Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35results about How to "Good space environment adaptability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

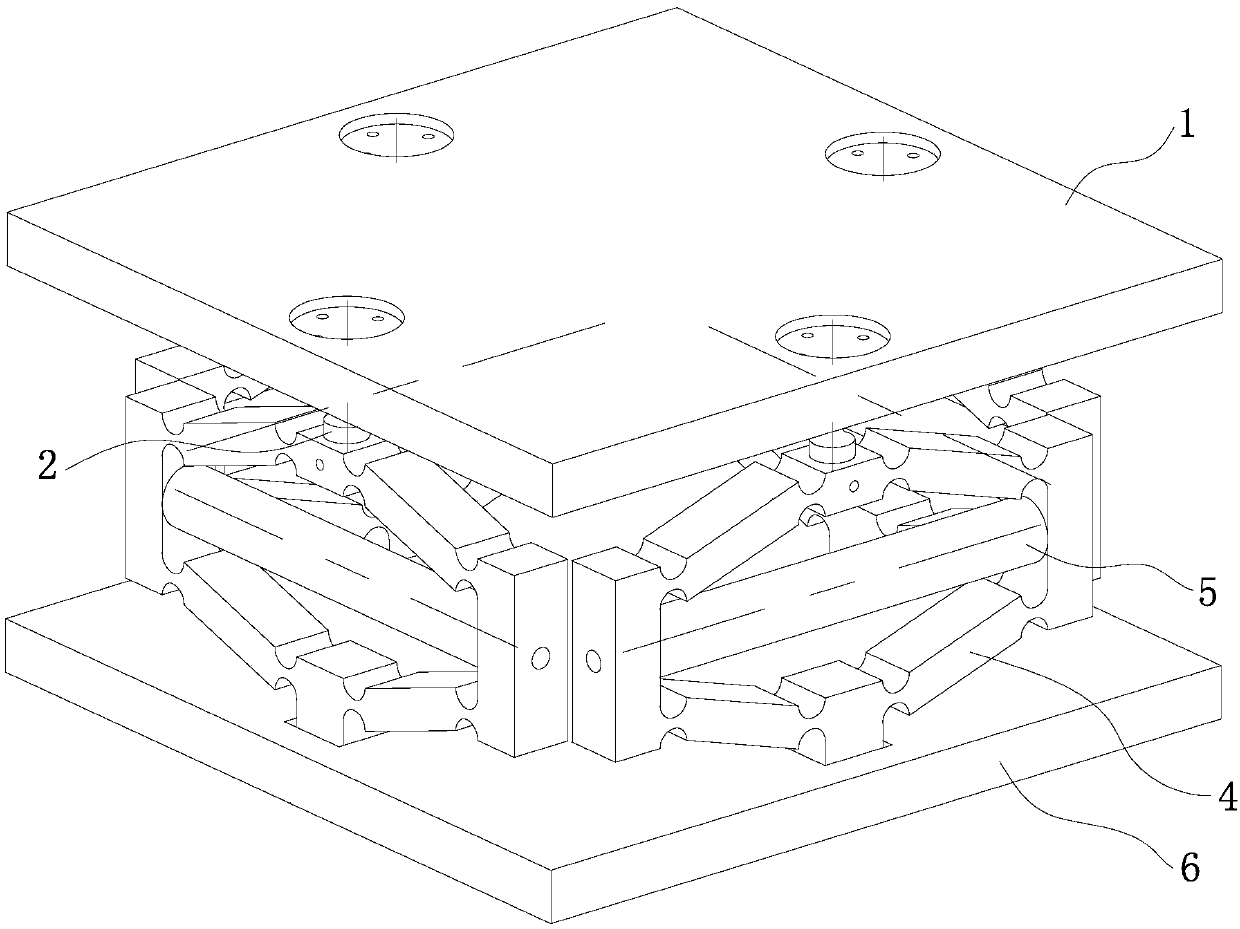

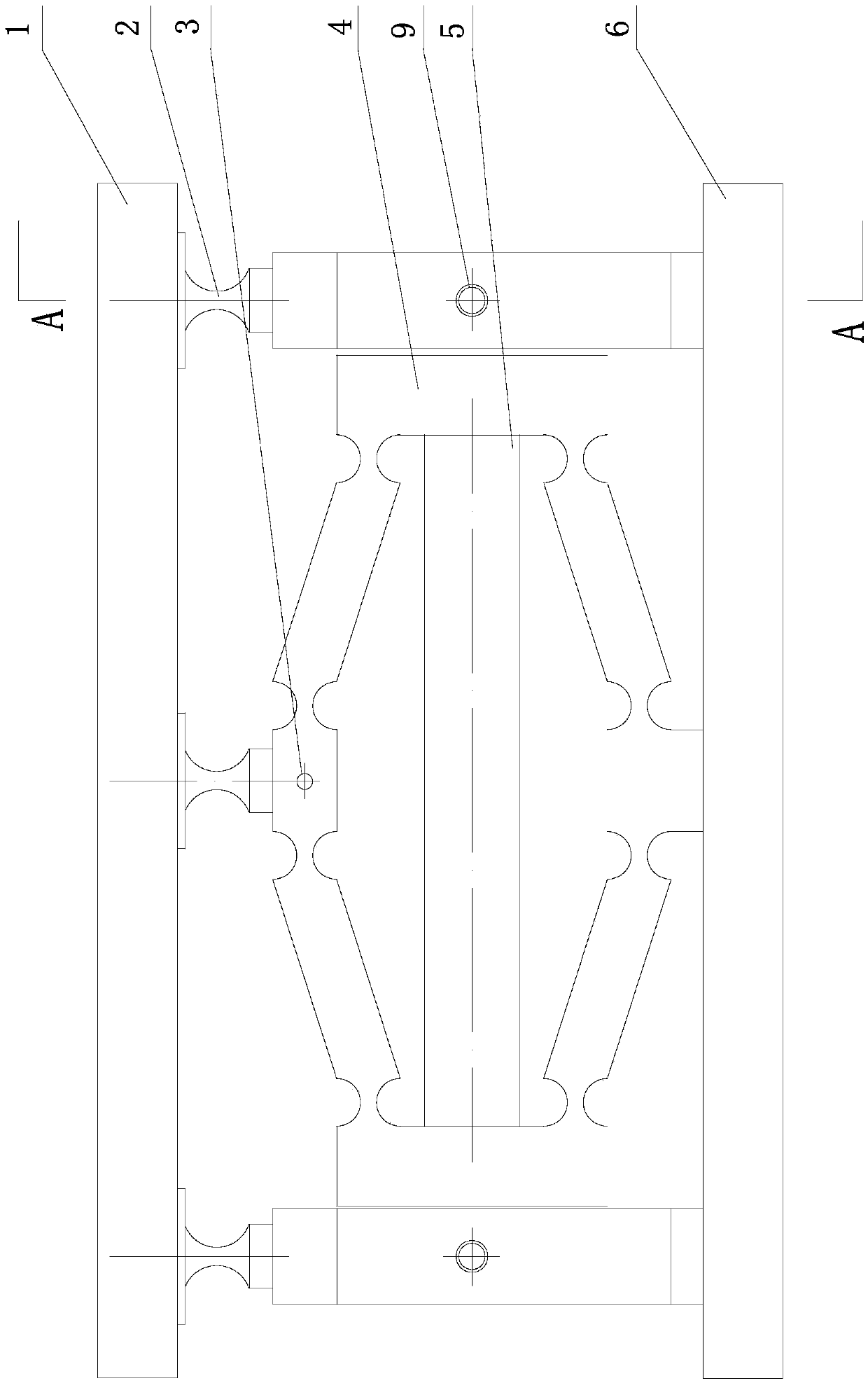

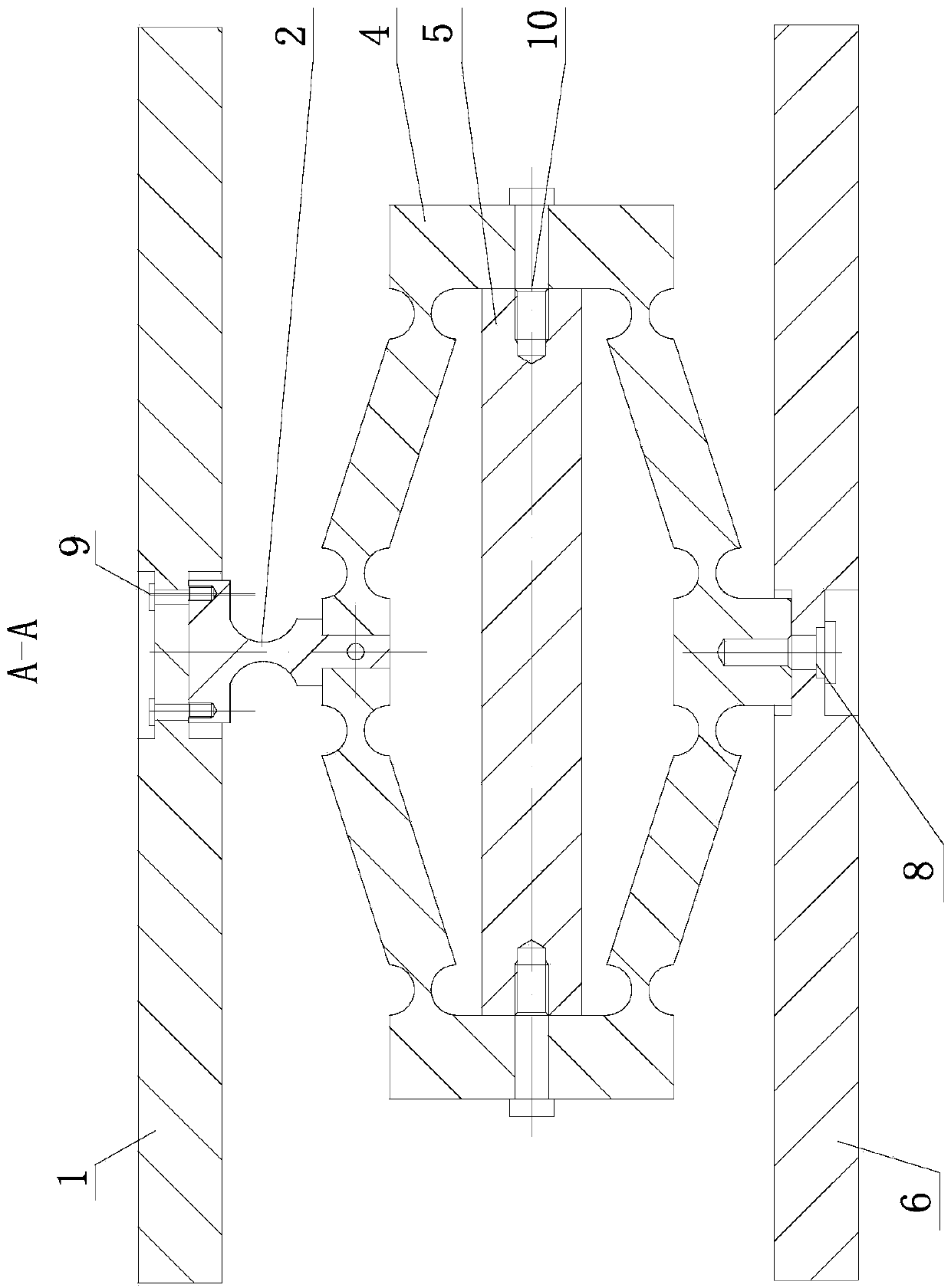

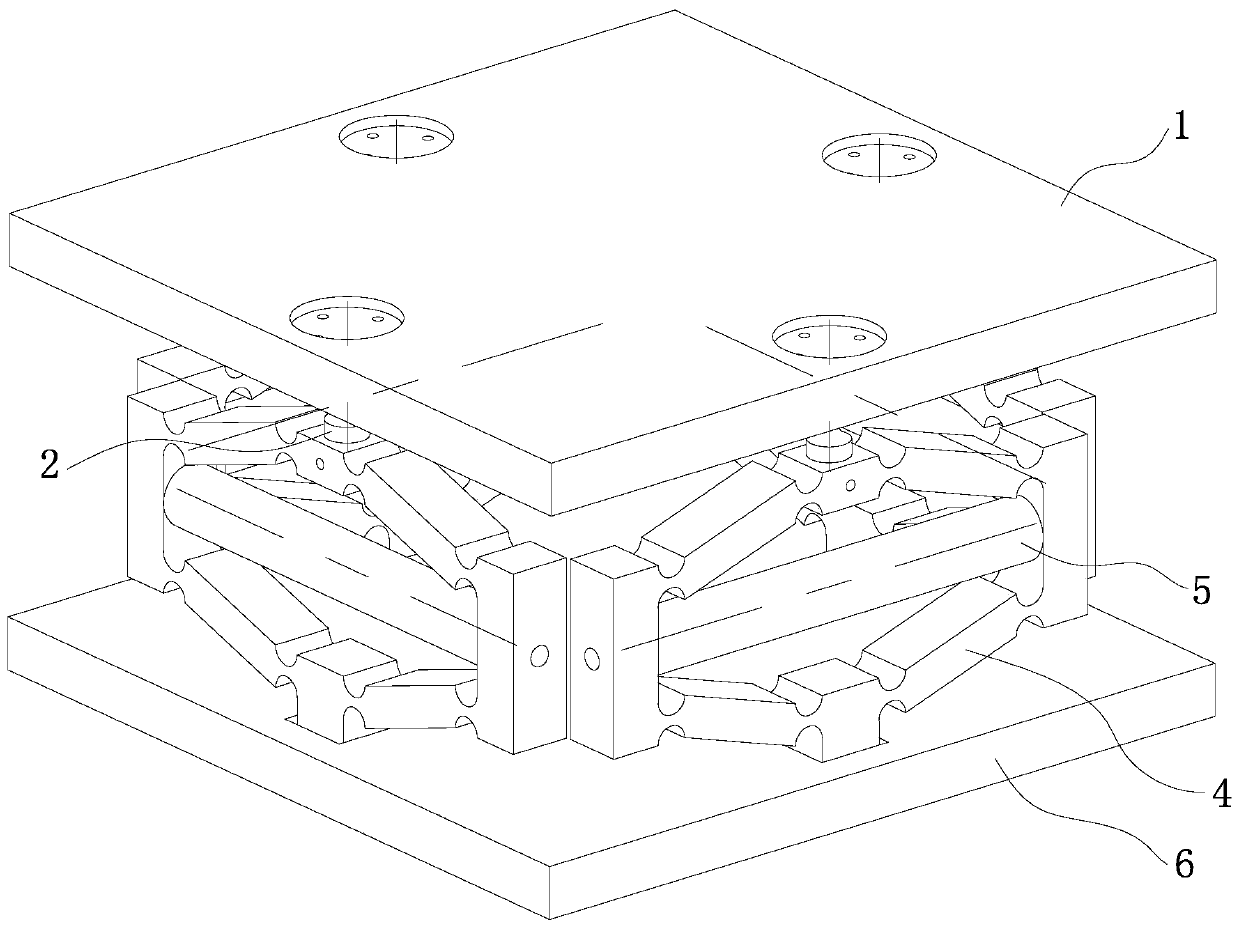

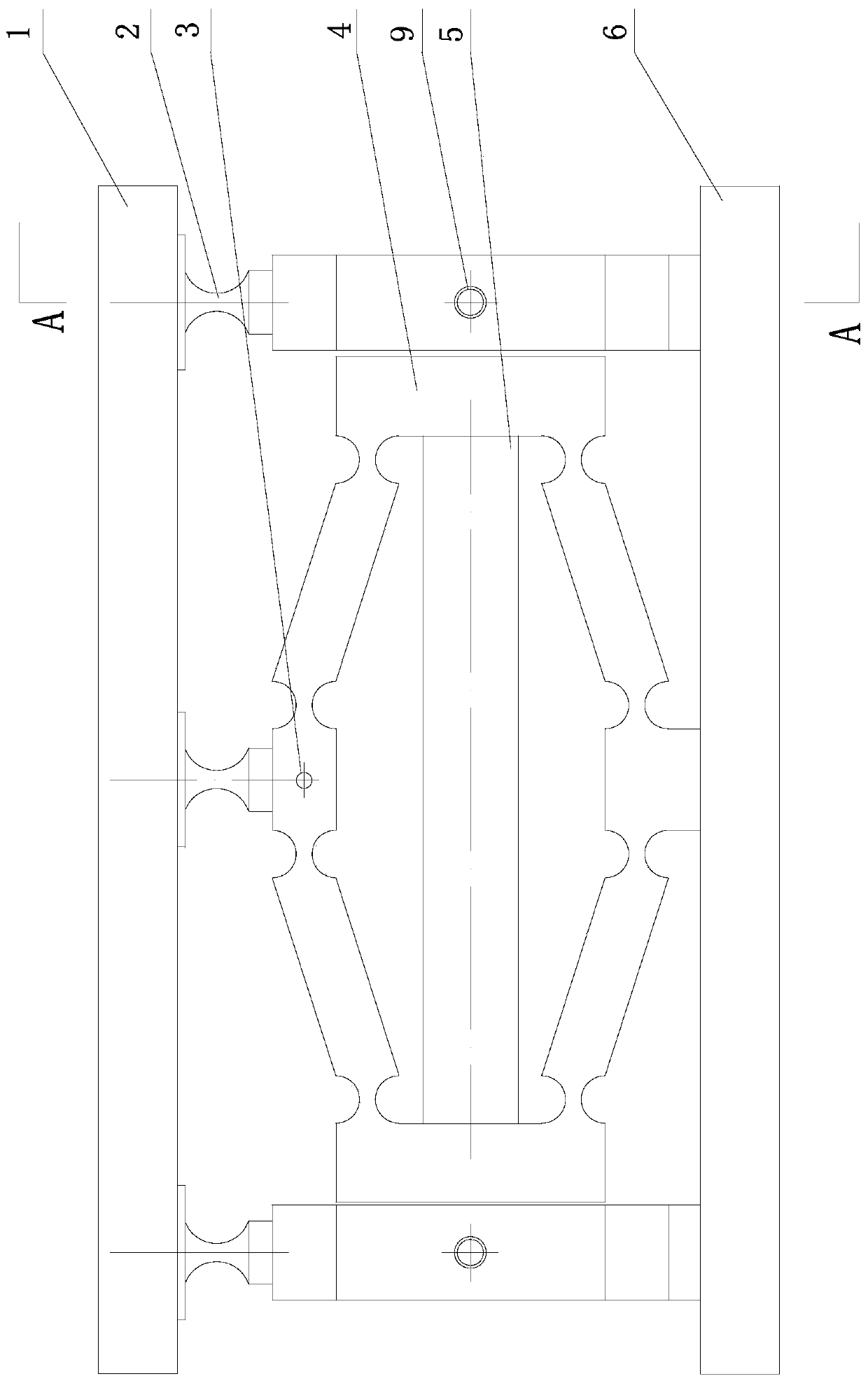

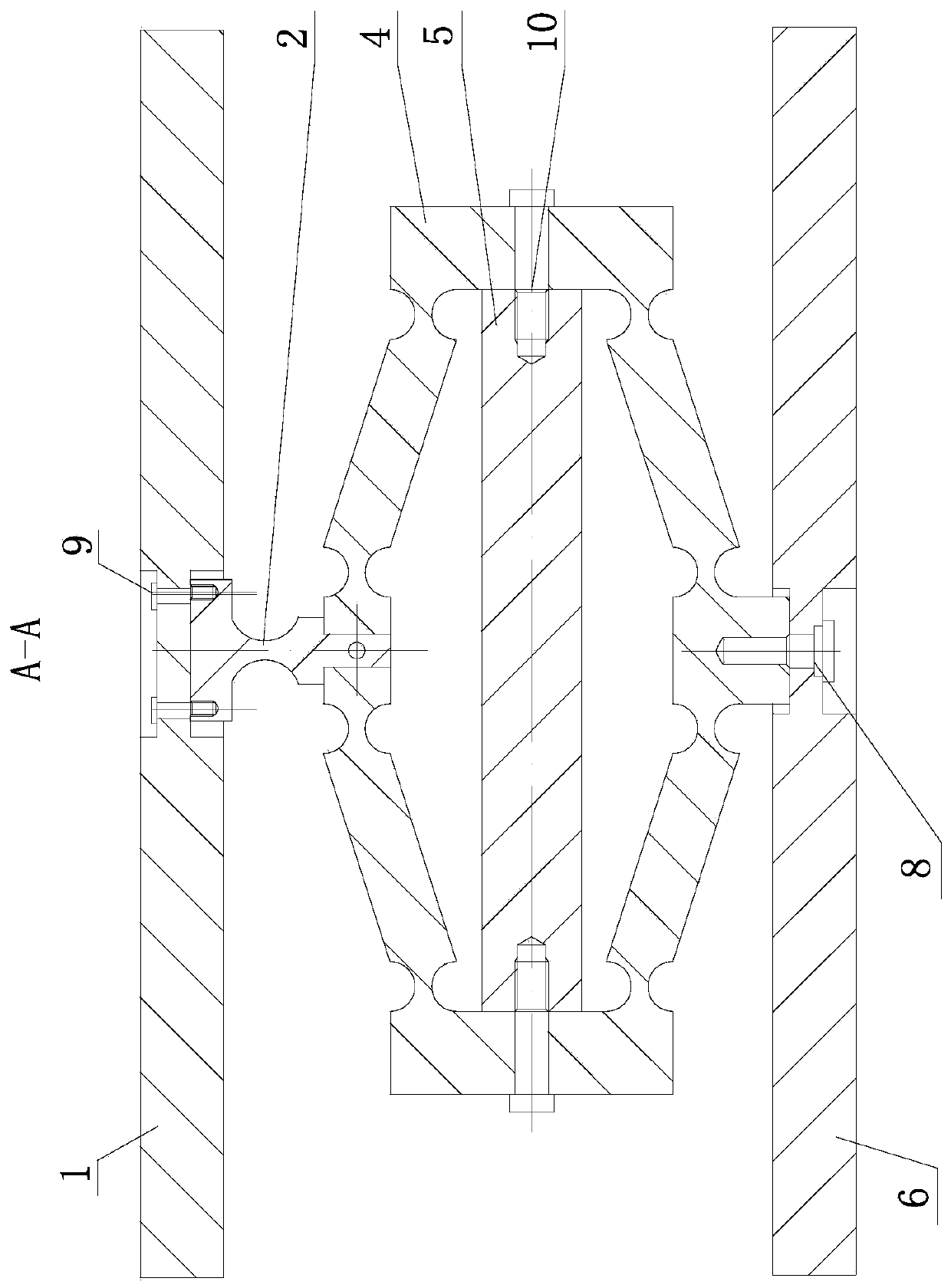

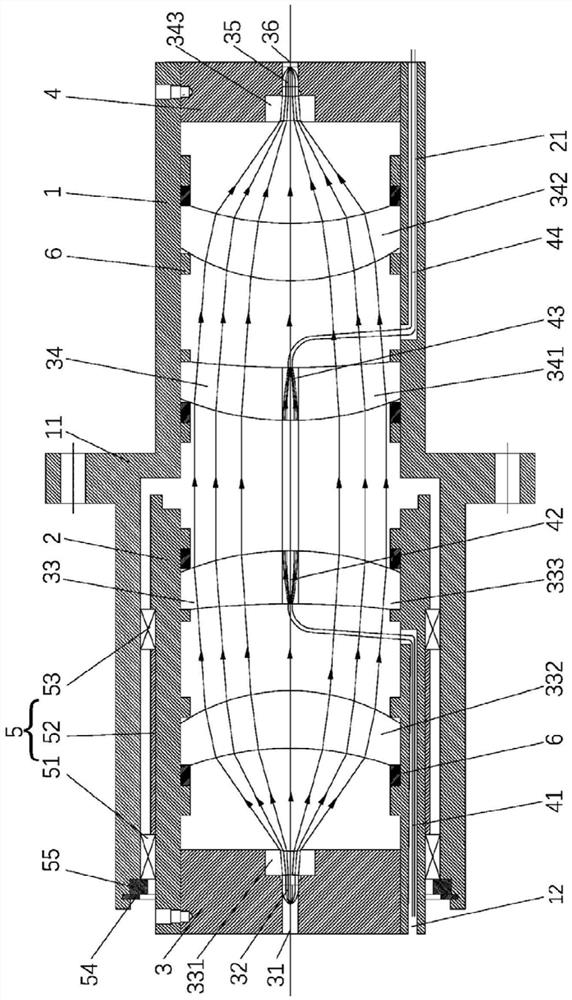

Symmetrical piezoelectric-driven two-dimensional directional adjusting mechanism and rotating platform angle adjusting method

ActiveCN109546887AWide range of angle adjustmentHigh precisionPiezoelectric/electrostriction/magnetostriction machinesElectricitySpace environment

A symmetrical piezoelectric-driven two-dimensional directional adjusting mechanism and a rotating platform angle adjusting method are provided. The invention relates to a piezoelectric driving deviceand an adjusting method. The symmetrical piezoelectric-driven two-dimensional directional adjusting mechanism comprises a rotating platform, a base, universal flexure hinges and four displacement amplifying units. Each displacement amplifying unit is mainly composed of a triangular amplifying structure and a piezoelectric ceramic actuator. The universal flexure hinges and the triangular amplifyingstructures are arranged between the rotating platform and the base. The rotating platform angle adjusting method comprises the following steps: gasless connection is carried out on the symmetrical piezoelectric-driven two-dimensional directional adjusting mechanism, and after installation, the initial height displacement deviation of the two symmetrical universal flexure hinges of the rotating platform is measured by using a laser displacement sensor; and then, the angle of the rotating platform is adjusted, and when the work is finished, the piezoelectric ceramic actuators are powered off and restored to the initial state. The symmetrical piezoelectric-driven two-dimensional directional adjusting mechanism and the rotating platform angle adjusting method are applied to the field of precision directional positioning and laser communication in a space environment.

Owner:HARBIN INST OF TECH

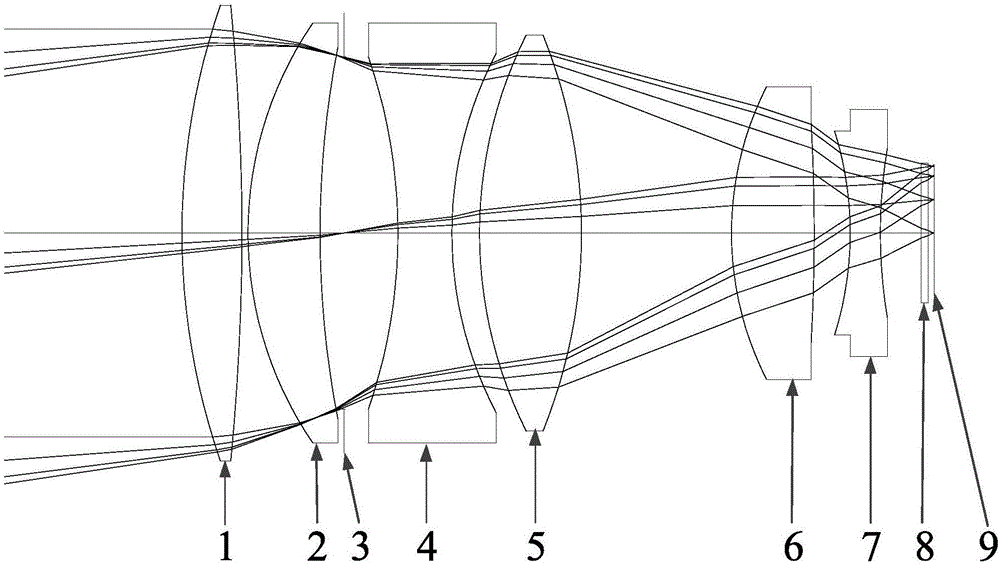

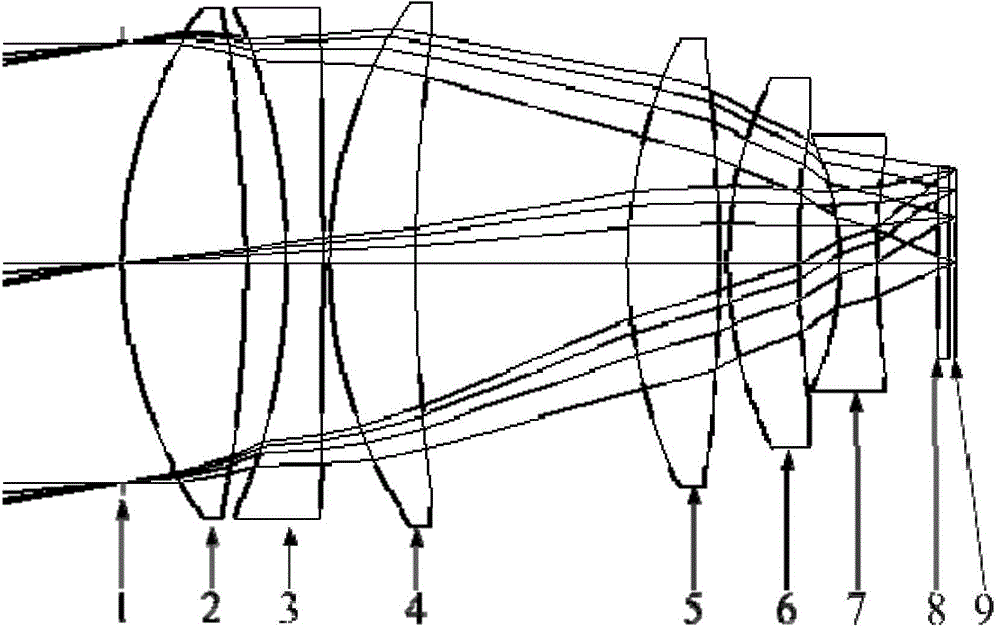

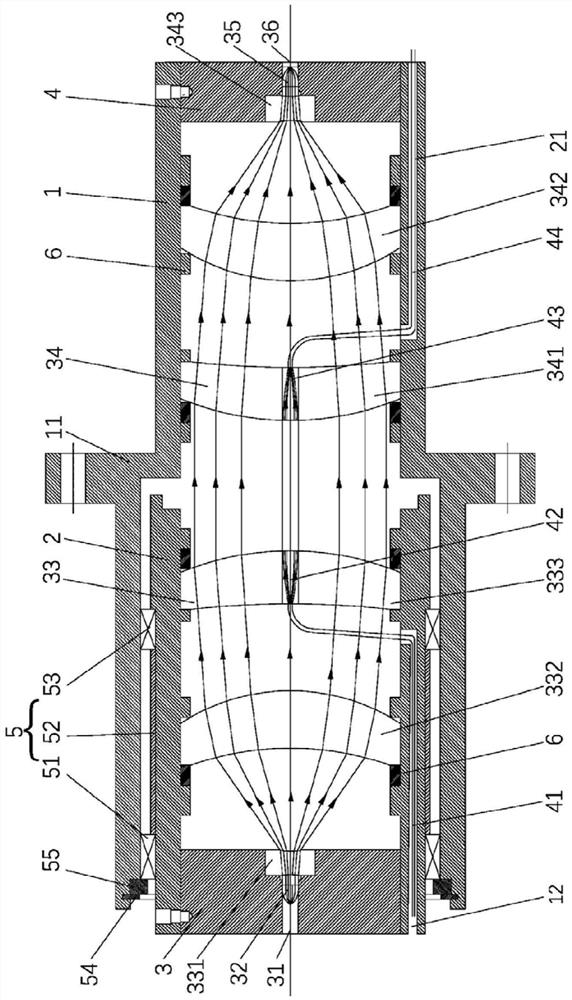

Optical system for miniaturization high-precision star sensor

ActiveCN106772936AHigh detection sensitivityComprehensive collectionMeasurement devicesOptical elementsImaging qualityMiniaturization

The invention provides an optical system for a miniaturization high-precision star sensor. According to the invention, a quasi-gauss lens structure is adopted and formed by 6 lenses; all the lenses are spherical lenses; and the glass of the first lens is made of fused quartz materials so that the first lens can be immediately used for correcting image difference and can be used as protection glass of the optical system. According to the optical system is characterized by wide spectrum, large view side and large relative aperture and has quite small distortion quantity in a quite wide spectrum range and view field; the concentration degree of confusion disc energy of each view field is uniformly distributed; the imaging quality is good; the system can work at a temperature from -50 DEG C to +70 DEG C and has good image quality and defocusing amount; and posture measurement of high-precision star sensor working in severe space and temperature can be met.

Owner:BEIJING INST OF CONTROL ENG

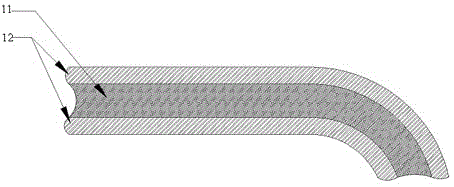

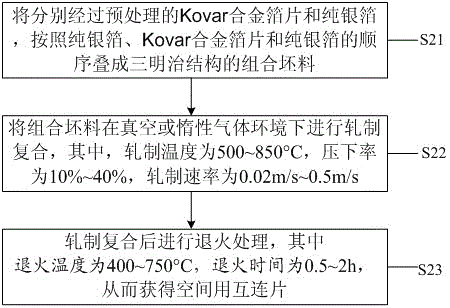

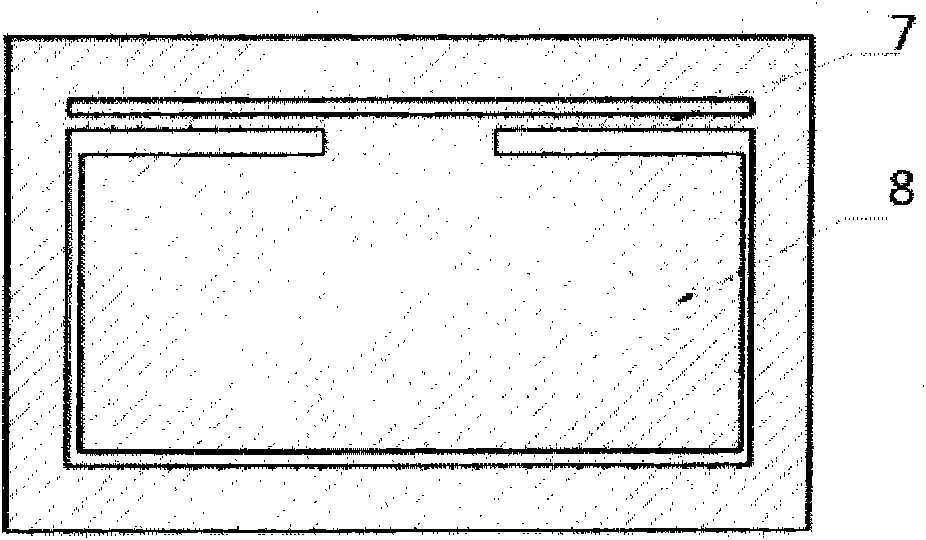

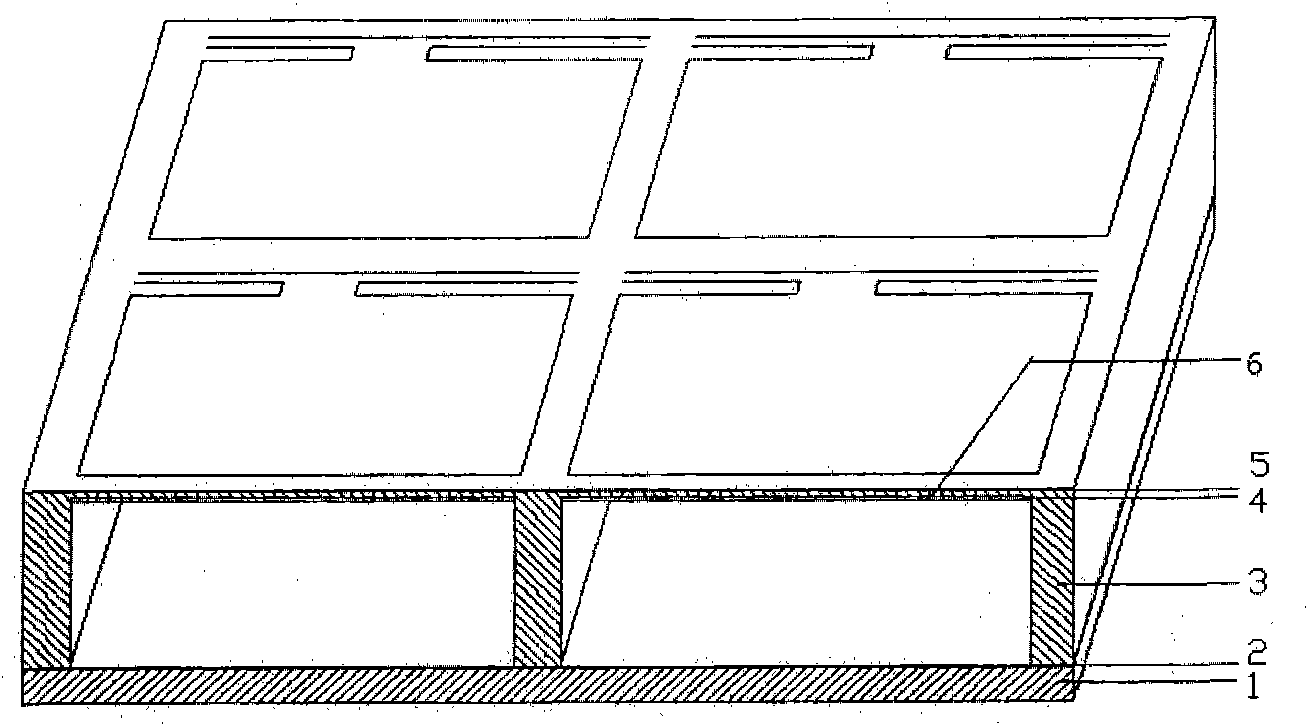

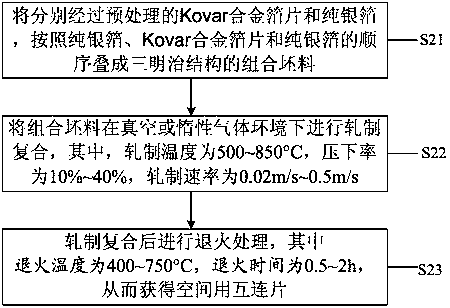

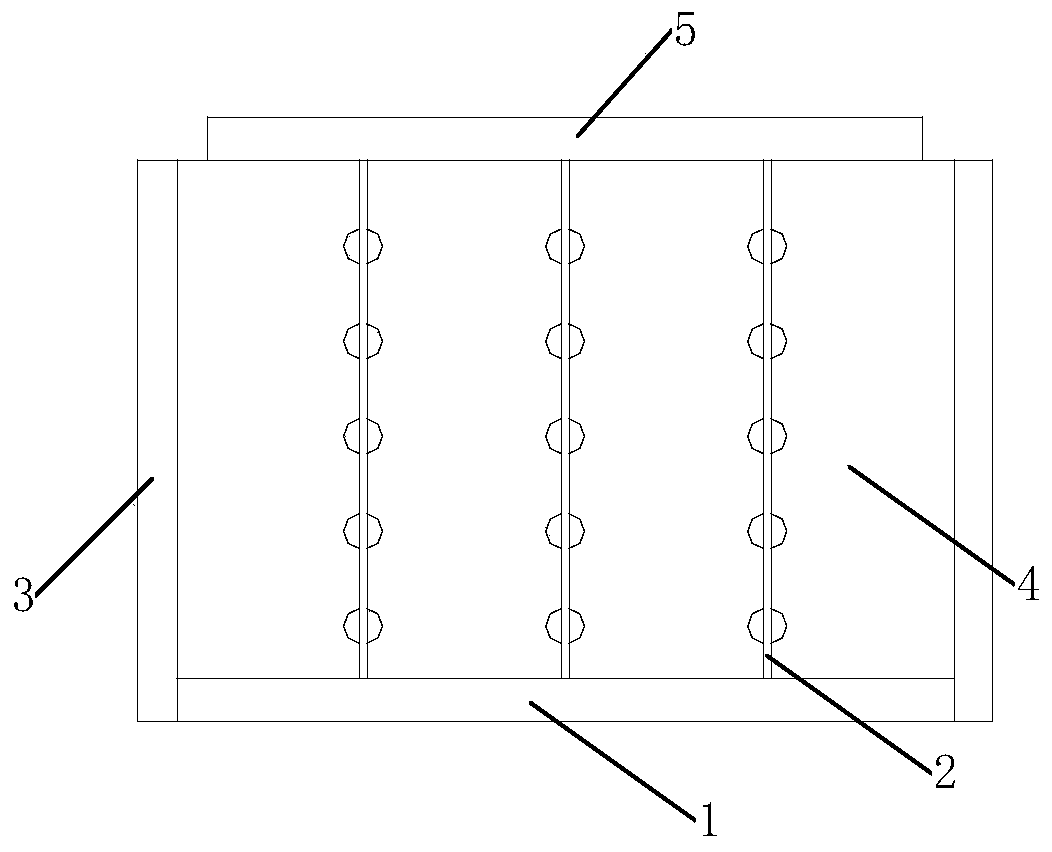

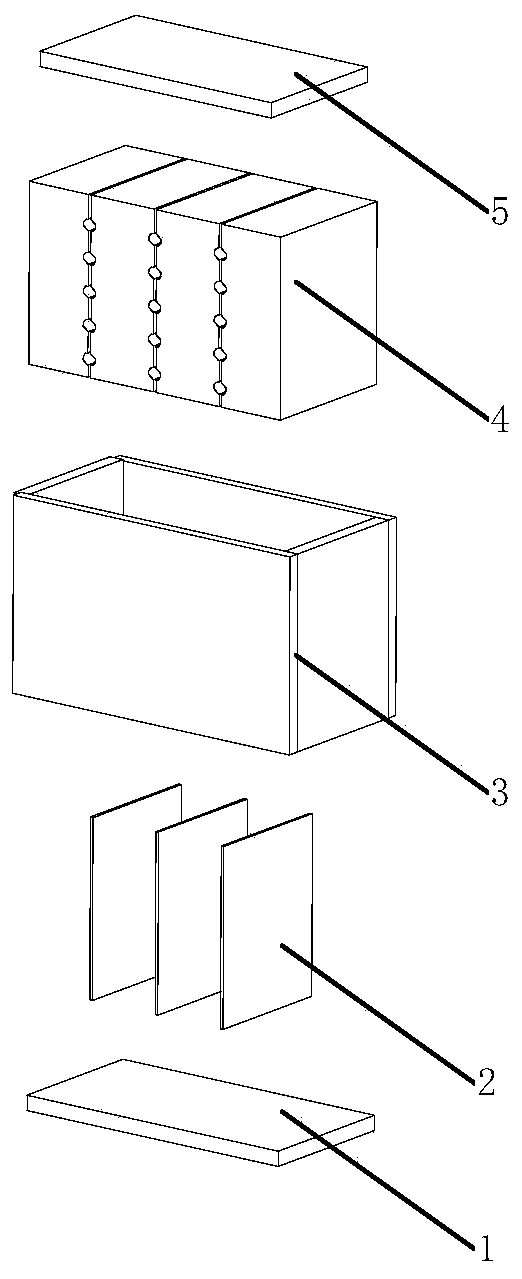

Spaceborne Kovar/silver metal laminated composite material and preparation method thereof

ActiveCN106711261AThe interface is firmly bondedGood space environment adaptabilityFinal product manufacturePhotovoltaic energy generationKovarInert gas

The invention relates to a spaceborne Kovar / silver metal laminated composite material and a preparation method thereof. The composite material comprises a Kovar alloy foil piece and two pure silver foils, and is characterized in that the pure silver foils acting as surface layers and the Kovar alloy foil piece acting as an interlayer form a laminated sandwich structure, and the top, middle and bottom layers form chemical bonds through rolling and bonding so as to be connected into an integral whole. The preparation method comprises the steps of laminating the pure silver foils and the Kovar alloy foil piece into a combined blank with a sandwich structure according to a sequence of the pure silver foil, the Kovar alloy foil piece and the pure silver foil; performing hot rolling and composite bonding on the combined blank; performing further annealing processing at the atmosphere of an inert gas after rolling and bonding, and acquiring a spaceborne Kovar / silver metal laminated composite material after annealing processing. The composite material has good space environment adaptability, thermal conductivity, electrical conductivity and weldability, and meets requirements of space electronic packaging applications; and the spaceborne Kovar / silver laminated composite material is simple in production process, sable and controllable in quality, convenient to operate and capable of realizing large-area automatic roll-to-roll batch production.

Owner:SHANGHAI INST OF SPACE POWER SOURCES

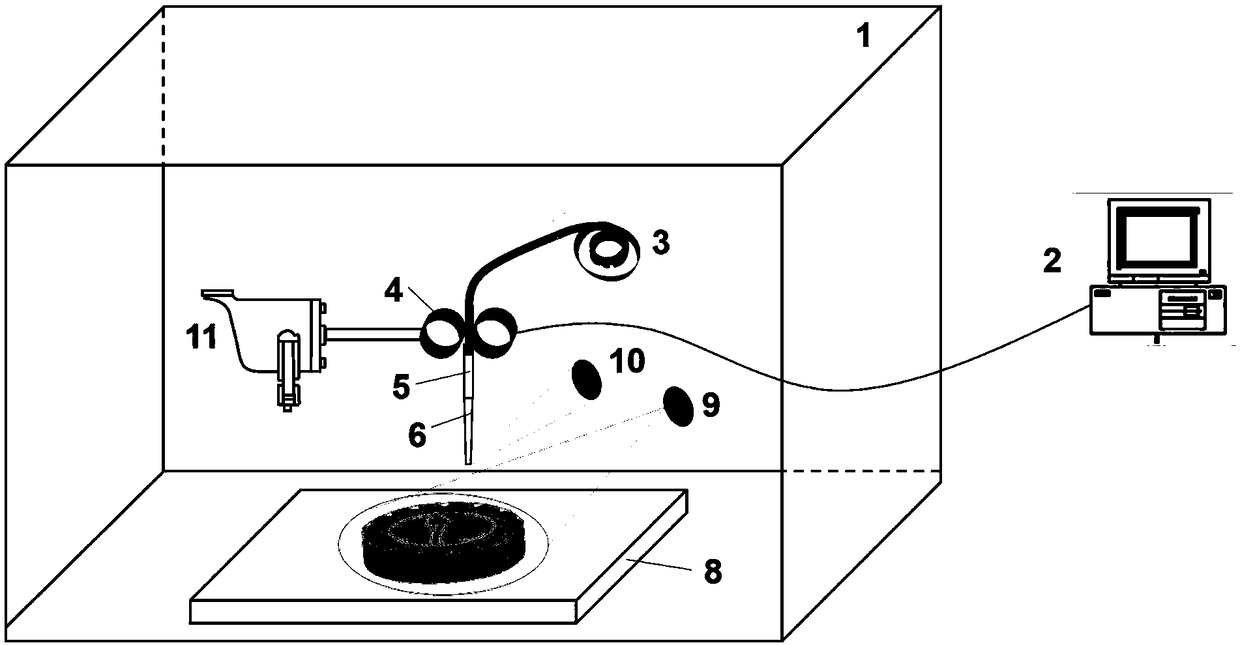

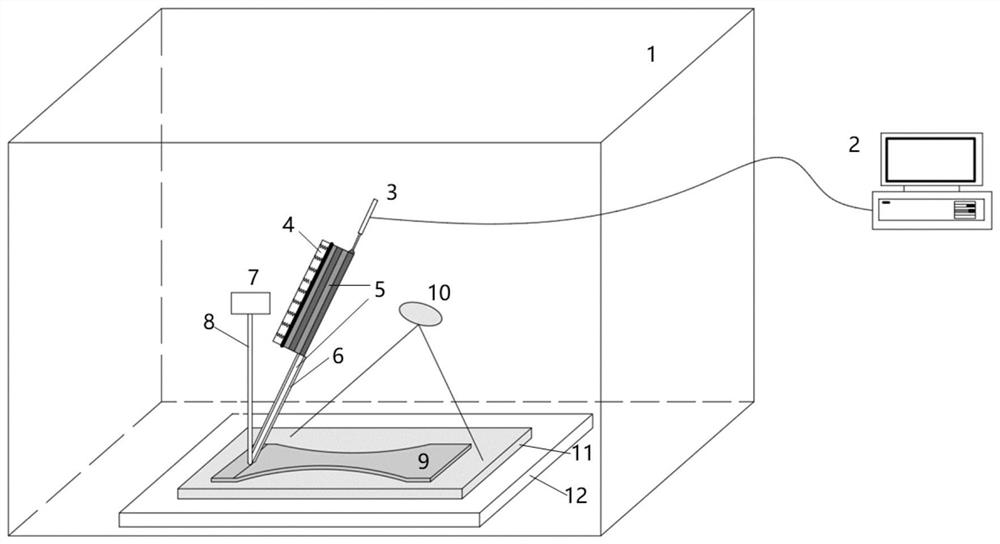

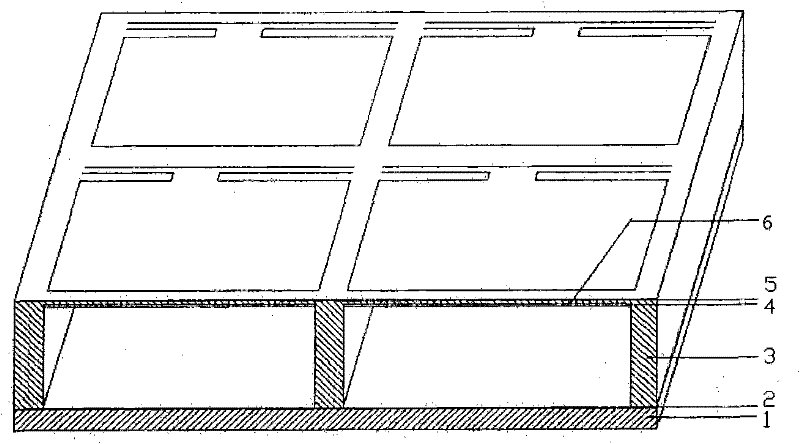

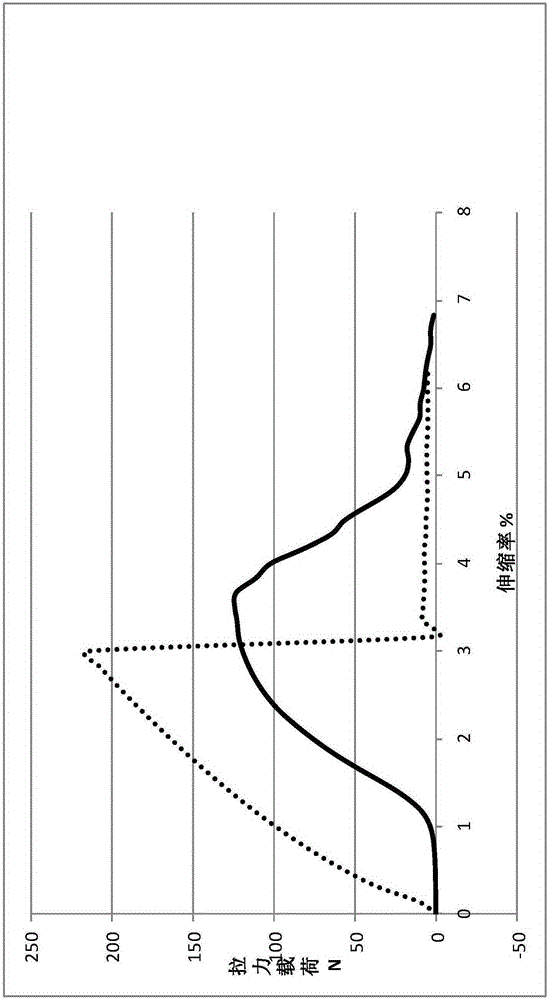

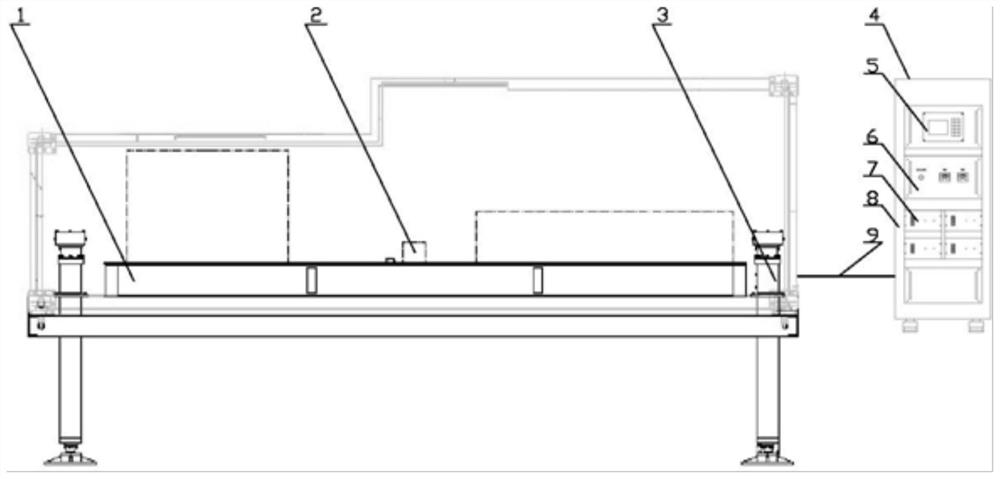

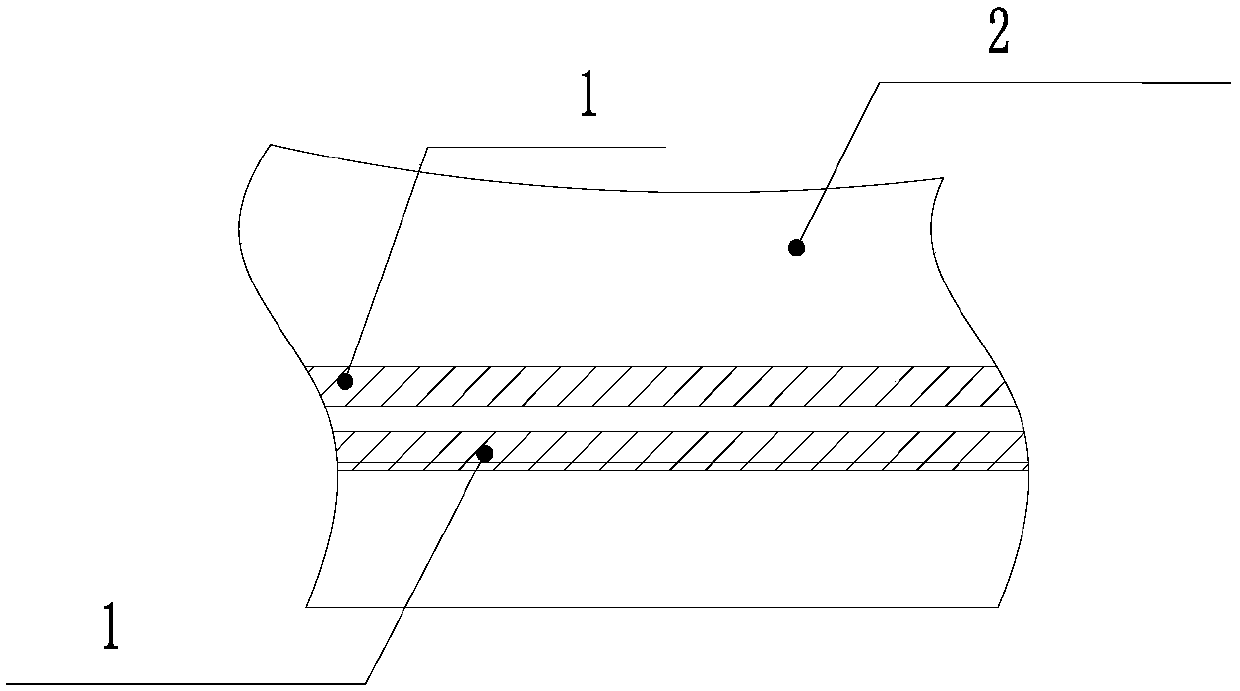

Space 3D printing system based on amorphous alloy superplastic welding

PendingCN109434112AAvoid the risk of high temperature crystallizationImprove job stabilityAdditive manufacturing apparatusSpace environmentOrbit

The invention discloses a space 3D printing system based on amorphous alloy superplastic welding. The space 3D printing system comprises a shell (1), a control unit (2), a workbench (8) arranged inside the shell (1), an amorphous alloy material (3), a heating device, a mechanical loading device (11) and a conveying device, wherein the mechanical loading device (11) controls the speed of the conveying device and the pressure load of a spray head (6) according to the material use requirements of 3D printing molding parts, and the heating device performs local heating and welding on the amorphousalloy material (3) to realize part molding. According to the space 3D printing system based on the amorphous alloy superplastic welding, the heating device only heats an area near the spray head, thecrystallization risk of amorphous alloy under a long-time high-temperature condition is avoided, and the amorphous alloy is heated to a superplastic state of a supercooled liquid phase area to realize molding, a laser or electron beam heating device is cancelled, the equipment working stability is increased, and the space 3D printing system based on the amorphous alloy superplastic welding is especially suitable for in-orbit fabrication in the space environment.

Owner:CHINA ACADEMY OF SPACE TECHNOLOGY +1

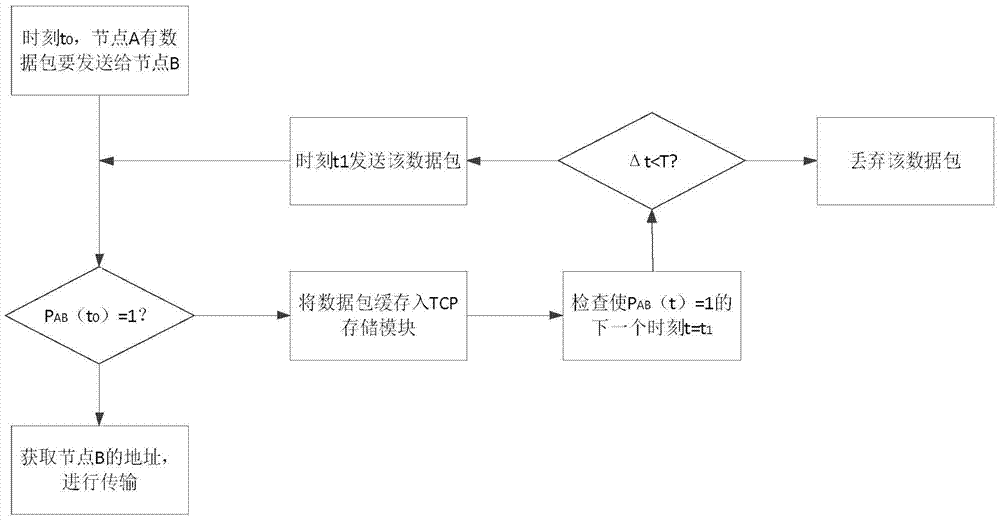

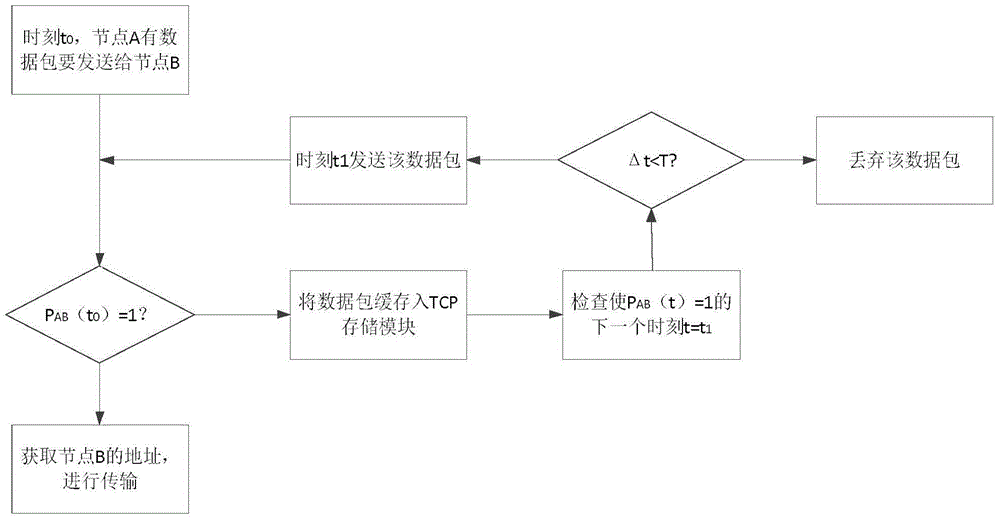

Method for reducing transmission control protocol (TCP) message loss in space information network

The invention provides a method for reducing transmission control protocol (TCP) message loss in a space information network. According to the method, data packet loss can be effectively reduced, link throughput can be improved, and unnecessary retransmission of a transmitting end in case of link disconnection is prevented. The method is implemented as follows: a transmitting storage module is added at a transmitting end of the TCP; according to a known motion track of a man-made satellite and a predictable characteristic of link disruption due to celestial body blocking, a communication time sequence PAB (t) between any nodes A and B is pre-arranged in the space information network with a node motion rule that can be followed, wherein when PAB (t) is equal to 1, nodes A and B are in a link communication state at the time t, when PAB (t) is equal to 0, nodes A and B are in a link disconnection state at time t; while the network operates, for any time t0, a sending node A firstly verifies the value of PAB(t0), if PAB (t0) is equal to 1, a data packet is sent to a target node B; and if PAB (t0) is equal to 0, the data packet is cached in the storage module of the TCP, and the cached data packet is extracted from the cache and is recovered and sent at next time when PAB (t) is equal to 1 and t is equal to t1.

Owner:10TH RES INST OF CETC

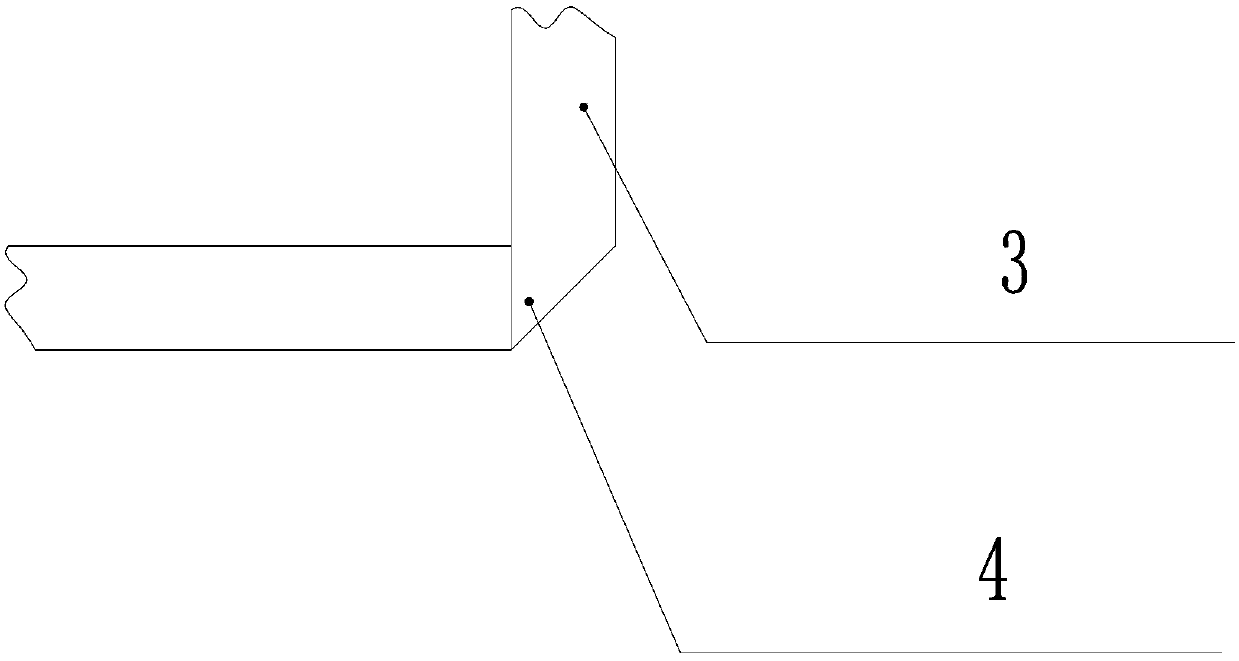

3D printing system and method suitable for micro-gravity space environment

InactiveCN111761063AResistant to atomic oxygen ablationAvoid cold weldingAdditive manufacturing apparatusControl cellEngineering

The invention discloses a 3D printing system suitable for a micro-gravity space environment. The 3D printing system comprises a housing (1) and a control unit (2) as well as a workbench (12) arrangedinside the housing (1), a base plate (11) arranged on the workbench (12), a feeding unit, and a processing head part, wherein the feeding unit comprises a storage device (4), a feeding mechanism (6) arranged at one end of the storage device (4) and an ejecting-out mechanism (3) arranged at the other end of the storage device (4); and the processing head part comprises a small laser unit (7). The invention further discloses a 3D printing method suitable for the micro-gravity space environment. The system avoids the crystallization risk that an amorphous alloy is connected and formed in a thermoplastic mode under a long-time high-temperature condition, can achieve coaxial feeding, is high in forming efficiency, guarantees uniform and continuous discharge, can form a part of any shape, can obtain a large-dimension amorphous alloy part with high forming quality, can keep good equipment work stability, and is especially suitable for on-track manufacturing in the space environment.

Owner:HUAZHONG UNIV OF SCI & TECH

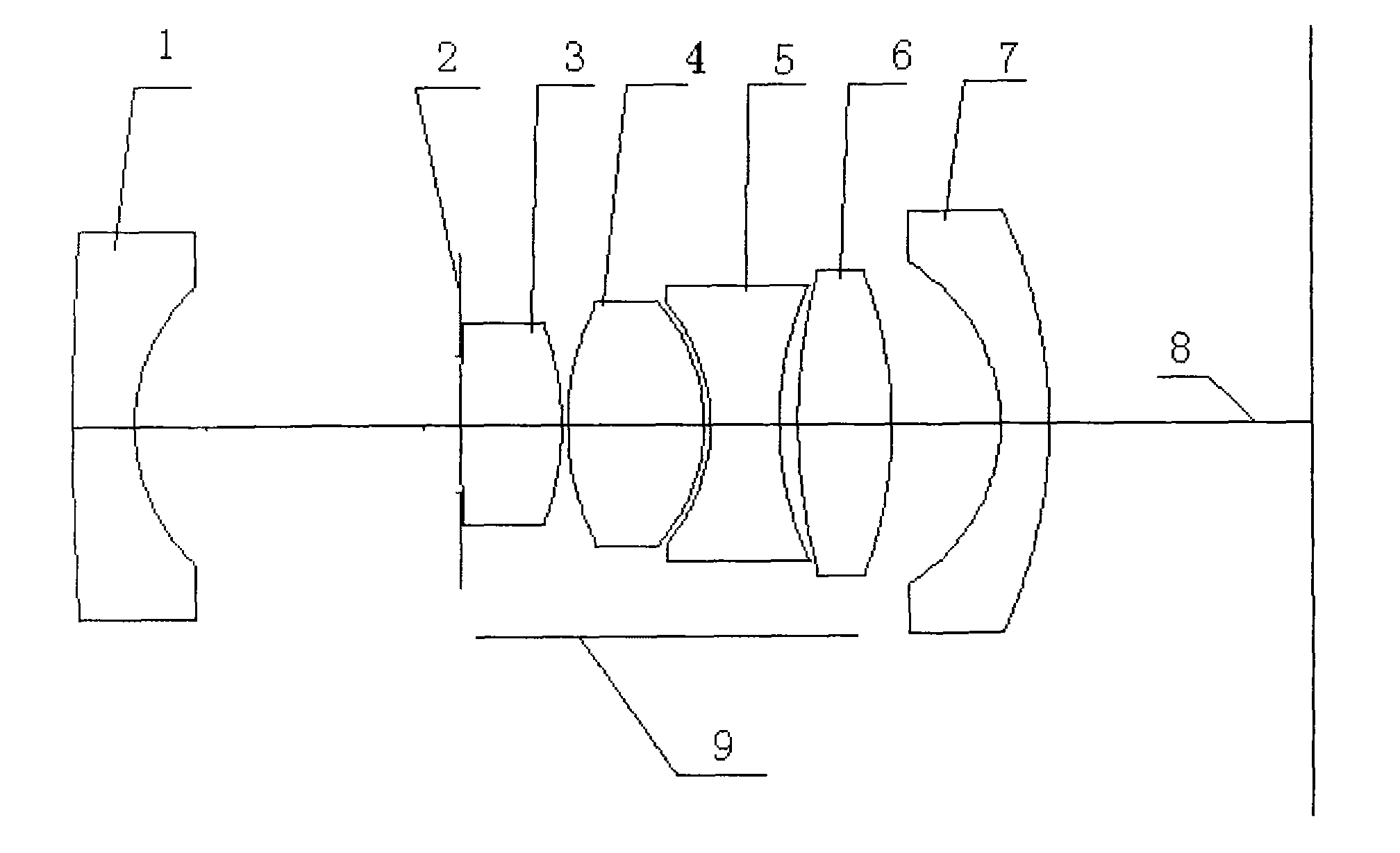

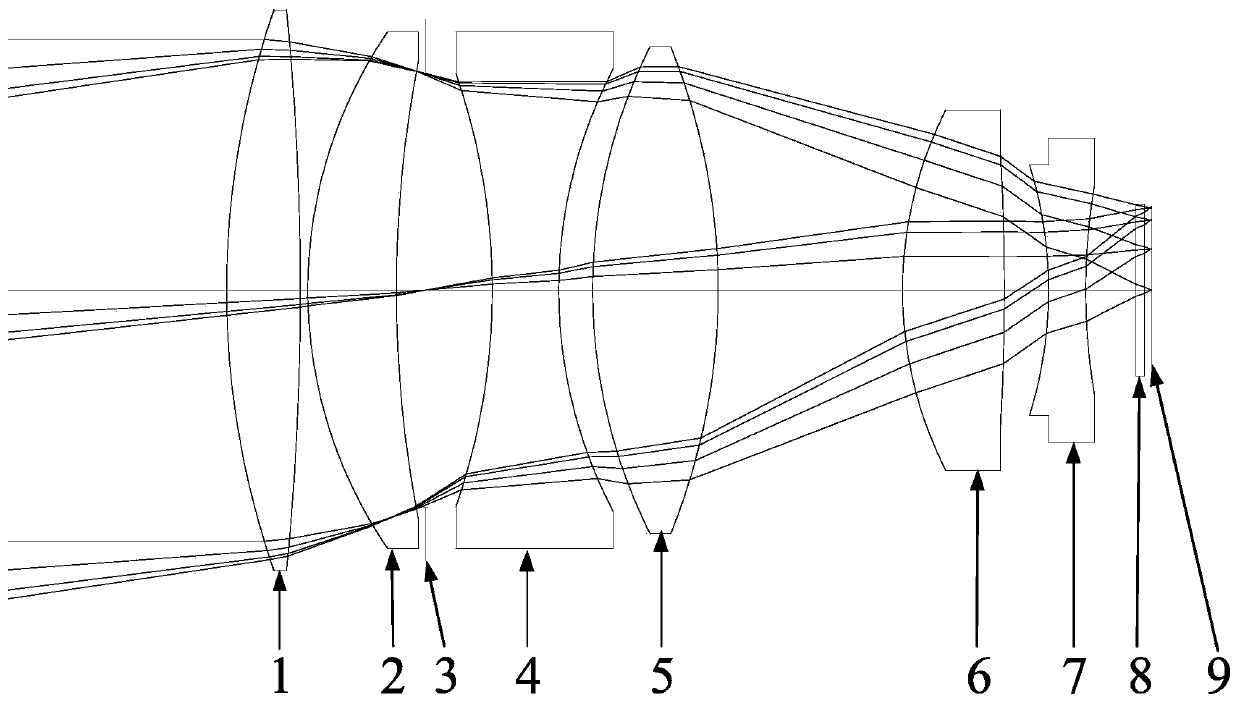

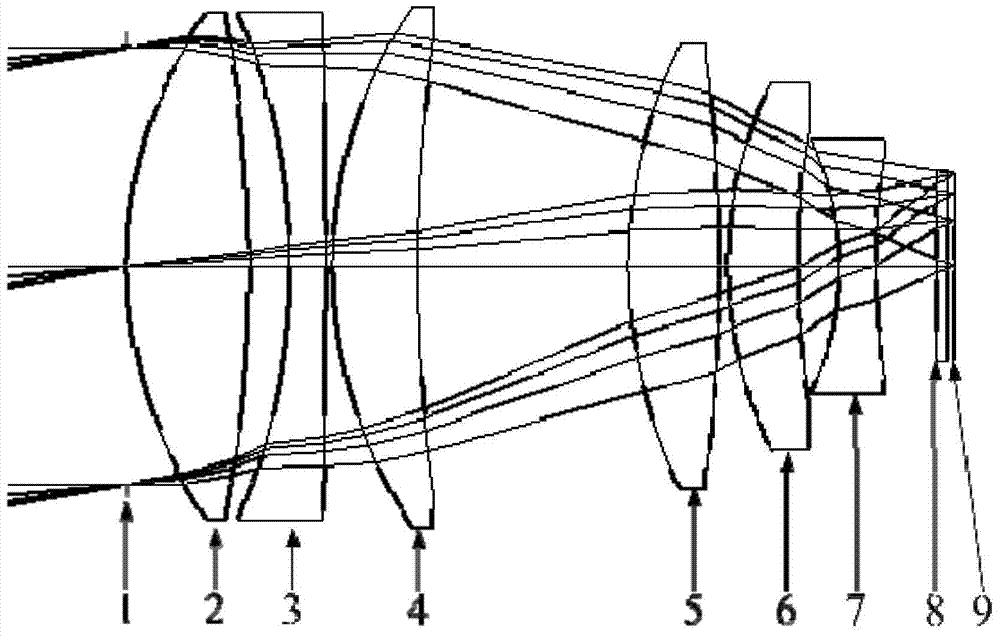

Optical system for star sensor

ActiveCN104833355ASpectral widthLarge spectrumNavigation by astronomical meansVisual field lossImaging quality

The invention relates to an optical system for a star sensor. The optical system is applied to high-precision star sensors. The optical system is of an improved peaceful structure and consists of six lenses, wherein the six lenses are all spherical lenses; an aperture diaphragm is arranged on first glass; the first glass is made of fused quartz, can be used for correcting aberration and can be used as protective glass of the optical system. The optical system has the characteristics of wide spectrum, large visual field, relative large aperture and the like; the distortion is very low in relatively large spectral range and visual fields, concentration ratios of discs of confusion of each visual field are uniformly distributed, and the imaging quality is good. The optical system can work in a temperature range from -40 DEG C to 50 DEG C, has good image quality and defocusing amount at each temperature point and can meet attitude measurement requirements of the high-precision star sensors working at severe space temperature environments.

Owner:BEIJING INST OF CONTROL ENG

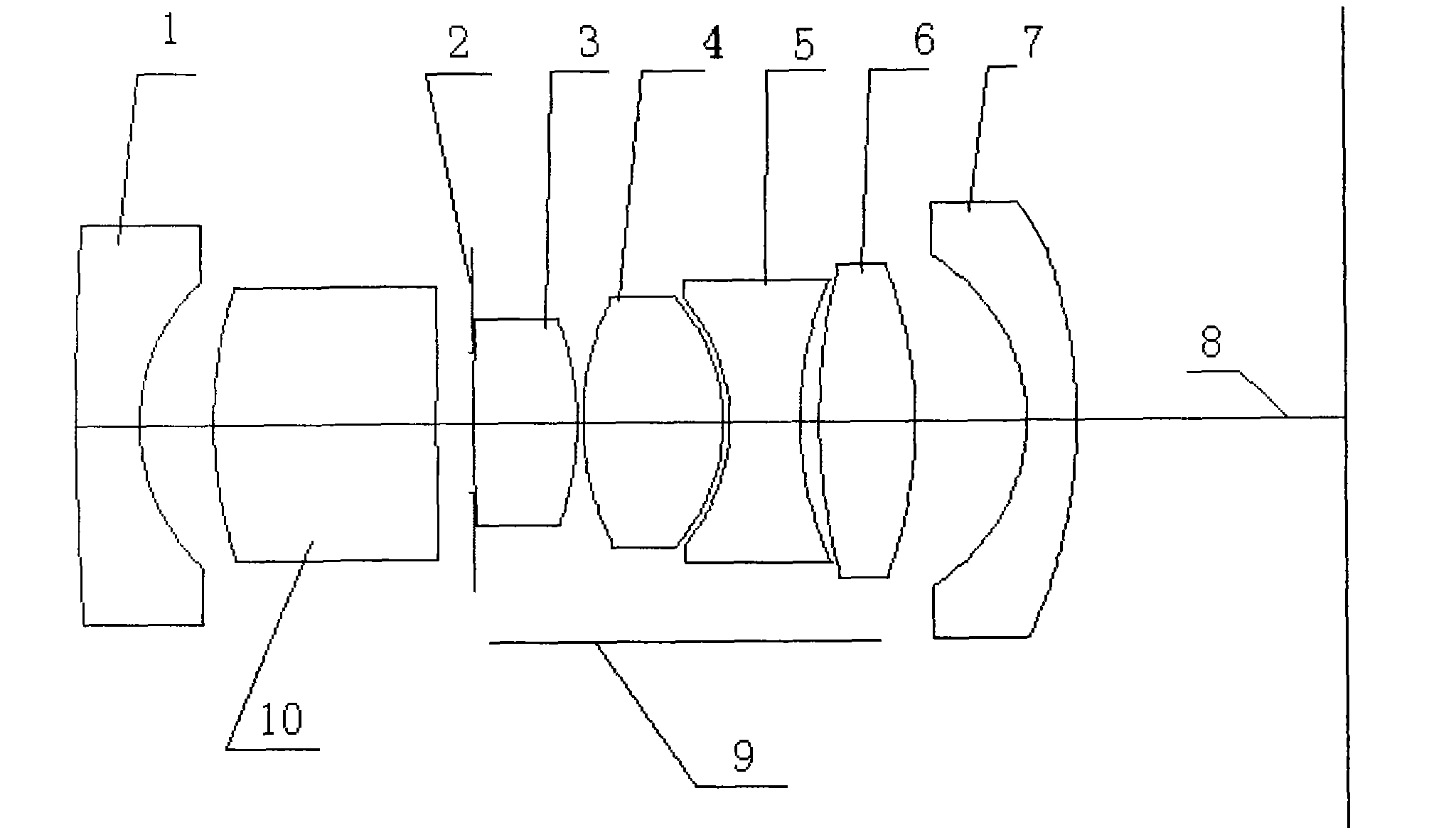

Ultraviolet wide-angle objective lens used for moon exploration

InactiveCN101634741AGood space environment adaptabilityGood for correcting astigmatismOptical elementsOptical axisNegative power

The invention relates to an ultraviolet wide angle objective lens which is used for moon exploration, comprising a front-end negative power lens (1), a rear-end negative power lens (7) and an intermediate-group lens with positive power, wherein, the front-end negative power lens (1), the intermediate-group lens and the rear-end negative power lens (7) are arranged on a same optical axis (8) in turn. The invention provides the ultraviolet wide angle objective lens which is capable of correcting aberration and distortion.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

Rigid-flexible coupling hyper-redundant intelligent sensing mechanical arm and using method thereof

PendingCN114227660AModularity hasStrong adaptability to space environmentProgramme-controlled manipulatorJointsControl engineeringElectric machinery

The rigid-flexible coupling hyper-redundant intelligent sensing mechanical arm comprises a mechanical arm body, an operation device and a driving mechanism are arranged at the front end and the rear end of the mechanical arm body respectively, and the mechanical arm body is formed by sequentially connecting a plurality of bending units; each bending unit comprises a plurality of middle sections connected in sequence, base sections are arranged at the two ends of each middle section, the base sections and the middle sections are of hollow cylindrical structures, the base sections and the middle sections are movably connected through cross hinges, and every two adjacent middle sections are movably connected through cross hinges; the driving mechanism comprises a plurality of driving motors, reels are arranged on rotating shafts of the driving motors, a plurality of tendon ropes are arranged in the bending unit, one ends of the tendon ropes are fixed to the front end of the bending unit, and the other ends of the tendon ropes are connected with the reels respectively. The mechanical arm has the advantages of modularization, super-redundancy self-adaption, high space environment adaptability, measurable tail end pose, perceptible external contact and the like, and can be used for capturing and grabbing non-cooperative and cooperative targets and internal investigation of complex cavities.

Owner:BEIJING INST OF SPACECRAFT SYST ENG +1

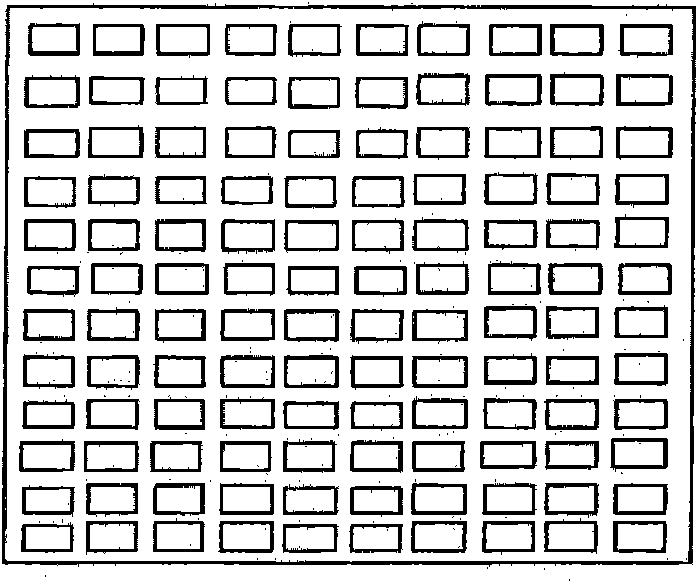

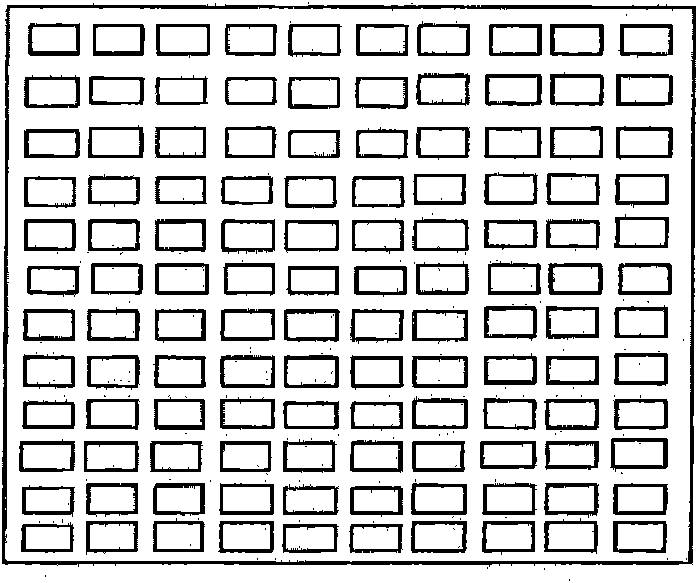

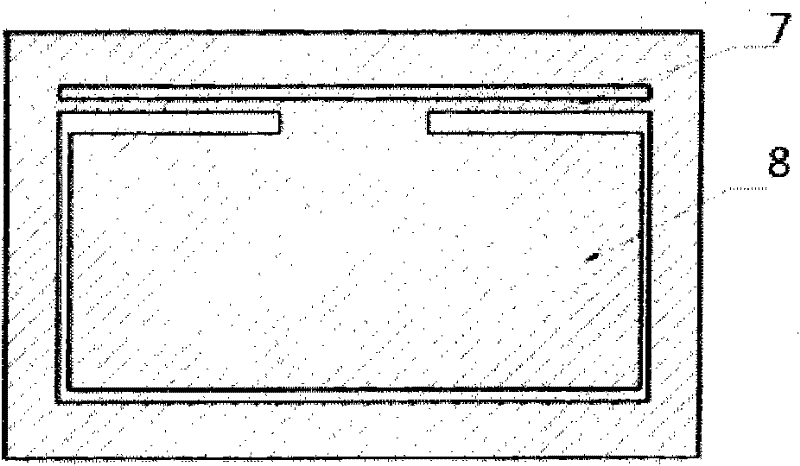

Method for manufacturing micromechanical shutter

ActiveCN102033425AExtend device lifeGood space environment adaptabilityDecorative surface effectsPhotomechanical apparatusPhotoresistCorrosion

The invention relates to a method for manufacturing a micromechanical shutter, which comprises the following steps of: 1) selecting a stainless steel substrate, preparing a layer of positive photoresist on the upper and lower surfaces of the substrate respectively, and pre-curing the photoresist; 2) exposing a rectangular hole array serving as a mask, wherein the pre-cured photoresist on the lower surface is not exposed; 3) developing the substrate, finishing full curing of the photoresist, then performing corrosion, removing the photoresist and cleaning the substrate; 4) spraying the positive photoresist on the upper and lower surfaces of the substrate, and pre-curing the photoresist; 5) on the photoresist on the lower surface of the substrate, exposing a twist beam type shutter corroding pattern array serving as a mask, wherein the upper surface of the substrate is not exposed; 6) developing the substrate, finishing full curing of the photoresist, then performing corrosion, removing the photoresist and cleaning the substrate; 7) manufacturing a shutter substrate; and 8) assembling and fixing the shutter blade structure and the substrate, and finishing upper and lower electrode leads. According to the method, the stainless steel is used as a structural material, so the micromechanical shutter has longer service life and higher reliability.

Owner:NO 510 INST THE FIFTH RES INST OFCHINA AEROSPAE SCI & TECH

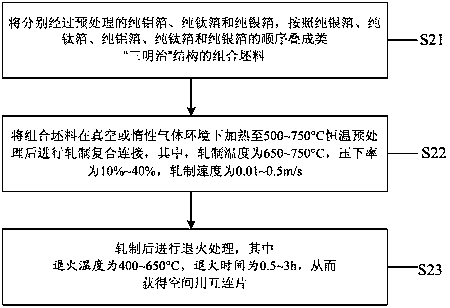

A kind of Kovar/silver metal layered composite material for space and preparation method thereof

ActiveCN106711261BThe interface is firmly bondedGood space environment adaptabilityFinal product manufactureAuxillary arrangementsChemical LinkageSurface layer

The invention relates to a spaceborne Kovar / silver metal laminated composite material and a preparation method thereof. The composite material comprises a Kovar alloy foil piece and two pure silver foils, and is characterized in that the pure silver foils acting as surface layers and the Kovar alloy foil piece acting as an interlayer form a laminated sandwich structure, and the top, middle and bottom layers form chemical bonds through rolling and bonding so as to be connected into an integral whole. The preparation method comprises the steps of laminating the pure silver foils and the Kovar alloy foil piece into a combined blank with a sandwich structure according to a sequence of the pure silver foil, the Kovar alloy foil piece and the pure silver foil; performing hot rolling and composite bonding on the combined blank; performing further annealing processing at the atmosphere of an inert gas after rolling and bonding, and acquiring a spaceborne Kovar / silver metal laminated composite material after annealing processing. The composite material has good space environment adaptability, thermal conductivity, electrical conductivity and weldability, and meets requirements of space electronic packaging applications; and the spaceborne Kovar / silver laminated composite material is simple in production process, sable and controllable in quality, convenient to operate and capable of realizing large-area automatic roll-to-roll batch production.

Owner:SHANGHAI INST OF SPACE POWER SOURCES

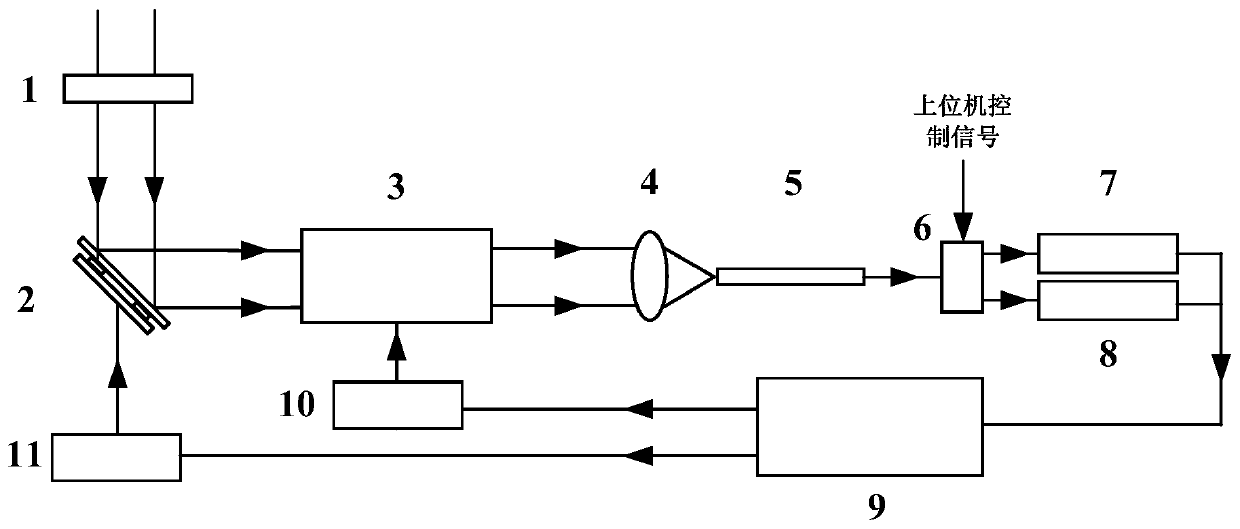

Electro-optical nutation coupling system and method for space laser communication

ActiveCN110601756AStrong vibrationNo mechanical movementFree-space transmissionElectromagnetic receiversCommunications systemNutation

The invention discloses an electro-optical nutation coupling system and method for space laser communication, and belongs to the field of laser communication. The system comprises a quarter-wave plate, a fast reflector, an electro-optical deflector, a coupling lens, a single-mode optical fiber, an optical switch, an incoherent receiving module, a coherent receiving module, a communication and angle error resolving module, an electro-optical deflector driving module and a fast reflector driving module. According to the invention, based on an electro-optic deflection effect, a non-mechanical electro-optical deflection device is adopted; two-dimensional scanning and nutation coupling of a laser beam are realized by controlling the electro-optical deflector; while communication information isdemodulated, extraction of tracking angle error amount of a laser signal and calculation of compensation amount are completed, and the electro-optical deflector and the rapid reflector are controlledto perform fine tracking compensation, so that high-precision tracking of the laser signal and stable and efficient coupling from spatial light to a single-mode optical fiber are realized. The methodcan be compatible with tracking angle error calculation and compensation under incoherent and coherent communication systems.

Owner:BEIJING RES INST OF TELEMETRY +1

A method for adjusting the angle of a rotating platform with a piezoelectrically driven two-dimensional pointing adjustment mechanism with a symmetrical structure

ActiveCN109546887BWide range of angle adjustmentHigh precisionPiezoelectric/electrostriction/magnetostriction machinesFlexure hingesActuator

A symmetrical piezoelectric-driven two-dimensional directional adjusting mechanism and a rotating platform angle adjusting method are provided. The invention relates to a piezoelectric driving deviceand an adjusting method. The symmetrical piezoelectric-driven two-dimensional directional adjusting mechanism comprises a rotating platform, a base, universal flexure hinges and four displacement amplifying units. Each displacement amplifying unit is mainly composed of a triangular amplifying structure and a piezoelectric ceramic actuator. The universal flexure hinges and the triangular amplifyingstructures are arranged between the rotating platform and the base. The rotating platform angle adjusting method comprises the following steps: gasless connection is carried out on the symmetrical piezoelectric-driven two-dimensional directional adjusting mechanism, and after installation, the initial height displacement deviation of the two symmetrical universal flexure hinges of the rotating platform is measured by using a laser displacement sensor; and then, the angle of the rotating platform is adjusted, and when the work is finished, the piezoelectric ceramic actuators are powered off and restored to the initial state. The symmetrical piezoelectric-driven two-dimensional directional adjusting mechanism and the rotating platform angle adjusting method are applied to the field of precision directional positioning and laser communication in a space environment.

Owner:HARBIN INST OF TECH

An optical system for a miniaturized high-precision star sensor

ActiveCN106772936BHigh detection sensitivityComprehensive collectionMeasurement devicesOptical elementsImaging qualityMiniaturization

The invention provides an optical system for a miniaturization high-precision star sensor. According to the invention, a quasi-gauss lens structure is adopted and formed by 6 lenses; all the lenses are spherical lenses; and the glass of the first lens is made of fused quartz materials so that the first lens can be immediately used for correcting image difference and can be used as protection glass of the optical system. According to the optical system is characterized by wide spectrum, large view side and large relative aperture and has quite small distortion quantity in a quite wide spectrum range and view field; the concentration degree of confusion disc energy of each view field is uniformly distributed; the imaging quality is good; the system can work at a temperature from -50 DEG C to +70 DEG C and has good image quality and defocusing amount; and posture measurement of high-precision star sensor working in severe space and temperature can be met.

Owner:BEIJING INST OF CONTROL ENG

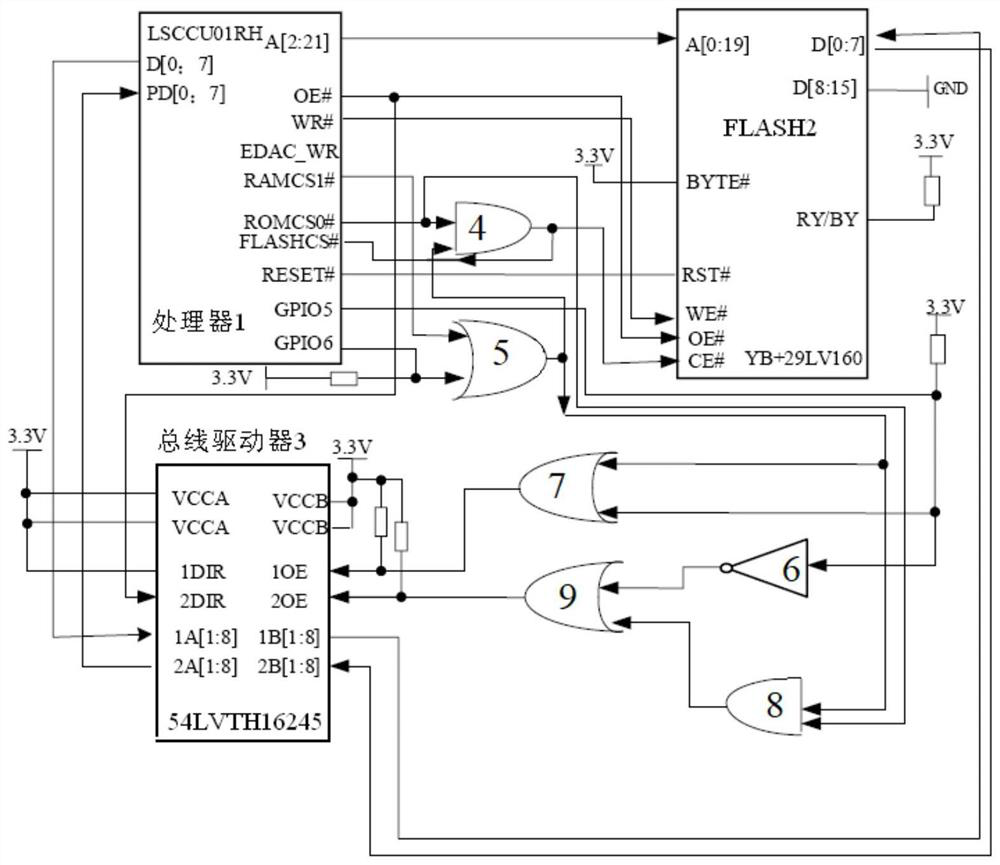

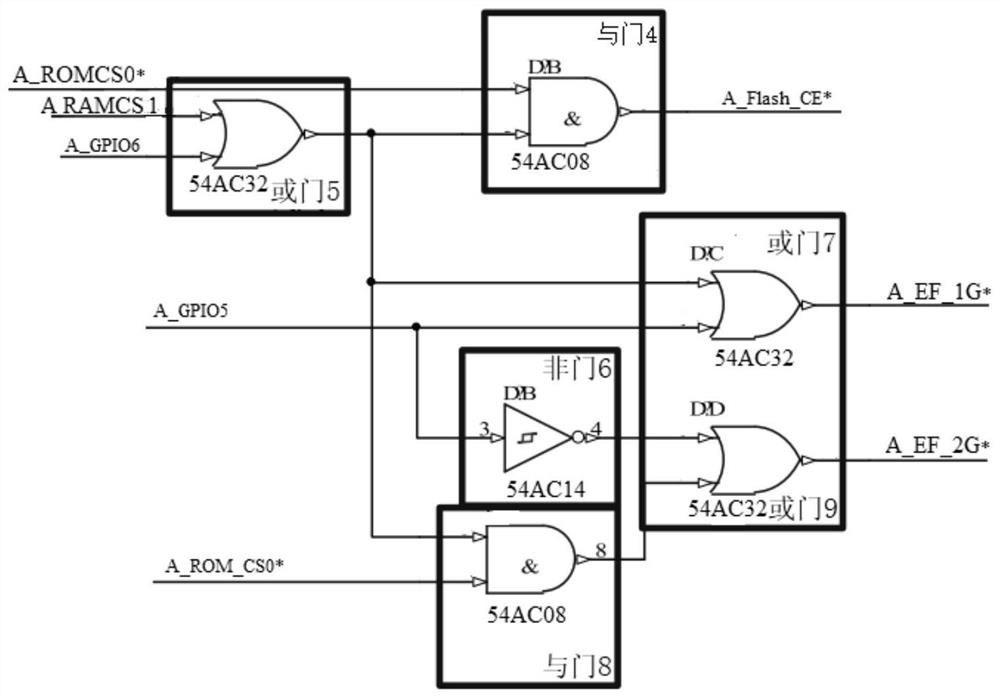

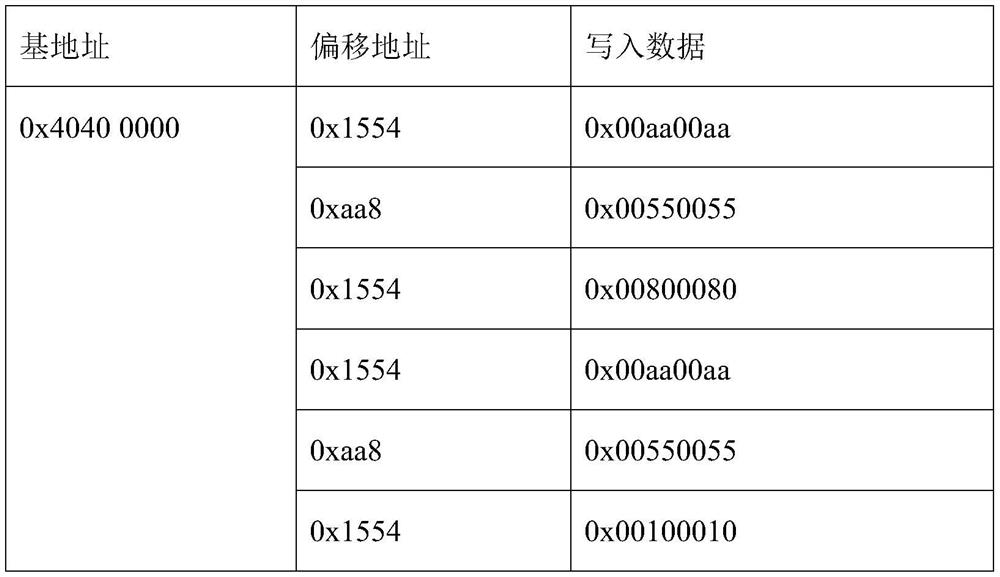

Extended EDAC check circuit and read-write method for extended Flash program storage area

ActiveCN111679933ADesign StandardizationMeet miniaturizationInput/output to record carriersStatic storageComputer architectureEngineering

The invention discloses an extended EDAC check circuit and a read-write method for an extended Flash program storage area. A bus driver, an AND gate, an OR gate and a NOT gate are added between a processor interface and an extended FLASH and used for achieving read-write operation of the extended FLASH2. A data line D [0:7] and a check bit PD [0:7] are connected with a data line of a FLASH throughthe bus driver, and in order to prevent data line conflicts, an OE enabling end of the bus driver is controlled to be gated through GPIO5, GPIO6 and AND gate, OR gate and NOT gate combinational logic; the extended EDAC check circuit and the read-write method can be applied to the FLASH external expansion EDAC function in the space computer miniaturized SIP module; the function can effectively improve the single event upset resistance of the FLASH as a program storage area space; on the premise that the function performance of the whole machine is met, the single event upset resistance of theFLASH serving as a program storage area in the space environment is greatly improved, the reliability of the whole machine is improved, and the requirements for standardization, miniaturization and localization of space computer design are met.

Owner:XIAN MICROELECTRONICS TECH INST

Porous mask plate capable of being recognized by APS solar sensor

ActiveCN101726994BSolve the problem of anti-moon dustGuaranteed to workNavigation by astronomical meansOriginals for photomechanical treatmentOptoelectronicsImage plane

The invention relates to a porous mask plate capable of being recognized by an APS solar sensor, which comprises a glass substrate and a film coating layer, wherein a film is coated on the lower surface of the glass substrate; at least 3 imaging pinholes are optically etched on the film coating surface of the glass substrate; the difference of the distance in at least one of the x direction and the y direction between any two imaging pinholes is not less than 20 pixels; and the side length of the square zone boundary of the imaging pinholes does not exceed d=L-2htan alpha (unit: mm), wherein L is the side length of the effective image plane of an image sensor in the APS solar sensor, h is the distance between the mask plate and the image plane of the image sensor, and alpha is the angle of field of the APS solar sensor. By adopting independent characteristics between holes in the porous array, the invention can quickly recognize contaminated pinholes, ensures high data updating rate of products, and is suitable for engineering application.

Owner:BEIJING INST OF CONTROL ENG

Method for manufacturing micromechanical shutter

ActiveCN102033425BExtend device lifeGood space environment adaptabilityDecorative surface effectsPhotomechanical apparatusPhotoresistNanotechnology

The invention relates to a method for manufacturing a micromechanical shutter, which comprises the following steps of: 1) selecting a stainless steel substrate, preparing a layer of positive photoresist on the upper and lower surfaces of the substrate respectively, and pre-curing the photoresist; 2) exposing a rectangular hole array serving as a mask, wherein the pre-cured photoresist on the lower surface is not exposed; 3) developing the substrate, finishing full curing of the photoresist, then performing corrosion, removing the photoresist and cleaning the substrate; 4) spraying the positive photoresist on the upper and lower surfaces of the substrate, and pre-curing the photoresist; 5) on the photoresist on the lower surface of the substrate, exposing a twist beam type shutter corroding pattern array serving as a mask, wherein the upper surface of the substrate is not exposed; 6) developing the substrate, finishing full curing of the photoresist, then performing corrosion, removingthe photoresist and cleaning the substrate; 7) manufacturing a shutter substrate; and 8) assembling and fixing the shutter blade structure and the substrate, and finishing upper and lower electrode leads. According to the method, the stainless steel is used as a structural material, so the micromechanical shutter has longer service life and higher reliability.

Owner:NO 510 INST THE FIFTH RES INST OFCHINA AEROSPAE SCI & TECH

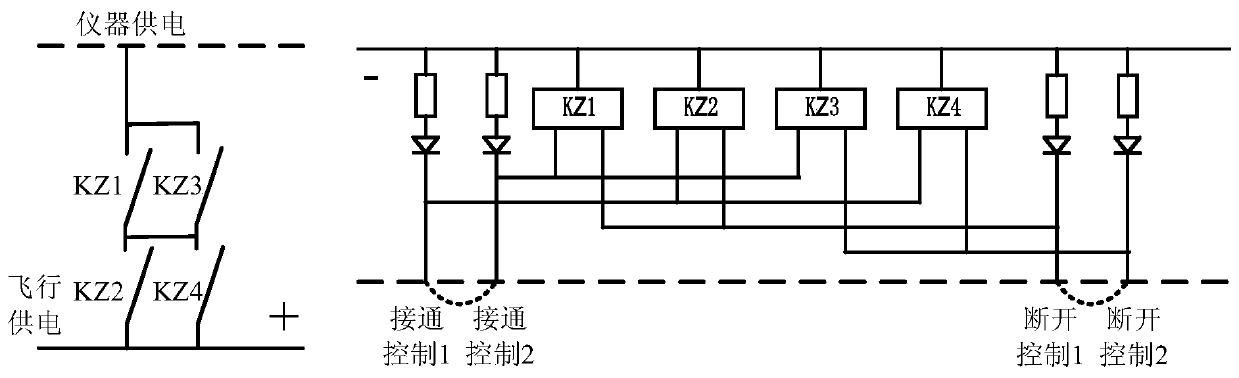

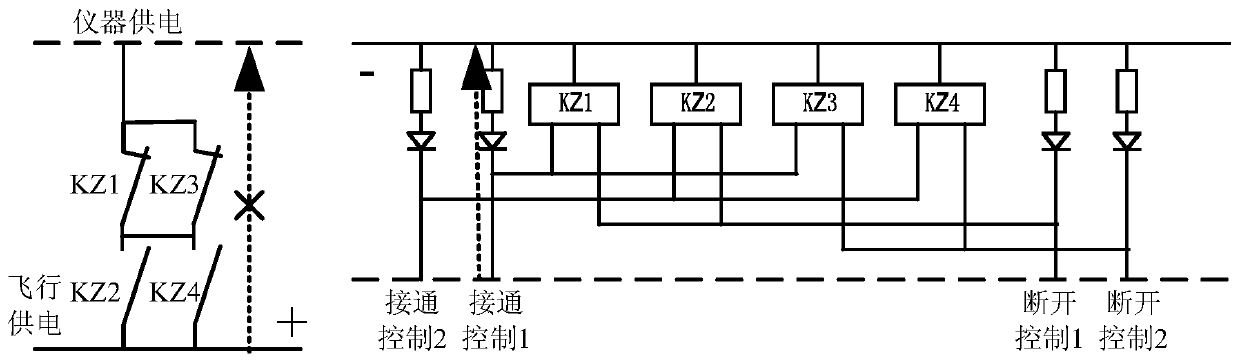

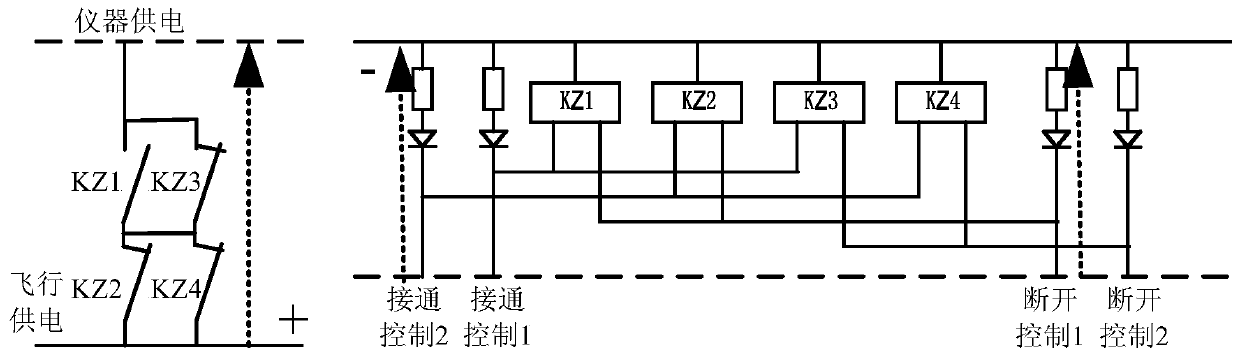

A traversal detection method suitable for redundant magnetic latching power supply and distribution lines

ActiveCN106646078BGood space environment adaptabilityImprove the immunityElectrical testingTest designDistribution power system

The invention discloses an intelligent detection circuit suitable for redundant magnetic latching supply and distribution lines. Test design is performed by a supply and distribution control line formed by magnetic latching relays KZ1 to KZ4, and a parallel control line is independently led out in a single machine. A bridging mode is achieved in a system so that a supply and distribution system can have more independent control nodes in unit testing. Without the addition of a special test wire, different combined logic control is performed on four signal control ports in the testing including a switching-on control port 1, a switching-on control port 2, a switching-off control port 1, and a switching-off control port 2. Simultaneously, voltage detection is performed on the power supply end of an instrument so as to achieve status confirmation of each relay contact of the KZ1 to KZ4 and achieve 100% measurement of the on-off states all contacts of the control paths.

Owner:BEIJING AEROSPACE AUTOMATIC CONTROL RES INST +1

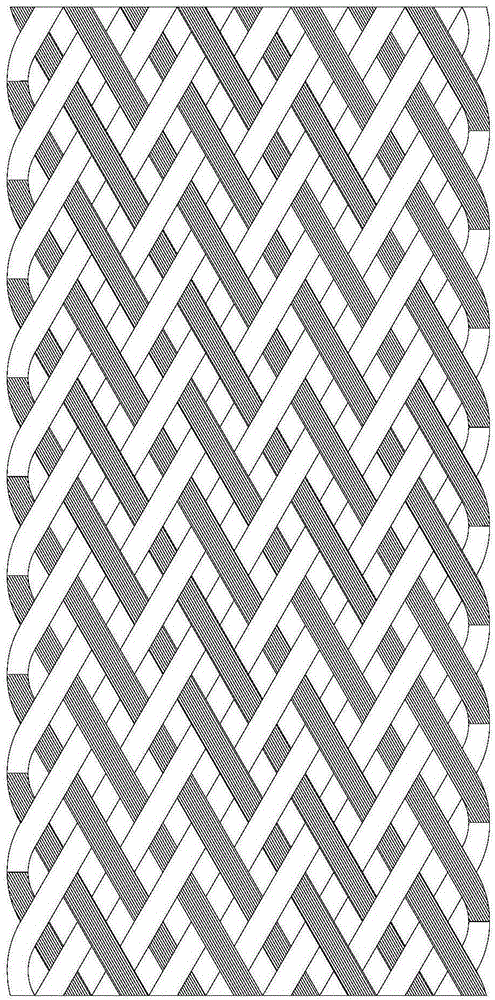

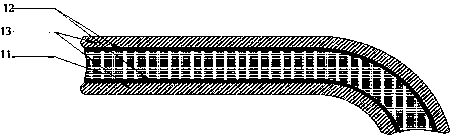

Braided structure thin cable applied to space solar battery array

InactiveCN105185430AAdaptableGood structural elongationBraided wire conductorsMetal/alloy conductorsCopper wireEngineering

The invention discloses a braided structure thin cable applied to a space solar battery array, and relates to the technical field of space solar array power transmission. The cable is characterized in that the thin cable is formed by braiding M wiring harnesses through a single layer braiding technology; each wiring harness is composed of N copper wires; the diameter range of each copper wire is between 0.02mm and 0.3mm; and M and N are natural numbers greater than two. According to the invention, the thin cable is formed by braiding M wiring harnesses through the single layer braiding technology; each wiring harness is composed of N copper wires; compared with a traditional single copper wire, the thin cable has better structural elongation; the thin cable has great adaptability for a complex thermal stress environment caused by space high and low temperature alternation; specific stress reduction measures are no longer designed; an installation process is easy; and the reliability and the safety of a product are improved.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST

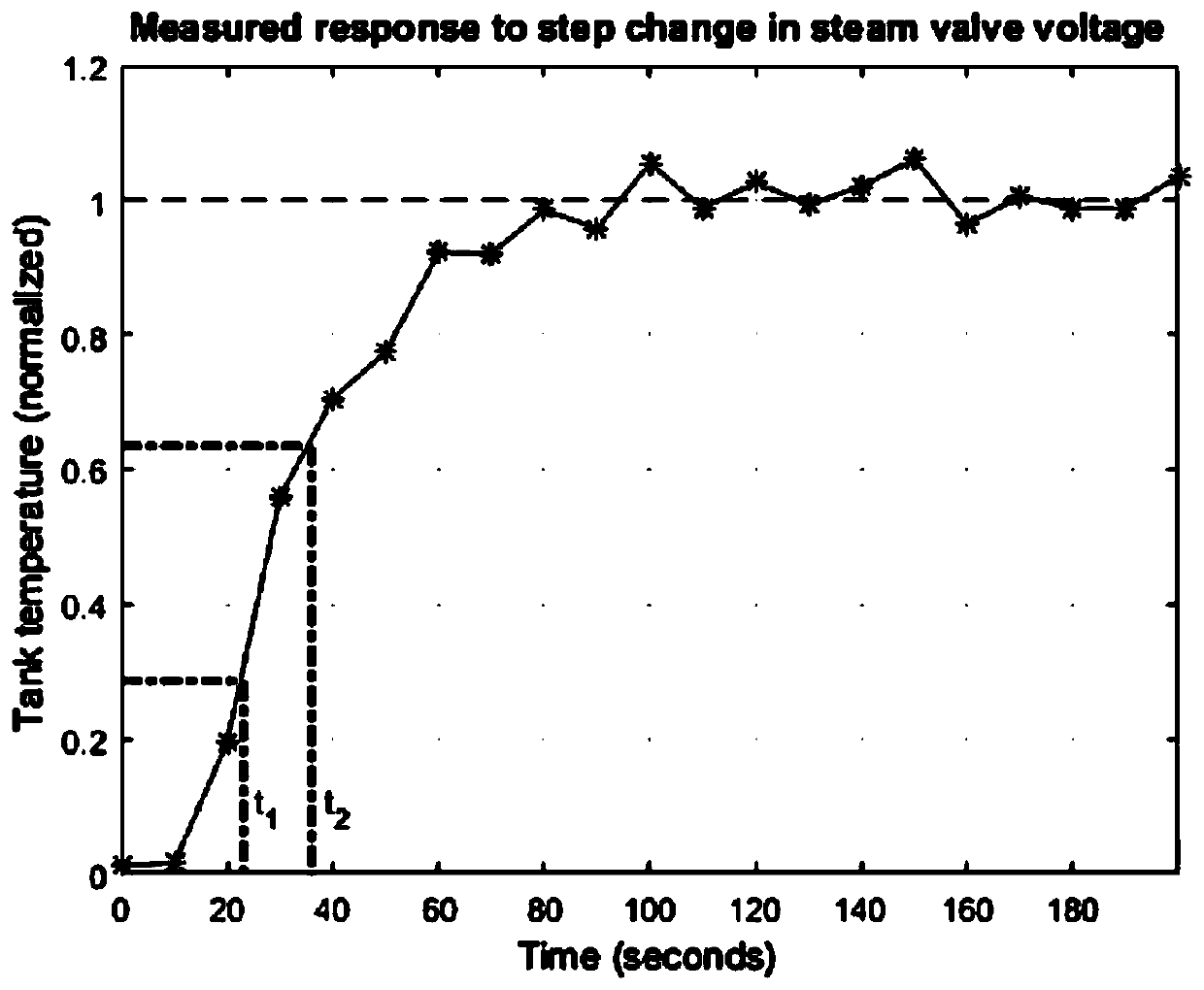

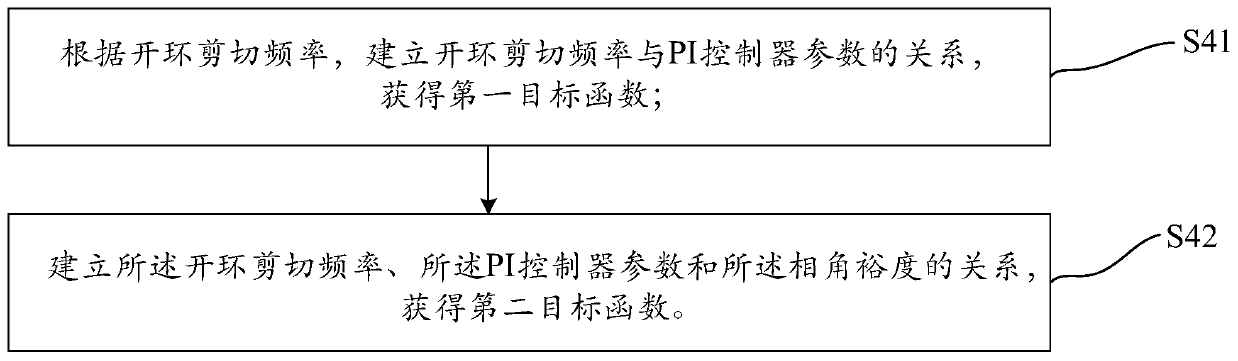

On-orbit self-tuning method of solar radiation monitor based on frequency domain analysis method

InactiveCN109765436AImprove space environment adaptabilitySolve the problem that cannot be applied in orbitElectromagentic field characteristicsPhotometry using electric radiation detectorsPhysicsFrequency domain

The invention relates to the technical field of radiation metrology, in particular to an on-orbit self-tuning method of a solar radiation monitor based on a frequency domain analysis method. The on-orbit self-tuning method comprises the steps that a temperature step response curve of a receiving cavity is obtained, and a mathematical model of the receiving cavity is identified; the mathematical model and an open-loop transfer function of a preset control strategy of a PI controller are established; and the relation between PI controller parameters and frequency domain performance index is established according to the frequency domain analysis method and the open-loop transfer function, an objective function is obtained, and the PI controller parameters are calculated. The method solves theproblem that a fast measurement algorithm of the solar radiation monitor cannot be applied on an orbit, the mathematical model of the receiving cavity is identified, the PI controller parameters areset according to a preset frequency domain performance index, when the working environment of the PI controller changes, the mathematical model of the receiving cavity can be corrected in real time, and spatial environment adaptability of the fast measurement algorithm based on the PI controller is improved.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

An optical system for a star sensor

ActiveCN104833355BSpectral widthLarge spectrumNavigation by astronomical meansVisual field lossConcentration ratio

The invention relates to an optical system for a star sensor. The optical system is applied to high-precision star sensors. The optical system is of an improved peaceful structure and consists of six lenses, wherein the six lenses are all spherical lenses; an aperture diaphragm is arranged on first glass; the first glass is made of fused quartz, can be used for correcting aberration and can be used as protective glass of the optical system. The optical system has the characteristics of wide spectrum, large visual field, relative large aperture and the like; the distortion is very low in relatively large spectral range and visual fields, concentration ratios of discs of confusion of each visual field are uniformly distributed, and the imaging quality is good. The optical system can work in a temperature range from -40 DEG C to 50 DEG C, has good image quality and defocusing amount at each temperature point and can meet attitude measurement requirements of the high-precision star sensors working at severe space temperature environments.

Owner:BEIJING INST OF CONTROL ENG

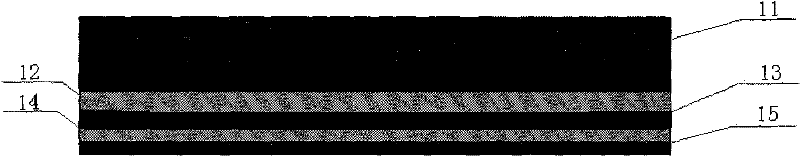

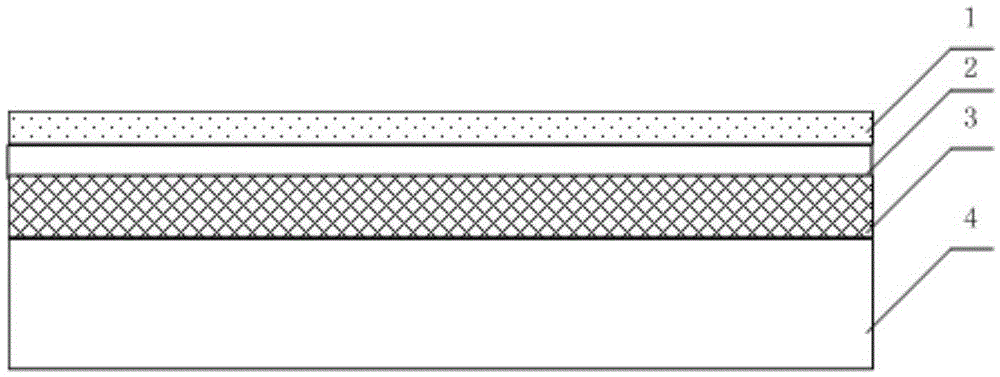

A label for attaching satellite surface and its manufacturing method

ActiveCN104260465BHigh emissivityImprove anti-staticSynthetic resin layered productsVacuum evaporation coatingEmissivityStatic performance

The invention provides a label for pasting a satellite surface. The label is mainly composed of a thin film base, a paint film layer, a transparent emissivity adjusting layer and a transparent anti-static layer, wherein the paint film layer is stuck on the thin film base; the transparent emissivity adjusting layer and the transparent anti-static layer are plated on the paint film layer; and the transparent emissivity adjusting layer is arranged between the transparent anti-static layer and the paint film layer. According to the label for pasting the satellite surface, a high-emissivity transparent thin film material and a conductive transparent thin film material are prepared on the surface of a paint film by a magnetron sputtering method, so that the paint film has high emissivity and anti-static performance.

Owner:LANZHOU INST OF PHYSICS CHINESE ACADEMY OF SPACE TECH

A kind of molybdenum/titanium/silver metal layered composite material for space and preparation method thereof

ActiveCN106711262BThe interface is firmly bondedGood welding performanceFinal product manufactureAuxillary arrangementsManufacturing technologyMaterials science

The invention relates to molybdenum / titanium / silver metal layered composite material used for space and a preparation method thereof. The composite material comprises a layer of pure molybdenum foil; two layers of pure titanium foils; and two layers of pure silver foils, wherein the foils are laminated into a similar "sandwich" structure according to the order of the pure silver foil, the pure titanium foil, the pure molybdenum foil, the pure titanium foil and the pure silver foil and connected as a whole, and the molybdenum-titanium interface and the silver-titanium interface are chemically and metallurgically bonded. The preparation method comprises the steps that a combined blank material of the similar "sandwich" structure is formed by orderly lamination; hot rolling composite connection is performed on the combined blank material, and annealing processing is further performed under the atmosphere of inert gas after hot rolling; and the molybdenum / titanium / silver metal layered composite material used for the space is obtained after annealing. The composite material has great space environment adaptability, thermal conductivity, electrical conductivity and weldability so as to meet the requirements of the space electronic packaging application; and the preparation method of the composite material realizes formation through hot rolling composite connection so that the manufacturing technology is simple, the quality is stable and controllable, operation is convenient and large-area automatic roll-to-roll batch production can be realized.

Owner:SHANGHAI INST OF SPACE POWER SOURCES

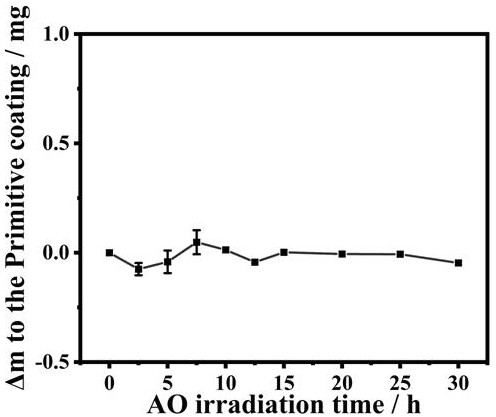

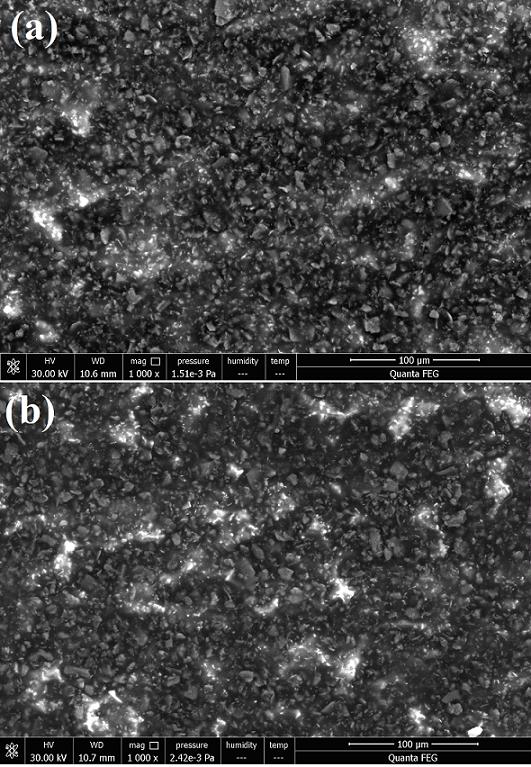

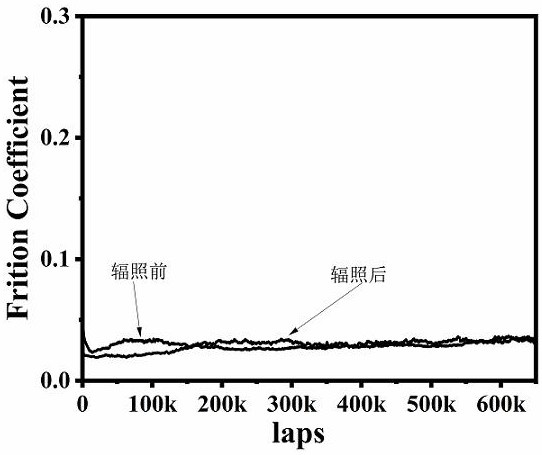

Polysiloxane long-acting lubricating protective paint with space environment resistance

PendingCN112126349AExcellent resistance to space environmentImprove stabilityCoatingsSolid componentPolymer science

The invention relates to a polysiloxane long-acting lubricating protective paint with space environment resistance. The paint is prepared by uniformly stirring and dispersing the following componentsin parts by weight: 20 parts of epoxy polysiloxane resin, 9-20 parts of disulfide compound slurry and 1.4-6 parts of amino curing agent at the rotating speed of 2800r / min and 3500r / min, so that the solid component content is 35 + / -10%. With the lubricating protective paint adopted, the space environment resistance and wear resistance of an existing space lubricating coating can be greatly improved. The protective paint has the characteristics of favorable adhesive force to the metal substrate, favorable flexibility, favorable impact resistance, long wear resistance, excellent space environmentresistance and the like, and can effectively prolong the service life of the related equipment in the space environment.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

A dual-channel optical fiber rotary connector with long space life

ActiveCN111796367BExtend working lifeReduce the degree of impactCoupling light guidesPigtailOptic system

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

A high damping thermal deformation releasing device

ActiveCN107524744BReduced stress responseIncrease the damping ratioLeaf springsElastic dampersDamping factorThermal deformation

Owner:BEIJING INST OF SPACECRAFT SYST ENG

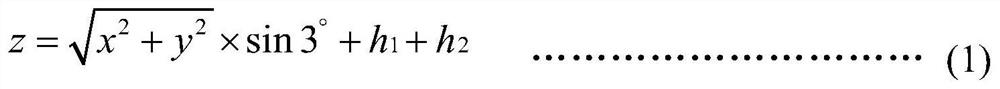

An automatically adjustable field high-precision bearing platform and leveling method

ActiveCN109141343BRealize automatic adjustmentSolve the problem of turning into a field testbedAngle measurementControl using feedbackOptical tableField tests

The invention discloses an automatically adjustable field high-precision bearing platform and a leveling method. The carrying platform includes: a cabin for carrying equipment; an optical platform located in the cabin for installing an optical system, the optical platform is provided with a detection unit for detecting the orientation of the optical platform; used to support the cabin an electric cylinder for leveling the cabin body; and an electric control device for controlling the electric cylinder to level the cabin body according to the orientation information of the optical platform detected by the detection unit. The invention realizes the automatic leveling of the high-precision bearing platform in the field, solves the problem of the cleanliness of the transmission optical path and the problem of poor environmental adaptability, and provides the platform conditions for the field test of the optoelectronic equipment; The structure reference has the characteristics of high precision and convenient use.

Owner:BEIJING INST OF ELECTRONICS SYST ENG

Method for reducing TCP (Transmission Control Protocol) message loss in space information network

The invention provides a method for reducing TCP (Transmission Control Protocol) message loss in a space information network, and aims at providing a method capable of reducing data packet loss efficiently, increasing link throughput and avoiding meaningless retransmission of a transmitting terminal when a link is disconnected. The method for reducing the TCP message loss in the space information network is realized through the following technical scheme comprising the steps of adding transmission and storage modules at a transmission end of a TCP; presetting a connection time sequence PAB(t) between any node A and a node B based on a known movement track of an artificial satellite and characteristics of link disconnection caused by shielding of a predictable celestial body in the space information network with a node movement rule to follow, wherein PAB(t)=1 indicates that the node A and the node B are in a link connection state at the moment t; and PAB(t)=0 indicates that the node A and the node B are in a link disconnection state at the moment t; firstly verifying the value of the PAB(t0) by the transmitting node A at any moment t0 in a network running process; if PAB(t0)=1, sending a data packet to the target node B; and if PAB(t0)=0, caching the data packet in a storage module of the TCP, wherein the cached data packet is extracted from the cache for transmission in the next moment t=t1 when the PAB (t) is enabled to be equal to 1.

Owner:10TH RES INST OF CETC

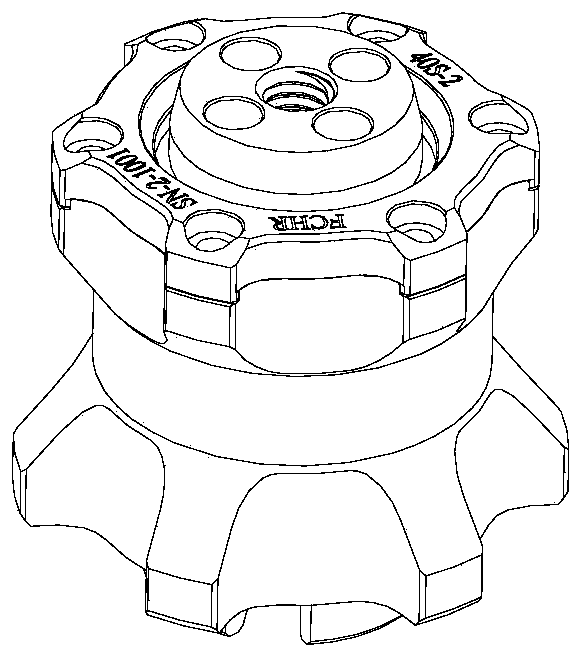

Space long-service-life dual-channel optical fiber rotary connector

ActiveCN111796367AExtend working lifeReduce the degree of impactCoupling light guidesEngineeringOptic system

The invention provides a space long-service-life dual-channel optical fiber rotary connector. The problems that an existing dual-channel optical fiber rotary connector is short in service life, largein loss, prone to failure and complex in structure are solved. The optical fiber rotary connector comprises a stator shell, a rotor sleeve, a first center channel unit, a second center channel unit, afront end cover and a rear end cover. The stator shell is of a sleeve structure, the rotor sleeve is installed on the front side of a cavity of the stator shell through a bearing assembly, the frontend cover is arranged at the front end of the rotor sleeve, and the rear end cover is arranged on the rear side of the cavity of the stator shell. The first central channel unit comprises a first rotor tail fiber, a first channel incident light collimation assembly, an optical system beam expanding assembly, an optical system coupling assembly, a channel receiver and a first stator tail fiber which are coaxially arranged in sequence; the second central channel unit comprises a first rotor tail fiber, a second channel incident light collimation assembly, a second channel receiver and a second stator tail fiber.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

Encapsulation method of thin cable with braided structure for space solar cell array

ActiveCN106653951BAdaptablePrevent oxidationFinal product manufacturePhotovoltaic energy generationEngineeringSolar battery

The invention discloses a packaging method for a weaving-structured thin cable for a space solar battery array. The packaging method is characterized by comprising the steps of 1, performing installation position positioning; 2, performing surface treatment on a packaging position; 3, performing blade coating of a packaging material; 4, performing cable cleaning and forming; 5, performing primary packaging of the cable; and 6, performing secondary packaging of the cable. By adoption of the technical scheme, the packaging dimensions and positions of the weaving-structured thin cable can be effectively controlled, so as to satisfy use requirements on cable packaging thickness by special space models; the thickness is not greater than 0.3mm after a cable with the thickness of 0.2mm is packaged; the packaging material adopted by the packaging method is high in high-temperature characteristic and low-temperature characteristic; and the packaged weaving-structured thin cable can keep high structural growth rate in a track working condition, and is high in adaptivity to a complex thermal stress environment caused by space high temperature and low temperature alternation, so that the reliability and safety of the product are improved.

Owner:中电科蓝天科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com