Coking wastewater oil removal treatment device and method

A technology for coking wastewater and oil treatment, which can be used in water/sewage treatment, natural water treatment, chemical instruments and methods, etc., and can solve problems such as coking wastewater pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

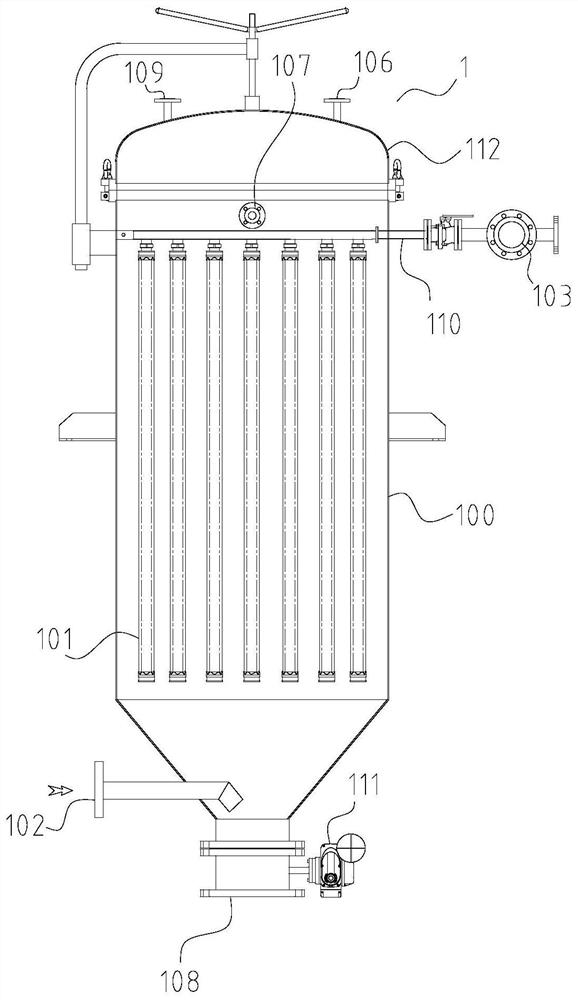

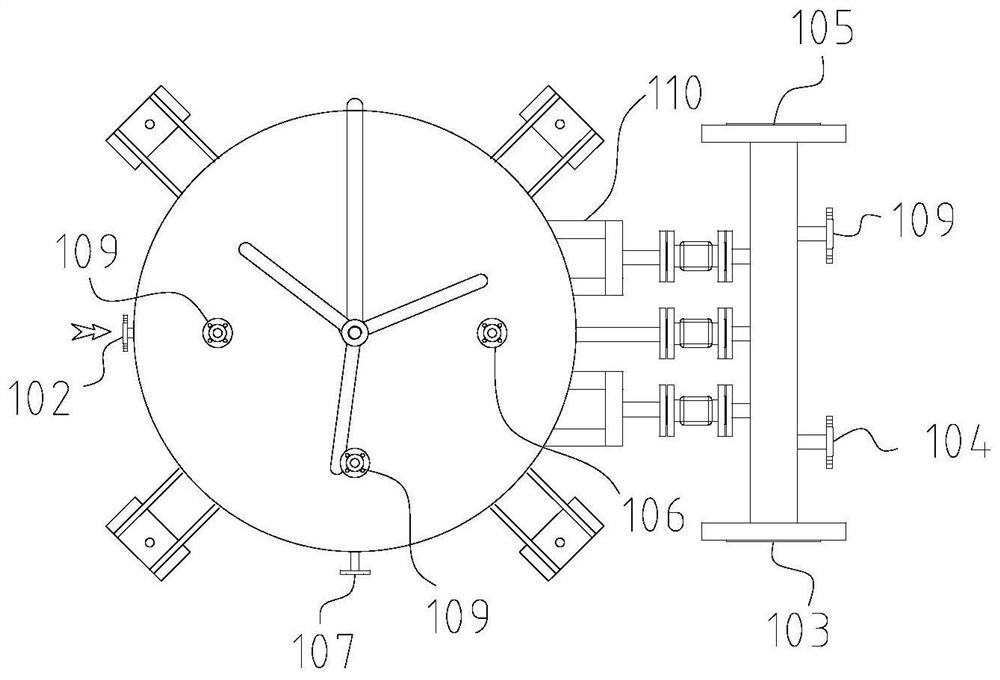

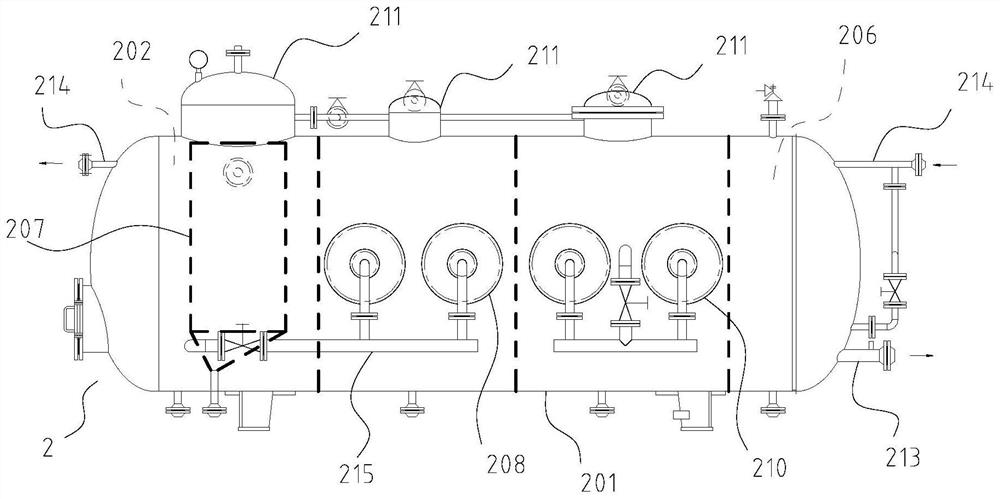

[0043] Such as figure 1 and image 3 As shown, a coking wastewater degreasing treatment device includes a coking wastewater pre-filter 1 and an oil-water separator 2. The coking wastewater is first filtered through the coking wastewater pre-filter 1, and then enters the oil-water separator 2 for oil-water separation.

[0044] The structure and working principle of the coking wastewater pre-filter 1 and the oil-water separator 2 will be introduced first.

[0045] combine figure 1 and figure 2 As shown, the coking wastewater pre-filter 1 is a vertical container equipped with a complete set of control system, which mainly treats sundries such as tar and coke powder in the coking wastewater. A plurality of porous filter elements 101, a filter cloth set on the periphery of the filter element 101, a liquid outlet pipe 103...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com