L-shaped special-shaped column and beam fabricated connecting joint

A technology for connecting nodes and special-shaped columns, which is applied in the field of L-shaped special-shaped column-beam assembled connection nodes, can solve the problems of restricting the development of assembled high-rise steel structure systems, brittle failure of beam-column joints, and slow construction speed, etc., to achieve the use of space Flexible layout, convenient design and high assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

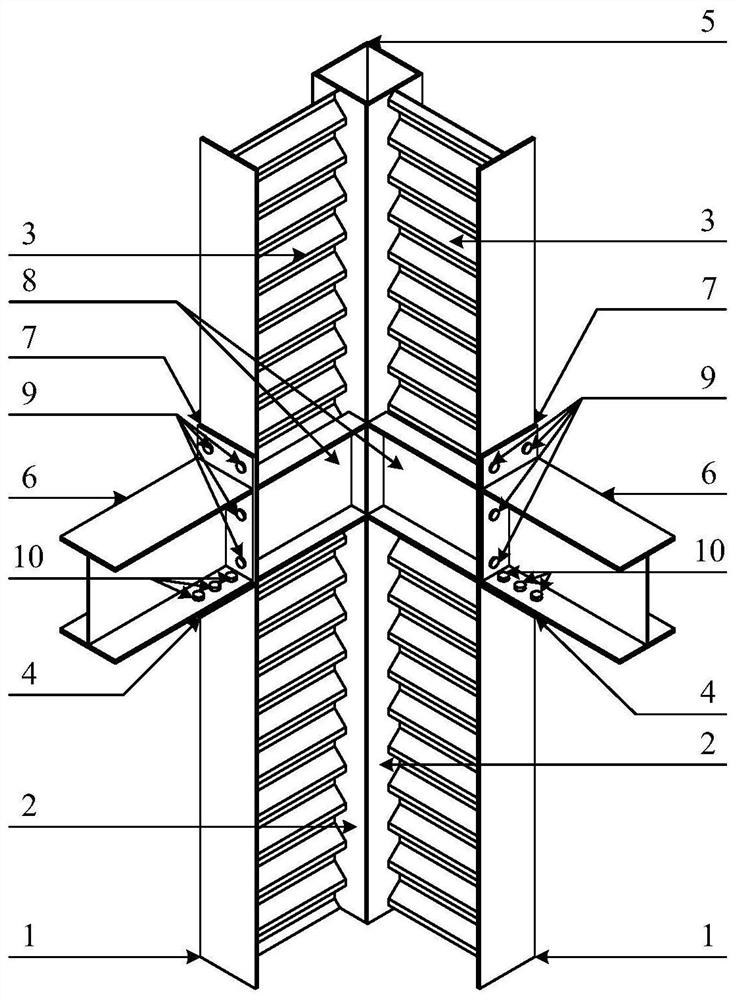

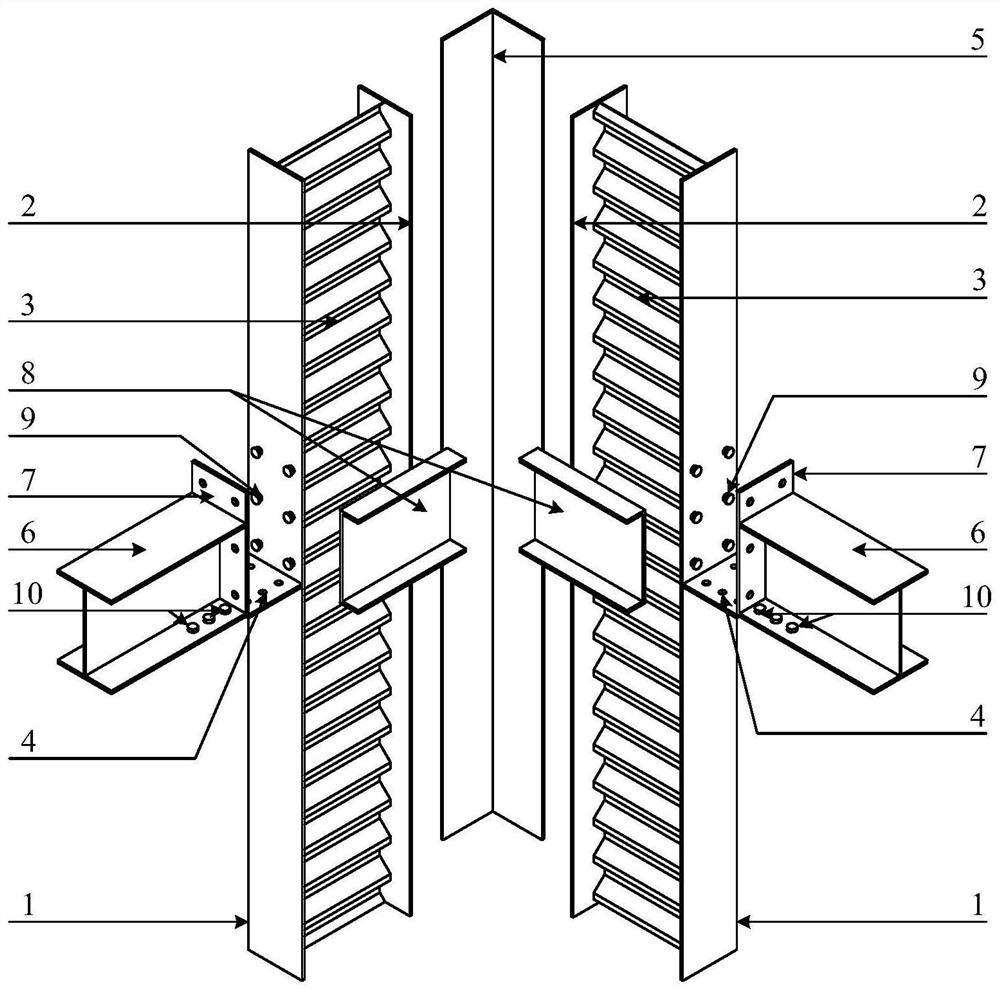

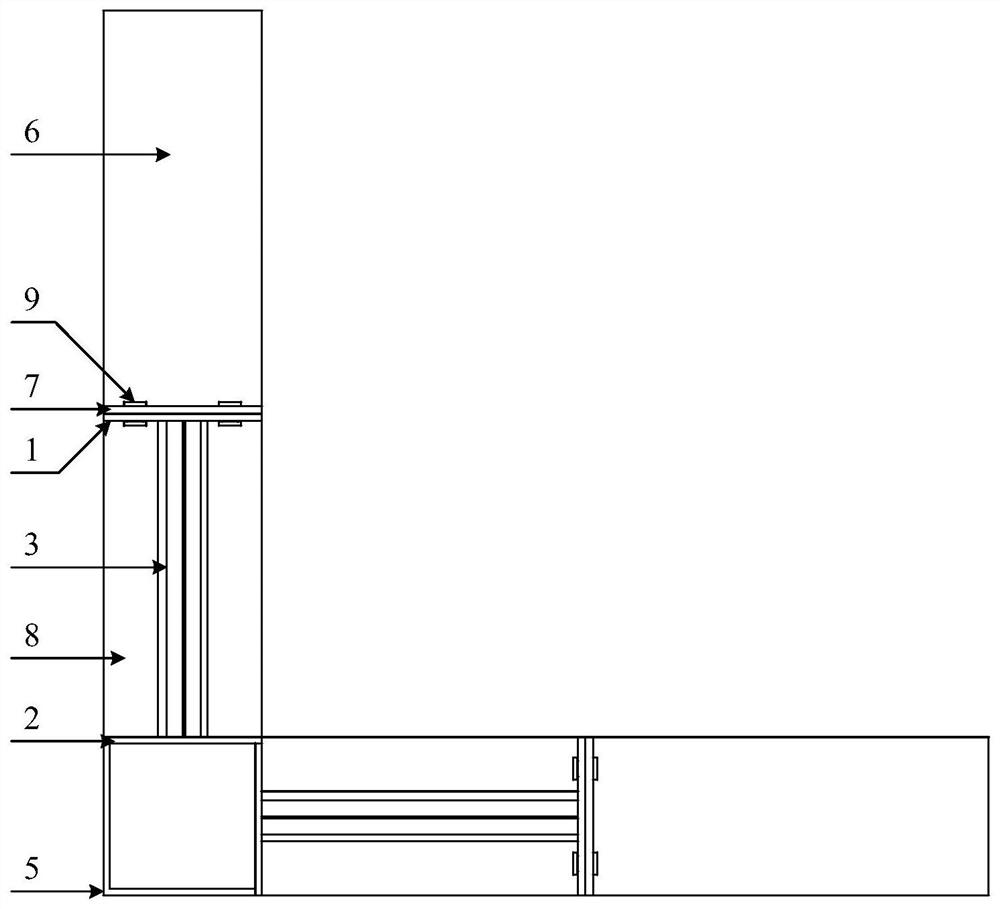

[0020] Attached below Figure 1~5 , detailing the implementation of this patent.

[0021] like Figure 1~5 As shown, the L-shaped special-shaped column-beam assembly connection node includes the following components:

[0022] 1——outer flange plate

[0023] 2—Inner flange plate

[0024] 3——corrugated board

[0025] 4——Pallet

[0026] 5——Angle column

[0027] 6——I-beam

[0028] 7——I-shaped beam end plate

[0029] 8——Channel steel connector

[0030] 9——The first high-strength bolt group

[0031] 10——The second high-strength bolt group

[0032] The specific connection mode of the beam-column node connection device of the present invention will be described in detail below with reference to the accompanying drawings.

[0033] The components of the node connection device of the present invention include: outer flange plate (1), inner flange plate (2), corrugated plate (3), supporting plate (4), angle steel column (5), I-shaped beam (6), I-beam end plate (7), channel stee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com