Preparation method of 6xxx/7xxx aluminum alloy composite

A composite material and aluminum alloy technology, which is applied in the field of preparation of 6xxx/7xxx aluminum alloy composite materials, can solve the problems that the material strength and anodizing performance cannot be improved to an excellent level at the same time, are limited, and deteriorate the anodizing effect. Excellent anodizing effect, the effect of large application potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

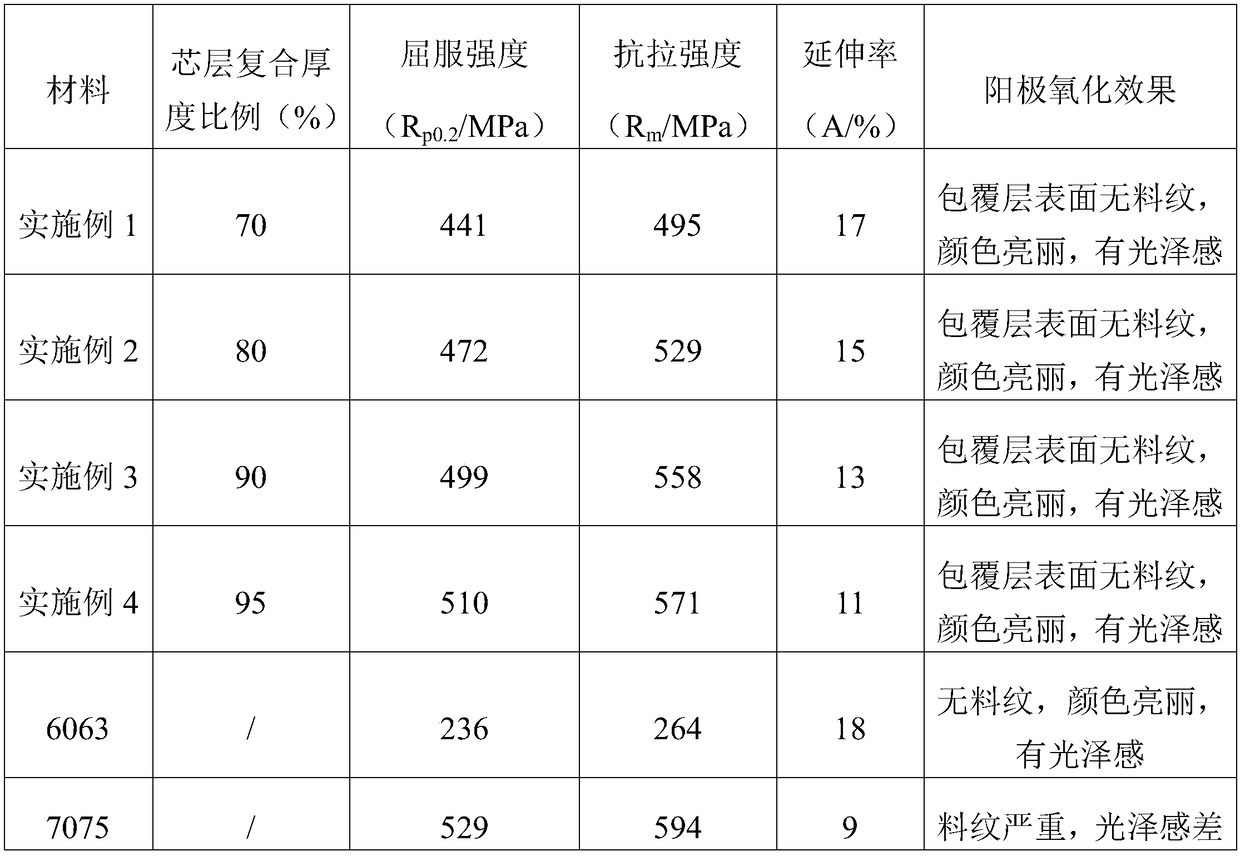

Examples

Embodiment 1

[0031] A 6xxx / 7xxx aluminum alloy composite material, including a core layer alloy and a cladding layer alloy, the core layer alloy is a high-strength 7xxx aluminum alloy, and the mass percentages of each element in the core layer alloy are Si 0.06%, Fe 0.15%, Cu 1.35%, Mn0.06%, Mg 2.40%, Cr 0.25%, Zn 5.85%, Ti 0.02%, the balance is Al and unavoidable elements; the cladding layer alloy is 6xxx aluminum alloy with excellent anodic oxidation effect, cladding The mass percentage of each element in the layer alloy is Si0.45%, Fe 0.18%, Cu 0.07%, Mn 0.05%, Mg 0.75%, Cr 0.02%, Zn 0.03%, Ti 0.03%, the balance is Al and unavoidable element; the preparation method of the 6xxx / 7xxx aluminum alloy composite material, the operation steps are as follows:

[0032] (1) Preparation of core layer alloy and cladding layer alloy plates: the raw materials of the core layer alloy and cladding layer alloy prepared above are melted and cast respectively to obtain core alloy ingots and cladding layer...

Embodiment 2

[0042] A 6xxx / 7xxx aluminum alloy composite material, including a core layer alloy and a cladding layer alloy, the core layer alloy is a high-strength 7xxx aluminum alloy, and the mass percentages of each element in the core layer alloy are Si 0.40%, Fe 0.25%, Cu 1.65%, Mn0.30%, Mg 2.75%, Cr 0.22%, Zn 5.60%, Ti 0.03%, the balance is Al and unavoidable elements; the cladding layer alloy is 6xxx aluminum alloy with excellent anodic oxidation effect, cladding The mass percentage of each element in the layer alloy is Si0.35%, Fe 0.35%, Cu 0.02%, Mn 0.03%, Mg 0.55%, Cr 0.1%, Zn 0.03%, Ti 0.03%, the balance is Al and unavoidable element; the preparation method of the 6xxx / 7xxx aluminum alloy composite material, the operation steps are as follows:

[0043] (1) Preparation of core layer alloy and cladding layer alloy plates: the raw materials of the core layer alloy and cladding layer alloy prepared above are melted and cast respectively to obtain core alloy ingots and cladding layers...

Embodiment 3

[0053] A 6xxx / 7xxx aluminum alloy composite material, comprising a core layer alloy and a cladding layer alloy, the core layer alloy is a high-strength 7xxx aluminum alloy, and the mass percentages of each element in the core layer alloy are Si 0.20%, Fe 0.25%, Cu 1.2%, Mn0.06%, Mg 2.1%, Cr 0.28%, Zn 6.1%, Ti 0.20%, the balance is Al and unavoidable elements; the cladding layer alloy is 6xxx aluminum alloy with excellent anodic oxidation effect, including The mass percentage of each element in the cladding alloy is Si 0.6%, Fe 0.08%, Cu 0.10%, Mn 0.10%, Mg 0.45%, Cr 0.02%, Zn 0.03%, Ti 0.03%, the balance is Al and unavoidable element; the preparation method of the 6xxx / 7xxx aluminum alloy composite material, the operation steps are as follows:

[0054] (1) Preparation of core layer alloy and cladding layer alloy plates: the raw materials of the core layer alloy and cladding layer alloy prepared above are melted and cast respectively to obtain core alloy ingots and cladding lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com