Device and method for bleed air backflow recycling multi-stage baffling microbubble flotation oil removal

A micro-bubble and air flotation technology, applied in chemical instruments and methods, flotation water/sewage treatment, multi-stage water treatment, etc., can solve problems such as short flow, low efficiency of dissolved air, and poor dissolution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

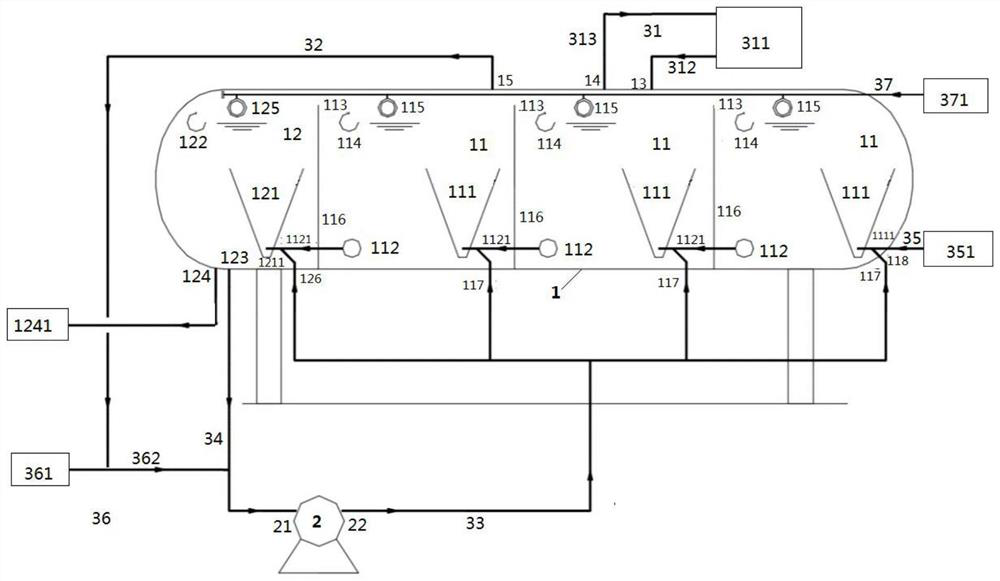

[0084] (1) The output reflux water at 70°C produced by the reflux chamber 12 and the nitrogen gas precipitated in the air flotation tank 1 enter the dissolved air pump 2 through the nitrogen gas bleed return pipeline 32 from the water suction and air supply port 21 to pressurize and dissolve to produce microbubbles The dissolved air water; the inlet pressure of the dissolved air pump 2 is 0.04MPa, and the outlet pressure is 1MPa; the particle size of the microbubbles is 20-30 μm; the gas-liquid ratio of the dissolved air water containing the microbubbles is 10%.

[0085] (2) The dissolved air water containing microbubbles enters the dissolved air water replenishment pipeline 33 through the dissolved air water outlet 22, and the oily produced raw water transported through the oily produced raw water pipeline 35 is in the dissolved air water replenished pipeline 33 It is mixed with the oil-containing production raw water pipeline 35 obliquely connected to the pipeline to obtain d...

Embodiment 2

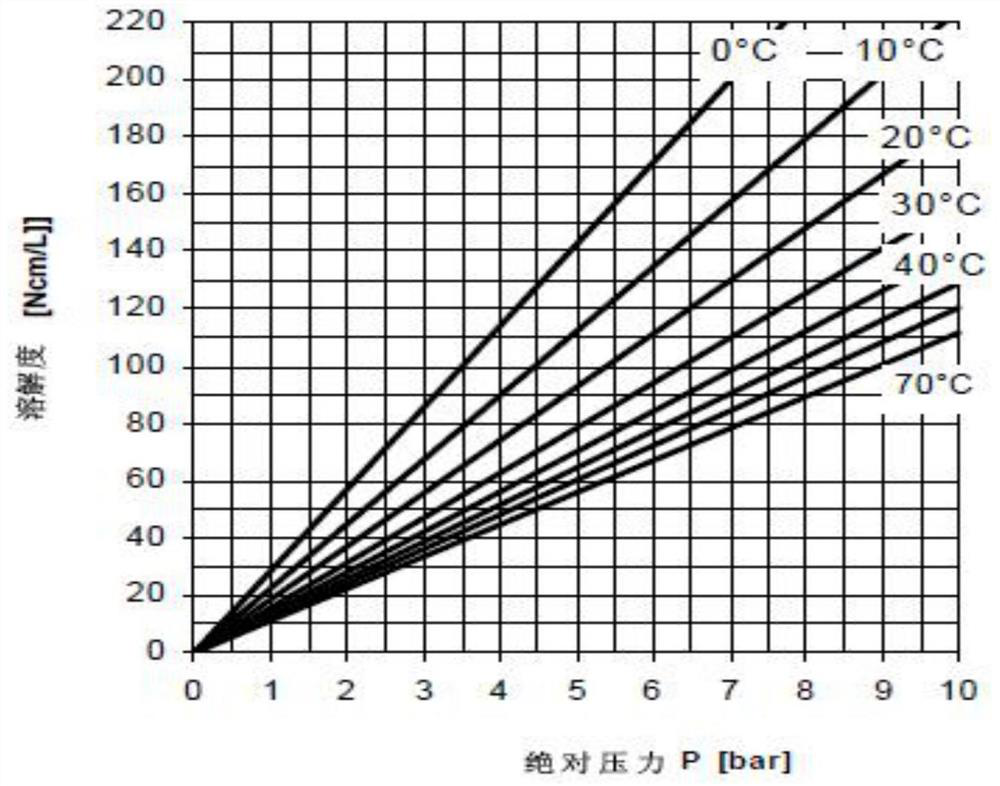

[0091] Carry out microbubble flotation oil removal according to the method for embodiment 1, the inlet pressure of dissolved air pump 2 and outlet pressure, the temperature of production reflux water, dissolved air pump gas-liquid ratio and air saturation solubility relationship in step (1) are as follows figure 2 shown. Depend on figure 2 It can be seen that the present invention controls the inlet pressure of the dissolved air pump 2 to 0.03-0.04MPa, and when the outlet pressure is controlled to 0.9-1.0MPa, the gas-liquid ratio can reach 10 after the water at 70°C is pressurized and mixed with the reflux nitrogen in the pump. %, the efficiency of dissolved air is high, and the outlet of the dissolved air pump can no longer be equipped with a gas-liquid separation tank, which avoids the waste of nitrogen at the outlet of the dissolved air pump.

Embodiment 3

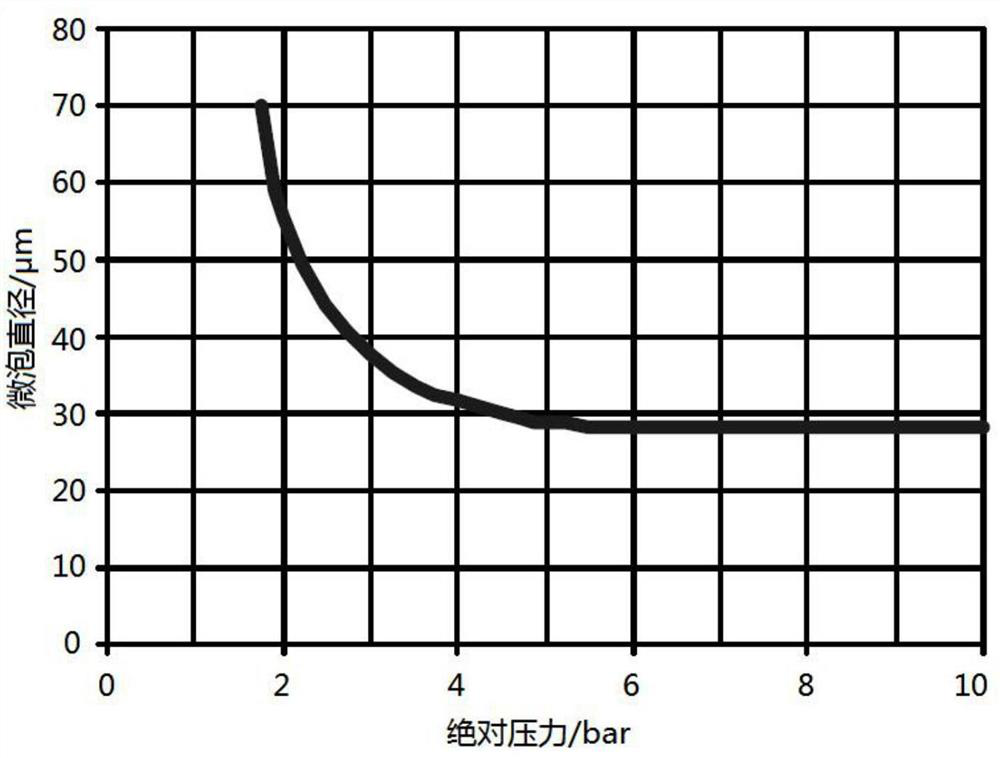

[0093] Carry out oil removal by microbubble flotation according to the method of embodiment 1, the outlet pressure of dissolved air pump 2 in step (1) and the diameter relationship figure of the microbubble that produces are as follows image 3 shown. Depend on image 3 It can be seen that the present invention controls the outlet pressure of the dissolved air pump to 0.9-1.0 MPa and then releases it under reduced pressure. The particle size of the generated microbubbles can be controlled at 20-30 μm. The oil contact area improves the degreasing effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com