A screw conveying degreasing process

A screw conveying and process technology, which is applied in the field of screw conveying oil removal technology, can solve the problems of poor drying effect, affecting drying effect, affecting process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

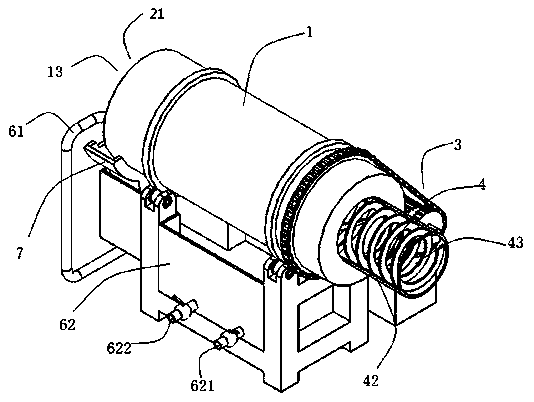

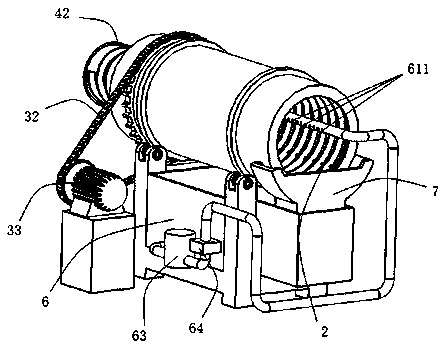

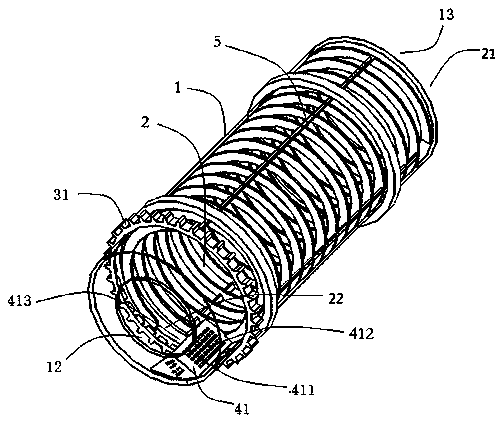

[0041] This embodiment provides a screw conveying degreasing device, such as figure 1 , 2 As shown, a screw conveyor drum 1 is included, and the screw conveyor drum 1 has an inlet and an outlet 12, and the inlet is used to input materials from the feeding mechanism into the screw conveyor drum 1, and the screw conveyor drum 1 It also includes a first spiral passage 2 arranged along its inner wall for conveying materials, and a material inlet 21 and a material outlet 22 arranged at both ends of the first spiral passage 2, and the material inlet 21 is arranged correspondingly to the inlet, so The material outlet 22 is set corresponding to the outlet 12, and the material entering the screw conveying drum 1 from the inlet enters the first spiral channel 2 from the material inlet 11; the screw conveying degreasing device It also includes a transmission mechanism 3 for driving the rotation of the screw conveyor drum 1, and the material driven by the screw conveyor drum 1 advances i...

Embodiment 2

[0055] This embodiment provides a process for degreasing using the degreasing device described in Embodiment 1, comprising the following steps:

[0056] A. The step of using the screw conveying drum 1 for screw conveying: the spiral conveying drum 1 includes a first spiral passage 2 for conveying materials arranged along its inner wall, and a material inlet 21 and a material inlet 21 arranged at both ends of the first spiral passage 2. Outlet 22, the material entering the spiral conveying drum 1 from the material inlet 21 advances in a spiral manner along the first spiral channel 2 in the spiral conveying drum 1, and finally advances to the material outlet 22;

[0057] B. The step of using degreasing agent and degreasing through degreasing assembly: using degreasing agent and degreasing the material through degreasing assembly 6 during the spiral advance of the material; The above-mentioned material outlet 22 enters the revolving conveying assembly 4, and is conveyed by the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com