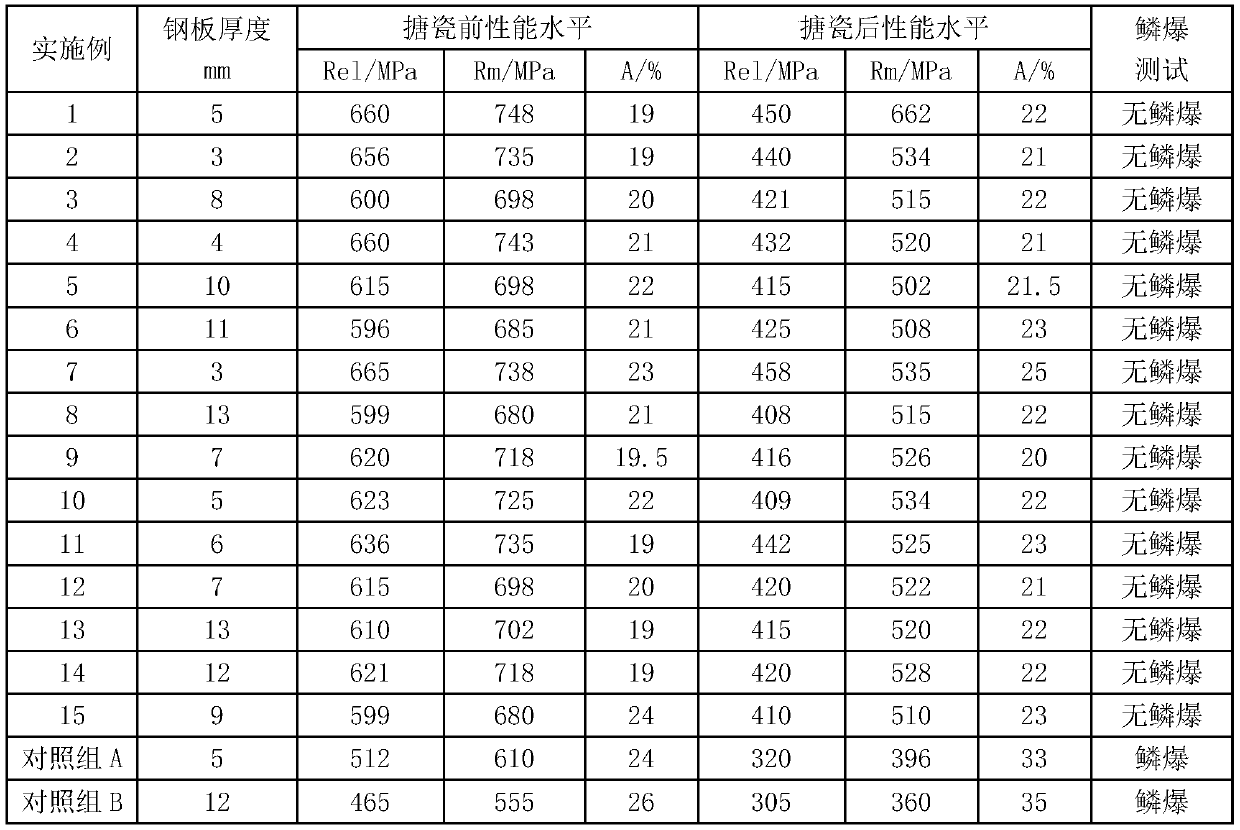

The invention relates to a hot rolled steel plate with the honed yield strength of 400 MPa for counterenamel. The hot rolled steel plate is prepared from, by mass percent, 0.08% to 0.15% of C, not larger than 0.10% of Si, 1.0% to 2.0% of Mn, 0.060% to 0.10% of P, not larger than 0.006% of S, not larger than 0.008% of N, 0.02% to 0.08% of Ti, 0.010% to 0.045% of Als, 0.020% to 0.055% of V, 0.01% to0.05% of Nb, 0.15% to 0.30% of Mo and the balance Fe and inevitable impurities. When the thickness of the hot rolled steel plate is larger than or equal to 8 mm, 0.0005% to 0.005% of B is added. Thehoned yield strength of the hot rolled steel plate is larger than or equal to 400 MPa. The hot rolled steel plate has good scute burst resisting performance, meanwhile, the honed yield strength can reach 400 MPa or above, and the requirement of a large enamel assembling structure can be met better.

Owner:ANGANG STEEL CO LTD

Hot-dip aluminizing zincium steel plate/belt for deep drawing and method for producing the same

ActiveCN101352946BImprove corrosion resistanceImprove high temperature resistanceHot-dipping/immersion processesFurnace typesChemical compositionSheet steel

The invention provides a deep drawing hot-dipped al-zn steel plate / strip and a production method thereof. The deep drawing hot-dipped al-zn steel plate / strip comprises an IF steel substrate and an alloy coating and the chemical constituents of the substrate (wt percent) are that C is less than or equal to 0.01, Si is less than or equal to 0.12, Mn is less than or equal to 0.6, P is less than or equal to 0.1, S is less than or equal to 0.045, Ti is less than or equal to 0.3 and the allowance is Fe and inevitable impurities. The production method comprises substrate degreasing treatment, annealing treatment and hot dipping, and the annealing treatment is carried out in a continuous annealing furnace and protective gas contents in the annealing furnace are 10 to 60 percent. The yield strength of the steel plate / strip of the invention reaches 140 to 220 MPa, the tensile strength is 260 to 350 MPa and the elongation is more than 30 percent; the production method of the invention is simple in production process and strong in operability.

Owner:BAOSHAN IRON & STEEL CO LTD

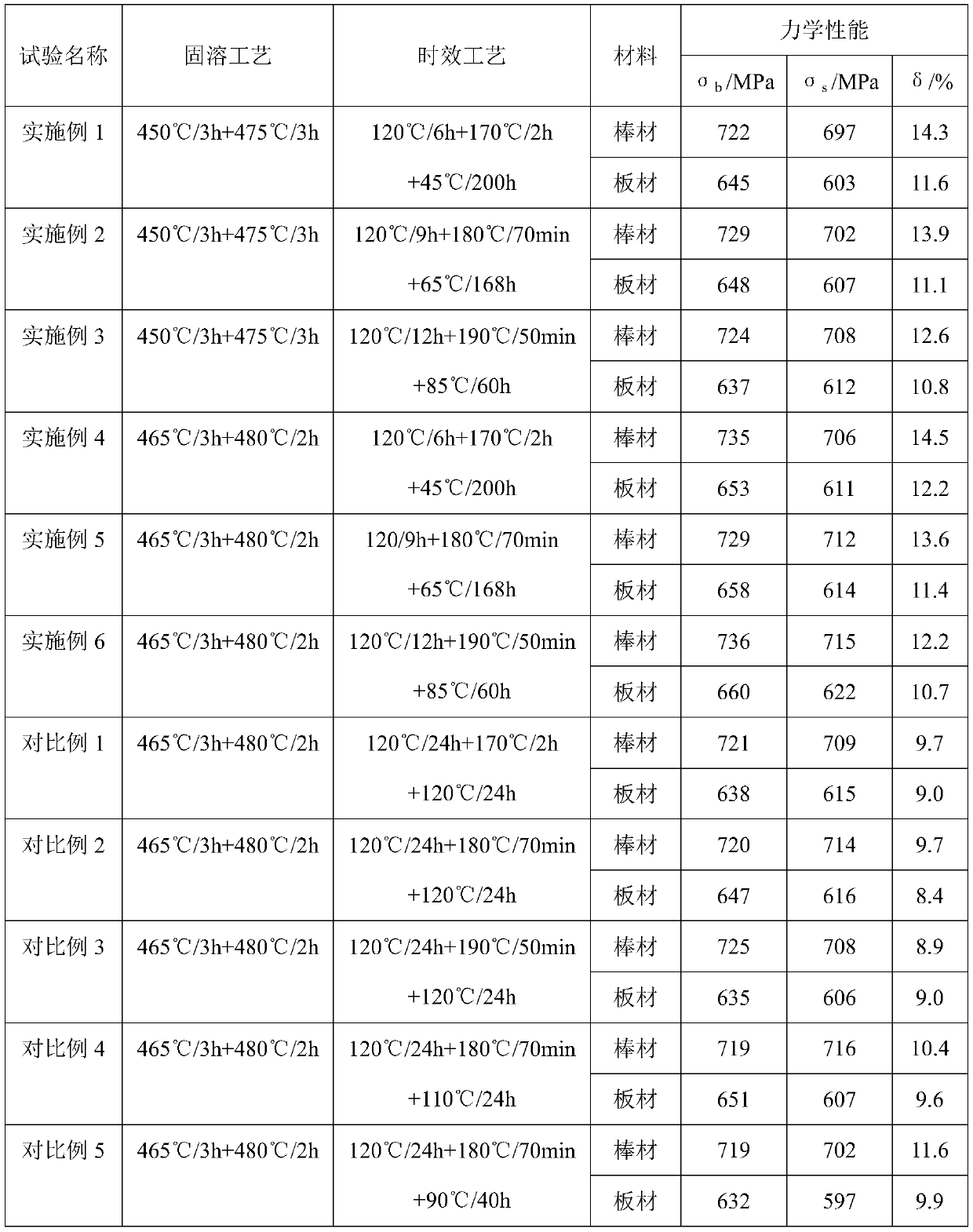

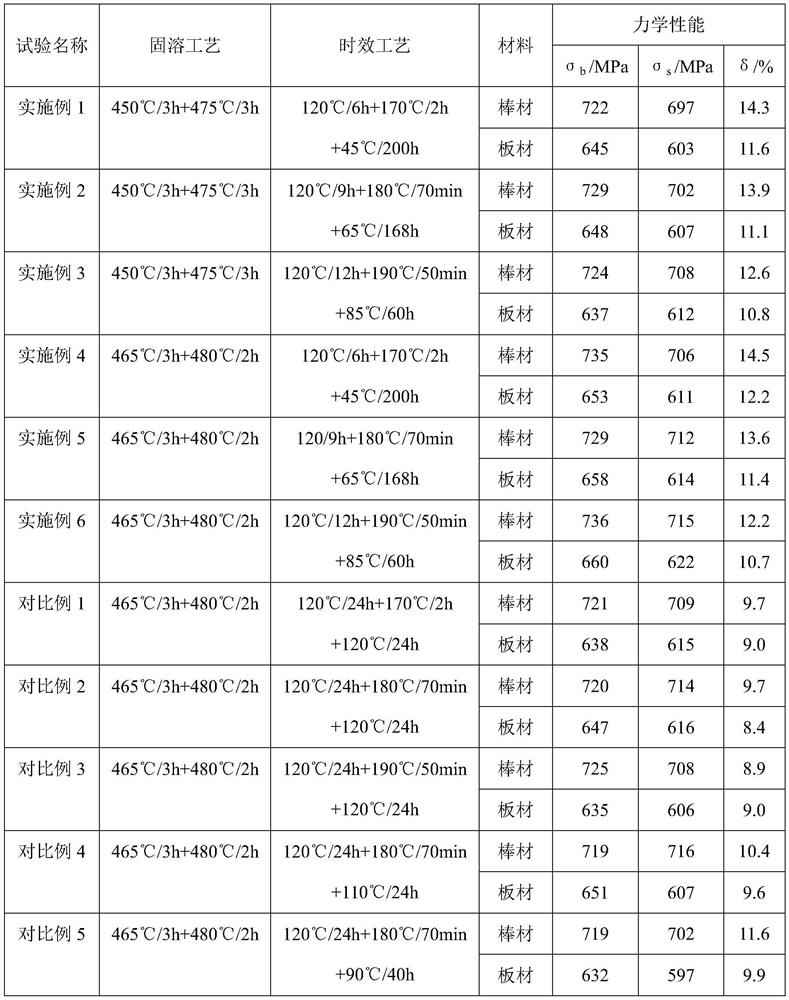

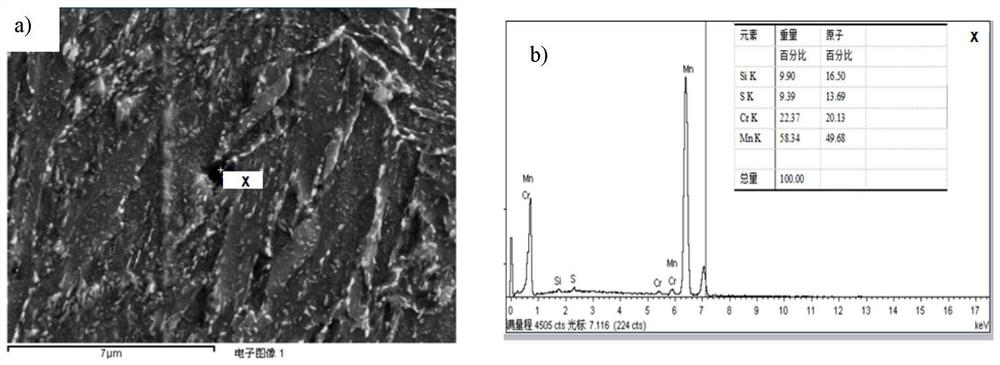

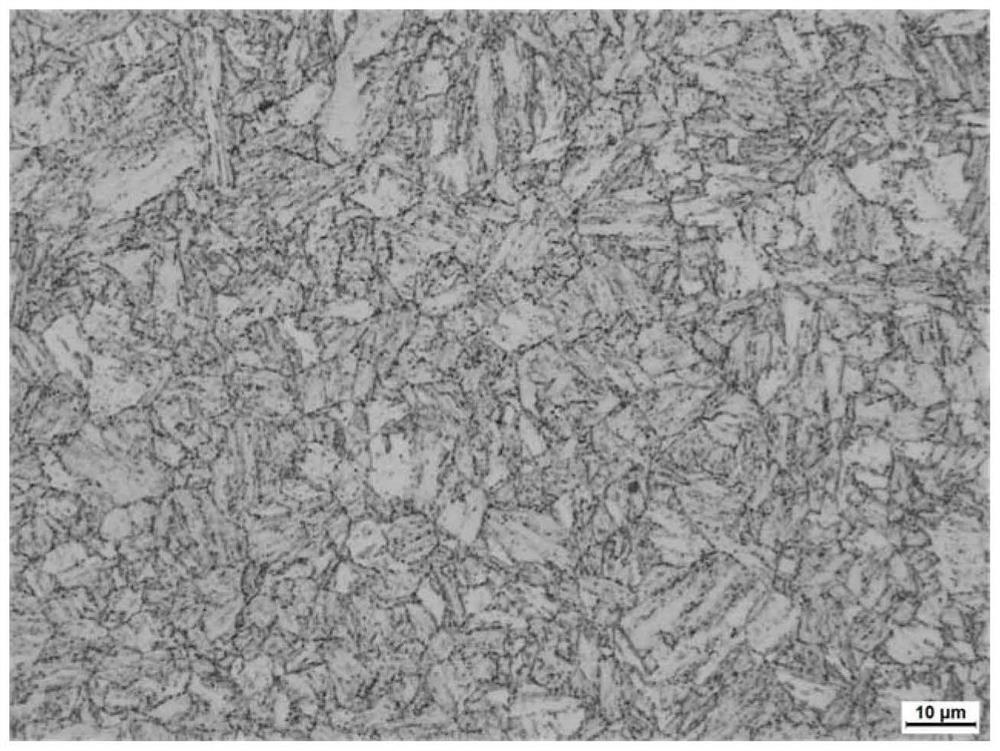

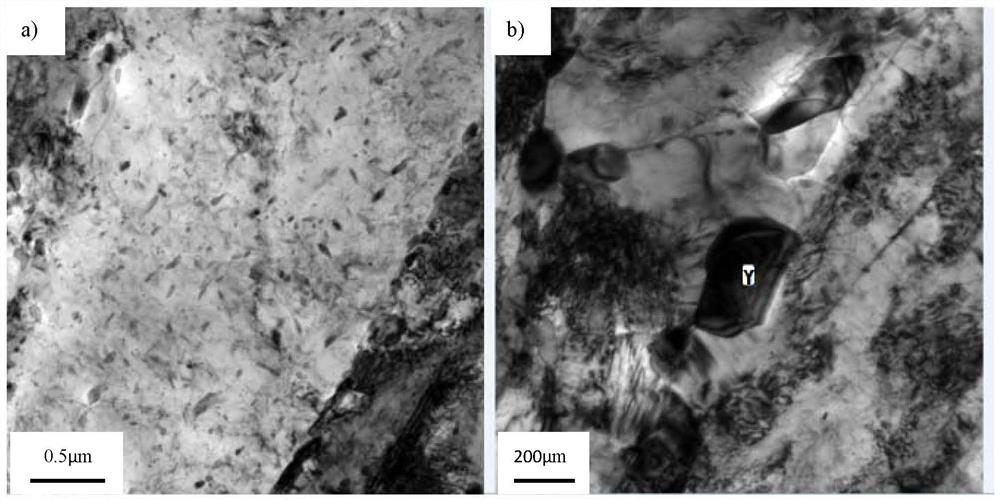

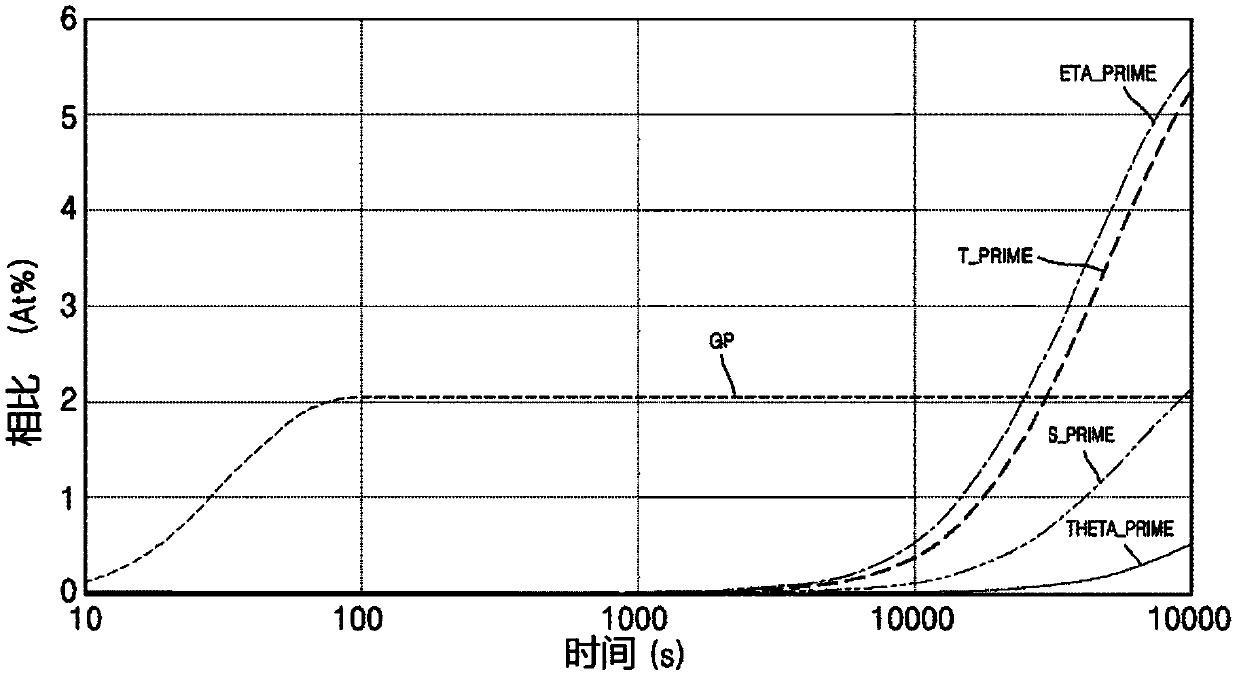

Heat treatment method for spray forming of 7055 aluminium alloy

ActiveCN109972064AGuaranteed Yield StrengthHas a yield strengthSolution treatment5005 aluminium alloy

The invention provides a heat treatment method for spray forming of a 7055 aluminium alloy. The heat treatment method includes the following steps of two-stage solid solution, retrogression low temperature reageing treatment, underaging pretreatment, regression treatment and low temperature reageing treatment. The two-stage solid solution comprises first-stage solid solution and second-stage solidsolution. Underaging is used as pretreatment before regression treatment, the number of eta phases in an alloy matrix is controlled, only a small amount of the eta phases are generated in the matrix,and thus it is guaranteed that the material has certain yield strength, subsequent regression treatment redissolves most of the GP regions in the matrix into the matrix, and the organization is prepared for a large number of dispersed GP regions precipitated by low temperature reaging. Meanwhile, regression treatment also avoids the aging process needing to take a long time to strengthen the phases in a single GP region to achieve the high strength and toughness of the 7055 aluminum alloy.

Owner:JIANGSU HAORAN SPRAY FORMING ALLOY

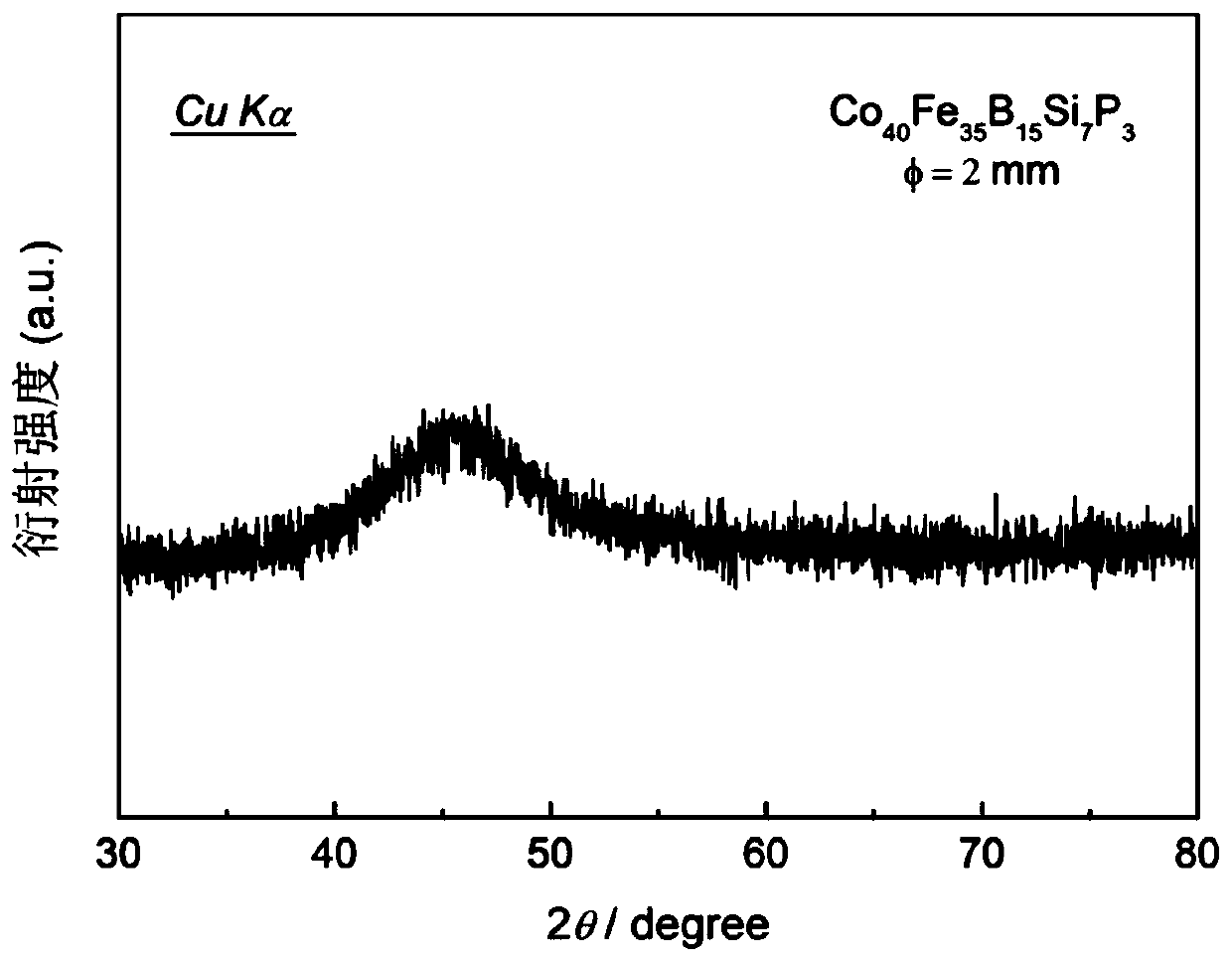

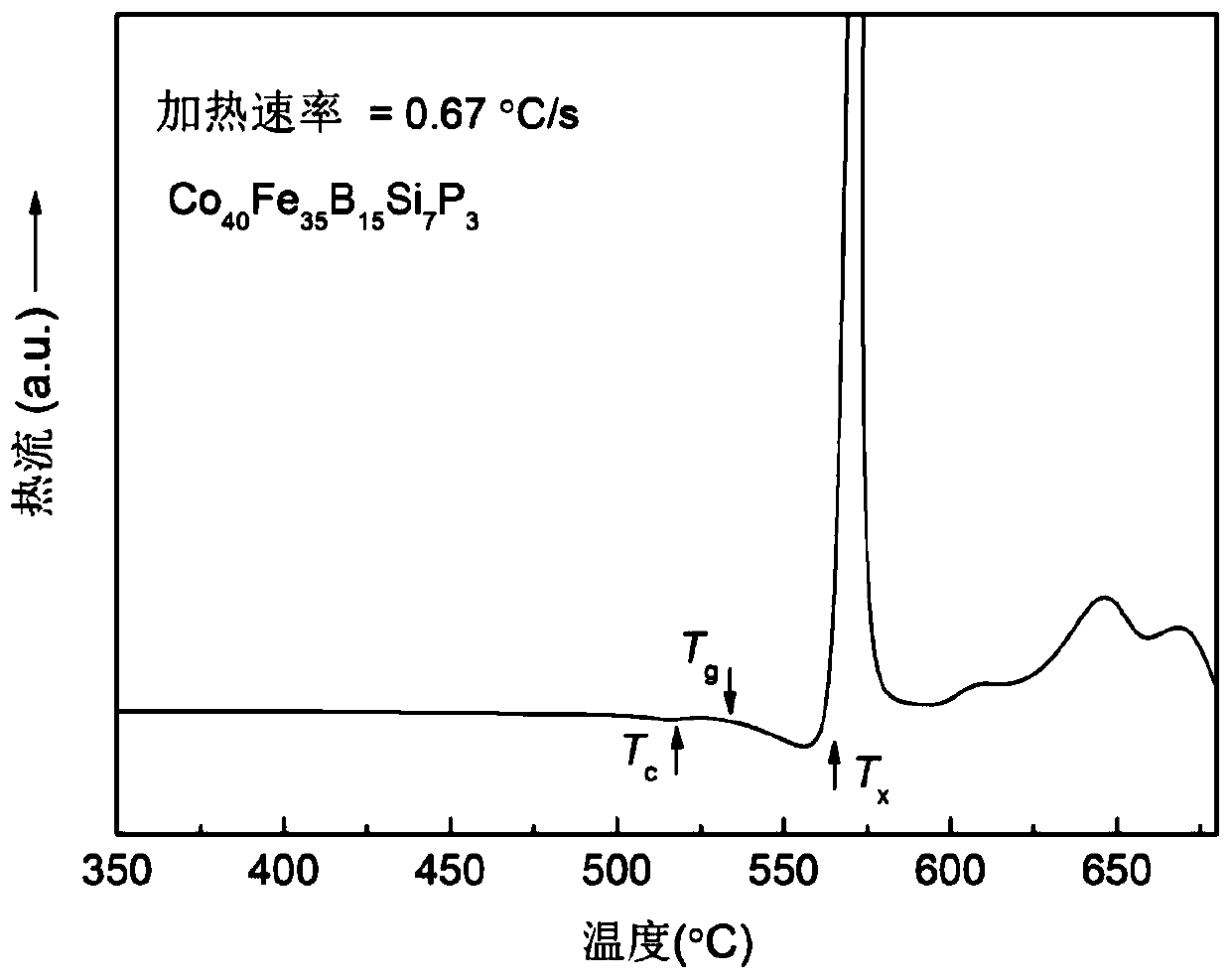

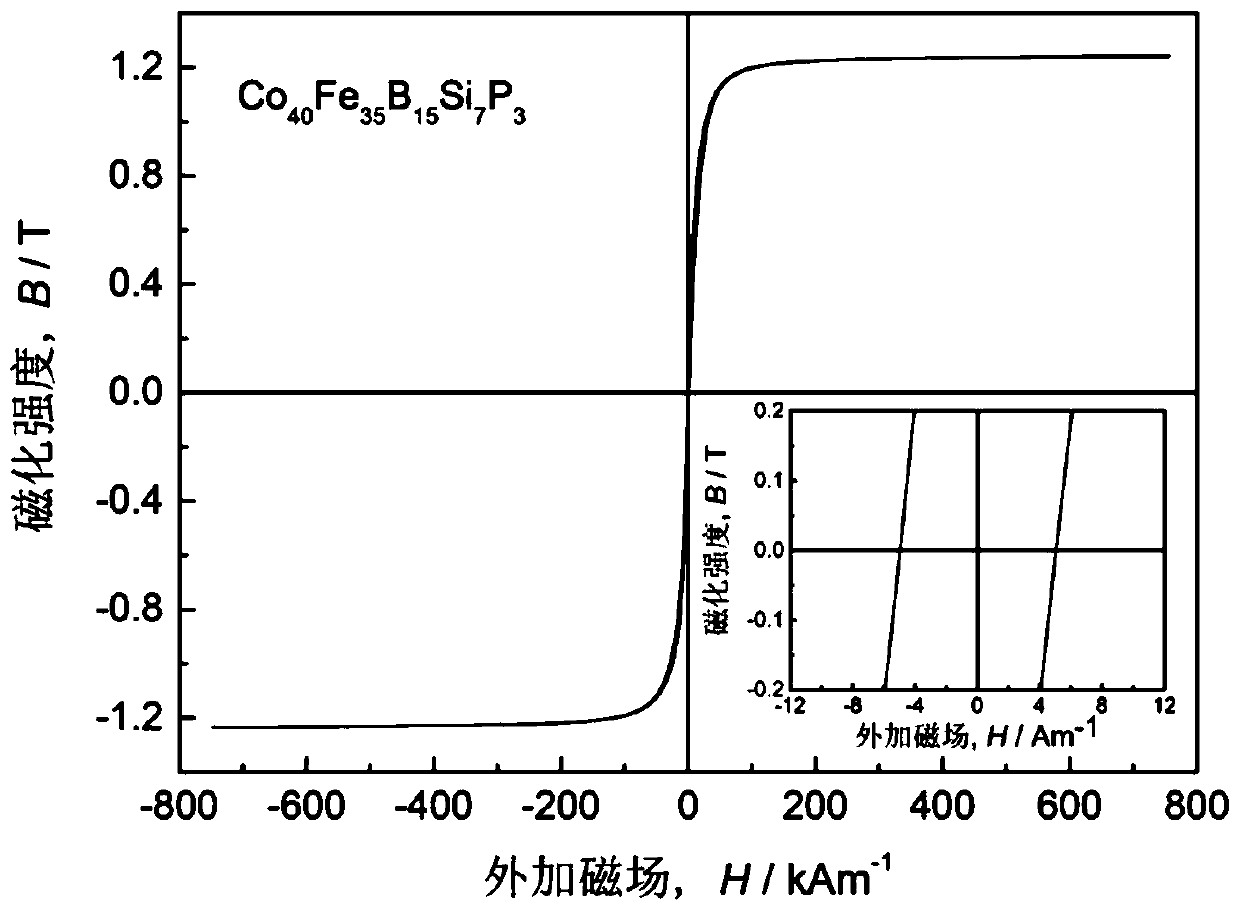

Soft magnetic Co-based bulk amorphous alloy with high saturation induction density and preparation method of amorphous alloy

ActiveCN111218625AStrong Amorphous Formation AbilityGood soft magneticFoundry mouldsMagnetic materialsRare-earth elementAmorphous metal

The invention provides a soft magnetic Co-based bulk amorphous alloy with high saturation induction density. The component formula of the alloy is CoaFebNicBdSiePfCg, a, b, c, d, e, f and g representatomic percent content of components respectively and meet following conditions: a is larger than 35 and smaller than or equal to 65, b is larger than or equal to 10 and smaller than or equal to 35, clarger than or equal to 0 and smaller than or equal to 5, the sum of b and c is larger than or equal to 10 and smaller than or equal to 35, d is larger than or equal to 5 and smaller than or equal to20, e is larger than or equal to 5 and smaller than or equal to 10, f is larger than or equal to 0 and smaller than or equal to 5, g is larger than or equal to 0 and smaller than or equal to 5, the sum of f and g is larger than or equal to 3, the sum of d, e, f and g is larger than or equal to 20 and smaller than or equal to 30, and the sum of a, b, c, d, e and f is equal to 100. The technical problems that the alloy cannot realize high amorphous forming ability and saturation magnetic induction (Bs) and cost are high due to the fact that existing Co-based bulk amorphous alloy contains pre-transition elements or rare earth element are solved.

Owner:DALIAN UNIV OF TECH

Steel sheet for cans, hot-rolled steel sheet to be used as the base metal and processes for production of both

In producing a steel sheet for cans, a steel sheet which consists substantially of ferrite single-phase structure and has a mean grain diameter of 7[mu]m or below and which exhibits a yield strength of 500MPa or above, a yield ratio of 0.9 or above, a total elongation of 10% or above, and deltar of -0.50 to 0 after coating and baking is produced by incorporating C: 0.01 to 0.12%, Si: 0.005 to 0.5%, Mn: 0.3 to 1.5%, P: 0.005 to 0.2%, Al: 0.10% or below, N: 0.012% or below, and Nb: 0.005 to 0.10% and combining solid solution hardening, precipitation hardening, and grain refinement hardening. The hot rolling is conducted principally under the conditions of FT of 870 DEG C or above, cooling rate after hot rolling of 40 DEG C / s or below, and CT of 620 DEG C or above to adjust the mean grain size of a hot-rolled sheet serving as material for the steel sheet for cans to 6[mu]m or above.

Owner:JFE STEEL CORP

Corrosion resistant copper alloy material for sensor chip

The invention relates to a corrosion resistant copper alloy material for sensor chips. The corrosion resistant copper alloy material mainly comprises copper, and further comprises 0.5-1.0 wt.% of zirconium, 0.1-0.2 wt.% of yttrium, 3-5 wt.% of platinum, 0.1-0.3 wt.% of chromium, 0.15-0.25 wt.% of cobalt, 0.3-0.5 wt.% of boron, 0.4-0.9 wt.% of manganese, 0.8-1.0 wt.% of silicon, 0.06-0.12 wt.% of iron and 0.4%-0.7% of magnesium. The material provided by invention has excellent sea water corrosion and flushing resistance, high wear resistance and high strength, and is applicable to highly corrosive environments; and the material has yield strength reaching 260-280MPa, tensile strength more than 520MPa, and the elongation of 68-75%, and good comprehensive properties.

Owner:WUXI NUIST WEATHER SENSOR NETWORK TECH

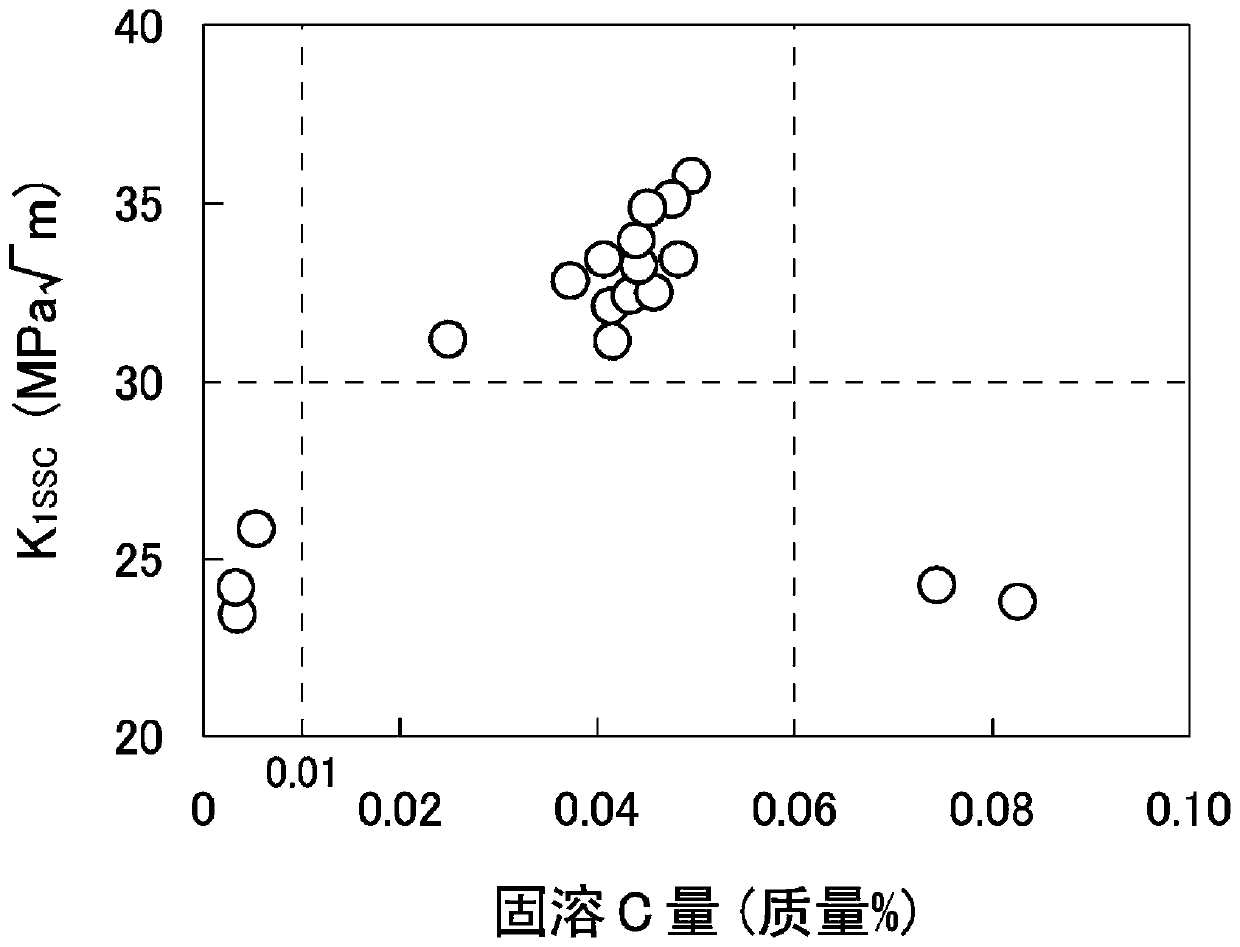

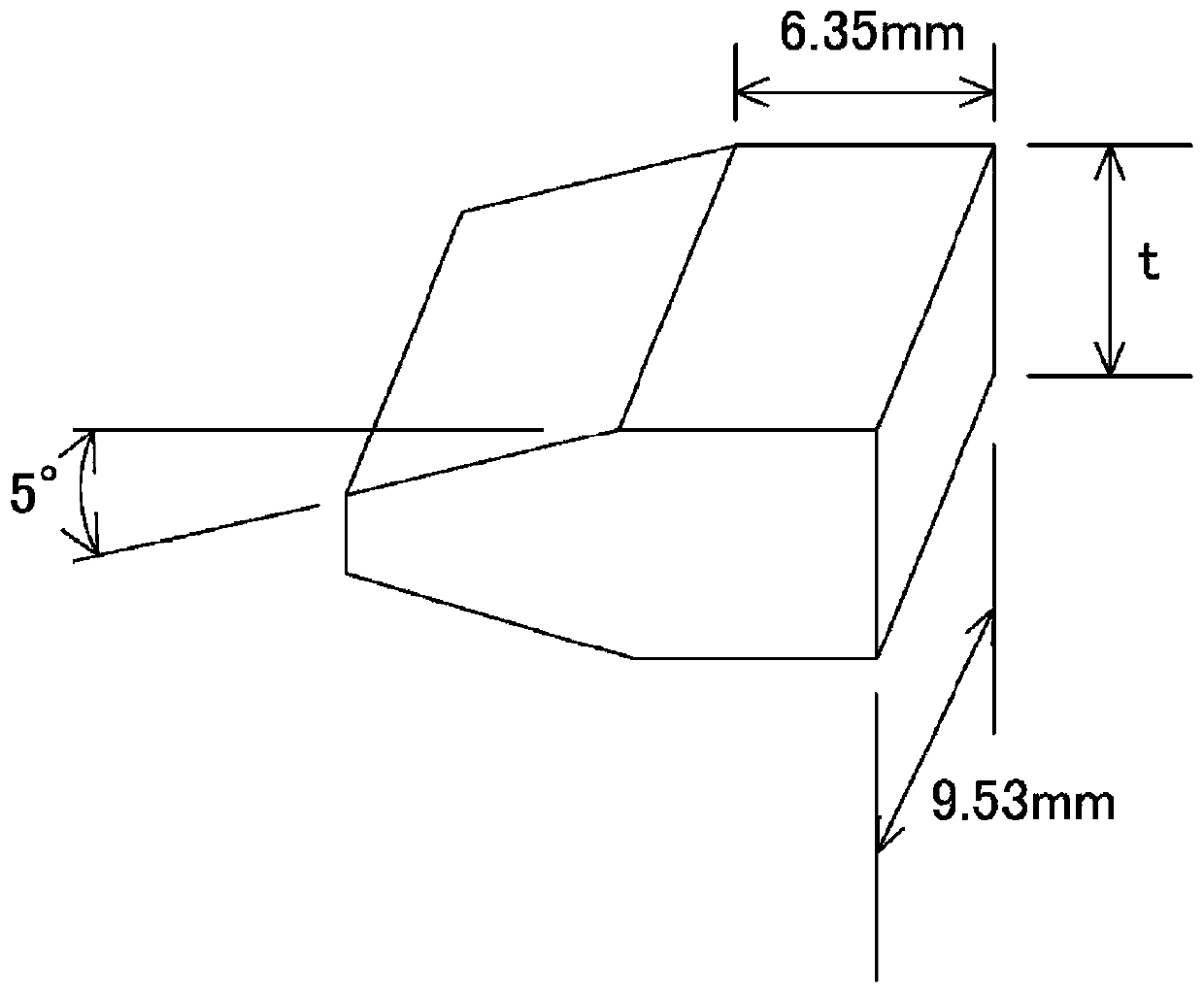

Steel material, and steel material manufacturing method

InactiveCN110234779AExcellent SSC resistanceHas a yield strengthFurnace typesHeat treatment furnacesChemical compositionSolid solution

Provided is a steel material that has a yield strength of 965MPa to 1069MPa (140ksi grade), and has superior SSC resistance. This steel material has a chemical composition that includes, by mass%, more than 0.50% and less than or equal to 0.80% C, 0.05% to 1.00% Si, 0.05% to 1.00% Mn, less than or equal to 0.025% P, less than or equal to 0.0100% S, 0.005% to 0.100% Al, 0.20% to 1.50% Cr, 0.25% to1.50% Mo, 0.002% to 0.050% Ti, 0.0001% to 0.0050% B, 0.002% to 0.010% N, and less than or equal to 0.0100% O, the remainder consisting of Fe and unavoidable impurities. The steel material includes 0.010mass% to 0.060mass% solid solution C. Furthermore, the yield strength is 965MPa to 1069MPa, and the yield ratio is greater than or equal to 90%.

Owner:NIPPON STEEL CORP

A kind of preparation method of centrifugal ductile iron pipe

ActiveCN104480382BImprove appearance qualityRefining material organizationLiquid surface applicatorsCoatingsIRON PREPARATIONSCast iron pipe

The invention discloses a method for preparing a centrifugal nodular cast iron pipe. The method discloses the preparation process of the centrifugal nodular cast iron pipe of high quality, the preparation process comprises a series of operation processes of molten iron preparation, nodulizing of molten iron, centrifugal casting, annealing treatment, pipe body shaping and coating protection and the like. The method is suitable for preparation of cast iron pipes of the specification of DN 80-1000 mm, the application range is wide, and the preparation process is simple. The cast iron pipe prepared through the method has the characteristics of being high in appearance quality, fine in material structure, high in production efficiency, long in service life and the like, and compared with existing steel pipes and gray iron pipes, the cast iron pipe prepared through the method has better decay resistance and tensile property.

Owner:SICHUAN CHUANJIAN PIPES

A kind of manufacturing method of high manganese steel seamless pipe

The invention relates to a manufacturing method for a seamless pipe, and in particular to a manufacturing method for a high manganese steel seamless pipe with high strength and corrosion resistance. The manufacturing method for the high manganese steel seamless pipe comprises the following steps that a high manganese steel ingot comprising, by weight percentage (%), 0.08-0.60% of C, 0.10-3.60% of Si, 15.00-28.00% of Mn, 0.02-4.50% of Al, no more than 0.045% of P, no more than 0.045% of S, 0.01-0.30% of Nb, 0.001-0.040% of N, 0.01-0.20% of Ti, 0.01-0.20% of V, and the balance Fe and inevitable impurities is kept warm for 6-8 hours at the temperature of 1150-1250 DEG C, the steel ingot is hot-forged into a cylindrical blank at the temperature of 850-1150 DEG C, then the cylindrical blank is covered with a heat preservation cover quickly for slow cooling, and the cylindrical blank is air-cooled to the room temperature 48 hours later by hoisting the cover away.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Pressure-resistant and pressure-relieving bricks for closed walls in coal mines and their masonry methods

InactiveCN103244145BExtended service lifeReduce maintenance timesUnderground chambersTunnel liningPolyesterBrick

The invention discloses pressure resistance and pressure relief bricks for a coal mine underground seal wall and a construction method of the seal wall. The pressure resistance and pressure relief bricks are formed by ceramsite and bounding agent; the bounding agent is formed by multi-iso-cyanogens phenol resin and polyester polyol; a weight ratio of the iso-cyanogens phenol resin and the polyester polyol is 1: 0.8 to 1: 1.2; and a weight ratio of the ceramsite and the bounding agent is 1: 1 to 1: 1.5. The construction method of the seal wall comprises adding a sand and rock bedding layer to a catching groove of the bottom face of a tunnel which is under the seal wall and performing construction above the sand and rock bedding layer with one or two layers of pressure resistance and pressure relief bricks; constructing a main wall body of the seal wall with red bricks; and constructing the connecting positions of the lateral side and the top face of the tunnel and the seal wall with one or two layers of pressure resistance and pressure relief bricks. When pressure is performed on the tunnel, the pressure resistance and pressure relief bricks well absorb the pressure due to the capability of contracting and deforming to be a half; accordingly the service life of the seal wall is prolonged; maintaining times of the seal wall are reduced; and the pressure resistance and pressure relief bricks can be reused to reduce the construction cost and maintenance cost of the seal wall.

Owner:TANGSHAN KAILUAN GUANGHUI EQUIP MFGCO +1

A forming process suitable for preparing water-cooled metal type centrifugal ductile iron pipe

The invention discloses a forming process suitable for preparing a water-cooling metal mold centrifugal nodular cast iron pipe. According to the forming process, pig iron is utilized, molten iron preparing, molten iron nodulizing, centrifugal casting and annealing are carried out, and then the finished cast iron pipe is obtained. The forming process comprises the steps of molten iron preparing, molten iron nodulizing, centrifugal casting and annealing, and the cast iron pipe conveyed out of an annealing furnace serves as the finished cast iron pipe after being cooled. The technological method discloses a series of preparing technologies from molten iron preparing, molten iron nodulizing and centrifugal casting to annealing in the finished high-quality water-cooling metal mold centrifugal nodular cast iron pipe preparing process, and is suitable for preparing the cast iron pipe of DN80-1000 mm. The forming process is wide in application range, and has the advantages that the appearance quality is high, the material texture is fine, the production efficiency is high, and the service life is long.

Owner:SICHUAN CHUANJIAN PIPES

A kind of industrial preparation method of water-cooled metal type centrifugal ductile iron pipe

The invention discloses an industrial preparing method of a water-cooling metal mold centrifugal nodular cast iron pipe. According to the method, pig iron is used, the technologies of molten iron preparing, molten iron nodulizing, centrifugal casting, annealing, shaping and coating are carried out, and then the finished cast iron pipe is obtained. The preparing method is suitable for preparing the high-quality metal mold centrifugal nodular cast iron pipe of DN80-1000 mm. The preparing process comprises a series of operation procedures such as molten iron preparing, molten iron nodulizing, centrifugal casting, annealing, shaping and coating, the preparing technology is simple, the prepared cast iron pipe has the advantages of being high in appearance quality, fine in material structure, high in production efficiency, long in service life and the like, and compared with an existing steel pipe and an existing gray iron pipe, the water-cooling metal mold centrifugal nodular cast iron pipe has better corrosion-resisting performance and tensile performance.

Owner:SICHUAN CHUANJIAN PIPES

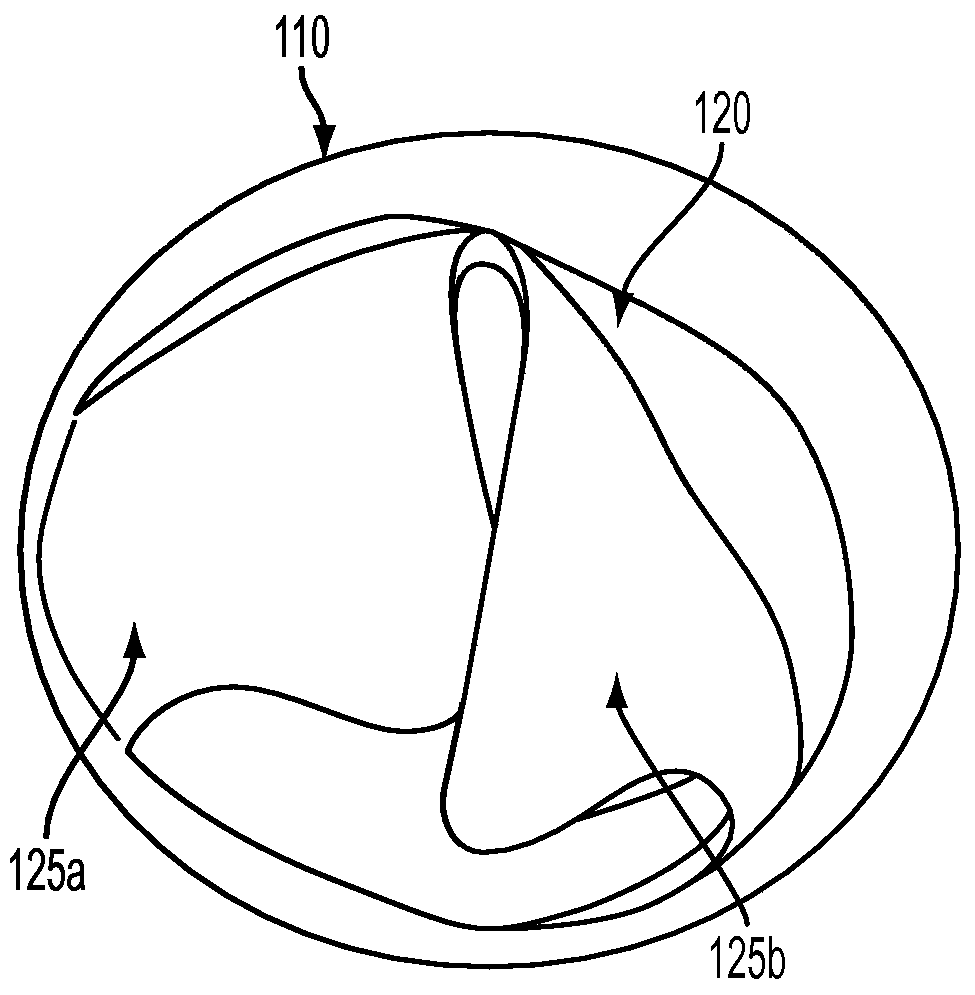

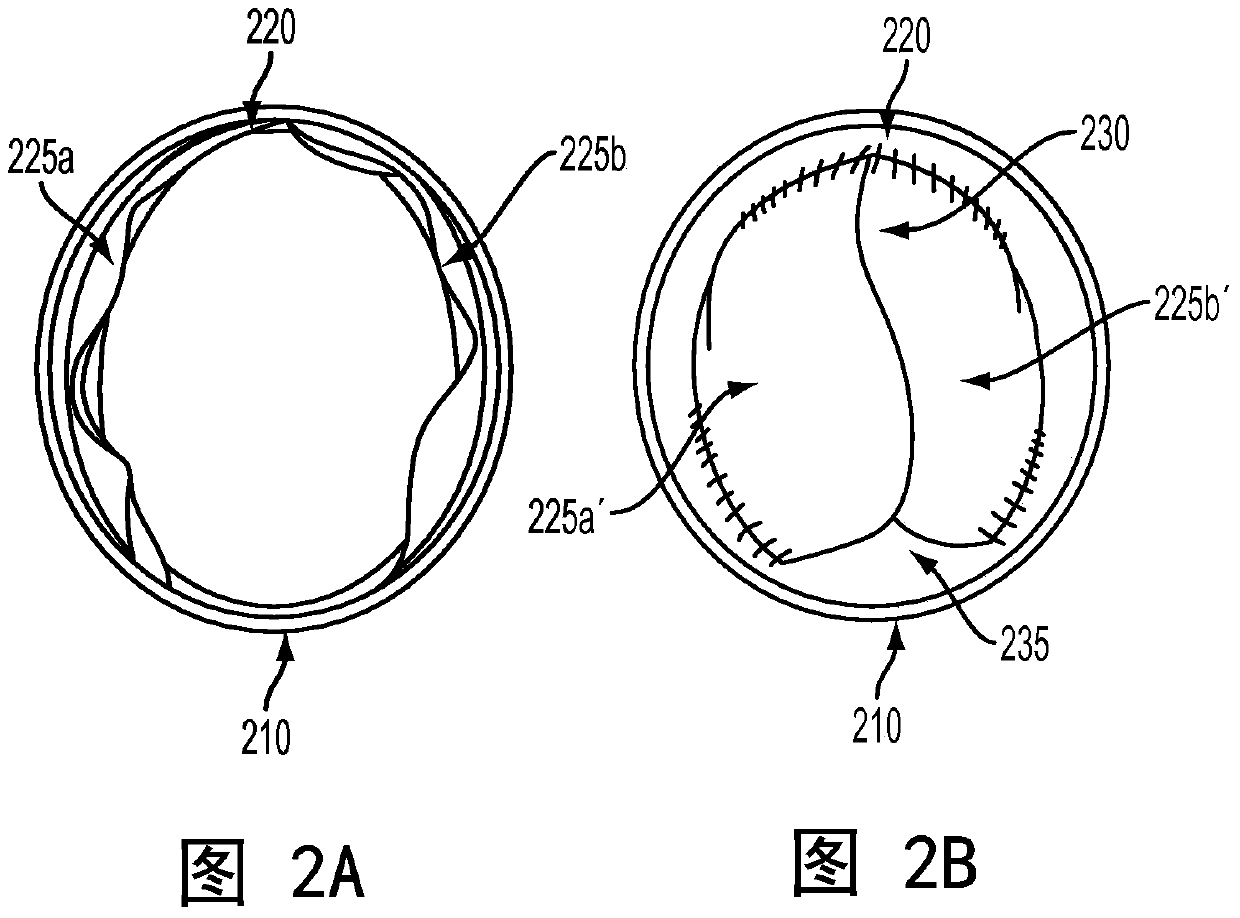

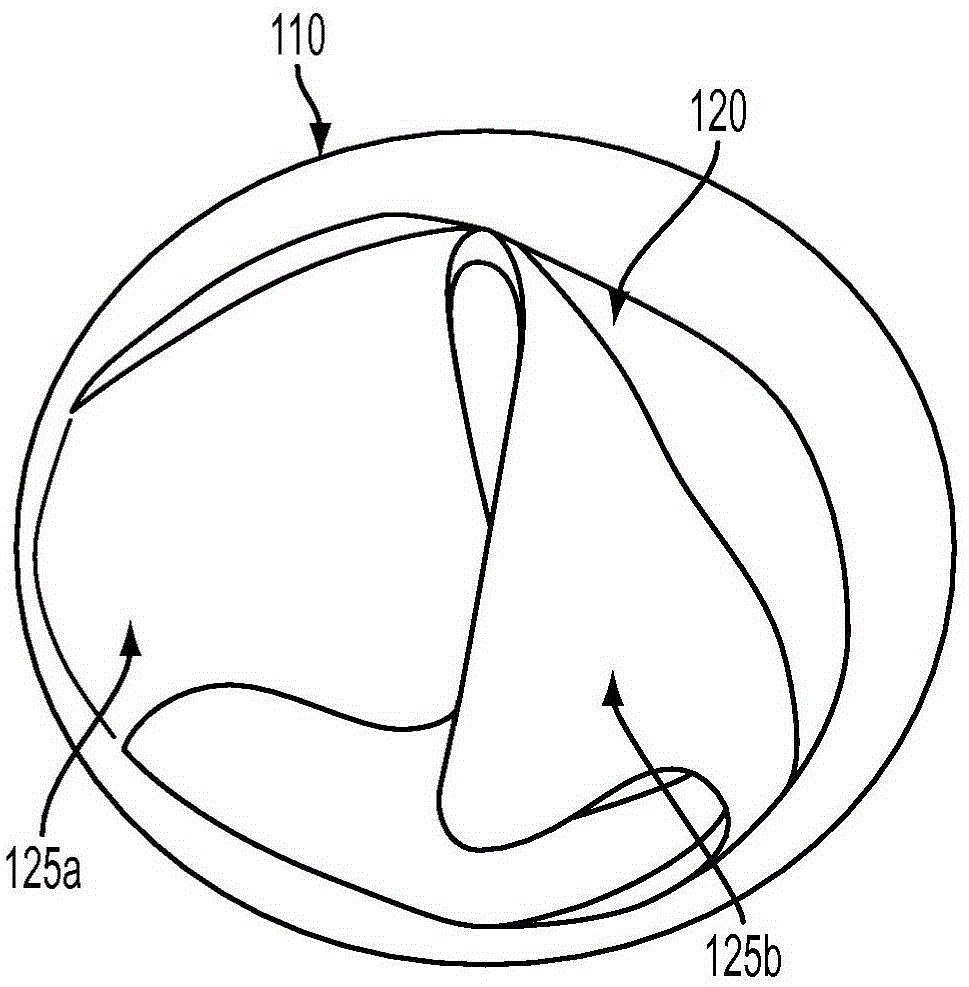

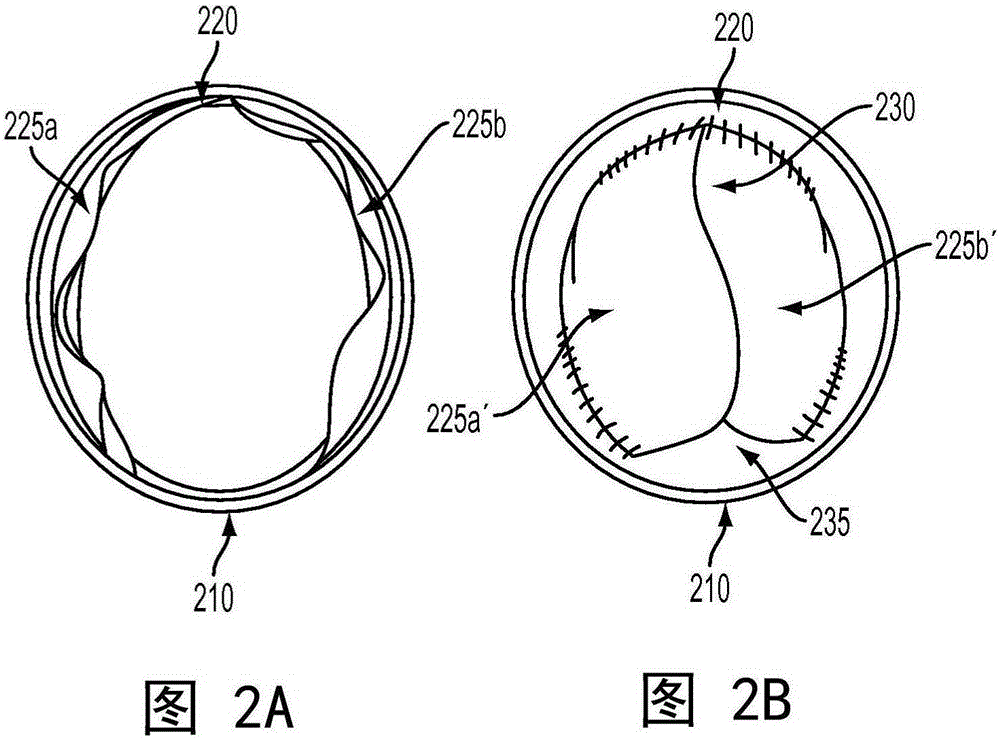

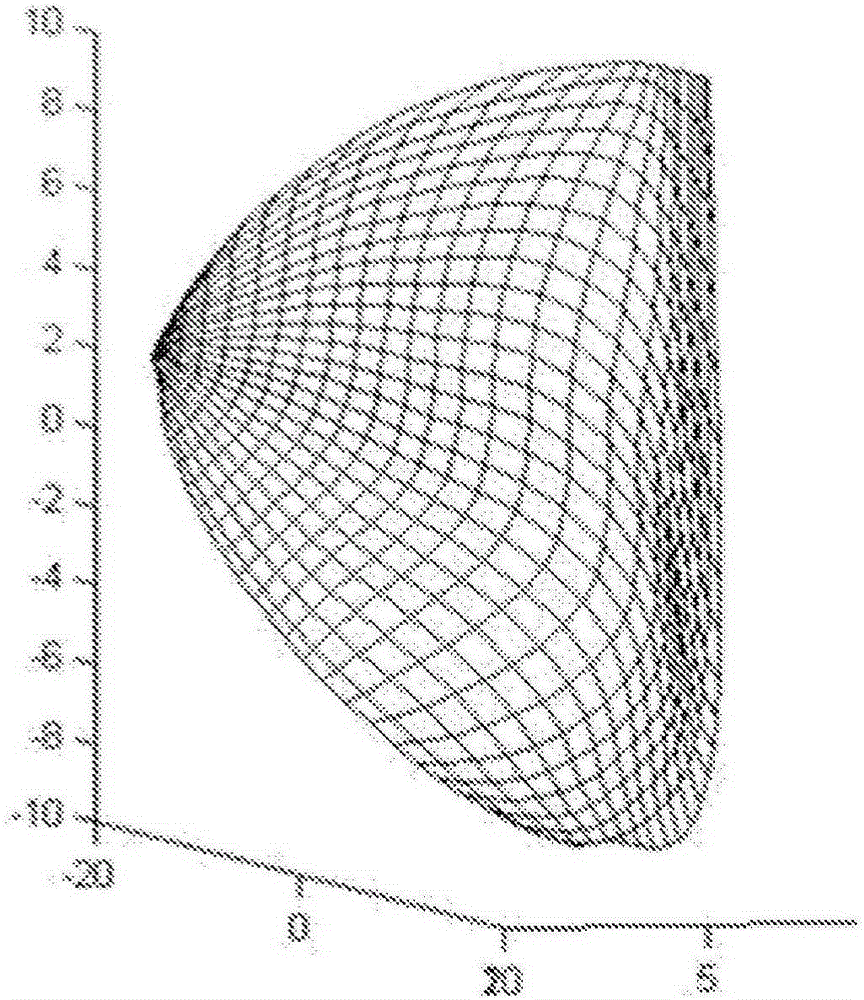

Expandable Implantable Catheter

ActiveCN105246430BHas ultimate tensile strengthHas a yield strengthProgramme controlVenous valvesVentricular outflow tractThrombus

An expandable valved catheter for pediatric right ventricular outflow tract (RVOT) reconstruction is disclosed. Valved catheters can provide long-term patency and resistance to thrombus and stenosis. The valved catheter can expand radially and / or longitudinally to accommodate the growing anatomy of the patient. Further, methods are disclosed for the production of valvated catheters based in part on plastically deformable biocompatible polymers, as well as computer-optimized valve designs developed for such expandable valvated catheters.

Owner:CARNEGIE MELLON UNIV

A heat treatment method for spray-formed 7055 aluminum alloy

ActiveCN109972064BGuaranteed Yield StrengthHas a yield strengthSolution treatmentUltimate tensile strength

The invention provides a heat treatment method for spray forming of a 7055 aluminium alloy. The heat treatment method includes the following steps of two-stage solid solution, retrogression low temperature reageing treatment, underaging pretreatment, regression treatment and low temperature reageing treatment. The two-stage solid solution comprises first-stage solid solution and second-stage solidsolution. Underaging is used as pretreatment before regression treatment, the number of eta phases in an alloy matrix is controlled, only a small amount of the eta phases are generated in the matrix,and thus it is guaranteed that the material has certain yield strength, subsequent regression treatment redissolves most of the GP regions in the matrix into the matrix, and the organization is prepared for a large number of dispersed GP regions precipitated by low temperature reaging. Meanwhile, regression treatment also avoids the aging process needing to take a long time to strengthen the phases in a single GP region to achieve the high strength and toughness of the 7055 aluminum alloy.

Owner:JIANGSU HAORAN SPRAY FORMING ALLOY

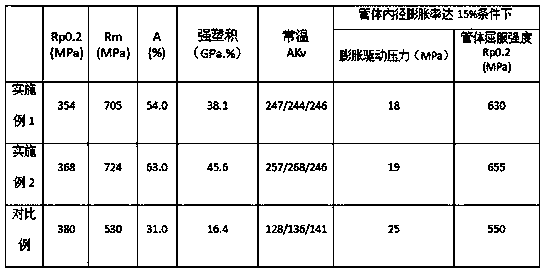

125ksi Hydrogen Sulfide Stress Corrosion Resistant High Strength Oil Casing Steel and Its Preparation Process

Owner:NORTHEASTERN UNIV LIAONING

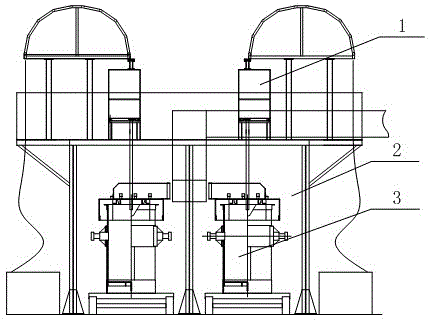

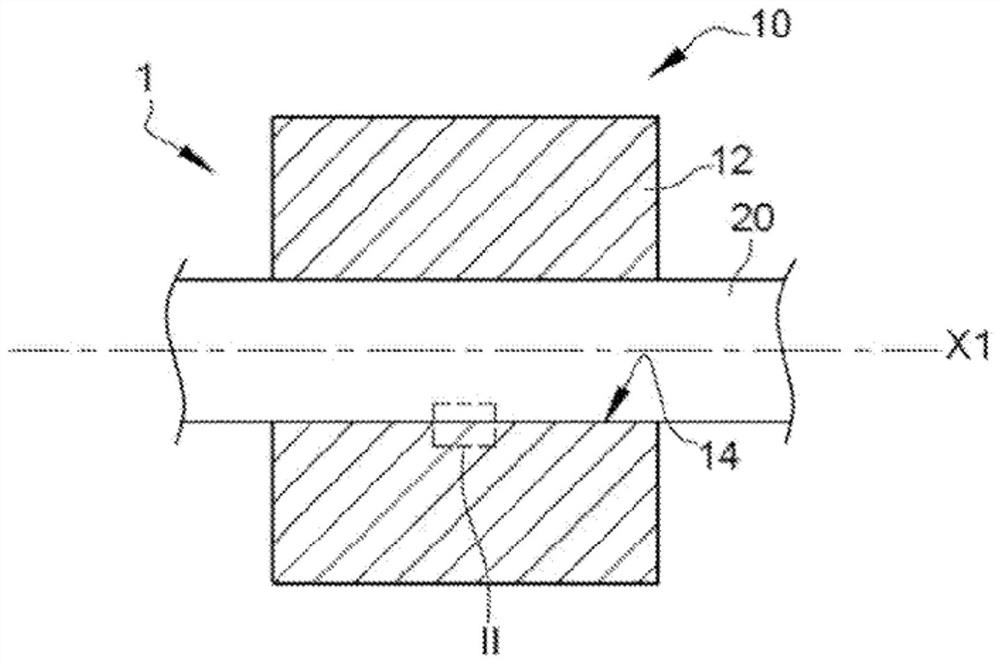

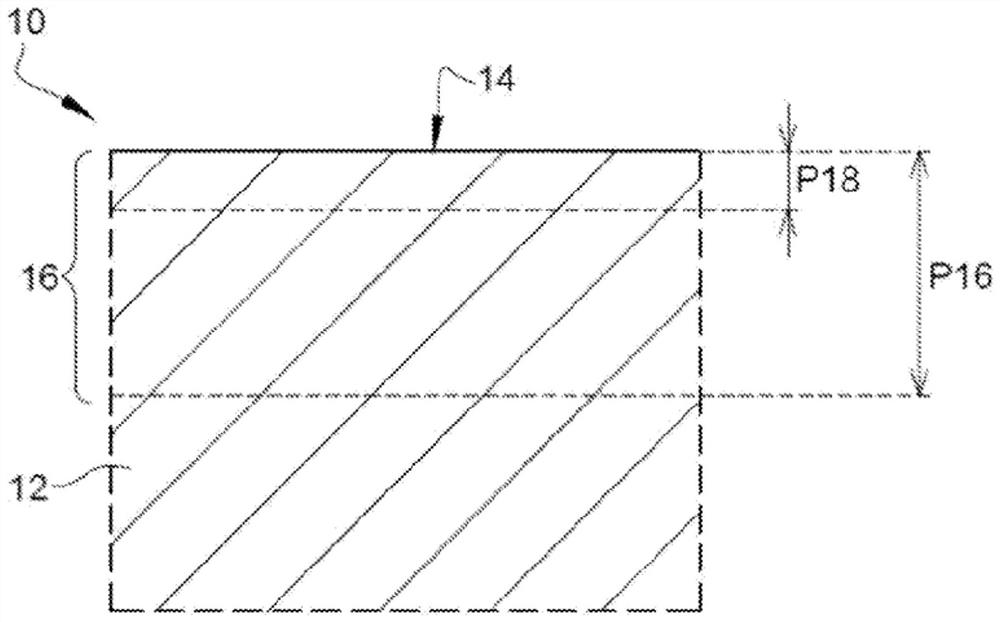

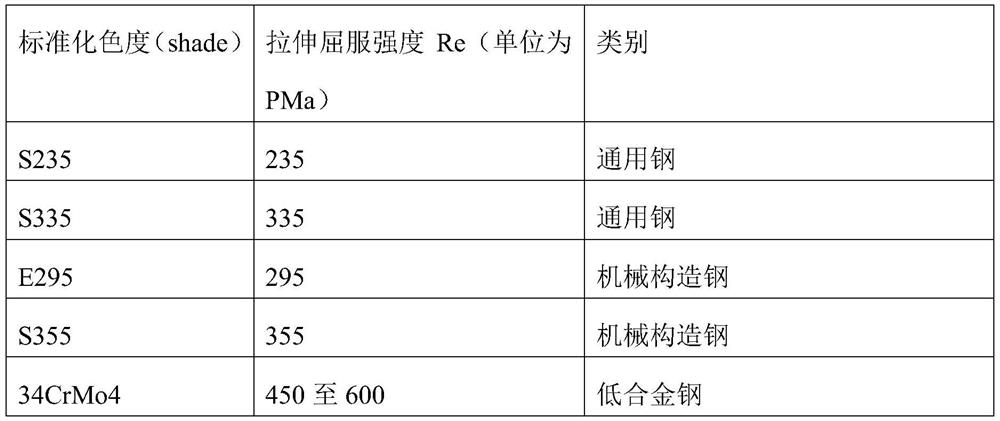

Guiding member, mechanical system comprising such a guiding member, and method for producing such a guiding member

PendingCN113853483AImprove performanceLong finishAgriculture tools and machinesDrilling accessoriesMetallic materialsMetal

The present invention relates to a guiding member (10), comprising a body (12) provided with a bore (14) for mounting a mobile element, the body (12) consisting of a metal material, characterized in that the bore (14) has a surface layer (16) that has undergone an anti-seizing treatment over a diffusion depth (P16) of less than or equal to 0.6 mm, the surface layer (16) having a hardness of greater than or equal to 500 Hv1 over a depth (P18) of between 5 and 50 mu m.

Owner:流体力学与摩擦公司

Expandable implantable conduit

ActiveCN105246430AHas ultimate tensile strengthHas a yield strengthProgramme controlVenous valvesComputer optimizationVentricular outflow tract

An expandable valved conduit for pediatric right ventricular outflow tract (RVOT) reconstruction is disclosed. The valved conduit may provide long-term patency and resistance to thrombosis and stenosis. The valved conduit may enlarge radially and / or longitudinally to accommodate the growing anatomy of the patient. Further, a method is disclosed for the manufacture of the valved conduit based in part on a plastically deformable biocompatible polymer and a computer-optimized valve design developed for such an expandable valved conduit.

Owner:CARNEGIE MELLON UNIV

Aluminum alloy and its manufacturing method

High strength aluminum alloys and methods of making and processing such alloys are disclosed. More specifically, aluminum alloys exhibiting improved mechanical strength are disclosed. The processing method includes homogenization, hot rolling, solutionization and multi-step quenching. In some cases, the processing step may further comprise annealing and / or cold rolling.

Owner:NOVELIS INC

Aluminum alloys and methods of making same

Disclosed are high-strength aluminum alloys and methods of making and processing such alloys. More particularly, disclosed are aluminum alloys exhibiting improved mechanical strength. The processing method includes homogenizing, hot rolling, solutionizing, and multiple-step quenching. In some cases, the processing steps can further include annealing and / or cold rolling.

Owner:NOVELIS INC

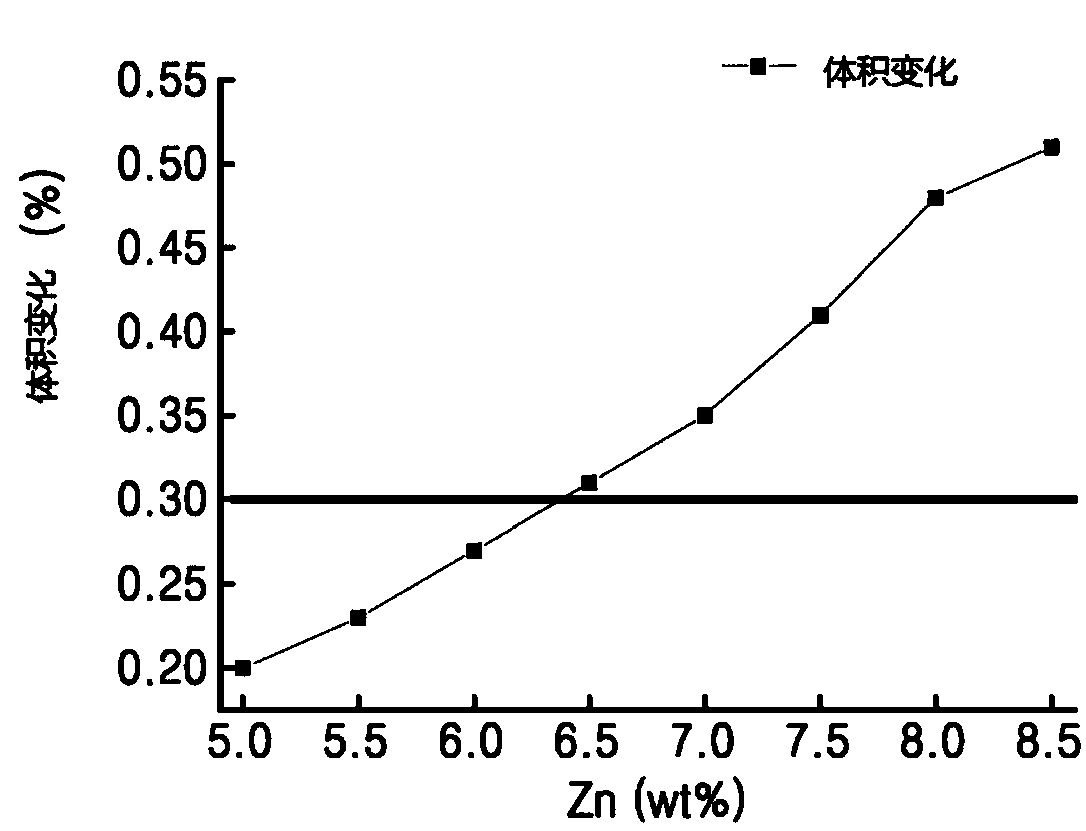

Deformed aluminum alloy

The invention provides a deformed aluminum alloy, the composition of which comprises: 5.5% to 6.0% by weight of Zn; 2.0% to 2.5% by weight of Mg; 0.2% to 0.6% by weight of Cu; 0.1% to 0.2% by weight Cr of 0.2 wt% or less (greater than 0 wt%) Fe; 0.2 wt% or less (greater than 0 wt%) of Mn; 0.2 wt% or less (greater than 0 wt%) of Si; 0.1 wt% or less (greater than 0 wt%) %) of Ti; 0.05% by weight or less (greater than 0% by weight) of Sr; the balance being Al.

Owner:KOREA AUTOMOTIVE TECH INST

A kind of gas shielded solid welding wire for ultra-high strength engineering machinery steel plate and its application

ActiveCN109807493BImprove low temperature impact toughnessLow yield ratioArc welding apparatusWelding/cutting media/materialsHigh intensityMaterials science

The invention belongs to the technical field of welding materials, and in particular relates to a gas-shielded solid welding wire for ultra-high-strength construction machinery steel plates, which comprises the following components in terms of mass percentage: C: 0.08-0.12%, Si: 0.70-0.90%, Mn: 1.65-1.85%, Cr: 0.45-0.65%, Ni: 2.3-2.5%, Mo: 0.40-0.70%, Ti: 0.08-0.15%, Zr: 0.04-0.08%, Nb: 0.05-0.10%, B : 0.004~0.006%, S: 0.005~0.015%, P≤0.010%, the balance is iron and unavoidable impurities. The present invention also provides the application of the above-mentioned gas-shielded solid welding wire, which is used for welding ultra-high-strength engineering machinery steel plates with a tensile strength of 960 MPa. The weld seam formed by welding with the solid welding wire provided by the invention has the advantages of good low-temperature impact toughness, low yield ratio, high strength, and beautiful shape; and the welding spatter is small, and the welding process performance is excellent; the use of argon-rich (80%Ar+20 %CO 2 ) gas shielded welding, the yield ratio of the deposited metal is ≤0.9, which is suitable for the welding of ultra-high-strength engineering machinery steel plates such as Q890 with a tensile strength of 960MPa.

Owner:WUHAN TEMO WELDING CONSUMABLES CO LTD

A kind of hot-rolled steel plate for 400mpa double-sided enamelling after enamel and its manufacturing method

ActiveCN109423576BGuaranteed Yield StrengthMeet the design requirementsUltimate tensile strengthHot rolled

The invention relates to a hot rolled steel plate with the honed yield strength of 400 MPa for counterenamel. The hot rolled steel plate is prepared from, by mass percent, 0.08% to 0.15% of C, not larger than 0.10% of Si, 1.0% to 2.0% of Mn, 0.060% to 0.10% of P, not larger than 0.006% of S, not larger than 0.008% of N, 0.02% to 0.08% of Ti, 0.010% to 0.045% of Als, 0.020% to 0.055% of V, 0.01% to0.05% of Nb, 0.15% to 0.30% of Mo and the balance Fe and inevitable impurities. When the thickness of the hot rolled steel plate is larger than or equal to 8 mm, 0.0005% to 0.005% of B is added. Thehoned yield strength of the hot rolled steel plate is larger than or equal to 400 MPa. The hot rolled steel plate has good scute burst resisting performance, meanwhile, the honed yield strength can reach 400 MPa or above, and the requirement of a large enamel assembling structure can be met better.

Owner:ANGANG STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com