Rapid aging of high strength 7xxx aluminum alloys and methods of making the same

An aluminum alloy, pre-aging technology, applied in the direction of chemical instruments and methods, metal layered products, layered products, etc., can solve problems such as expensive processing steps and low-efficiency manufacturing processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

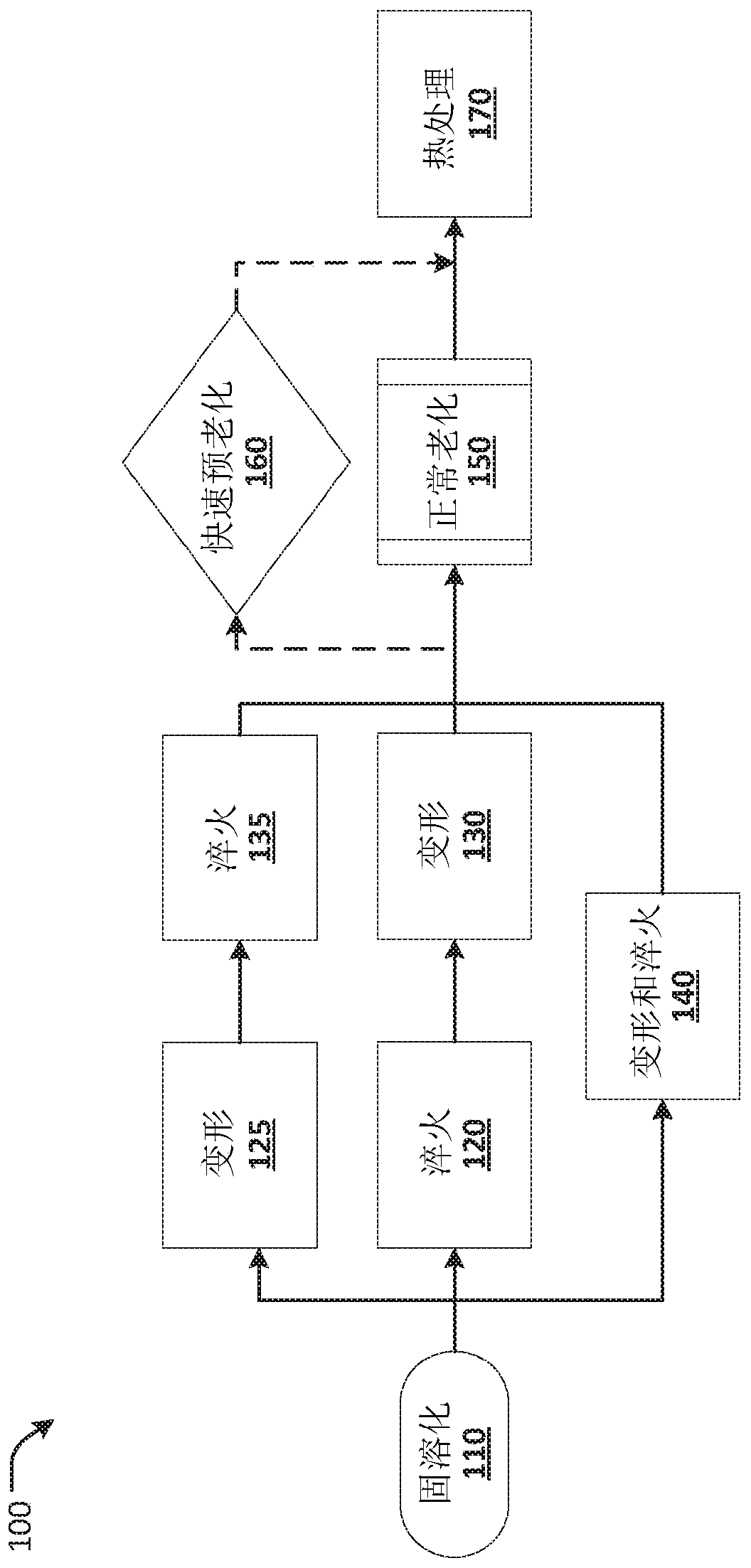

[0064] Example 1: Exemplary Method of Making 7xxx Series Aluminum Alloy Articles

[0065]An exemplary method 100 for processing an alloy as described herein is at figure 1 shown in . Fabricated 7xxx series aluminum alloy sheet, plate or sheet material (referred to as the F temper) is solutionized (at 110) at a temperature of at least 460°C for a period of at least 60 seconds. After solutionization, the aluminum alloy was quenched (at 120) with water at a temperature of about 55°C to room temperature. After the quenching step 120, the aluminum alloy is deformed (at 130) to produce an aluminum alloy article.

[0066] In another method as described herein, an aluminum alloy article is deformed and quenched (at 140) in one step. The aluminum alloy article is placed in a cooling mold at a temperature between about 380°C and about 480°C, deformed and mold quenched to form the aluminum alloy article.

[0067] In yet another method as described herein, after solutionizing, the al...

example 2

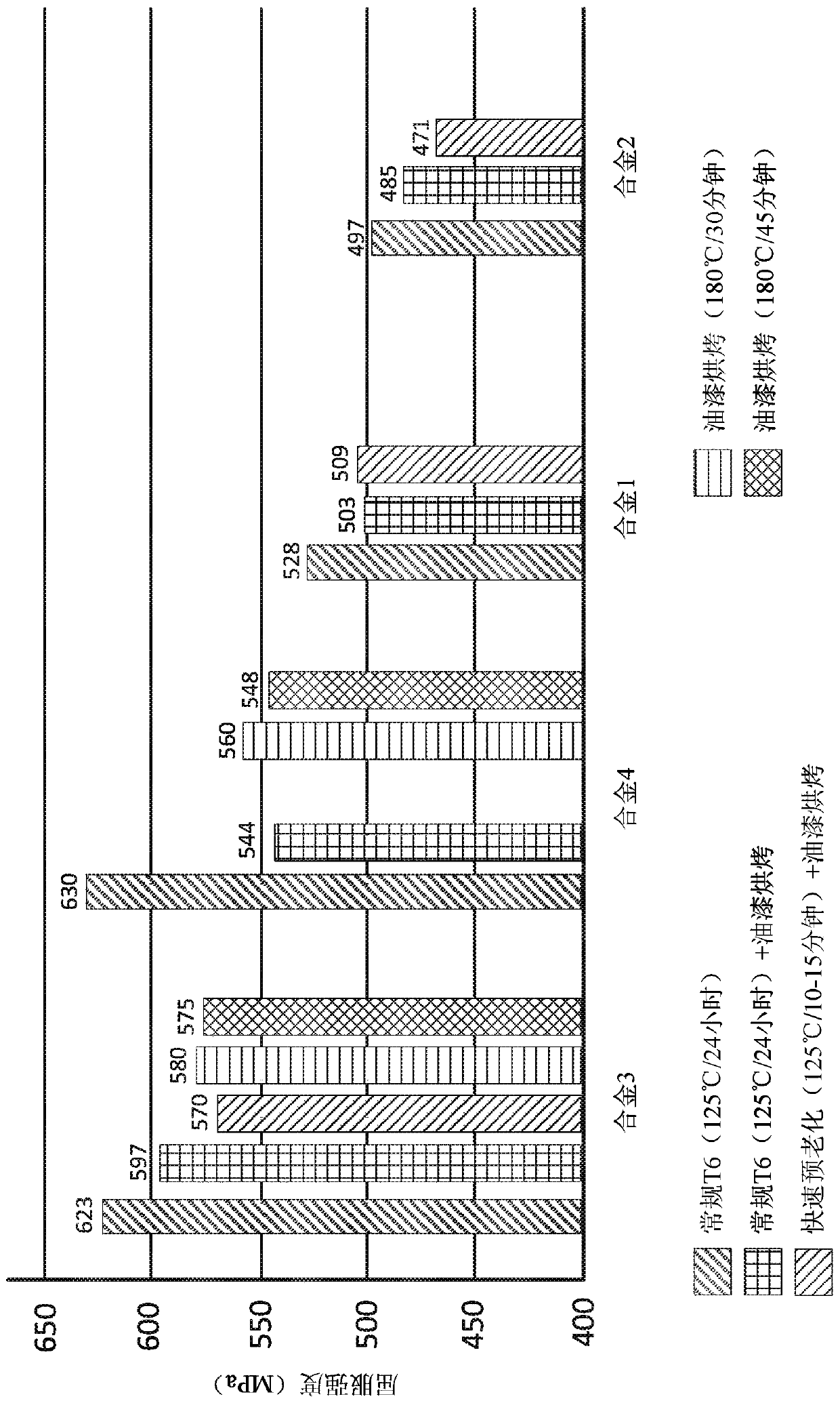

[0069] Example 2: Effect of rapid pre-aging temperature on mechanical properties

[0070] Six 7xxx series alloys were prepared for strength testing (see Table 1). Alloys 1-6 were prepared by the same method. The alloy is solutionized, quenched and deformed. Samples from each alloy were (1) conventionally aged by heating at 125°C for 24 hours (bringing the material to a "T6" temper); (2) conventionally aged by heating at 125°C for 24 hours with paint bake (to bring the material to a "T6" temper); (3) perform the rapid pre-aging method described herein by heating at 125°C for 10-15 minutes, followed by a paint bake (to bring the material to a T8x temper); (4 ) the rapid pre-aging method described herein by heating at 180°C for 30 minutes (to bring the material to a T8x temper); or (5) the rapid pre-aging method described herein by heating at 180°C for 45 minutes (to bring the material to a T8x temper); Material reaches T8x temper).

[0071] Table 1

[0072]

[0073]

...

example 3

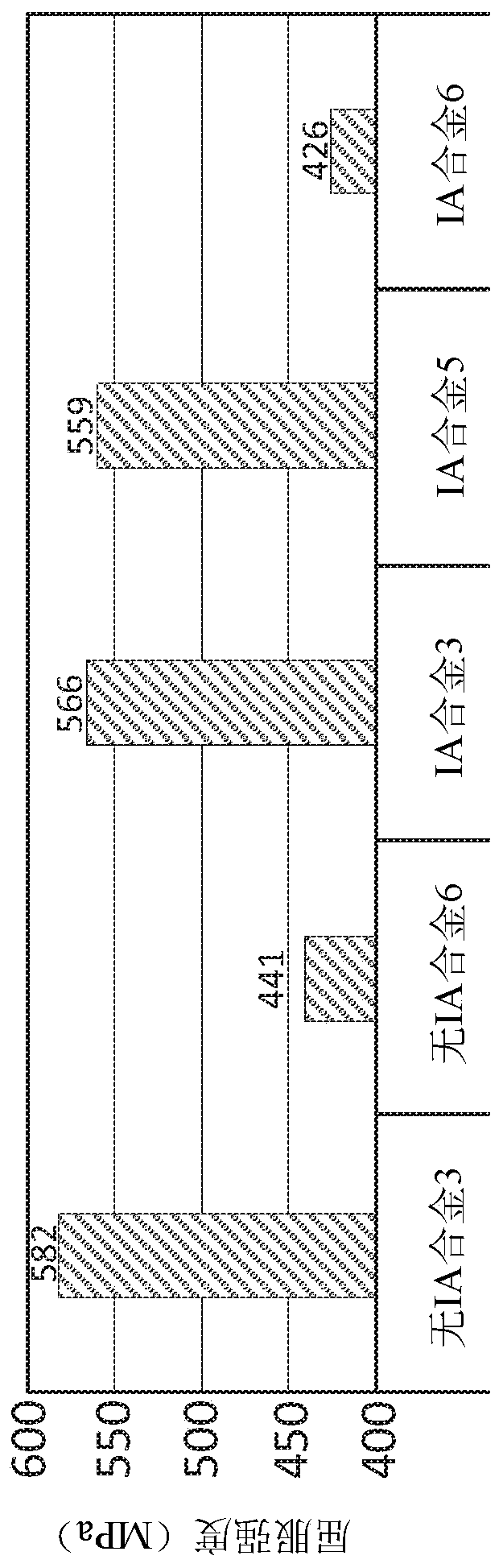

[0079] Example 3: Effect of Annealing on Mechanical Properties

[0080] Alloys 3, 5 and 6 (see Table 1) were prepared by hot rolling, optional annealing, cold rolling, solutionizing, quenching, deformation, exemplary rapid aging and paint bake at 180°C for 30 minutes. image 3 The effect of annealing on the yield strength of the alloy is shown. An optional annealing step (ie, intermediate annealing between hot and cold rolling) was performed on samples designated "IA" and no optional annealing step was performed on samples designated "No IA". Annealing is performed by heating the coiled alloy product to a temperature of about 410°C at a heating rate of about 50°C / hour. The coiled alloy product was then soaked at about 410°C for about 1 hour, cooled to about 350°C and soaked at about 350°C for about 2 hours. The coil is then allowed to cool to room temperature.

[0081] like image 3 As shown, the samples processed without the optional annealing step exhibit higher yield st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com