Braided structure thin cable applied to space solar battery array

A solar cell array, thin technology, applied in the direction of braided wire conductors, metal/alloy conductors, etc., can solve the problem that cannot meet the needs of flexible solar wing battery circuits, cannot meet the application requirements of special models for thin cables, and the circular cross-section wires are not suitable. It has problems such as structural elongation, and achieves good space environment adaptability, good adaptability, and the effect of preventing oxidation and erosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

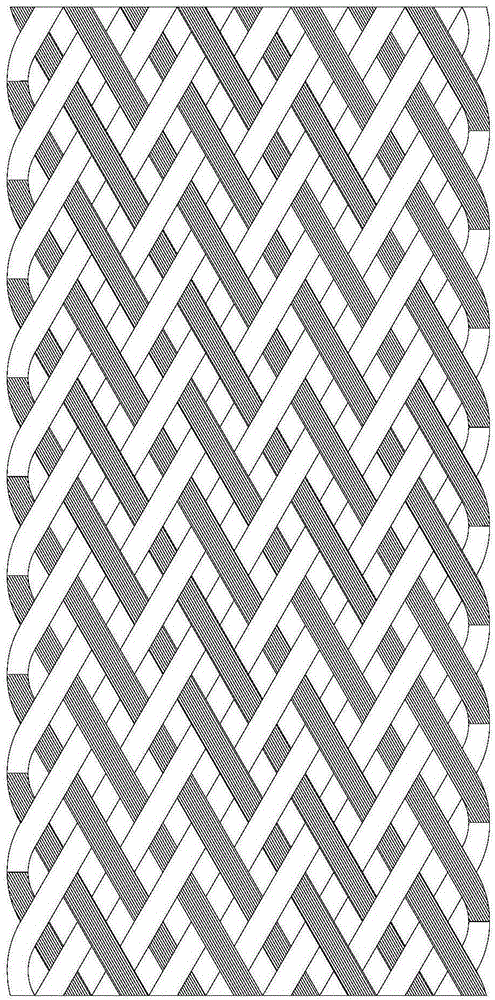

[0024] see figure 1 , a thin cable with a braided structure for a space solar cell array, the thin cable includes an M-spindle wire harness, the above-mentioned M-spindle wire harness is woven into a thin-shaped cable through a single-layer braiding technique, and each ingot wire harness is composed of N copper wires, usually Under the condition, N copper wires do not need to be twisted, that is, they are in parallel relationship; under the premise of satisfying the current transmission function of the conductor material, the diameter range of each copper wire is 0.02mm-0.3mm; where: M and N are A natural number greater than 2. In actual use, the thin cable section generally adopts the following two sizes:

[0025] One: The width range of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com