Construction method for underground buildings by rotary-spray shaft digging method cooperating with semi-inverse method

A construction method and reverse method technology, applied in the direction of building structure, construction, underwater structures, etc., can solve the problems of no bearing capacity of the well body, horizontal drift of the wellbore, sedimentation, etc., to ensure safety and quality, and speed up the construction progress , The effect of saving engineering investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

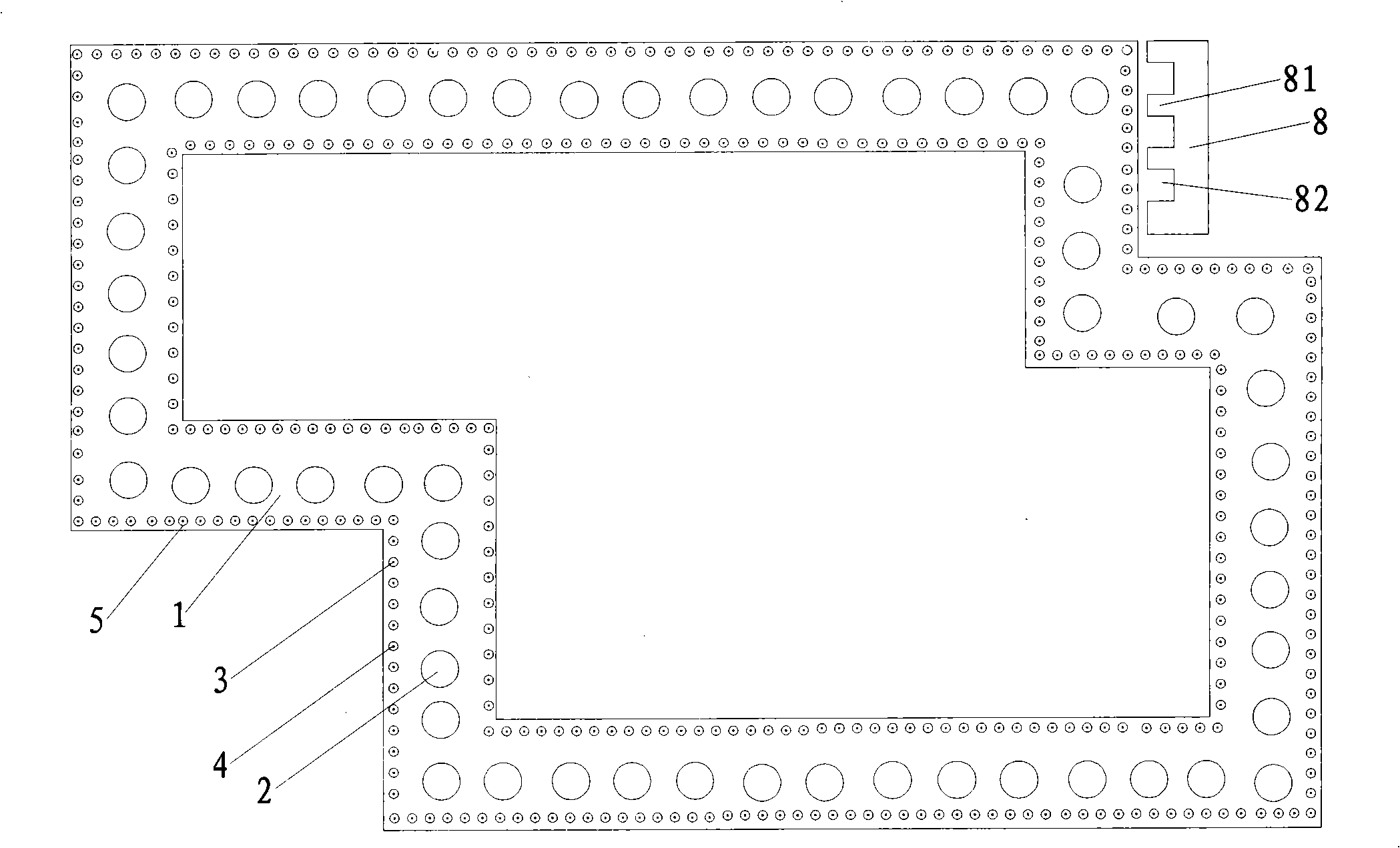

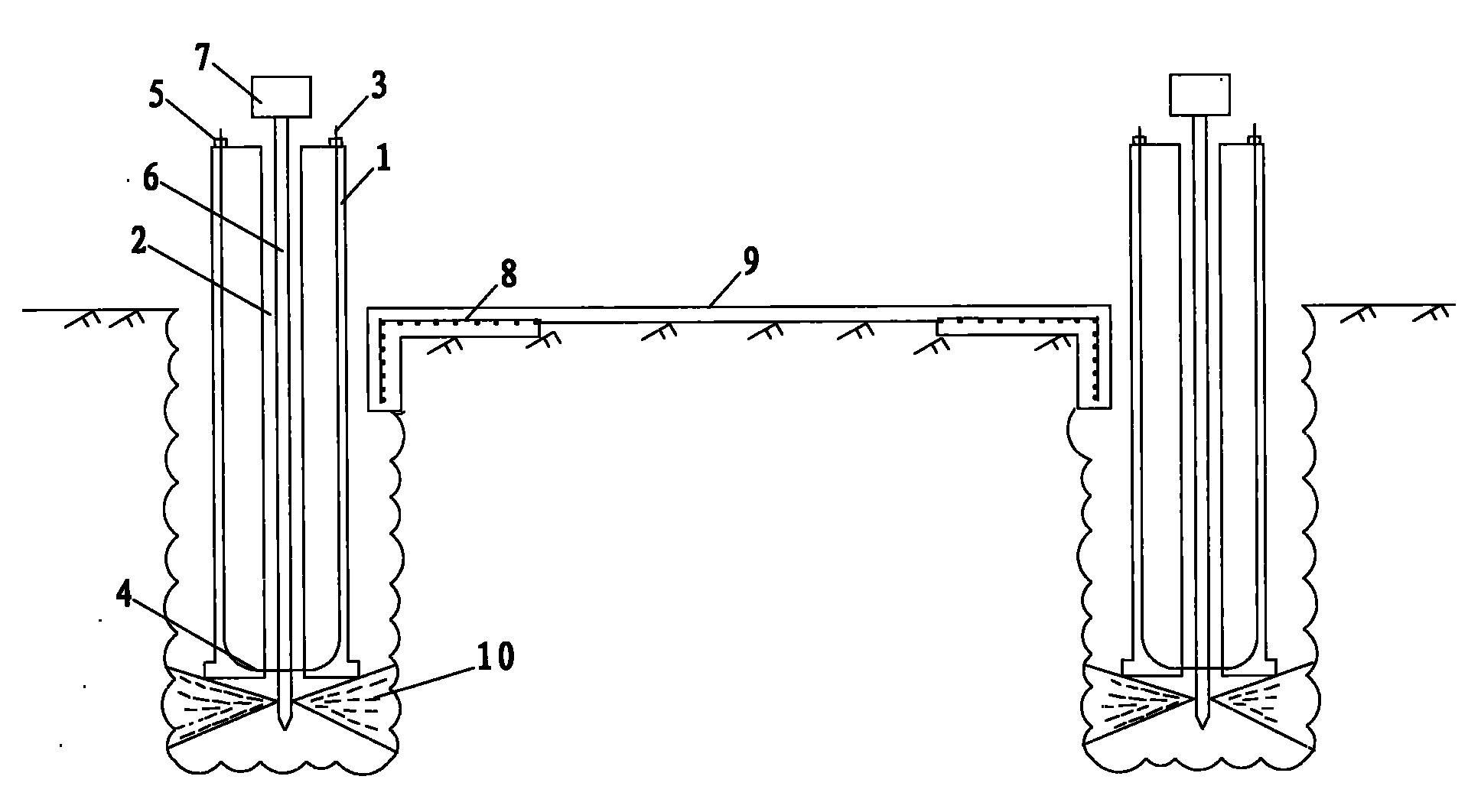

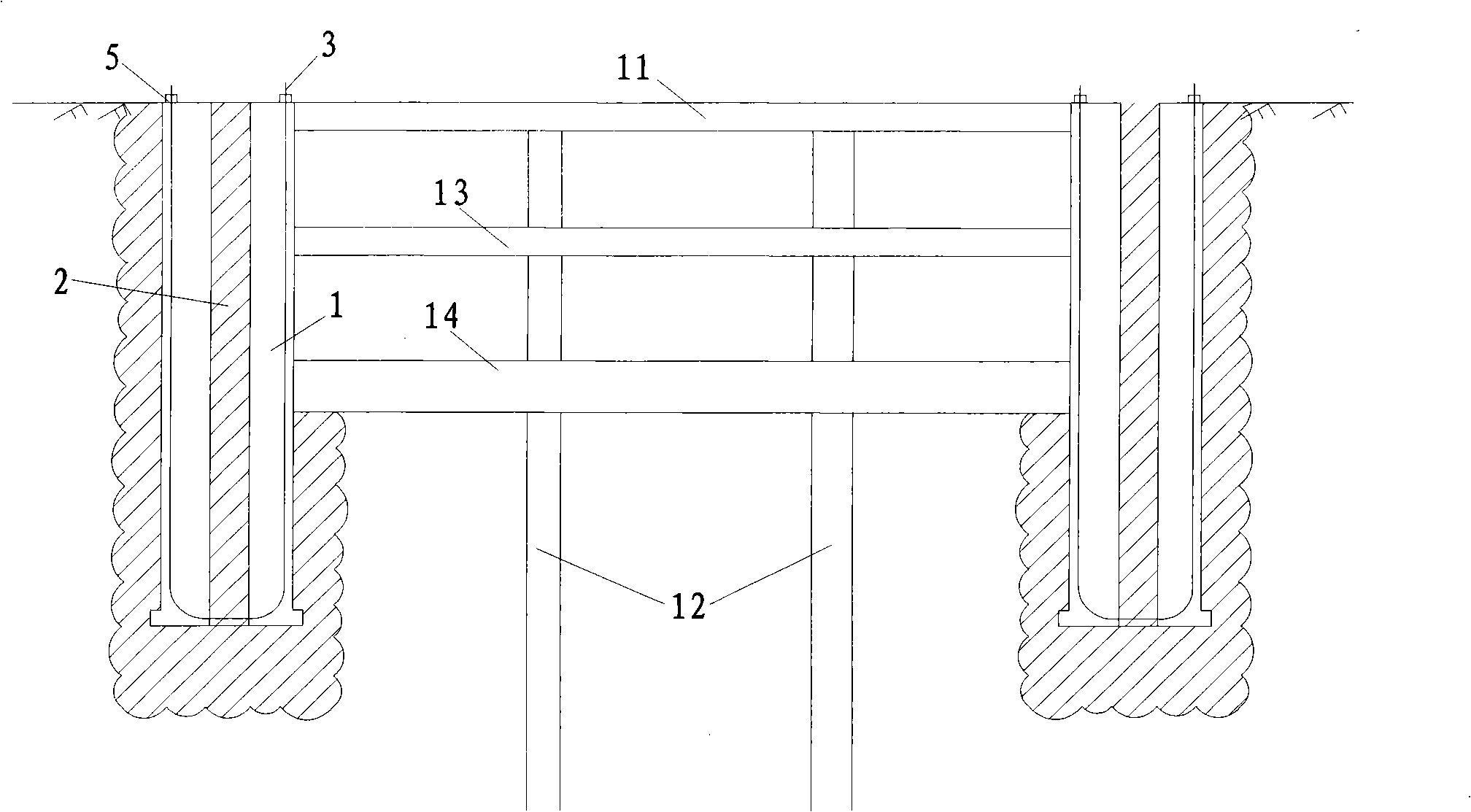

[0028] Such as figure 1 , 2 As shown, the outer wall 1 of the underground building of the present invention (such as the basement of large civil buildings, public underground garages and subway stations, etc.) is prefabricated on the ground, and the bottom of the outer wall does not have a blade foot, and adopts a flat foot structure. The width is slightly wider than that of the upper wall, and the reinforcement of the external wall can all be reinforced by common building materials, or all or part of the vertical reinforcement of the external wall can be made of prestressed steel strands 3 on the inner and outer layers. The steel strands are passed through the thin-walled steel pipe 4, the inner diameter of the steel pipe 4 is slightly larger than the diameter of the steel strands, and the bottoms of the thin-walled steel pipes on the inner a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com