Automatic cleaning device for oily fume purifying

An automatic cleaning and oil fume purification technology, applied in the direction of oil fume removal, application, household stoves, etc., can solve the problems of unclean oil removal and affect the separation effect of oil fume, and achieve the effect of ensuring the effect of oil removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

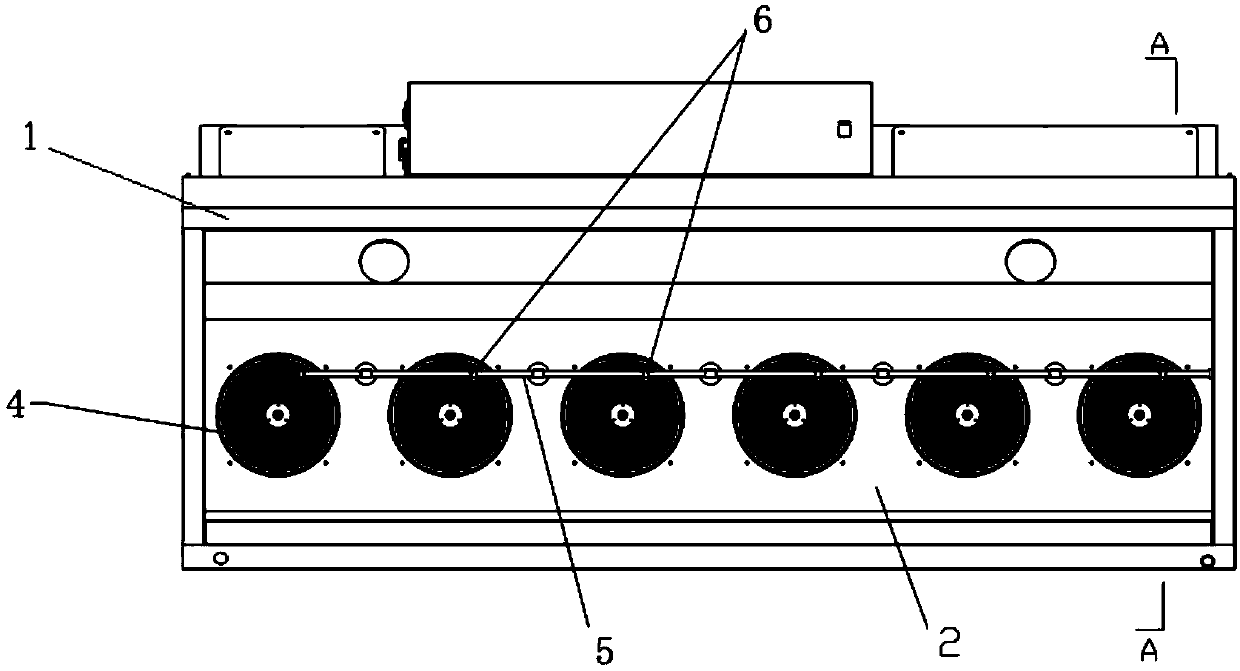

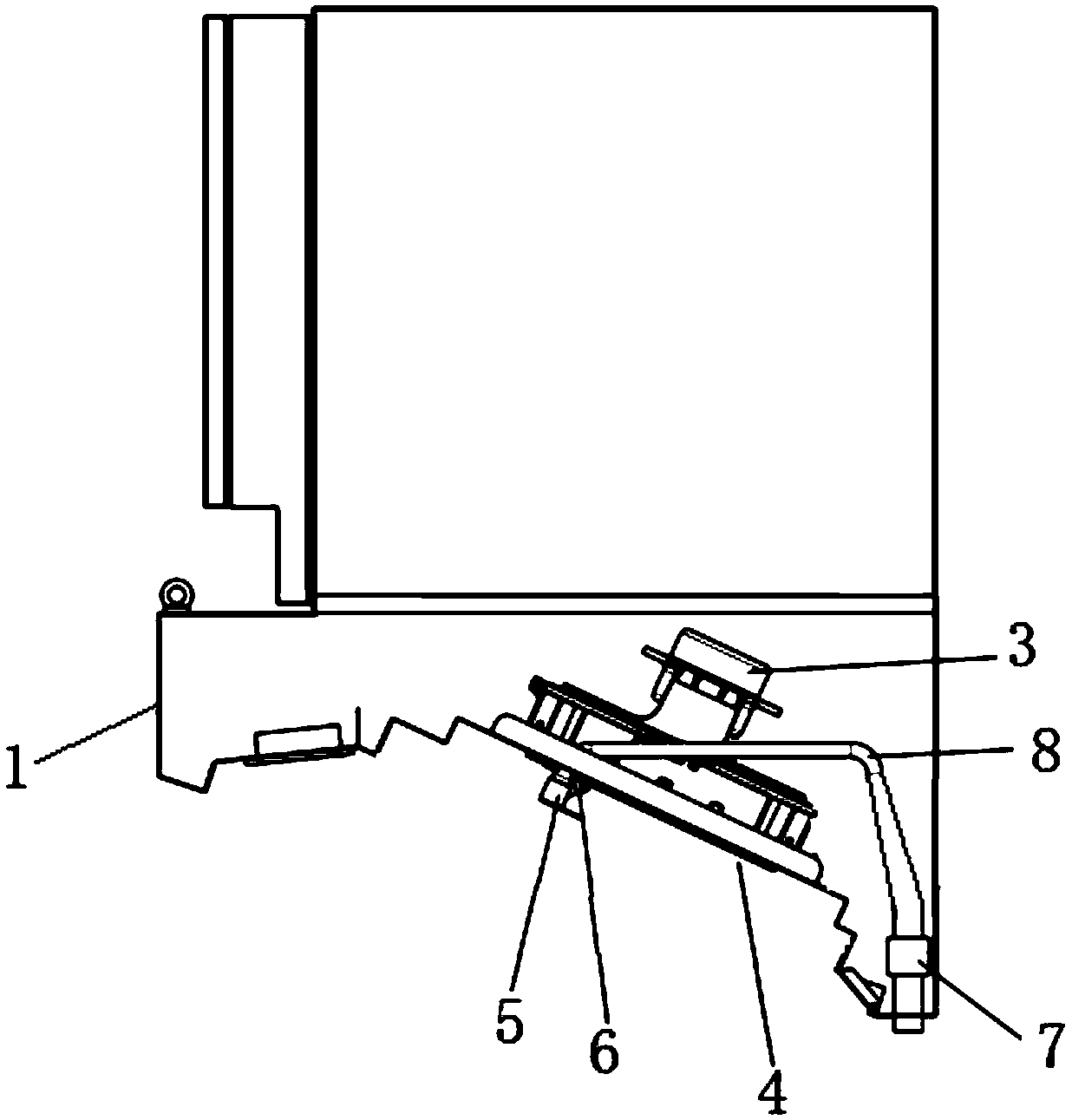

[0016] Implementation mode one: if Figure 1~2 , an automatic cleaning device for oil fume purification, comprising a oil fume separation box 1, a baffle plate 2 is provided at the smoke inlet end of the oil fume separation box 1, and oil fume separation valves connected to a drive motor 3 are evenly embedded on the baffle plate. The device 4 is also provided with a cleaning structure for automatically cleaning the oil fume separator on the baffle. There are six oil fume separators 4; the oil fume separators 4 are evenly arranged in a single row. The cleaning structure includes a cleaning pipe 5 arranged on the baffle plate 2, and the cleaning pipe 5 is uniformly arranged with nozzles 6 facing the oil fume separator; there are 6 nozzles corresponding to the oil fume separator one by one. Certainly, according to the actual situation, there is at least one oil fume separator 4 , and the oil fume separators may be uniformly arranged in an array or evenly arranged in a single row...

Embodiment approach 2

[0018] Implementation mode two: if figure 1 , 3 On the basis of Embodiment 1, a heater 9 is provided on the upper water pipe 8 to heat the liquid in the upper water pipe at any time or as required, thereby enhancing the cleaning effect.

Embodiment approach 3

[0019] Implementation mode three: if figure 1 , 4 , On the basis of the second embodiment, the front end of the oil fume separator 4 is provided with an air equalizing net 10, so that the smoke is evenly dispersed on each oil fume purifier, and the purification effect is better.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com