Chemical oil removal device capable of supplementing active ingredients

A technology for chemical degreasing and active ingredients, applied in the field of chemical degreasing equipment, can solve problems such as poor oil removal effect and slow treatment process, and achieve the effect of improving degreasing efficiency, reducing energy consumption and ensuring degreasing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

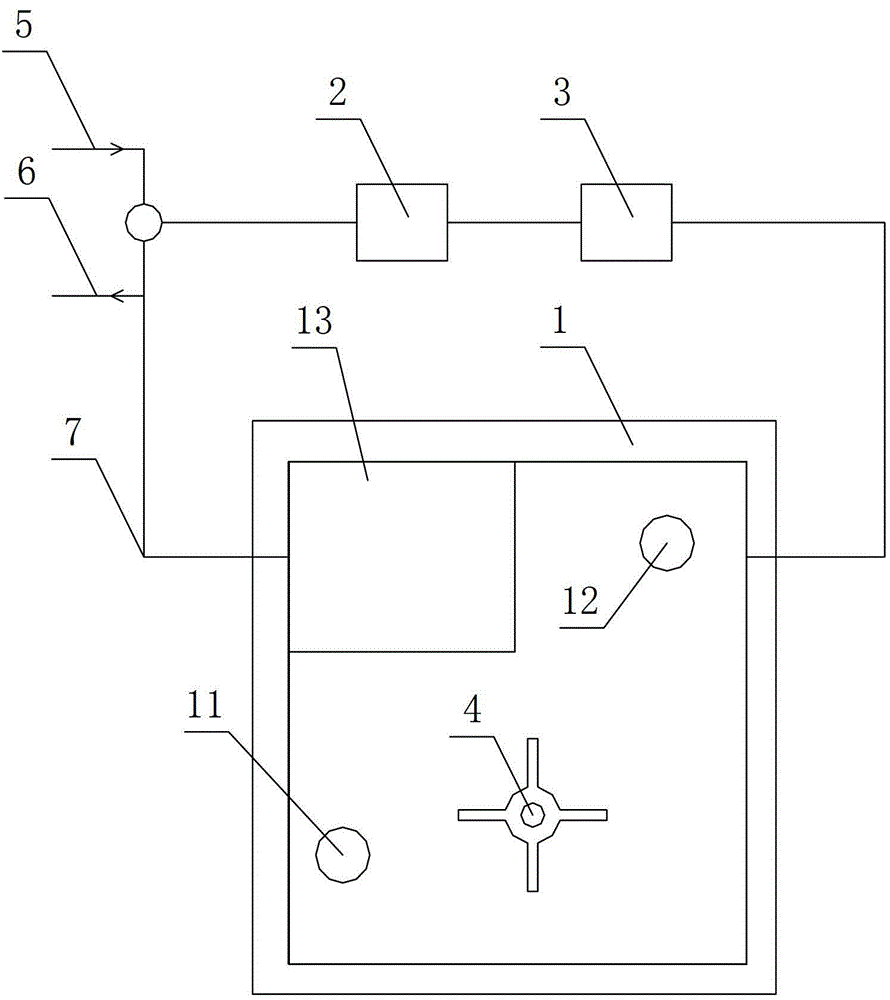

[0018] A kind of chemical degreasing equipment with supplementable active ingredients is proposed, including degreasing chamber 1, degreasing chamber 1 is provided with feed port 13 for introducing metal parts, feed port 13 is provided with an end of degreasing chamber 1 that can be sealed cover. The degreasing chamber 1 is also provided with a hot water inlet 12 for injecting hot water for dissolving the degreasing powder, and the hot water inlet 12 is provided with a valve. The degreasing chamber 1 is also provided with a water outlet 11 for discharging the waste liquid from the degreasing chamber 1 after degreasing the surface of the metal parts. The agitator 4 is arranged in the degreasing chamber 1, which is used for stirring during the degreasing process. Stirring can aggravate the friction between the surface of the metal part and the solution, which is helpful for degreasing. Although the degreasing chamber 1 adopts a closed structure, it can Prevent heat loss in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com