Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

150results about How to "Good anodizing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-strength aluminum alloy with excellent oxidation effect and preparation method and application thereof

ActiveCN107385290AExcellent anode decoration effectAvoid problemsHigh intensityUltimate tensile strength

The invention discloses a high-strength aluminum alloy with an excellent oxidation effect and a preparation method and application thereof. The alloy comprises the following components in percentage by mass: 0.6-0.9% of Si, 0.8-1.1% of Mg, not more than 0.20% of Fe, 0.5-1.0% of Cu, 0.2-0.5% of Mn, 0.015-0.03% of Ti, 0.0006-0.0012% of B, less than 0.15% of the total quantity of other impurities, and the balance Al, wherein the mass ratio of Mg to Si is Mg / Si=1.15-1.45. The aluminum alloy is higher in strength and excellent in anodic oxidation performance, welding performance and stress corrosion resistance, and can be used for manufacturing high-strength and high-decorativeness industrial aluminum alloy materials, such as electronic structural parts and light vehicle parts.

Owner:GUANGDONG HOSHION IND ALUMINUM CO LTD

Aluminum alloy digital electronic product case and application thereof

ActiveCN103484737AWide versatilityExcellent Die CastingSurface reaction electrolytic coatingMetal casingsDie castingMechanical property

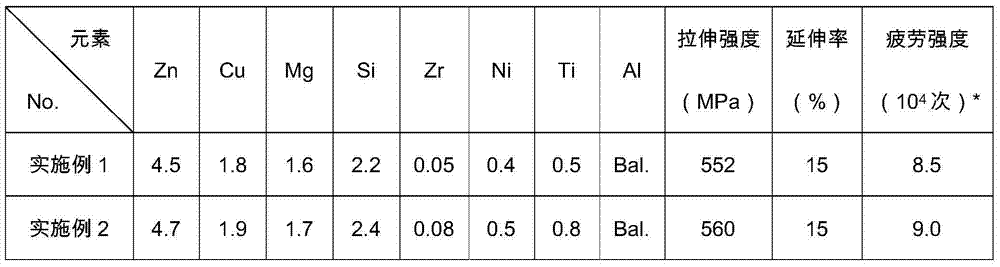

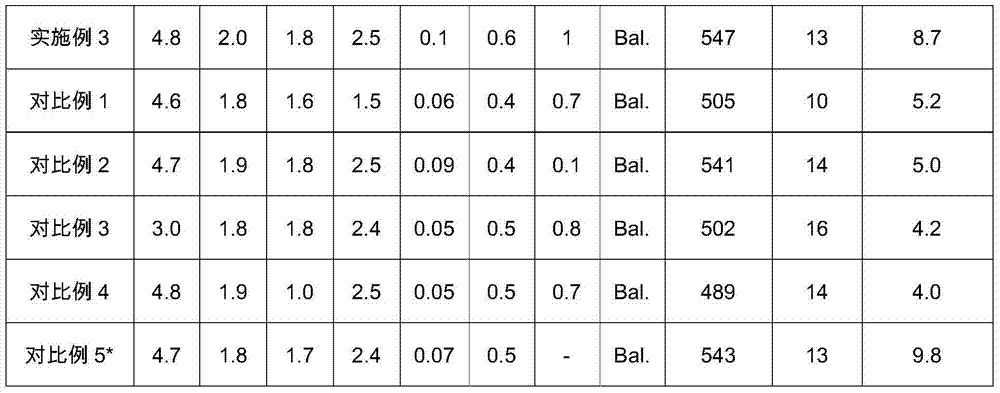

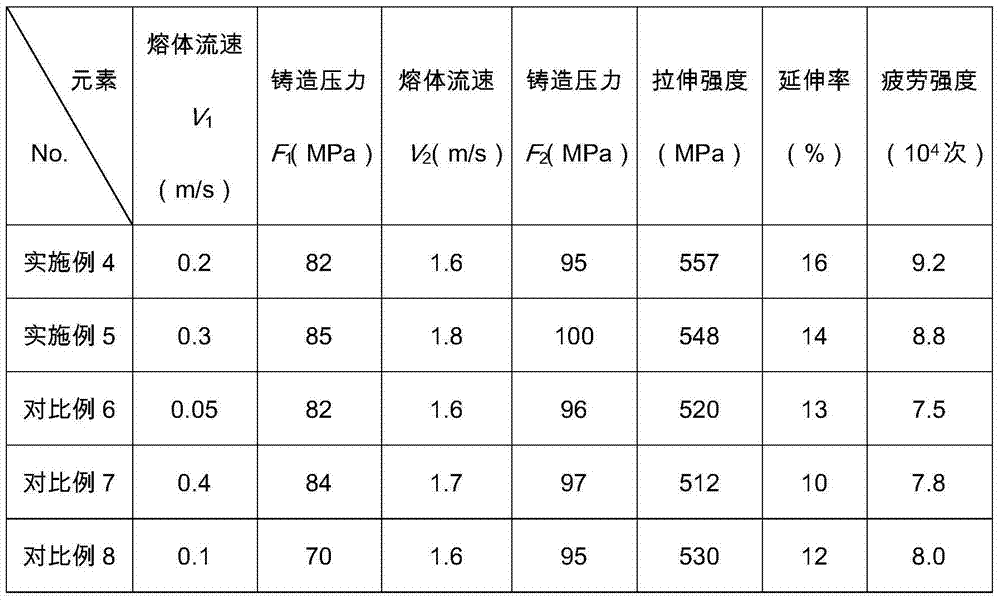

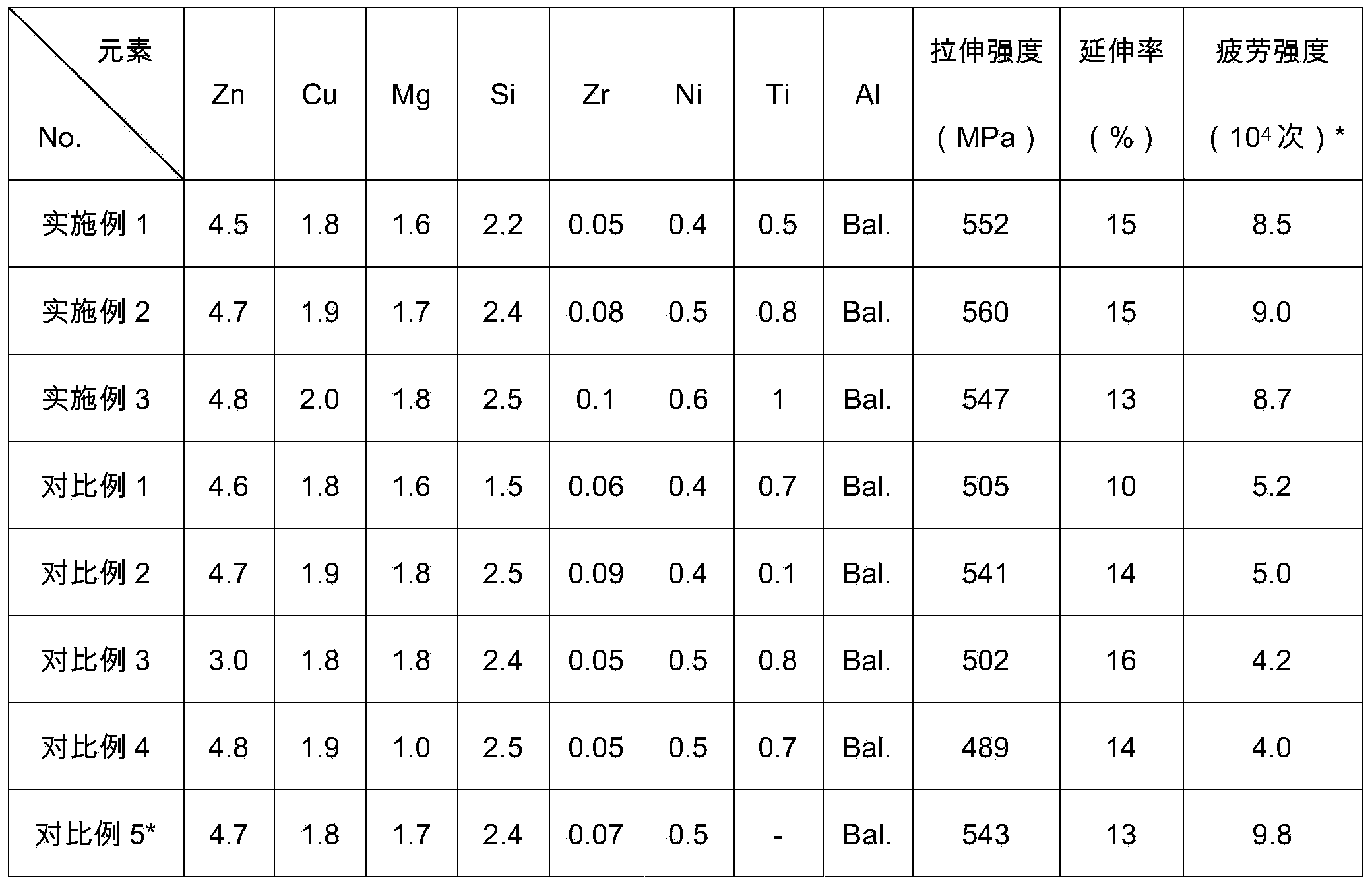

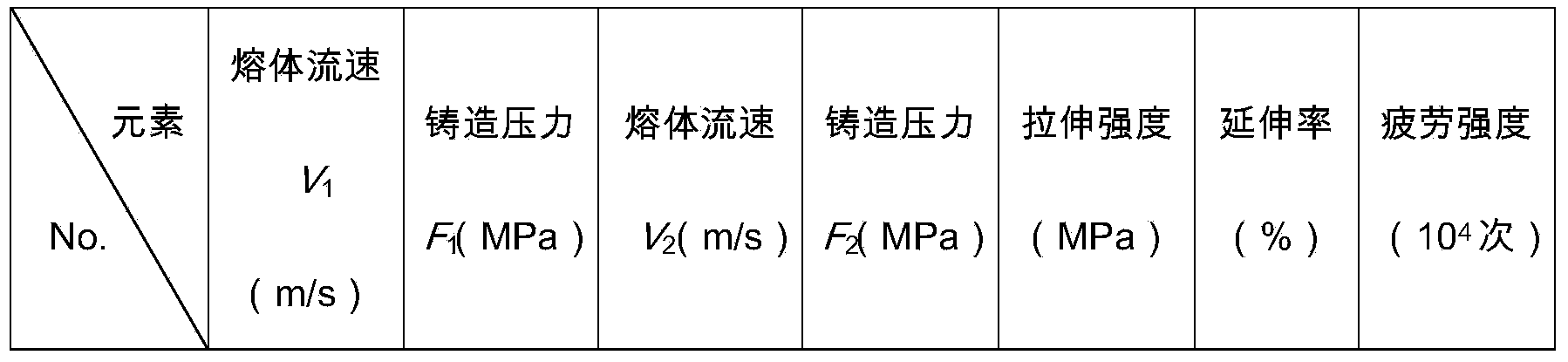

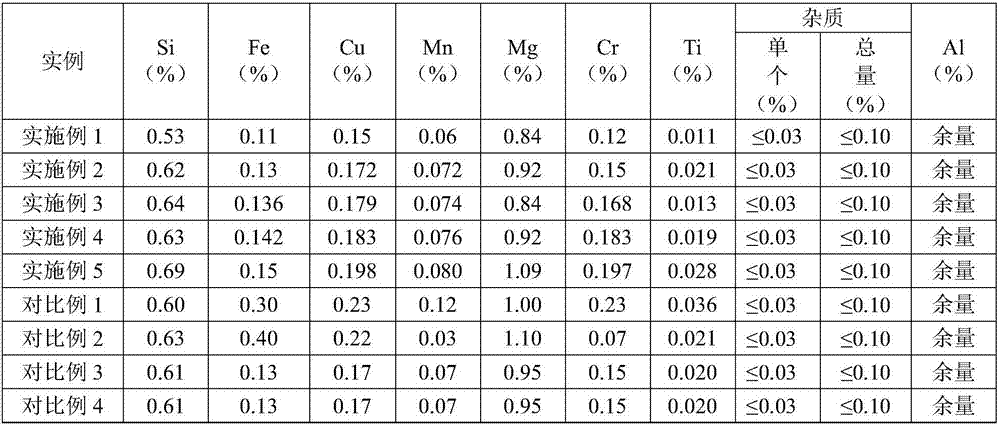

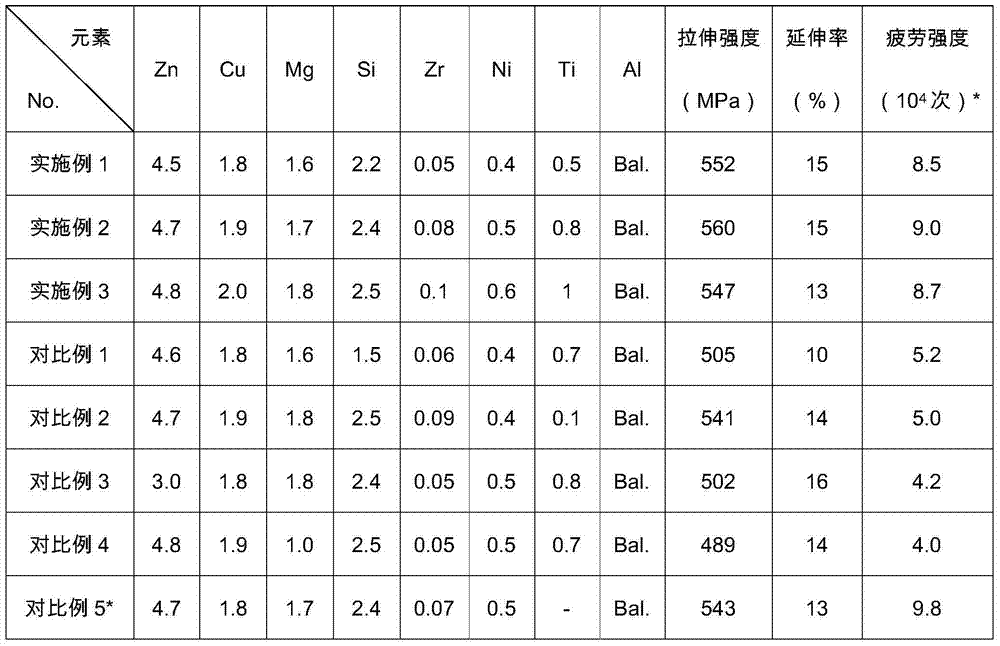

The invention provides an aluminum alloy digital electronic product case. An aluminum alloy comprises the components in percentage by weight as follows: 4.5-4.8% of Zn, 1.8-2.0% of Cu, 1.6-1.8% of Mg, 2.2-2.5% of Si, 0.05-0.1% of Zr, 0.4-0.6% of Ni, 0.5-1% of Ti and the balance of aluminum and inevitable impurities. To be specific, the aluminum alloy with excellent die casting and anodic oxidation properties for the case is obtained through simple alloy elements and moderate matching firstly, meanwhile, appropriate raw materials and a melting process are adopted, the die casting and mechanical properties of the alloy are guaranteed, an optimal anoxic oxidation treatment process and parameters are selected after die casting, so that the die-casting aluminum alloy with excellent properties for a digital electronic product is obtained, and then the digital electronic product case is obtained finally through shaping and coating.

Owner:苏州利达铸造有限公司

Aluminium die-cast alloy

ActiveCN103343268AImprove mechanical propertiesGood anodizing effectMechanical propertyAnodic oxidation

The invention discloses an aluminium die-cast alloy which mainly contains Si, Cu, Fe, Mn, Mg, Zn, Ti and LaCe elements. The aluminium die-cast alloy is characterized in that weight content of all the elements are respectively as follows: 0.5% to 2.0% of Si, 0.1% to 0.5% of Cu, 0.3% to 0.8% of Fe, 0.5% to 1.0% of Mn, 2.0% to 4.0% of Mg, 0.8% to 2.0% of Zn, 0.15% to 0.2% of Ti and 0.6% to 0.8% of LaCe. The aluminium die-cast alloy has the good anodic oxidation ability, mechanical property and corrosion resisting property.

Owner:嘉宜科技(惠州)有限公司

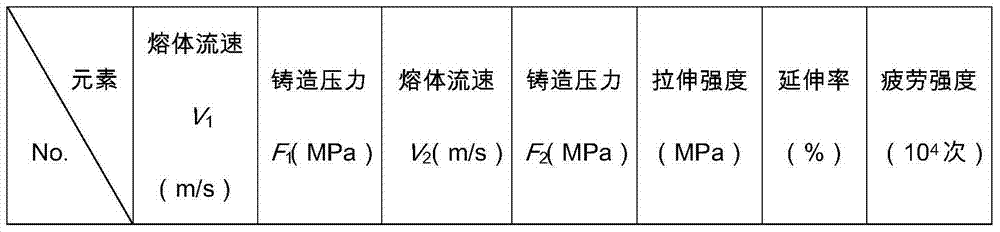

Aluminum die-casting alloy for digital electronic product

ActiveCN103526088AGuaranteed performanceSuppress deterioration of fatigue performanceAnodisationAlloy elementAnodic oxidation

The invention provides an aluminum die-casting alloy for a digital electronic product, wherein the composition proportion (wt.%) of the alloy is 4.5-4.8 of Zn, 1.8-2.0 of Cu, 1.6-1.8 of Mg, 2.2-2.5 of Si, 0.05-0.1 of Zr, 0.4-0.6 of Ni, 0.5-1 of Ti and the balance of aluminum and inevitable impurities. Specifically, the aluminum alloy having excellent die-casting and anodic oxidation properties is obtained from simple alloy elements in an appropriate proportion, meanwhile, proper materials and a proper melting process are adopted, so that the property of the alloy is guaranteed, the optical anodic oxidation treatment process and parameters are chosen after die casting, and the aluminum die-casting alloy for the digital electronic product having excellent properties is obtained.

Owner:苏州利达铸造有限公司

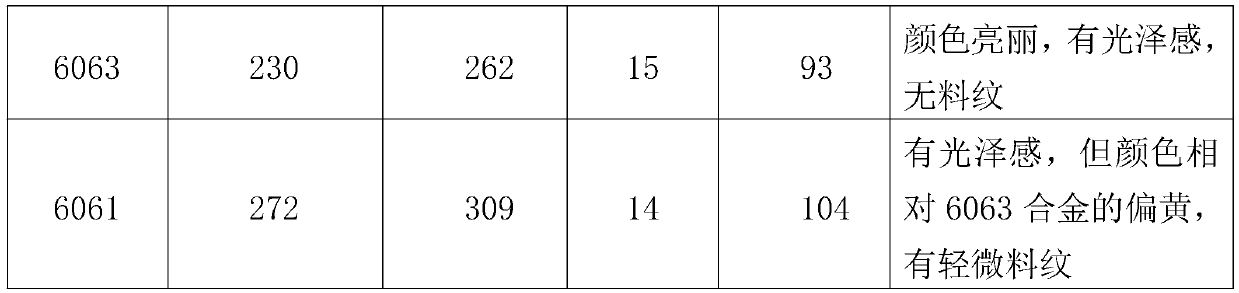

High-performance 6XXX aluminum alloy for outer part of electronic product and machining method thereof

ActiveCN105238962AHighlight substantive featuresSignificant progressRoom temperatureUltimate tensile strength

The invention relates to a high-performance 6XXX aluminum alloy for an outer part of an electronic product and a machining method thereof. The alloy comprises the following components: 0.5-1.2 wt% of Si, 0.5-1.2 wt% of Mg, Cu not more than 0.1 wt%, Mn not more than 0.10 wt%, Cr not more than 0.10 wt%, Zr not more than 0.10 wt%, Ti not more than 0.10 wt%, Zn not more than 0.10 wt%, Fe not more than 0.20 wt%, and the balance of Al and inevitable impurities. The machining process of the aluminum alloy comprises the following steps: firstly, a cast rod is uniformly heated from room temperature to 540-570 DEG C with the heating speed of 30-200 DEG C / h for keeping 10-30 hours, and is quickly cooled; the material is extruded after preheating, is cooled in water online, is quenched, and is straightened; and finally, the artificial aging is performed. As the content of main alloy element in the 6XXX aluminum alloy is reasonably adjusted, the material both has higher strength and better anodic oxidization effect; and the alloy material is an ideal material for manufacturing the outer part of the electronic product, and is broad in market application prospect.

Owner:苏州中色研达金属技术有限公司 +1

Die-casting aluminum alloy with anode being oxidable

The invention belongs to the technical field of aluminum alloy, in particular to die-casting aluminum alloy with the anode being oxidable. The aluminum alloy is composed of, by weight, 0.3%-0.5% of Si, 0-0.1% of Cu, 0.8%-1.5% of Mg, 0-0.05% of Zn, 0-0.35% of Fe, 1.0%-1.5% of Mn, 0.5%-2.0% of Ti, 0-0.008% of Sn, 0-0.008% of Pb and the balance Al. Compared with the prior art, all the elements are utilized reasonably, and the content of all the elements is limited within a reasonable range, so that the die-casting aluminum alloy with the anode being oxidable which is good in die-casting performance and excellent in anodic oxidation performance is obtained, and the die-casting aluminum alloy is suitable for aluminum alloy structural components with the anode being oxidable and high in surface treatment effect requirement.

Owner:DONGGUAN AO PRECISION DIECASTING CO LTD

Production method of aluminum strip for cosmetic bottle cap

The invention discloses a production method of an aluminum strip for a cosmetic bottle cap. The production method comprises the steps of: (1) preparation of an ingot and adoption of a new alloy, wherein the ingot comprises the following elements in percentage by weight: not more than 0.08% of Si, not more than 0.1% of Fe, not more than 0.03% of Cu, not more than 0.02% of Mn, not more than 0.02% of Mg, not more than 0.02% and not less than 0.01% of Ti, and the balance of Al; (2) surface milling; (3) uniform heating; (4) hot rolling; (5) cold rough rolling; (6) cleaning; (7) intermediate annealing; (8) cold finish rolling; (9) stretching, bending, straightening and cleaning of trimmings; and (10) checking. The aluminum strip has such excellent characteristics as smooth and bright surface, stable mechanical performance, precise dimensional tolerance, easy punch forming, low earing ratio after punching of the bottle cap and good anodizing effect, and is suitable for producing top-grade cosmetic bottle cap.

Owner:DALISHEN ALUMINUM

6061G aluminum alloy for smart phone and processing method thereof

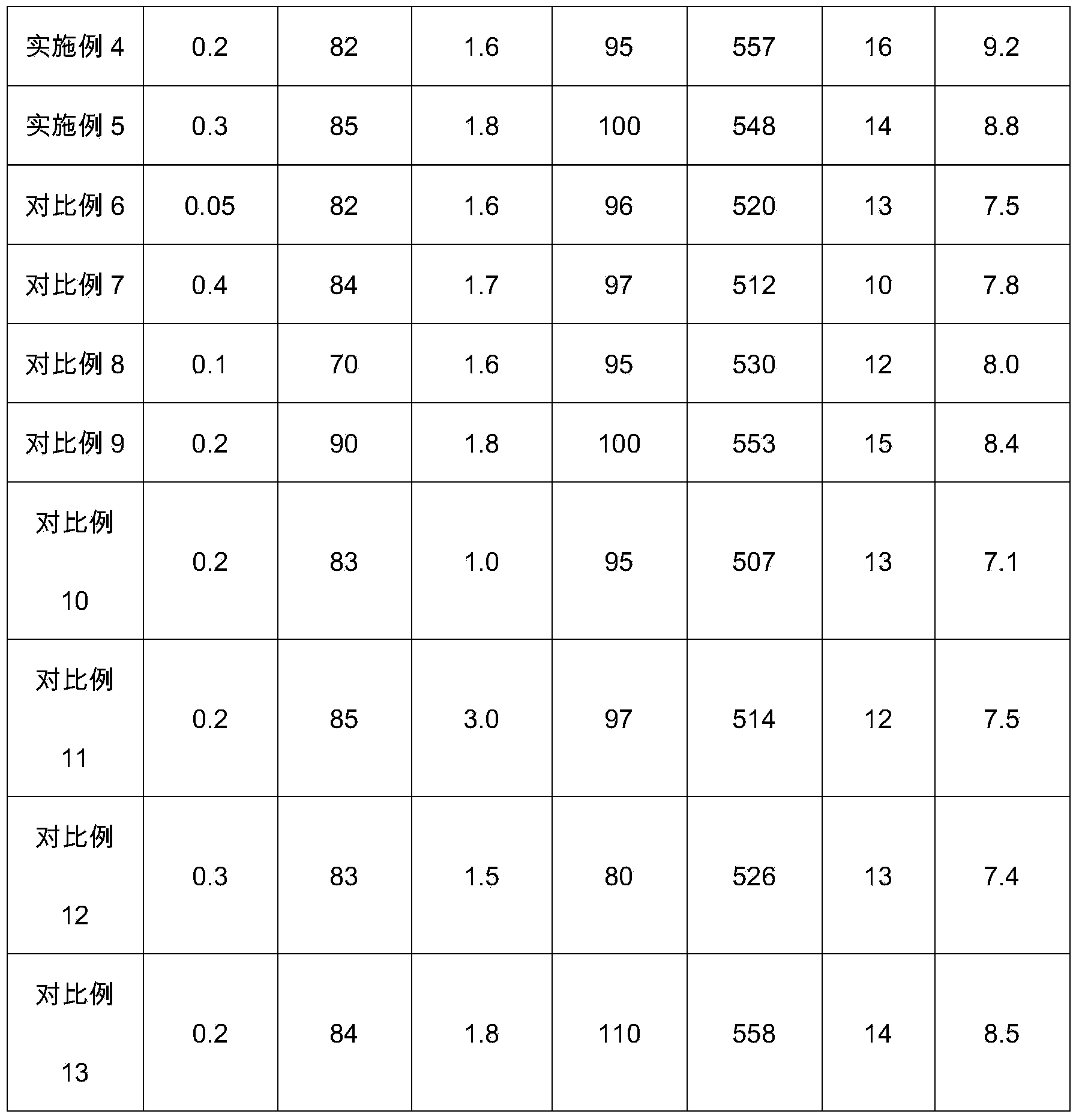

The invention discloses a 6061G aluminum alloy for a smart phone and a processing method thereof. The aluminum alloy comprises the following components in percentages by weight: 0.50-0.70% of Si, 0.11-0.15% of Fe, 0.15-0.20% of Cu, 0.06-0.08% of Mn, 0.80-1.10% of Mg, 0.11-0.20% of Cr, 0.01-0.03% of Ti and the balance of Al and inevitable impurities. The corresponding processing method comprises the following eight steps: ingot casting, homogenizing annealing, hot rolling, cold rolling, intermediate annealing, secondary cold rolling, solid solution treatment and final aging treatment successively. An aluminum product, with the components of the aluminum alloy, obtained by means of the processing method has an extremely excellent anodizing effect, meets the sand blasting of extremely thin 205-210-mesh zircon sand, is an ideal aluminum alloy material, which is used for 6-series mobile phone appearance part having high demand on strength and anodizing effect, and is wide in market application prospect.

Owner:TIANJIN ZHONGWANG ALUMINUM IND CO LTD

Anodic oxidation treatment process of die-casting aluminum alloy for digital electronic product

ActiveCN103484916AExcellent Die CastingGood anodizing effectSurface reaction electrolytic coatingAlloyMaterials science

The invention provides die-casting aluminum alloy for a digital electronic product and a corresponding anodic oxidation treatment process of the die-casting aluminum alloy. The conditions of primary anodic oxidation are that sulfuric acid is 100 to 120 g / L, citric acid is 10 to 15 g / L, lactic acid is 5 to 8 g / L, the current density is 0.8 to 1 A / dm<2>, the voltage is 15 to 18 V, and the oxidation time is 15 to 20 min; and the conditions of secondary anodic oxidation are that mixed sulfuric acid and aluminum sulfate (the molar ratio is 10:1) is 120 to 150 g / L, citric acid is 15 to 20 g / L, lactic acid is 5 to 8 g / L, the current density is 1.2 to 1.5 A / dm<2>, the voltage is 18 to 20 V, and the oxidation time is 60 to 80 min. The die-casting aluminum alloy for the digital electronic product with excellent performance is obtained through an optimal secondary oxidation process and reasonable parameter control.

Owner:苏州利达铸造有限公司

Al-Mg-Si-Cu alloy and preparation method and application thereof

The invention discloses Al-Mg-Si-Cu alloy and a preparation method and application thereof. The Al-Mg-Si-Cu alloy comprises, by mass, 0.6%-0.8% of Si, 1.0%-1.2% of Mg, 0.25%-0.5% of Fe, 0.2%-0.4% of Cu, 0.1%-0.15% of Mn, 0.1%-0.2% of Cr, 0.10%-0.20% of Zn, 0-0.10% of Ti, smaller than 0.15% of other impurities, and the balance Al. The Al-Mg-Si-Cu alloy has high strength and excellent anodic oxidation performance, meanwhile also has great chip cutting performance and can be used for manufacturing industrial aluminum alloy materials, such as electronic equipment structural connecting pieces, with high-quality requirements for high strength, decorative surfaces and a large quantity of CNC processing.

Owner:中山瑞泰铝业有限公司

High-performance 5xxx series aluminium alloy and processing method thereof

The invention discloses a high-performance 5xxx series aluminium alloy and a processing method thereof. The high-performance 5xxx series aluminium alloy comprises the components: 2.0-5.0wt% of Mg, less than or equal to 0.10wt% of Si, less than or equal to 0.10wt% of Cu, less than or equal to 0.10wt% of Mn, less than or equal to 0.10wt% of Cr, less than or equal to 0.1wt% of Ti, less than or equal to 0.20wt% of Fe, and the balance Al and unavoidable impurities. The processing method of the high-performance 5xxx series aluminium alloy comprises the steps that a cast ingot is subjected to homogenizing annealing, is heated to 420-440 degrees from room temperature and is subjected to heat preservation for 4-10h, then is heated to 460-530 degrees and is subjected to heat preservation for 5-12h; hot rolling is carried out with the initial rolling temperature being 460-530 degrees and the finish rolling temperature being below 360 degrees; and a cold rolled blank is subjected to follow-up cold rolling, and intermediate annealing is carried out for one time when the total reduction is 40-70%. Through adjusting the contents of elements in the 5xxx series aluminium alloy and the processing technique, the structure of the 5xxx series aluminium alloy is uniform, and the 5xxx series aluminium alloy has high strength and good anodic oxidation performance.

Owner:苏州中色研达金属技术有限公司 +1

Aluminum alloy and preparation method thereof

InactiveCN108359864AImprove mechanical propertiesGood anodizing effectNonferrous metalMechanical property

The invention belongs to the technical field of nonferrous metals and relates to an aluminum alloy and a preparation method thereof. The aluminum alloy comprises the following components in percentageby weight: more than or equal to 0.50% and less than or equal to 1.20% of Mg, more than or equal to 0.45% and less than or equal to 1.20% of Si, more than 0% and less than or equal to 0.80% of Cu, more than 0% and less than or equal to 0.30% of Mn, more than 0% and less than or equal to 0.20% of Cr, more than 0% and less than or equal to 0.05% of Ti, and more than 0% and less than or equal to 0.15% of Fe. According to the aluminum alloy, the contents of elements such as Mg, Si and Cu are adjusted and enhanced, so that the aluminum alloy is excellent in mechanical property and excellent in anodic oxidation efficiency, and the surface color of the aluminum alloy is bright and uniform.

Owner:GUANGDONG HONGKING NEW MATERIALS TECH CO LTD

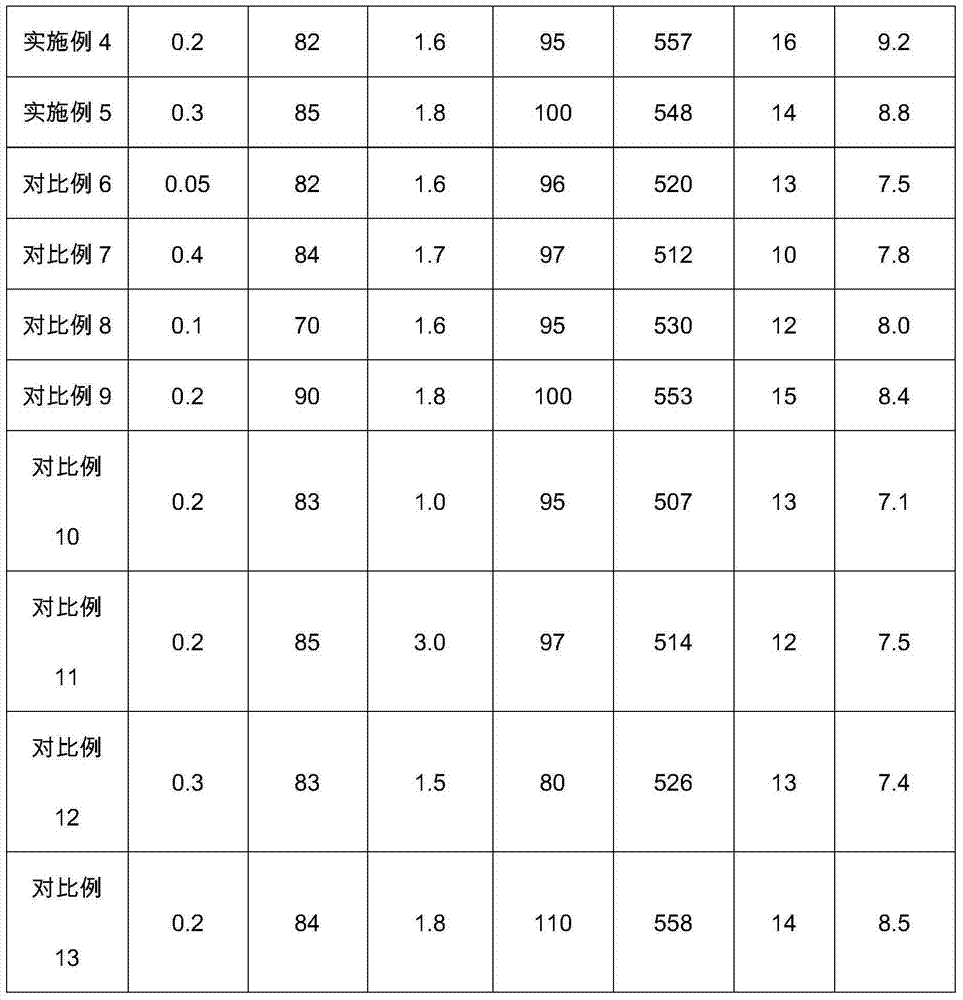

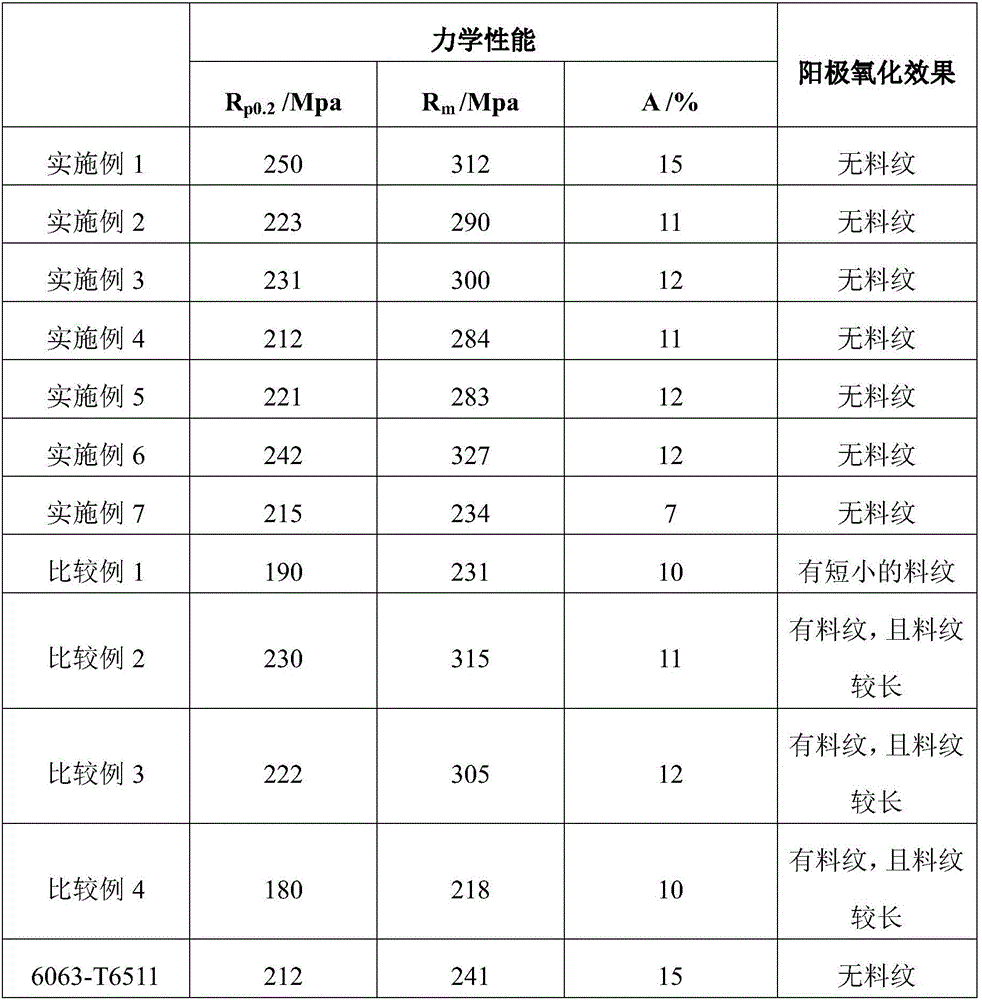

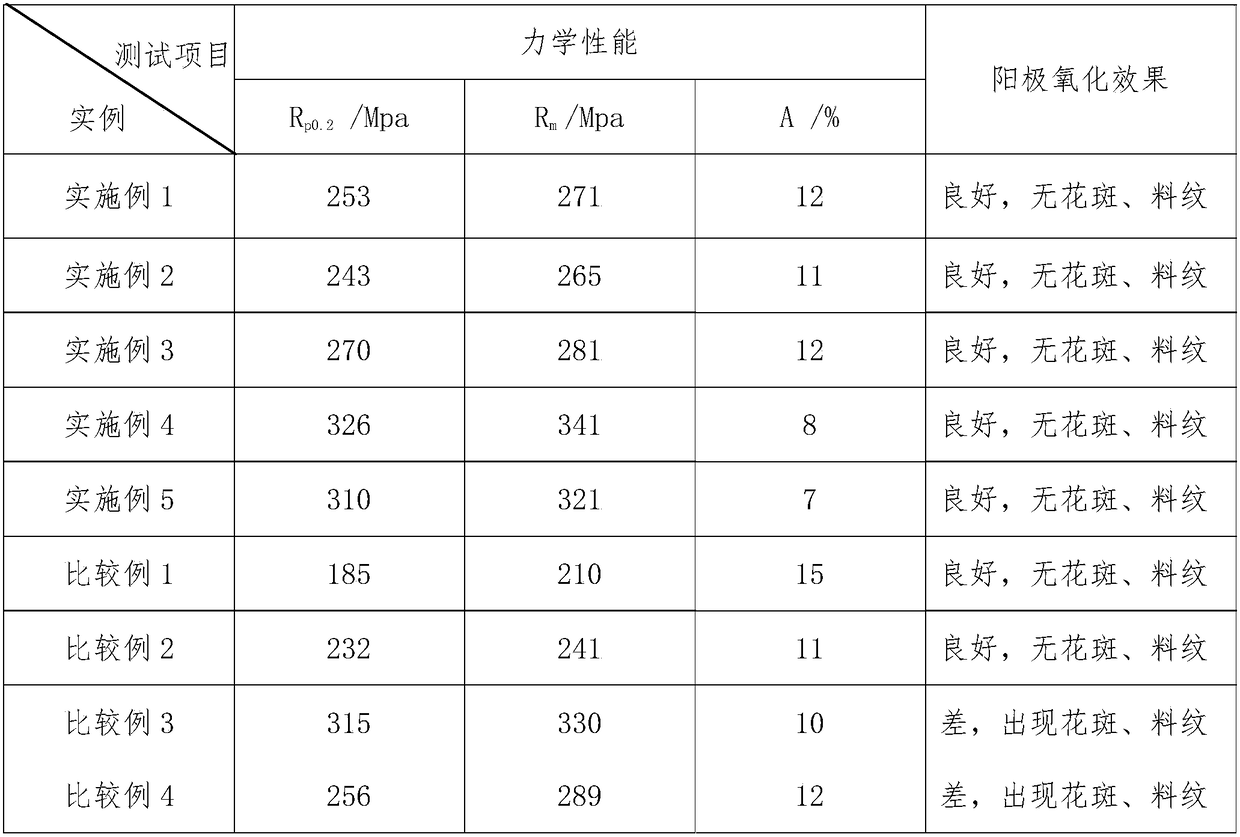

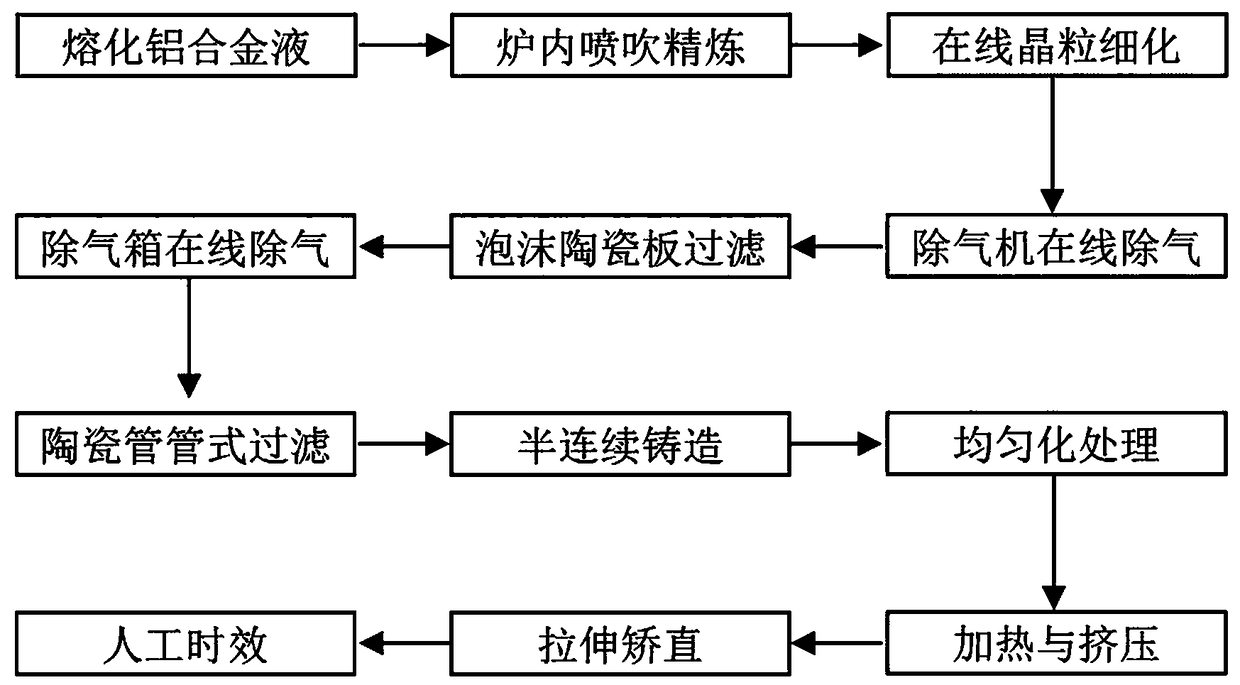

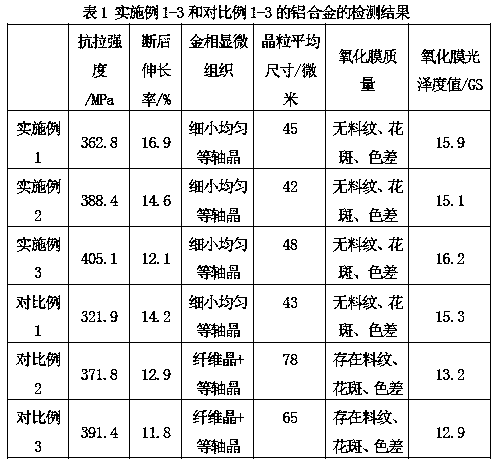

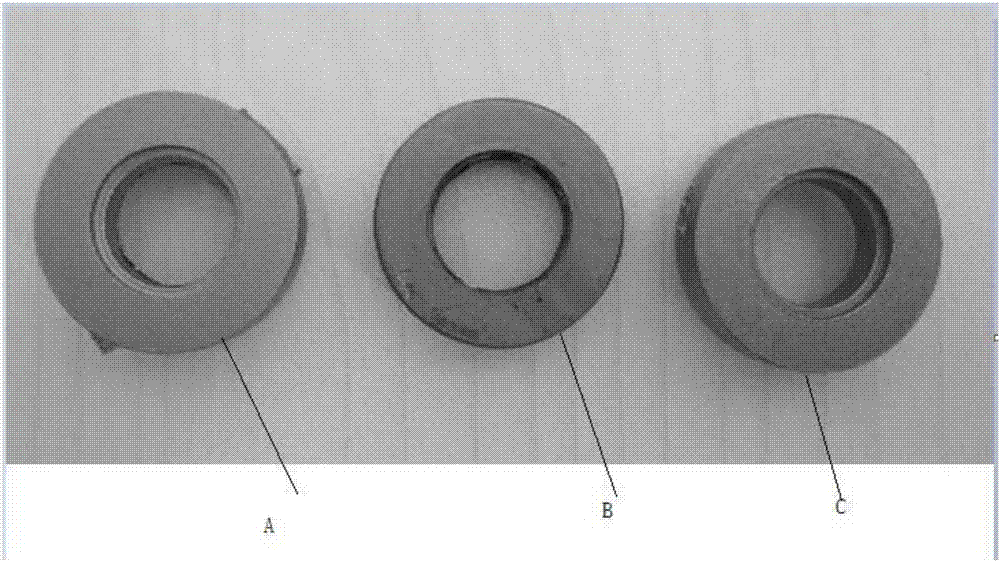

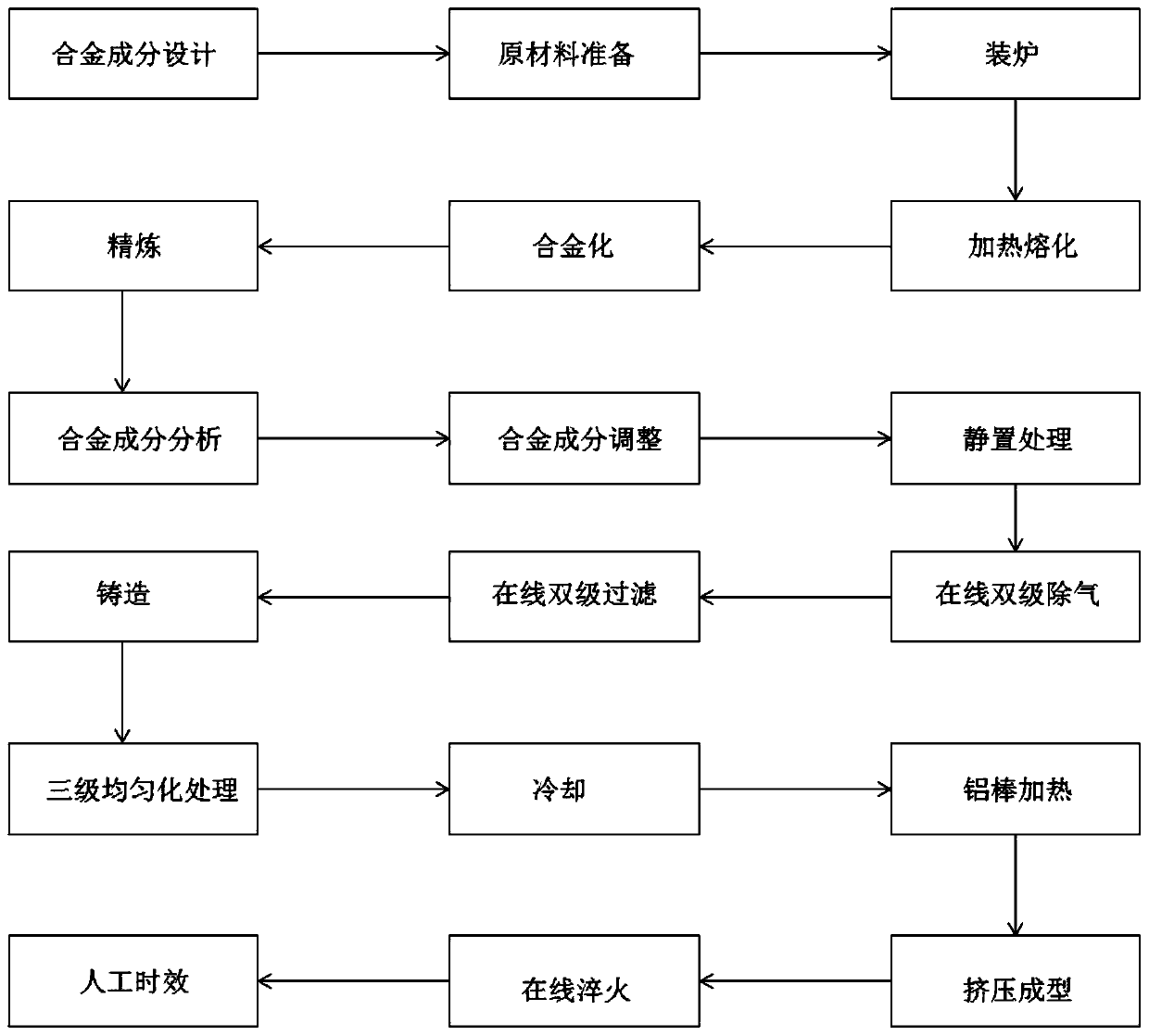

High-strength aluminum alloy for electronic equipment and preparation and extrusion method of high-strength aluminum alloy

ActiveCN108330354ASolve the strength problemSolve the contradiction between oxidation performanceIngot castingHigh intensity

The invention discloses high-strength aluminum alloy for electronic equipment and a preparation and extrusion method of the high-strength aluminum alloy. The high-strength aluminum alloy is Al-Mg-Si-Cu series high-strength aluminum alloy. The preparation and extrusion method comprises the following steps: fusion and preparation of aluminum alloy solution, jetting and refining in a furnace, onlinegrain refinement, online twin-stage degassing filtering, semicontinuous casting, ingot casting homogenization, heating and extruding, online quenching, stretcher straightening and artificial ageing. According to the preparation and extrusion method, through optimizing design of constituent composition and the preparation and extrusion technology of aluminum alloy, the cleanliness and constituent uniformity of aluminum alloy are improved, so that the extruded aluminum alloy obtains tiny equiaxed grains with perfect recrystallization, the defects including bank mark, piebaldness and chromatic aberration of an oxidation film are eliminated, and the quality and yield of the oxidation film are improved and increased; and the extruded aluminum alloy is suitable for manufacturing the appearance structural component of portal electronic equipment and meets the light and thin design demands of the electronic equipment.

Owner:GUANGDONG INST OF NEW MATERIALS

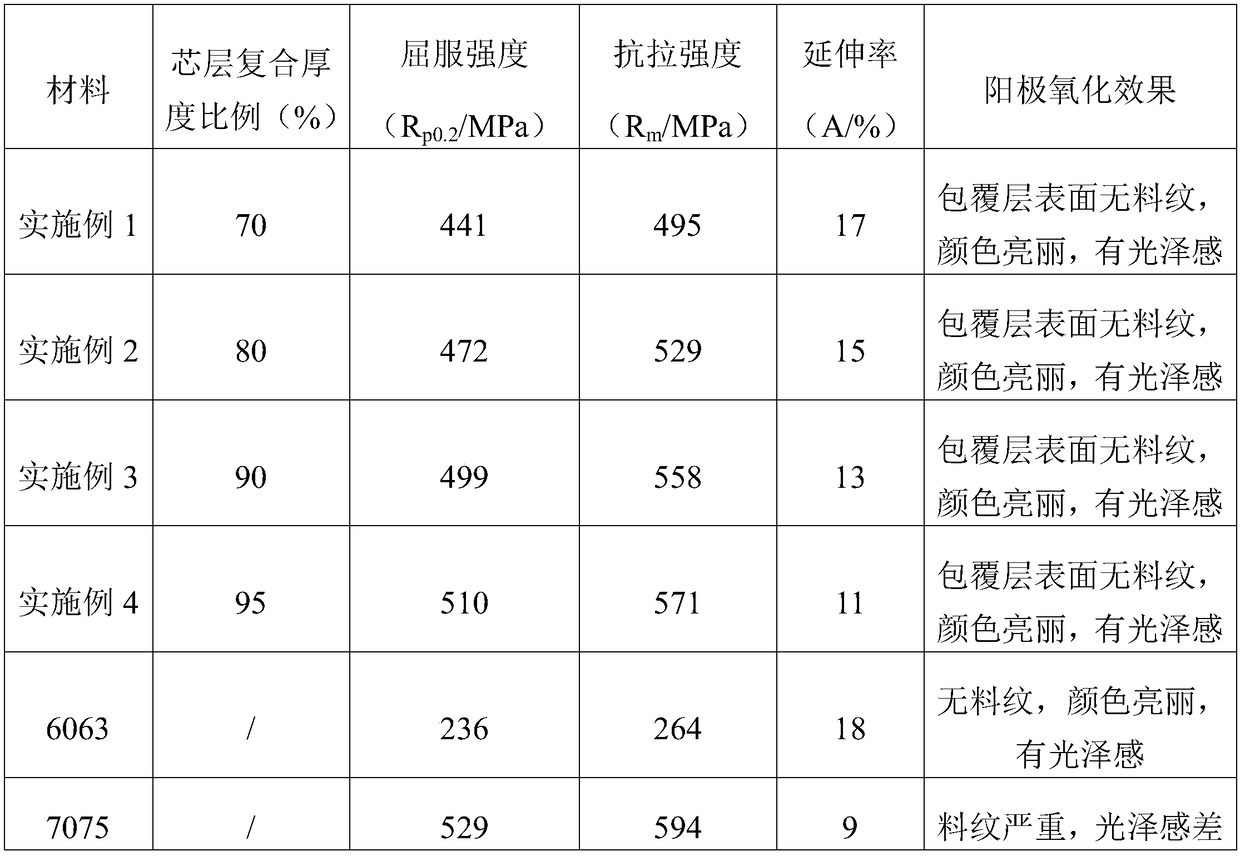

Preparation method of 6xxx/7xxx aluminum alloy composite

The invention discloses a 6xxx / 7xxx aluminum alloy composite. The 6xxx / 7xxx aluminum alloy composite comprises a core layer alloy and a coating layer alloy. A preparation method of the 6xxx / 7xxx aluminum alloy composite comprises the steps that (1) preparation of the core layer alloy and the coating layer alloy plates is carried out; (2) surface treatment is carried out; (3) welding fixing is carried out; (4) preheating and hot rolling are carried out; (5) a cutting plate is transversely cut; (6) solution hardening is carried out; (7) stretching is carried out; (8) aging is carried out; and (9) saw cutting is carried out, and thus the finished 6xxx / 7xxx aluminum alloy composite is obtained. The 6xxx / 7xxx aluminum alloy composite is prepared by a rolling complex mode, and technologies of the solution hardening and the aging are limited at the same time, so that the 6xxx / 7xxx aluminum alloy composite obtains high strength, has the characteristic of an excellent anodic oxidation effect, can meet the requirement of a high-end electronic product on the appearance and strength, is an ideal material for manufacturing an appearance piece of the electronic product and has very high utilization potentiality.

Owner:广西南南铝加工有限公司

Preparation method of 1xxx/7xxx aluminium-alloy composite material

ActiveCN108909138AHigh hardnessHigh strengthLamination ancillary operationsLaminationHardnessAlloy composite

The invention discloses a preparation method of a 1xxx / 7xxx aluminium-alloy composite material. The preparation method comprises the following steps of: (1) preparation of a core-layer alloy casting plate and a coating-layer alloy casting plate; (2) surface treatment: respectively carrying out surface treatment on the core-layer alloy casting plate and the coating-layer alloy casting plate obtained in the step (1); (3) welding fixation: carrying out welding fixation on the core-layer alloy casting plate and the coating-layer alloy casting plate after surface treatment in the step (2) accordingto a coating-layer / core-layer combined mode; (4) preheating and hot rolling: preheating the alloy casting plate welded in the step (3), carrying out hot-rolling bonding and following machining according to the thickness of a finished product after the heating is finished to obtaining a product. The preparation method disclosed by the invention has the beneficial effects that two layers of aluminium-alloy composite plates have the characteristics of high hardness and high strength, meanwhile the anodic oxidation effect of an electronic product is obviously improved, so that after the anode ofthe electronic product is oxidized and colored, the surface has metallic luster and is uniform in color.

Owner:广西南南铝加工有限公司

6061 aluminum alloy for 3C product appearance piece and processing method of 6061 aluminum alloy

ActiveCN106868357AGood anodizing effectSurface reaction electrolytic coatingSolution treatmentSand blasting

The invention relates to a 6061 aluminum alloy for a 3C product appearance piece and a processing method of the 6061 aluminum alloy. The micro elements in the aluminum alloy comprise, by mass percentage, smaller than or equal to 0.05wt% of Mn, 0.05-0.10wt% of Cr and smaller than or equal to 0.10wt% of Fe. The processing method includes that a cast ingot is heated to 360-420 DEG C at the speed of 20-50 DEG C / h, heat preservation is performed for 8-12 h, then the cast ingot is heated to 540-570 DEG C at the speed of 20-50 DEG C / h, and heat preservation is performed for 10-20 h; then hot rolling and cold rolling are performed; a cold rolled plate is subjected to solution treatment; and finally, aging treatment is performed, and heat preservation is performed for 1-24 h at 150-220 DEG C. By means of the technical scheme, a 6061 aluminum alloy plate material can be subjected to sand blasting treatment by using number 203-205 zircon sand in the anode oxidization manufacturing procedure, the anode oxidizing effect is extremely good, and the anode oxidization material stripe defect can be avoided.

Owner:苏州中色研达金属技术有限公司 +1

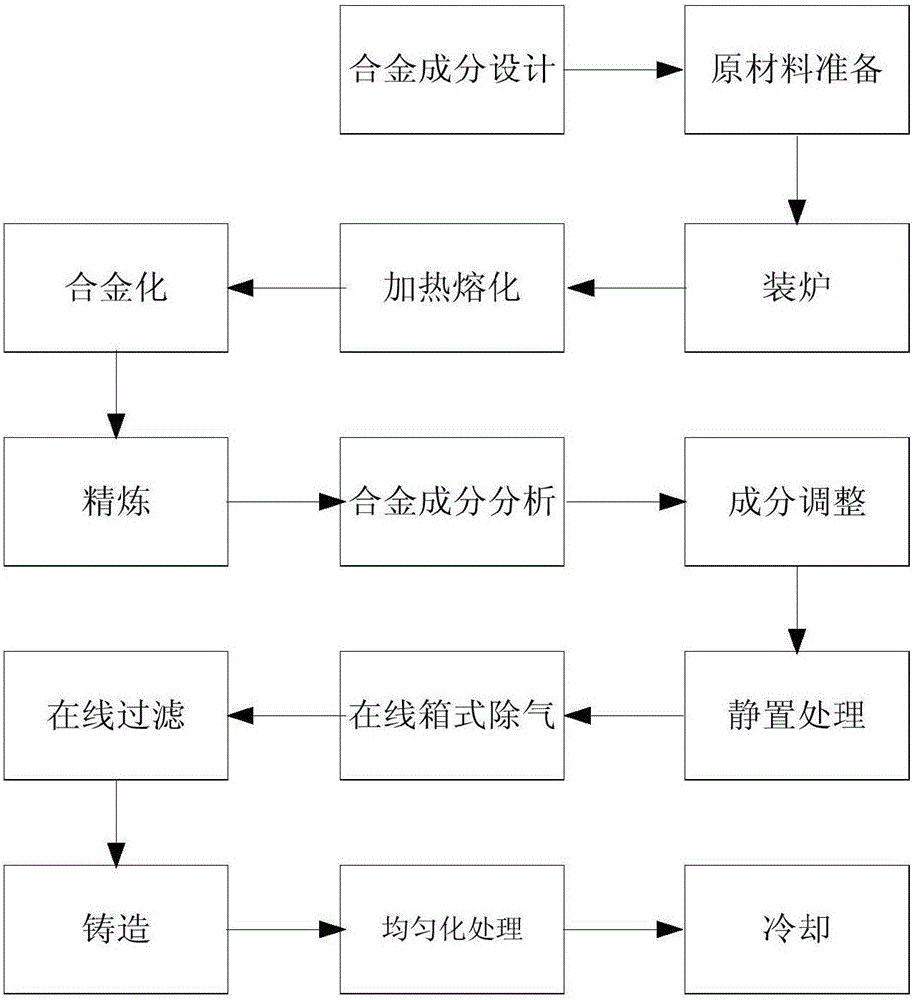

Preparation method of Al-Mg-Si series aluminum alloy die forging for inhibiting coarse grain structure

ActiveCN113245486AGood anti-fatigueGood anodizing effectHeating/cooling devicesGrain structureAnodic oxidation

The invention relates to a preparation method of an Al-Mg-Si series aluminum alloy die forging for inhibiting a coarse grain structure. Aluminum alloy comprises the following components in percentage by mass: 0.4-1.5% of Mg, 0.3-1.5% of Si, 0.01-0.7% of Cu, 0.01-0.3% of Fe, 0.01-1.0% of Mn, 0.001-0.25% of Zr, 0.01-0.5% of Cr, 0.001-0.25% of Sc, 0.01-0.1% of V, 0.01-0.25% of Ti and other transition elements. The preparation method comprises the steps of melt cleaning treatment, near-forged multi-rod hot top casting, multi-stage speed control homogenization, room-temperature or high-temperature die forging forming, two-stage solid solution and aging treatment. The prepared die forging has no coarse grain or coarse grain structure characteristic, is excellent in fatigue resistance and anodic oxidation performance, and can be used for preparing aluminum alloy structural parts of vehicles and transportation tools.

Owner:D MAG KUNSHAN NEW MATERIAL TECH CO LTD +1

Preparation method of anodizable die-casting aluminum alloy

The invention discloses a preparation method of anodizable die-casting aluminum alloy. The preparation method includes following steps: putting aluminum ingot and aluminum-nickel alloy into a smelting furnace for smelting, and adding ferralia when temperature is increased to 830-850 DEG C; stirring molten metal for several times, and standing; adding a magnesium agent; putting hot-mold aluminum ingot and aluminum-nickel alloy into the molten metal, and adding a sodium-free refining agent when the molten metal is cooled to 780-800 DEG C; adding an alterant when temperature of molten alloy is 780-800 DEG C, and stirring the molten alloy to enable the alterant to be completely smelted; deslagging, sufficiently stirring, and taking a sample for laboratory test; feeding nitrogen into the molten alloy; casting if ingredients of the laboratory test are within a set range, and maintaining temperature of the molten metal at 760-770 DEG C during casting. By the preparation method, the defect that anodization of existing die-casting aluminum alloy cannot be realized is overcome.

Owner:GUANGZHOU ZHIYUAN ALLOY PROD CO LTD

6-series aluminum alloy and machining method thereof

The invention discloses a 6-series aluminum alloy and a processing method thereof. The 6-series aluminum alloy includes: magnesium (Mg): 0.6-1.0 wt%; silicon (Mg): 0.4-0.8 wt%; manganese (Mn): ≤0.04 wt%; Titanium (Ti): ≤0.04 wt%; Iron (Fe): ≤0.10 wt%; Copper (Cu): ≤0.05 wt%; Chromium (Cr): ≤0.01 wt%; ) and unavoidable impurities. The invention optimizes the components of the 6 series aluminum alloy and controls the processing technology, so that the size and distribution of the intermetallic compounds are better controlled, and finally the material has a better anodic oxidation effect.

Owner:杨仲彬

Aluminum alloy and preparation method thereof

The invention provides an aluminum alloy and a preparation method of the aluminum alloy. The aluminum alloy comprises, by weight, 5%-8% of Zn, 1.2%-3.2% of Mg, 0.001%-0.15% of Ga, 0.001%-0.1% of V, 0.001%-0.2% of Ti, not larger than 0.2% of Si, not larger than 0.2% of Fe, not larger than 0.2% of Cu and the balance Al and inevitable impurity elements. The aluminum alloy keeps high yield strength, and the yield strength reaches over 440 MPa; and meanwhile, the aluminum alloy keeps good anodic oxidation performance, and an oxidation film is silvery white and uniform and bright in color and luster.

Owner:BYD CO LTD

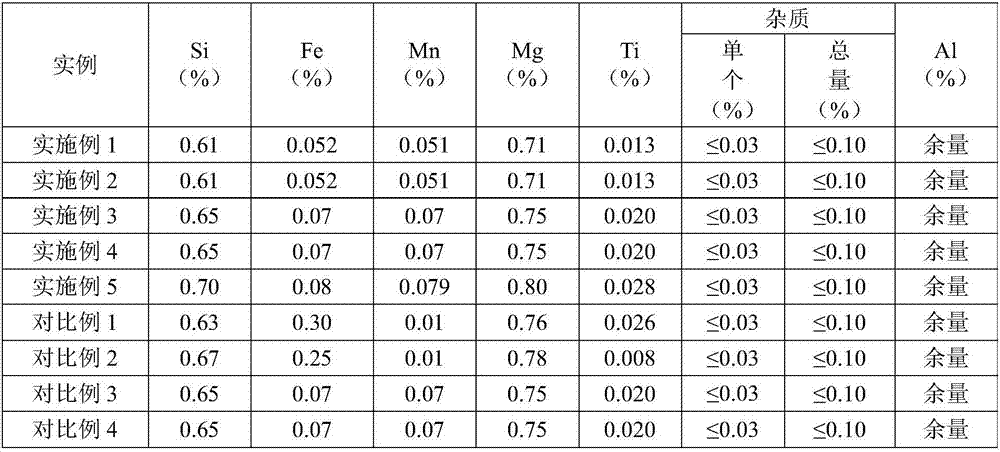

6063G aluminum alloy for smartphone and machining method of 6063G aluminum alloy

The invention discloses a 6063G aluminum alloy for a smartphone and a machining method of the 6063G aluminum alloy. The aluminum alloy comprises, by mass, 0.60%-0.70% of Si, 0.05%-0.08% of Fe, 0.05%-0.08% of Mn, 0.70%-0.80% of Mg, 0.01%-0.03% of Ti and the balance Al and inevitable impurities. The corresponding machining method sequentially includes eight steps including ingot casting, homogenizing annealing, hot rolling, cold rolling, intermediate solid solution treatment, secondary cold rolling, finished product annealing and final aging treatment. An aluminum product has the excellent anodic oxidation effect through the aluminum alloy ingredients and the machining method, extremely-fine 205-210-mesh zircon sand blasting treatment is met, and the 6063G aluminum alloy is a six-serial smartphone appearance piece ideal aluminum alloy material meeting the moderate strength requirement and having very high requirement for anodic oxidation treatment, and the market application prospect is wide.

Owner:TIANJIN ZHONGWANG ALUMINUM IND CO LTD

3D laser etching light-cured UV coating and preparation method thereof

InactiveCN106752860AGood anodizing effectOvercome the defect of easy collision crackingFireproof paintsAnti-corrosive paintsLaser etchingButyl acetate

The invention relates to the technical field of UV coatings, in particular to a 3D laser etching light-cured UV coating and a preparation method of the 3D laser etching light-cured UV coating. The UV coating comprises the following raw materials in parts by weight: 3 to 8 parts of polyfunctional monomers, 8 to 10 parts of aliphatic bifunctional urethane acrylate, 12 to 15 parts of aliphatic trifunctional urethane acrylate, 10 to 15 parts of aliphatic tetrafunctional urethane acrylate, 8 to 12 parts of aliphatic hexa-functional urethane acrylate, 8 to 12 parts of aliphatic nona-functional urethane acrylate, 2.5 to 4.8 parts of photoinitiators, 0.3 to 0.5 part of a leveling agent, 20 to 25 parts of butyl acetate and 20 to 25 parts of MEK butanone. According to the invention, the adhesion between a UV paint layer generated by the 3D laser etching light-cured UV coating and a base coat layer and between the UV paint layer and a surface paint layer is good, so that the shedding phenomenon is not easily generated.

Owner:东莞市惠尔明高分子材料科技有限公司

High-strength anodizing die-casting aluminium alloy and preparation method thereof

ActiveCN107447134ATo promote floatingImprove filtration efficiency5005 aluminium alloy6061 aluminium alloy

The invention belongs to the technical field of aluminium alloy and particularly relates to high-strength anodizing die-casting aluminium alloy and a preparation method thereof. Mg, Mn, Fe, Zn, Mo, Zr, Cr and Al constitute die-casting alloy elements, and the high-strength anodizing die-casting aluminium alloy is prepared by a smelting procedure and a die-casting procedure. The types, the contents and the adding modes of all the alloy elements are strictly controlled, so that lots of the elements mainly exist in a matrix in a solid solution format under the die-casting (fast cooling) condition; Zr and Mo ensure more uniform alloy tissue and refined crystal grains, so that the alloy has high strength and favorable die-casing performance and excellent anodizing performance; on a die-casting machine, die-casting molding can be performed by a die to directly obtain the required product without heat treatment or deformation, so that the production cost is greatly lowered; and the high-strength anodizing die-casting aluminium alloy is suitable for thin-walled shell members demanding much on the strength, the die-casting performance and the anodizing demand of the aluminium alloy.

Owner:苏州慧驰轻合金精密成型科技有限公司

Preparation method of large-size 6061 aluminum alloy plate for semiconductor equipment

PendingCN112593100AImprove machining accuracyMeet the requirements of shape and position stabilityIngotStress relief

The invention discloses a preparation method of a large-size 6061 aluminum alloy plate for semiconductor equipment. The preparation method comprises the following steps of smelting and casting a proportioned aluminum alloy to obtain an aluminum alloy cast ingot; enabling the obtained aluminum alloy cast ingot to be subjected to homogenizing heat treatment, machining, preheating and hot rolling, and obtaining the large-specification aluminum alloy plate; and enabling the large-specification aluminum alloy plate obtained after the hot rolling to be pre-stretched, enabling the pre-stretched plateto be subjected to solution hardening, then conducting stretching and leveling, and conducting artificial aging. According to the preparation method, microstructure distortion energy segregation generated in the rolling process of the ultra-thick and ultra-wide 6061 plate can be eliminated or even, quenching internal stress generated by solid solution quenching is lower and more even, meanwhile,stress relief stretching after the quenching is combined, the residual internal stress is almost completely eliminated, the subsequent machining precision of the plate is remarkably improved, and therequirement of semiconductor equipment on high form and location stability of the aluminum plate is met.

Owner:广西南南铝加工有限公司

Aluminum alloy mobile phone shell and manufacturing method thereof

InactiveCN105238963AHigh strengthMaintain fine grain structureTelephone set constructionsUltimate tensile strengthImpurity

An aluminum alloy mobile phone shell is made of an aluminum alloy material which comprises 0.8%-1.5% of Mg, 0.4%-0.9% of Si, 0.2%-1.2% of Co, and the balance Al and inevitable impurities. The aluminum alloy material for manufacturing the aluminum alloy mobile phone shell comprises 0.8%-1.5% of Mg, 0.4%-0.9% of Si, 0.2%-1.2% of Co, and the balance Al and inevitable impurities. A method for manufacturing the aluminum alloy mobile phone shell comprises the step of forming the aluminum alloy mobile phone shell through the aluminum alloy material. The aluminum alloy material is especially suitable for manufacturing the mobile phone shell with the high-strength requirement, and meets the requirements of thin-walled shell members with high appearance and performance requirements.

Owner:HUACHENG DONGGUAN METAL TECH CO LTD +1

Mobile phone shell and preparation process thereof

InactiveCN107299260AMaintain fine grain structureHigh strengthCoatingsTelephone set constructionsPunchingUltimate tensile strength

The invention provides a mobile phone casing and a preparation process thereof. The mobile phone casing contains the following raw materials in parts by weight: 1-1.8 parts of Mg, 0.5-1.1 parts of Si, 0.3-1 part of Co, and the balance is Al and Unavoidable impurities. The aluminum alloy shell provided by the present invention has very excellent stamping performance and high strength, and is especially suitable for the preparation of mobile phone shells that need to be stamped and formed through multiple passes, and at the same time require high strength, and meet high appearance and performance requirements. Requirements for thin-walled shell members. The coated decorative film layer makes the mobile phone shell have the advantages of high brightness and metal texture, and has high brightness and good adhesion.

Owner:合肥展游软件开发有限公司

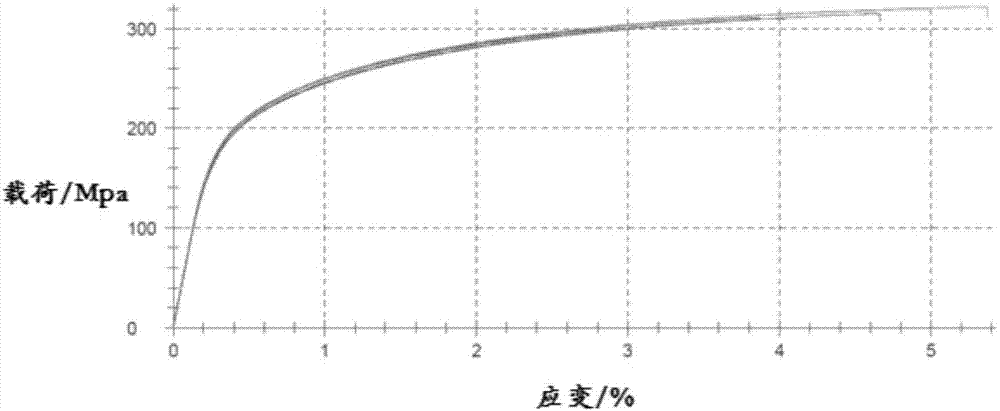

Production process of high-performance 6061 aluminum alloy for cell phone card slot and key materials

InactiveCN109536792AImprove metallographic structureImprove the ratio of ingredientsSolution treatmentMetal machining

The invention belongs to the technical field of aluminum alloy metal machining and discloses a production process of a high-performance 6061 aluminum alloy for cell phone card slot and key materials.According to the production process, a high-performance 6061 aluminum alloy plate is obtained through the steps of smelting and casting, homogenization treatment, machining face-milling, hot rolling,cold rolling to the finished product thickness, solution treatment and quenching at a continuous quenching line, manual aging treatment and the like, the tensile strength Rm of the high-performance 6061 aluminum alloy plate reaches 300 MPa or above, the hardness HV of the high-performance 6061 aluminum alloy plate reaches 90 or above, and on the one hand, the high-performance 6061 aluminum alloy plate has good machining performance and can be suitable for early CNC machining of the cell phone card slot and key materials; and on the other hand, the high-performance 6061 aluminum alloy plate hasgood anodic oxidation performance, can be oxidized into various bright colors and thus is quite attractive, a layer of uniform and luster-consistent protecting film is formed on the surfaces of the materials after oxidation, the hardness and abrasion resistance of a cell phone card slot and keys are greatly improved, and the service life of a product is prolonged.

Owner:郑州明泰实业有限公司

Al-Zn-Mg-Cu alloy and preparation process

The embodiment of the invention provides an Al-Zn-Mg-Cu alloy and a preparation process. The alloy has, in a T6 state, a tensile strength [sigma]b >= 590 MPa, a yield strength [sigma]0.2 >= 560 MPa, aspecific elongation [delta] >= 12%, has excellent anodizing performance and no continuous oxide film cracks while having high strength, and is suitable for use as a portable electronic device housingor frame structure material.

Owner:GUANGDONG HOSHION IND ALUMINUM CO LTD

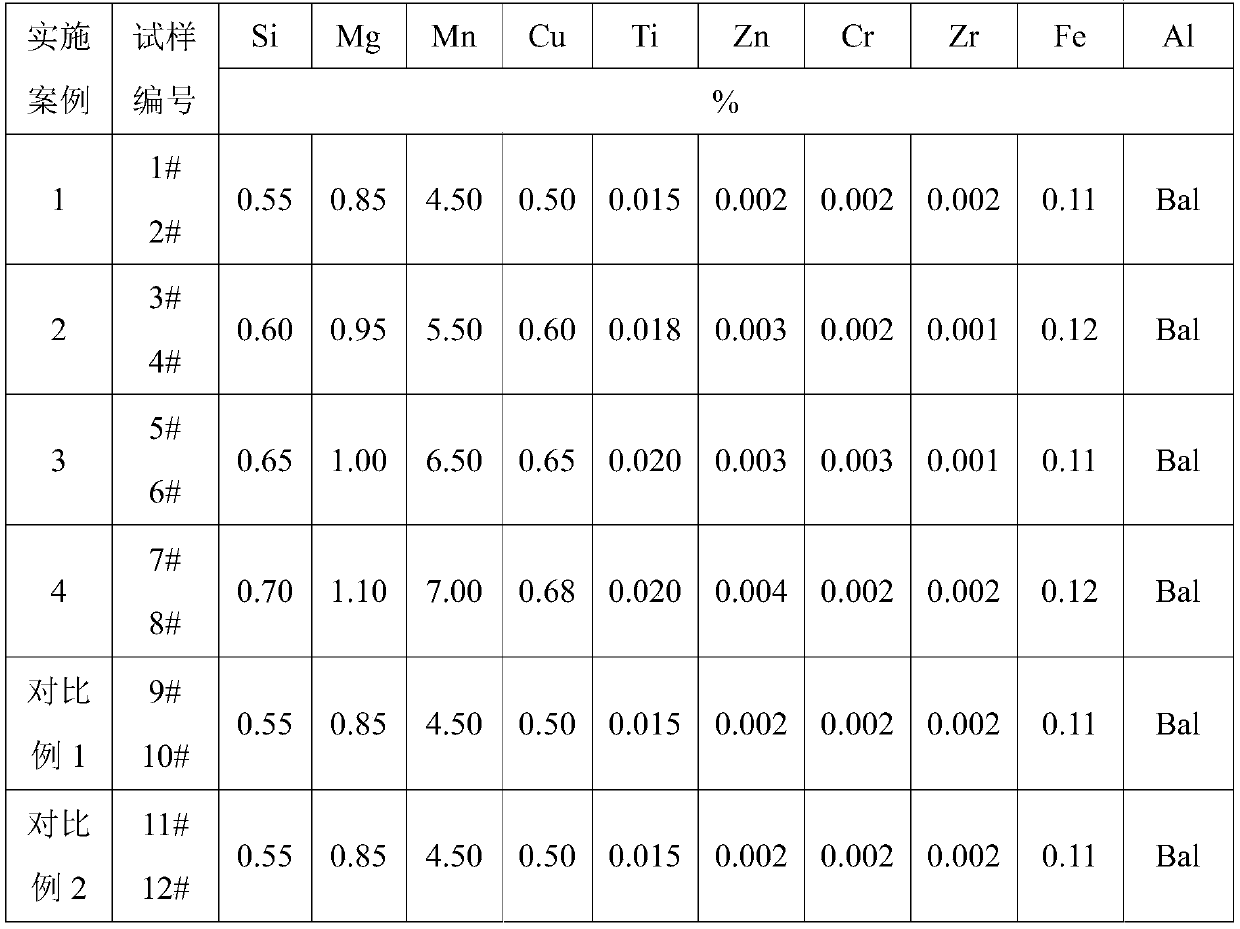

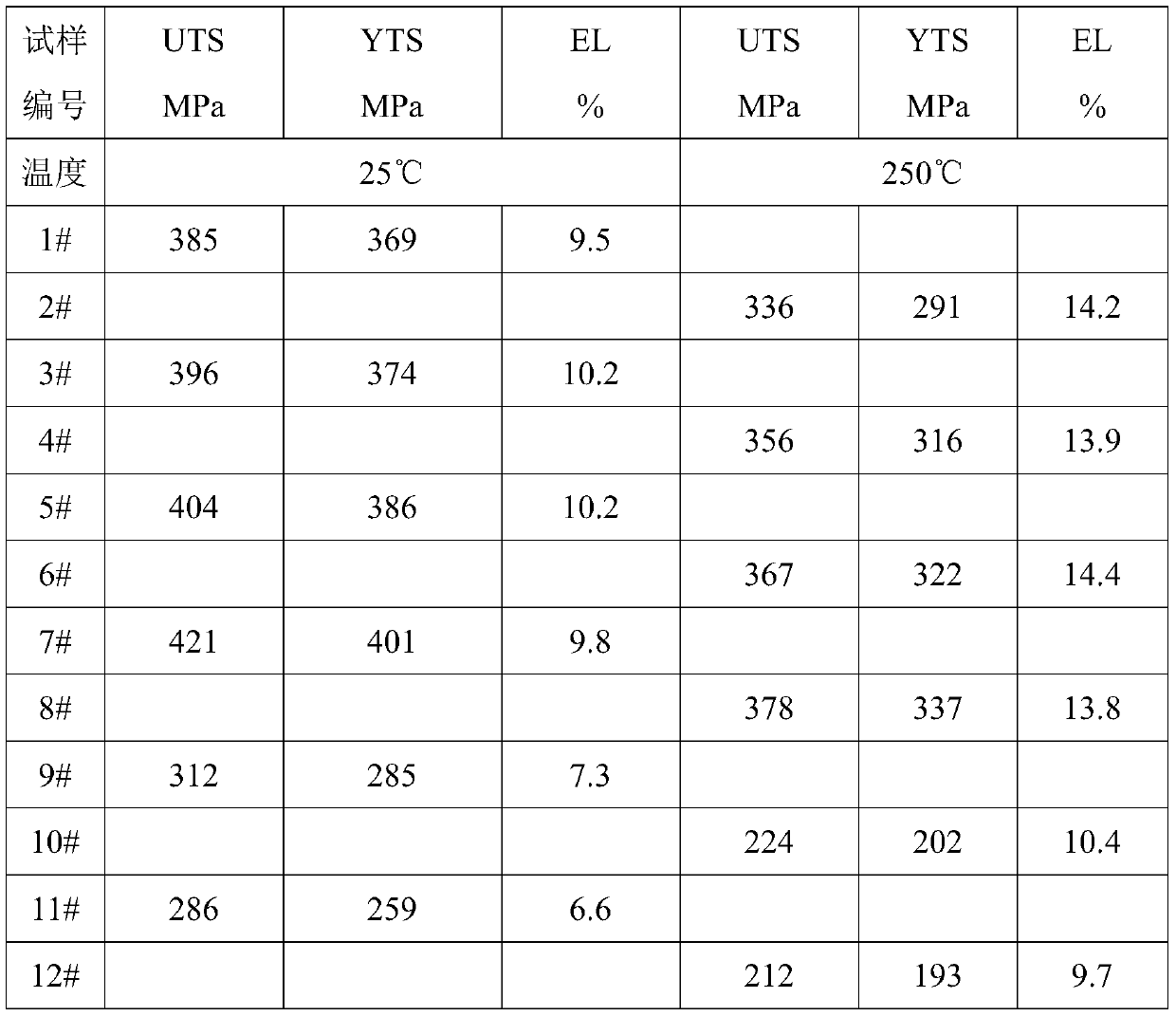

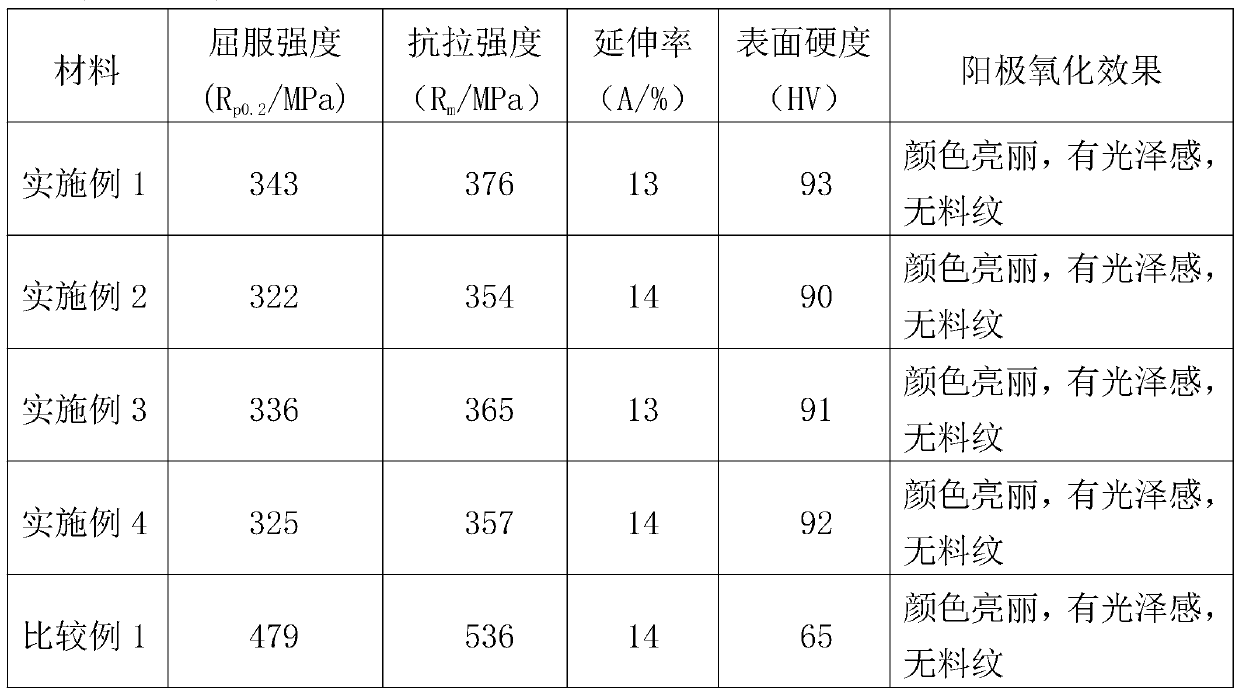

High-melting-point heat-resisting wrought aluminum alloy and preparation method thereof

The invention provides a high-melting-point heat-resisting wrought aluminum alloy and a preparation method thereof. Composition elements of the aluminum alloy comprise, by mass percentage, 0.45%-0.75%of Si, 0.80%-1.20% of Mg, 3.50%-10.50% of Mn, 0.40%-0.80% of Cu, 0.01%-0.05% of Ti and the balance aluminum and impurity elements. The aluminum alloy is high in melting point and excellent in heat resisting performance, the high-temperature size stability performance is excellent, meanwhile, the anode oxidization performance is good, and the vision effect of exquisite appearance can be obtained.

Owner:同曦集团有限公司

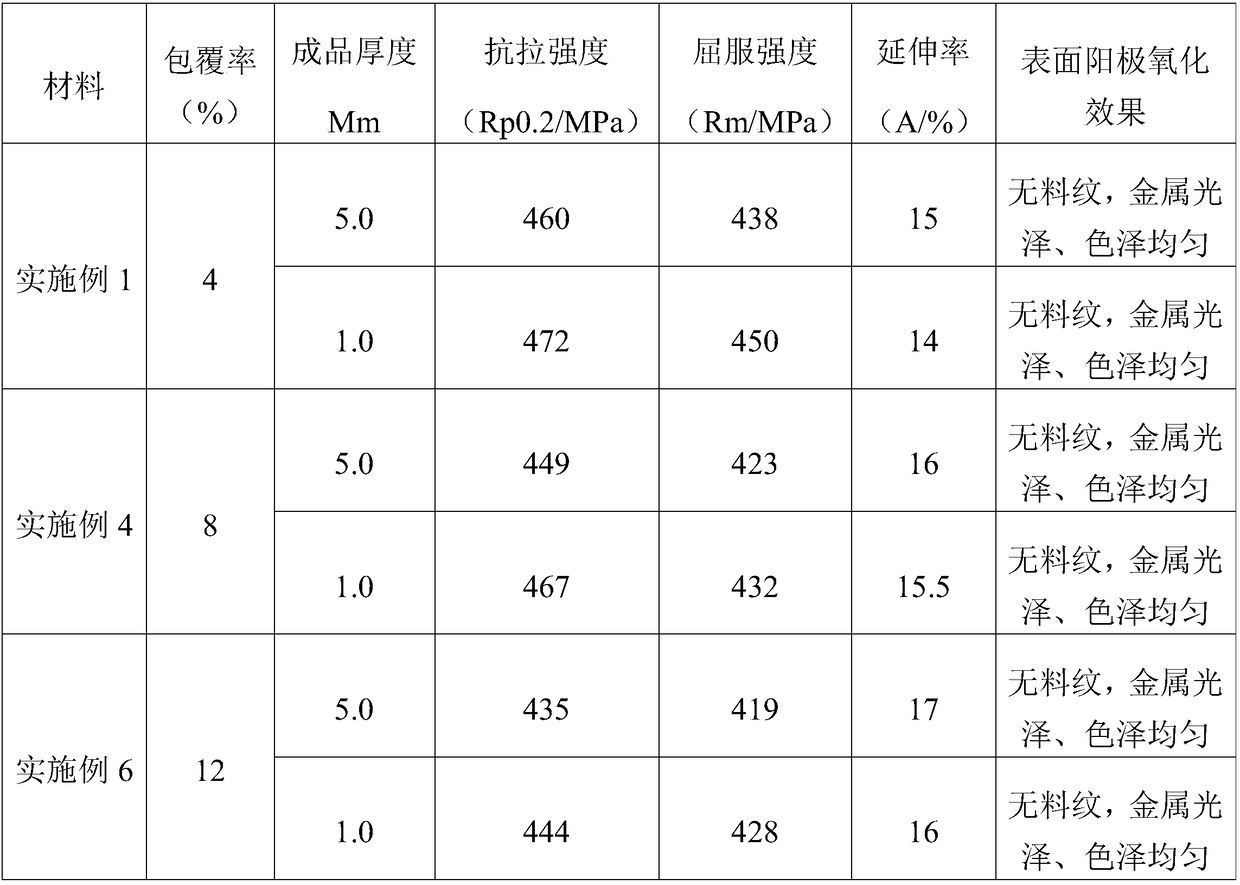

Preparation method of aluminum alloy composite material for outer part of electronic product

ActiveCN109957690AGood anodizing effectHigh strengthMetal rolling arrangementsAlloy compositeSolid solution

The invention relates to a preparation method of an aluminum alloy composite material, in particular to a preparation method of the aluminum alloy composite material for an outer part of an electronicproduct. The preparation method of the aluminum alloy composite material comprises the following steps: carrying out preparation of core layer alloys and cladding layer alloy plates, carrying out surface treatment, carrying out welding and fixing, carrying out pre-heating, carrying out hot rolling, carrying out cold rolling, carrying out solid-solution hardening, and carrying out aging to obtainan aluminum alloy composite material finished product. According to the preparation method of the aluminum alloy composite material disclosed by the invention, rolling compounding on a 6-series aluminum alloy with low alloying and high anode oxidation performance and a 6-series aluminum alloy with higher strength is carried out, so that an aluminum alloy composite material product for the outer part of the electronic product is prepared. Compared with a single 6-series aluminum alloy material in the prior art, the product prepared by adopting the method disclosed by the invention has the bothcharacteristics of high strength and excellent anode oxidation effect, and therefore, the product is a desired material which is used for manufacturing the outer part of the electronic product.

Owner:广西南南铝加工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com