Efficient degreasant special for natural leather

A technology of natural leather and degreasing agent, which is applied in leather degreasing, small raw hide/big raw hide/leather/fur treatment, small raw hide/large raw hide/leather skin/fur chemical treatment, etc. It can solve the complex composition of sewage and the amount of foam generated Large, unfavorable leather cleaning and other problems, to achieve the effect of reducing pollution, mild chemical properties, and reducing cleaning water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

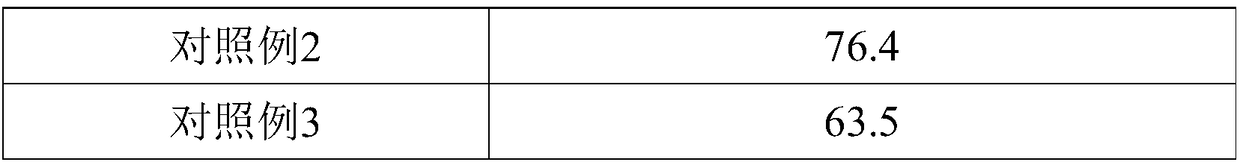

Examples

Embodiment 1

[0023] (1) Mix 10g of water treatment grade polyglutamic acid and 3g of poloxamer 188, then add water to dissolve, and add dilute sulfuric acid dropwise to adjust the pH of the solution to 4-5, and then heat to reflux and keep stirring. After concentrating under reduced pressure, a paste with a solid content of 75-85% is made. After the paste is naturally cooled to room temperature, it is sent to a freeze dryer. The dried solid is made into a micronized powder, namely, polyglutamic acid- Poloxamer esters;

[0024] (2) Add the prepared polyglutamic acid-poloxamer ester, 10g PEG-60 hydrogenated castor oil, 5g sodium lauroyl glutamate, 2g polyethylene oxide, 3g chitosan to 20g decyl glucoside. The sugar quaternary ammonium salt, 1g hydrolyzed polymaleic anhydride and 0.5g disodium ethylenediaminetetraacetic acid are thoroughly mixed and then ball milled by a ball mill until the discharge particle size is less than 30μm to obtain a degreasing agent.

Embodiment 2

[0026] (1) Mix 10g of water treatment grade polyglutamic acid and 5g of Poloxamer 188 and dissolve in water, and add dilute sulfuric acid dropwise to adjust the pH of the solution to 4-5, then heat to reflux and keep stirring. After the reaction is over After concentrating under reduced pressure, a paste with a solid content of 75-85% is made. After the paste is naturally cooled to room temperature, it is sent to a freeze dryer. The dried solid is made into a micronized powder, namely, polyglutamic acid- Poloxamer esters;

[0027] (2) Add the prepared polyglutamic acid-poloxamer ester, 15g PEG-60 hydrogenated castor oil, 8g sodium lauroyl glutamate, 3g polyethylene oxide, 2g chitosan to 15g decyl glucoside. The sugar quaternary ammonium salt, 1g hydrolyzed polymaleic anhydride and 0.5g disodium ethylenediaminetetraacetic acid are thoroughly mixed and then ball milled by a ball mill until the discharge particle size is less than 30μm to obtain a degreasing agent.

Embodiment 3

[0029] (1) Mix 10g of water treatment grade polyglutamic acid and 5g of Poloxamer 188 and dissolve in water, and add dilute sulfuric acid dropwise to adjust the pH of the solution to 4-5, then heat to reflux and keep stirring. After the reaction is over After concentrating under reduced pressure, a paste with a solid content of 75-85% is made. After the paste is naturally cooled to room temperature, it is sent to a freeze dryer. The dried solid is made into a micronized powder, namely, polyglutamic acid- Poloxamer esters;

[0030] (2) Add the prepared polyglutamic acid-poloxamer ester, 15g PEG-60 hydrogenated castor oil, 8g sodium lauroyl glutamate, 3g polyethylene oxide, 2g chitosan to 15g decyl glucoside. The sugar quaternary ammonium salt, 1g hydrolyzed polymaleic anhydride and 0.5g disodium ethylenediaminetetraacetic acid are thoroughly mixed and then ball milled by a ball mill until the discharge particle size is less than 30μm to obtain a degreasing agent.

[0031] Modificat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com