Preparation method of 1xxx/7xxx aluminium-alloy composite material

A composite material and aluminum alloy technology, applied in the field of preparation of 1xxx/7xxx aluminum alloy composite materials, can solve the problems of low anode yield, difficult anodization, poor color and luster, achieve uniform color and luster, improve anodization effect, hardness and high-strength effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

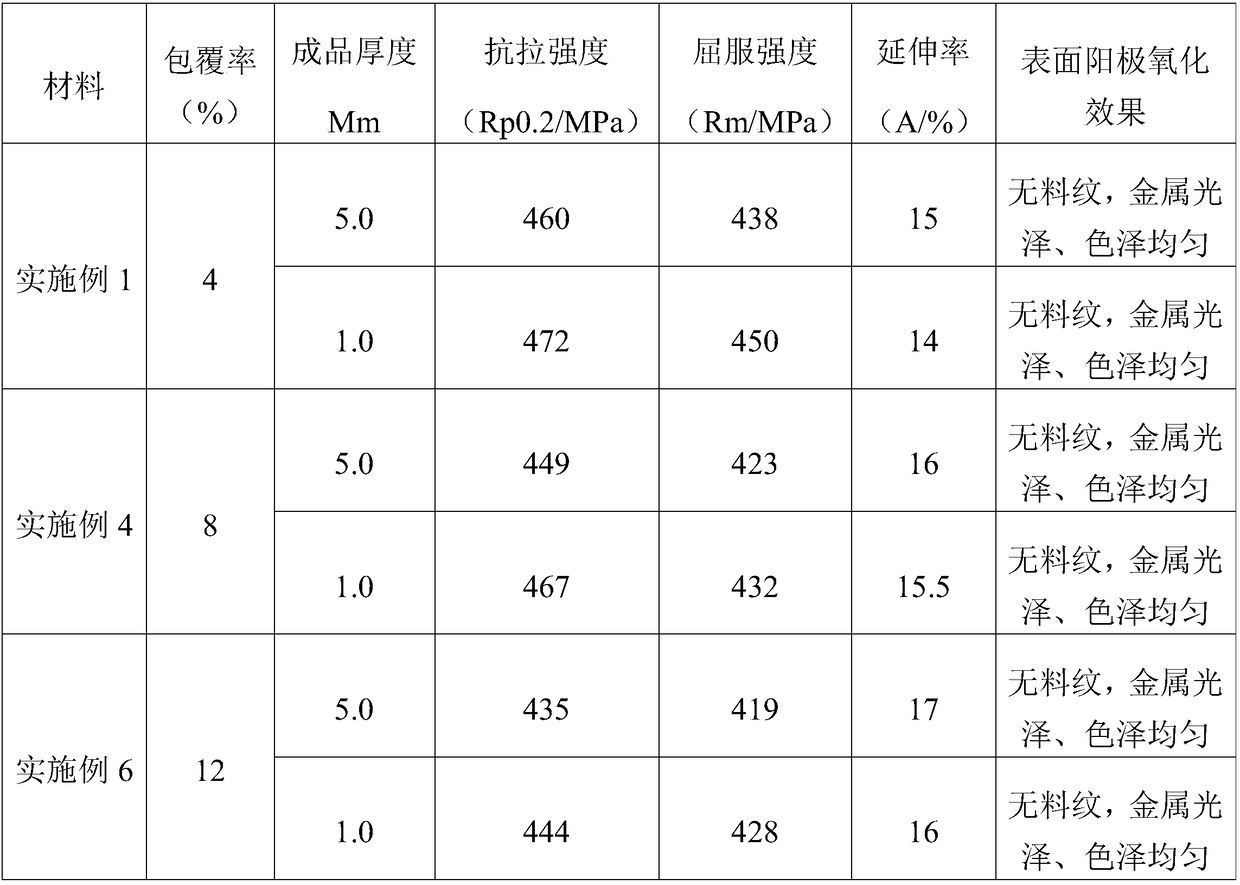

Examples

Embodiment 1

[0022] A 1xxx / 7xxx aluminum alloy composite material, including a core layer alloy and a cladding layer alloy, and the composition of the cladding layer alloy is composed of the following components in terms of mass percentage: Si 0.10%, Fe0.12%, Cu0.02%, Mn0.02% , Mg0.01%, Zn0.01%, Cr 0.007%, Zr 0.006%, the rest is composed of Al and unavoidable impurities; the mass percentage of each element in the core alloy is Si0.20%, Fe0.35%, Cu0.18%, Mn0.06%, Mg1.50%, Zn5.6%, Ti≤0.025%, Cr 0.005%, Zr 0.006%, the rest is composed of Al and unavoidable impurities; the 1xxx / 7xxx aluminum The preparation method of the alloy composite material, the operation steps are as follows:

[0023] (1) Preparation of core layer alloy and cladding layer alloy cast plate: batching according to the designed core layer and cladding layer alloy composition, after melting, degassing and filtering, the melting temperature is 710 ~ 760 ° C, through degassing and filtering The process reduces the hydrogen con...

Embodiment 2

[0028] When the 1xxx / 7xxx aluminum alloy composite material required by the customer is delivered as a coil, the operation of step (4) is: preheating and hot rolling: put the alloy cast plate welded in step (3) into the heating furnace for preheating, The heating temperature is 420°C, and the temperature is kept for 10 hours. After the heating is completed, it is taken out of the furnace and enters the rolling mill for hot rolling to a thickness of 5mm to obtain a composite coil. The composite coil is subjected to solid solution and quenching. The solution temperature is 450°C, kept for 60 minutes, and quenched for 100 minutes; Carry out aging, the aging temperature is 120°C, heat preservation for 24 hours, and air cooling after taking out the furnace, the finished product 1xxx / 7xxx aluminum alloy composite material is obtained, and the quality inspection, packaging, warehousing and delivery of the obtained finished product are carried out.

[0029] All the other operations are...

Embodiment 3

[0031](4) Preheating and hot rolling: put the welded alloy cast plate in step (3) into a heating furnace for preheating, the heating temperature is 420°C, and keep it warm for 10 hours. The final rolling temperature is controlled above 280°C to obtain composite coils. The composite coils are cold-rolled, re-coiled, cleaned and trimmed, and intermediate annealed. Roll, then solution quenching in air cushion furnace, solution temperature 450°C, speed 25m / mim, water quenching, and then aging, aging temperature 130°C, holding time 20 hours, out of the furnace and air cooling, to obtain 1xxx / 7xxx finished products with a width of 1200mm Aluminum alloy composite materials, quality inspection, packaging, warehousing and delivery of finished products.

[0032] All the other operations are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com