Composite pier with dumbbell-shaped concrete filled steel tubes, and structure and method for collection with cushion cap

A technology for concrete-filled steel tubes and connecting structures, which is applied in bridges, bridge construction, bridge parts, etc., can solve the problems of large lateral stiffness, poor seismic performance, and high bearing capacity, and achieves less wet work, less on-site workload, and high resistance to damage. The effect of high bending stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, and the described specific embodiments are only for explaining the present invention, and are not intended to limit the present invention.

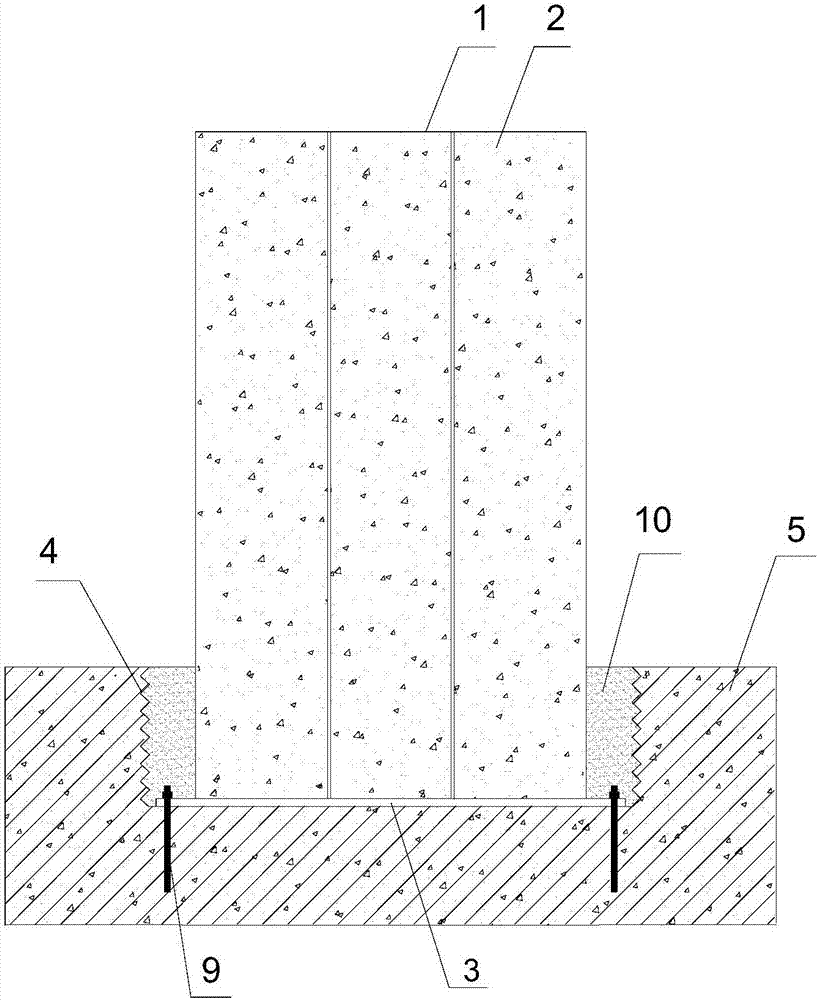

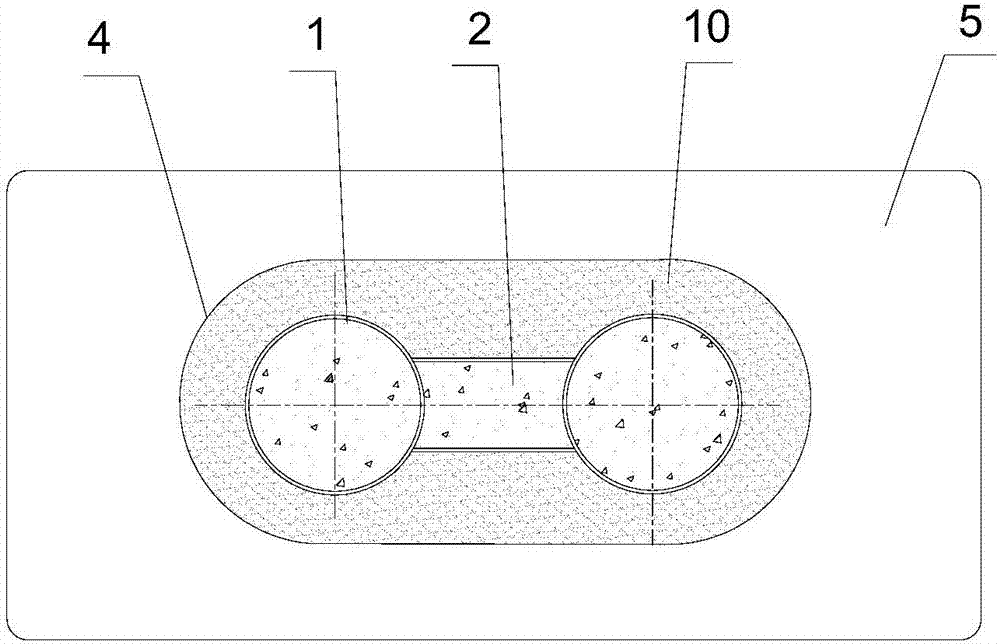

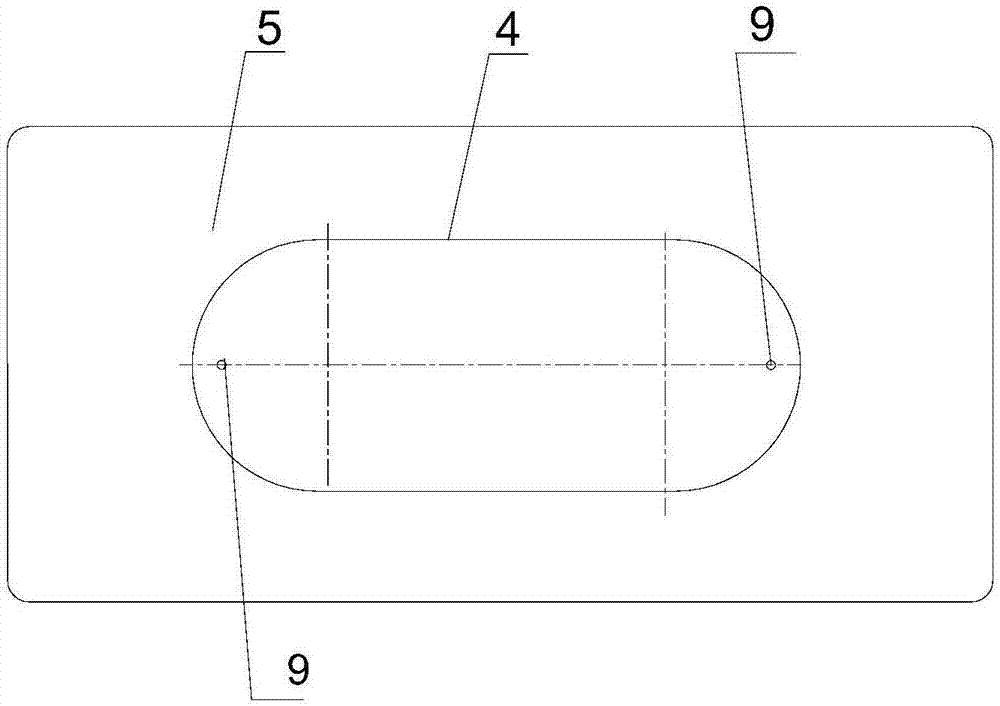

[0034] A kind of dumbbell-shaped steel pipe concrete composite pier proposed in the present invention comprises dumbbell-shaped steel pipe 1, such as Pic 4-1 and Figure 4-2 As shown, the dumbbell-shaped steel pipe 1 is composed of two round steel pipes 6 and a double-layer steel plate 7 welded between the two round steel pipes 6. The lines connecting the centroids are symmetrically distributed, and the welding between the double-layer steel plate 7 and the two round steel pipes 6 adopts fillet welding. The bottom of the dumbbell-shaped steel pipe 1 is welded with an end plate 3 by a fillet weld. The outer profile of the end plate 3 is larger than the outer profile of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com