Aluminum shell cleaning machine automatic production line multi-groove continuous oil removal system

A technology for automatic production lines and cleaning machines, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve the problems of inconsistent results, the cleaning environment cannot meet environmental protection requirements, and the efficiency is low. The effect of oil removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The technical solutions of the present invention will be clearly and completely described below through specific embodiments.

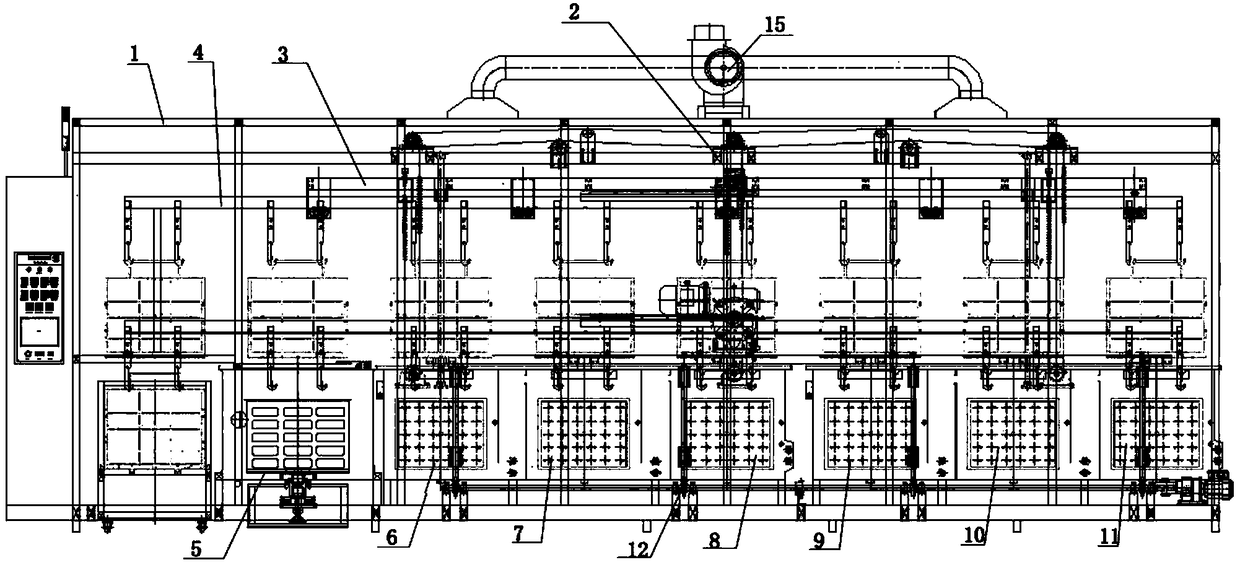

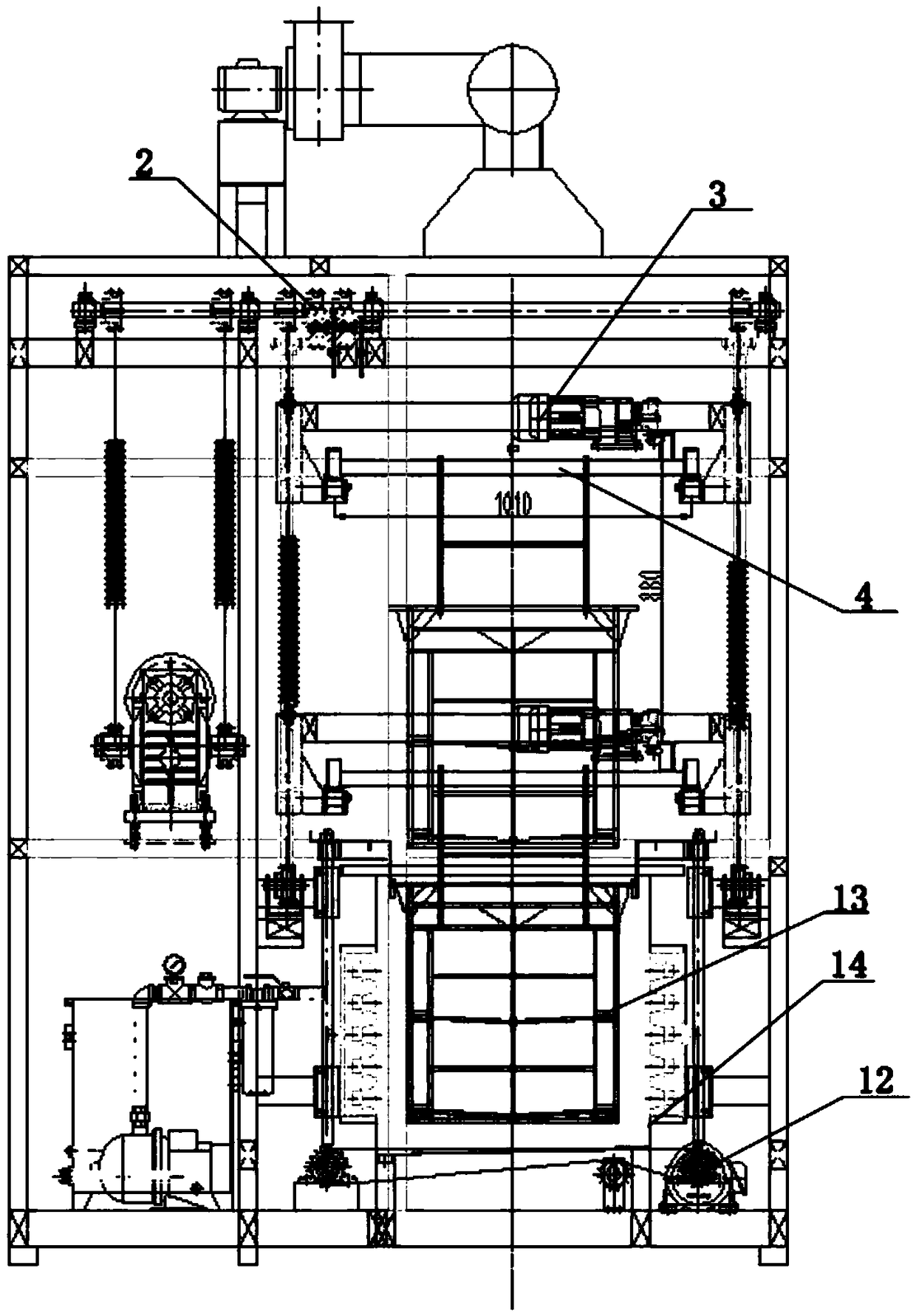

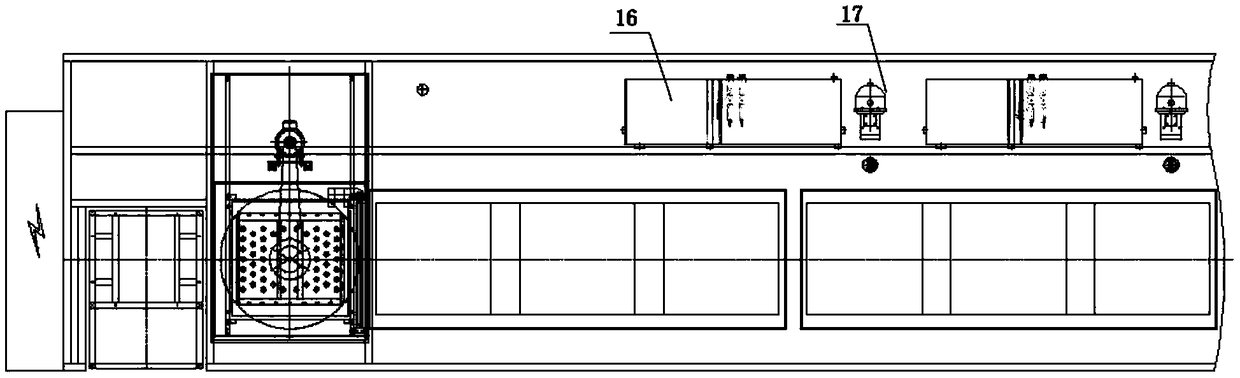

[0039] Such as Figure 1-16 As shown, it is the multi-groove continuous degreasing system of the automatic production line of the aluminum shell cleaning machine of the present invention, including the frame 1, the dobby lifting mechanism 2, the dobby lifting frame 3, the dobby traversing frame 4, the oil throwing tank 5, and the degreasing tank One 6, oil removal tank two 7, oil removal tank three 8, oil removal tank four 9, oil removal tank five 10, oil removal tank six 11 and simulation shaking mechanism 12. The dobby lifting mechanism 2 is arranged on the top of the frame, the dobby lifting mechanism 2 drives the lifting dobby lifting frame 3 to move up and down, the dobby lifting frame 3 is connected with the dobby traversing frame 4, and the dobby traversing frame 4 moves along the dobby Lifting frame 3 moves left and right. The bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com