Surface deoiling device for steel pipe machining

A technology for steel pipes and suction pipes, applied in the field of surface oil removal devices for steel pipe processing, can solve the problems of reducing the working efficiency of oil removal devices, inconvenient placement and removal of steel pipes, and unfavorable oil removal operations, saving time and labor, avoiding The effect of secondary pollution and improving the quality of oil removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

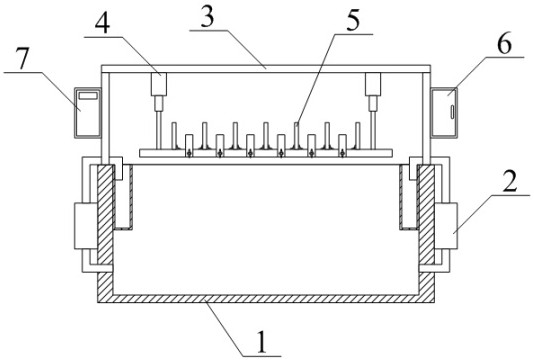

[0023] as attached figure 1 to attach Figure 4 shown

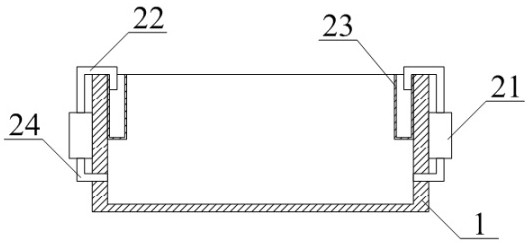

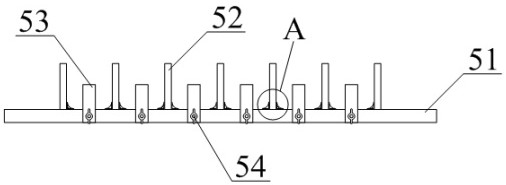

[0024] The invention provides a surface degreasing device for steel pipe processing, comprising a soaping box 1, a filter assembly 2, a support frame 3, a hydraulic rod 4, a placement assembly 5, an electric control cabinet 6 and a PLC controller 7, the support frame 3 Installed on the outer edge above the soaping box 1; the filter assembly 2 adopts two, and the filter assembly 2 is installed in the middle position above the two sides of the soaping box 1; the hydraulic rod 4 adopts four, and the hydraulic rod 4 Installed on the top four corners of the inside of the support frame 3; the placement assembly 5 is arranged above the soaping box 1, and the top four corners of the placement assembly 5 are connected to the lower end of the hydraulic rod 4 by a wire rope; the electric control cabinet 6 is installed on the support The middle position on one side of the frame 3; the PLC controller 7 is installed in the middle pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com