A kind of alkaline lotion and preparation method thereof

A technology of alkaline washing liquid and solution, applied in the field of low temperature liquid storage tank preparation, can solve the problems of unmaintainable, difficult to achieve vacuum, easily contaminated with oil and dust, etc., and achieve the effect of preventing corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

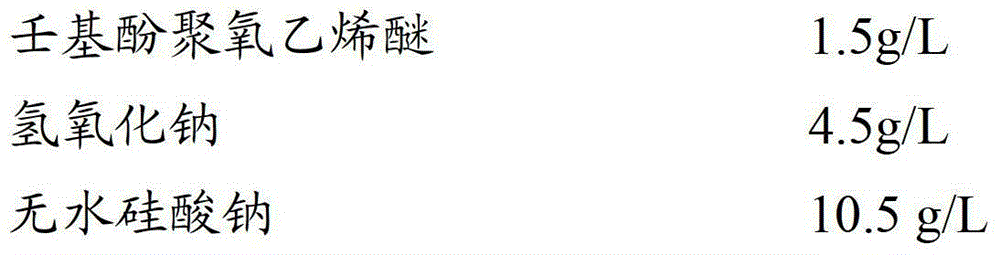

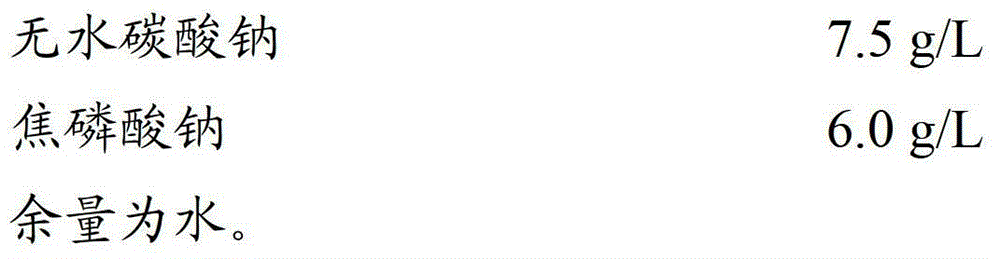

[0019] Prepare an alkaline wash as follows:

[0020] Step 1, using water as a solvent to prepare the following five solutions respectively: A nonylphenol polyoxyethylene ether solution with a mass concentration of 5%, sodium hydroxide solution with a mass concentration of B of 15%, and anhydrous solution with a mass concentration of C of 35%. Sodium silicate solution, D mass concentration is 25% anhydrous sodium carbonate solution, E mass concentration is 20% sodium pyrophosphate solution;

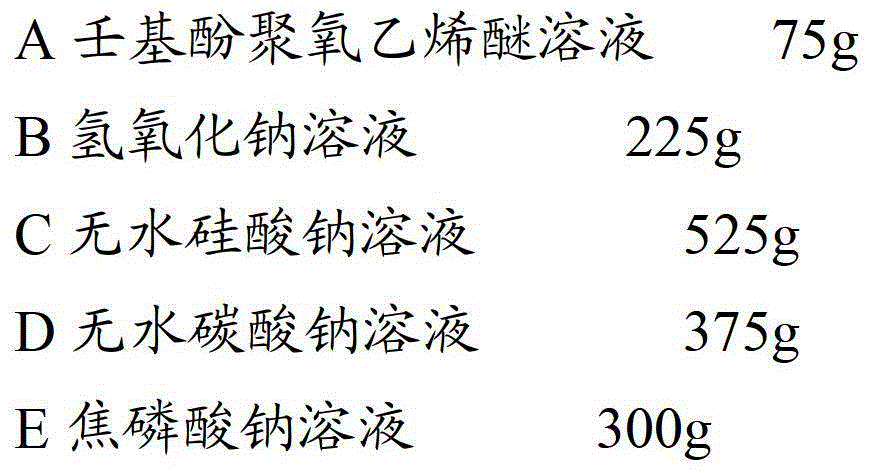

[0021] Step 2: weigh the above solution by the following mass:

[0022]

[0023] Mix the above components at room temperature, add water to dilute to 50L, and complete the preparation to obtain the alkaline lotion of the present invention.

[0024] Brush 3-5 times on the surface of the steel to be treated. After standing for 15 minutes, rinse it with water through a high-pressure water gun. The wastewater is diluted and neutralized to neutral.

[0025] The degreasing effect of this em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com