Industrial preparing method of water-cooling metal mold centrifugal nodular cast iron pipe

A centrifugal ductile iron and metal mold technology is applied to the entire preparation of water-cooled metal centrifugal ductile iron pipes, and the industrial preparation of water-cooled metal centrifugal ductile iron pipes can solve the problems of desulfurization, improper spheroidizing treatment, and the use of iron casting pipes. Shortened life, affecting the quality of cast iron pipes, etc., to achieve the effect of good application effect, high production efficiency and high appearance quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

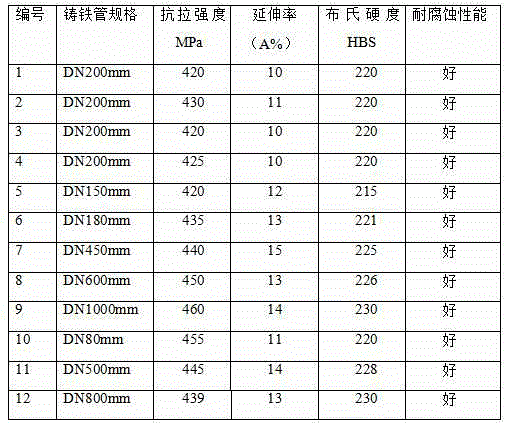

[0045] The existing patent documents related to the preparation of cast iron pipes include CN102000797A, CN101921945A, CN102981492A, etc., which include the source of molten iron, spheroidizing and annealing of molten iron involved in the production process of cast iron pipes. However, for the production process of cast iron pipes, Its complete preparation process includes a series of production steps from smelting, molten iron spheroidizing inoculation treatment, casting, heat treatment to shaping and coating, combined with the current situation of continuous growth in demand for cast iron pipes in my country, in order to obtain stable high-quality cast iron To meet the urgent needs of the current cast iron pipe industry, the present invention proposes an industrial preparation method for water-cooled metal type centrifugal nodular cast iron pipes. And the preparation process of obtaining the finished cast iron pipe after the coating process.

[0046] In this example, the specif...

Embodiment 2

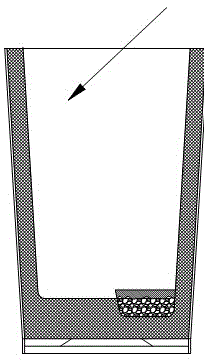

[0057] The difference between this embodiment and Embodiment 1 is that: in step (2), the spheroidization process involved in this embodiment is the flushing spheroidization method, figure 1 It is a schematic diagram of the structure of the spheroidization package, such as figure 1 as shown, figure 1 In the middle right groove from bottom to top are nodularizer and inoculant, figure 1The direction of the arrow symbol in the middle is the direction of the molten iron rushing in. In this method, the molten iron prepared in step (1) is aimed at the side of the embankment where no nodulizer is added, and the iron is tapped at a rate of 25kg / s. The amount of iron reaches 1 / 2 of the height of the spheroidizing ladle, stop for 3s, and then tap iron at a tapping rate of 80kg / s until the ladle is full to obtain spheroidized molten iron. The spheroidized molten iron contains 0.035% magnesium, which The fluctuation value of carbon equivalent is 0.03%.

Embodiment 3

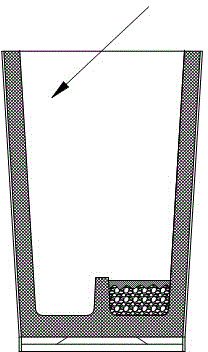

[0059] The difference between this embodiment and Embodiment 1 is that: in step (2), the spheroidization process involved in this embodiment is the flushing spheroidization method, figure 2 It is a schematic diagram of the structure of the spheroidization package, such as figure 2 as shown, figure 2 In the middle right groove from bottom to top are nodularizer and inoculant, figure 2 The direction of the arrow symbol in the middle is the direction of the molten iron rushing in. In this method, the molten iron prepared in step (1) is aimed at the side of the embankment where no nodulizer is added, and the iron is tapped at a rate of 35kg / s. The amount of iron reaches 1 / 3 of the height of the spheroidizing ladle, pause for 5s, and then tap iron at a tapping rate of 120kg / s until the ladle is full to obtain spheroidized molten iron. The spheroidized molten iron contains 0.035% magnesium, which The fluctuation value of carbon equivalent is 0.02%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com