Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Guaranteed vertical bearing capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

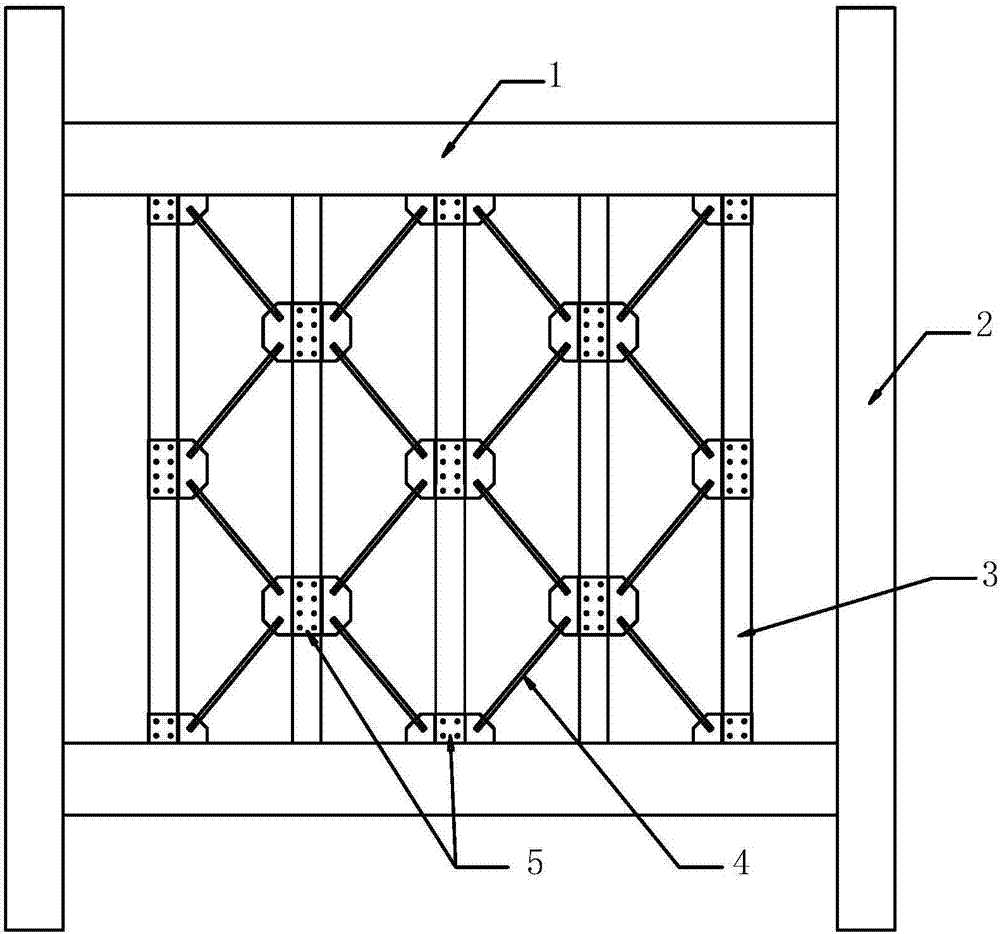

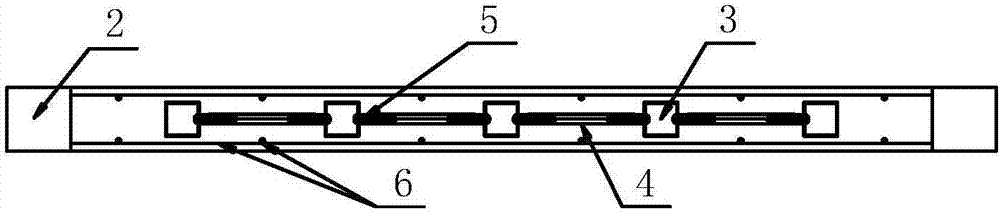

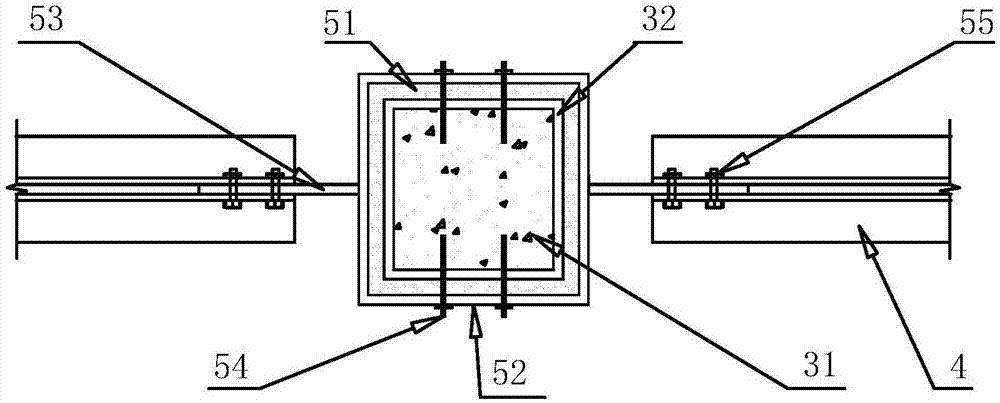

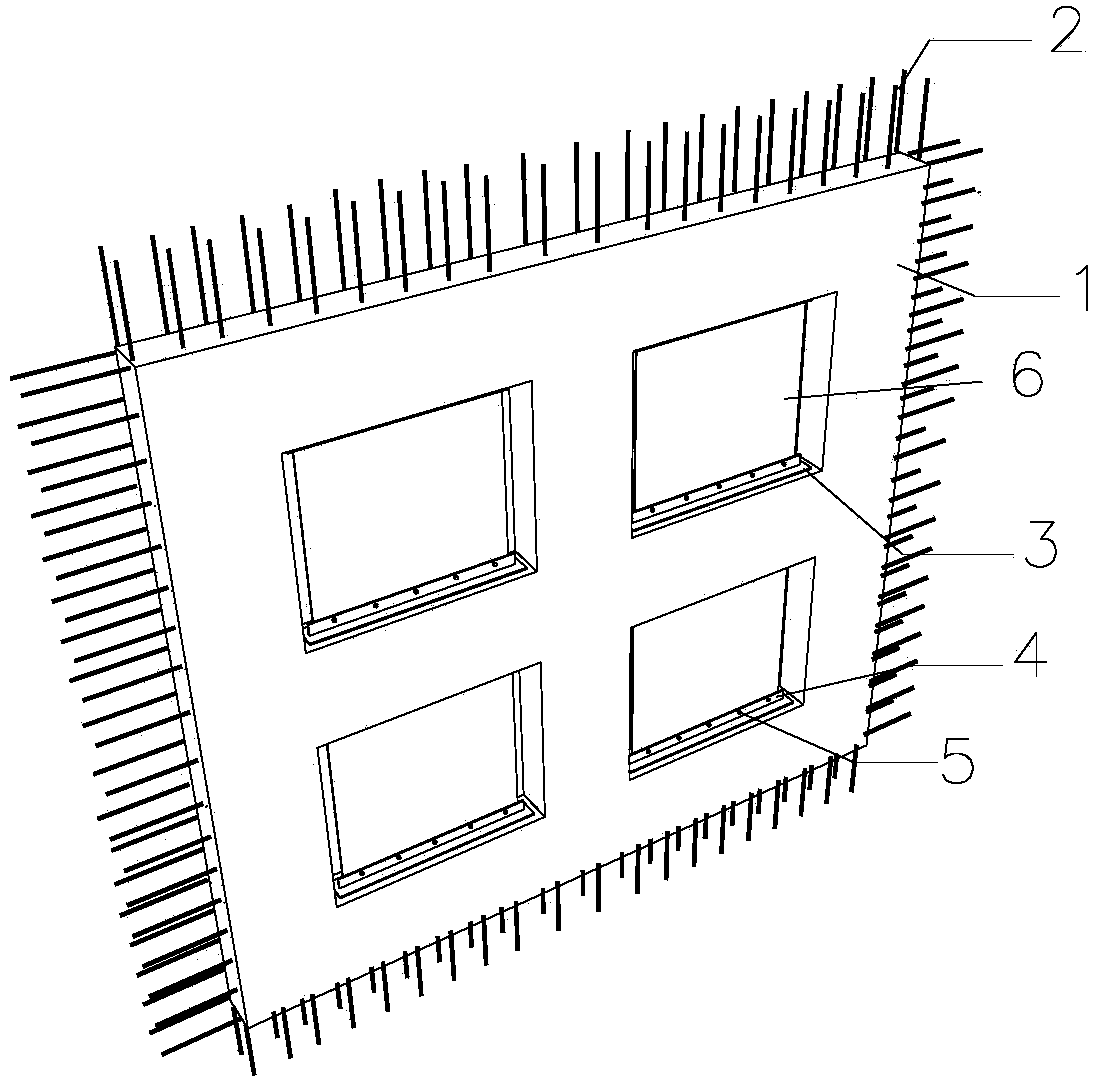

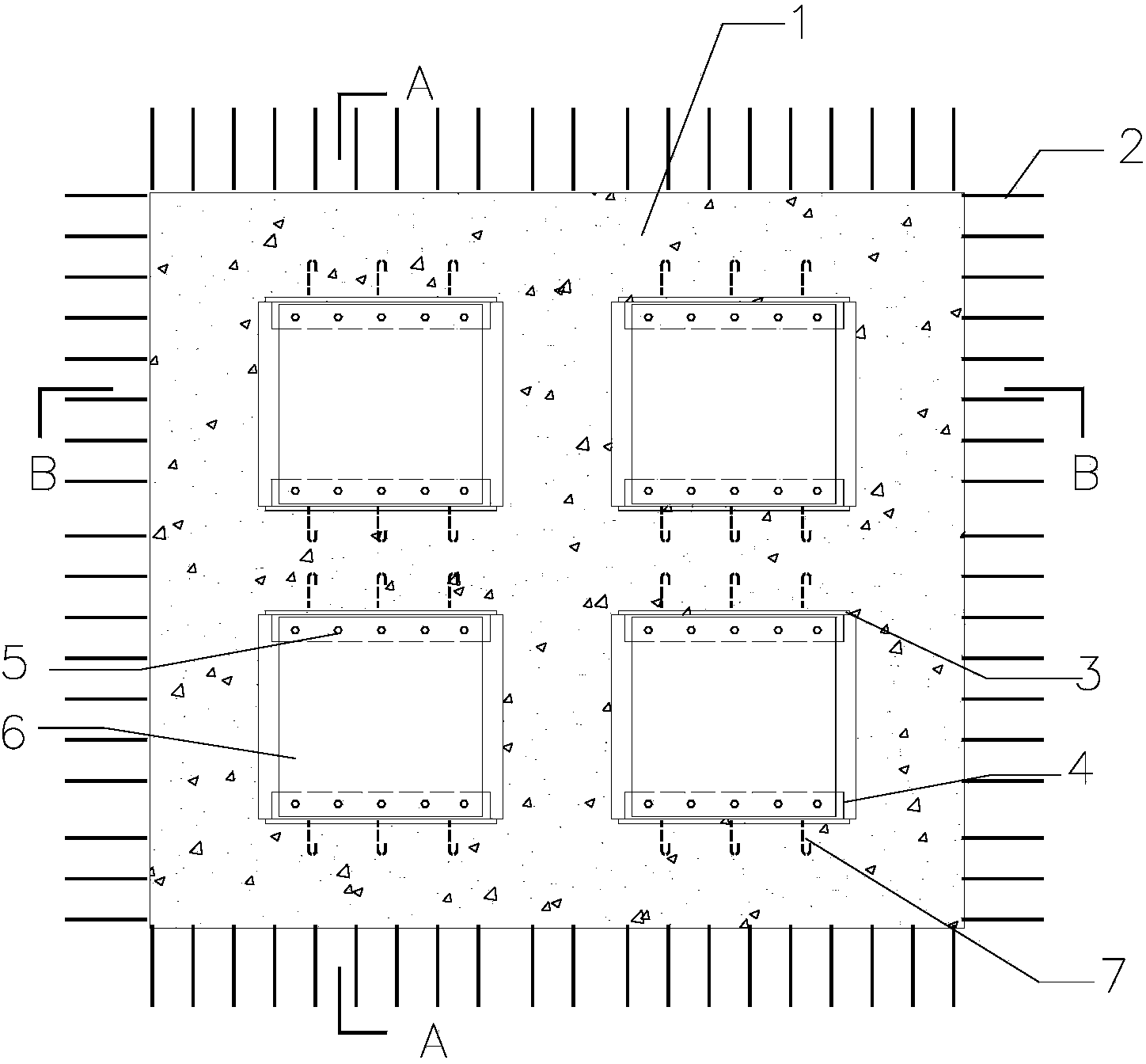

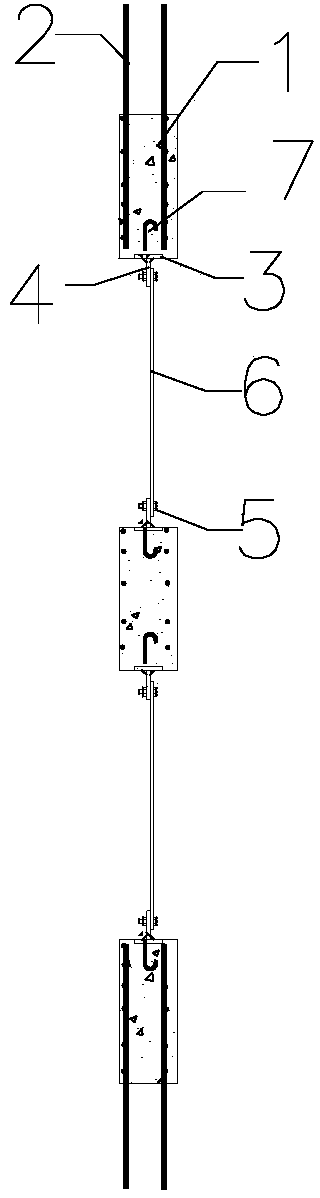

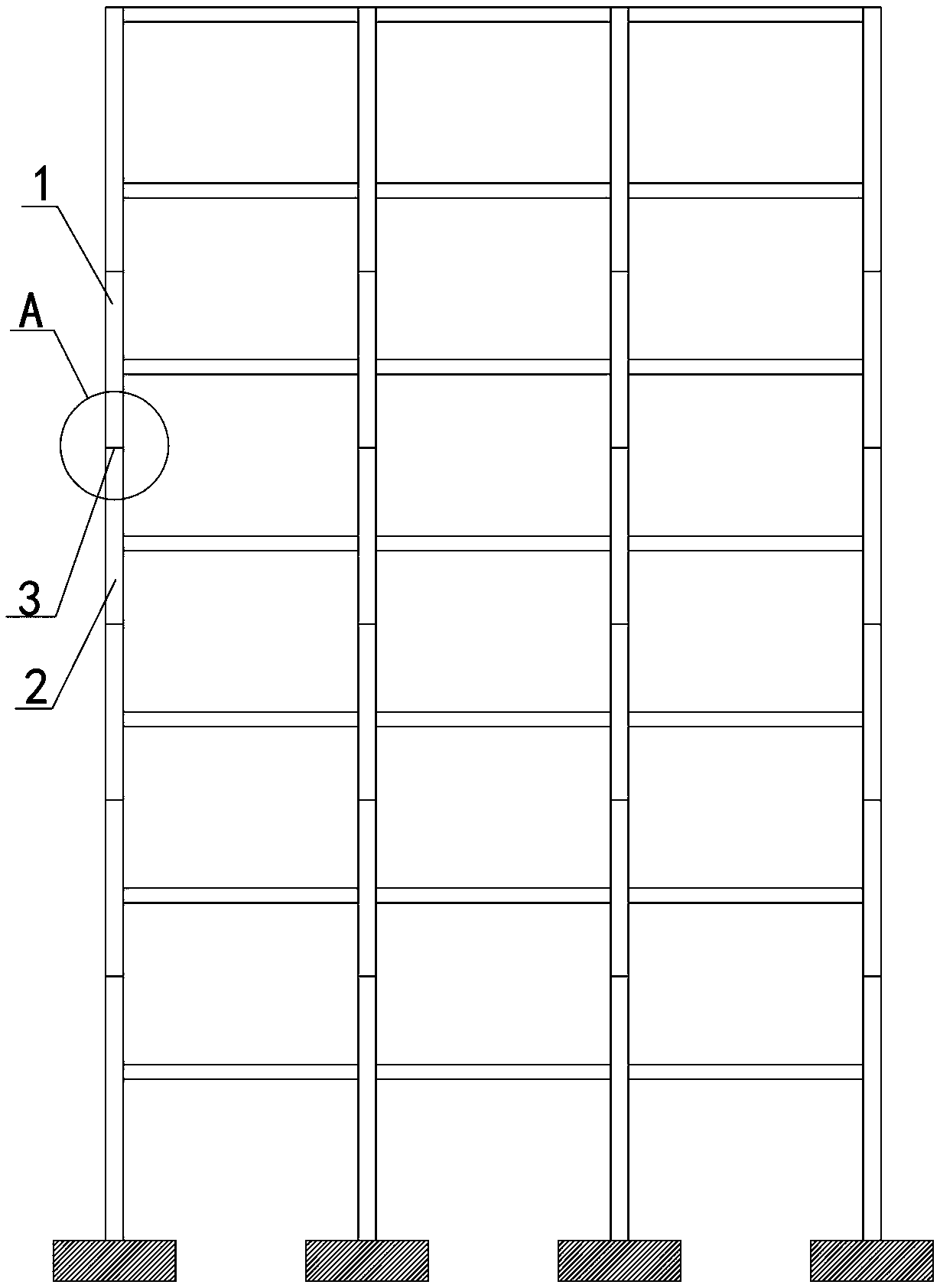

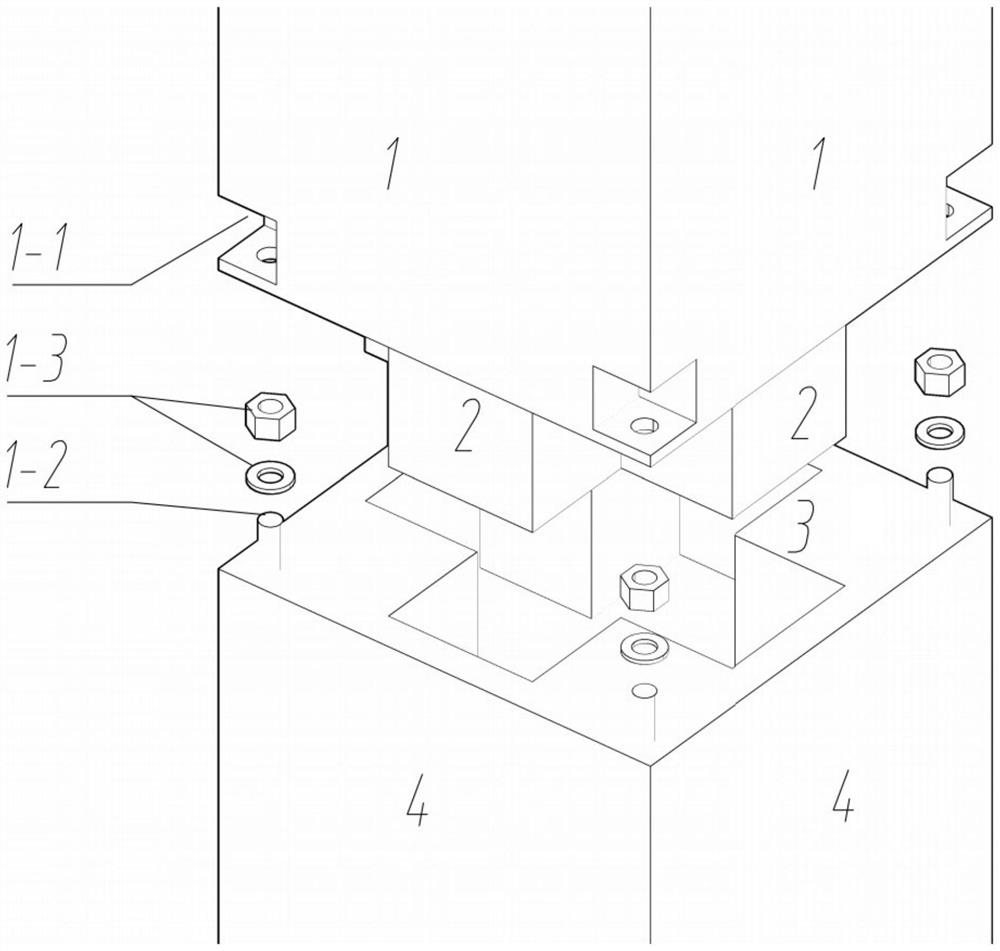

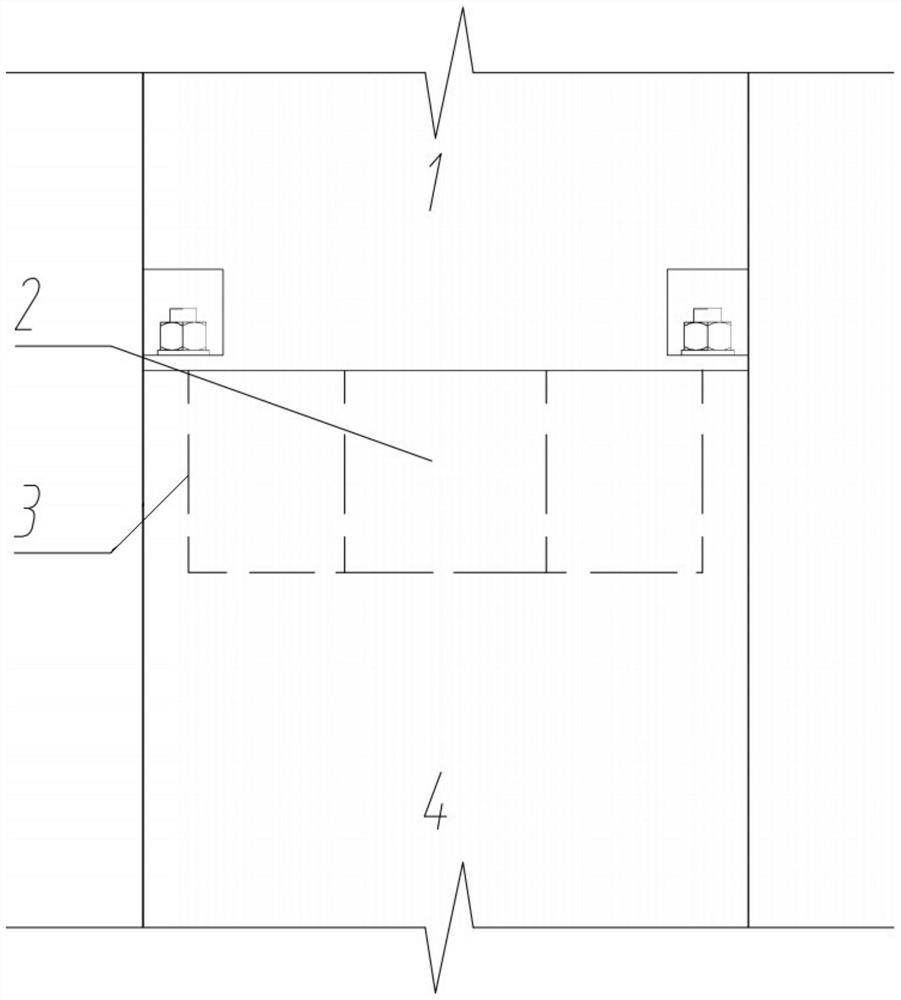

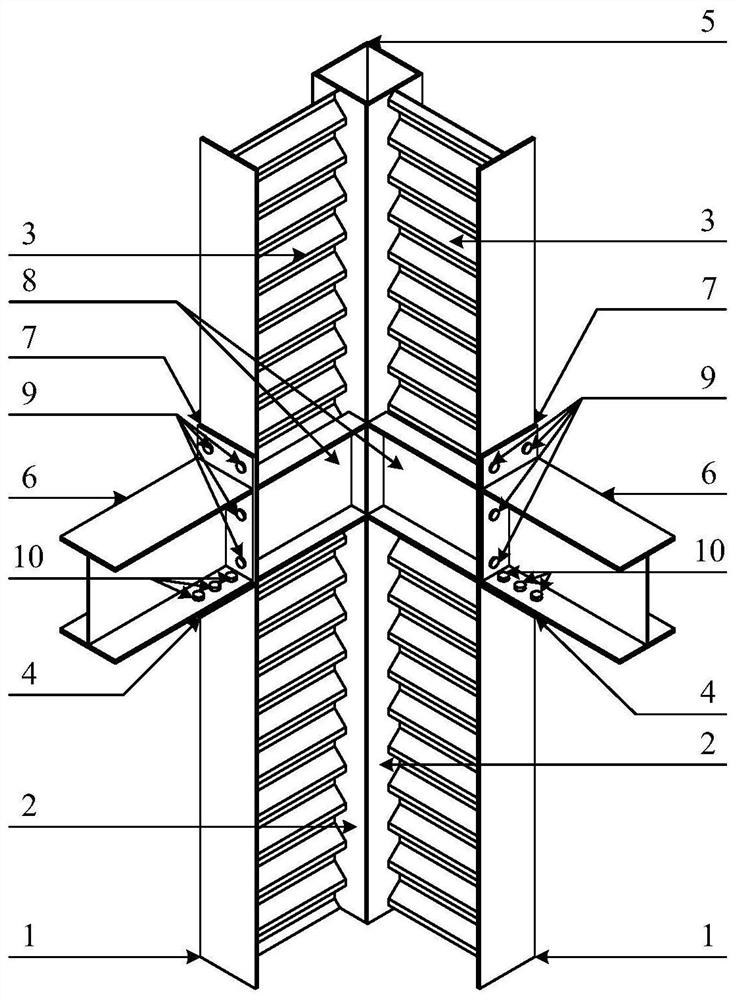

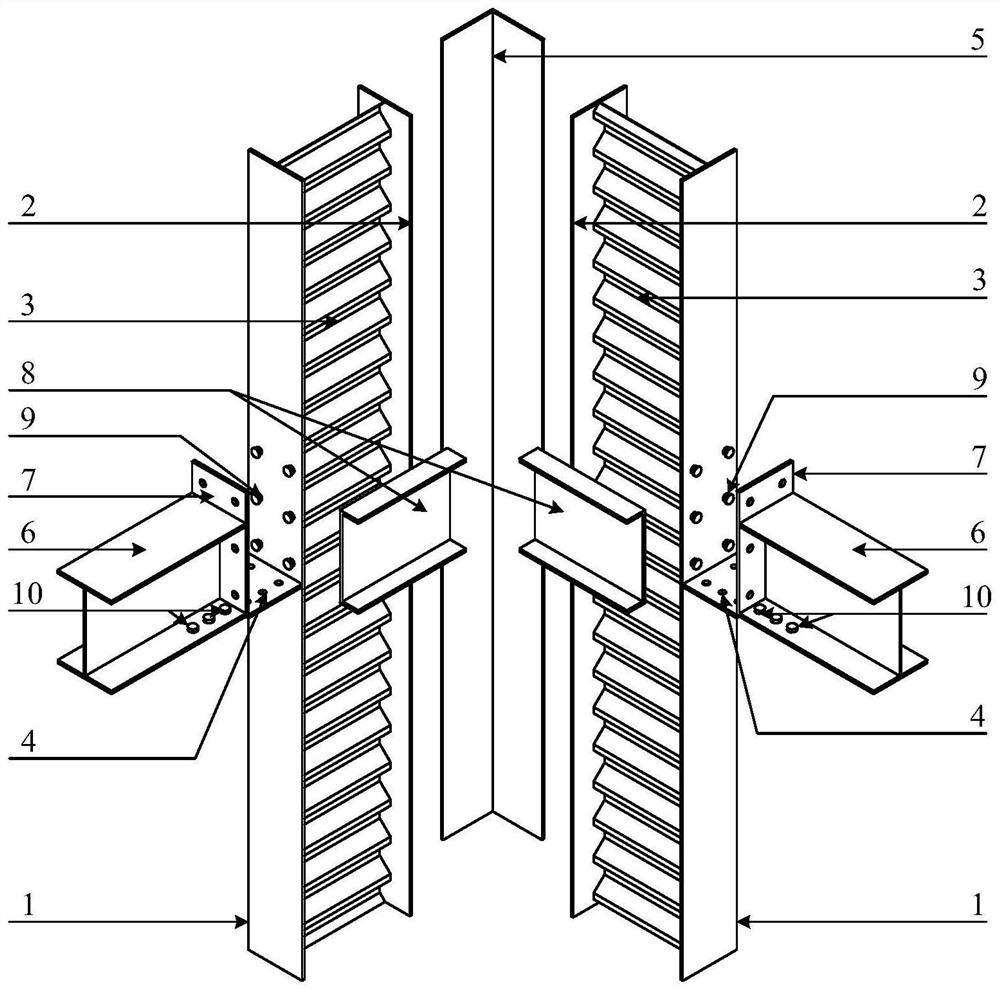

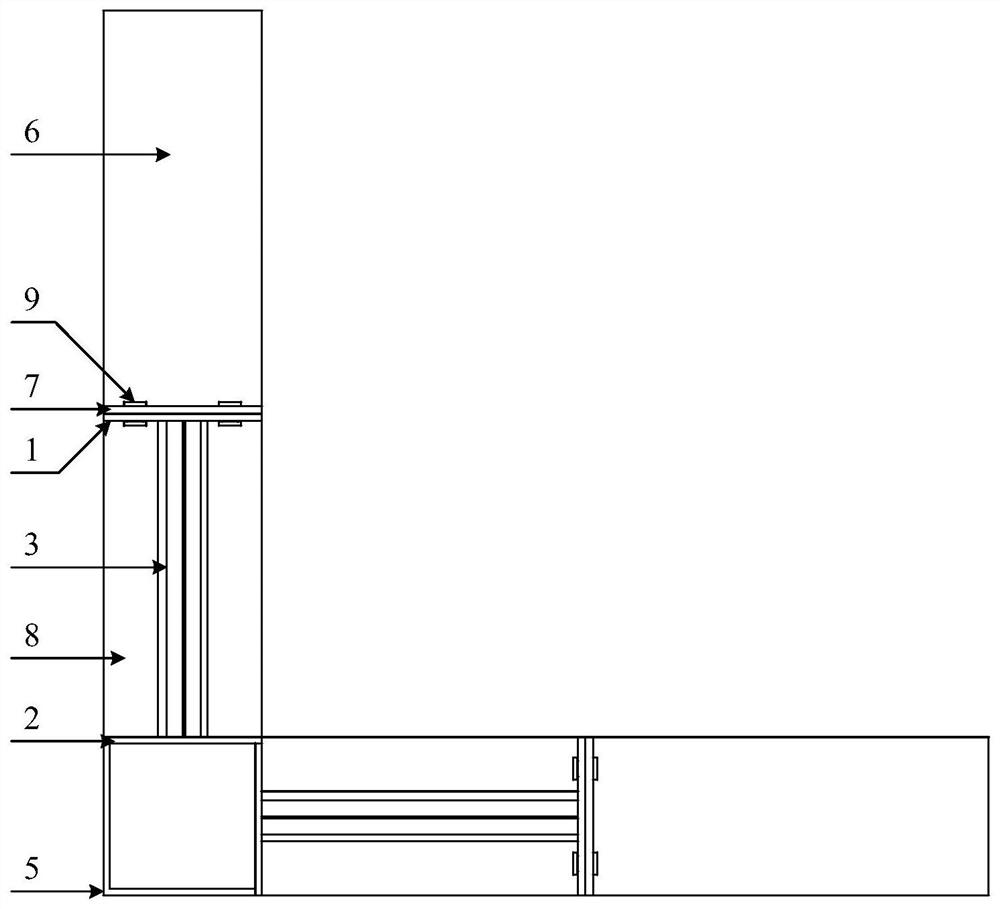

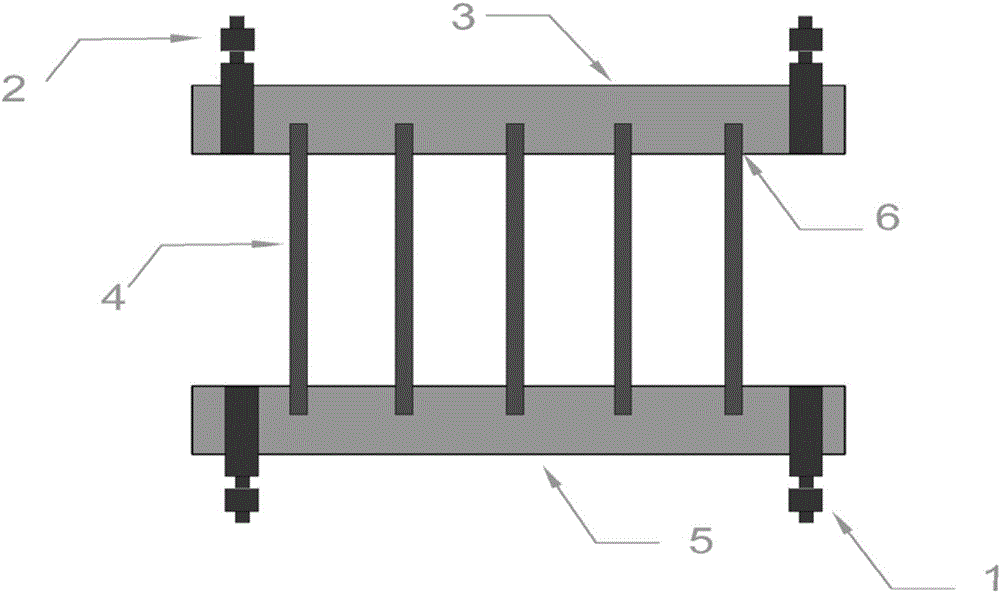

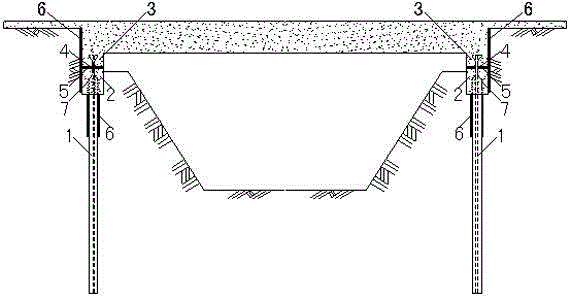

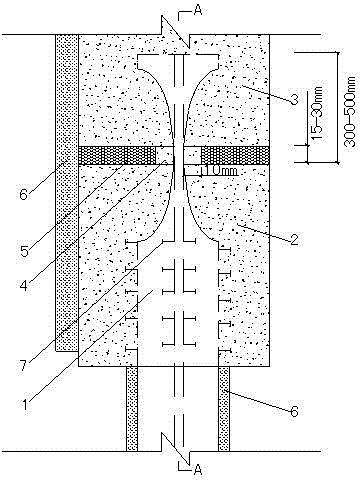

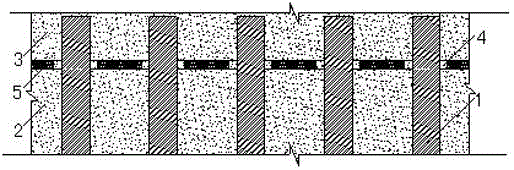

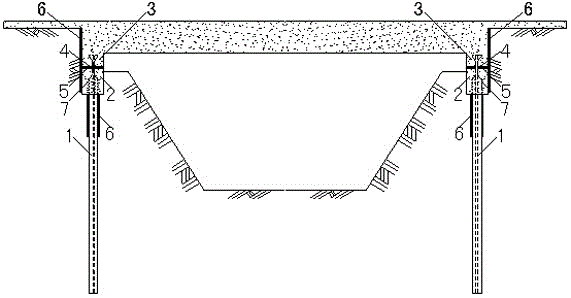

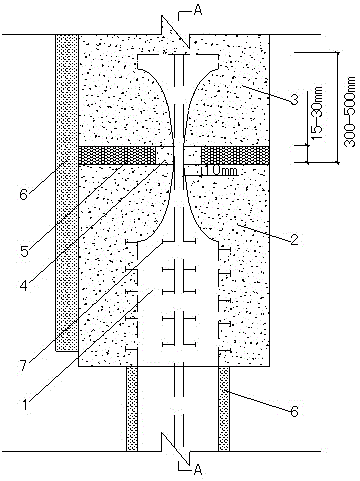

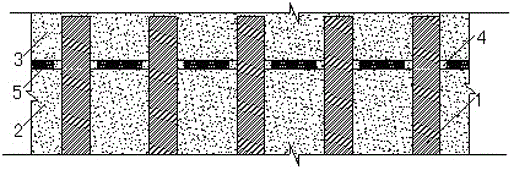

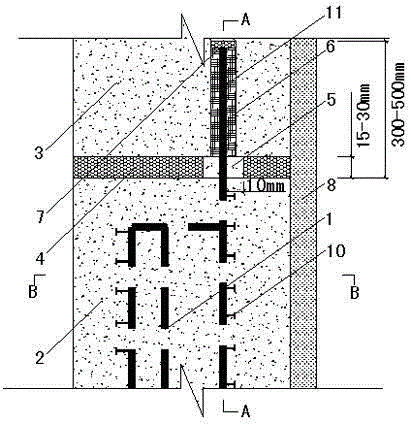

Concrete filled steel tube row column shear wall with structural steel support and manufacturing method thereof

ActiveCN106869367AGood axial compression performanceGuaranteed vertical bearing capacityWallsHoopingRebar

The invention discloses a concrete filled steel tube row column shear wall with a structural steel support and a manufacturing method thereof. The shear wall comprises prefabricated concrete filled steel tubular columns arranged at certain intervals, structural steel supporting components, sleeve connecting components for connecting structural steel and concrete filled steel tubes, concrete poured into a wall space in a filling mode, and steel bar nets which are used for preventing early cracking of the concrete and arranged on two sides of a wall body in advance. The shear wall gives full play to the good axial compressive performance of the concrete filled steel tubular columns. The rigidity of the wall body is increased due to addition of the structural steel supporting components. A rubber pad layer is arranged in each sleeve connecting component, so that partial damage at the joints of the concrete filled steel tubular columns and the supporting components is reduced to a certain extent. Bulging of steel tubes is restrained due to the hooping function of sleeves to the concrete filled steel tubes, and the three layers of defenses including the concrete, the structural steel support and the concrete filled steel tubes are formed. The combined shear wall has high bearing capacity and a good anti-seismic property, most of the components are prefabricated components and are convenient to splice after being conveyed to a construction site, and work time is saved.

Owner:TIANJIN UNIV

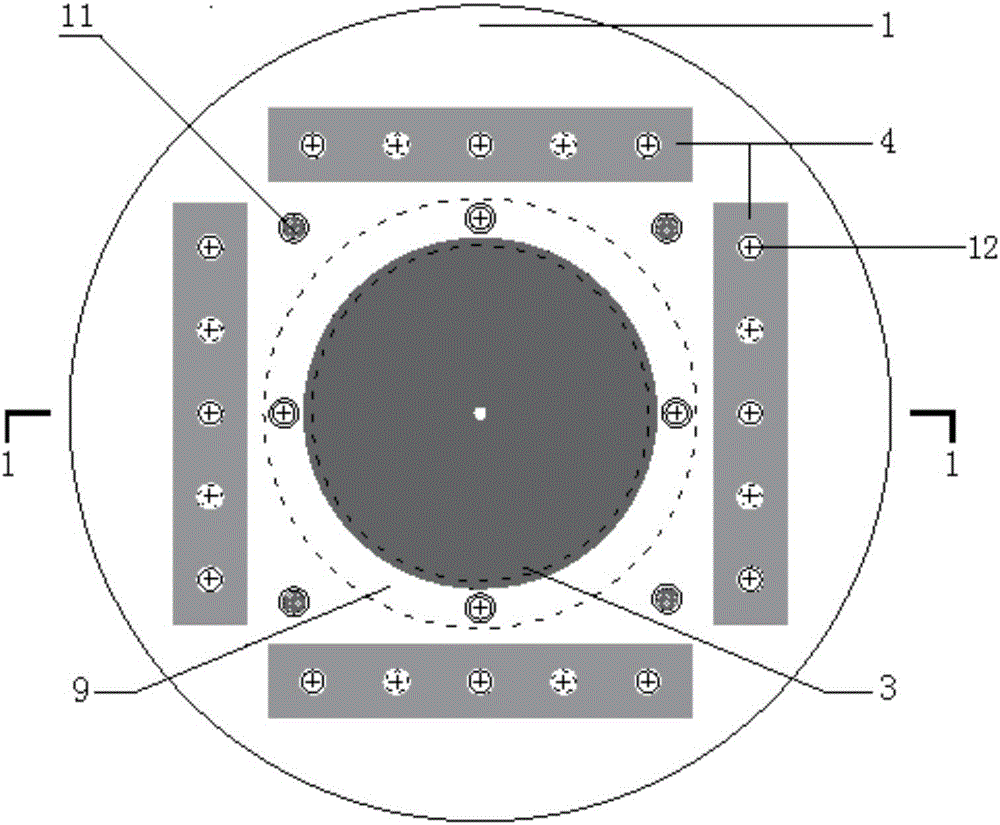

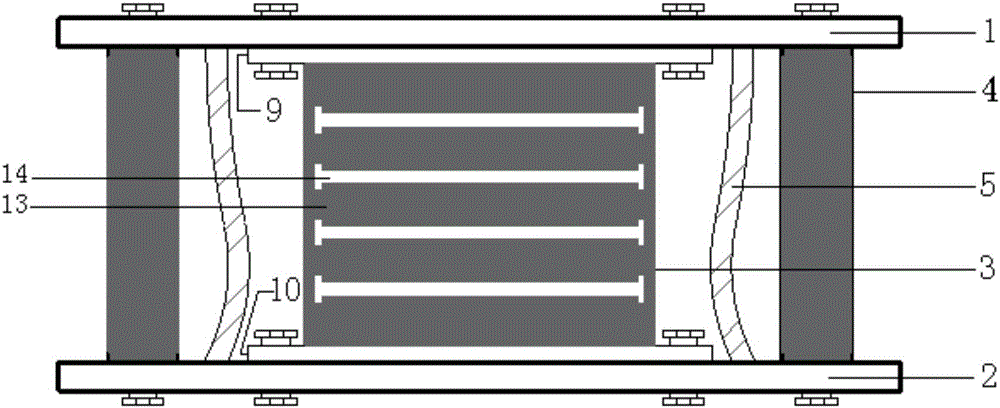

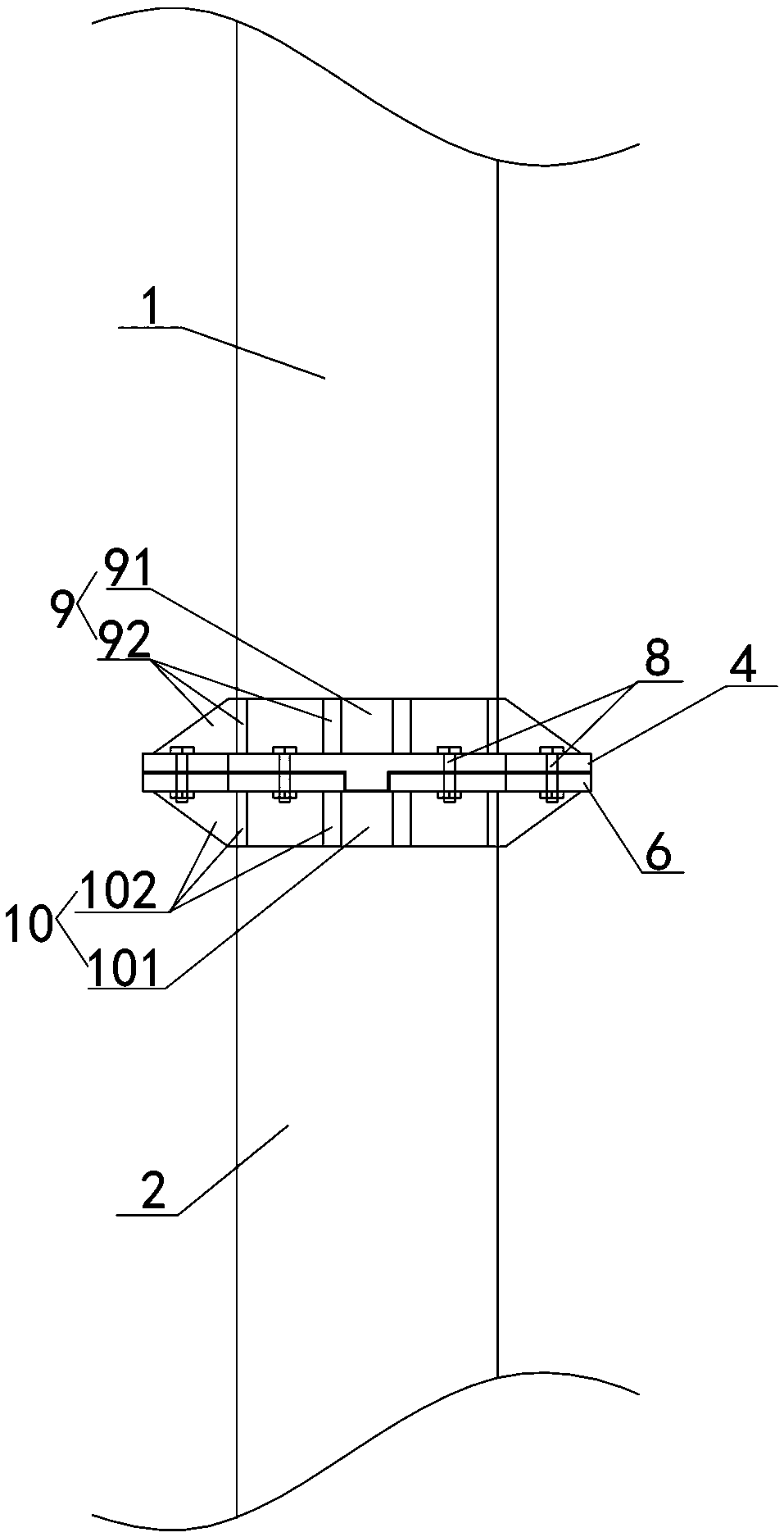

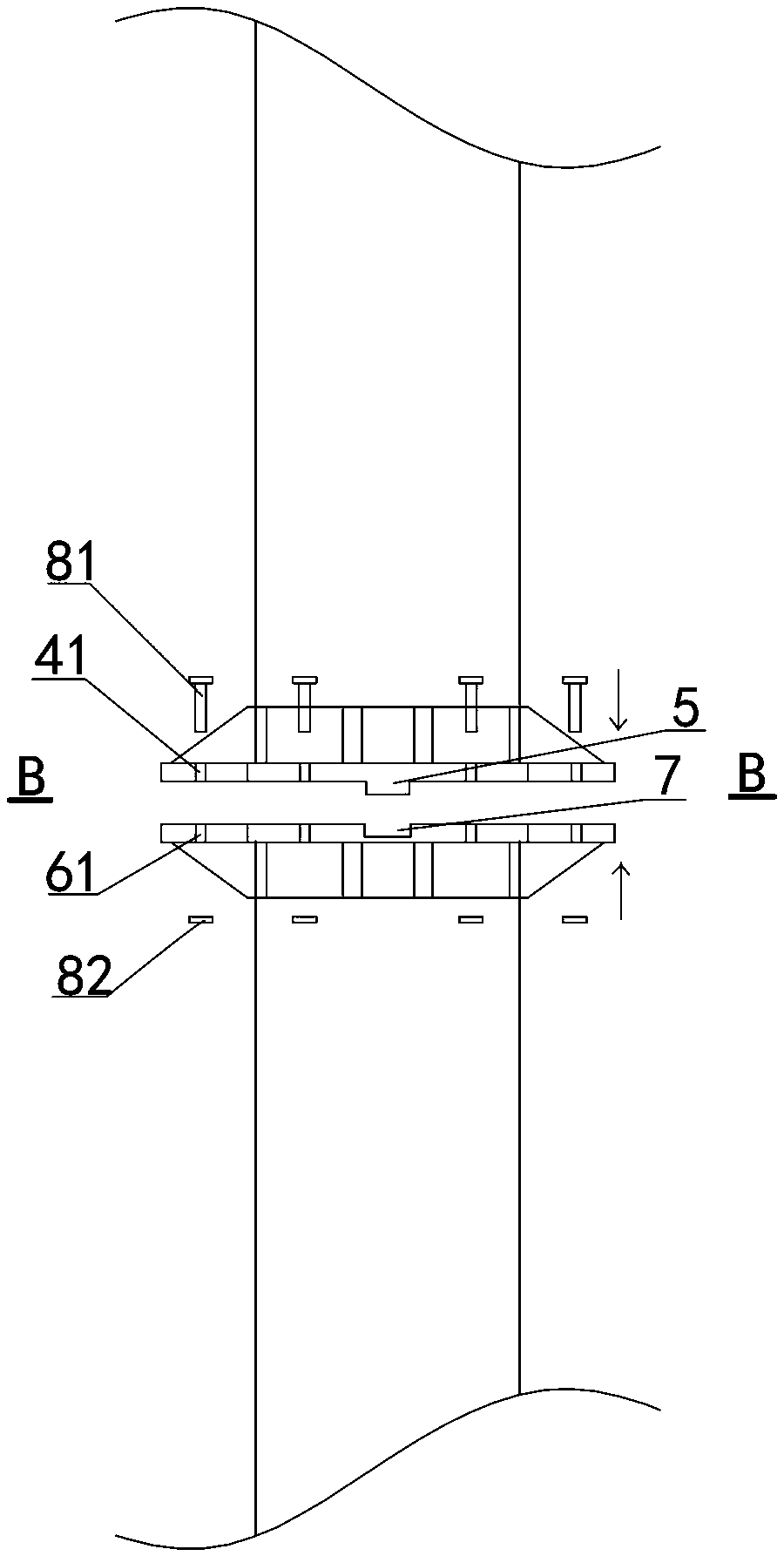

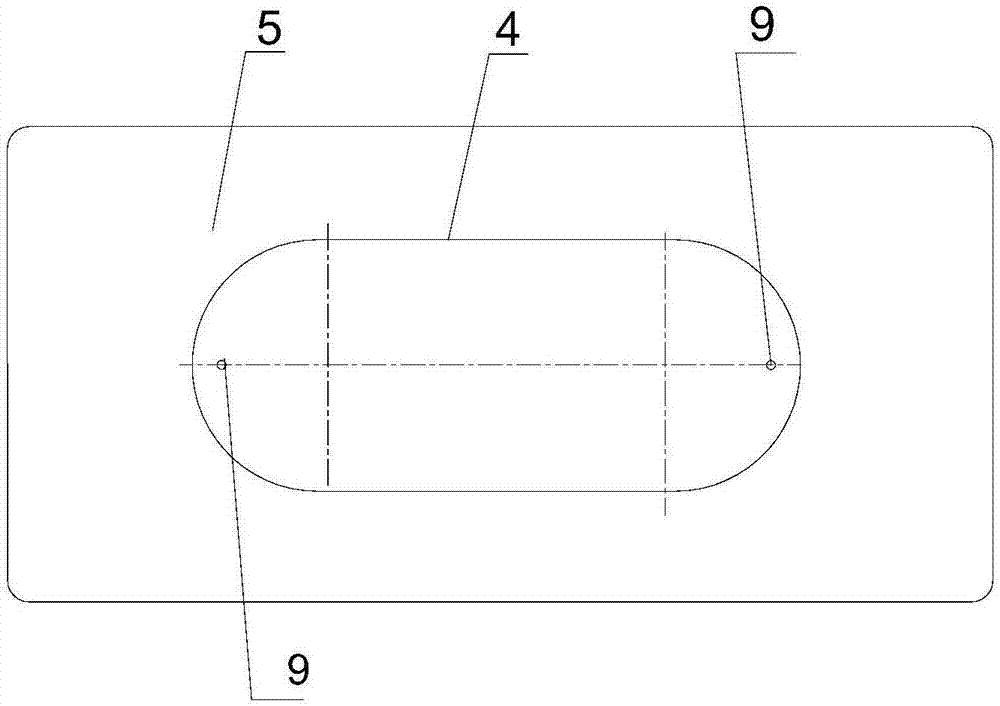

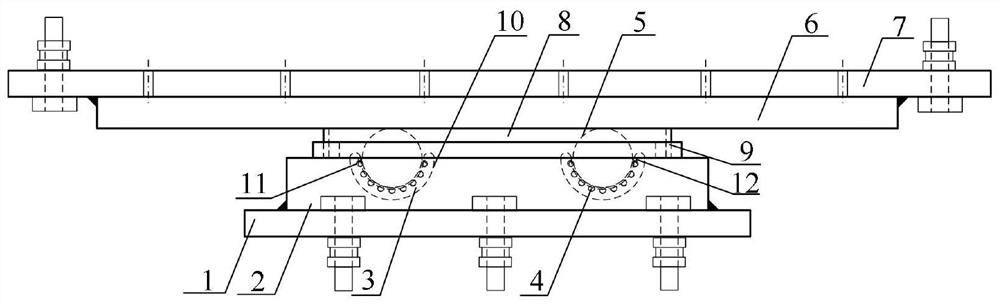

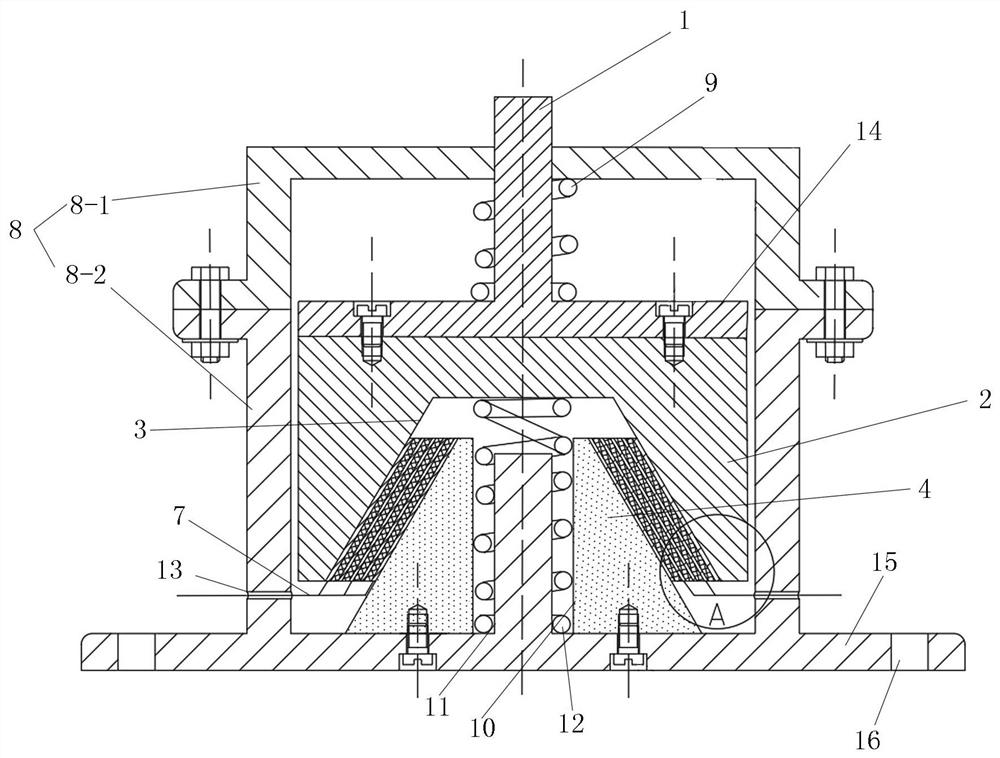

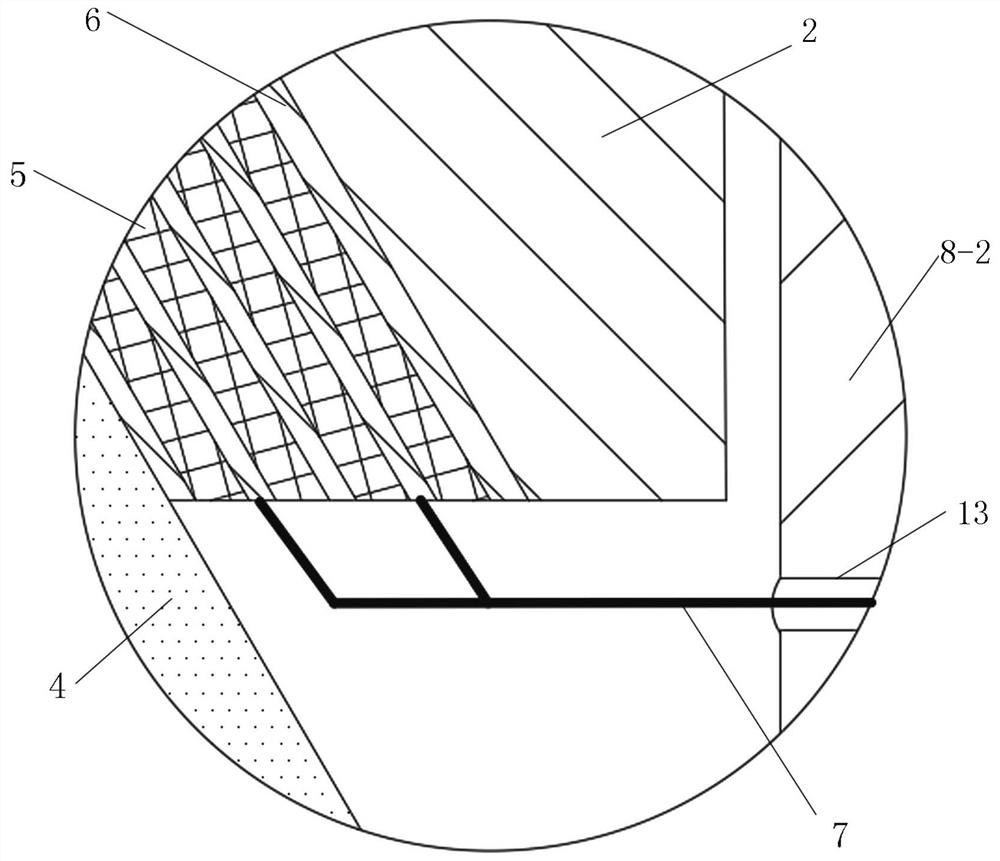

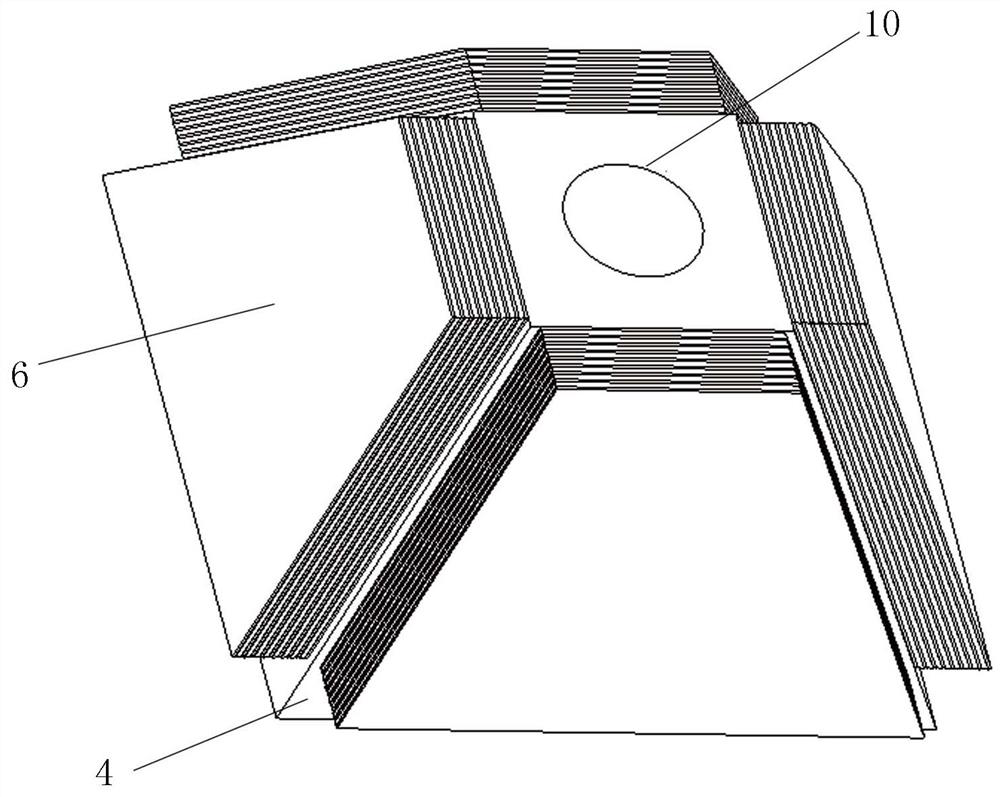

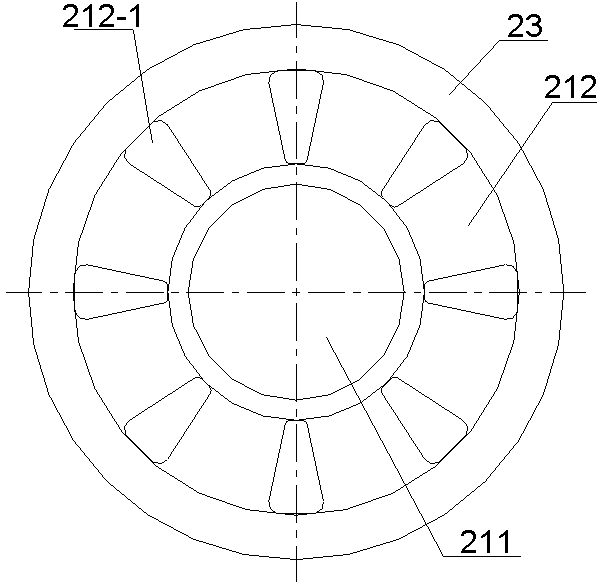

Multi-directional and broad-frequency domain vibration/seismic insulation and reduction device

ActiveCN106836925ASafe and stable operationImproved and increased horizontal vibration isolationBridge structural detailsProtective buildings/sheltersViscoelastic dampingAgricultural engineering

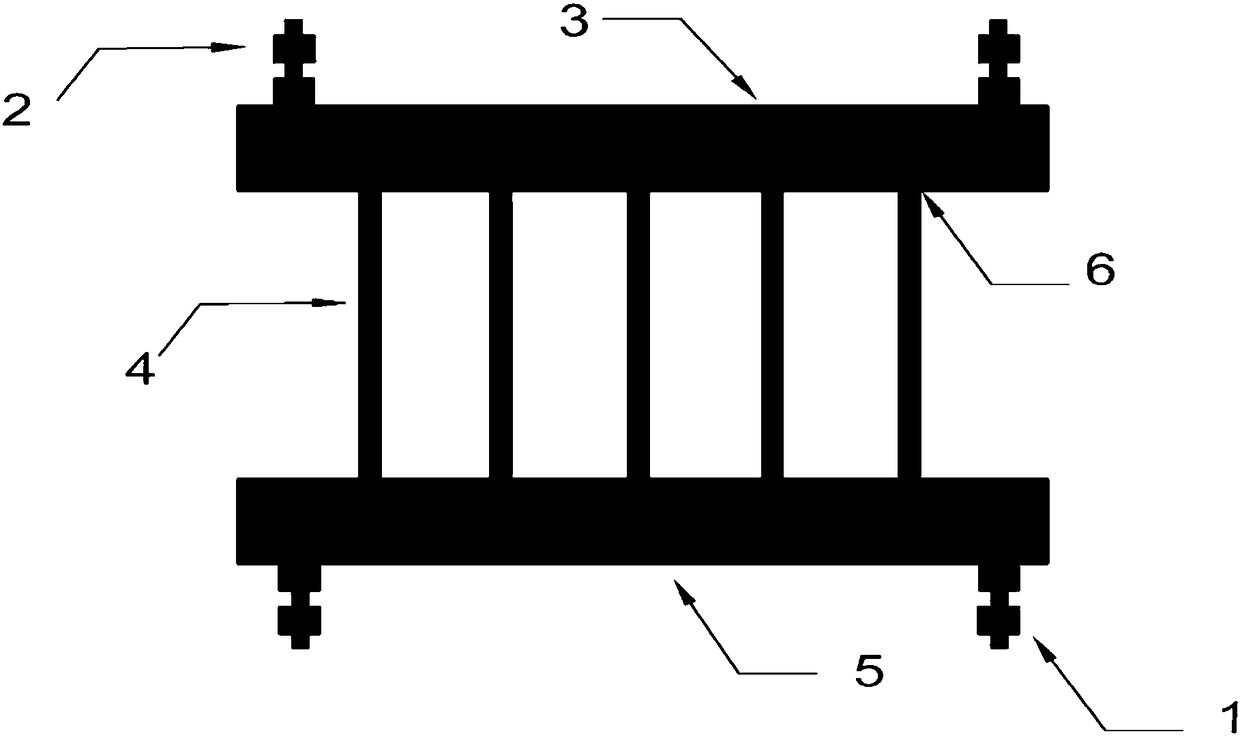

The invention discloses a multi-directional and broad-frequency domain vibration / seismic insulation and reduction device comprising an upper steel plate and a lower steel plate which are arranged oppositely and further comprising a viscoelastic supporting seat located between the upper steel plate and the lower steep plate. The viscoelastic supporting seat is fixedly connected with the upper steel plate and the lower steel plate through bolts. A viscoelastic damper is arranged outside the viscoelastic supporting seat and fixedly connected with the upper steel plate and the lower steel plate through bolts. The viscoelastic damper is composed of an upper gear frame and a lower gear frame which are mutually engaged as well as a viscoelastic material covering the upper gear frame and the lower gear frame. A certain gap is formed between the upper gear frame and the lower gear frame and filled with a vulcanized viscoelastic material. An anti-pulling steel rope is arranged between the viscoelastic supporting seat and the viscoelastic damper and fixedly connected with the upper steel plate and the lower steel plate through connecting buckles. According to the vibration / seismic insulation and reduction device, within board frequency, good vibration / seismic insulation and reduction performance in the horizontal and vertical direction is achieved, good robustness and stability are achieved while performance is high.

Owner:SOUTHEAST UNIV

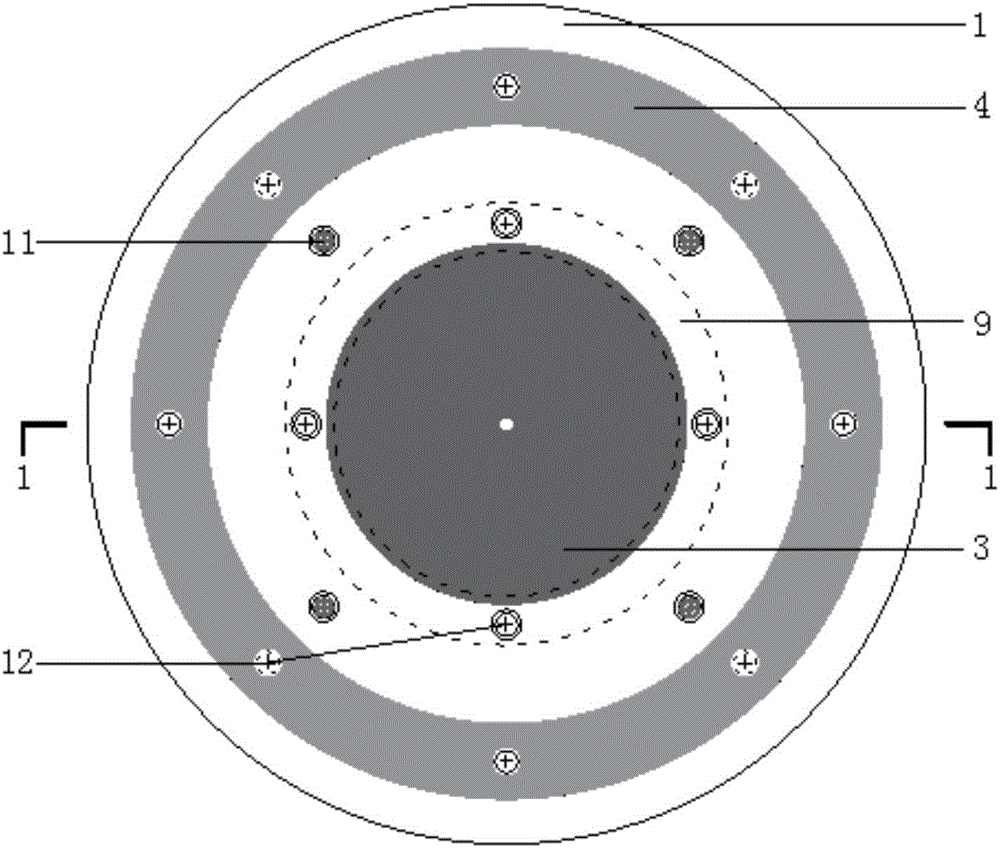

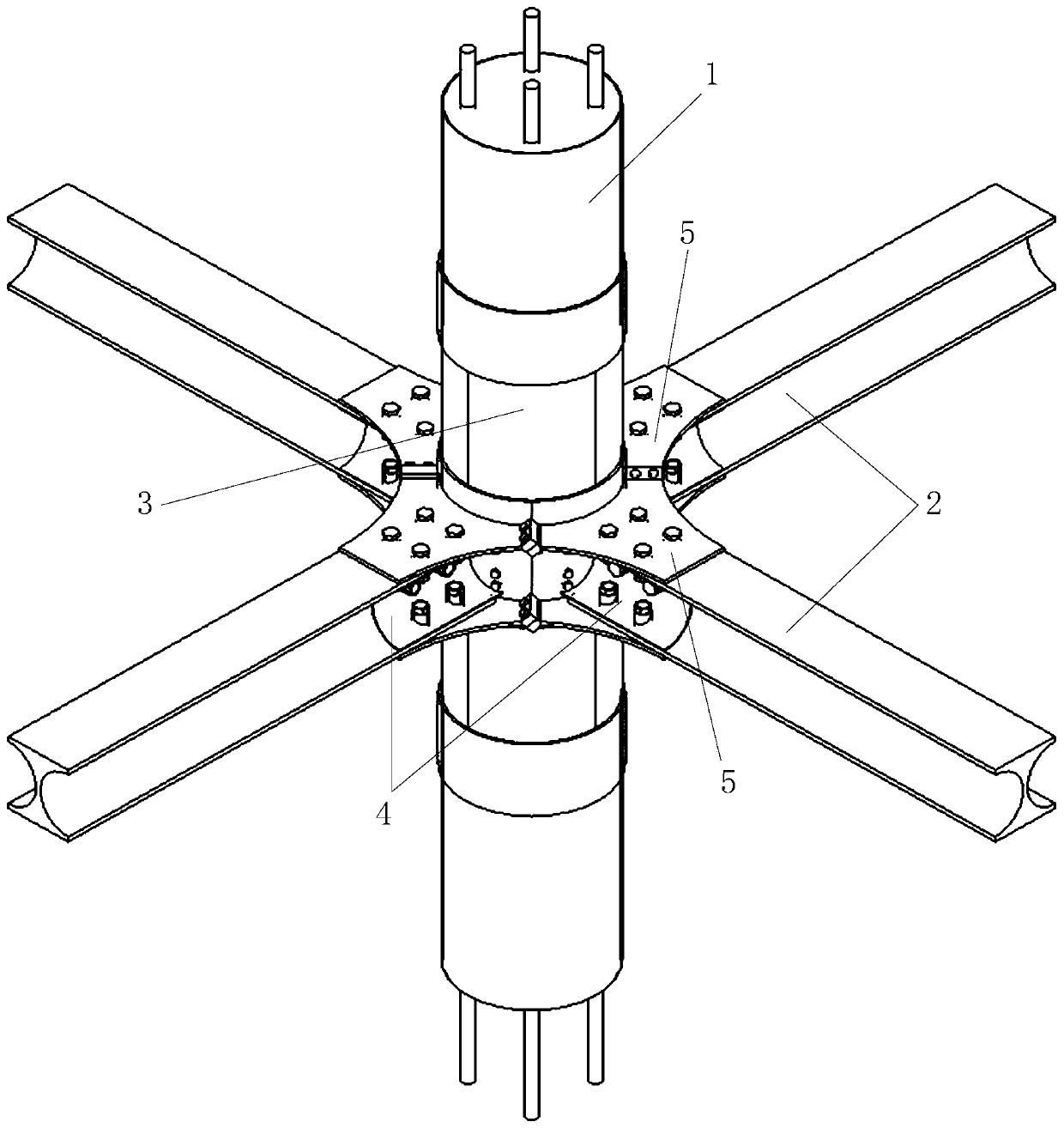

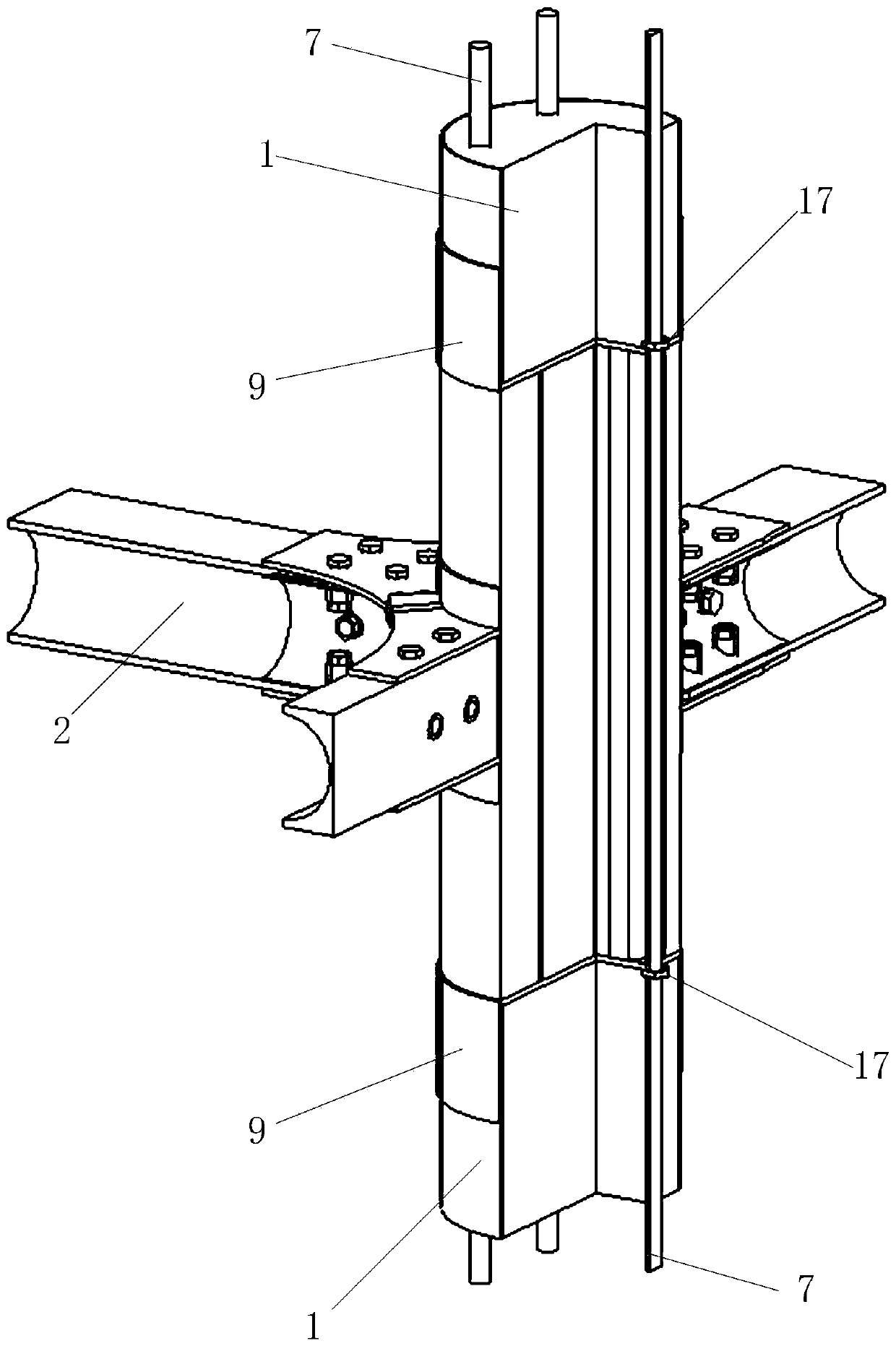

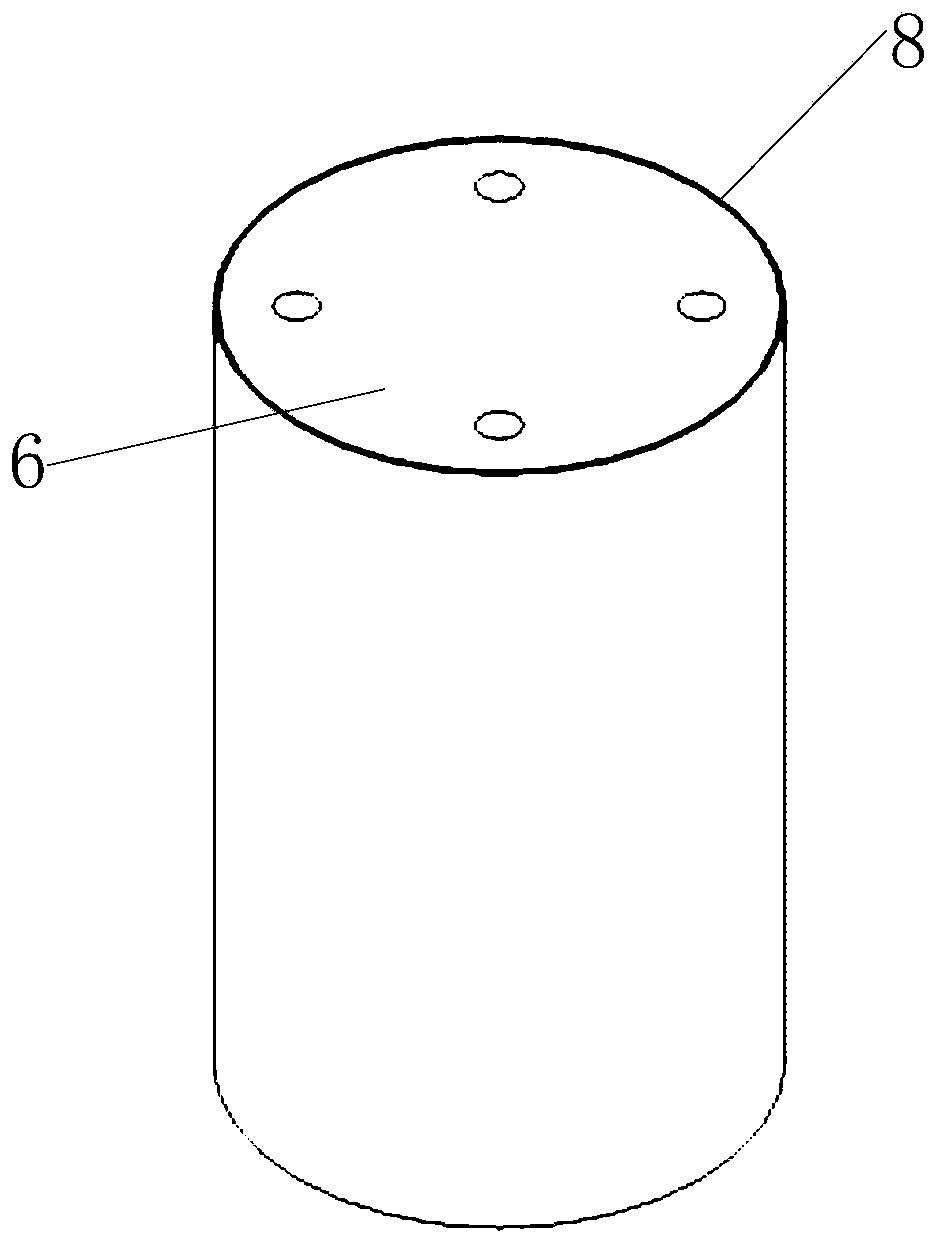

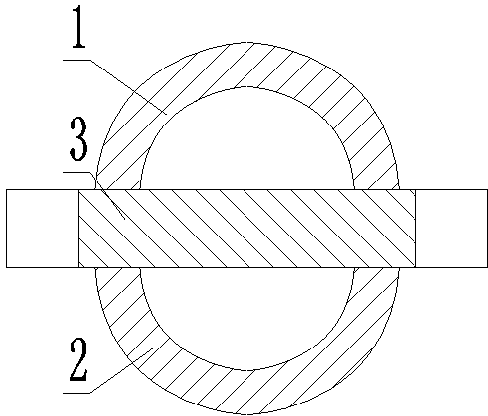

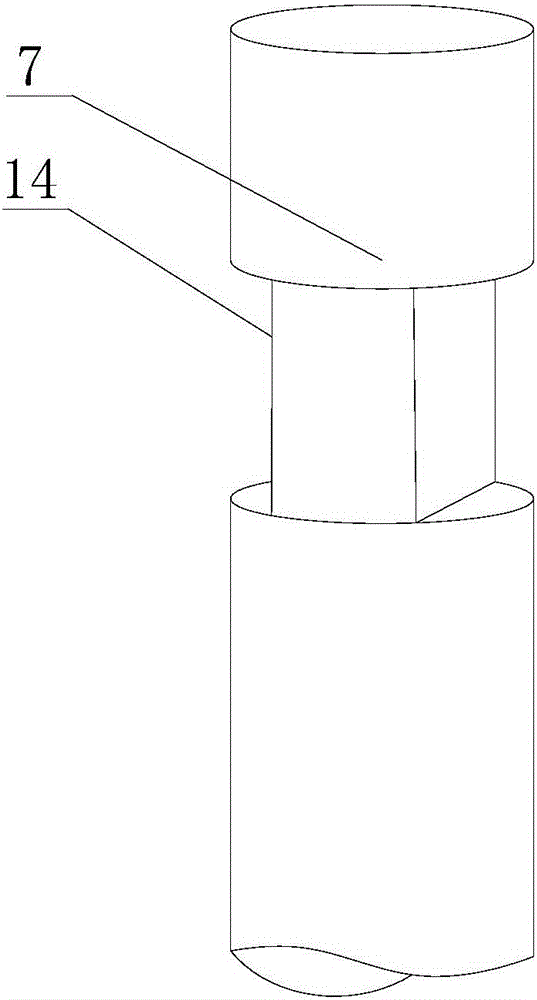

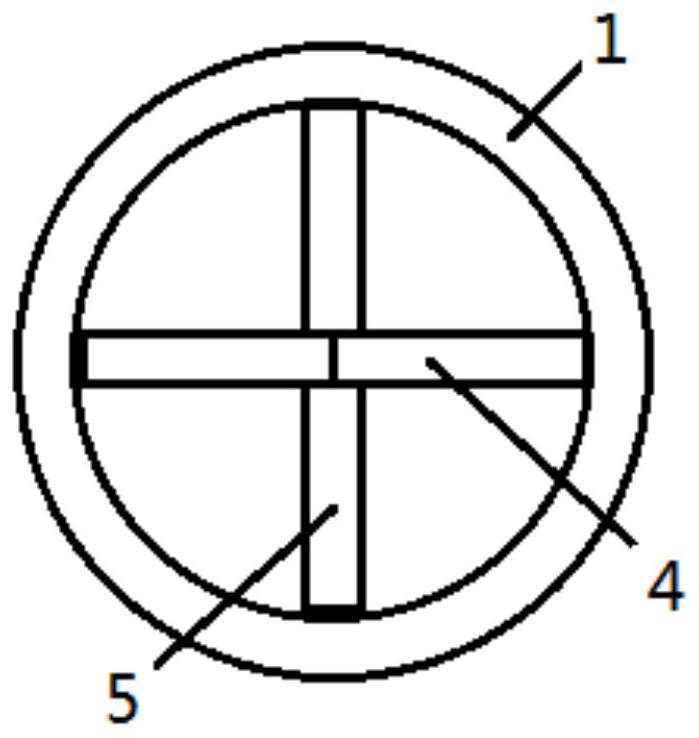

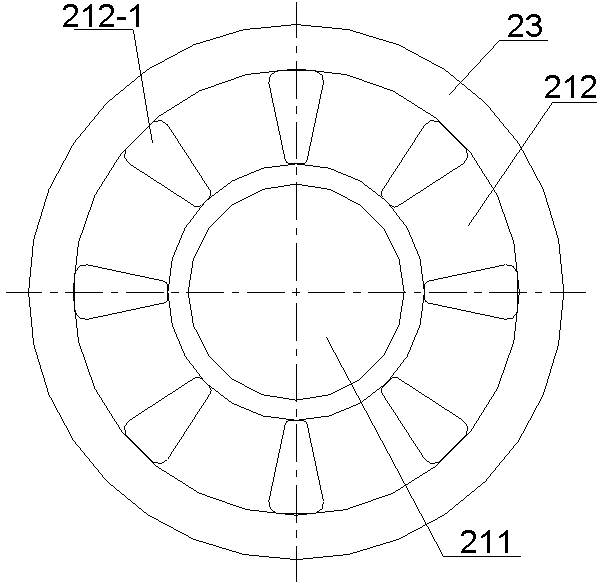

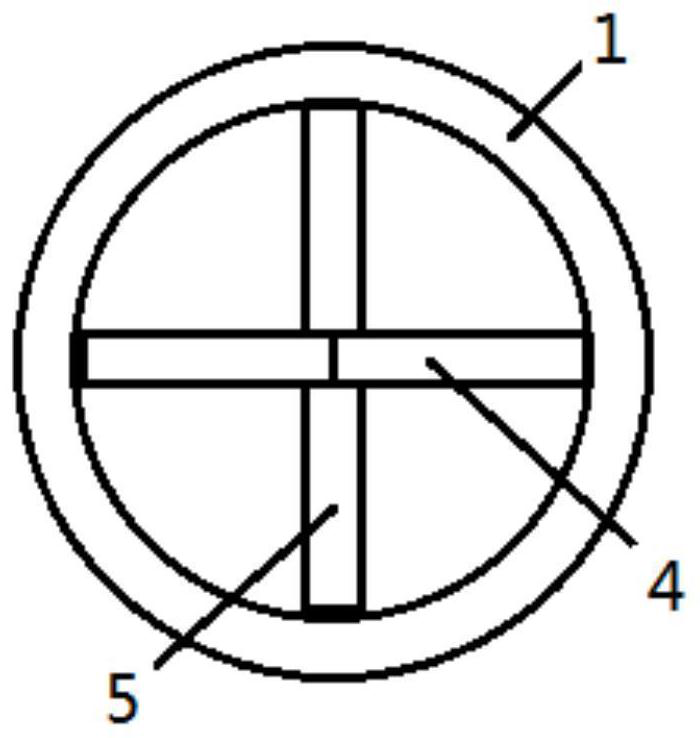

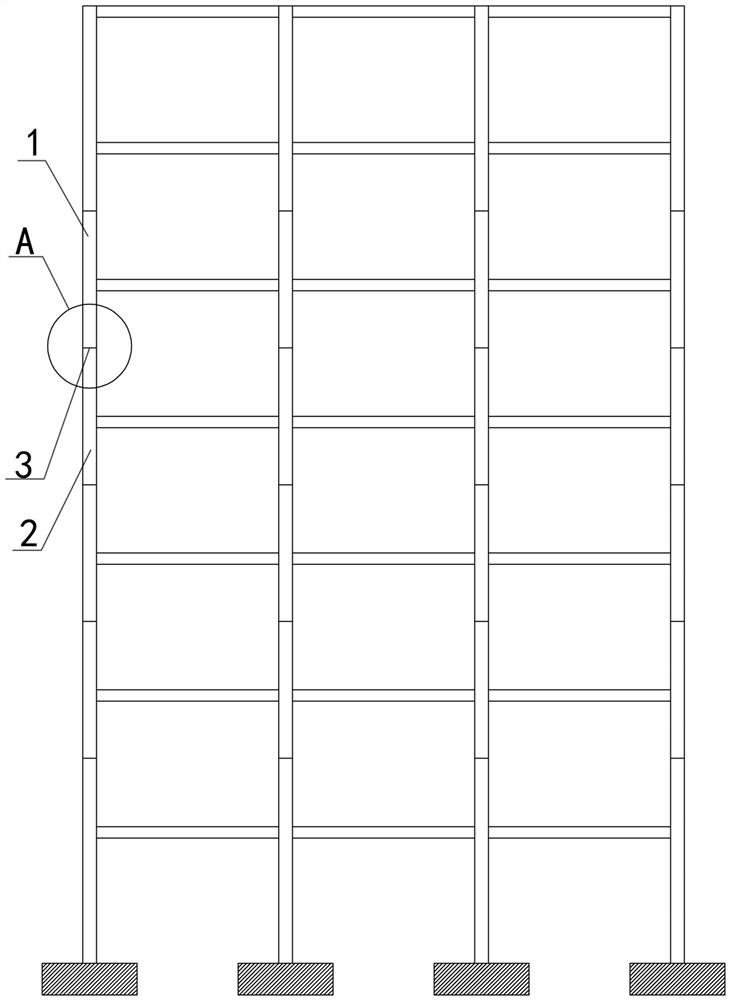

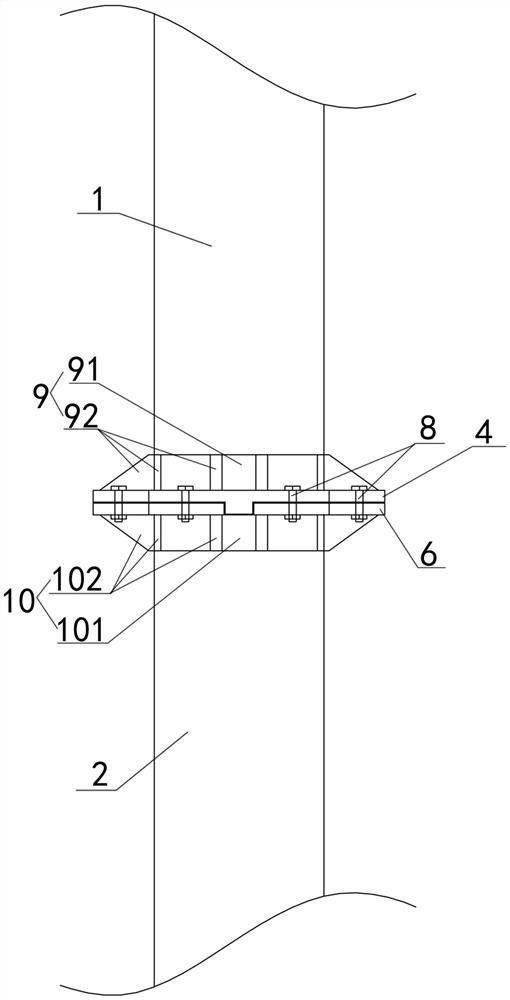

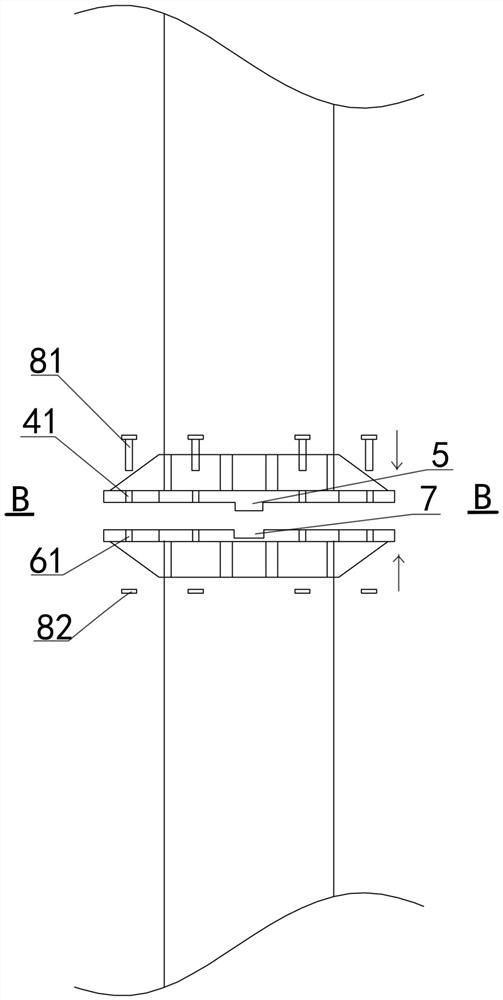

Round sleeve steel-wood assembly node and mounting method thereof

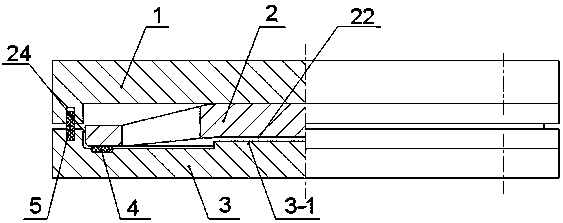

ActiveCN110331782AGuaranteed vertical bearing capacityImprove the seismic performance of structuresBuilding constructionsSolid woodHorizontal force

The invention discloses a round sleeve steel-wood assembly node. The round sleeve steel-wood assembly node comprises an FRP round wood column, an X-shaped wood beam, a core connecting component, splicing outer ring plates and an arc-shaped connector, wherein the core connecting component consists of upper and lower round steel sleeve plates, a connecting sleeve, round solid wood, filling wood blocks, and the like; the FRP round wood column and the core connecting component are connected, are plugged through circular steel sleeve plates in a mode of penetrating through reinforcing steel bars, and are connected by injecting glue into gaps of the reinforcing steel bars; the X-shaped wood beam is connected to the core connecting component through the arc-shaped connector; and the splicing outer ring plates and bolts are fixed to realize assembly connection. According to the scheme adopted by the invention, the node structure adopts a connecting sleeve design, so that bearing force is high,vertical force transmission is guaranteed to be free of influences, and a horizontal force transmission way and a vertical force transmission way are not crossed; during field construction mounting,glue connection and glue bonding are adopted, so that operation is simple, mounting is quick, assembly type mounting is complete, and design requirements of a wood structure building with special vertical load can be met, and therefore, the round sleeve steel-wood assembly node has great market potential in a medium and high-rise wood building.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

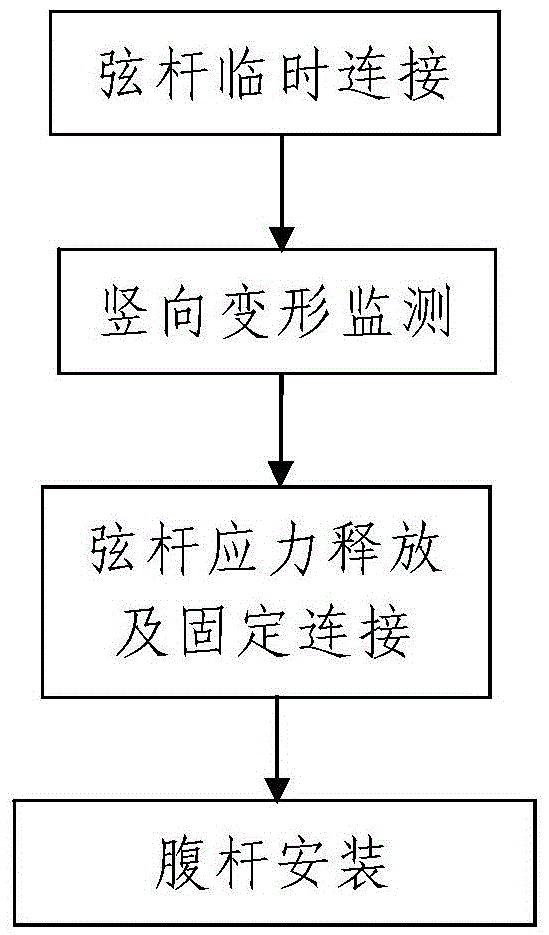

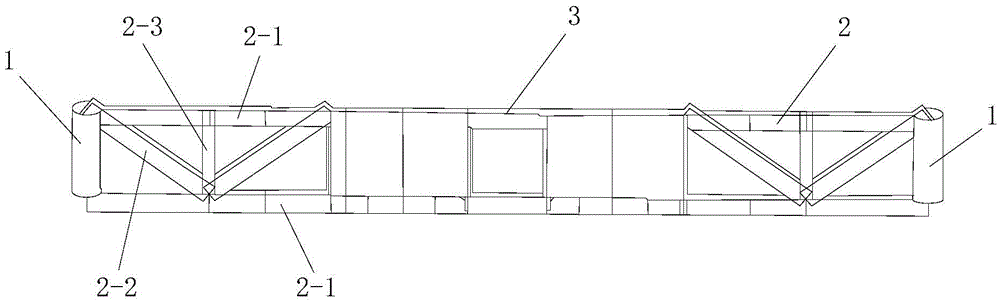

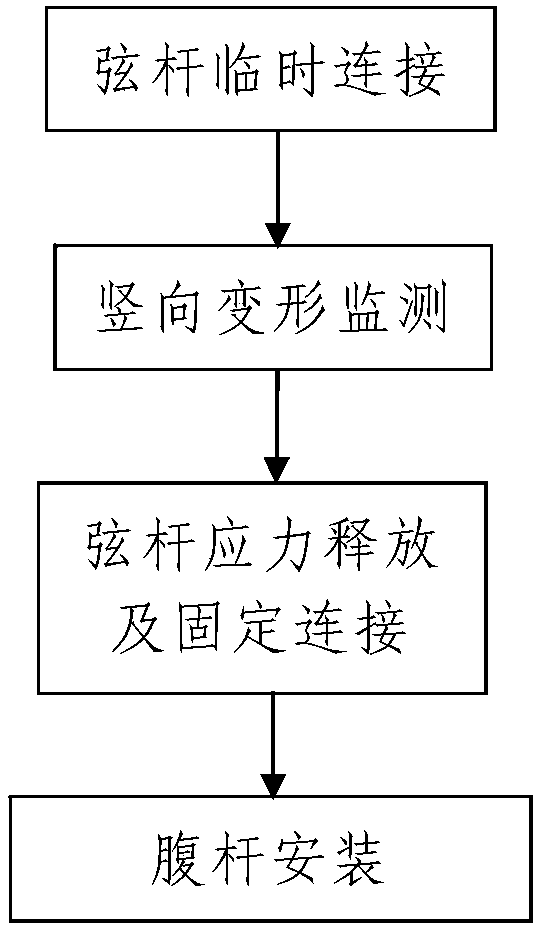

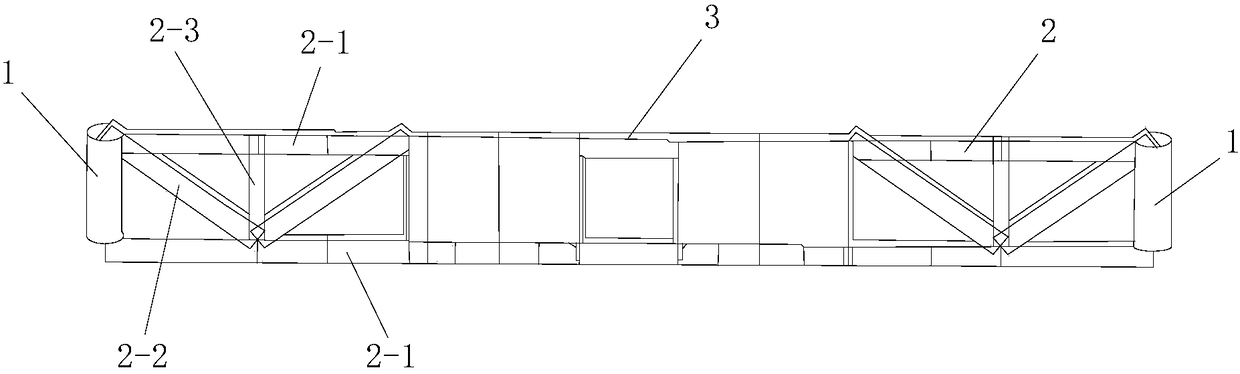

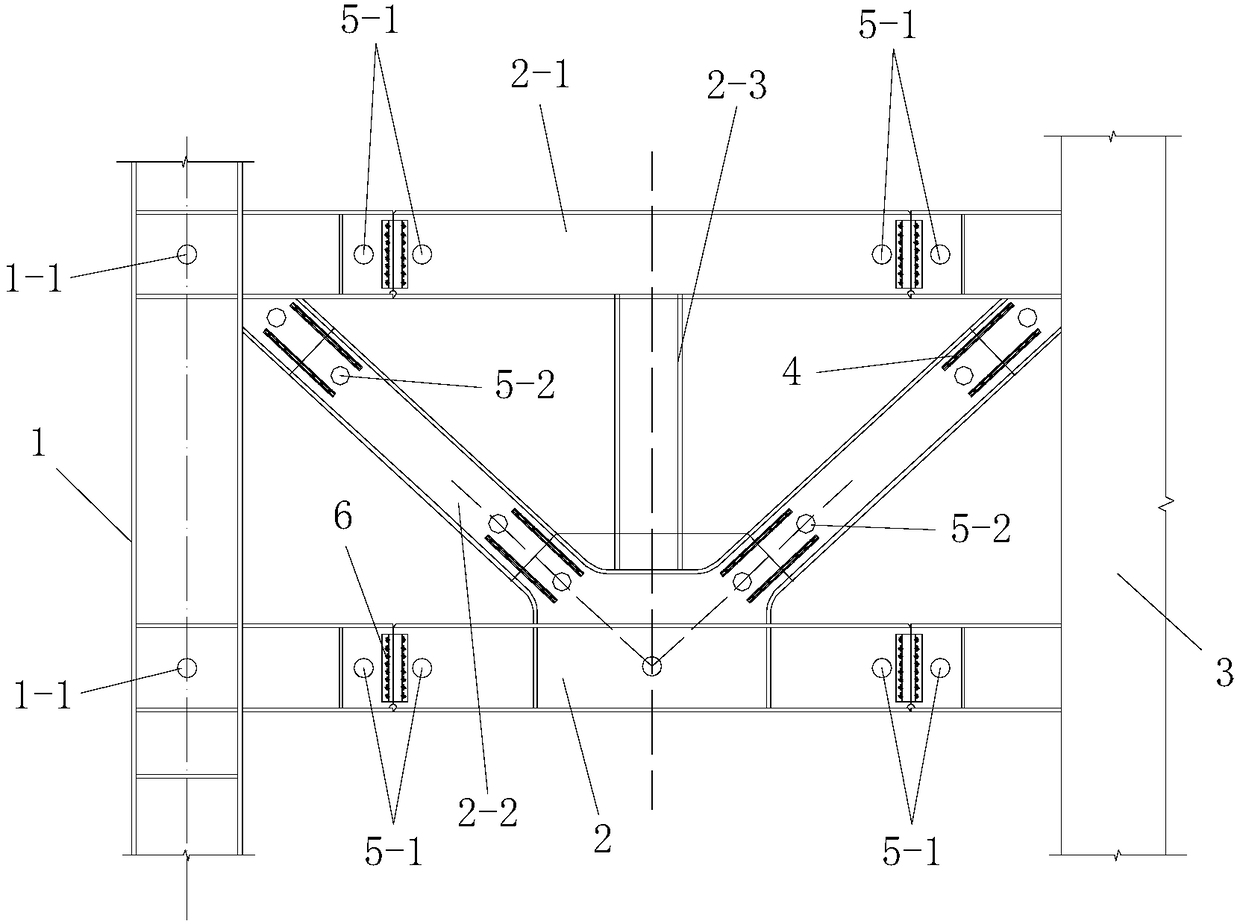

Delay connection installation method for outrigger of super high-rise building in steel frame-core tube structure

InactiveCN105672481AThe method steps are simpleReasonable designBuilding constructionsDeformation monitoringSteel frame

The invention discloses a delay connection installation method for an outrigger of a super high-rise building in a steel frame-core tube structure. A constructed super high-rise building is in a steel frame-core tube structure which comprises a core cylinder and a peripheral frame located on the outside of the core tube, and a core cylinder in a outrigger reinforcing layer is connected with a frame column through an outrigger; the outrigger comprises an upper chord member, a lower chord member and a plurality of web members; when the outrigger in the outrigger reinforcing layer is installed, a delay connection method is used for installation, the installation process comprises the steps that I, temporary connection of the chord members; II vertical deformation monitoring: strain of the core tube and the frame column which are connected by the two chord members in the vertical direction is monitored; III, chord member stress release and fixed connection; IV, web member installation. According to the delay connection installation method for the outrigger of the super high-rise building in the steel frame-core tube structure, the steps are simple, the design is reasonable, the operation is easy and convenient, the use effect is good, and the problem that early failure of the outrigger is caused due to vertical deformation difference of the frame column and the core tube can be effectively solved.

Owner:SHAANXI ACAD OF ARCHITECTONICS

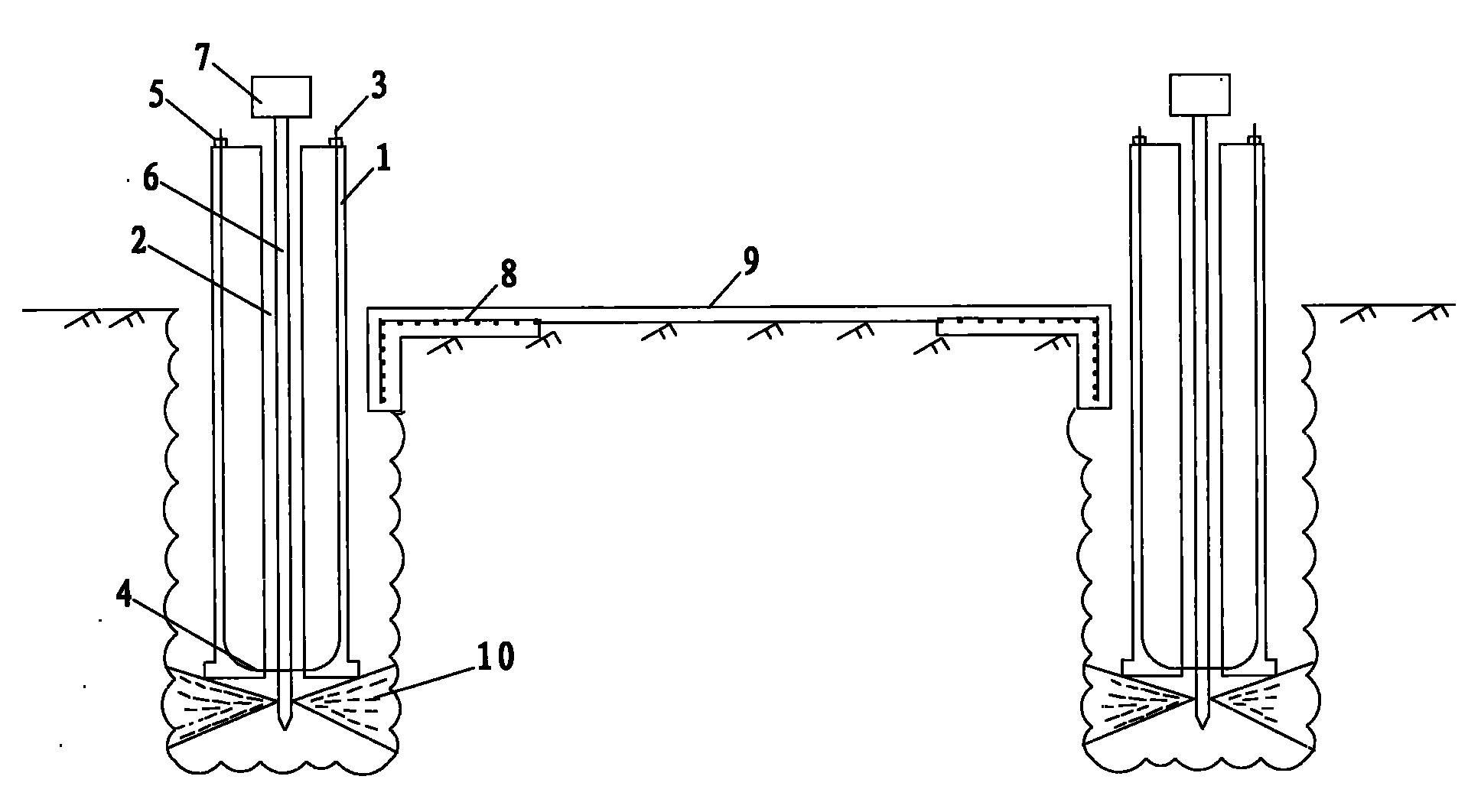

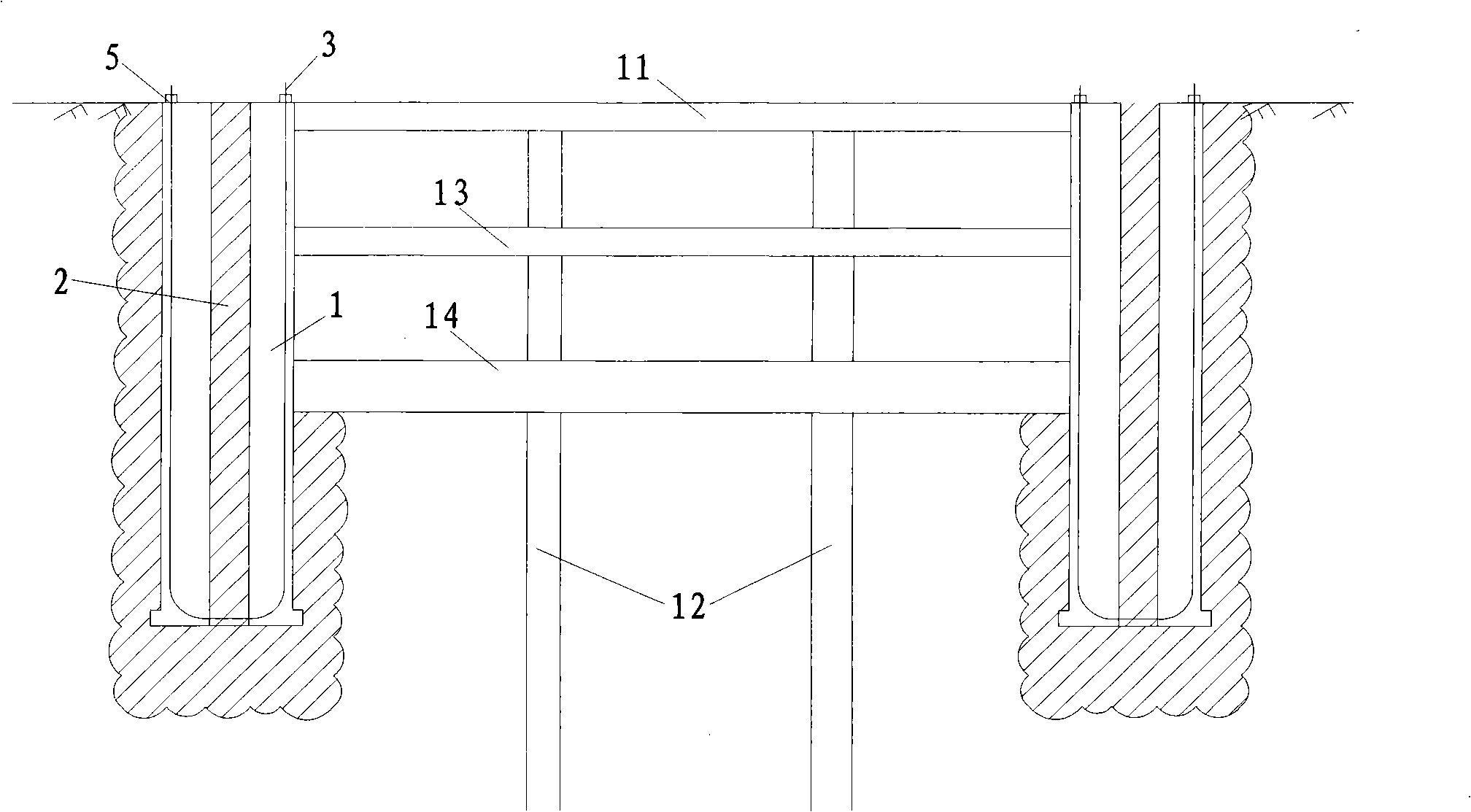

Construction method for underground buildings by rotary-spray shaft digging method matching with semi-inverse method

InactiveCN101338567AGuaranteed positioningGuaranteed verticalityArtificial islandsBuilding constructionsBasementSubway station

The invention discloses a construction method for underground building combining a rotary jet grouting open caisson method and a semi-inverse method, which relates to the building construction technical field. An underground structure outer wall is integrally preformed on the ground, and the construction method comprises the following construction steps: firstly, a groove is dug, and a guide wall is constructed; secondly, prestress is applied to a preformed underground structure outer wall: after the concrete strength of the preformed wall reaches 70 percent, the prestress is applied and the preformed underground structure outer wall is locked with a prestressed anchorage device; thirdly, jet grouting open caisson is performed to the whole preformed outer wall; fourthly, when the preformed outer wall is sunk to a set depth, mortar is changed to perform the mortar solidifying at the groove bottom and on the groove wall; fifthly, the underground structure is constructed through the semi-inverse method. The construction method adopts the integral jet grouting open caisson method to perform the underground structure, which not only saves a great amount of construction investment and guarantees the security and the quality, but also accelerates the construction progress and shortens the construction period. The construction method is particularly suitable for the rapid construction of underground buildings, such as the basement of a large-scale civil architecture, a public underground garage and a subway station.

Owner:万勇 +3

Fabricated light-weight energy consumption wall component of shear wall

InactiveCN103669644ASolve self-importanceSolve the problem of low prefabrication level of interior wallsWallsShock proofingReinforced concreteShearing deformation

The invention discloses a fabricated light-weight energy consumption wall component of a shear wall. The wall component comprises a reinforced concrete wallboard. Holes are arranged in the reinforced concrete wallboard, energy consumption parts are fixed in the holes and comprise hole pre-burying boards, connecting plates and yielding energy consumption steel plates, the hole pre-burying boards are pre-buried in the reinforced concrete wallboard, the connecting plates are vertically and medially connected to inner sides of the hole pre-burying boards, and the top and bottom of each yielding energy consumption steel plate are connected with the corresponding connecting plate. According to the wall component, the holes are arranged, so the weight of the component is lightened, earthquake force borne by the wall is reduced, the component can be conveniently transported, transportation cost is reduced, meanwhile hoisting pressure in the construction process is relieved, construction safety is guaranteed, and construction efficiency is improved; the steel plate shear wall type energy consumption parts are arranged in the holes, shear deformation of hole positions occurs under the action of shear force, energy consumption of the steel plates is achieved through buckling, damage to the concrete wallboard can be reduced, and safety of the shear wall under the earthquake action is effectively guaranteed.

Owner:TIANJIN UNIV RES INST OF ARCHITECTRUAL DESIGN & URBAN PLANNING +1

Bending and shearing separation type prefabricated assembly-type frame column and construction method thereof

InactiveCN108487457AConnection quality is easy to controlEasy maintenance inspectionBuilding constructionsBending momentEconomic feasibility

The invention discloses a bending and shearing separation type prefabricated assembly-type frame column and a construction method thereof. A column section comprises an upper column section body and alower column section body; the spliced position of the column section bodies is located at a bending moment anti-bending point; a horizontal bottom-end steel seal plate is pre-embedded in the bottomend face of the column section, and a downwards externally-protruding shear key is arranged on the lower surface of the bottom-end steel seal plate; a horizontal top-end steel seal plate is pre-embedded in the top end face of the column section, and a downwards internally-sunken shear key groove which is matched with the shear key is formed in the upper surface of the top-end steel seal plate; thebottom-end steel seal plate and the top-end steel seal plate are tightly attached; the shear key is downwards clamped into the shear key groove, and the shear key and the shear key groove are tightlymatched; and the top-end steel seal plate and the bottom-end steel seal plate are fixedly connected into a whole through an anti-bending piece. According to the bending and shearing separation type prefabricated assembly-type frame column, bending and shearing members are separated, the vertical bearing capacity of the frame column can be guaranteed, the anti-seismic requirement is met, the structure is simple, processing, construction and mounting are convenient, and meanwhile the economically feasible performance cost ratio is high.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

Non-damage energy dissipation prefabricated assembly-type frame structure system and construction method thereof

InactiveCN108487456AAchieve destructionClear mechanicsProtective buildings/sheltersShock proofingEngineeringDamping ratio

The invention discloses a non-damage energy dissipation prefabricated assembly-type frame structure system and a construction method thereof. The non-damage energy dissipation prefabricated assembly-type frame structure system comprises foundations, prefabricated frame columns connected with the foundations and prefabricated frame beams connected with the prefabricated frame columns, and further comprises energy dissipation dampers arranged between the interlayer prefabricated frame beams. The prefabricated frame columns and the foundations are connected through column foot connecting structures, the beams and the columns are connected through beam and column connecting structures, and the prefabricated frame columns are connected through column joint connecting structures. The shortcomings of an existing prefabricated assembly structure system are overcome, all joints adopt the ideas of bending and shearing separation, strong shearing and weak bending, and bending shearing elasticity,the anti-earthquake requirement is met, the structure is simple, processing is convenient, construction and mounting are convenient, and meanwhile the economically feasible performance cost ratio ishigh. The energy dissipation devices are further arranged, the viscous fluid dampers are arranged between the interlayer beams to conduct energy dissipation so as to increase the damping ratio of thestructure, the earthquake response of the structure is reduced, it is guaranteed that large earthquake members are not damaged, and thus repairing is avoided.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

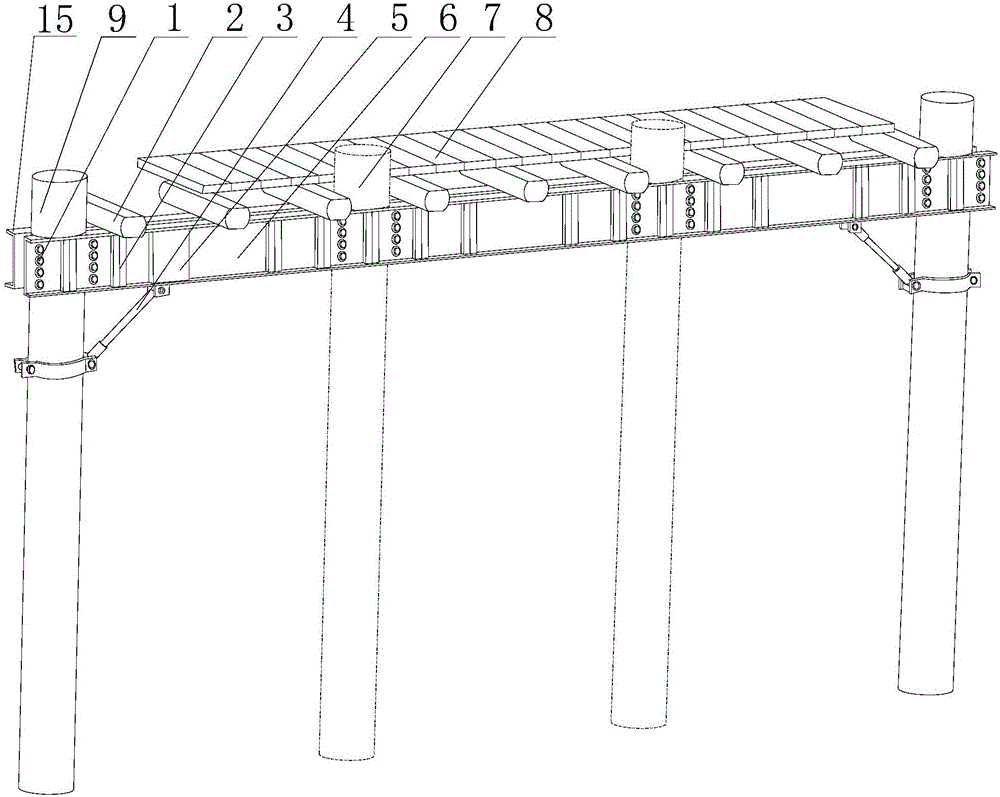

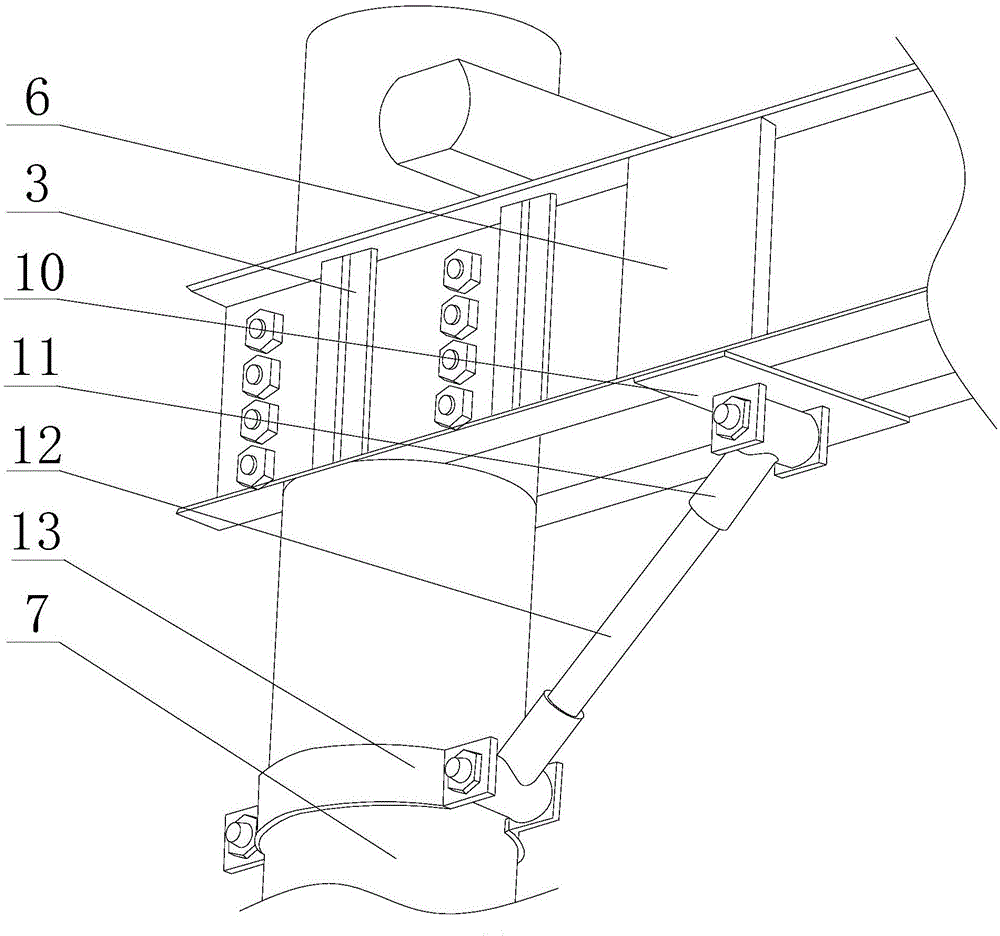

Integrated extruding, forming and manufacturing method for truss-type pile leg chord of self-elevating platform

ActiveCN104384849AIncrease profitDense and uniform structureArtificial islandsExtrusion diesPunchingEngineering

The invention discloses an integrated extruding, forming and manufacturing method for a truss-type pile leg chord of a self-elevating platform, in particular to a manufacturing method for a pile leg chord of the self-elevating platform, and belongs to the technical field of steel structure manufacturing in ocean engineering. The method comprises the following steps: firstly, determining the weight of a steel ingot material, namely, calculating the total weight of required steel materials according to the cross-sectional area of the pile leg chord to be manufactured; secondly, manufacturing a blank, namely, determining the weight of the blank requiring extruding by calculating after the length of the chord is determined; performing steel ingot thickening, steel ingot punching, ingot body lengthening and finishing; thirdly, preparing a mould, namely, pre-manufacturing an extrusion mould according to the shape of the required chord, wherein the moulds comprise an extrusion cylinder, a base plate, an extrusion mould, a mandrel and a male mould pressure head; fourthly, extruding integrally, namely, integrally extruding the manufactured blank material at a uniform speed on a 40,000-ton vertical press; fifthly, shaping and straightening; sixthly, quenching and tempering; seventhly, tooth machining, namely placing a finished chord on a flame cutting machine, and performing tooth cutting and machining according to a tooth form.

Owner:CHINA FIRST HEAVY IND

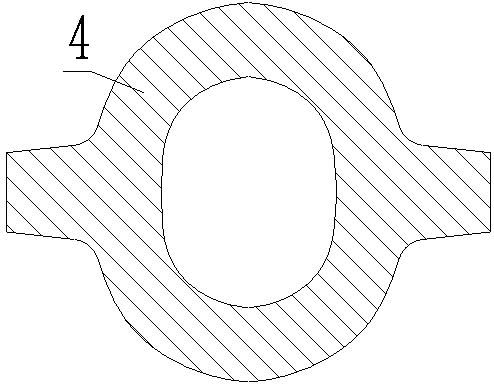

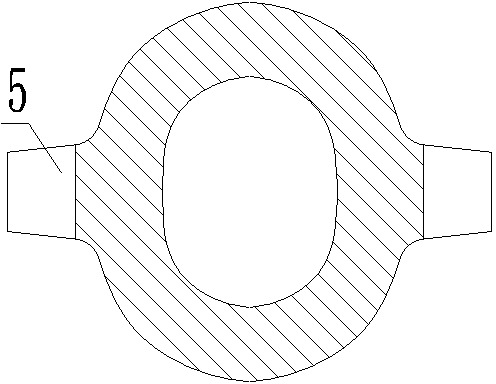

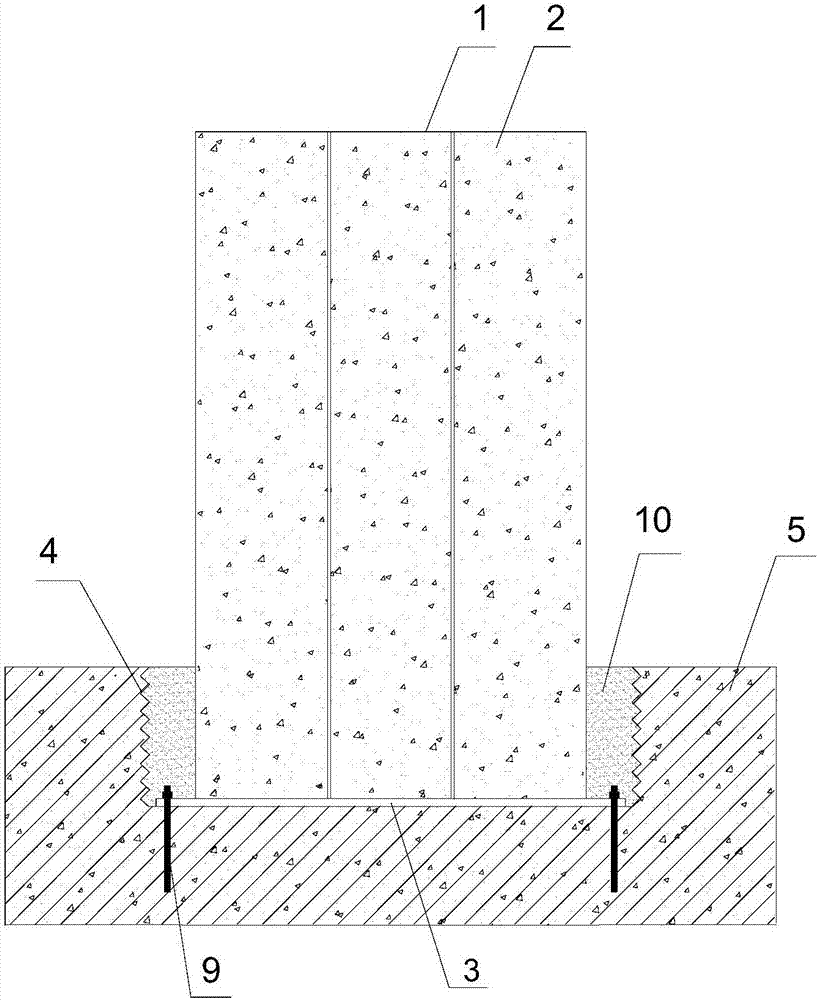

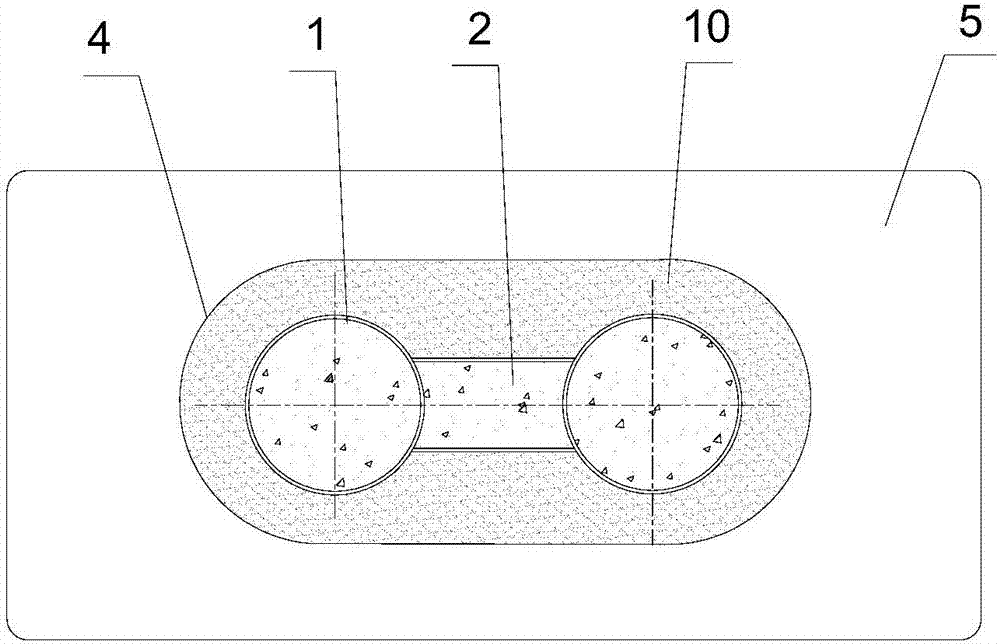

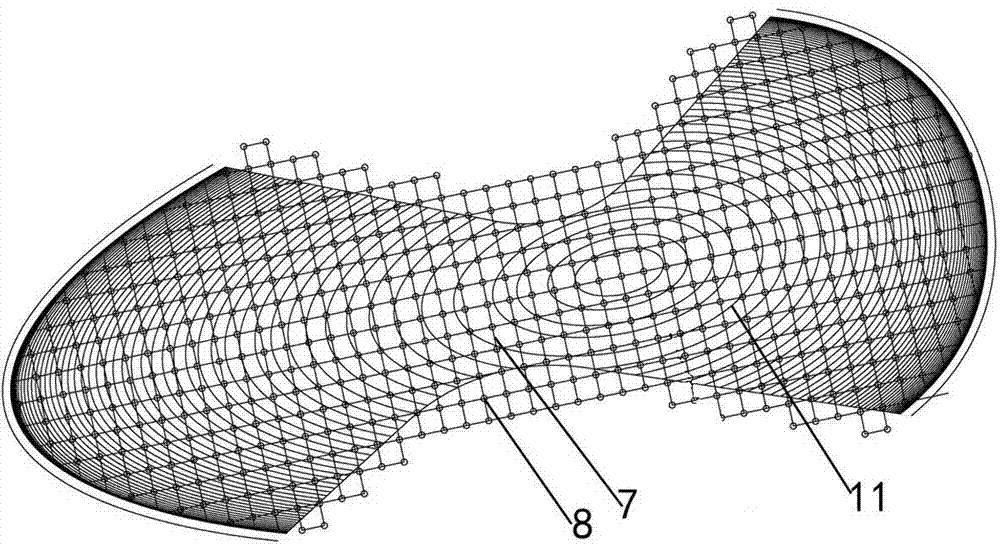

Composite pier with dumbbell-shaped concrete filled steel tubes, and structure and method for collection with cushion cap

ActiveCN107190635AAvoid the disadvantages of poor constraint effectReduce the cross-sectional areaBridge structural detailsBridge erection/assemblyReinforced concreteRebar

The invention discloses a composite pier with dumbbell-shaped concrete filled steel tubes. The pier comprises two round steel tubes and a dumbbell-shaped steel tube which is welded between the two round steel tubes, composed of two layers of steel plates and symmetric along a form center connecting line of the two round steel tubes, wherein the two layers of steel plates and the round steel tubes are welded by angle welding seams. An end plate is welded on the bottom of the dumbbell-shaped steel tube; the outer profile of the end plate is larger than the outer profile of the cross section of the dumbbell-shaped steel tube; one anchor bolt hole is formed in two sides of the end plate along the horizontal bridge direction of the pier; and the dumbbell-shaped steel tube is filled with concrete. The pier and a cushion cap are connected through embedding of a grouting corrugated sleeve. According to the invention, the dumbbell-shaped steel tube and the reinforced concrete cushion cap are pre-cast components; factory pre-fabrication requirements can be satisfied; assembly is achieved on site; and rapid construction is carried out. The pier disclosed by the invention is characterized by high axial and flexural bearing capacities, high ductility and high horizontal rigidity; construction is convenient; on-site operations and web operations are fewer; demands for rapid construction can be satisfied; and the pier is applicable to major bridge projects especially high pier structures.

Owner:TIANJIN UNIV

Cross tenon type vertical bolt connecting joint of fabricated concrete frame structure

PendingCN113047430AImprove assembly efficiencyImprove the standardization of constructionStrutsPillarsDuctilityMortise and tenon

The invention provides a cross tenon type vertical bolt connecting joint of a fabricated concrete frame structure. The cross tenon type vertical bolt connecting joint comprises an upper concrete column and a lower concrete column; a cross tenon is arranged at the bottom of the upper concrete column and is in matched inserted connection with a cross mortise formed in the top of the lower concrete column; bolt connecting grooves are formed in the four corners of the upper concrete column and above the cross tenon. Bolts vertically penetrate the four corners of the bottom of the upper concrete column from the four corners of the lower concrete column, stretch into the bolt connecting grooves and are fastened through nuts; the vertical bearing force of the upper concrete column and the lower concrete column is transmitted through cross mortise and tenon joint, and the force transmission section is the same as the section area of the concrete columns; meanwhile, integral stirrups are arranged at the joint so as to enhance the axial bearing force, the core position of the joint is in a three-direction pressed state under the axial pressure state exceeding the bearing force, ductility damage is generated, and the vertical bearing force is guaranteed; and bolt connection only bears the vertical loads of the columns, bears part of axial force in the normal state, bears pull force under the earthquake action and is clear in stress. The cross tenon type vertical bolt connecting joint has the beneficial effects of being simple in structure, convenient to construct, efficient in assembly and high in shear bearing capacity.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Construction method for underground buildings by rotary-spray shaft digging method cooperating with semi-inverse method

InactiveCN101338567BImprove construction progressShorten the construction periodArtificial islandsBuilding constructionsBasementPre stress

The invention discloses a construction method for underground building combining a rotary jet grouting open caisson method and a semi-inverse method, which relates to the building construction technical field. An underground structure outer wall is integrally preformed on the ground, and the construction method comprises the following construction steps: firstly, a groove is dug, and a guide wallis constructed; secondly, prestress is applied to a preformed underground structure outer wall: after the concrete strength of the preformed wall reaches 70 percent, the prestress is applied and the preformed underground structure outer wall is locked with a prestressed anchorage device; thirdly, jet grouting open caisson is performed to the whole preformed outer wall; fourthly, when the preformed outer wall is sunk to a set depth, mortar is changed to perform the mortar solidifying at the groove bottom and on the groove wall; fifthly, the underground structure is constructed through the semi-inverse method. The construction method adopts the integral jet grouting open caisson method to perform the underground structure, which not only saves a great amount of construction investment and guarantees the security and the quality, but also accelerates the construction progress and shortens the construction period. The construction method is particularly suitable for the rapid constructionof underground buildings, such as the basement of a large-scale civil architecture, a public underground garage and a subway station.

Owner:万勇 +3

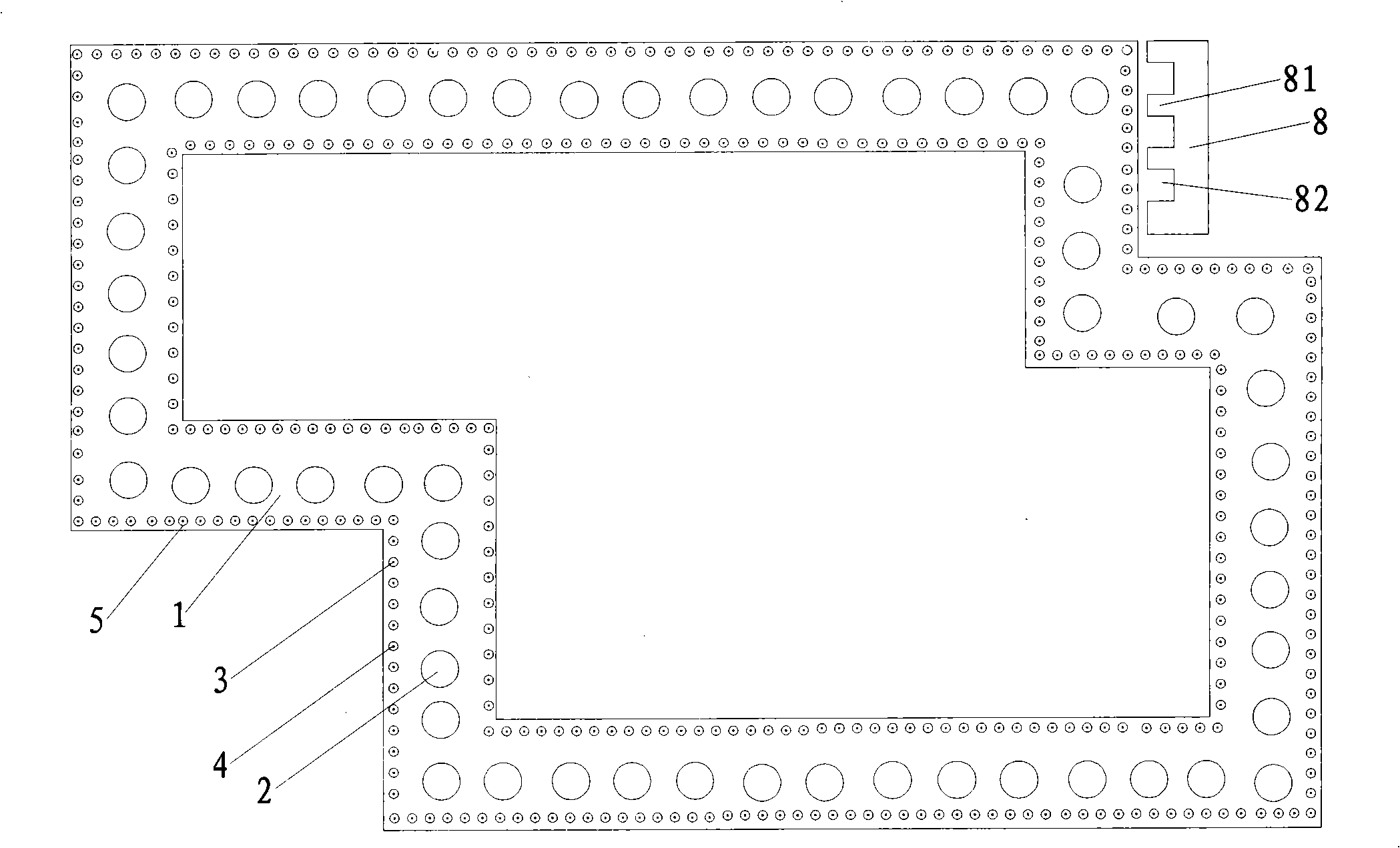

Removing-column spatial expansion structure for column-and-tie wood constructions and implementation method of removing-column spatial expansion structure

ActiveCN106545089AStable supportGuaranteed vertical bearing capacityGirdersJoistsContinuous useSpatial expansion

The invention discloses a removing-column spatial expansion structure for column-and-tie wood constructions and an implementation method of the removing-column spatial expansion structure. The removing-column spatial expansion structure comprises two side columns, wherein clamping grooves are formed in two side walls of the side columns; a penetrating square-column I is fixed into the clamping grooves in the side walls of the same side of the two side columns; a penetrating square-column II is fixed into the clamping grooves in the side walls of the other sides of the two side columns; and supporting pieces connected with the bottoms of the penetrating square-column I and the penetrating square-column II are arranged on the side columns. Owing to reasonable structural configuration and connection of the penetrating square-column I and the penetrating square-column II and arrangement of the supporting pieces, the original wood construction style and features of column-and-tie wood construction dwellings are maintained to the utmost extent while the internal effective continuous use space of the column-and-tie wood construction dwellings is remarkably increased, the wood constructions subjected to removing-column spatial expansion can be guaranteed to have high bearing capability and favorable anti-earthquake property, and the removing-column spatial expansion structure can be applied and popularized in the column-and-tie wood construction dwellings which are used as shops in ancient towns or historical streets of various regions with different earthquake fortification intensities.

Owner:SICHUAN INSITITUTE OF BUILDING RES

L-shaped special-shaped column and beam fabricated connecting joint

InactiveCN112302169AReduce side shiftImprove lateral stiffnessStrutsPillarsAbnormal shapedLateral stiffness

The invention discloses an L-shaped special-shaped column and beam fabricated connecting joint, and belongs to the technical field of structural engineering. The L-shaped special-shaped column and beam fabricated connecting joint is composed of a special-shaped column, I-shaped beams, channel steel connecting pieces and high-strength bolt groups. Manufacturing and welding parts of steel componentsare completed in a factory, the welding quality is easy to control, only each prefabricated component needs to be hoisted, and is connected through a high-strength bolt on a construction site, and the construction efficiency is high; and the connecting joint has the advantages of mechanical property and practical property at the same time, and specifically, in the aspect of the mechanical property, the connecting joint makes full use of the bearing capacity and the lateral stiffness of the special-shaped column, and has the good anti-seismic property; and in the aspect of the practical property, the connecting joint emphatically achieves the rapid assembly concept, and solves the "protruding column" problem in a house.

Owner:BEIJING UNIV OF TECH

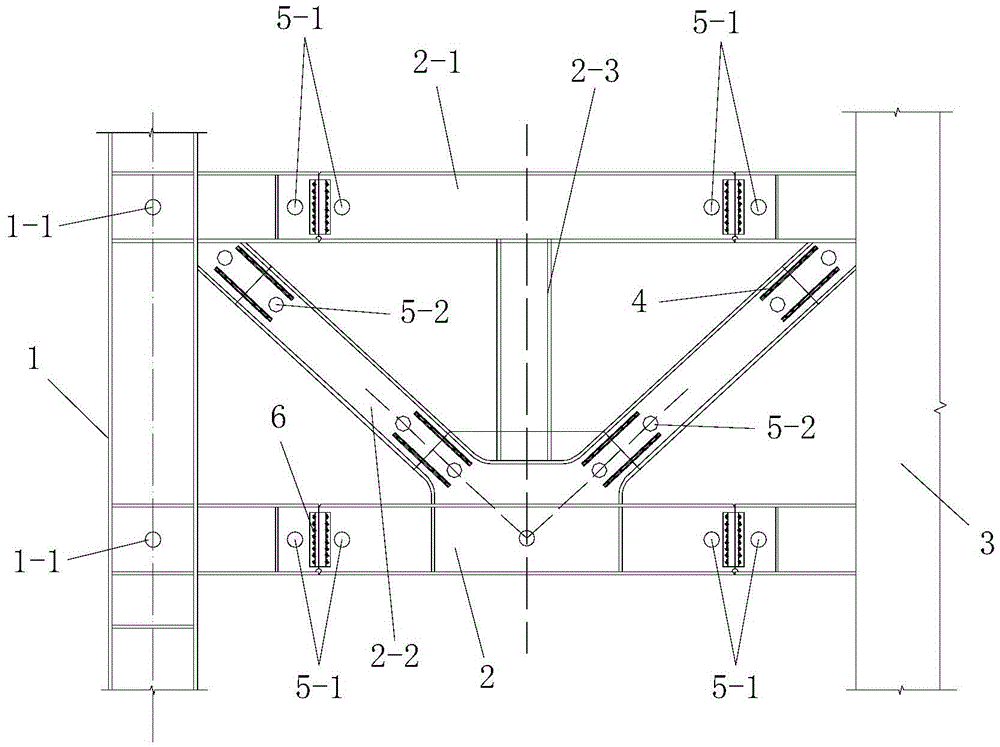

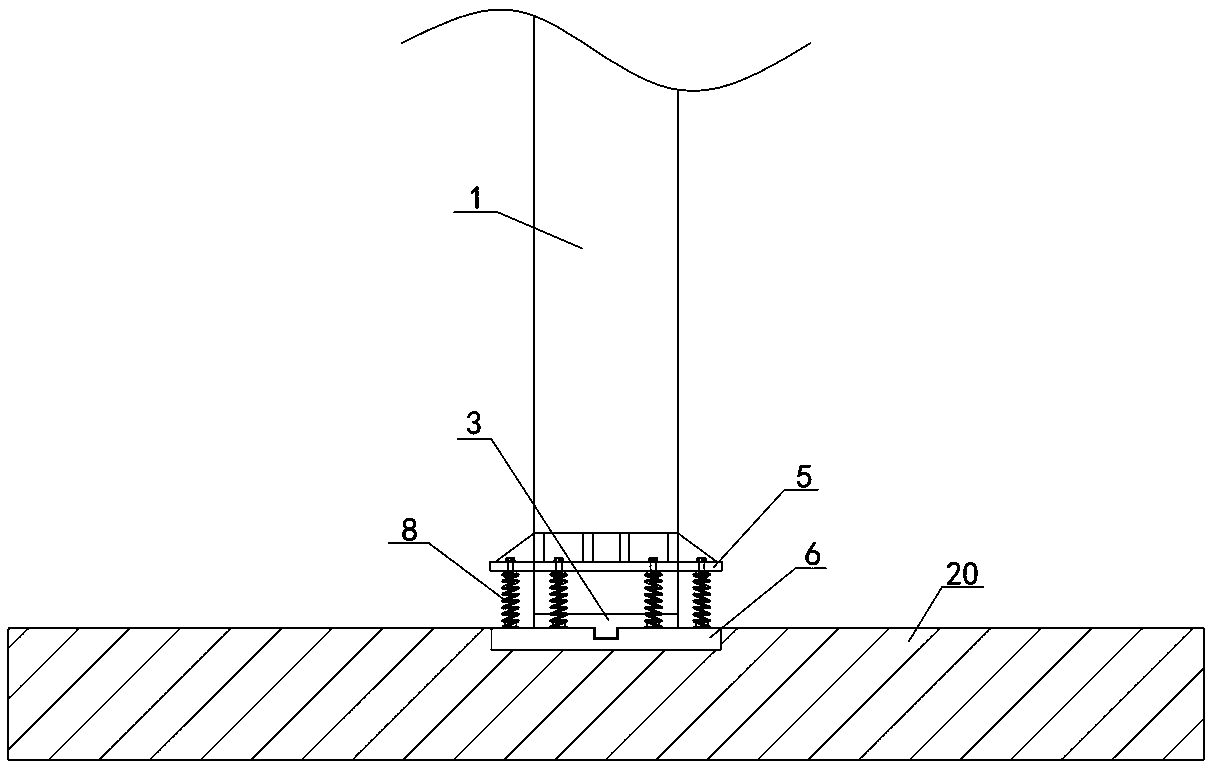

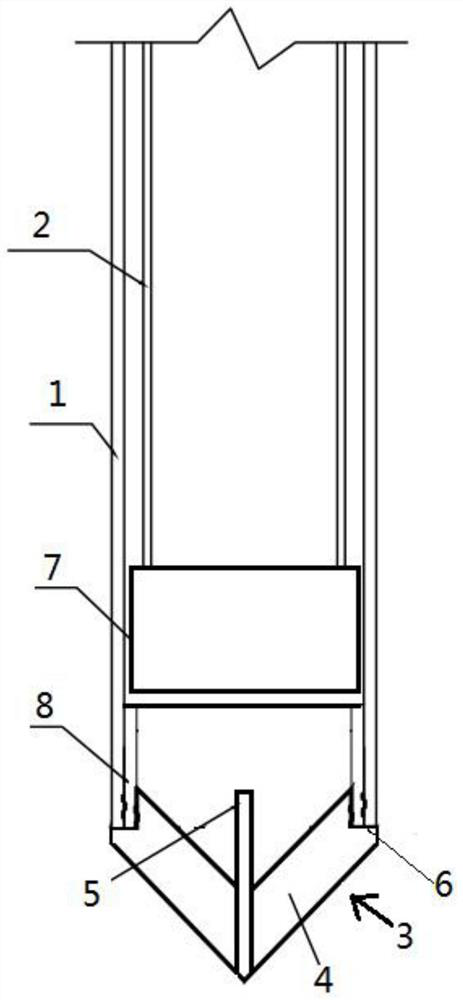

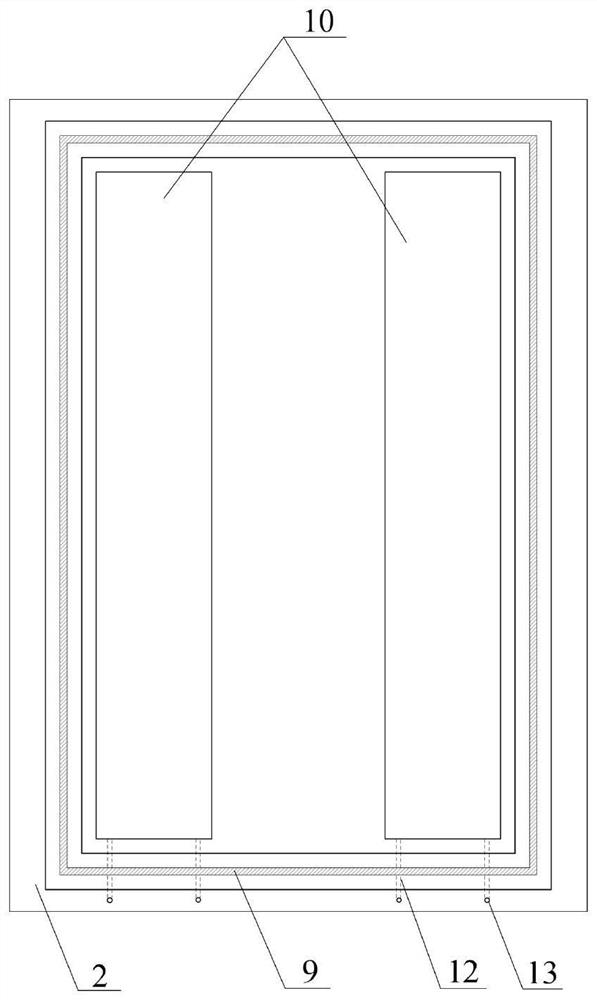

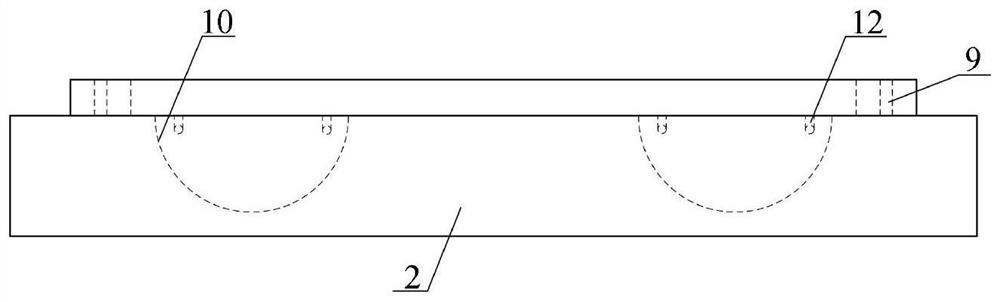

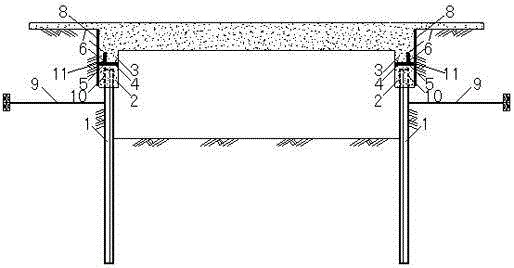

Wood sliding shock-insulation support

ActiveCN106400977AEnsure stabilityGuaranteed vertical bearing capacityProtective buildings/sheltersShock proofingEnvironmental resistanceRecovery performance

A wood sliding shock-insulation support comprises an upper connecting plate and a lower connecting plate. The upper connecting plate is provided with upper bolts used for being connected with an upper structure. The lower connecting plate is provided with lower bolts used for being connected with a lower structure. A plurality of holes are symmetrically formed in the upper connecting plate and the lower connecting plate, and wood rods are inserted in the holes and located between the upper connecting plate and the lower connecting plate. The wood sliding shock-insulation support has the advantages of being high in vertical bearing capacity and small in horizontal rigidity, is capable of guaranteeing the sliding shock-insulation effect of the upper structure of the support under the action of an earthquake, and has the characteristics of being environmentally friendly in use material, low in manufacturing cost and simple in structure. The wood material is high in toughness, light in self structure, high in elasticity recovery performance and capable of being reset automatically when the action of an earthquake is small.

Owner:西安华清科教产业(集团)有限公司

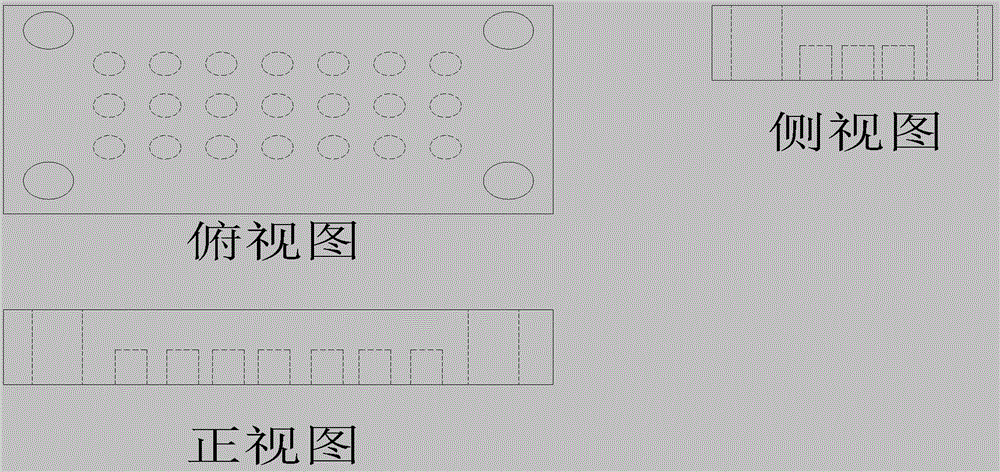

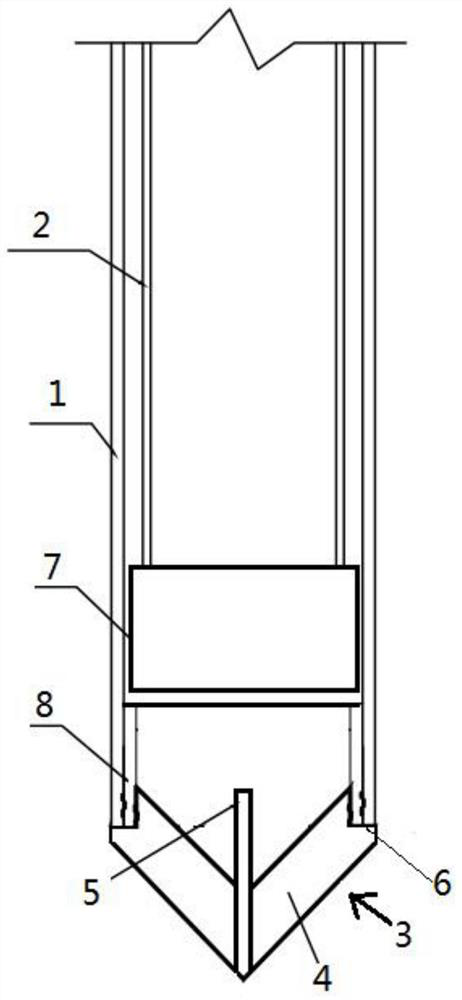

Cast-in-place concrete pile expanding equipment and construction method of cast-in-place concrete pile

PendingCN114508306AImprove ground breaking abilityIncreased ground breaking areaBulkheads/pilesDrilling machines and methodsStructural engineeringGeotechnical engineering

The invention provides diameter expanding equipment for a cast-in-place concrete pile, which comprises an outer sleeve component, an inner sleeve component, an outer sleeve component, an inner sleeve component and an outer sleeve component, the soil breaking structure is arranged on the lower end face of the outer sleeve component, a gap allowing concrete to pass through in the axial direction of the outer sleeve component is formed between the soil breaking structure and the outer sleeve component, and the soil breaking structure is of a structure with the wide upper portion and the narrow lower portion. The invention further provides a construction method of the cast-in-place concrete pile adopting the expanding equipment.

Owner:JIANGXI JIYE SCI & TECH

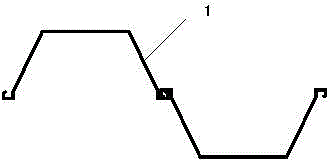

Novel integral abutment bridge with dog-bone shaped connecting structure and construction method

InactiveCN104562921AImprove longitudinal deformation abilityGuaranteed vertical bearing capacityBridge structural detailsBridge erection/assemblyFatigue damageRubber material

The invention discloses a novel integral abutment bridge with a dog-bone shaped connecting structure and construction method. The bridge comprises an end beam, a pile cap and an H-shaped supporting steel pile; a weak shaft of an H-shaped steel pile body is bent; the pile cap is connected with the end beam by the dog-bone shaped connecting structure, wherein the dog-bone shaped connecting structure is that a compressing rubber material fills in a connecting clearance between the pile cap and the end beam, and the pile cap and the end beam are connected through the H-shaped steel pile. According to the bridge, the H-shaped steel pile can bear the vertical load through the surface friction and even the end part, and moreover, the characteristics that the lateral rigidity of the weak shaft is low is utilized well; the rigidity of the connecting part is reduced by the dog-bone shaped connecting structure between the pile cap and the end beam, thus the rotating capacity of the connecting part is improved, the longitudinal deformation capacity of the bridge is increased, the allowable length of the bridge of the type is raised, a pile foundation is avoided excessive lateral displacement, the vertical bearing capacity of the pile is ensured, the internal force of the pile body is decreased, the fatigue damage of the temperature deformation of the bridge to the pile body is reduced, and as a result, the service life of the bridge is prolonged.

Owner:FUZHOU UNIV

Rolling friction support for supporting columns of underground subway station

ActiveCN112302187AGuaranteed to slide freelyReduce frictional resistanceArtificial islandsProtective buildings/sheltersArchitectural engineeringStructural engineering

The invention discloses a rolling friction support for supporting columns of an underground subway station. The rolling friction support is mainly composed of a lower connecting plate, a lower base plate, a stainless steel arc plate, balls, steel bars, an upper base plate, an upper connecting plate and a dustproof cover. The lower connecting plate is fixed to the lower end face of the lower base plate, the stainless steel arc plate is fixedly installed in semi-cylindrical grooves and provided with a plurality of long-strip-shaped grooves, the steel bars, the balls and the upper base plate arein rolling contact, the dustproof cover is embedded in a fixing inserting groove and forms a closed space with the upper base plate, a connecting channel is formed in the lower base plate, the long-strip-shaped grooves are in communication with oil injection holes through the connecting channel, and the upper connecting plate is fixed to the upper end face of the upper base plate. Free sliding ofthe supporting columns and cross beams of the underground subway station is achieved through the rolling friction support, and relative horizontal deformation of the supporting columns under the earthquake action is reduced. The rolling friction support is clear in concept, clear in principle, high in vertical bearing capacity, easy to produce, convenient to maintain and long in service life.

Owner:BEIJING UNIV OF TECH

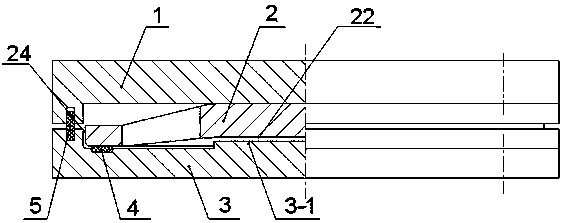

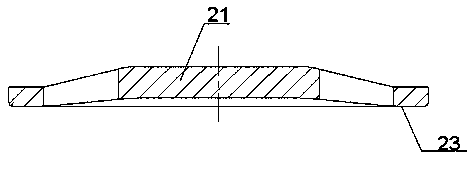

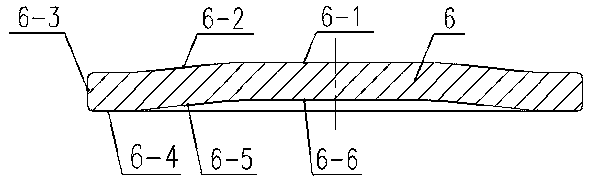

High-load-bearing full-sealed disk-type structure vibration isolation device

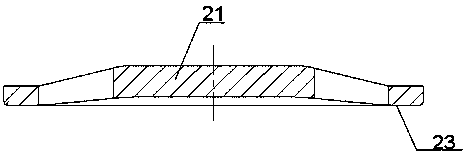

ActiveCN108775367AGuaranteed vertical deformationGuaranteed flexibilitySpringsSprings/dampers design characteristicsVertical vibrationStructural engineering

The invention provides a high-load-bearing full-sealed disk-type structure vibration isolation device. The vibration isolation device mainly comprises a cover plate, a disk-type structure vibration isolator and a bottom basin. The disk-type structure vibration isolator is arranged between the cover plate and the bottom basin in a surrounded mode. The disk-type structure vibration isolator is of acentral symmetry structure. The center of the disk-type structure vibration isolator protrudes upwards to form an elastic deformation part. The outer edge of the elastic deformation part extends outwards to form a supporting part. The center of the elastic deformation part serves as a supporting platform. The upper surface of the supporting platform makes contact with and is matched with the lowersurface of the cover plate. The lower surface of the supporting platform does not make contact with the upper surface of the bottom basin. The periphery of the supporting platform is connected with ataper tube section inclined downwards. The supporting platform is connected with the supporting part through the taper tube section. The taper tube section is provided with a plurality of holes. Thethickness of the taper tube section gradually decreases from the supporting platform to the supporting part. The high-load-bearing full-sealed disk-type structure vibration isolation device achieves the vibration isolation effect in a pure structure form and is placed on a supporting part of a vibration isolated body to reduce the vertical stiffness appropriately, and the vertical fundamental frequency keeps away from the main frequency of vibration of the upper structure. Accordingly, the vertical vibration isolation function is achieved.

Owner:LUOYANG SUNRUI SPECIAL EQUIP

Delayed connection installation method of outrigger truss in super high-rise steel frame-core tube structure

InactiveCN105672481BThe method steps are simpleReasonable designBuilding constructionsDeformation monitoringSteel frame

The invention discloses a delayed connection installation method of an outrigger truss of a super high-rise steel frame-core tube structure. The outer frame of the outrigger truss reinforcement layer is connected between the core tube and the frame column through the outrigger truss; the outrigger truss includes two upper and lower chords and multiple webs; During installation, the delayed connection method is used for installation and the installation process is as follows: 1. Temporary connection of chords; 2. Vertical deformation monitoring: the vertical strains of the core tube and frame columns connected by two chords Monitoring; 3. Chord stress release and fixed connection; 4. Web installation. The method of the invention has simple steps, reasonable design, convenient operation and good application effect, and can effectively solve the problem of premature failure of the outrigger truss due to the vertical deformation difference between the frame column and the core tube.

Owner:SHAANXI ACAD OF ARCHITECTONICS

Construction method of integral abutment bridge with dog-bone connection structure

InactiveCN104562921BImprove longitudinal deformation abilityGuaranteed vertical bearing capacityBridge structural detailsBridge erection/assemblyFatigue damageRubber material

The invention discloses a novel integral abutment bridge with a dog-bone shaped connecting structure and construction method. The bridge comprises an end beam, a pile cap and an H-shaped supporting steel pile; a weak shaft of an H-shaped steel pile body is bent; the pile cap is connected with the end beam by the dog-bone shaped connecting structure, wherein the dog-bone shaped connecting structure is that a compressing rubber material fills in a connecting clearance between the pile cap and the end beam, and the pile cap and the end beam are connected through the H-shaped steel pile. According to the bridge, the H-shaped steel pile can bear the vertical load through the surface friction and even the end part, and moreover, the characteristics that the lateral rigidity of the weak shaft is low is utilized well; the rigidity of the connecting part is reduced by the dog-bone shaped connecting structure between the pile cap and the end beam, thus the rotating capacity of the connecting part is improved, the longitudinal deformation capacity of the bridge is increased, the allowable length of the bridge of the type is raised, a pile foundation is avoided excessive lateral displacement, the vertical bearing capacity of the pile is ensured, the internal force of the pile body is decreased, the fatigue damage of the temperature deformation of the bridge to the pile body is reduced, and as a result, the service life of the bridge is prolonged.

Owner:FUZHOU UNIV

Diameter expanding equipment of cast-in-place concrete pile and construction method of cast-in-place concrete pile

PendingCN113622824AImprove ground breaking abilityIncreased ground breaking areaBulkheads/pilesDrilling machines and methodsStructural engineeringGeotechnical engineering

The invention provides diameter expanding equipment for a cast-in-place concrete pile. The diameter expanding equipment comprises an outer sleeve component, an inner sleeve component adapted to be mutually nested with outer sleeve component, and a soil breaking structure, the soil breaking structure is arranged on the lower end face of the outer sleeve component, a gap allowing concrete to pass through in the axial direction of the outer sleeve component is formed between the soil breaking structure and the outer sleeve component, and the soil breaking structure is of a structure with the wide upper portion and the narrow lower portion. The invention further provides a construction method of the cast-in-place concrete pile adopting the expanding equipment.

Owner:JIANGXI JIYE SCI & TECH

A bending-shear separated prefabricated frame column and its construction method

InactiveCN108487457BMaintain shear elasticityEasy to controlBuilding constructionsBending momentGeotechnical engineering

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

Construction method of a semi-rigid integral abutment bridge supported by concrete piles

InactiveCN104562923BEnhanced longitudinal deformation capabilityExtended service lifeBridge structural detailsFoundation engineeringPile capAbutment

The invention relates to a semi-rigid-joint integral type abutment bridge supported by a concrete pile and a construction method. The semi-rigid-joint integral type abutment bridge supported by the concrete pile comprises an end beam, a pile cap, and a concrete pile which is inserted into the earth surface to be used as a supporting pile; a weak shaft of the concrete pile body is bent to form a semi-rigid-joint structure with the end beam; the semi-rigid-joint structure is that neoprene fills in a joint seam of the pile cap and the end beam, and the pile cap and the end beam are connected through a main rib in the concrete pile; the longitudinal deformation capacity of the bridge is improved through the semi-rigid-joint structure between the pile body and the end beam, the allowable bridge length is increased, and therefore, a pile foundation is avoided cracking due to excessive large pulling stress, the damage of temperature deformation of the bridge to a pile body can be reduced, the vertical bearing capacity of the pile is ensured, and the service life of the bridge is prolonged.

Owner:FUZHOU UNIV

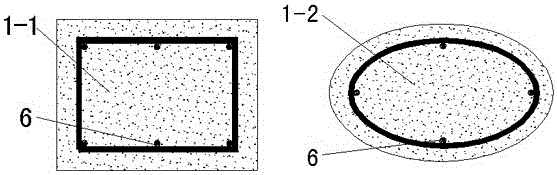

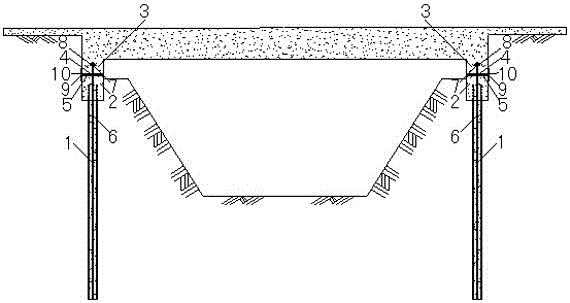

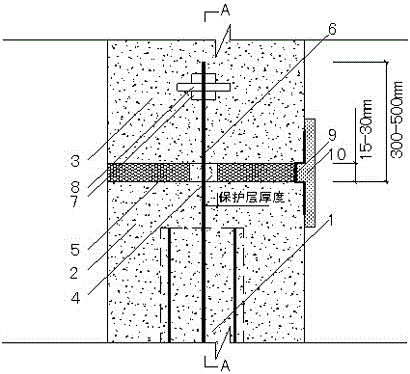

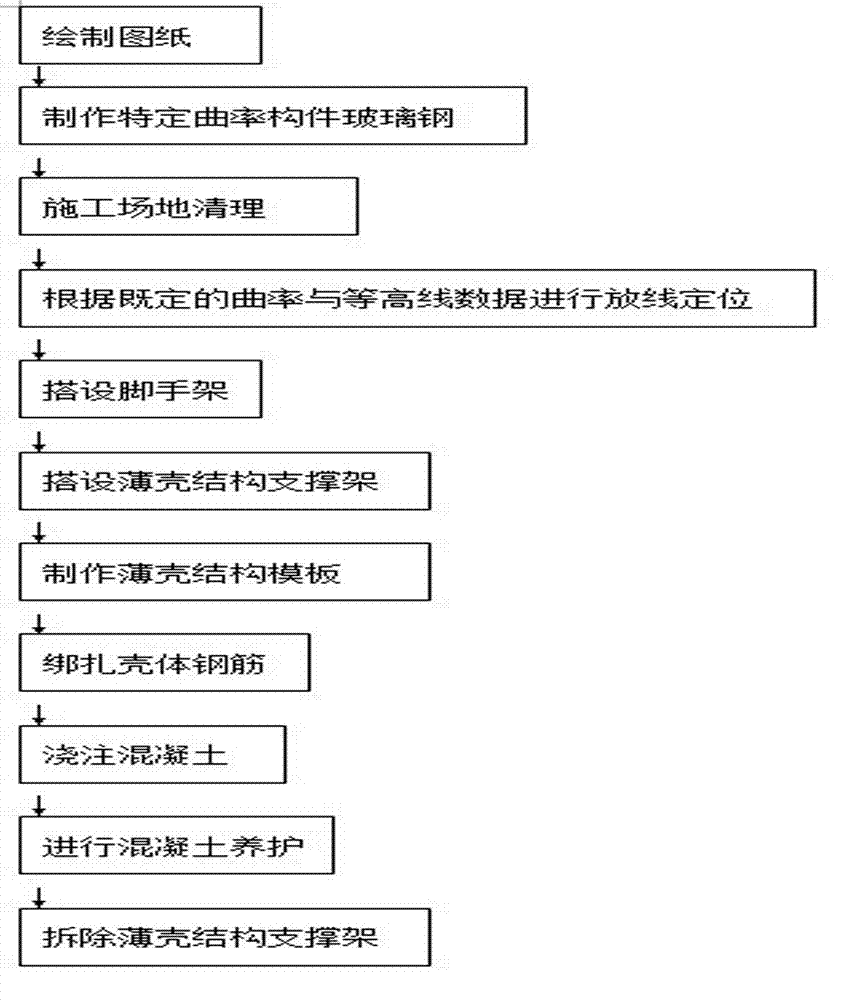

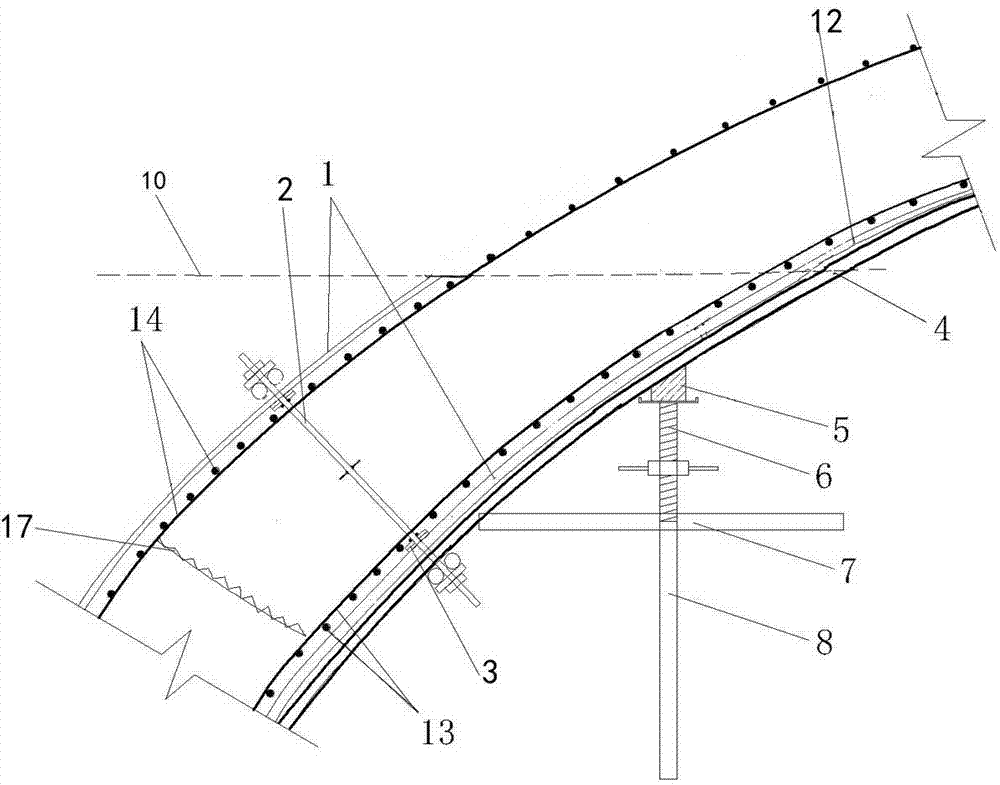

Construction method of large-span multi-curvature thin-shell reinforced concrete structures

ActiveCN103590603BFast unificationImprove unityForms/shuttering/falseworksBuilding material handlingWire gauzeControl line

A large-span multi-curvature thin shell reinforced concrete structure construction method specifically includes the steps of making drawings, manufacturing and building glass fiber reinforced plastics, cleaning a construction site, carrying out paying-off positioning according to an established curvature and contour line data, setting up supporting frames, setting up thin shell structured supporting frames, manufacturing thin shell structured formworks, binding shell reinforcing steel bars, pouring concrete, dismounting formwork supporting frames and the like. According to the construction method, a contour line mode is adopted to carry out disassembling on the formworks by being coordinated with a control line, so rapid erection is achieved and the construction time is saved. The portion, close to the bottom of a shell is made of dual-side glass fiber reinforced plastic formworks, and formwork sealing is carried out by using steel wire gauze arranged at intervals, so vertical bearing capacity is guaranteed, the problem in large-gradient concrete construction is solved, and the slanting thrust of the structure on frame bodies is removed effectively. In addition, concrete subsection symmetrical pouring is adopted, so the stress of a supporting system can be balanced, and the problem of difficult construction caused by big shell size and steep gradient can be solved.

Owner:THE THIRD CONSTR ENG CO LTD OF CHINA CONSTR SECOND ENG BUREAU

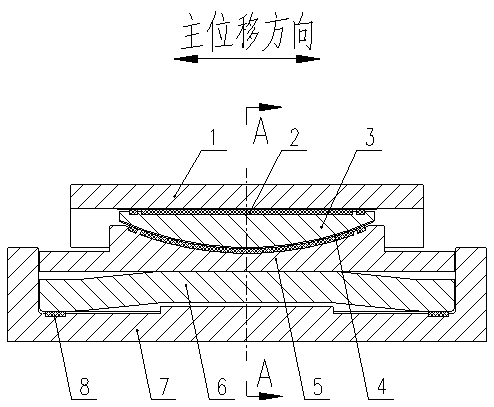

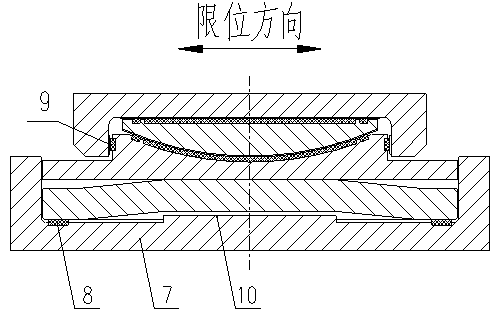

A vertical vibration isolation spherical steel bearing with a disc structure vibration isolator

ActiveCN108730394BGuaranteed flexibilityReduce vertical stiffnessFriction dampersVertical vibrationStructural engineering

A vertical vibration-isolation spherical steel support with a disc structure vibration isolator, the disc structure vibration isolator is set in the space surrounded by the uppermost seat plate of the vertical spherical steel support, or the vertical spherical steel support In the space surrounded by the lowest seat plate, or between any two adjacent seat plates of the vertical spherical steel support, the disc structure vibration isolator is an axisymmetric structure, so that the side of the disc structure vibration isolator There is a deformation gap between the inner side walls of the seat plate at the position. This patent is based on the spherical steel support, by adding a disc structure vibration isolator with vibration isolation function, so that it forms an upper and lower series connection with the support. Structure, the overall vertical stiffness of the support is appropriately reduced, and the vertical fundamental frequency is far away from the main frequency of the vibration of the upper structure of the support, so as to realize the vertical vibration isolation function.

Owner:LUOYANG SUNRUI SPECIAL EQUIP

Electrorheological elastomer vibration isolator in compression-shear mixed mode

PendingCN112901710AHigh material utilizationAvoid the disadvantages of failure damageSpringsNon-rotating vibration suppressionElastomerClassical mechanics

The invention relates to an electrorheological elastomer vibration isolator, in particular to the electrorheological elastomer vibration isolator in a compression-shear mixed mode. The invention provides a novel electrorheological elastomer vibration isolator in order to solve the problem that an existing intelligent vibration isolation support of an electrorheological elastomer is low in utilization rate of material performance of the electrorheological elastomer, the novel electrorheological elastomer vibration isolator comprises a shell, a gland located in the shell and a supporting table with a conical surface, the bottom face of the supporting table is located in the center of the bottom of the shell, the gland is located above the supporting table, a groove matched with the supporting table is formed in the bottom face of the gland, multiple layers of electrode plates are fixedly arranged between the side wall of the groove and the side wall of the supporting table, the electrorheological elastomer is fixedly arranged between every two adjacent electrode plates, so that the electrorheological elastomer located between the groove of the gland and the supporting table achieves compression-shear composite deformation, and the top of the gland is fixedly connected with a vibration isolation compression rod extending out of the top of the shell, so that the material utilization rate of the electrorheological elastomer is improved.

Owner:TAIYUAN UNIV OF TECH

A wooden sliding shock-isolation bearing

ActiveCN106400977BEnsure stabilityGuaranteed vertical bearing capacityProtective buildings/sheltersShock proofingRecovery performanceEngineering

A wood sliding shock-insulation support comprises an upper connecting plate and a lower connecting plate. The upper connecting plate is provided with upper bolts used for being connected with an upper structure. The lower connecting plate is provided with lower bolts used for being connected with a lower structure. A plurality of holes are symmetrically formed in the upper connecting plate and the lower connecting plate, and wood rods are inserted in the holes and located between the upper connecting plate and the lower connecting plate. The wood sliding shock-insulation support has the advantages of being high in vertical bearing capacity and small in horizontal rigidity, is capable of guaranteeing the sliding shock-insulation effect of the upper structure of the support under the action of an earthquake, and has the characteristics of being environmentally friendly in use material, low in manufacturing cost and simple in structure. The wood material is high in toughness, light in self structure, high in elasticity recovery performance and capable of being reset automatically when the action of an earthquake is small.

Owner:西安华清科教产业(集团)有限公司

A high-load fully sealed disc structure vibration isolation device

ActiveCN108775367BGuaranteed flexibilityReduce coefficient of frictionSpringsSprings/dampers design characteristicsVertical vibrationFundamental frequency

A high-load full-sealed disc structure vibration isolation device mainly includes a cover plate, a disc structure vibration isolator and a bottom basin. The vibrator is a center-symmetrical structure, its central part protrudes upwards to form an elastic deformation part, and the outer edge of the elastic deformation part extends outwards to form a support part. The center of the elastic deformation part is a support platform, and the upper surface of the support platform and the cover The lower surface of the plate contacts and cooperates with each other. The lower surface of the support platform does not contact the upper surface of the bottom basin. A plurality of holes are opened on the segment, and the thickness of the cone segment gradually decreases from the support platform to the support portion. The invention realizes the vibration isolation effect in the form of a pure structure, is placed on the support part of the vibration-isolated body, and the vertical stiffness is appropriately reduced, and the vertical fundamental frequency is far away from the main frequency of the vibration of the upper structure, thereby realizing the vertical vibration isolation function.

Owner:LUOYANG SUNRUI SPECIAL EQUIP

A semi-rigid integral seamless bridge structure supported by steel sheet piles and its construction method

InactiveCN104563149BLarge horizontal displacementIncreased longitudinal deformation capabilityBridge structural detailsBulkheads/pilesAbutmentEarth surface

Owner:FUZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com