Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37results about How to "Guaranteed degreasing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Trapping method and trapping system for tar in coal gas

InactiveCN106433804AAvoid it happening againLow investment costDispersed particle separationVapor condensationElectricityTrapping

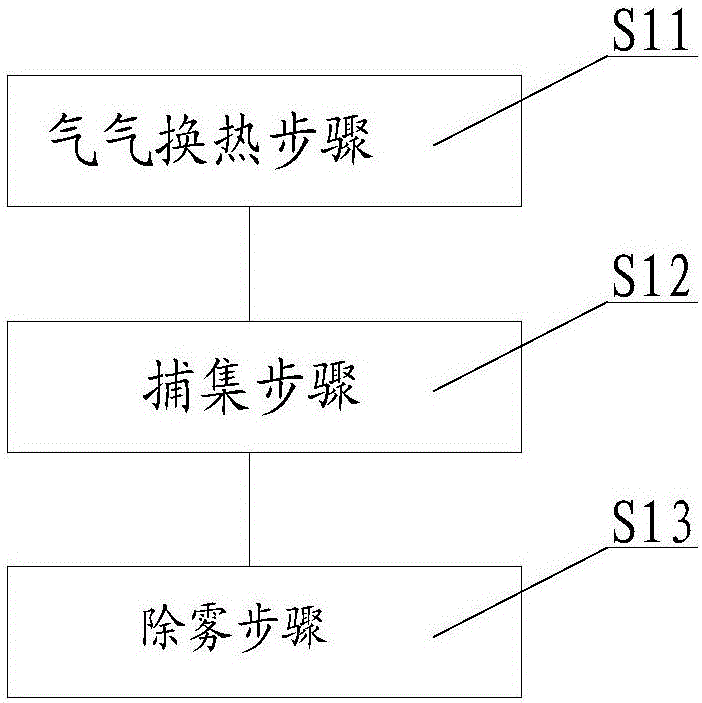

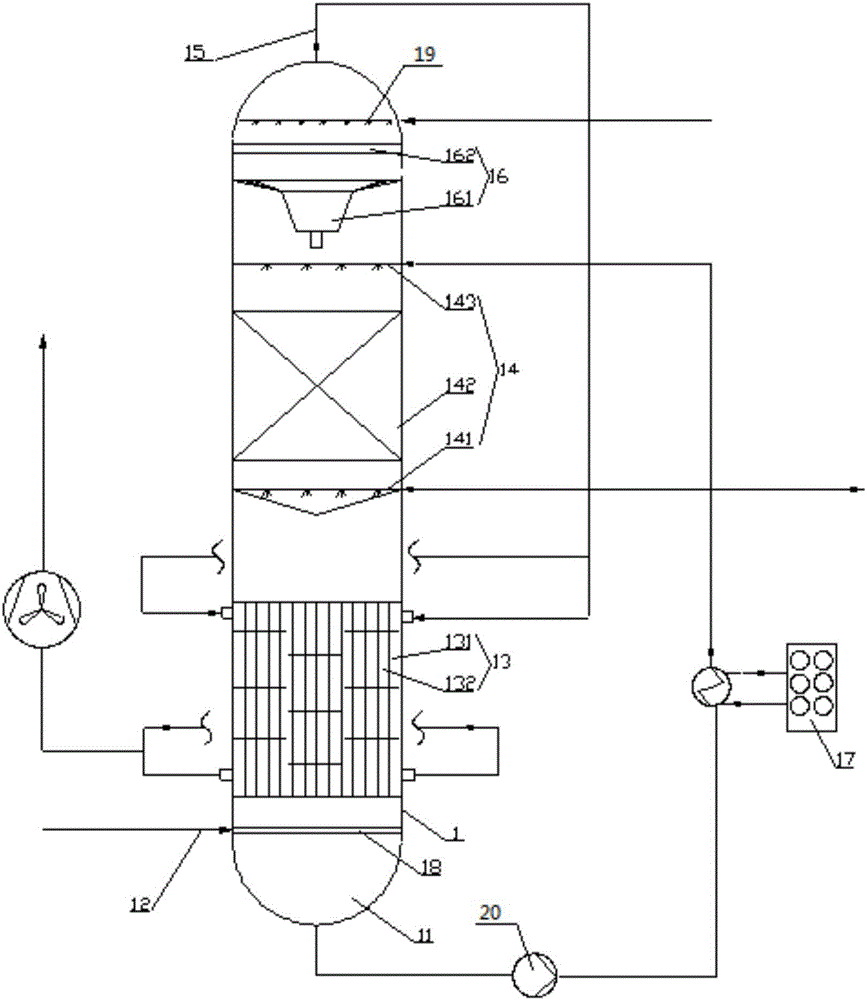

The invention discloses a trapping method for tar in coal gas. The trapping method comprises steps as follows: gas-gas heat exchange: low-temperature gas exchanges heat with high-temperature coal gas, heat of the high-temperature gas is recovered, and the use amount of spray tar is reduced; trapping: low-temperature tar is sprayed on the high-temperature coal gas subjected to heat exchange, so that tar gas in the coal gas is condensed, separated out and recovered through trapping; defogging: tar fog drops about to escape are recovered gradually by use of a two-stage defogger. With the adoption of the tar trapping method, tar can be removed from the coal gas repeatedly, that is, the better tar recovery effect is realized in a tar washing manner. Compared with an existing technology for trapping tar through washing, firstly, the tar trapping method cannot produce a large amount of refractory wastewater, so that the investment, production and operation costs of wastewater treatment equipment are reduced; secondly, the trapping rate is high and secondary investment of an electrical tar precipitator is reduced. Besides, the invention further provides a trapping system for the tar in the coal gas.

Owner:内蒙古京能锡林煤化有限责任公司

Down feather rapid degreasing technology

InactiveCN108166263AEfficient removalGood degreasing effectFibre treatmentDry-cleaning apparatus for textilesSewageSewage treatment

The invention discloses a down feather rapid degreasing technology, and relates to the technical field of down feather processing. The technology comprises following steps: (1) primary preheating; (2)primary degreasing; (3) primary rinsing; (4) secondary preheating; (5) secondary degreasing; and (6) secondary rinsing. Through preheating operation before a degreasing agent is sprayed, grease on down feathers is activated, and thus the degreasing effect is enhanced. The degreasing effect is guaranteed through twice degreasing, and the grease on down feathers is effectively removed. By using a degreasing agent, the degreasing effect is guaranteed, at the same time, the using amount of water is reduced, and the degreasing rate can reach 99% or more. Furthermore, the wastewater generated by degreasing is easy to process, and after a simple treatment, the sewage can be directly discharged.

Owner:马斌祥

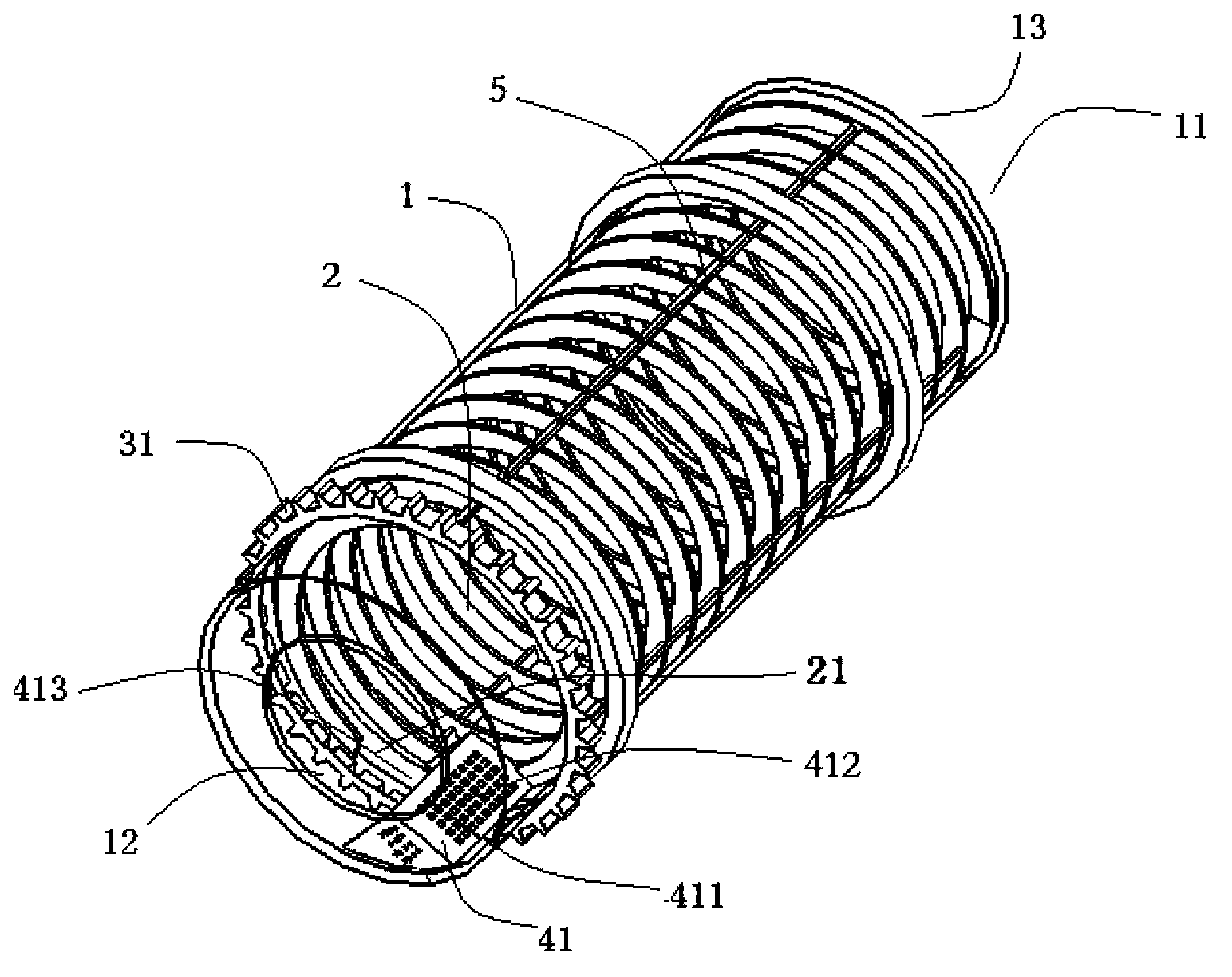

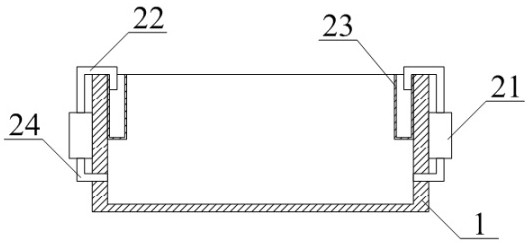

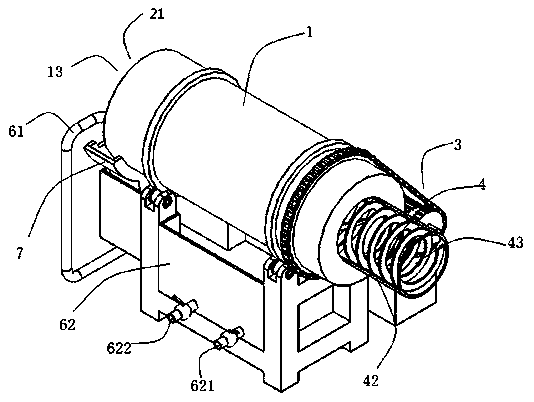

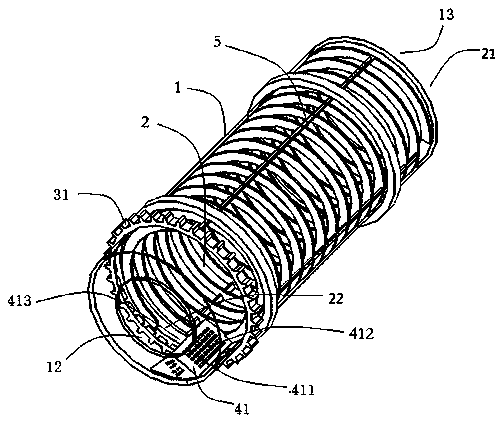

Screw conveying and degreasing device

ActiveCN104117520AAvoid enteringSimple structurePackagingCleaning using liquidsEngineeringMechanical engineering

The invention discloses a screw conveying and degreasing device. The screw conveying and degreasing device comprises a screw conveying roller, a transmission mechanism and a degreasing assembly and further comprises a passing and conveying assembly and a passing roller. The passing and conveying assembly is used for receiving materials output by a first screw channel and conveying the materials to a receiving mechanism of the next working procedure. The passing and conveying assembly includes a bucket fixedly arranged on the inner wall of the screw conveying roller, the bucket is provided with a bucket opening opposite to a first screw outlet of the first screw channel, and a drainage outlet of cleaning fluid is formed in the bucket. One end of the passing roller penetrates through a screw conveying outlet of the screw conveying roller and is located in the screw conveying roller, the other end of the passing roller is connected with the receiving mechanism of the next working procedure, the end, located in the screw conveying roller, of the passing roller is arranged in a closed mode, and a receiving opening is formed in the side wall, close to the closed end, of the passing roller, corresponds to the bucket opening and is used for receiving materials dumped by the bucket. The situation that the cleaning and degreasing part conveys the materials to a drying segment for drying is not affected, and meanwhile the cleaning fluid of the cleaning and degreasing part can be prevented from entering the drying segment.

Owner:SHENZHEN KAIZHONG PRECISION TECH CO LTD

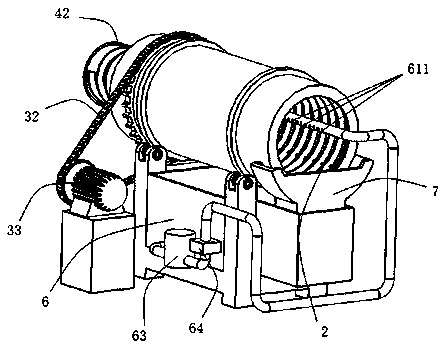

Spiral conveying and degreasing process

ActiveCN104117493AWon't enterAvoid enteringPackagingCleaning using liquidsProcess engineeringMechanical engineering

The invention provides a spiral conveying and degreasing process. In the spiral conveying step, a circulation conveying assembly is arranged and comprises a bucket and a circulation roller, wherein the bucket is fixedly arranged on the inner wall of a spiral conveying roller and provided with a bucket opening; the bucket opening is opposite to a first spiral outlet of a first spiral channel, and a cleaning fluid filtering port is formed in the bucket; one end of the circulation roller penetrates through a spiral conveying outlet of the spiral conveying roller and is located in the spiral conveying roller, and the other end of the circulation roller is connected with a material receiving mechanism in the next process; the end, located in the spiral conveying roller, of the circulation roller is closed, and a receiving port corresponding to the bucket opening is formed in the sidewall, close to the closed end, of the circulation roller and used for receiving materials dumped by the bucket. By the adoption of the spiral conveying and degreasing process, the process that a degreasing portion conveys the materials to a drying section for drying is not affected, and degreasing agents of the degreasing portion can also be prevented from entering the drying section.

Owner:SHENZHEN KAIZHONG PRECISION TECH CO LTD

Automatic cleaning device for oily fume purifying

PendingCN107638740AGuaranteed degreasing effectDomestic stoves or rangesLighting and heating apparatusEngineeringDrive motor

The invention relates to the technical field of oily fume purifying, in particular to an automatic cleaning device for oily fume purifying. The automatic cleaning device comprises an oily fume separating tank, wherein a fume inlet of the oily fume separating tank is equipped with a baffle plate; oily fume separators which are connected with a drive motor are uniformly distributed and embedded intothe baffle plate; and cleaning structures for automatically cleaning the oily fume separator are further arranged on the baffle plate. The automatic cleaning device can clean the oily fume separatorsanytime when the equipment normally works, so that the oil removal effect is guaranteed.

Owner:中山市康丽净油烟净化科技有限公司

Efficient degreasant special for natural leather

ActiveCN108642217AReduce pollutionReduce processing difficultyLeather degreasingWater useDecyl glucoside

The invention discloses an efficient degreasant special for natural leather, and relates to the technical field of leather processing. The efficient degreasant comprises raw materials, by weight, 15-20 parts of decyl glucoside, 10-15 parts of PEG-60 hydrogenated castor oil, 5-10 parts of lauroyl sodium glutamate, 5-10 parts of water treatment level polyglutamic acid, 1-5 parts of poloxamer 188, 1-5 parts of polyoxyethylene, 1-5 parts of chitosan quaternary ammonium salt, 0.5-3 parts of hydrolytic polymaleic anhydride and 0.1-1 part of ethylenediamine tetraacetic acid disodium salt. The degreasing rate of the prepared degreasant reaches 80% or above, the degreasant belongs to a low foam type degreasant, only a small quantity of foams are generated after the degreasant is dissolved into water, and therefore the follow-up water using quantity is reduced; and meanwhile, the prepared degreasant is mild in chemical property, and the fiber structure of the natural leather cannot be damaged.

Owner:嘉兴宏麟皮化有限公司

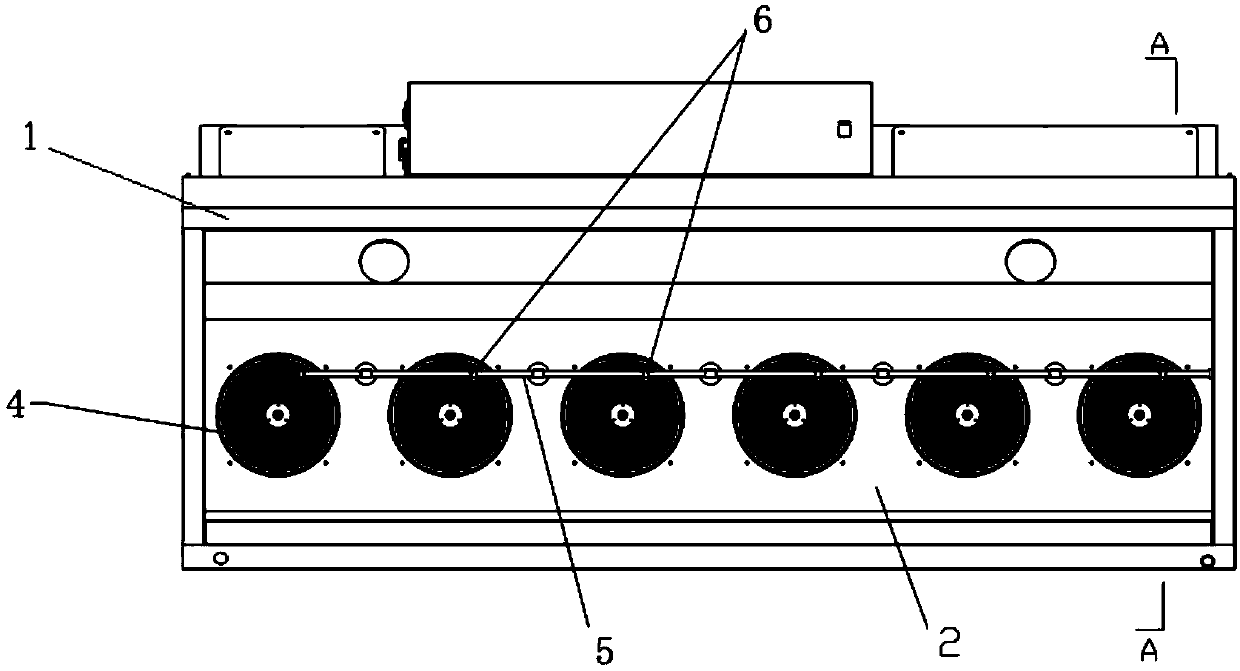

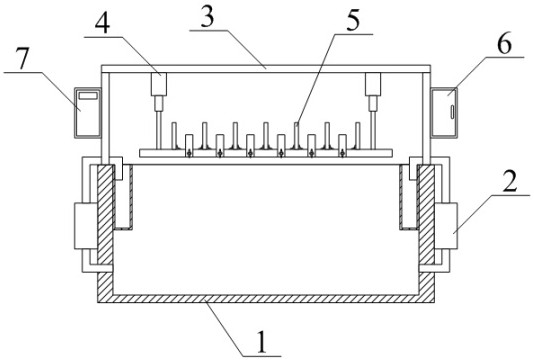

Degreasing device

PendingCN108301010AEasy to realize scrubbingGuaranteed degreasing effectCleaning using toolsSteel beltEngineering

The invention relates to the technical field of steep strip machining, in particular to a degreasing device, which can effectively guarantee the degreasing effect. The degreasing device comprises a degreasing box; and a spraying head is mounted in the degreasing box, and is connected with an alkali liquid box through a liquid inlet pipeline. The degreasing device is characterized in that the degreasing box is provided with a feeding rubber roller pair at an inlet end and a water stop rubber roller pair at an outlet end; a brushing roller mechanism is mounted in the degreasing box, and comprises a front bracket and a back bracket; upper brushing rollers and lower rubber rollers are mounted on the front bracket in a staggered manner; and upper rubber rollers and lower brushing rollers are mounted on the back bracket in a staggered manner.

Owner:WUXI CITY XIDONG RUBBER & PLASTICS MACHINERY

Method for oxidizing brake master cylinder

The invention discloses a method for oxidizing a brake master cylinder, which comprises the following steps of: 1, hanging, namely hanging the brake master cylinder to a rack special for oxidizing the brake master cylinder; 2, performing weak acid oil removal treatment; 3, preparing anode oxidizing tank liquor; 4, performing anode oxidization treatment; and 5, taking out the brake master cylinder, cleaning, and performing enclosed drying treatment. The brake master cylinder treated by the method meets the industrial requirements on quality such as film thickness, roughness, hardness and the like.

Owner:JIANGSU RUIER LONGDING IND CO LTD

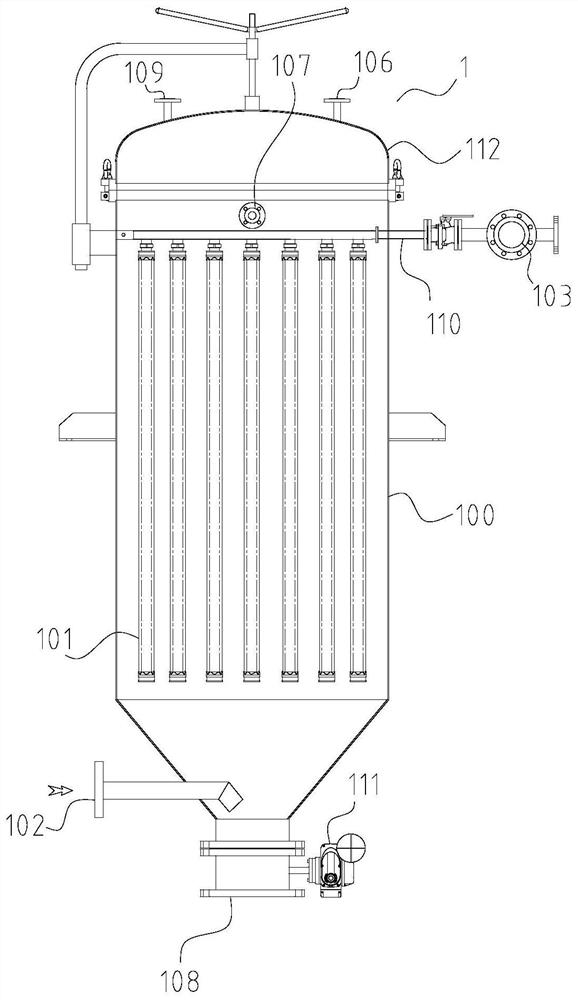

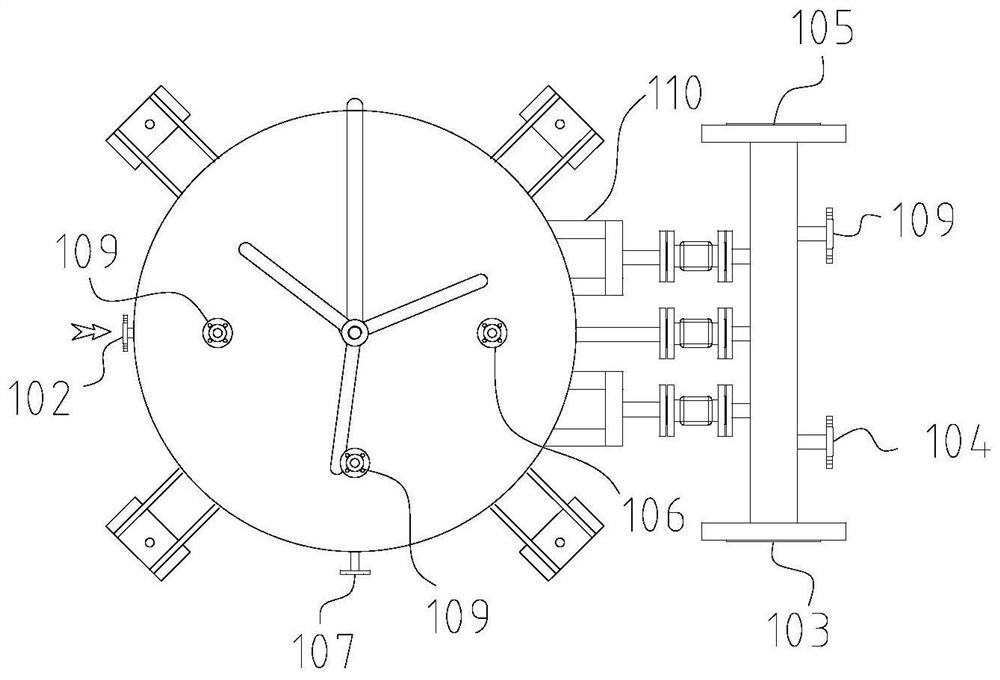

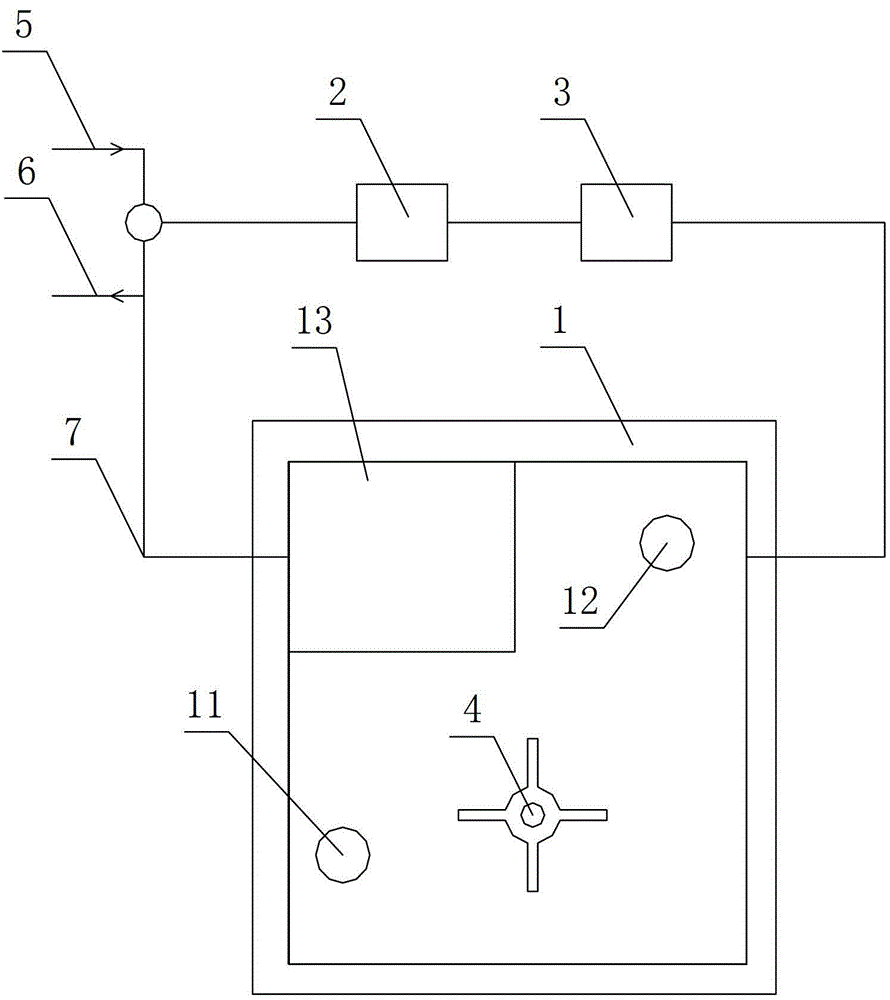

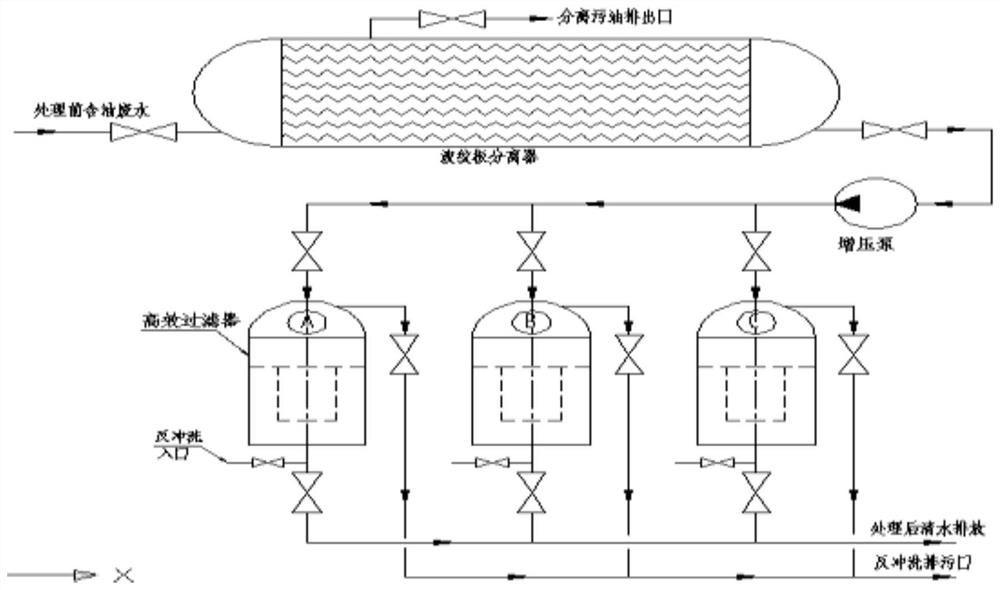

Coking wastewater oil removal treatment device and method

PendingCN111807540AEasy to handleGuaranteed degreasing effectWater/sewage treatment by centrifugal separationFatty/oily/floating substances removal devicesThermodynamicsFiltration

The invention relates to a coking wastewater oil removal treatment device and method. The device comprises a coking wastewater pre-filter and an oil-water separator, the coking wastewater pre-filter comprises a barrel, a filter element installed in the barrel, filter cloth arranged outside the filter element in a sleeving mode, a liquid outlet pipe connected with the filter element, a blowback pipe, a circulating pipe and a liquid inlet pipe connected with the barrel, a forward blowing port is formed in the barrel, a slag discharging port is formed in the bottom of the barrel, the other end ofthe circulating pipe is connected with the barrel, the oil-water separator comprises a tank body, and a rotational flow gathering and filtering cavity, a primary coarse filtration gathering cavity, aW-shaped corrugated plate cavity, a secondary fine filtration adsorption cavity and a water outlet transition cavity which are arranged in the tank body, a water inlet pipe connected with the rotational flow gathering and filtering cavity and a water outlet pipe connected with the water outlet transition cavity are arranged on the tank body, an oil collecting bag is arranged at the top of the tank body and is connected with an oil outlet pipe, and the liquid outlet pipe is connected with the water inlet pipe. The invention further relates to a method for treating coking wastewater by using the coking wastewater oil removal treatment device. The problem that coking wastewater is difficult to treat is solved.

Owner:青岛百利达环保科技有限公司

A fluorocarbon coating process for building materials

InactiveCN108889588AGuaranteed degreasing effectEnhanced adhesion and corrosion resistancePretreated surfacesCoatingsIonRadiation protection

The invention discloses a fluorocarbon coating process for building materials, which comprises the following steps: pretreatment, primer coating, drying and cooling, back coating, drying and cooling,middle coating, drying and cooling, surface coating, drying and cooling, and winding up. As that aluminum plate is treat by the roll coating proces, the aluminum plate can not be further corroded dueto residual metal impurity ions, The defatting effect of the substrate is fully guaranteed, the adhesion and corrosion resistance of the substrate and the coating are enhanced, and the aluminum plateobtained by the fluorocarbon coating process is provided with the advantages of strong corrosion resistance, low thermal conductivity, radiation protection and good decorative effect after the aluminum plate is backcoated, primed, medium coated and surface coated. The aluminum plate obtained by the fluorocarbon coating process has the advantages of strong corrosion resistance, low thermal conductivity, and good decorative effect.

Owner:安徽墙煌彩铝科技有限公司

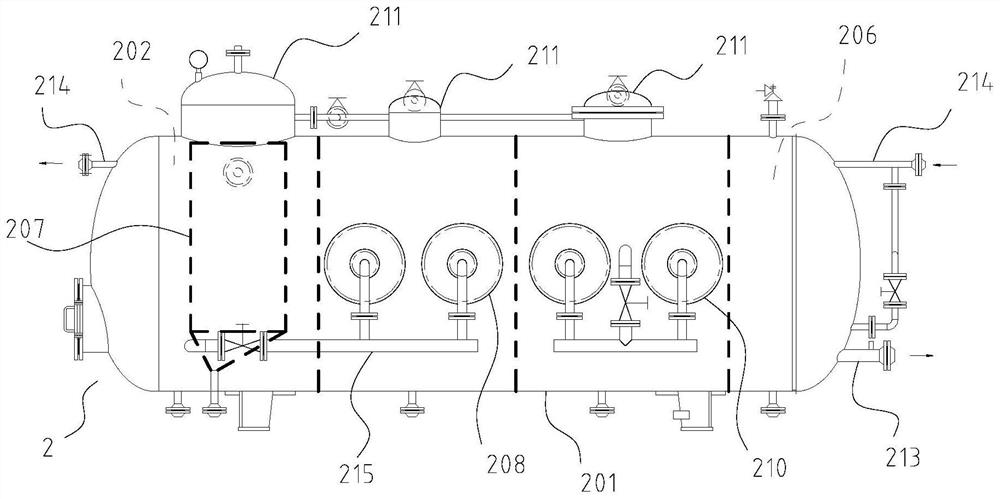

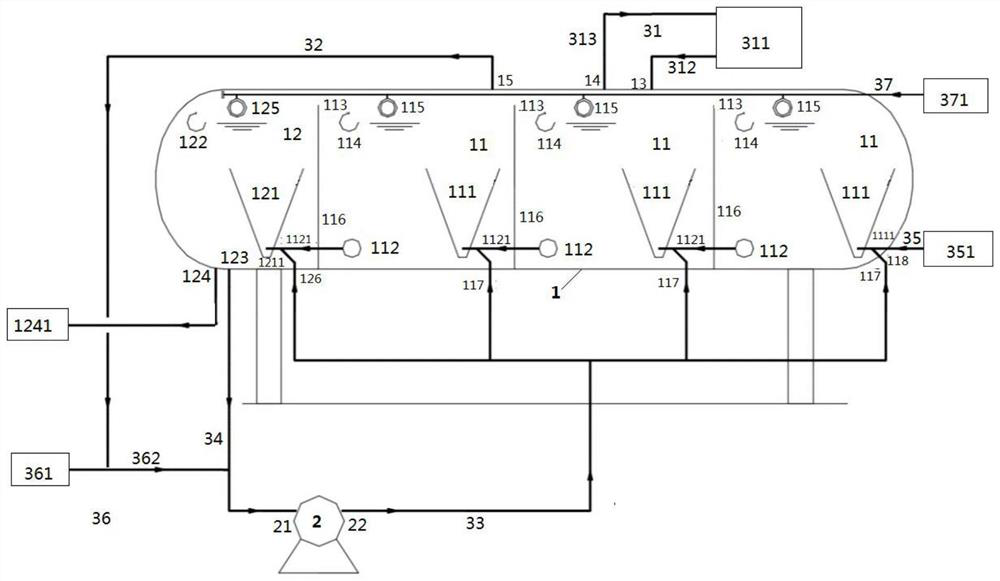

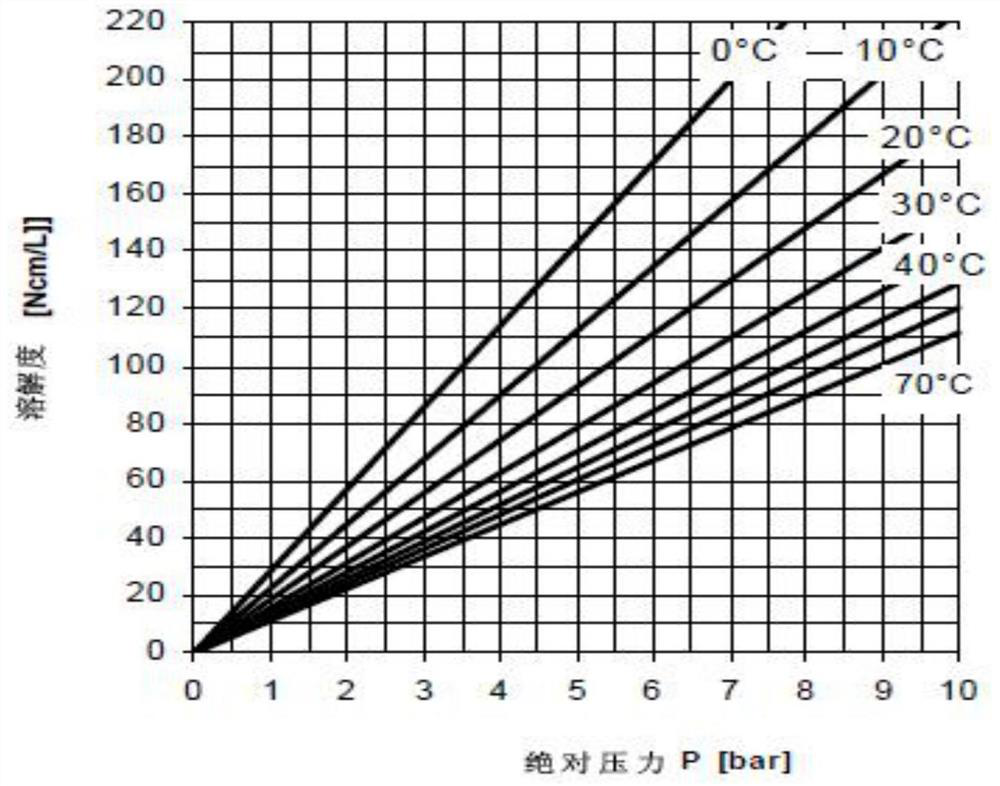

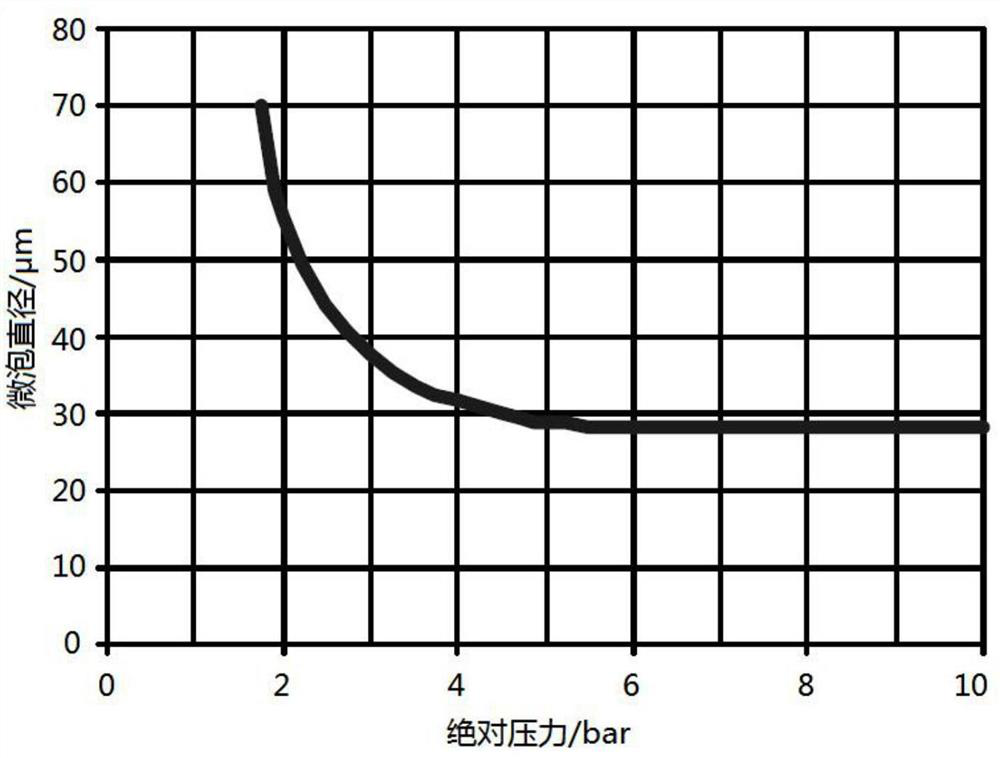

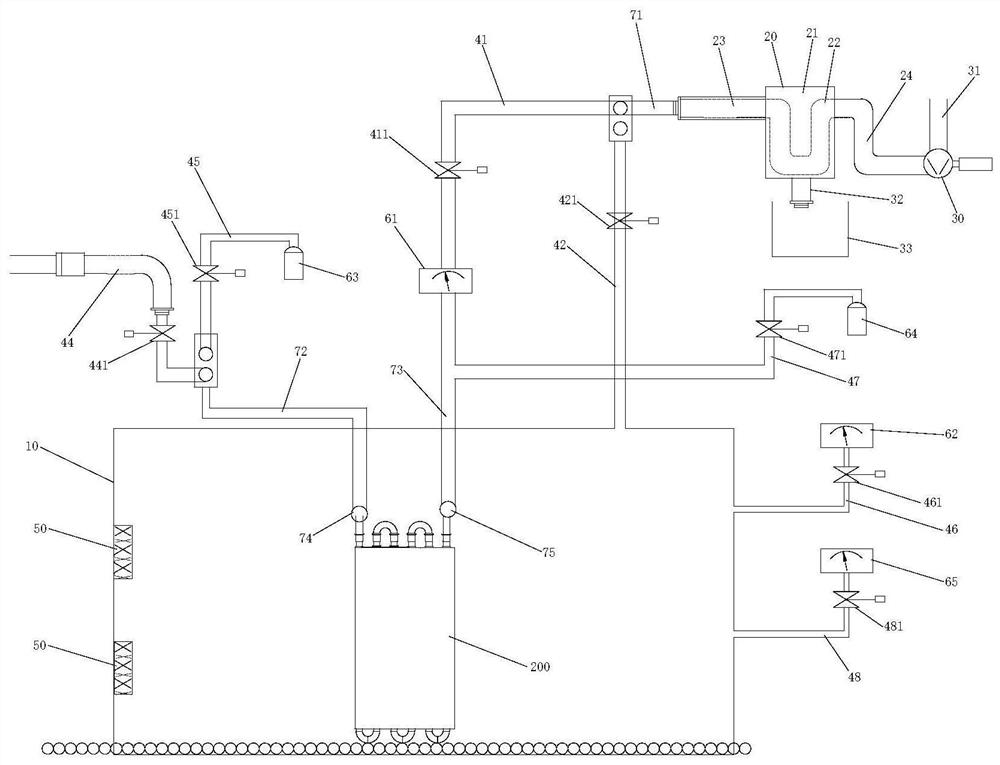

Device and method for bleed air backflow recycling multi-stage baffling microbubble flotation oil removal

PendingCN114477350ASmall granularitySmall particle sizeWaste water treatment from quariesWater contaminantsAir pumpOil field

The invention provides a device and a method for deoiling by entraining, refluxing and reusing multistage baffling microbubble flotation, and relates to the technical field of deoiling of oilfield produced water. The multistage baffling microbubble flotation oil removal device for entrained air backflow recycling comprises an air flotation tank, a dissolved air pump and an electric control system, and a vortex reactor, a T-shaped water passing opening and an adjustable oil collecting groove are arranged in the air flotation tank; a nitrogen pressure automatic balancing pipeline system, a nitrogen entraining return pipeline, a dissolved air water replenishing pipeline, a dissolved air water return pipeline and an oil-containing raw water extraction pipeline are arranged outside the air floatation tank; the air dissolving efficiency is improved and the particle size of microbubbles is reduced by controlling the inlet and outlet pressure of an air dissolving pump; the vortex reactor slows down the bubble gathering and floating speed and prevents short flow; according to the nitrogen pressure automatic balancing pipeline system, a stable gas phase space can be formed at the inner top of the air floatation tank, the liquid level is kept stable, separated nitrogen serves as a gas source of the gas dissolving pump to be recycled, and the consumption of the nitrogen is greatly reduced.

Owner:SINOPEC SSC +1

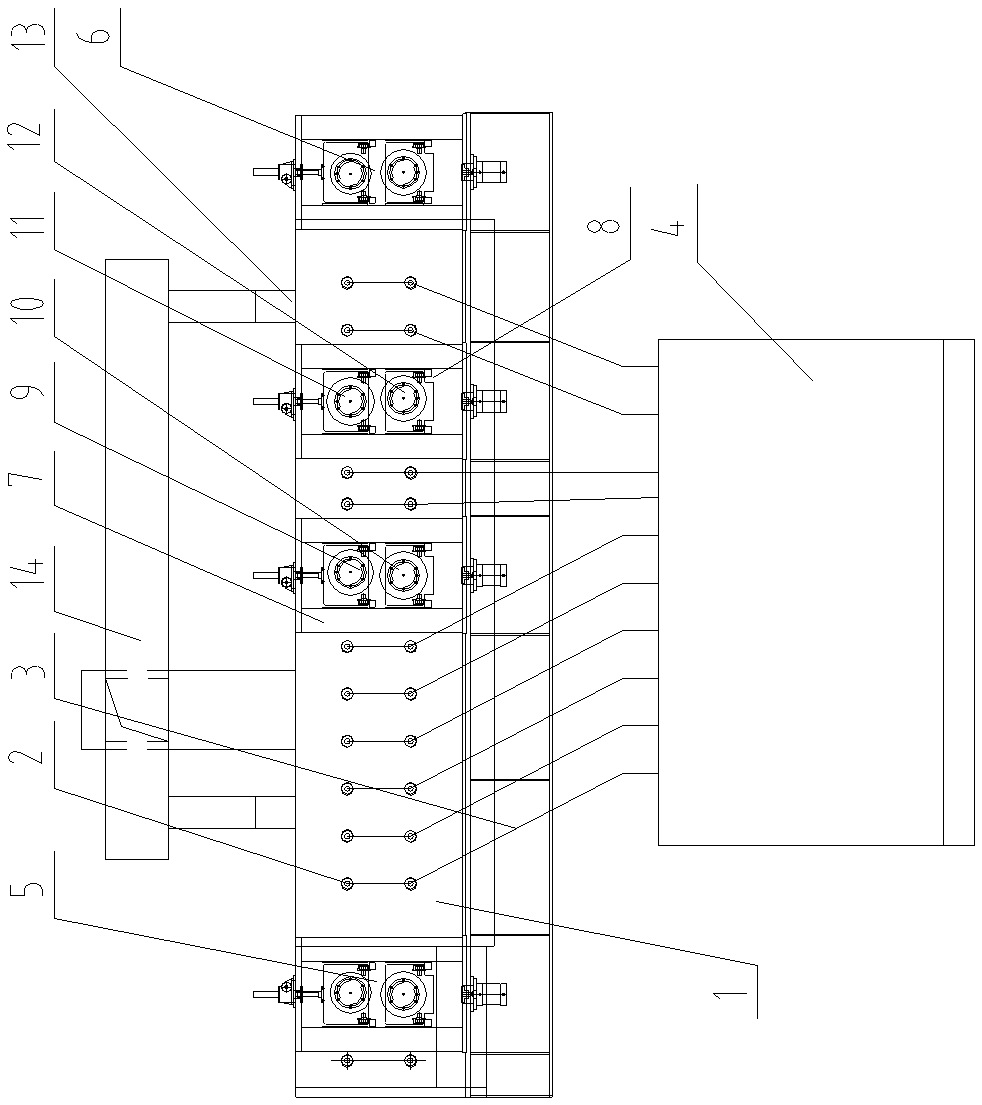

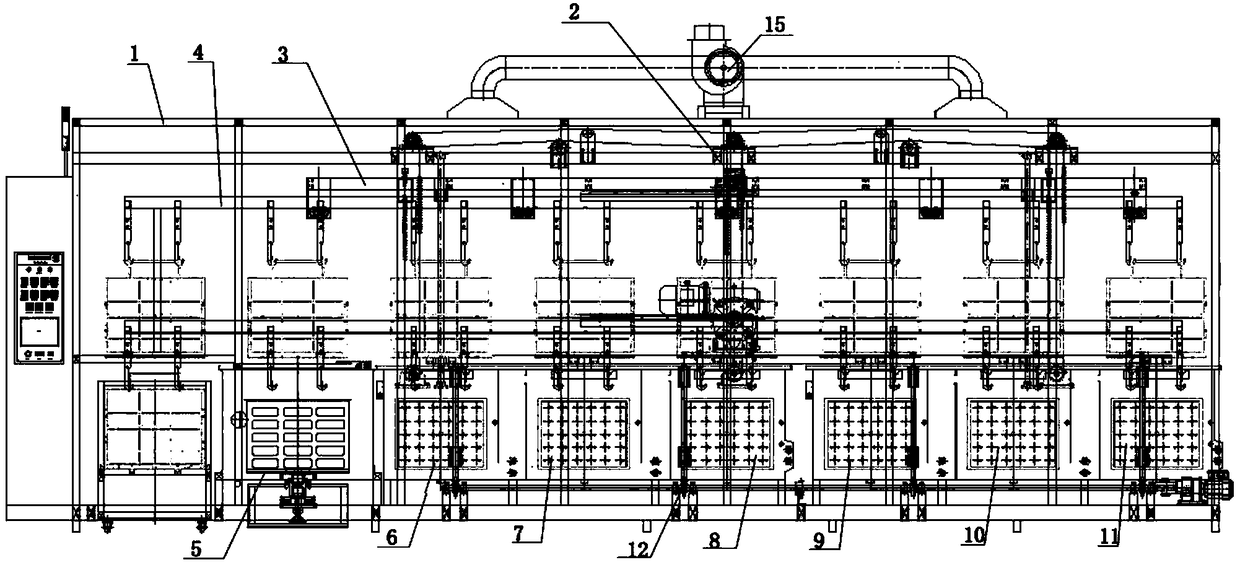

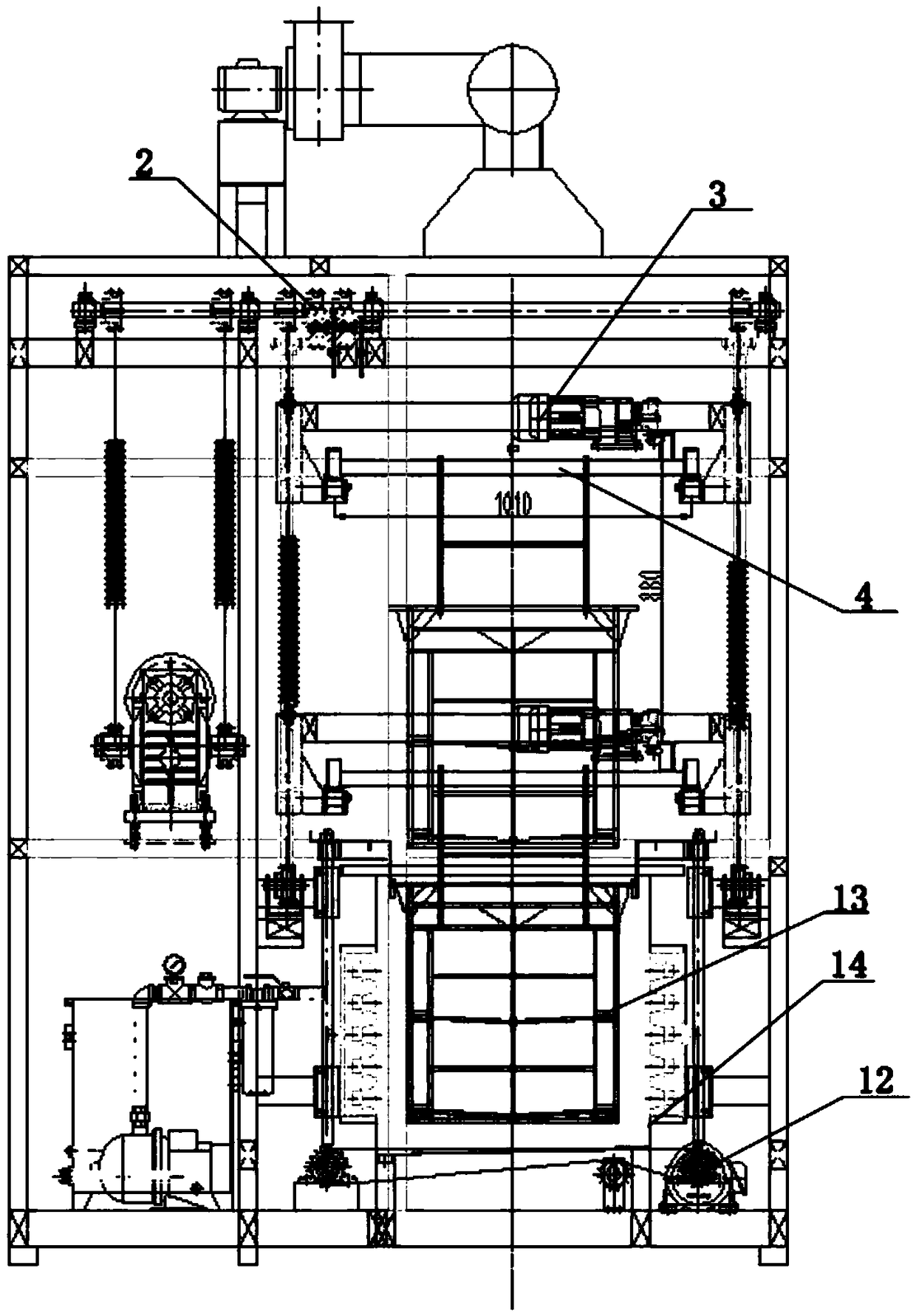

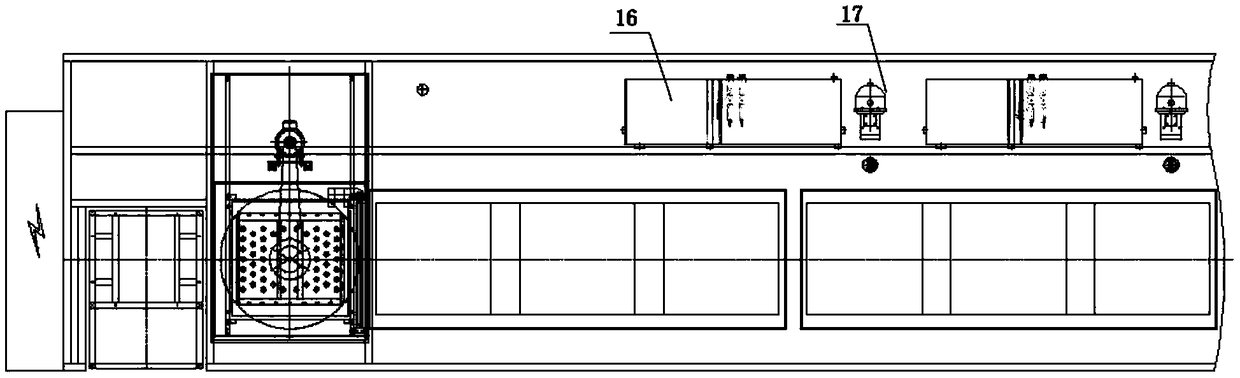

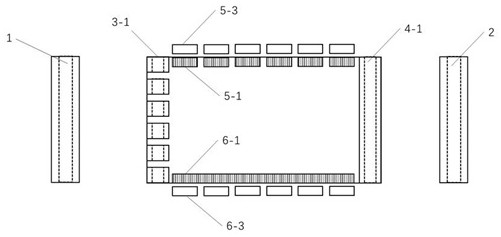

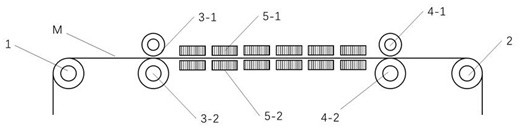

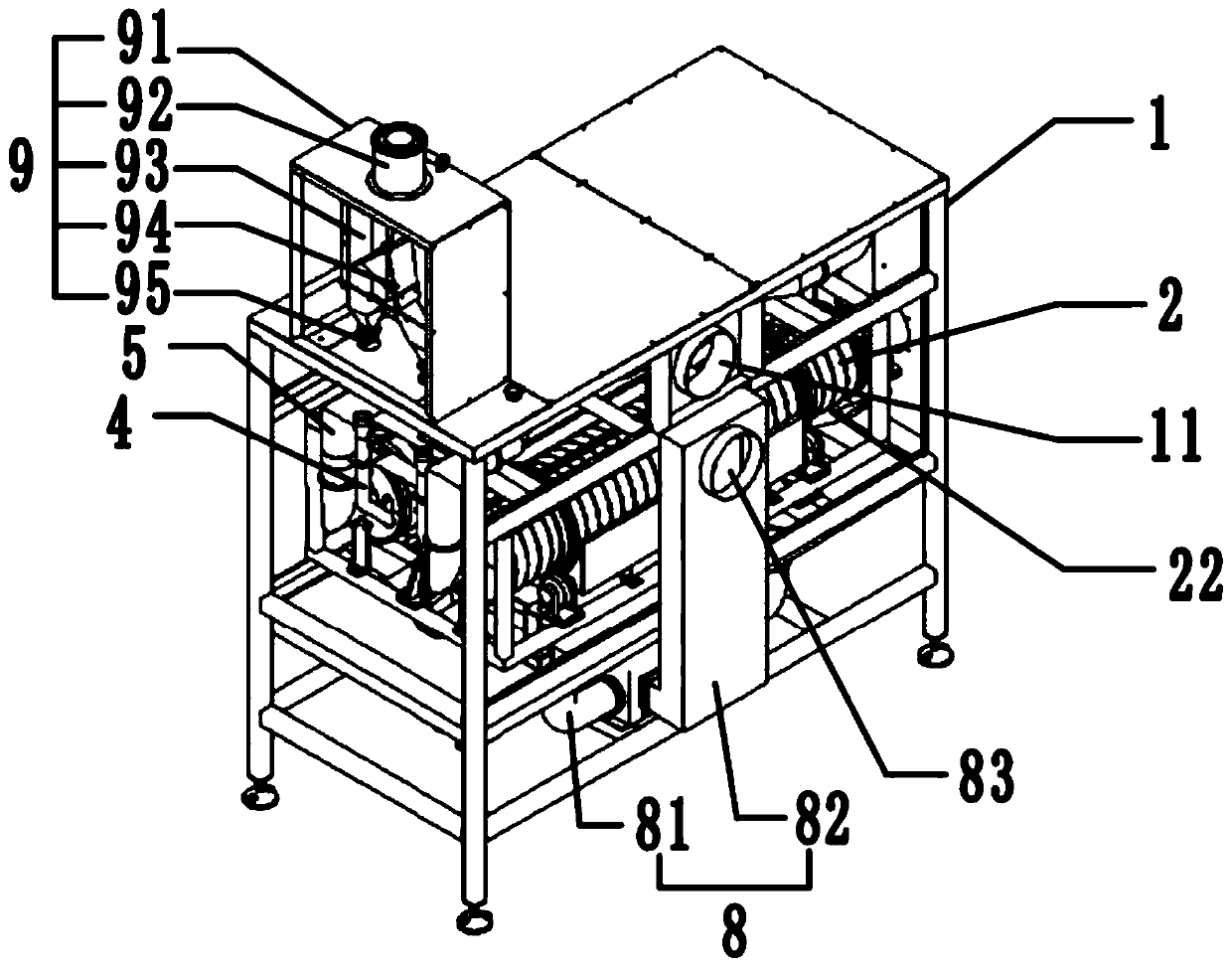

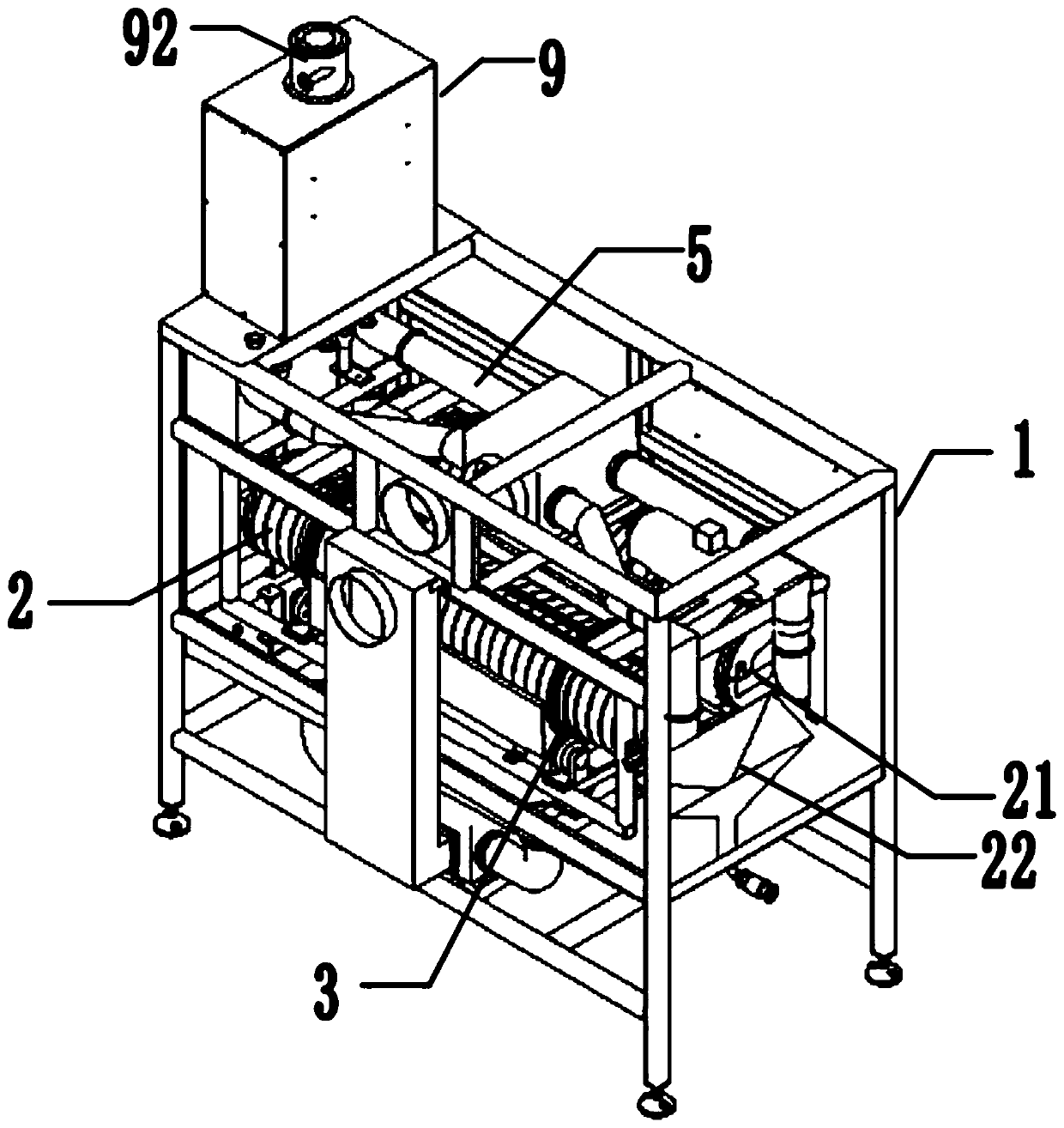

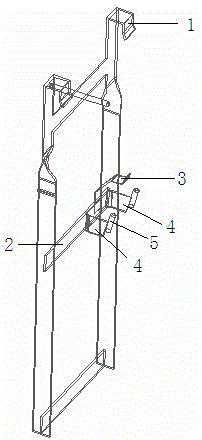

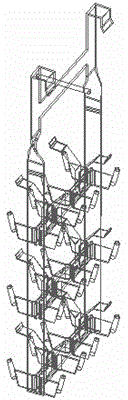

Aluminum shell cleaning machine automatic production line multi-groove continuous oil removal system

PendingCN109317457AGuaranteed degreasing effectKeep clean environmentCleaning using liquidsProduction lineMoving frame

The invention discloses an aluminum shell cleaning machine automatic production line multi-groove continuous oil removal system. The system comprises a machine frame, a multi-arm lifting mechanism, amulti-arm lifting frame, a multi-arm transverse moving frame, an oil throwing groove, a plurality of oil removing grooves and a simulation shaking mechanism, the multi-arm lifting mechanism is arranged at the top of the machine frame, the multi-arm lifting mechanism is connected with the multi-arm transverse moving frame through the multi-arm lifting frame, the multi-arm lifting mechanism drives the multi-arm lifting frame to move up and down, the multi-arm transverse moving frame moves left and right along the multi-arm lifting frame, the oil throwing groove and the plurality of oil removinggrooves are sequentially formed in the bottom of the machine frame from left to right, groove bodies are arranged in the oil throwing groove and the oil removing grooves, and the simulation shaking mechanism for shaking the groove bodies in the oil removing grooves up and down are further arranged at the bottom of the machine frame. According to the system, human-simulation up-down shaking operation is realized, and the oil removal effect of the inner wall and the outer wall of the aluminum shell is ensured.

Owner:JIANGDONG ELECTRONIC MATERIALS CO LTD

Oil-containing high-concentration phenol-ammonia wastewater treatment device and process

PendingCN113716776AHigh removal rateHigh recovery rateFatty/oily/floating substances removal devicesWater contaminantsOil separationProcess engineering

The invention discloses an oil-containing high-concentration phenol-ammonia wastewater treatment device and process. The oil-containing high-concentration phenol-ammonia wastewater treatment device comprises an oil removal reaction tank, an oil removal separation tank, an extraction sieve-plate tower, a deacidification tower, a deamination tower and the like. Oil substances in wastewater are removed and recovered by adopting demulsification, gravity settling and pre-extraction methods, and various phenols and ammonia substances in water are effectively treated by combining a complexing extraction method and a stripping method, so that efficient removal and recovery of phenols and ammonia are realized, and cyclic utilization of an extraction agent is ensured. According to the process technology, the removal rate of petroleum substances in the wastewater is larger than 90%, the removal rate of total phenols is larger than 85%, the removal rate of NH4-N is larger than 95%, oil, phenol ammonia and acidic substances can be efficiently and economically removed and recycled through quality-divided advanced treatment of the wastewater, and the process technology is high in reliability and high in adaptability to sewage and has good economic benefits and social benefits.

Owner:CHINA CONSTR IND & ENERGY ENG GRP CO LTD

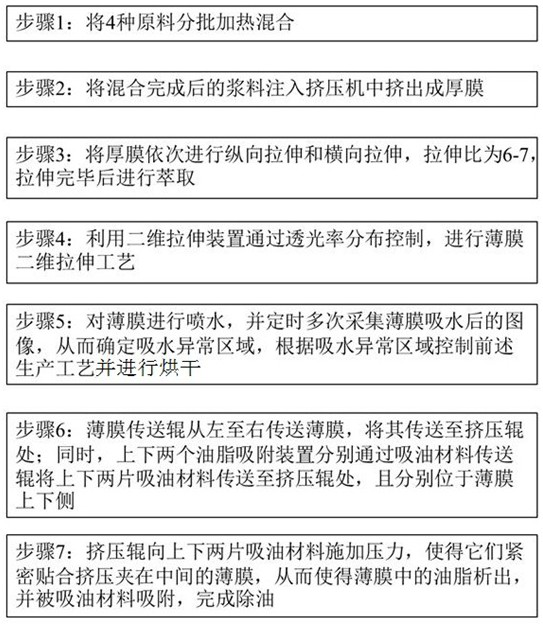

Film without grease residue and preparation method thereof

ActiveCN111933867AReduce usageAvoid damageLi-accumulatorsCell component detailsCresolSilicon dioxide nanoparticles

The present invention provides a film without grease residue and a preparation method thereof. The method comprises the steps of: mixing and heating polyethylene, paraffin oil, silicon dioxide nanoparticles and 4, 4'-sulfo-bis(6-tert-butyl-m-cresol) in batches, performing extrusion molding, performing transverse stretching and longitudinal stretching respectively, and performing two-dimensional stretching; and after stretching is finished, feeding the film into an oil removal device, and carrying out oil removal operation on the film under the action of an extrusion roller and an oil absorption material, so as to prepare the lithium battery diaphragm without grease residues.

Owner:河南银金达新材料股份有限公司

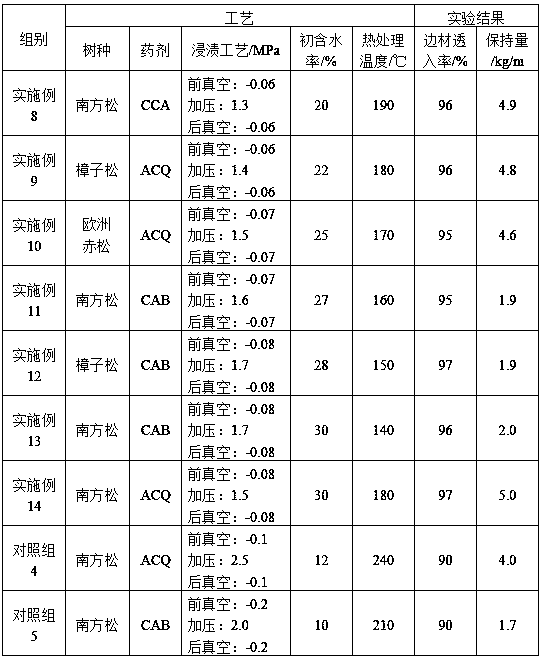

A kind of outdoor material degreasing treatment method and its anticorrosion treatment method

ActiveCN109049201BAvoid oily situationsGuaranteed degreasing effectWood treatment detailsThermal wood treatmentProcess engineeringEnvironmental engineering

Owner:丰胜(广州)建材有限公司

Surface deoiling device for steel pipe machining

The invention provides a surface deoiling device for steel pipe machining. The surface deoiling device for steel pipe machining comprises a soaping box, filtering assemblies, a supporting frame, hydraulic rods, a placing assembly, an electric control cabinet and a PLC. According to the surface deoiling device, due to the arrangement of the placing assembly, during use, steel pipes are placed between baffles, the steel pipes are supported and limited through base plates, and the phenomenon that the steel pipes move is avoided; the hydraulic rods are adopted to drive the placing assembly to movedownwards, the steel pipes are conveniently placed in the soaping box, deoiling operation is conducted through soaping liquid, the hydraulic rods drive the placing assembly to move upwards, the steelpipes are conveniently taken out, time and labor are saved, and the working efficiency of the deoiling device is improved; due to the arrangement of the filtering assemblies, a circulating pump conveys the soaping liquid into a filtering box through a liquid suction pipe and a liquid conveying pipe, impurities in the soaping liquid are removed through a filtering net in the filtering box, the deoiling effect of the soaping liquid is guaranteed, secondary pollution caused by the impurities to the steel pipes is avoided, the filtering box is taken down regularly to remove the impurities in thefiltering box, and normal operation of the filtering assemblies is guaranteed.

Owner:天长市康弘石油管材有限公司

Chemical oil removal device capable of supplementing active ingredients

ActiveCN102995042BGood emulsifying effectHigh oil removal efficiencyBULK ACTIVE INGREDIENTActive ingredient

Owner:泰州市海通资产管理有限公司

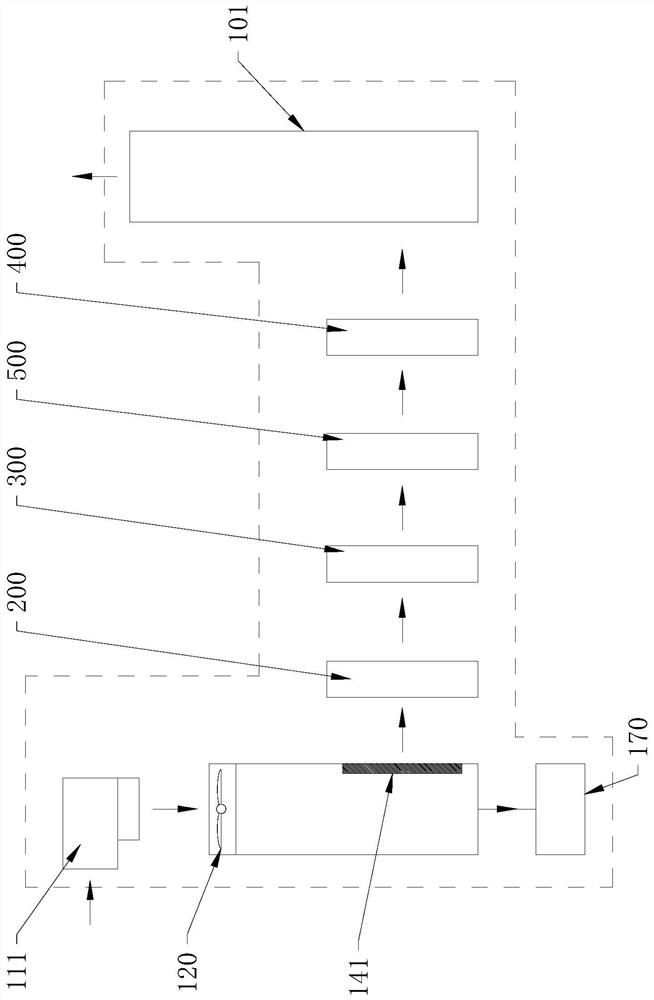

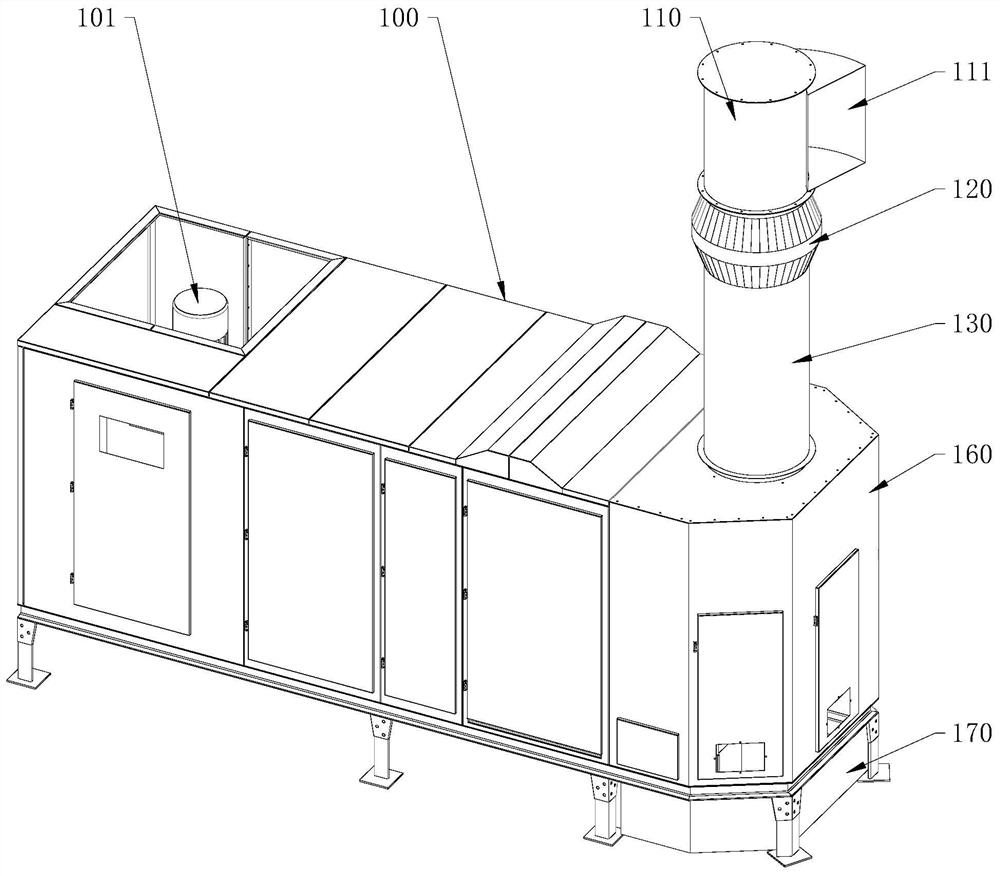

Intelligent purification system for industrial lampblack

PendingCN113694669AImprove purification qualitySolve the single functionCombination devicesGas treatmentActivated carbonFlue gas

The invention provides an intelligent industrial lampblack purification system, which belongs to the technical field of industrial lampblack purification equipment and comprises a water washing device, an air system and a water system. The water washing device comprises a water washing pipe longitudinally connected to the flue gas pipeline, a rotational flow plate, a water washing nozzle and a water-proof net plate; the air system comprises a purification box and an air duct penetrating through the purification box; a primary filter screen, an electric field filter module, an ultraviolet module and an activated carbon module are sequentially arranged in the air duct; the electric field filtering module comprises a plurality of ionization plates; the ultraviolet module comprises a plurality of ultraviolet lamp tubes; the activated carbon module comprises a plurality of activated carbon boxes; the water system comprises a circulating water tank located below the washing pipe and a circulating water pipe connected with the circulating water tank and the washing nozzle. According to the intelligent purification system for industrial oil smoke, smoke is purified in multiple modes, so that the problem that existing industrial oil smoke purification equipment is single in function is solved, the oil smoke purification quality is improved, and the oil removal effect and smoke purification are guaranteed.

Owner:张家口航科环保设备有限公司

Emergency disposal method and equipment for emergency transformer oil of extra-high voltage power station

ActiveCN114797177AEasy to handleEfficient degreasing abilityLiquid separation auxillary apparatusOther chemical processesPower stationSorbent

The invention discloses an emergency disposal method and equipment for emergency transformer oil of an extra-high voltage power station in the technical field of environmental protection. The emergency disposal method mainly comprises the following steps: firstly, collecting an oil-water mixture leaked to an accident oil pool by using an oil bag; then carrying out oil-water separation on the collected oil-water mixture by using a polymer corrugated plate to obtain a pretreated oil-water mixture; carrying out oil-water separation on the pretreated oil-water mixture by using an adsorption tank; the adsorption tank adopts a chitosan adsorbent; separating impurities such as adsorbent powder by adopting a pressurization method; and finally discharging the treated wastewater.

Owner:孝感市光源电力集团有限责任公司

A self-circulating chemical degreasing method

The invention discloses a self-circulation type chemical degreasing method. The method comprises the following steps: injecting hot water into a degreasing chamber; injecting degreasing powder into the hot water in the degreasing chamber to form solution; starting a stirrer to stir the solution; enabling metal parts to enter the degreasing chamber to be soaked in the solution; acquiring the first temperature of the solution in real time; and comparing the first temperature with the preset second temperature, and gradually extracting and heating the solution in the degreasing chamber and then circulating the solution back to the degreasing chamber when the first temperature is lower than the second temperature. The method has the beneficial effects that the wastewater after treatment is easy to treat; the degreasing effect is good; and the degreasing speed is high.

Owner:山东益华生物科技有限公司

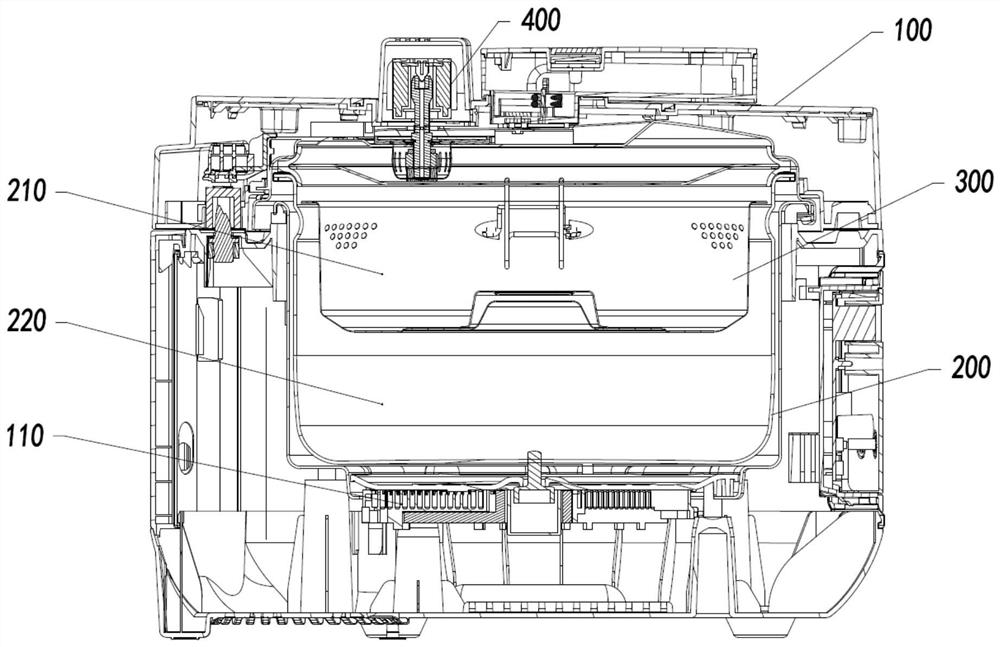

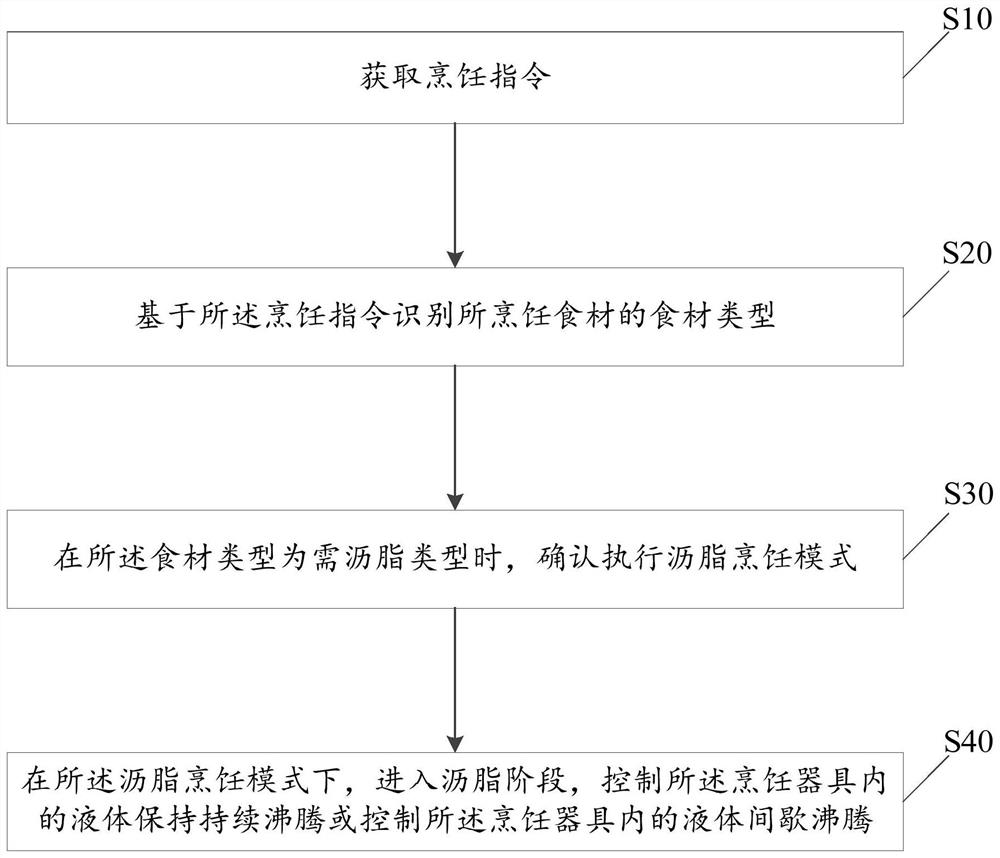

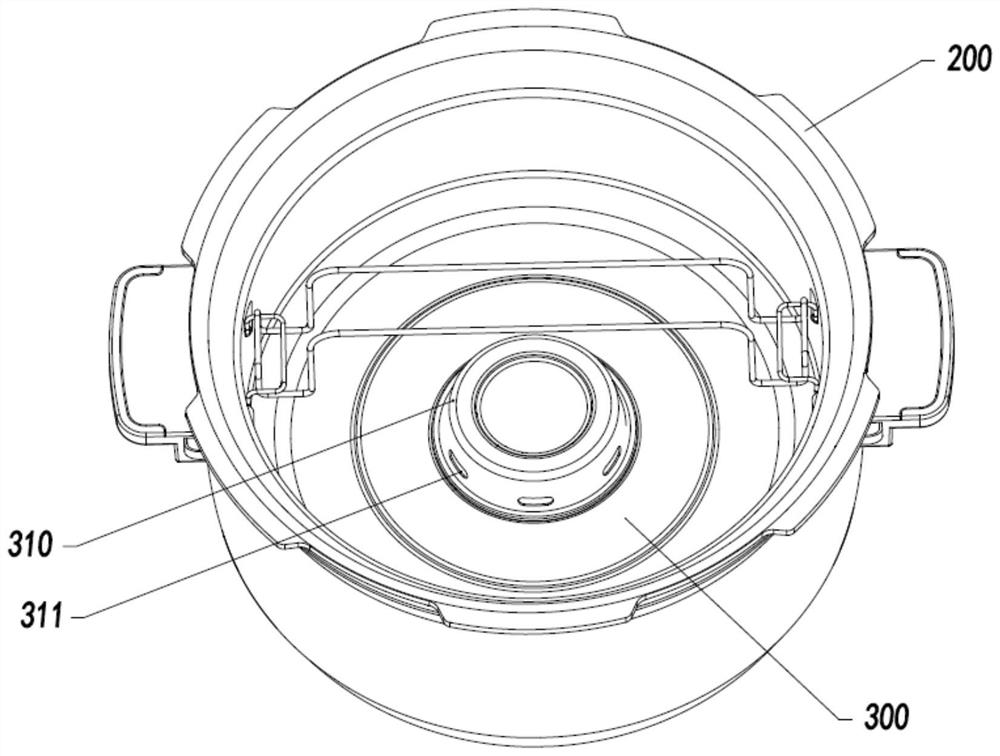

Cooking utensil control method and cooking utensil

PendingCN114680605AIn line with personalized usage habitsDietary preference controlPressure-cookersProcess engineeringFood material

The invention discloses a cooking utensil control method and a cooking utensil, a fat draining kettle can be placed in the cooking utensil, and the control method comprises the steps of obtaining a cooking instruction; identifying a food material type of a cooked food material based on the cooking instruction; when the food material type is the type needing fat draining, it is confirmed that a fat draining cooking mode is executed, in the fat draining cooking mode, a fat draining stage is entered, and liquid in the cooking utensil is controlled to keep boiling continuously or liquid in the cooking utensil is controlled to boil intermittently. After the cooking procedure is started, whether the fat draining kettle is placed or not is judged firstly, after it is confirmed that the fat draining kettle is placed, the cooking procedure is started, and a fat draining cooking mode can be started automatically. The problem that a user forgets to input a fat draining instruction when needing to cook low-fat food or forgets to place a fat draining kettle, and consequently fat draining cannot be achieved can be solved.

Owner:HONGYANG HOME APPLIANCES

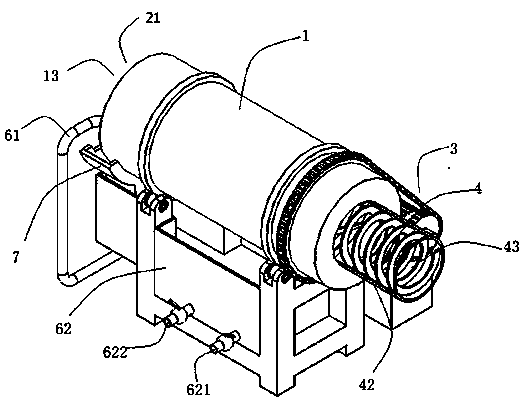

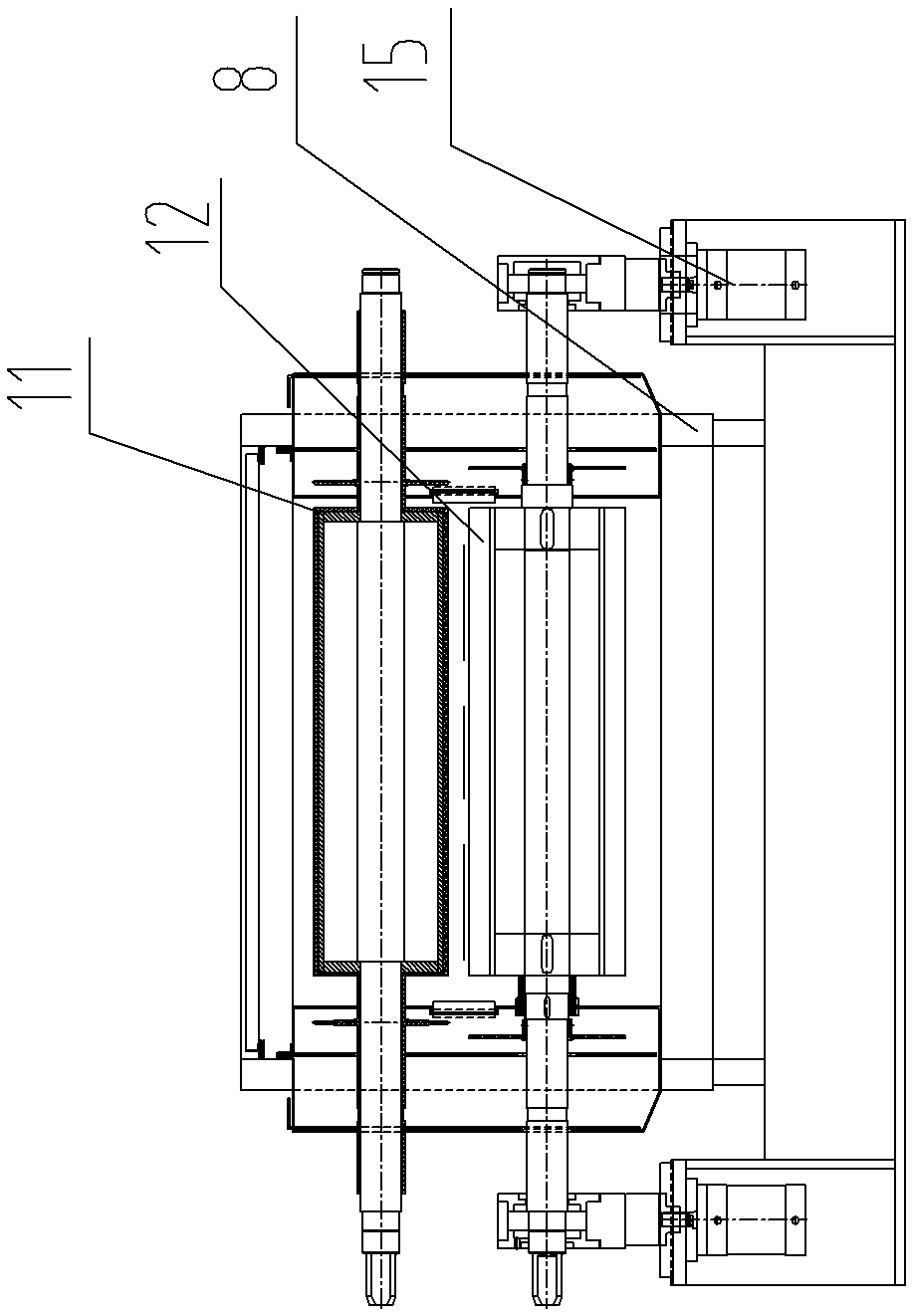

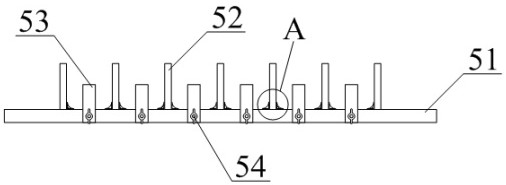

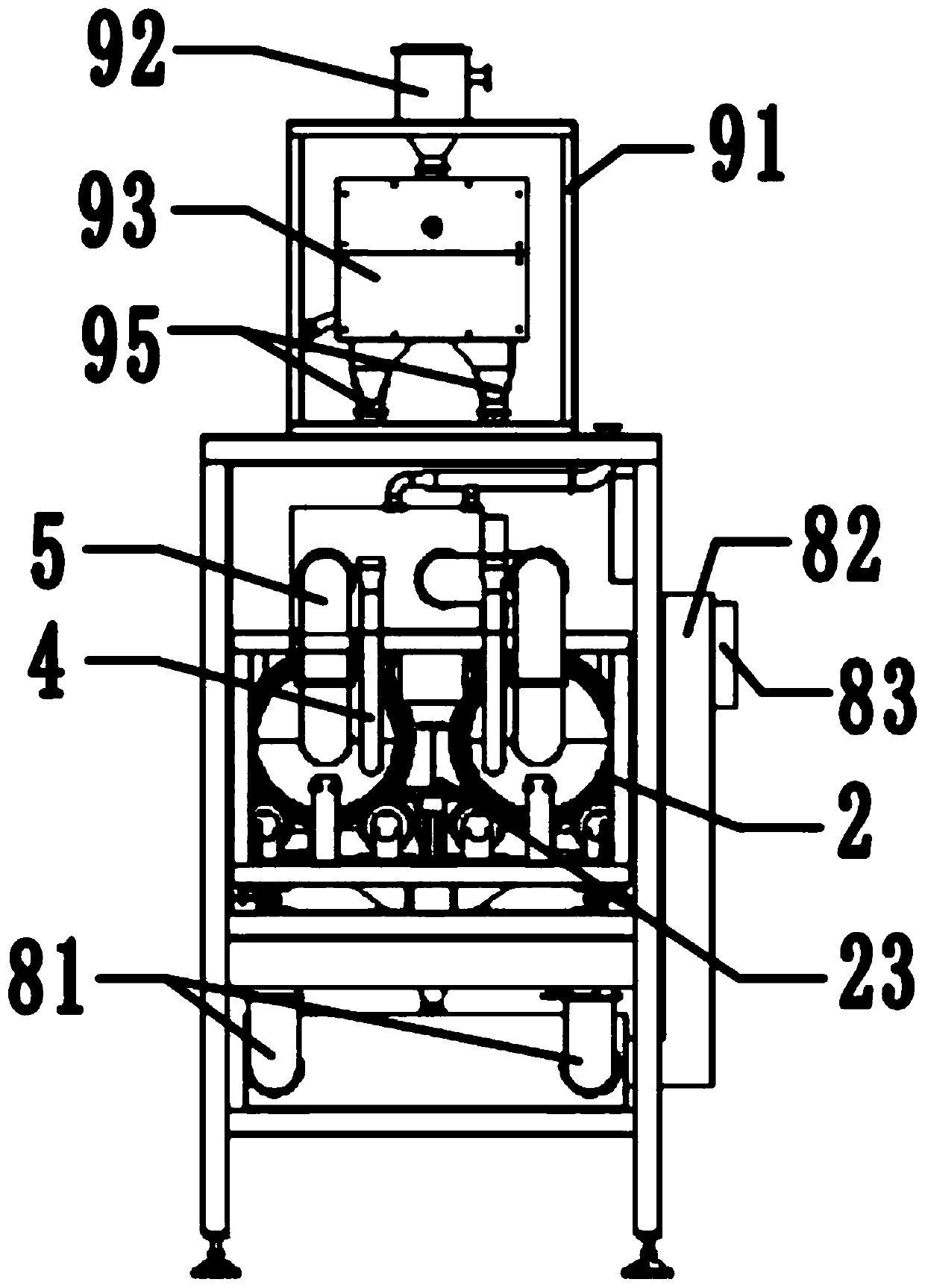

Continuous deoiling machine for surface of drop pill products

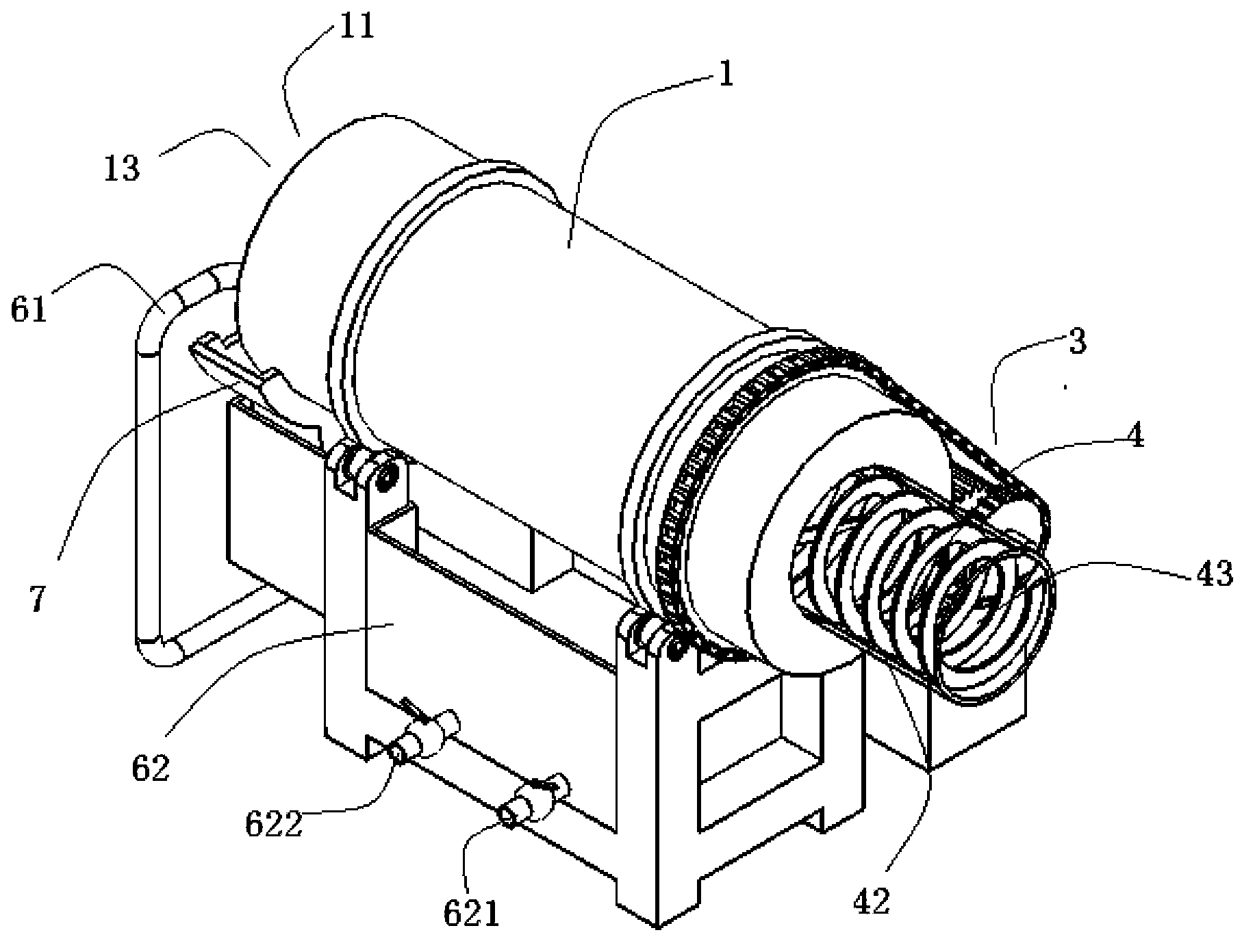

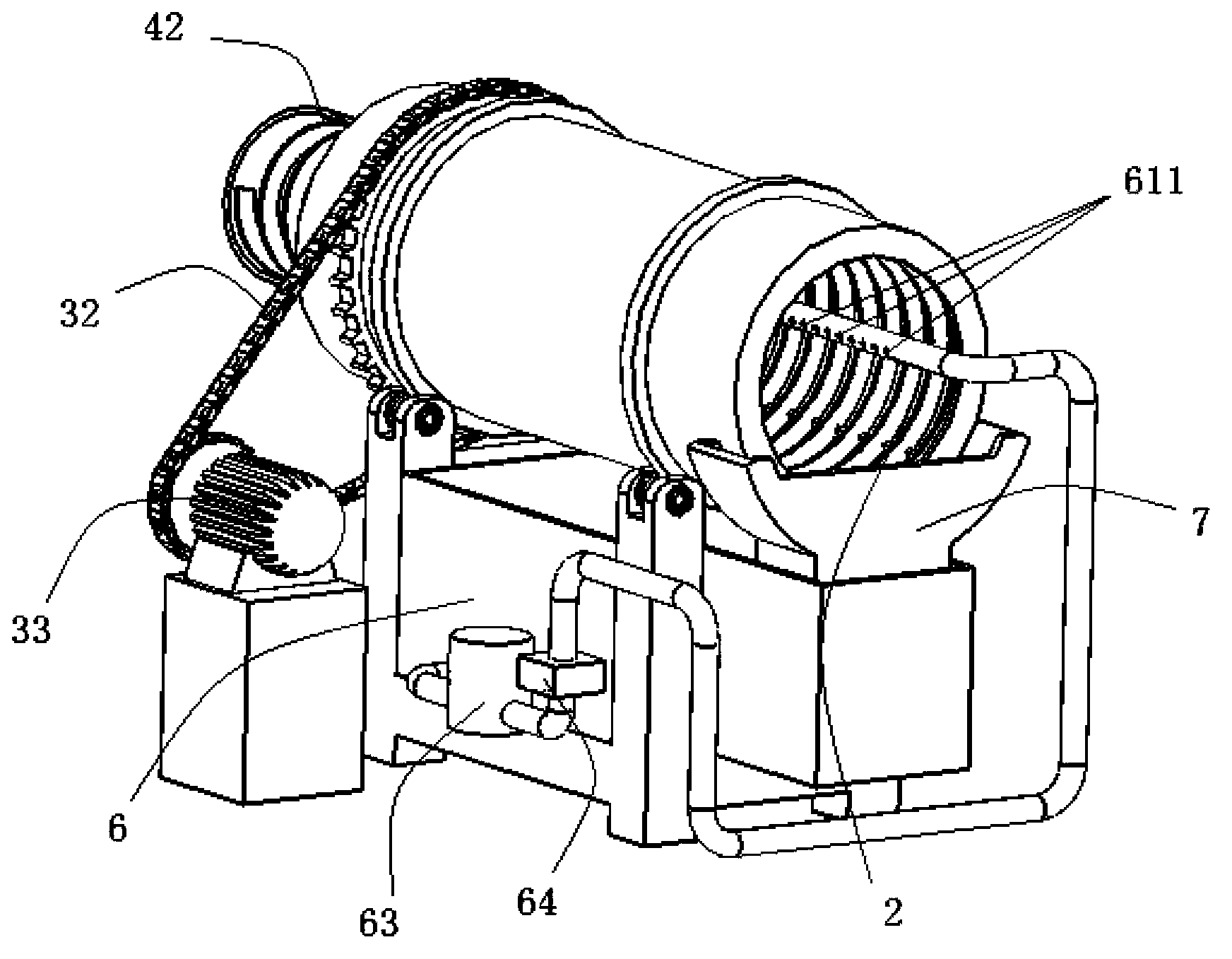

PendingCN111150659AGuaranteed degreasing effectReduced impact on deoiling qualityDrying gas arrangementsPharmaceutical product form changeEngineeringMechanical engineering

The invention provides a continuous deoiling machine for the surface of drop pill products. The deoiling machine includes a casing, two adjacent sets of rotary drums which are arranged in the casing and a driving mechanism for driving the rotary drums to rotate, wherein one end of each of the two sets of rotary drums is inserted into a material inlet pipe, the inner cavities of the rotary drums penetrate through an air inlet pipe, and the air inlet pipe is connected with an external source of treated clean and dry air; and a plurality of groups of air holes are evenly formed in the air inlet pipe in the direction of the axis of the air inlet pipe. Through adoption of the deoiling machine, continuous deoiling treatment of inlet materials and outlet materials of the drop pill products is achieved, and oil on the drum walls of the rotary drums can be cleaned during deoiling, so that the deoiling effect is ensured, online cleaning of devices is achieved, and the production efficiency is high.

Owner:PHARM TECH TIANJIN

A screw conveying degreasing process

ActiveCN104117493BWon't enterAvoid enteringPackagingCleaning using liquidsMechanical engineeringHelix

Owner:SHENZHEN KAIZHONG PRECISION TECH CO LTD

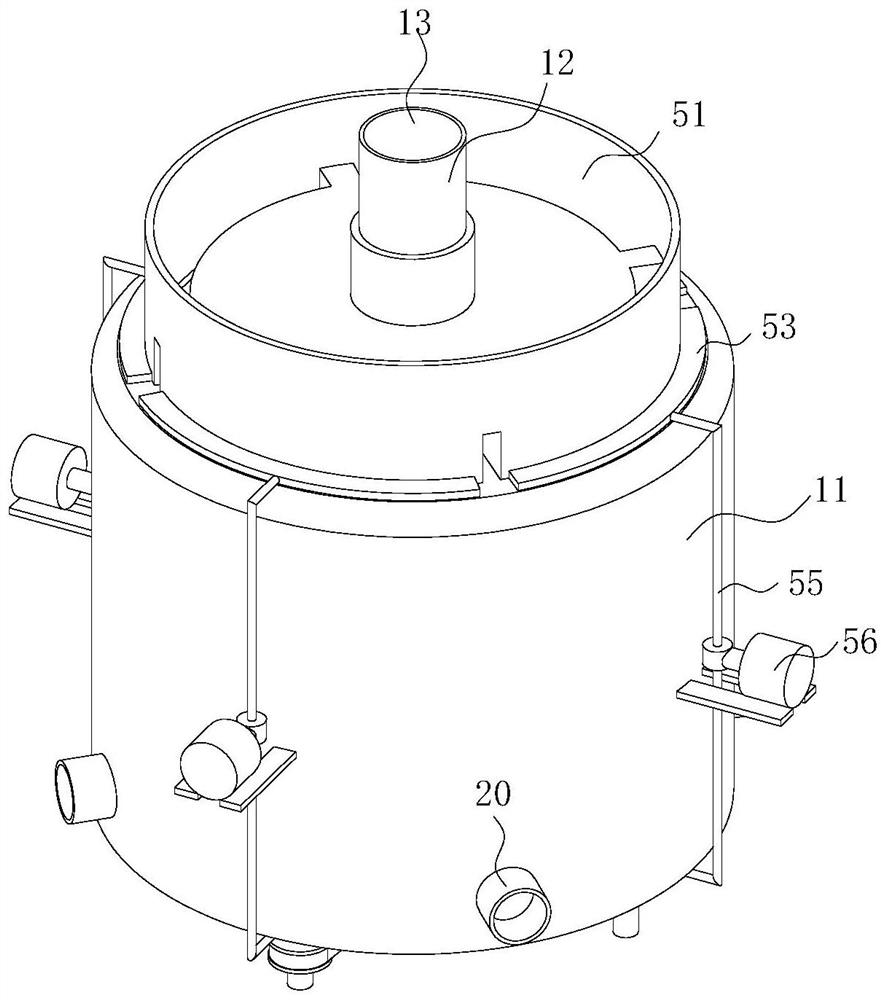

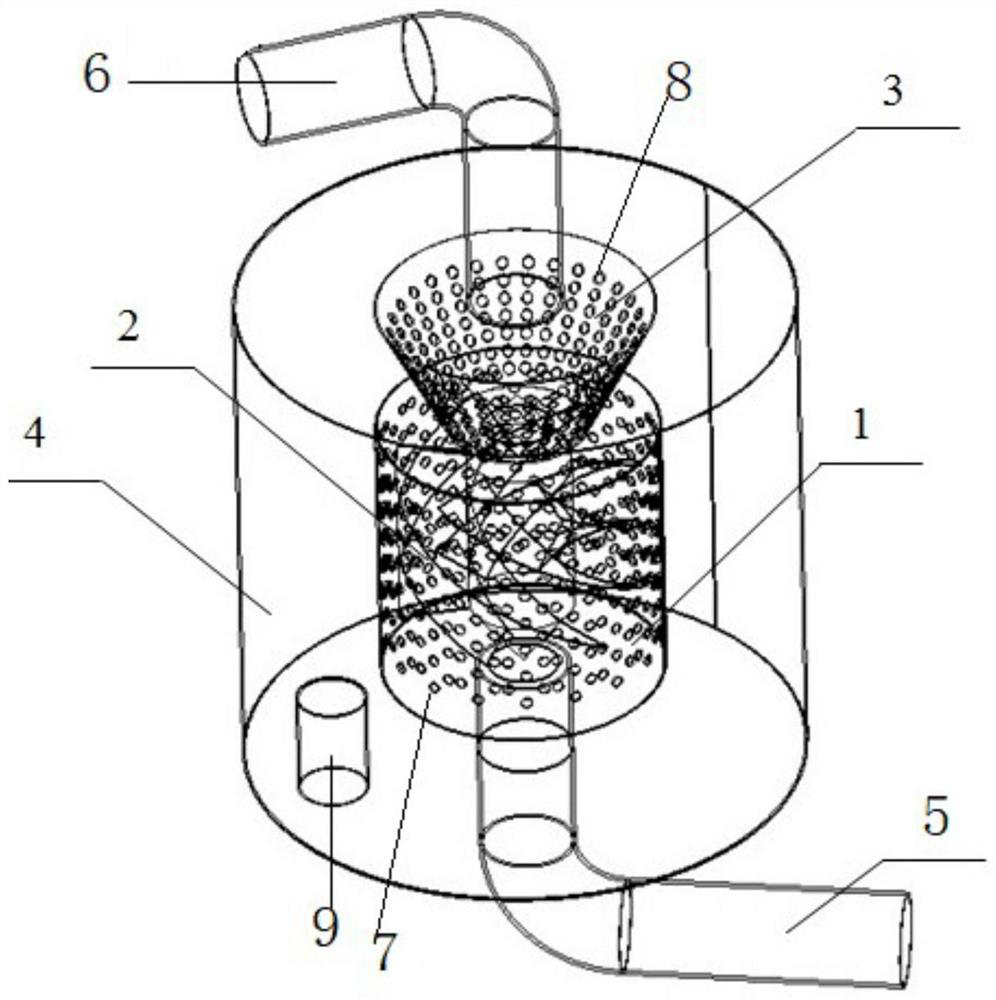

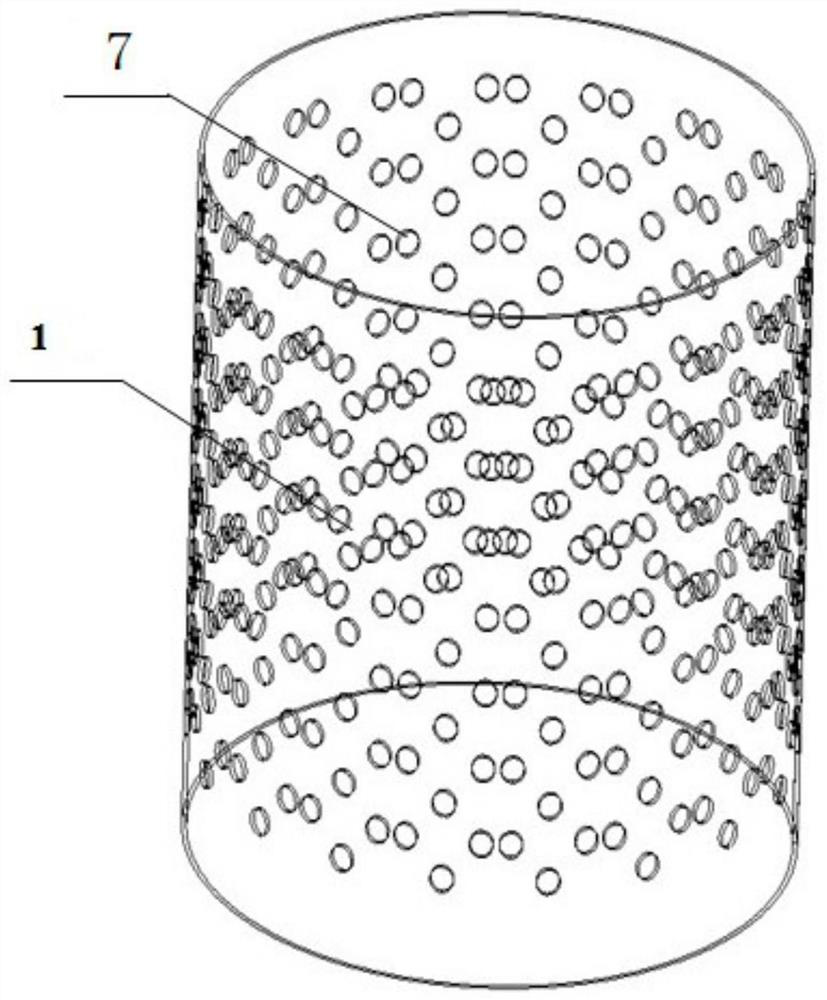

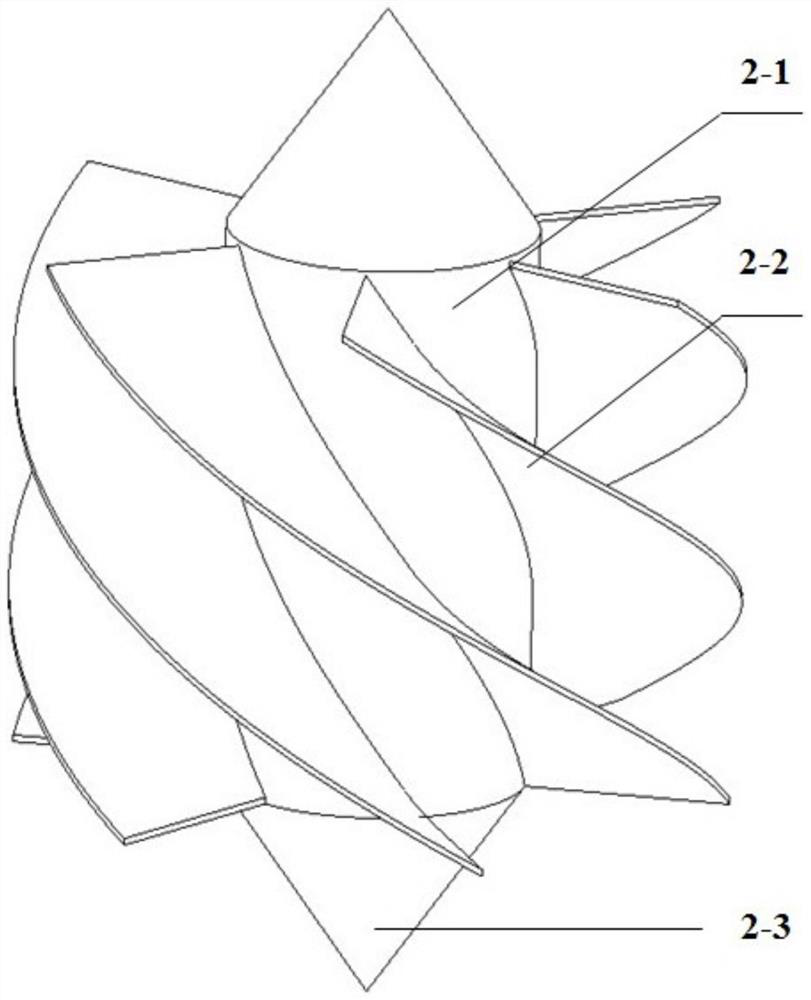

Novel oil-water separation device for oil field water treatment

PendingCN112125420AGuaranteed degreasing effectSimple processWaste water treatment from quariesWater/sewage treatment by centrifugal separationOil fieldOil water

The invention discloses a novel oil-water separation device for oil field water treatment, which comprises a separated water collecting cylinder; a cyclone centrifugal working cylinder is arranged inthe separated water collecting cylinder, and a cyclone assembly is arranged in the cyclone centrifugal working cylinder. A secondary separation conical barrel is further arranged between the upper endof the cyclone centrifugal working barrel and the inner side wall of the top of the separated water collecting barrel, the bottom surface of the separated water collecting barrel is further connectedwith a liquid inlet pipe communicated with the bottom of the cyclone centrifugal working barrel, and the top of the separated water collecting barrel is further connected with an oil outlet pipe communicated with the top of the secondary separation conical barrel; a water outlet is further formed in the bottom of the separated water collecting cylinder. According to the novel oil-water separationdevice for oil field water treatment, the problem that in the prior art, the oil removal effect is not ideal or the cost is high is solved.

Owner:YANCHANG OIL FIELD

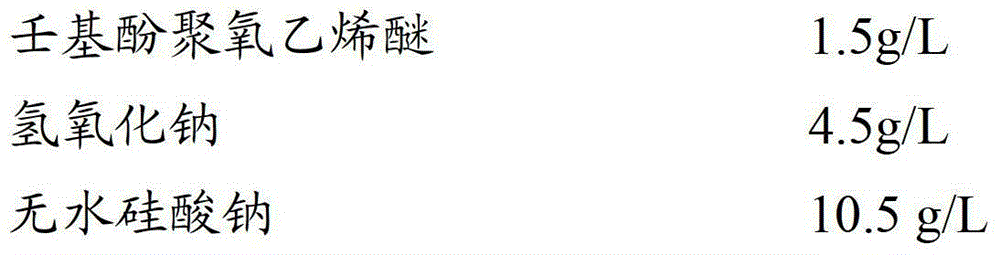

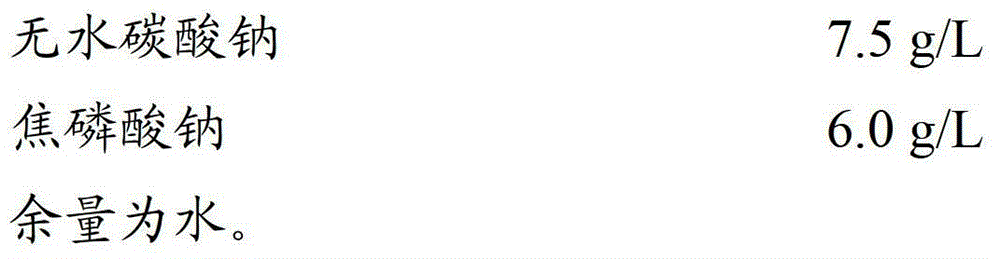

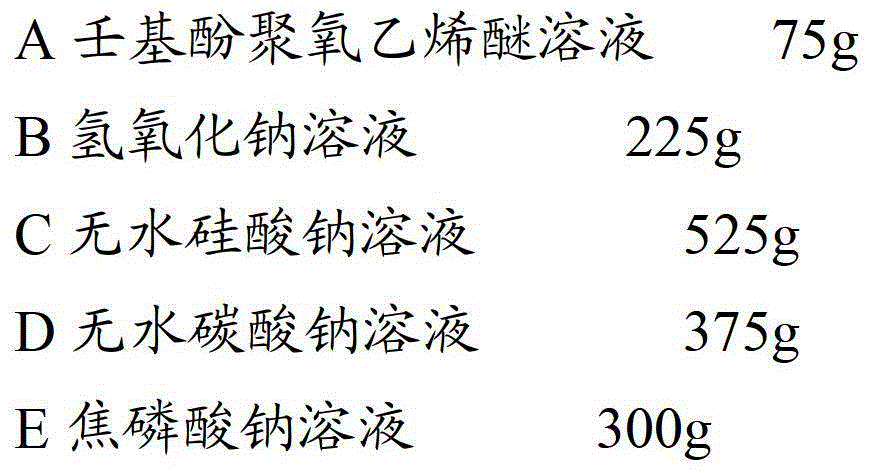

A kind of alkaline lotion and preparation method thereof

The invention discloses an alkaline washing solution. The alkaline washing solution is characterized in that the alkaline washing solution is prepared from the raw materials in percentage by weight: 1.5g / L of polyoxyethylene nonylphenyl ether, 4.5g / L of sodium hydroxide, 10.5g / L of anhydrous sodium silicate, 7.5g / L of anhydrous sodium carbonate, 6.0g / L of sodium pyrophosphate and the balance of water. The alkaline washing solution disclosed by the invention is used for steel washing of the outer surface of an inner container and the inner surface of a housing during the preparation process of a low-temperature liquid storage tank, and after washing by the alkaline washing solution, the degreasing effect of the outer surface of the inner container and the inner surface of the housing can be ensured, and the surface grease residual quantity is not more than 50mg / m<2>; the alkaline concentration can achieve the lowest level and further prevent the corrosion of steel; and after washing, the vacuum degree between the outer surface of the inner container and the inner surface of the housing can be ensured to be maintained in a stipulated range.

Owner:NINGBO MINGXIN CHEM MACHINERY

Method for oxidizing brake master cylinder

The invention discloses a method for oxidizing a brake master cylinder, which comprises the following steps of: 1, hanging, namely hanging the brake master cylinder to a rack special for oxidizing the brake master cylinder; 2, performing weak acid oil removal treatment; 3, preparing anode oxidizing tank liquor; 4, performing anode oxidization treatment; and 5, taking out the brake master cylinder, cleaning, and performing enclosed drying treatment. The brake master cylinder treated by the method meets the industrial requirements on quality such as film thickness, roughness, hardness and the like.

Owner:JIANGSU RUIER LONGDING IND CO LTD

Self-circulation type chemical degreasing method

The invention discloses a self-circulation type chemical degreasing method. The method comprises the following steps: injecting hot water into a degreasing chamber; injecting degreasing powder into the hot water in the degreasing chamber to form solution; starting a stirrer to stir the solution; enabling metal parts to enter the degreasing chamber to be soaked in the solution; acquiring the first temperature of the solution in real time; and comparing the first temperature with the preset second temperature, and gradually extracting and heating the solution in the degreasing chamber and then circulating the solution back to the degreasing chamber when the first temperature is lower than the second temperature. The method has the beneficial effects that the wastewater after treatment is easy to treat; the degreasing effect is good; and the degreasing speed is high.

Owner:山东益华生物科技有限公司

A highly efficient degreasing agent for natural leather

ActiveCN108642217BReduce pollutionReduce processing difficultyLeather degreasingPolyethylene oxideDecyl glucoside

The invention discloses a high-efficiency degreasing agent specially used for natural leather, relates to the technical field of leather processing, and comprises the following raw materials in parts by weight: 15-20 parts of decyl glucoside, 10-15 parts of PEG-60 hydrogenated castor oil, laurel Sodium acyl glutamate 5‑10 parts, water treatment grade polyglutamic acid 5‑10 parts, poloxamer 188 1‑5 parts, polyethylene oxide 1‑5 parts, chitosan quaternary ammonium salt 1‑5 parts 0.5-3 parts of hydrolyzed polymaleic anhydride, 0.1-1 parts of disodium edetate. The degreasing rate of the degreasing agent prepared by the present invention reaches more than 80%, and it is a low-foaming degreasing agent. After being dissolved in water, only a small amount of foam is produced, thereby reducing the amount of subsequent cleaning water; at the same time, the degreasing agent is mild in chemical properties and will not damage Fiber structure of natural leather.

Owner:嘉兴宏麟皮化有限公司

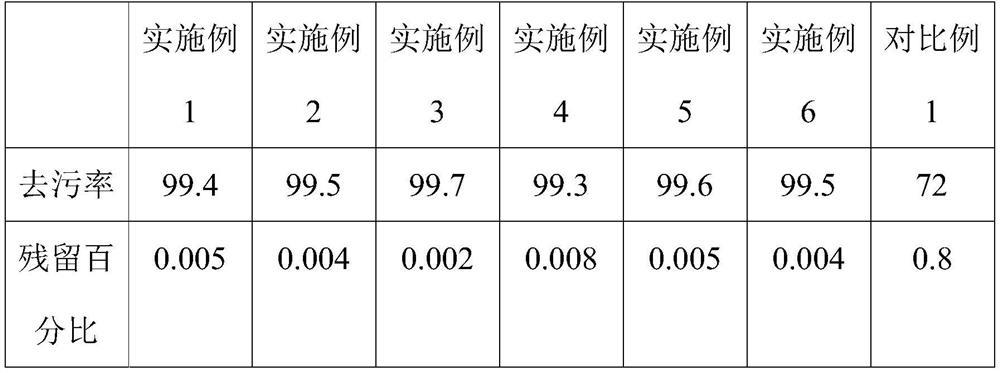

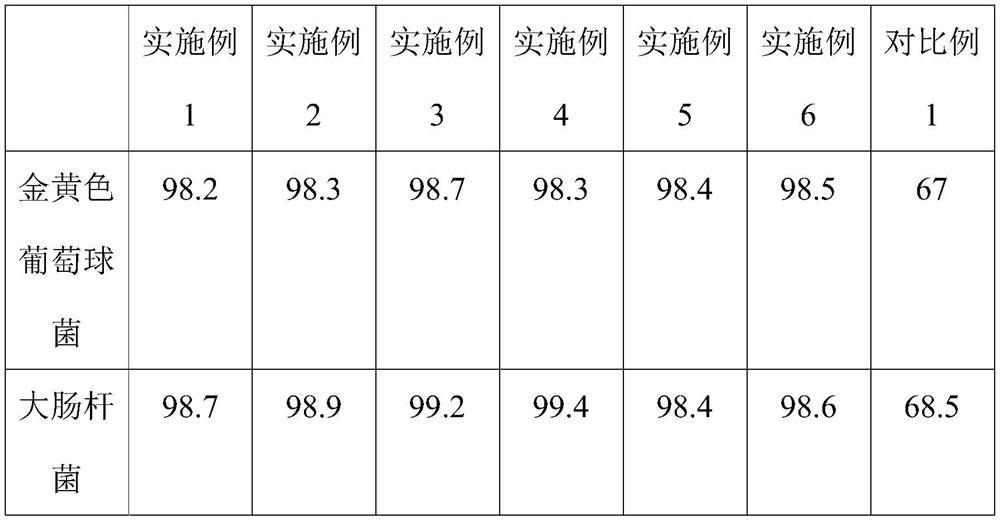

Detergent cream with strong oil removal property

InactiveCN113980742AHigh thermodynamic stabilityGuaranteed degreasing effectInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsActive agentIon exchange

The invention belongs to the technical field of daily chemicals, and particularly relates to a detergent cream with strong oil removal property. The detergent creamis prepared from the following raw materials in percentage by mass: 50-60% of an anionic surfactant, 5-10%of SiO2-poly-(allyl hydrochloride)-Mn, 7-12%of a chelating agent, 1-6%of a thickening agent, 6-8%of edible salt, 0.1-0.6%of kathon, 0.3-0.8%of essence and the balance of water. According to the technical scheme, Mn<2+> is added due to the fact that the Mn<2+> can attack carboxylic acid in fat-based oil through ion exchange reaction, decarboxylation or splitting decomposition to achieve the purpose of removing oil stains, poly-(allyl hydrochloride) is grafted to SiO2 nano particles, and the poly-(allyl hydrochloride) with positive electricity can be combined with an anionic surfactant, so that the detergent cream prepared from the anionic surfactant has better thermodynamic stability compared with traditional detergent cream, and the degreasing effect of the detergent cream is guaranteed.

Owner:佛山市橙洁士洗涤剂有限公司

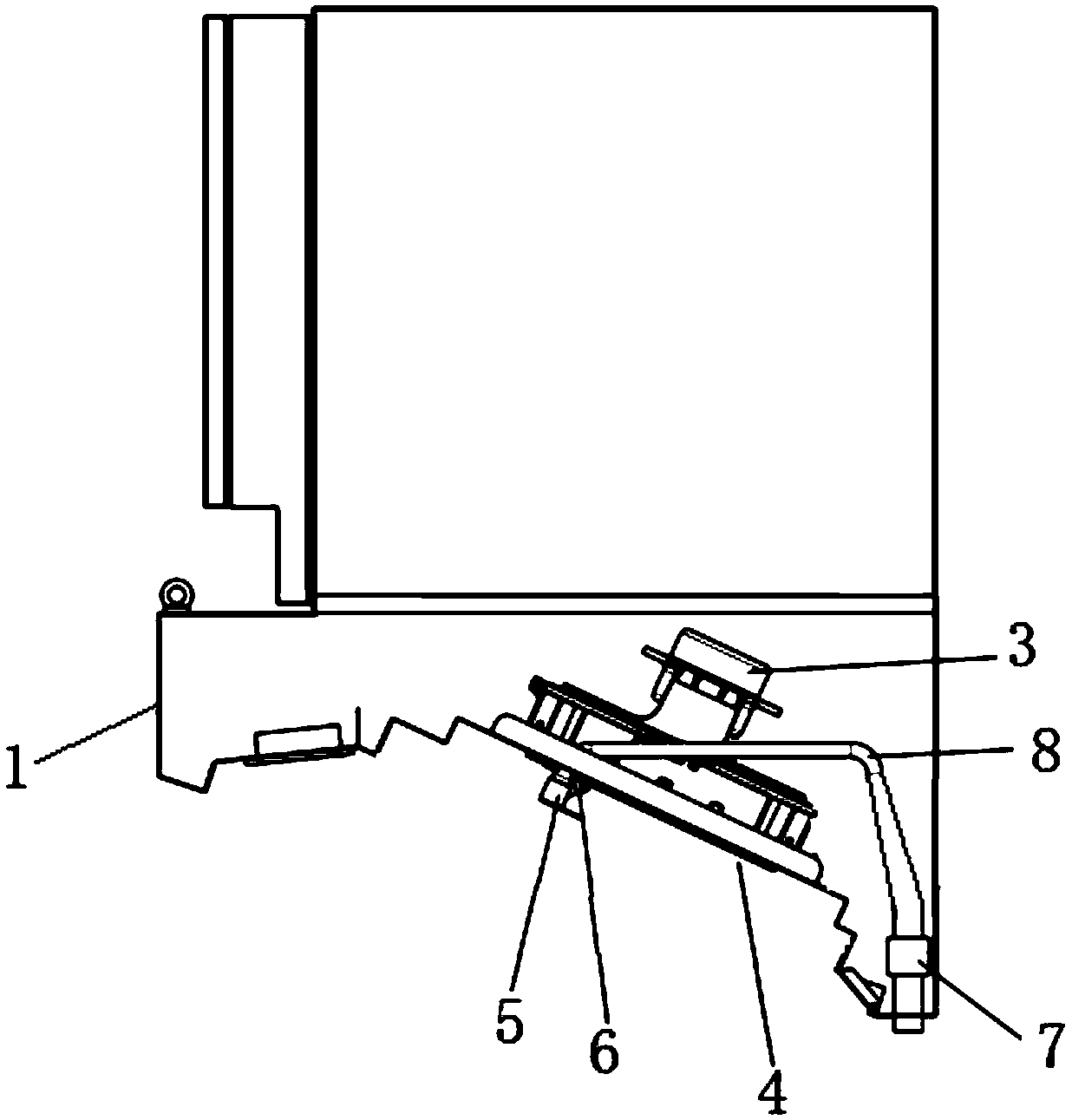

Heat exchanger detection device

PendingCN113008481AGuaranteed degreasing effectGood degreasing effectDetection of fluid at leakage pointMeasurement of fluid loss/gain rateEngineeringVacuum pump

The invention provides a heat exchanger detection device, which comprises a vacuum box used for accommodating a heat exchanger and provided with a first opening communicated with a cavity of the vacuum box; a condensation component comprising a condensation cavity and a separation part, and the separation part being located in the condensation cavity, the separation part being provided with a separation cavity, an inlet and an outlet, and the inlet and the outlet being both communicated with the separation cavity; the outlet of the heat exchanger and the first opening being both connected with the inlet in an on-off mode; a vacuum pump, an inlet of the vacuum pump being communicated with the discharge port. The heat exchanger detection device is used for solving the problem that in the prior art, the oil removal effect of a drying and oil removal mode of a heat exchanger is poor.

Owner:ZHUHAI GREE INTELLIGENT EQUIP CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com