Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

43results about How to "Fully degassed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Micro-alloying steel for oil gas transport seamless pipeline and its preparation method

InactiveCN101186994AElimination of abnormal tissueImprove toughnessTemperature control deviceForeign matterChemical composition

The invention discloses micro-alloying seamless pipeline steel and process for preparation. According to weight percentage, the range of the chemical components of the invention includes that C holds 0.08% to 0.20%, Si is equal to or less than 0.04%, Mn takes 0.60% to 1. 50%, S is equal to or less than 0.015%, P is equal to or less than 0.025%, Al is equal to or less than 0.04%, Ti is equal to or less than 0.04%, H is equal to or less than 2.5*10-4%, O is equal to or less than 25*10-4%, the rest is Fe and unavoidable foreign matters. The process for preparation comprises technique steps, including smelting, refining, continuous casting, hot rolling and slow cooling. Round steel with the size of phi 70 to 150 millimeters can be produced by the process for preparation. The seamless pipeline steel of the invention has perfect anti-sulphide stress corrosion (SSC resistance) capability and anti-HIC property. The pipeline steel which can substitute for welding pipe can be utilized in the filed of oil pipeline and the like, and the invention increases the reliability of material and adaptability of variety, in particular being adaptable for the low submarine temperature and corrosion-resistant environment and for manufacture of thick-walled tubes.

Owner:LAIWU IRON & STEEL GRP

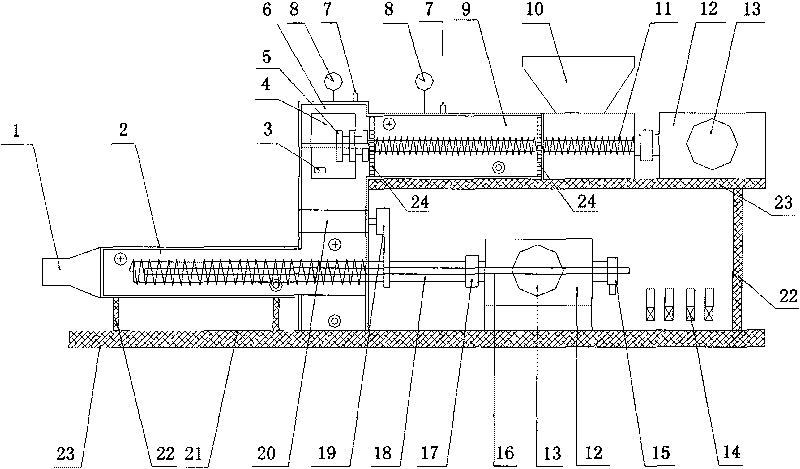

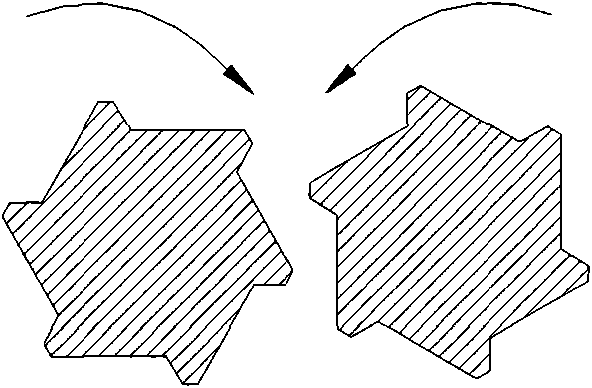

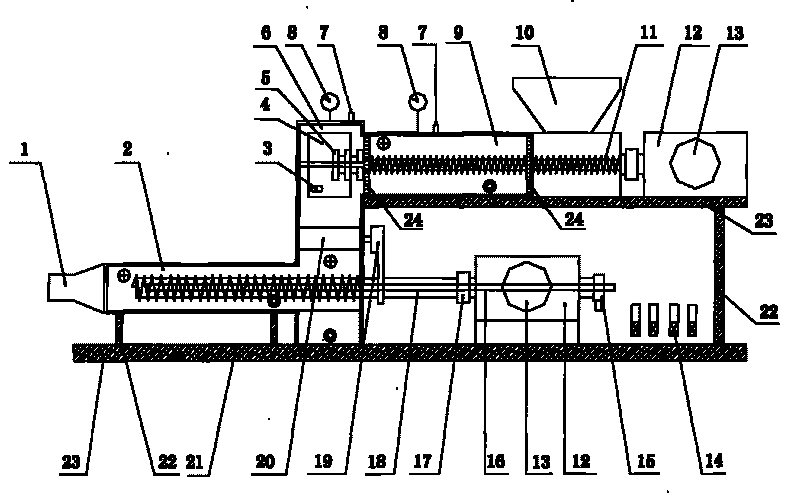

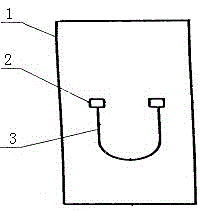

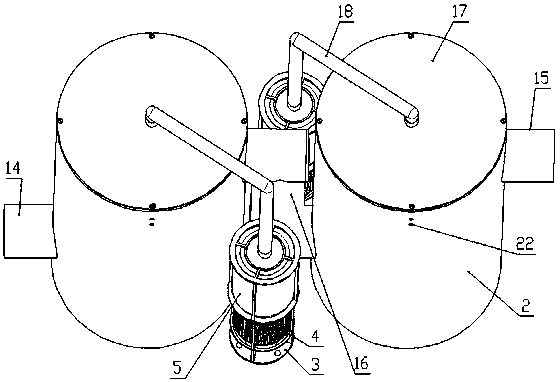

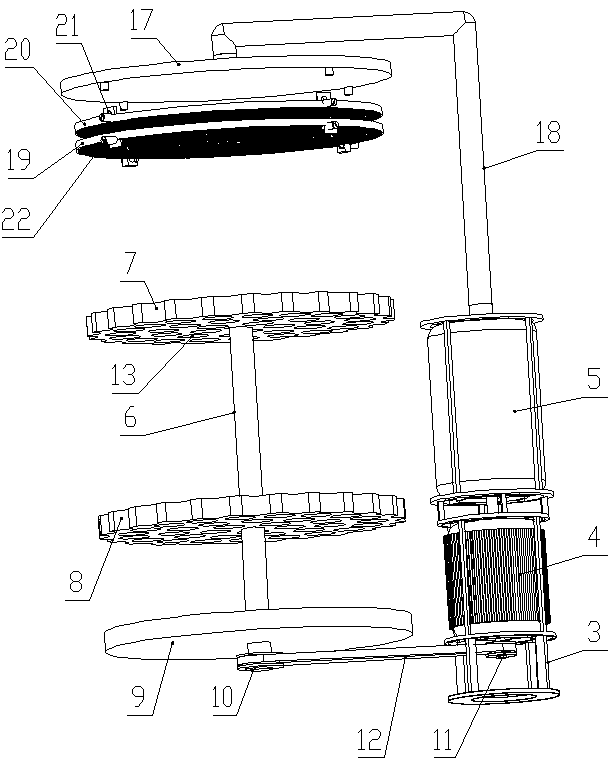

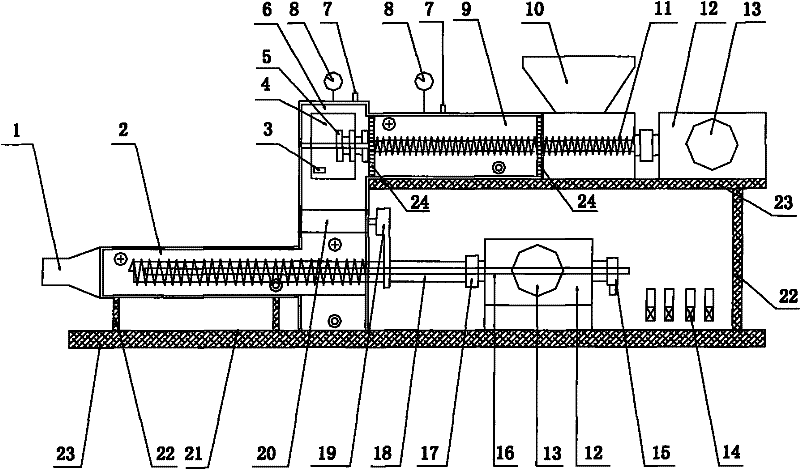

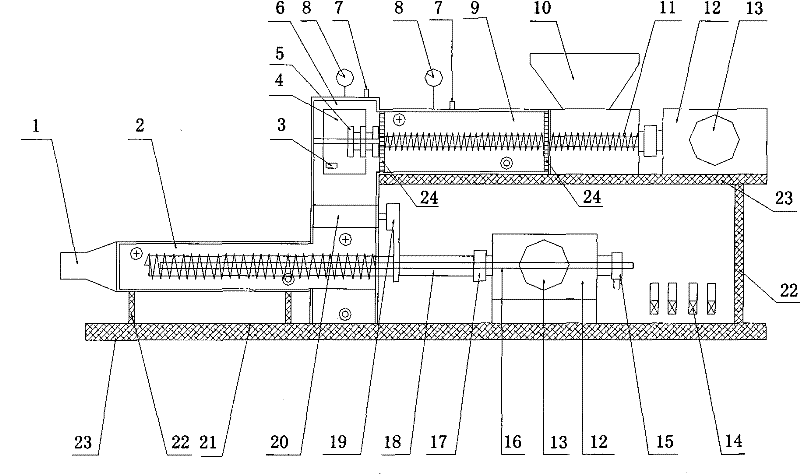

Honeycombed ceramic slurry water cooling vacuum refiner

The invention provides a honeycombed ceramic slurry water cooling vacuum refiner, comprising a slurry feed cylinder, slurry stirring shafts with helical blades, a vacuum chamber, a pumping hole, two kneading rollers, a photoelectric control device, a transmission mechanism, a hollow extruding shaft with helical blades, a slurry discharge cylinder, a fence which has section area close to and slightly smaller than the slurry feed cylinder, a cooling water device, a frame, a speed reducer and a variable-frequency motor, wherein the front end of the slurry stirring shafts with helical blades is provided with a slurry scraping knife. The slurry feed cylinder consists of two cylinders which are communicated, the section plane of the slurry feed cylinder is in a shape of a lying 8, and is communicated in the middle; the outlet end of the slurry feed cylinder is provided with the fence and the pumping port to form primary vacuum area; one slurry stirring shaft with the helical blade extends into each single cylinder, and is supported by a bearing with a seal ring; a bearing at the front end of the slurry stirring shaft is provided with a plurality of slurry scraping knives consisting of crossed blades; the fence is arranged at the outlet of the slurry feed cylinder; the upper end of the vacuum chamber is provided with the pumping port to ensure the vacuum chamber and the slurry discharge cylinder to form a secondary vacuum area; the lower part of the vacuum chamber is provided with two kneading rollers which are engaged with each other; the slurry outlet on the front part of the slurry discharge cylinder is a cone with narrowing opening.

Owner:NANJING KERUI SPECIAL CERAMICS +1

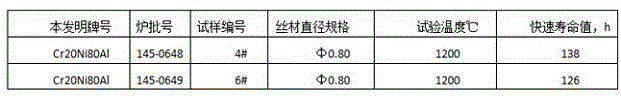

High-resistant chromium-nickel electric heating alloy and preparation process thereof

The invention discloses a high-resistant chromium-nickel electric heating alloy and a preparation process thereof. The chemical formula of the high-resistant chromium-nickel electric heating alloy is Cr20Ni80Al; the raw material formula of the high-resistant chromium-nickel electric heating alloy comprises the following components in percentage by weight: less than or equal to 0.03 percent of C, 1.40 to 1.60 percent of Si, less than or equal to 0.30 to 0.50 percent of Mn, less than or equal to 0.020 percent of P, less than or equal to 0.015 percent of S, 20.5 to 21.50 percent of Cr, less than or equal to 0.10 percent of Ti, less than or equal to 3.5 to 3.7 percent of AL, less than or equal to 1.00 percent of Fe, less than or equal to 0.2 percent of Zr, and the balance of Ni and inevitable impurities. According to the high-resistant chromium-nickel electric heating alloy, the electrical resistivity of the electric heating alloy is improved; the electrical characteristics are better; the anti-oxidation performance of an alloy material is improved; the high-temperature strength of the alloy is improved; the service life of the alloy is prolonged.

Owner:JIANGSU XINHUA ALLOY ELECTRIC

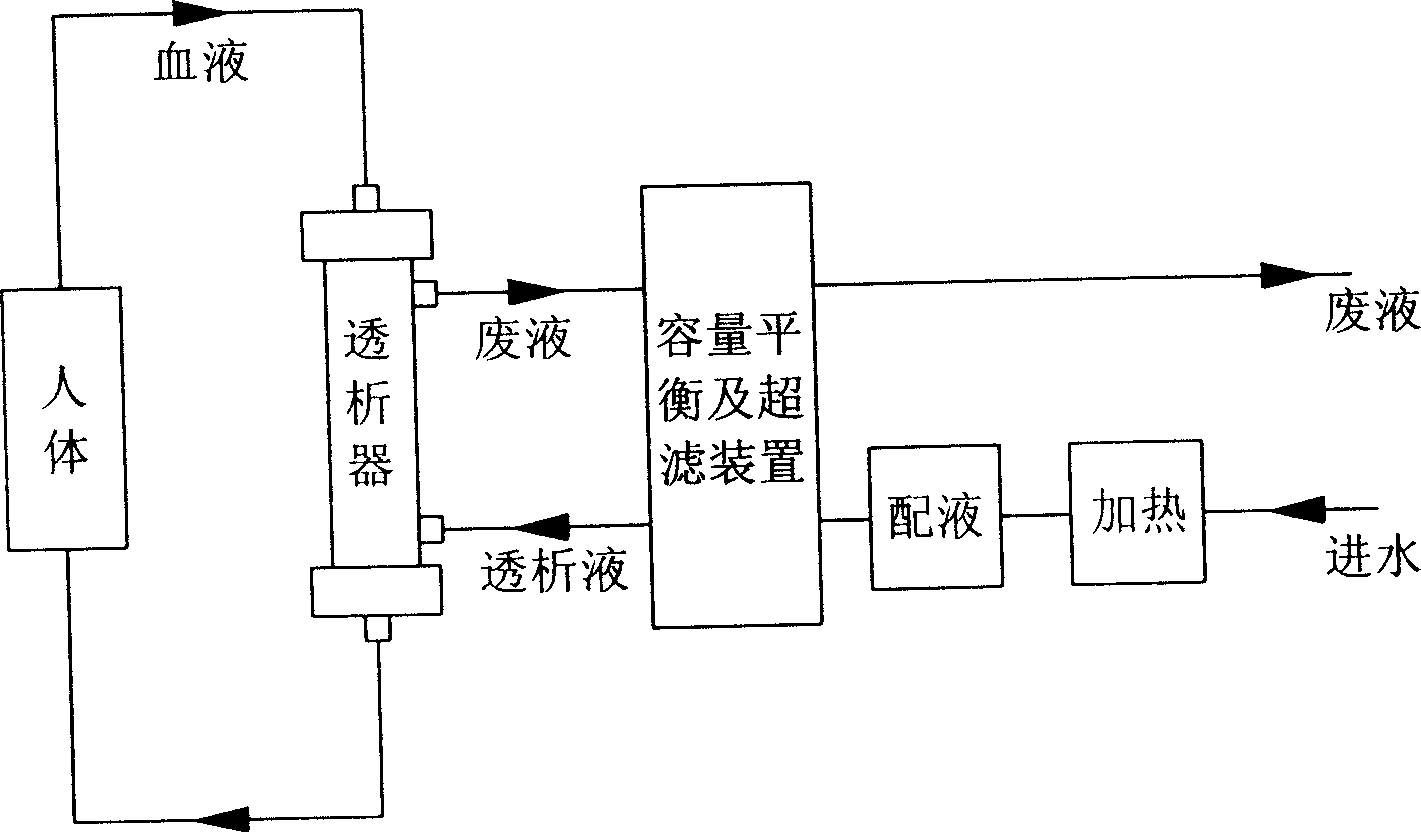

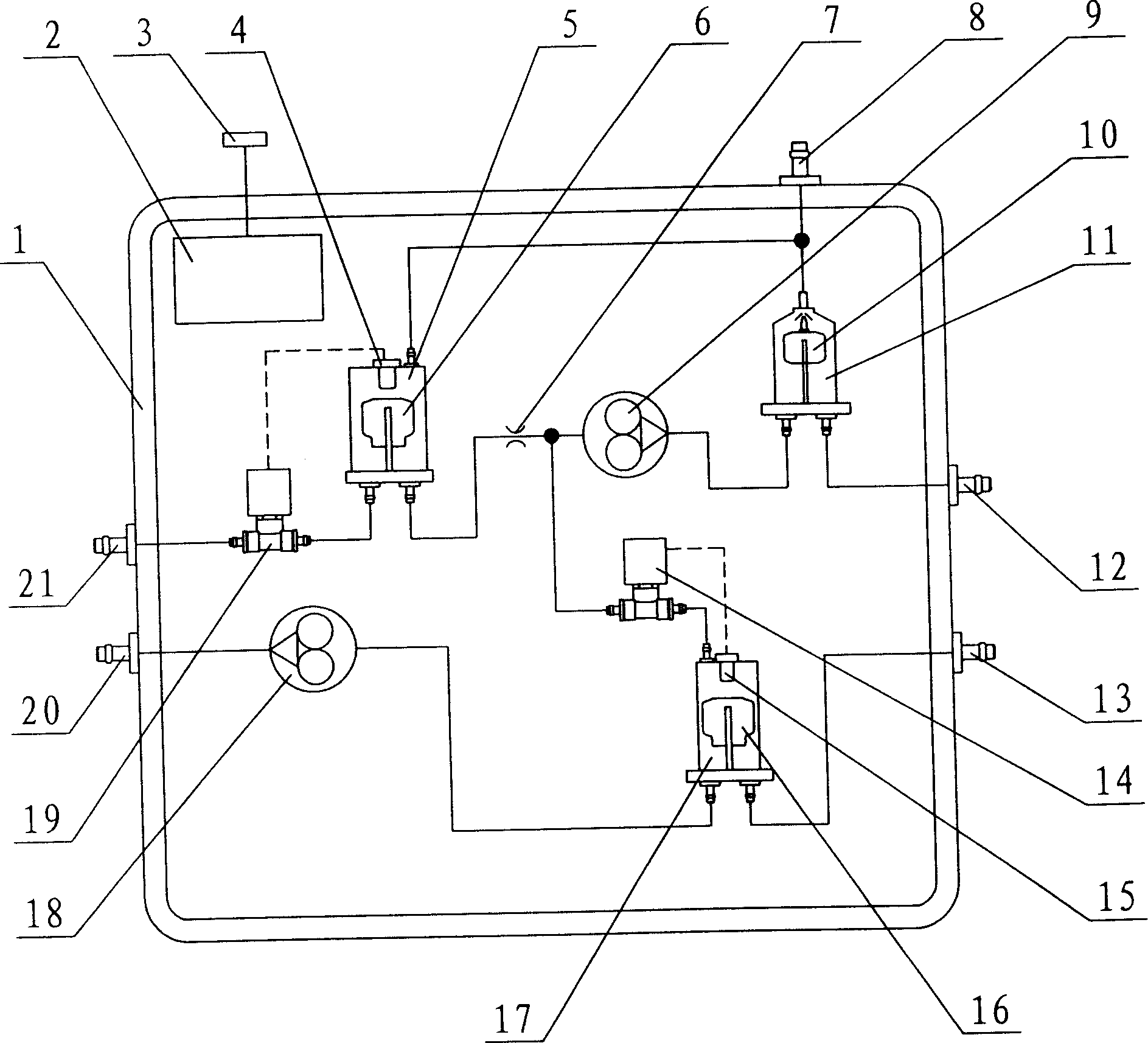

De-airing device for purifying blood

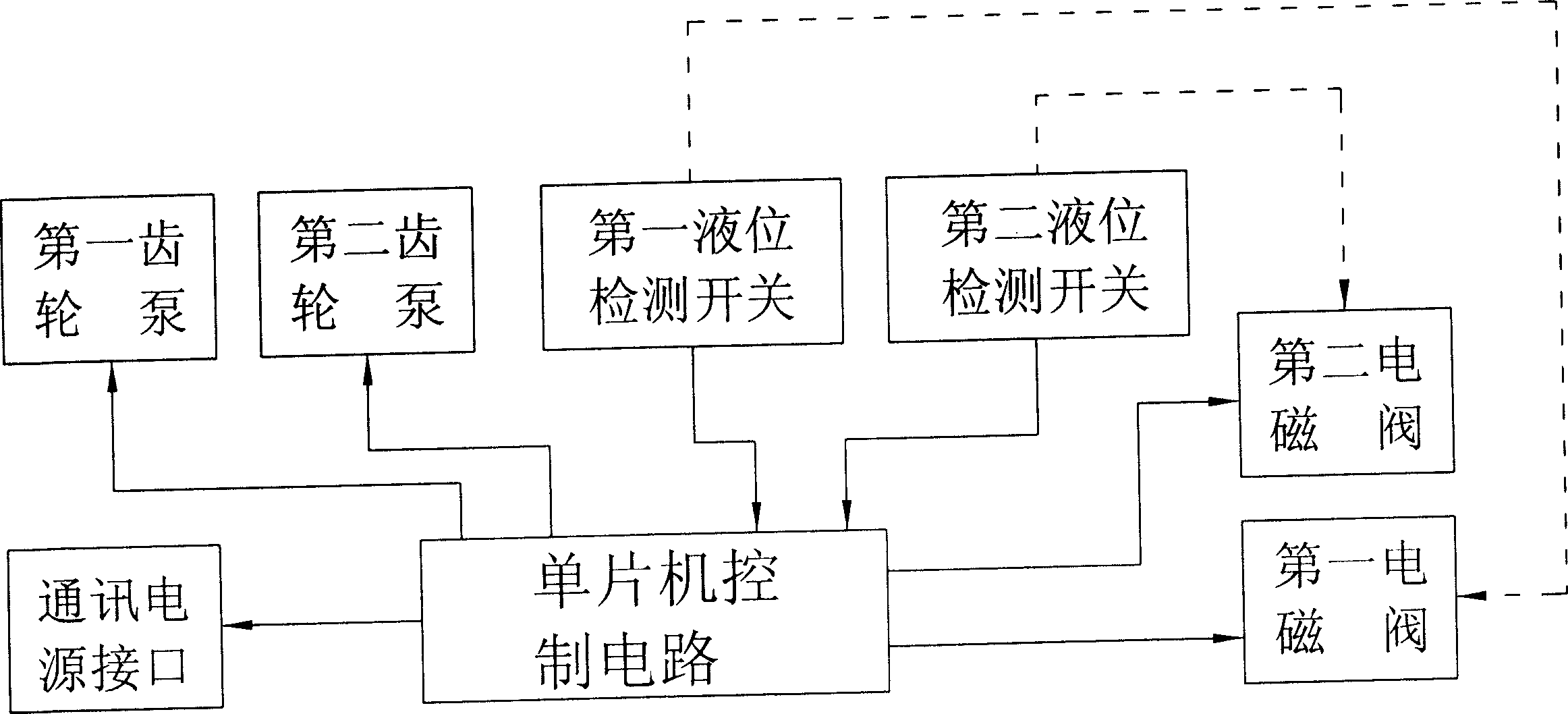

The de-airing device for purifying blood has one box with water inlet, water outlet, air exhaust, dialysate joint and waste liquid joint. The water inlet is connected to the liquid inlet of the flow controlling choke; the liquid outlet of the flow controlling choke is connected to two pipelines, including the first pipeline connected to the liquid inlet of the first de-airing tank via a gear pump and the second pipeline connected to the liquid exhaust of the second de-airing tank via a second solenoid valve; the liquid outlet and the air exhaust of the first de-airing tank are connected separately to the dialysis joint and the air exhaust joint pipeline; and the liquid inlet and the liquid outlet of the second de-airing tank are connected separately to the waste liquid joint pipeline and the water outlet joint via a second gear pump. The present invention can avoid air embolism to blood for normal dialysis treatment.

Owner:SWS HEMODIALYSIS CARE CO LTD

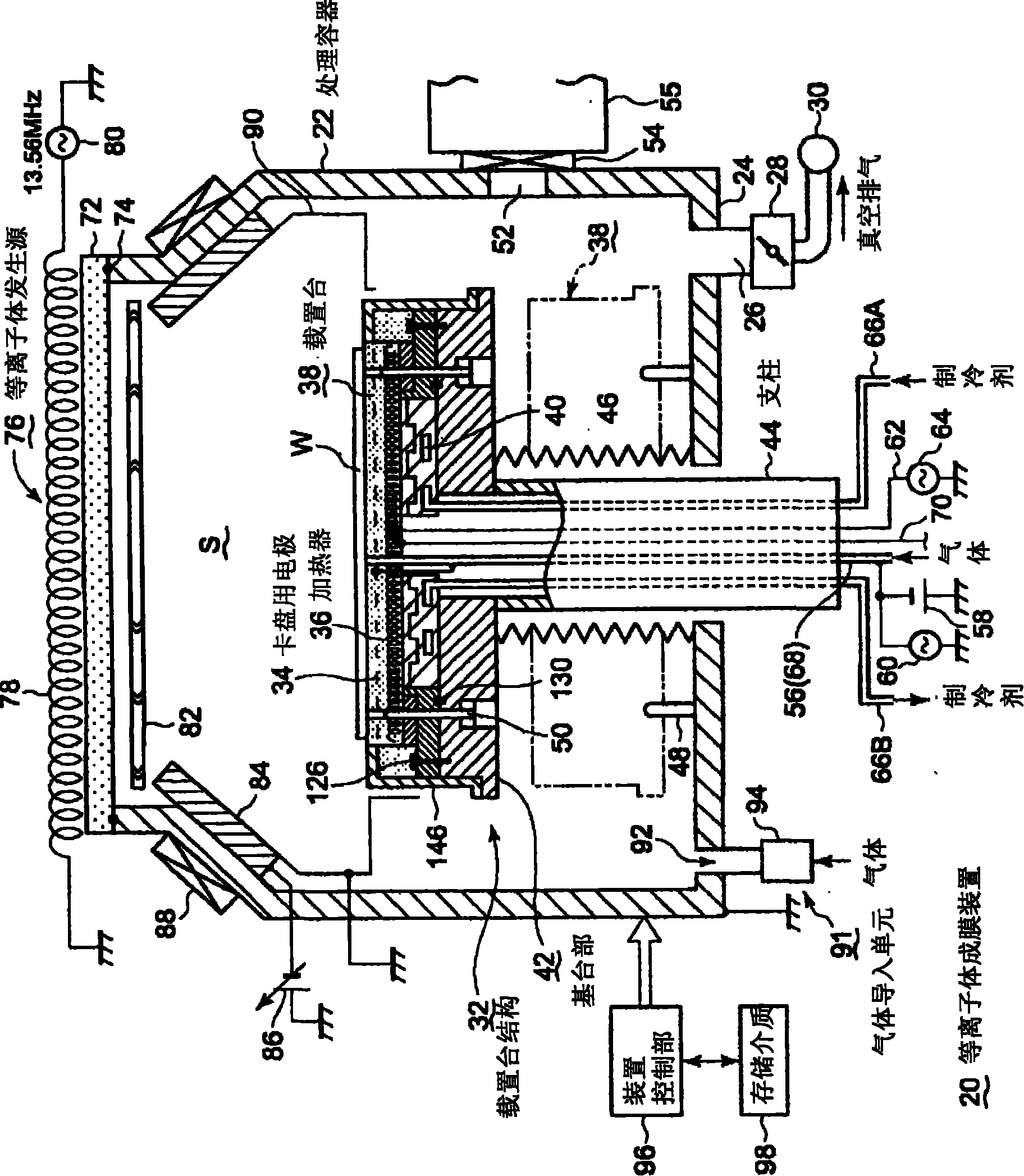

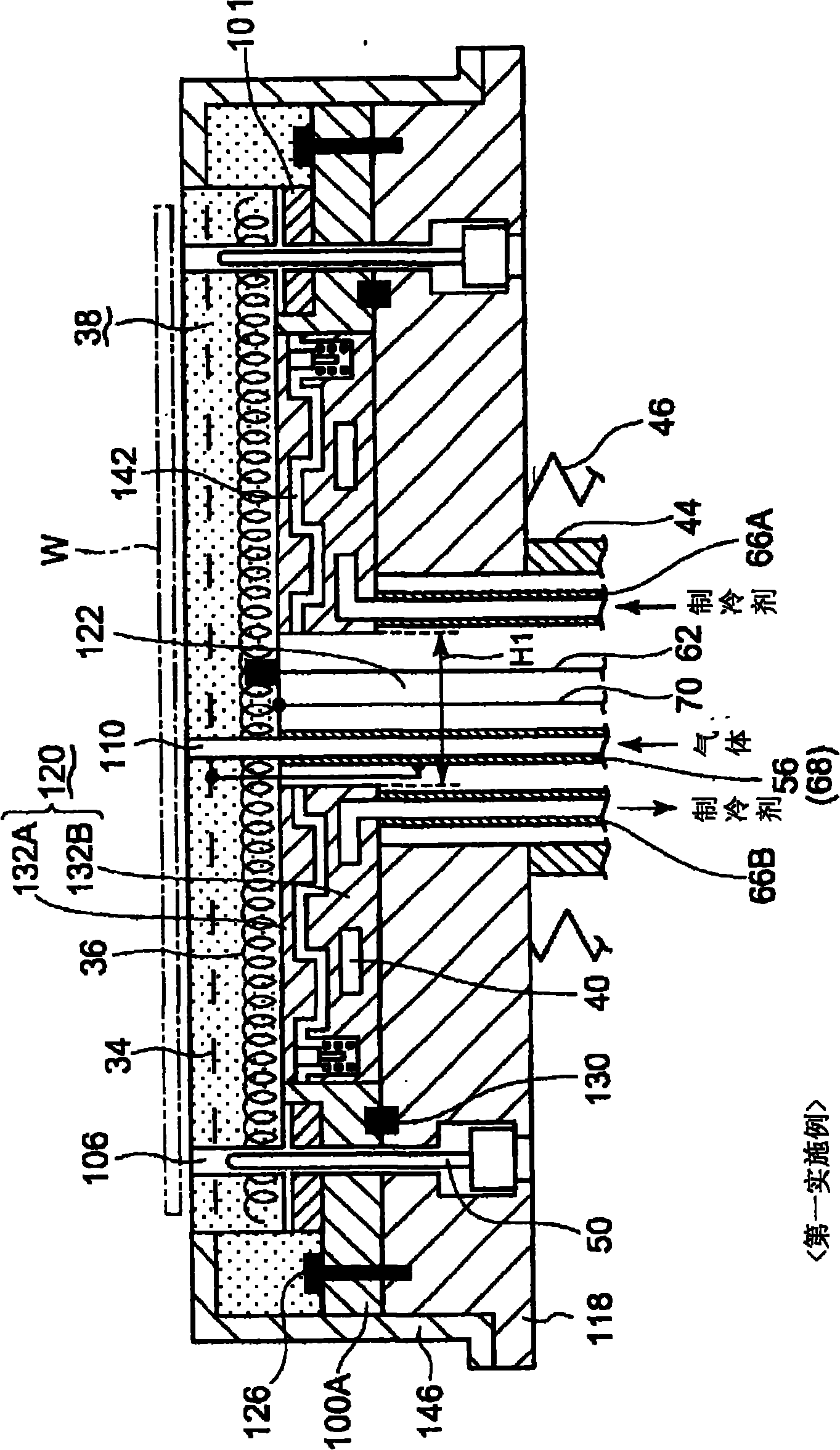

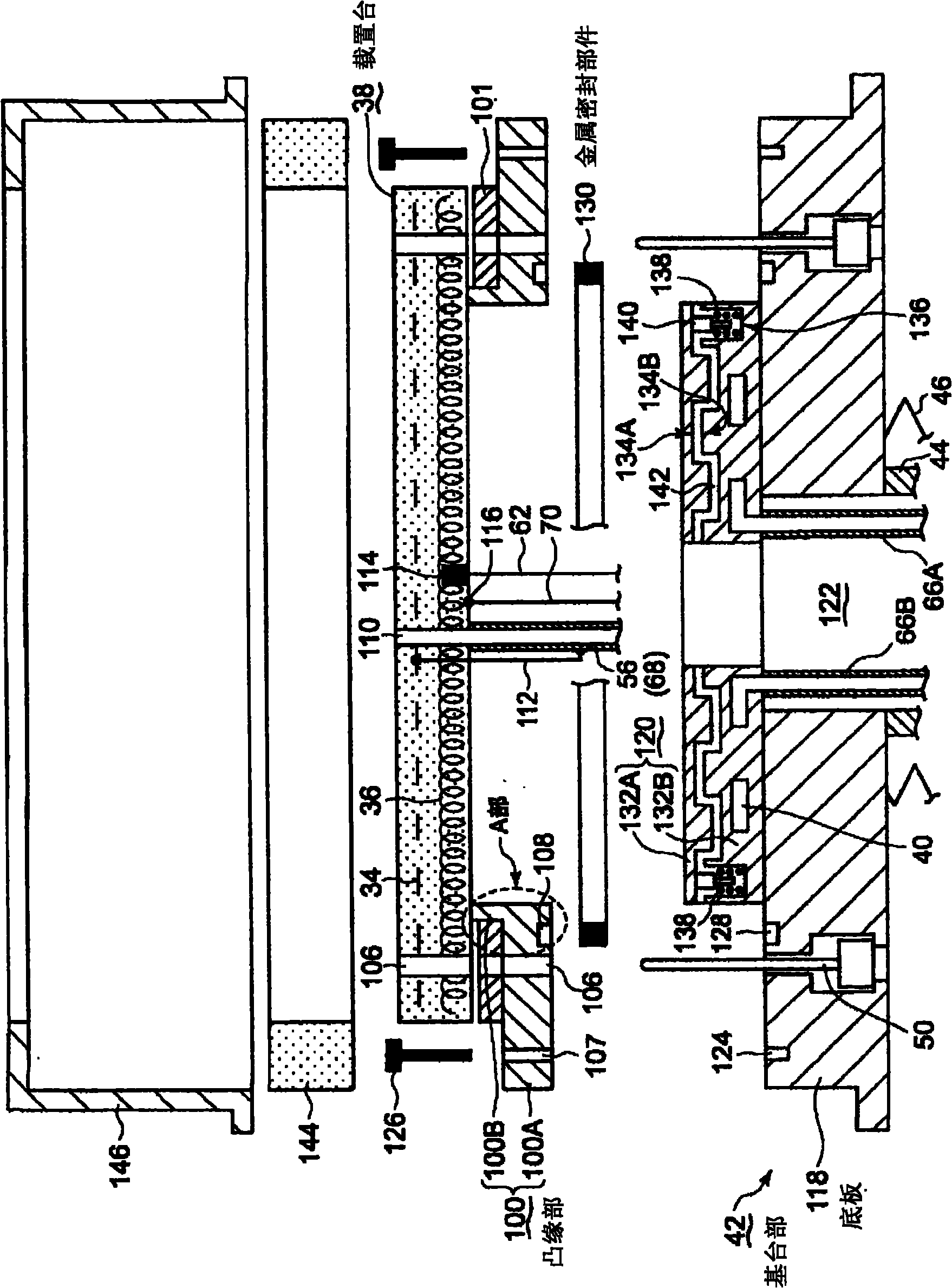

Mounting table structure and plasma film forming apparatus

ActiveCN101840878AExcellent action and effectFully degassedElectric discharge tubesVacuum evaporation coatingVacuum levelEngineering

The present invention provides a mounting table structure capable of enduring a high temperature and maintaining at a high vacuum level in a processing chamber by sufficiently performing a degassing treatment. The mounting table structure for mounting thereon an object to be processed to form a metal-containing thin film on the object includes a ceramic mounting table in which a chuck electrode and a heater are embedded, and a metal flange connected to a bottom surface of a peripheral portion of the mounting table. The mounting table structure further includes a metal base which is joined to the flange by screws and has a coolant path for flowing a coolant therein, and a metal seal member interposed between the flange and the base.

Owner:TOKYO ELECTRON LTD

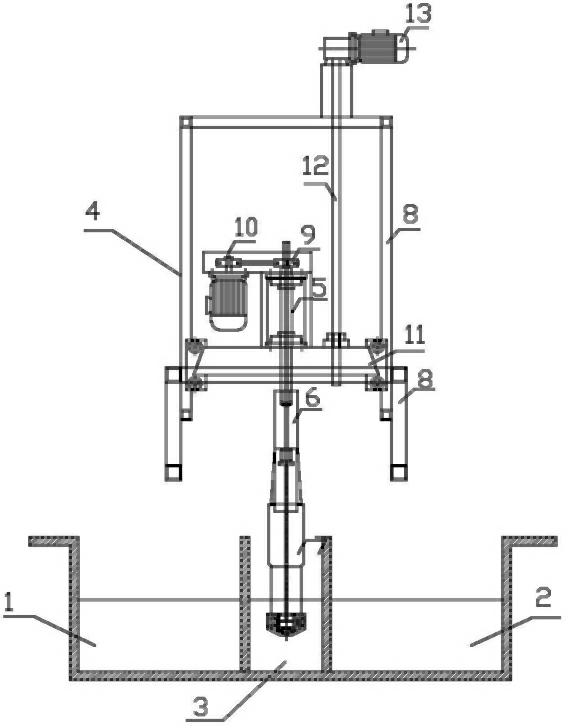

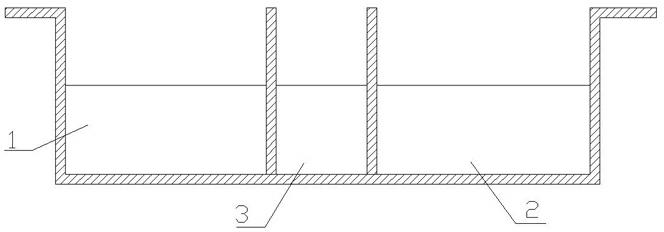

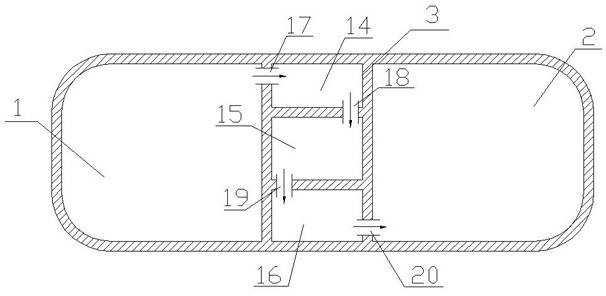

Device and method for continuous smelting of high-purity high-conductivity copper

The invention discloses a device and a method for continuous smelting of high-purity high-conductivity copper, which comprises a smelting furnace, a heat preserving furnace and a degassing device. A compartment is mounted between the smelting furnace and the heat preserving furnace, the degassing device is mounted on the upper portion of the compartment and comprises a frame, and a spindle is vertically sleeved on the frame and connected with a spindle motor through a rotary connector. A metal rotary rod is sleeved to the lower end of the spindle, a graphite rotary rod is sleeved on the metal rotary rod, and the spindle is movably connected with a heat insulating device which is connected with a lifting motor through a lifting screw. The production process is simple while production is stable by using the continuous smelting device, and the continuous degassing device is mounted in the compartment II which is additionally arranged between the smelting furnace and the heat preserving furnace, so that degassing and deoxidizing effects can be fully guaranteed, and stability of liquid level of the heat preserving furnace can be further guaranteed. Oxygen-free copper produced by the device and the method is low in oxygen content and high in conductivity, the oxygen content is smaller than or equal to 5ppm, and the conductivity is larger than or equal to 101% of IACS (international annealed copper standard).

Owner:浙江力博实业股份有限公司

Rapid degassing method of vacuum induction furnace

InactiveCN102212652AImprove degassing effectFully degassedProcess efficiency improvementOxygenVacuum pump

The invention discloses a rapid degassing method of a vacuum induction furnace. The method comprises the following steps: (1) according to the requirements of steel components, calculating weight of the needed scrap steel raw material and pre-deoxidizer as well as various alloys, weighing the materials, and pre-drying the pre-deoxidizer and the alloys; (2) placing the scrap steel raw material in a crucible, and placing the pre-deoxidizer and the alloys in a storage bin; (3) closing a vacuum chamber of the vacuum induction furnace and vacuumizing for 3-8 minutes; (4) transferring electrochemical steel into an inductor, then keeping vacuum degree at 0.05-0.1Pa, and continuously vacuumizing for 10-20 minutes; (5) stopping vacuumizing, charging argon into the vacuum chamber until pressure reaches 500-700Pa, starting a vacuum pump for vacuumizing to 0.05-0.1Pa, and then maintaining the vacuum degree for 10-20 minutes; (6) stopping vacuumizing, and then filling argon into the vacuum chamber until pressure reaches 500-700Pa; (7) adding the pre-deoxidizer and the alloys in the storage bin to molten steel for full circulation; and (8) naturally cooling the molten steel for 5-10 minutes in a vacuum state and then performing vacuum breaking and demoulding. Practices prove that, in the molten steel treated by the degassing method, the contents of the carbon element, the nitrogen element and the oxygen element are extremely low and are respectively not more than 15ppm, not more than 15ppm and not more than 20ppm.

Owner:武钢集团有限公司

Method for preparing ultra-high purity difluoromono-chloroethane

InactiveCN103012053AMultiple faultsSuppress generationHalogenated hydrocarbon separation/purificationMolecular sieveWater chlorination

The invention provides a method for preparing ultra-high purity difluoromono-chloroethane, which comprises the following steps: mixing raw materials at a mole ratio of 1.15:1 and feeding the mixture into a photochlorination reactor for reaction, feeding the reactant into a two-stage water absorption HCL tower and a two-stage alkali liquor absorption chlorine gas tower to remove HCL and chlorine; feeding the obtained product into a dry buffer tank; compressing the gas from the dry buffer tank with a single-stage oil-free compressor and feeding the compressed gas into a degassing tower and a rectifying tower for degassing and rectifying to obtain difluoromono-chloroethane with moisture; and then removing the moisture with a molecular sieve drier to obtain a pure difluoromono-chloroethane product. According to the method, the production flow of the difluoromono-chloroethane is shortened, the reaction conversion rate is high, the by-products are few, the rectifying efficiency is high, the raw materials and the energy consumption are reduced, the purity of the product is high and the production of the whole set of device is safe and economic.

Owner:TAIXING MEILAN CHEM

Preparation method of auricularia auricular polysaccharide beverage

ActiveCN104366640ASolve the difficult problem of being sticky and difficult to prepare fungus serum productsLow viscosityFood preparationFood extractionViscosityPolysaccharide

The invention discloses a preparation method of an auricularia auricular polysaccharide beverage. The preparation method comprises the following steps: A) draining and grinding soaked auricularia auricula; and B) leaching auricularia auricula by virtue of hot water and stirring, so that water phase and solid phase are fully contacted and filtered. Furthermore, by virtue of the preparation method disclosed by the invention, ground auricularia auricula can be enzymatically hydrolyzed. The preparation method disclosed by the invention avoids such processes as polysaccharide precipitation, drying, powder preparation, and the extracted auricularia auricular polysaccharide is directly dissolved in an extracting solution; moreover, the extracted auricularia auricular polysaccharide is good in fluidity, low in viscosity and easy to filter. The entire process preparation method is simple and rapid, sufficient in extraction, high in efficiency, and suitable for scaled industrial production.

Owner:HULUNBEIER MENGTIANYUAN BIOTECH

Device and method for preparing ultra-high purity difluoromono-chloroethane

InactiveCN103012054ASuppress generationMultiple faultsHalogenated hydrocarbon separation/purificationMolecular sievePhysical chemistry

The invention provides a device and a method for preparing ultra-high purity difluoromono-chloroethane. The device comprises a heat exchangeable photochlorination reactor, an HCL-removing tower, a chlorine-removing tower, a dry buffer tank, a single-stage oil-free compressor, a degassing tower, a rectifying tower, a molecular sieve drier and a product tank. The method comprises the following steps: mixing raw materials and feeding the mixture into a photochlorination reactor for reaction, feeding the reactant into a two-stage water absorption HCL tower and a two-stage alkali liquor absorption chlorine gas tower to remove HCL and chlorine; feeding the obtained product into a dry buffer tank; compressing the gas from the dry buffer tank with a single-stage oil-free compressor and feeding the compressed gas into a degassing tower and a rectifying tower for degassing and rectifying to obtain difluoromono-chloroethane with moisture; and then removing the moisture with a molecular sieve drier to obtain a pure difluoromono-chloroethane product. According to the device and the method, the production flow of the difluoromono-chloroethane is shortened, the reaction conversion rate is high, the by-products are few, the rectifying efficiency is high, the raw materials and the energy consumption are reduced, the purity of the product is high and the production of the whole set of device is safe and economic.

Owner:TAIXING MEILAN CHEM

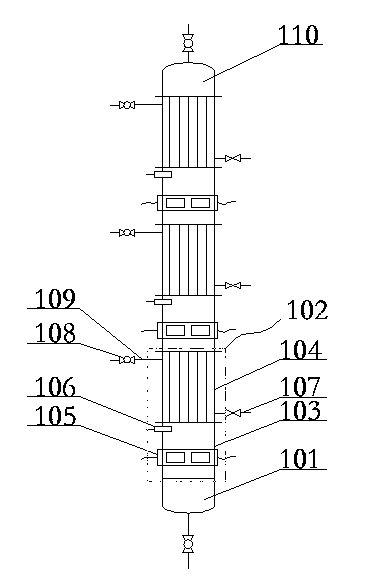

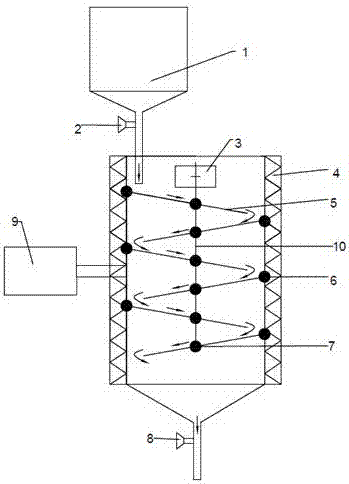

Metal powder degassing method and device

ActiveCN107234237AIncrease exposureFully degassedTransportation and packagingMetal-working apparatusMetal powderVacuum pump

A metal powder degassing method comprises the following steps: (1) closing a powder feeding vacuum valve, opening a powder discharging vacuum valve, opening a vacuum pump and a heating body, and degassing a sheath connected between an enclosed tank body and the powder discharging vacuum valve at the temperature lower than 600 DEG C; (2) when the vacuum degree of the enclosed tank body is lower than 0.01 Pa, adjusting the inclination angle of each powder spreading plate to 8-15 degrees through a control rod, wherein the vibration frequency is 50-100 Hz; (3) opening the powder feeding vacuum valve, wherein the powder dropping rate is lower than 80 kg / h; (4) in the powder dropping process, reducing the powder dropping rate if the vacuum degree is higher than 0.01 Pa; and (5) if the segregation of powder occurs, reducing the inclination angle of each powder spreading plate, improving the vibration frequency, and spreading the powder. A metal powder degassing device comprises a series of powder spreading plates, wherein the powder spreading plates are connected with the side wall of the enclosed tank body through hinges and connected with the control rod through sliding supports, thereby forming a folded-line path for the powder flow; through the control rod, the inclination angle of each powder spreading plate can be controlled and the vibrations can be transferred; and the gas adsorbed in the gaps among powder particles and on the surfaces of the powder particles can be effectively removed, thereby remarkably improving the part manufacturing performance after powder consolidation.

Owner:SINO EURO MATERIALS TECH OF XIAN CO LTD

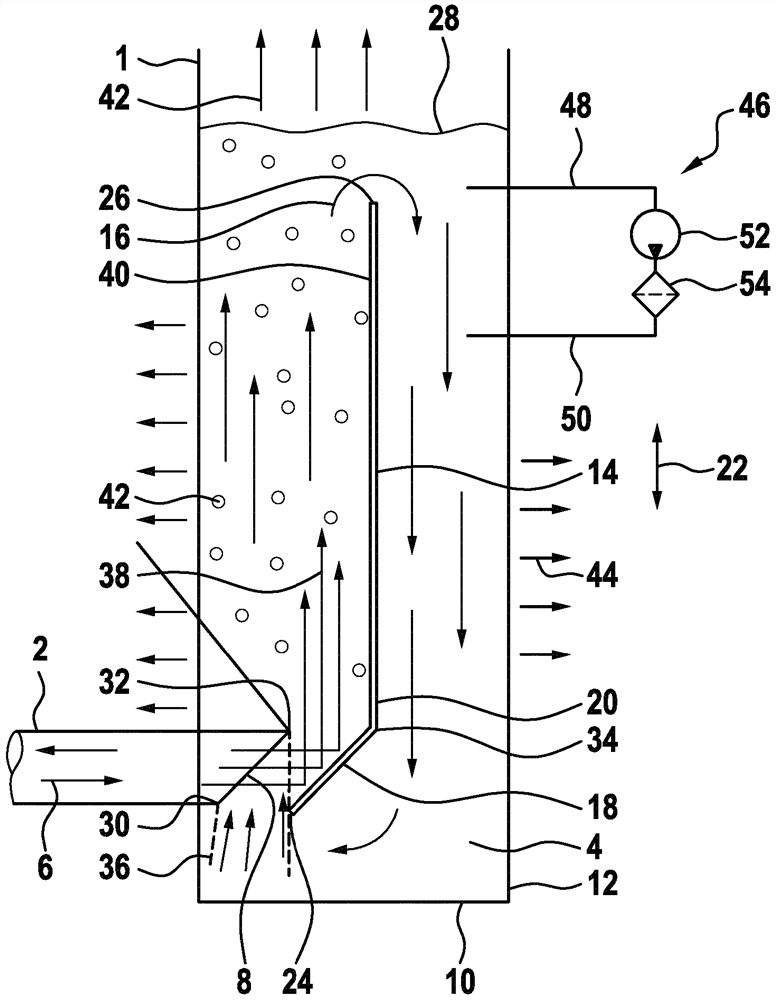

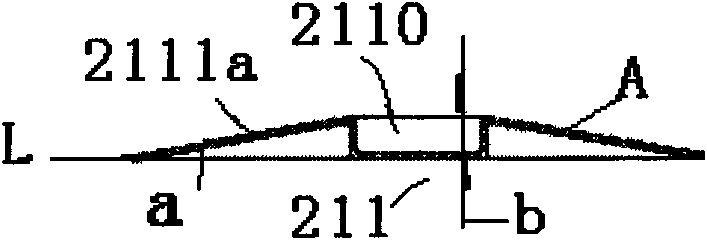

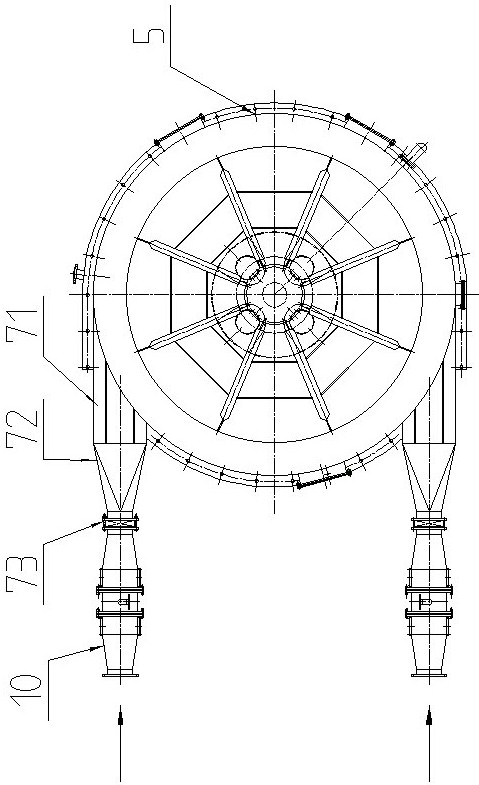

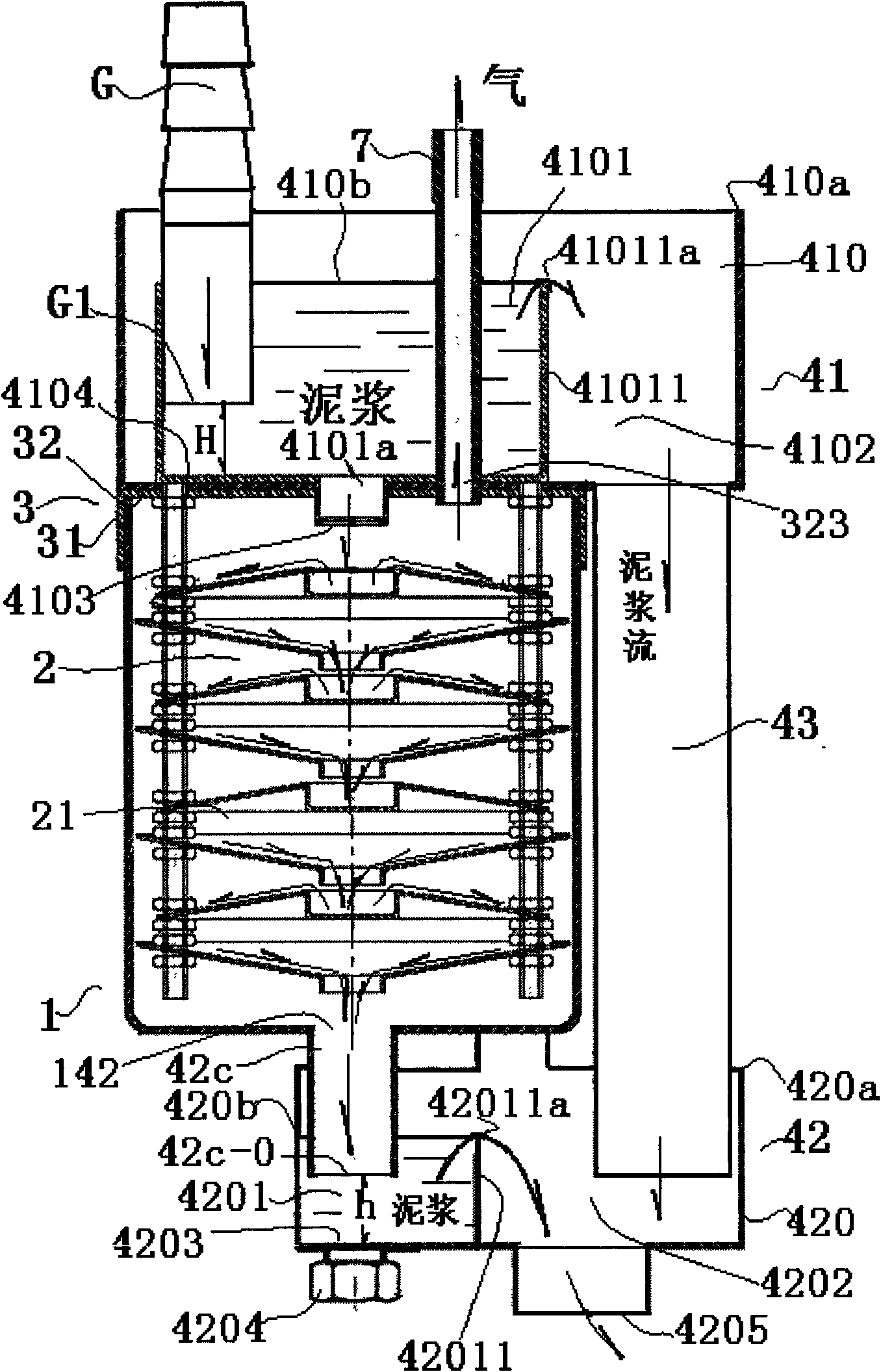

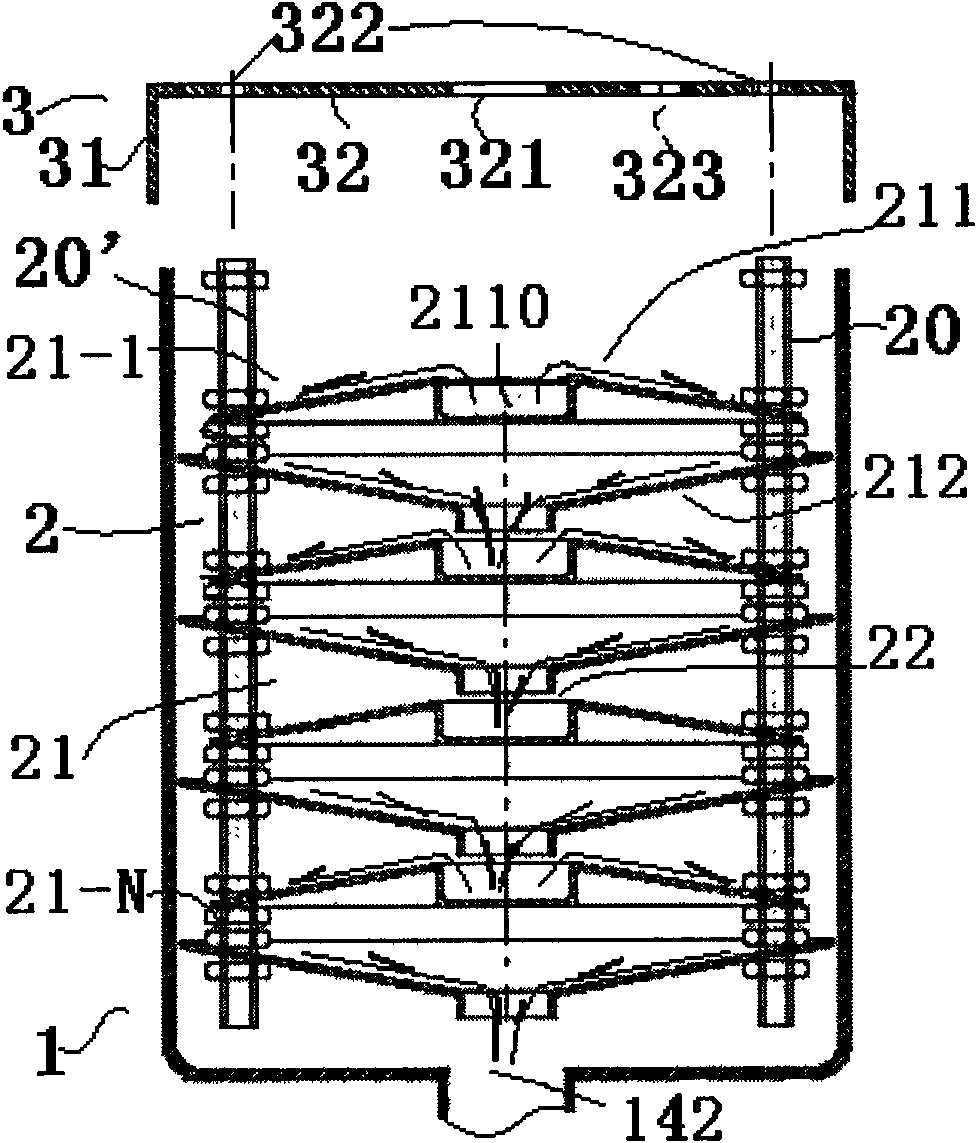

Passive degasser

ActiveCN102133490AGuaranteed accuracyGuarantee the true gas contentLiquid degasificationWithdrawing sample devicesPetroleumEngineering

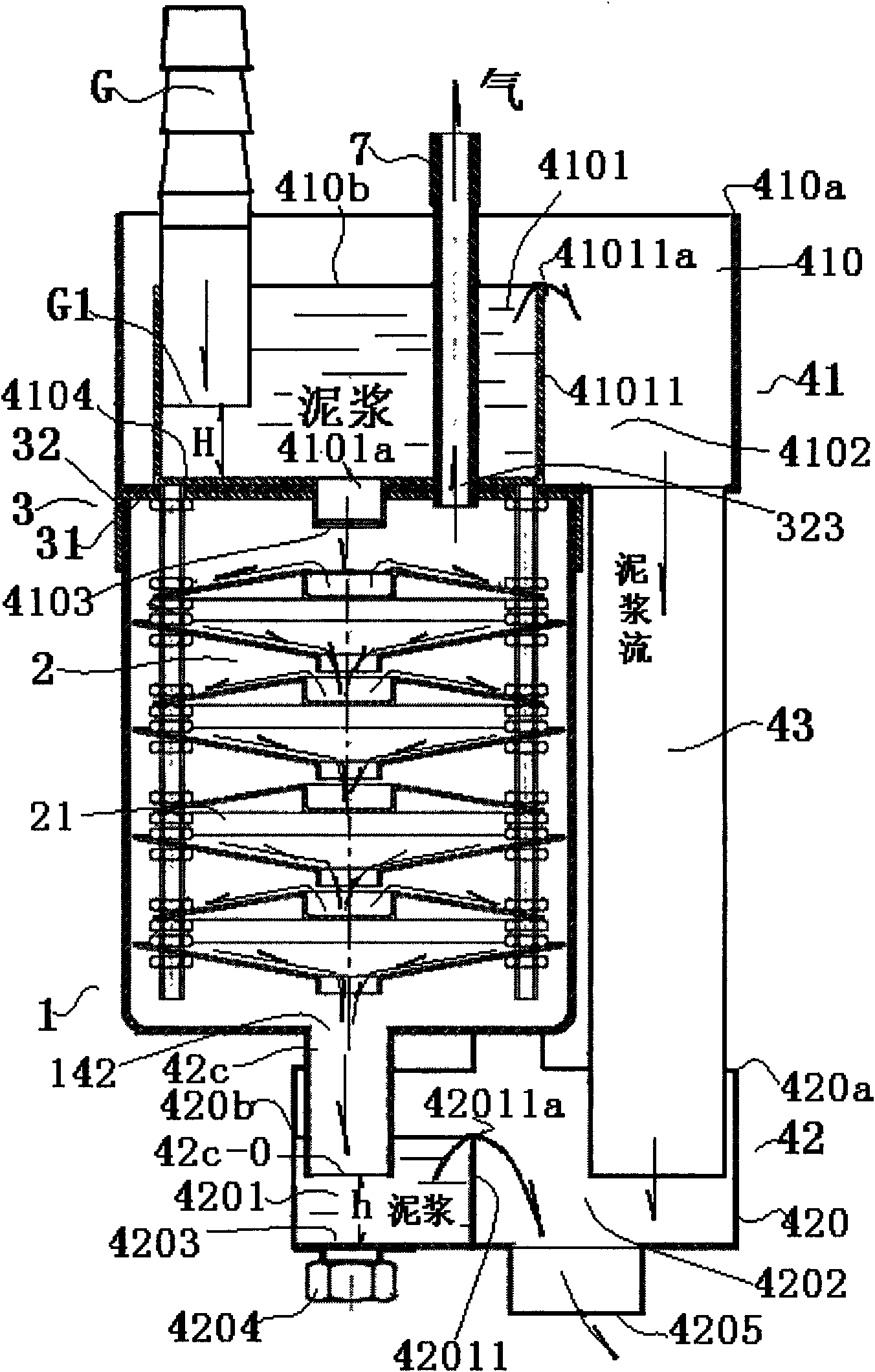

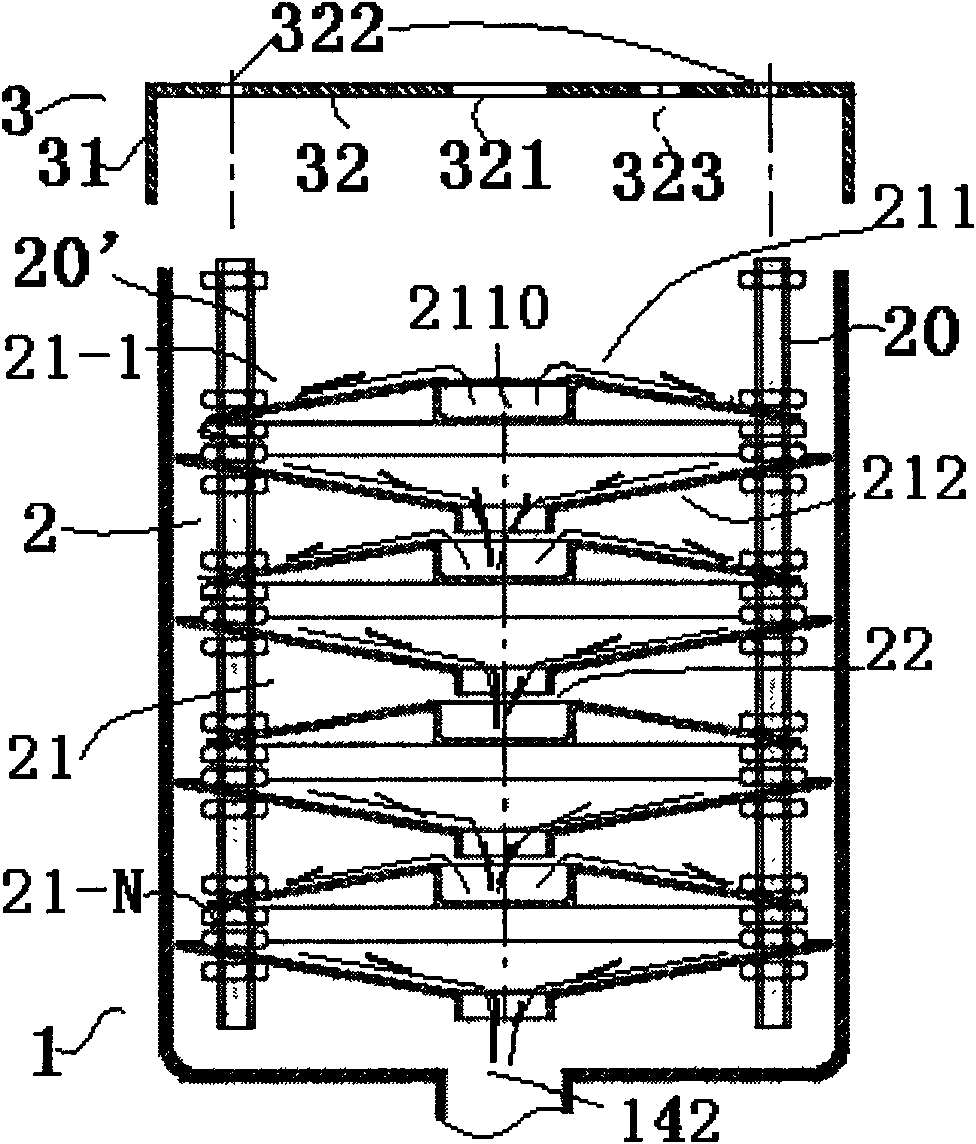

The invention provides a passive degasser relating to a device for on line detaching gas in slurry lifted during oil exploration drilling, which is particularly suitable for the passive degasser. The passive degasser comprises a pot body, wherein the pot body is provided with a slurry inlet and a slurry outlet; the upper part of the pot body is the slurry inlet end; the lower end of the pot body is the slurry outlet end; and a slurry treatment body is arranged in the pot body. In the invention, the slurry treatment body is arranged to disperse and degas the slurry to be treated, and under a circumstance of having no power source drive, the slurry can be further diffused, that is fully dispersed, therefore, the degassing efficiency is effectively increased; and an airtight construction is arranged on the pot body to ensure that the slurry can be under an airtight condition in the whole degassing process of the degasser and all the gases collected by a sample air pump are the gases detached in treating the slurry in the pot body so as to provide guarantee for the accuracy of sample gas collecting data and for detecting the true gas content of a stratum.

Owner:天津港保税区鑫利达石油技术发展有限公司

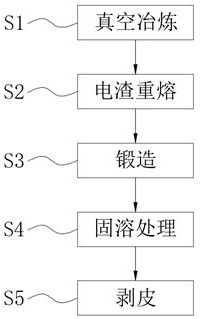

Preparation method of novel nickel-based material for petroleum valve rod

The invention provides a preparation method of a novel nickel-based material for a petroleum valve rod. The preparation method comprises the steps of vacuum smelting, electroslag remelting, forging, solution treatment and peeling. The method is reasonable in process design, the component proportion design of all raw materials is optimized, hot working plasticity is improved, the yield is high, the service life of an alloy is prolonged, meanwhile, return materials in a proper proportion are added into the raw materials, and the alloy material cost can be reduced.

Owner:江苏新核合金科技有限公司

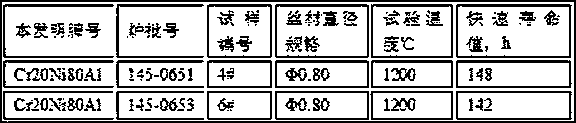

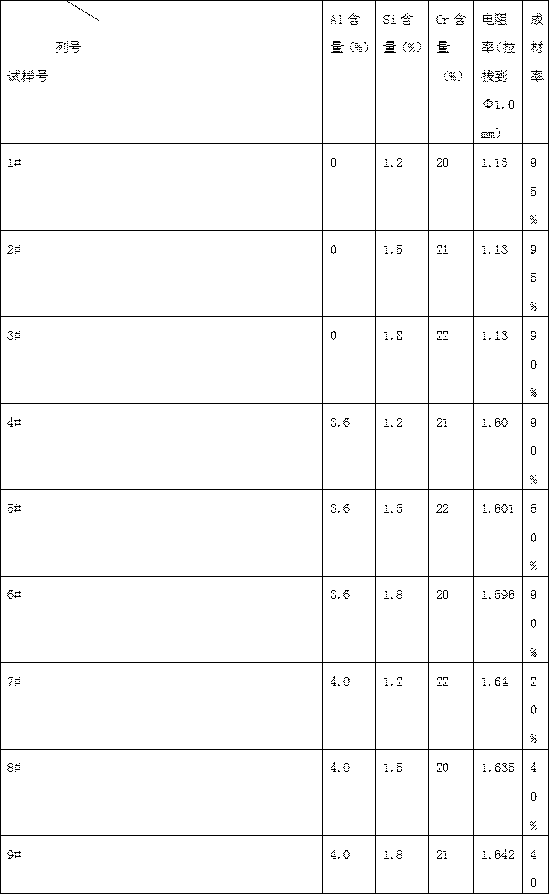

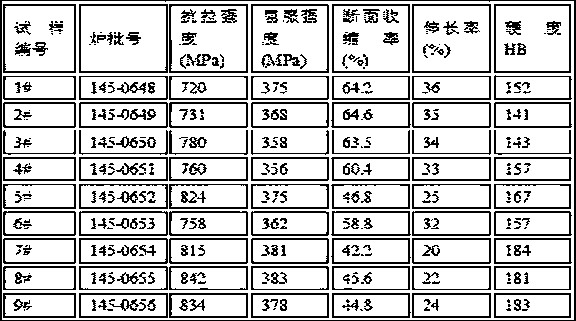

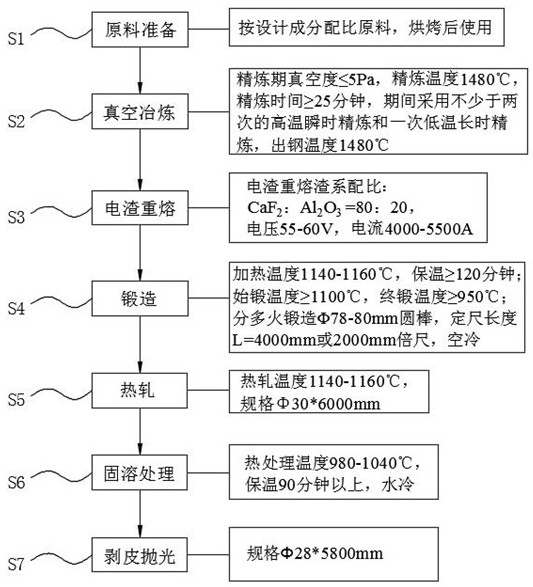

Novel high-resistance electrothermal alloy Cr20Ni80Al and preparation method thereof

InactiveCN109055823AFully degassedHigh resistivityThermal dilatationElectrical resistance and conductance

The invention provides a novel high-resistance electrothermal alloy Cr20Ni80Al, and further provides a preparation process of the novel high-resistance electrothermal alloy Cr20Ni80Al. The constituentelements of the novel high-resistance electrothermal alloy Cr20Ni80Al include, by weight percentage, C<=0.03%, Si:1.40-1.60, Mn<=0.50%, P<=0.020%, S<=0.015%, Cr:20.5-21.50%, Ti<=0.10%, Al:3.0-3.7%, Fe<=1.00%, Zr<=0.2%, and the balance of Ni and unavoidable impurities. Compared with prior electrothermal alloys, the novel high-resistance electrothermal alloy Cr20Ni80Al has the excellent performances of being higher in resistivity, longer in service life, very good in processing performance, excellent in oxidation resistance, small in thermal expansion coefficient, good in high temperature strength, etc., and is of great economic significance to improving production efficiency, ensuring product quality and reducing production costs.

Owner:JIANGSU XINHUA ALLOY ELECTRIC

Alloy material for petroleum valve rod and preparation method thereof

The invention provides an alloy material for a petroleum valve rod. The alloy material for the petroleum valve rod comprises the following chemical components in percentage by weight: 0.04-0.08% of C,not more than 0.35% of Si, not more than 0.35% of Mn, not more than 0.015% of P, not more than 0.015% of S, 0.30-0.80% of Al, 0.002-0.006% of B, 17.0-21.0% of Cr, 2.80-3.30% of Mo, 50.0-55.0% of Ni,4.75-5.50% of Nb+Ta, 0.75-1.15% of Ti, not more than 0.001% of Pb, not more than 0.0005% of Bi, not more than 0.0005% of Ag, not more than 0.01% of Ca, not more than 0.01% of Mg, not more than 0.20% of Cu, not more than 1.0% of Co and the balance of Fe and inevitable impurities. According to the alloy material for the petroleum valve rod, by adopting a vacuum smelting and electroslag remelting duplex smelting method, Ni-Mg alloy is added for deoxidation through refining, so that the alloy purity can be improved, impurity inclusions are reduced, sufficient alloy degassing and uniform metallographic structure and chemical components are guaranteed, the prepared alloy material possesses excellent high-temperature strength, wear resistance and corrosion resistance and is applied to manufacturing of petroleum valve rods, the comprehensive performance of the petroleum valve rod can be improved, and the service life of the petroleum valve rod is prolonged.

Owner:江苏新核合金科技有限公司

00Cr20Mo16 welding wire and production process thereof

ActiveCN111015019AGuaranteed welding effectImprove mechanical propertiesWelding/cutting media/materialsSoldering mediaMetallurgyMaterials science

The invention provides a 00Cr20Mo16 welding wire and a production process thereof. The welding wire is prepared from, by weight percentage, 0-0.03% of C, 0-0.3% of Si, 0.6-1.0% of Mn, 0-0.01% of P, 0-0.01% of S, 19.5-21.0% of Cr, 15.2-16.5% of Mo, 0-0.06% of Cu, 0-0.06% of Co, 0-0.15% of Ti, 0-0.03% of N, 0-2.0% of Fe and the balance Ni. According to the 00Cr20Mo16 welding wire and the productionprocess thereof, by optimizing alloy components and the manufacturing process, the finished product of the welding wire is high in yield and excellent in welding performance and can be applicable to asevere environment.

Owner:JIANGSU XINHUA ALLOY ELECTRIC

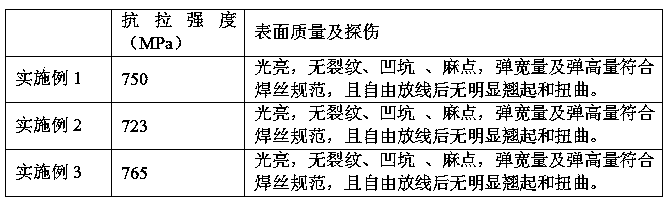

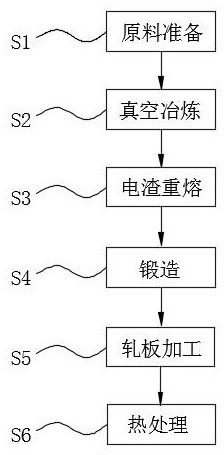

High-temperature fan corrosion-resistant alloy and preparation method thereof

InactiveCN112458339AGood high temperature strengthHigh temperature corrosion resistanceCorrosionTa element

The invention provides a high-temperature fan corrosion-resistant alloy. The alloy comprises the following elements, in percentage by weight, of 0.05% to 0.10% of C, less than or equal to 0.70% of Si,less than or equal to 0.70% of Mn, less than or equal to 0.012% of P, less than or equal to 0.008% of S, 20.0% to 23.0% of Cr, 0.60% to 1.50% of Al, less than or equal to 2.0% of Fe, 10.0% to 13.0% of Co, 0.20% to 0.60% of Ti and the balance Ni and inevitable impurities. A preparation method of the high-temperature fan corrosion-resistant alloy comprises the steps of raw material preparation, vacuum smelting, electroslag remelting, forging, plate rolling and heat treatment. According to the alloy and the method, components and a process of the alloy are optimally designed, the alloy has the advantages of being good in high-temperature strength, high in high-temperature corrosion resistance and high in oxidation resistance, and the service life of a high-temperature fan can be prolonged.

Owner:江苏新核合金科技有限公司

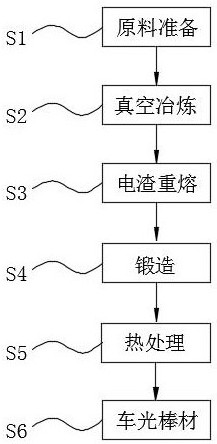

Nickel-based alloy for high-temperature fan shaft and preparation method thereof

InactiveCN112458340AExtended service lifeImprove high temperature strengthChemical compositionUltimate tensile strength

The invention provides a nickel-based alloy for a high-temperature fan shaft. The nickel-based alloy comprises the following elements of, in percentage by weight, 0.05-0.10% of C, less than or equal to 0.70% of Si, less than or equal to 0.70% of Mn, less than or equal to 0.012% of P, less than or equal to 0.008% of S, 20.0-23.0% of Cr, 0.60-1.50% of Al, less than or equal to 2.0% of Fe, 10.0-13.0%of Co, 0.20-0.60% of Ti and the balance Ni and inevitable impurities. A preparation method of the nickel-based alloy for the high-temperature fan shaft comprises the steps of raw material preparation, vacuum smelting, electroslag remelting, forging, heat treatment and bar turning. The nickel-based alloy prepared through the method has the advantages of being good in high-temperature strength, high in high-temperature corrosion resistance and high in oxidation resistance, the alloy purity is high, impurities are few, metallographic structures and chemical components are uniform, the nickel-based alloy is applied to manufacturing of the high-temperature fan shaft, and the service life of a high-temperature fan can be prolonged.

Owner:江苏新核合金科技有限公司

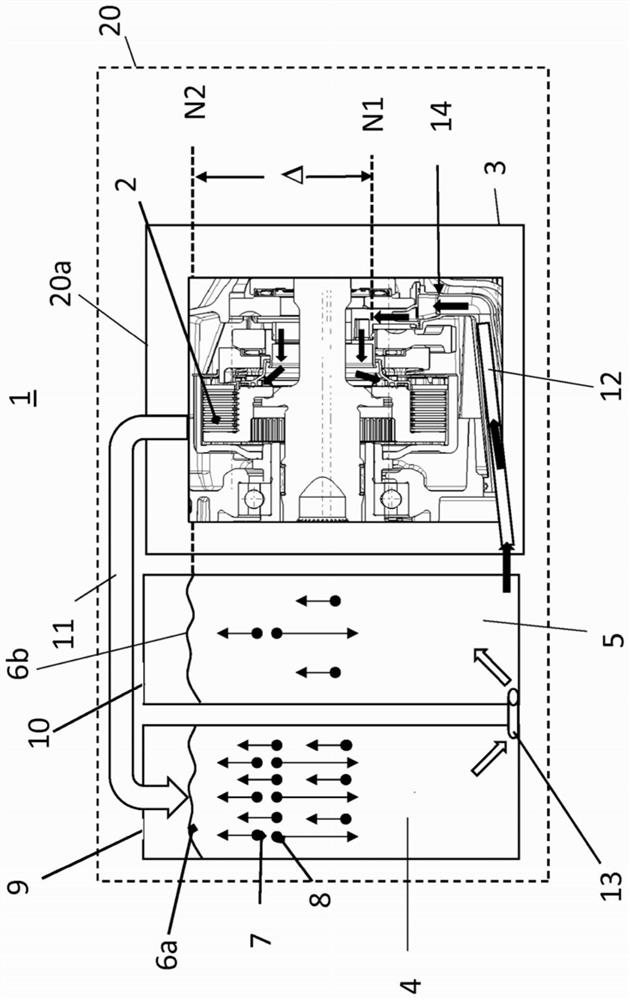

Oil consuming system

PendingCN112204269AFully degassedQuick degassingFriction clutchesCouplingsThermodynamicsProcess engineering

The invention relates to an oil consuming system, and the system comprises at least one rotary component and at least one oil supply flow from an oil reservoir, the oil consuming system having an oilreturn flow to a first reservoir and an oil supply flow via at least one second reservoir.

Owner:MAGNA POWERTRAIN AG & CO KG

Vacuum oil injection structure of large oil-immersed transformer and oil conservator and working method of vacuum oil injection structure

PendingCN112071574AEnsure reasonable partial dischargeFully degassedTransformers/inductances coolingThermodynamicsTransformer oil

The invention relates to a vacuum oil injection structure of a large oil-immersed transformer and an oil conservator and a working method of the vacuum oil injection structure, the vacuum oil injection structure of the large oil-immersed transformer and the oil conservator comprises the large oil-immersed transformer with an oil inlet and a first negative pressure port, and the oil conservator isarranged above the large oil-immersed transformer; a vacuum oil injection transition oil tank is arranged beside the large oil-immersed transformer, a third communicating pipeline with a third butterfly valve is connected between the vacuum oil injection transition oil tank and the oil conservator, a second communicating pipeline with a second butterfly valve is connected between the oil conservator and the large oil-immersed transformer, and a first butterfly valve is arranged on the first negative pressure port. And a second negative pressure opening communicating with the vacuum pump is formed in the vacuum oil injection transition oil tank, an inlet of the vacuum pump is connected with the first end of the first connecting pipeline, and the second end of the first connecting pipeline is connected with the first butterfly valve or the second negative pressure opening. According to the invention, vacuum oil injection of transformer oil conservators of various types can be achieved ina matched mode. And sufficient degassing of the oil conservator and reasonable partial discharge of the transformer are ensured.

Owner:FUZHOU TIANYU ELECTRIC

Micro-alloying steel for oil gas transport seamless pipeline and its preparation method

InactiveCN100587098CExcellent resistance to hot and cold cracksGood anti-HIC performanceTemperature control deviceForeign matterLine tubing

The invention discloses micro-alloying seamless pipeline steel and process for preparation. According to weight percentage, the range of the chemical components of the invention includes that C holds0.08% to 0.20%, Si is equal to or less than 0.04%, Mn takes 0.60% to 1. 50%, S is equal to or less than 0.015%, P is equal to or less than 0.025%, Al is equal to or less than 0.04%, Ti is equal to orless than 0.04%, H is equal to or less than 2.5*10-4%, O is equal to or less than 25*10-4%, the rest is Fe and unavoidable foreign matters. The process for preparation comprises technique steps, including smelting, refining, continuous casting, hot rolling and slow cooling. Round steel with the size of phi 70 to 150 millimeters can be produced by the process for preparation. The seamless pipelinesteel of the invention has perfect anti-sulphide stress corrosion (SSC resistance) capability and anti-HIC property. The pipeline steel which can substitute for welding pipe can be utilized in the filed of oil pipeline and the like, and the invention increases the reliability of material and adaptability of variety, in particular being adaptable for the low submarine temperature and corrosion-resistant environment and for manufacture of thick-walled tubes.

Owner:LAIWU IRON & STEEL GRP

tank

An oil tank for a hydraulic system is disclosed, the oil tank having a connecting line via which oil can be supplied to the oil tank and via which oil can be drained from the oil tank. In this case, a diverter plate is arranged in the oil tank in order to guide the oil supplied or discharged via the connecting lines in a defined manner.

Owner:ROBERT BOSCH GMBH

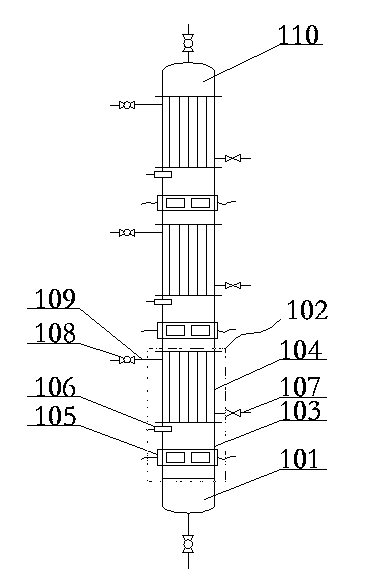

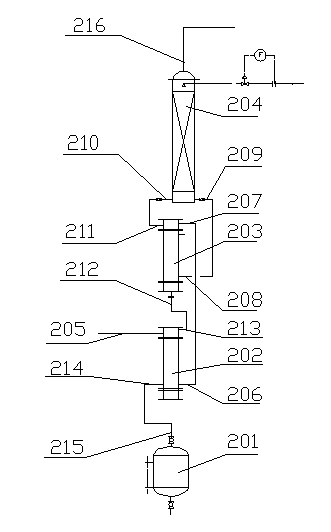

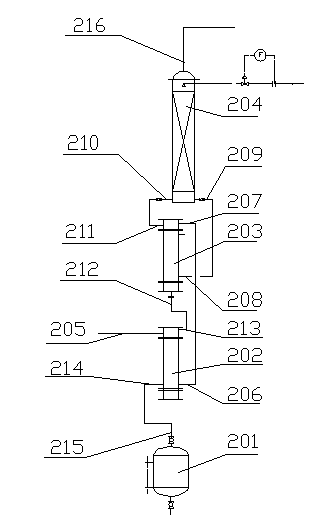

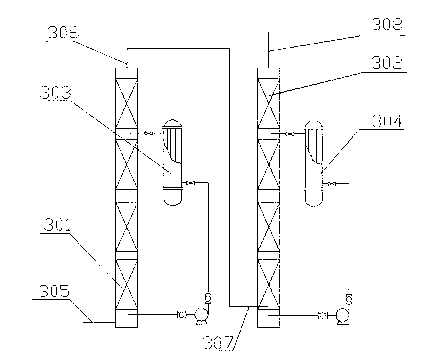

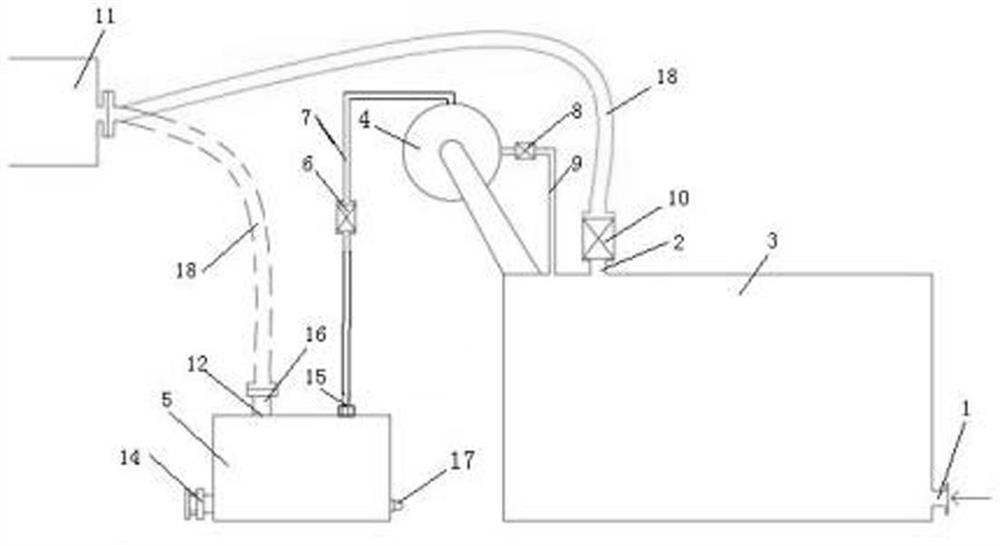

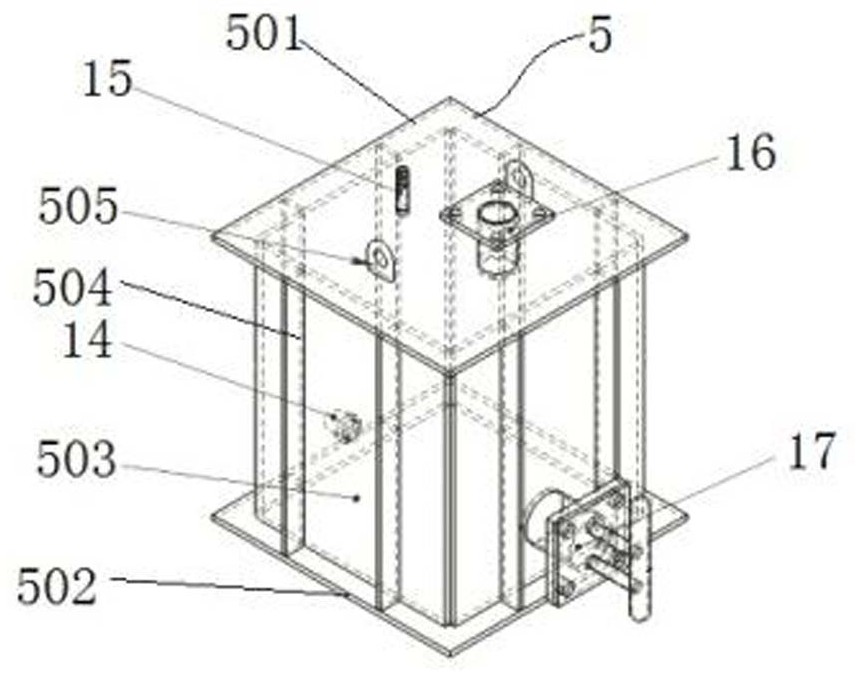

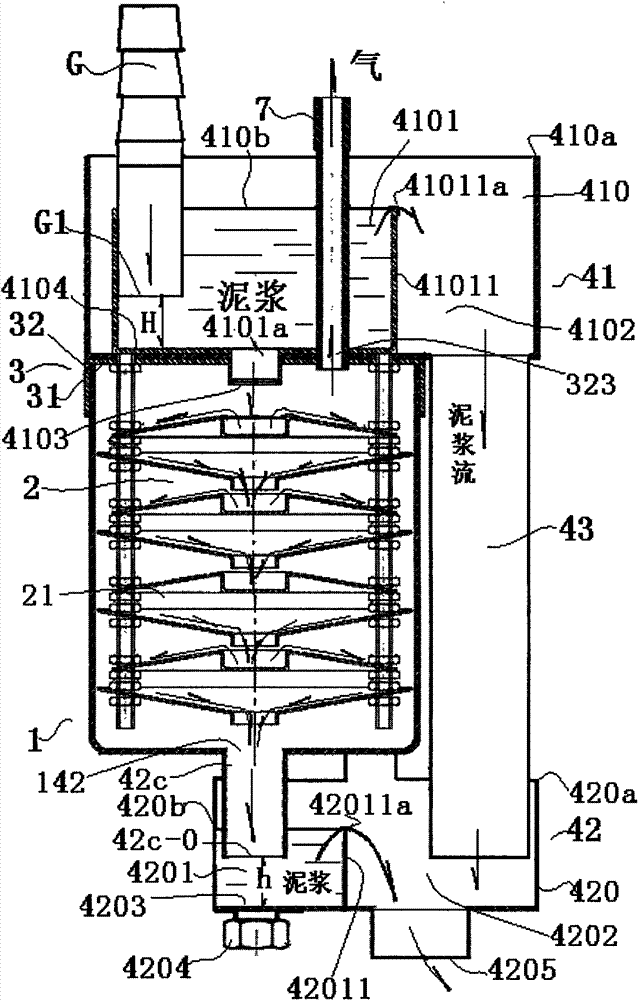

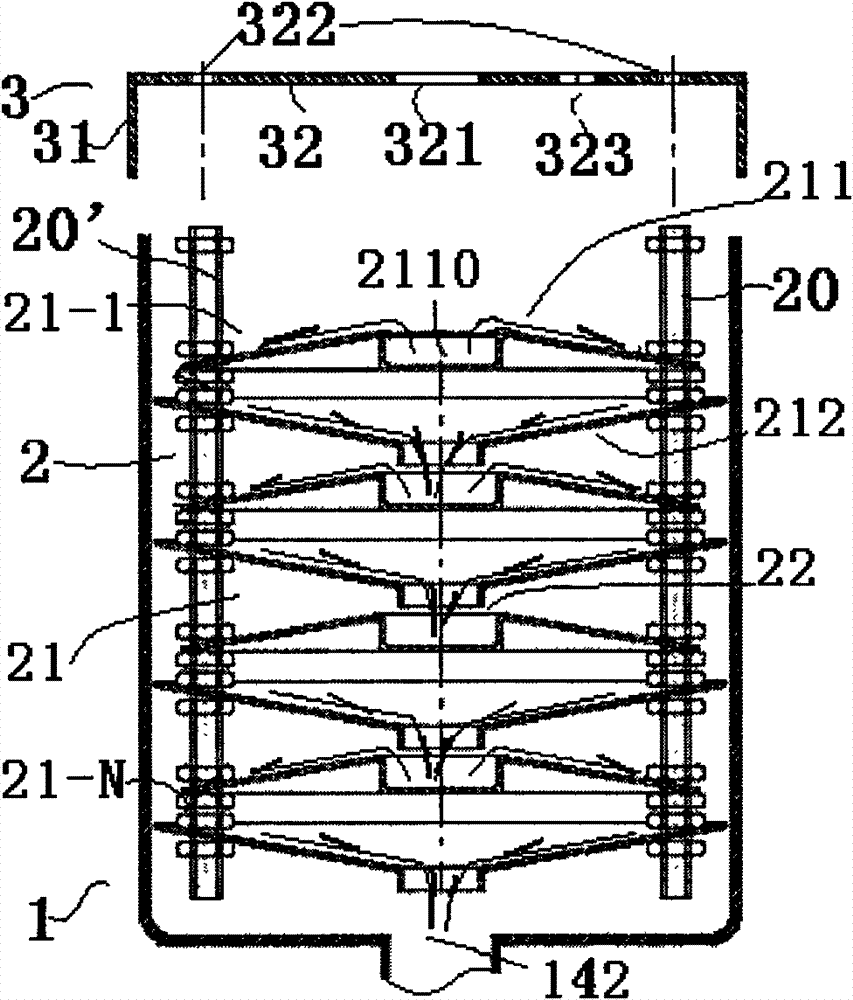

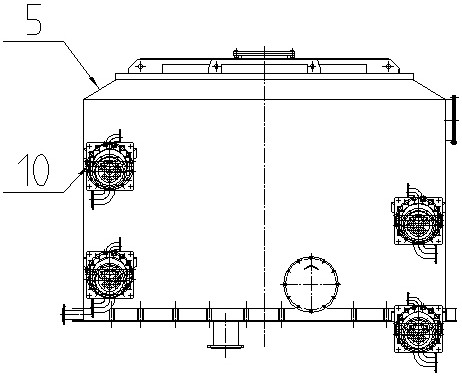

Oil well cementing cement degassing device

An oil well cement bubble removing device comprises a shell. Two stirring and air exhausting systems are arranged in the shell. Each stirring and air exhausting system comprises a stirring tank, an installation frame, a motor, a vacuum pump, a stirring shaft, an upper stirring disk and a lower stirring disk. The motors and the vacuum pumps are arranged on the installation frames. The lower portion of one side of each stirring tank is provided with a cement inlet pipe connector, and the upper portion of the other side of each stirring tank is provided with a cement outlet pipe connector. The cement inlet pipe connector of one stirring and air exhausting system and the cement outlet pipe connector of the other stirring and air exhausting system both penetrate the side portions of the shell and extend out, and the other cement inlet pipe and the other cement outlet pipe are connected through a middle connecting pipe. The top of each stirring tank is provided with a tank cover. The top of each tank cover is provided with an air exhausting hole. The vacuum pumps are connected with the air exhausting hole through an air exhausting pipe. The oil well cement bubble removing device is simple in overall structure, the oil well cement bubble removing device is additionally arranged on the premise of not changing the original pipeline design, and the oil well cement bubble removing device is reliable in principle and capable of greatly lowering the bubble content in cement and achieves better effect after cement solidification.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

Passive degasser

ActiveCN102133490BGuaranteed accuracyGuarantee the true gas contentLiquid degasificationWithdrawing sample devicesDegasserAir pump

The invention provides a passive degasser relating to a device for on line detaching gas in slurry lifted during oil exploration drilling, which is particularly suitable for the passive degasser. The passive degasser comprises a pot body, wherein the pot body is provided with a slurry inlet and a slurry outlet; the upper part of the pot body is the slurry inlet end; the lower end of the pot body is the slurry outlet end; and a slurry treatment body is arranged in the pot body. In the invention, the slurry treatment body is arranged to disperse and degas the slurry to be treated, and under a circumstance of having no power source drive, the slurry can be further diffused, that is fully dispersed, therefore, the degassing efficiency is effectively increased; and an airtight construction is arranged on the pot body to ensure that the slurry can be under an airtight condition in the whole degassing process of the degasser and all the gases collected by a sample air pump are the gases detached in treating the slurry in the pot body so as to provide guarantee for the accuracy of sample gas collecting data and for detecting the true gas content of a stratum.

Owner:天津港保税区鑫利达石油技术发展有限公司

Novel 4017 aluminum alloy sheet for coating material and preparation method thereof

ActiveCN114836657AImprove recycling efficiencyGuarantee the surface quality of casting and rolling productionProcess efficiency improvementMetal rolling arrangementsThin slabAluminium alloy

The invention belongs to the technical field of aluminum alloy manufacturing, and particularly relates to a novel 4017 aluminum alloy sheet for a coating material and a preparation method of the 4017 aluminum alloy sheet. The novel 4017 aluminum alloy sheet for the coating material comprises the following alloy chemical components in percentage by mass: 1.35 to 1.4 percent of Si, 0.4 to 0.55 percent of Fe, 0.12 to 0.17 percent of Cu, 1.05 to 1.15 percent of Mn, 0.25 to 0.45 percent of Mg, 0.05 percent of Cr, 0.1 percent of Zn, 0.025 to 0.035 percent of Ti and the balance of Al. The novel 4017 aluminum alloy thin plate for the coating material is processed through the procedures of smelting, refining, cast rolling, cold rolling, primary intermediate annealing, cold rolling, secondary intermediate annealing, foil rolling of a finished product, pulling, straightening, cleaning and straightening, the lower limit tensile strength and the ductility of the processed finished product are far higher than those of a traditional aluminum alloy thin plate for a 4-series coating material, and the comprehensive performance is outstanding.

Owner:HENAN MINGTAI AL INDUSTRIAL CO LTD

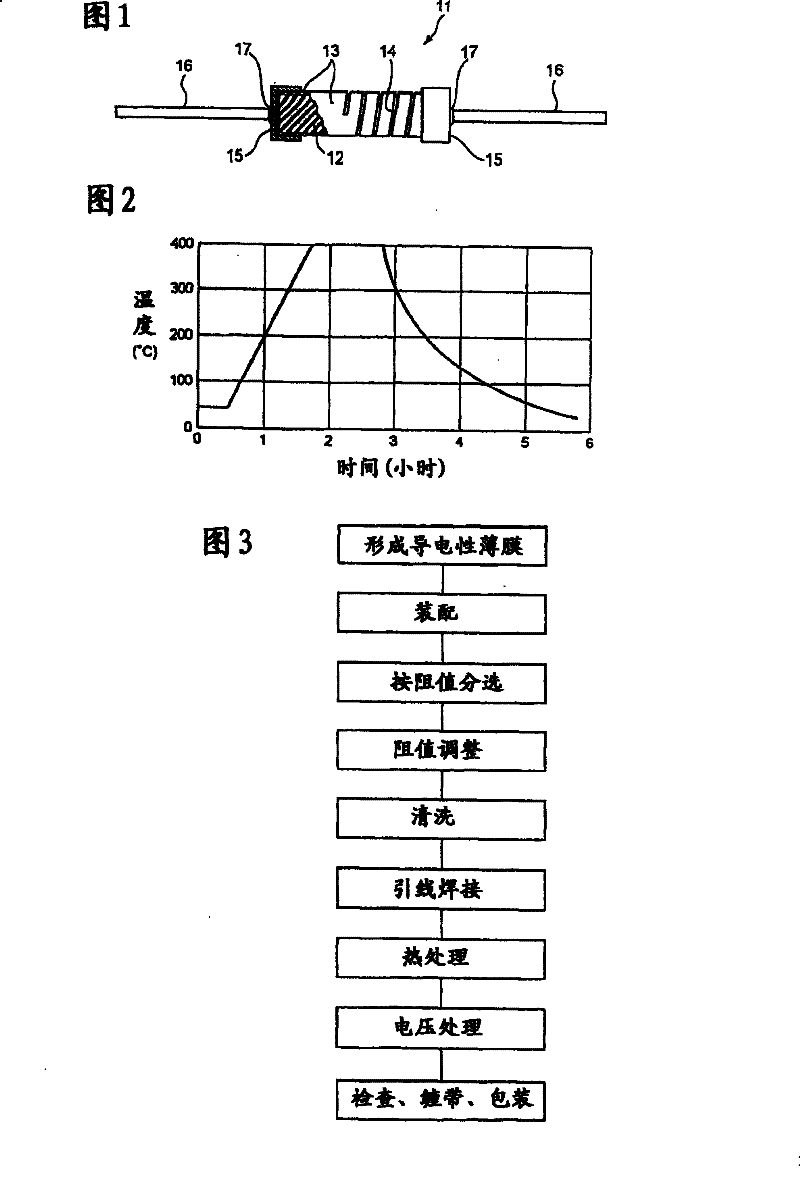

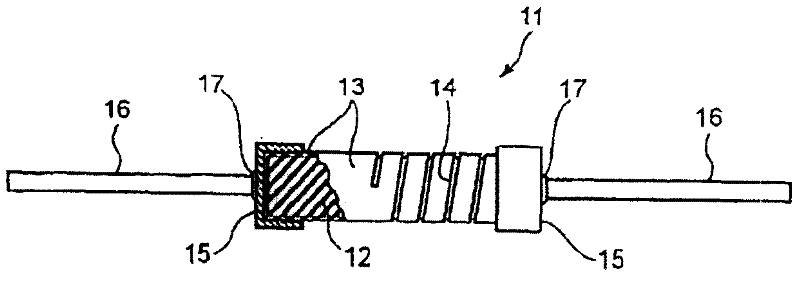

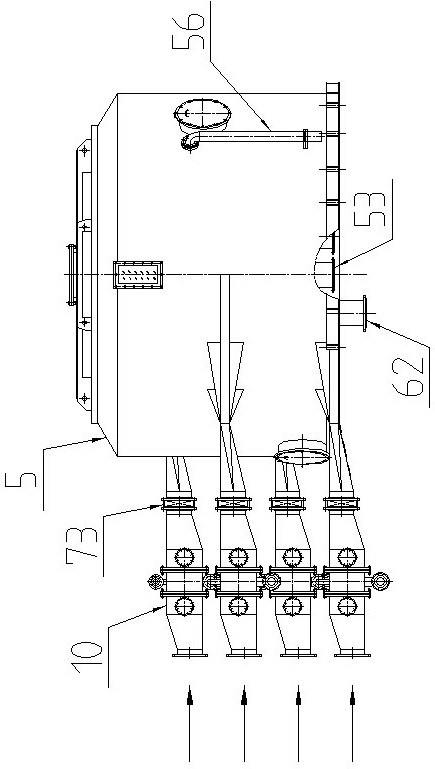

Electric resistor with lead wire and manufacturing method thereof

InactiveCN101221844BImprove reliabilityReduce productionResistors adapted for applying terminalsResistive material coatingCelsius DegreeEngineering

The invention provides a resistor with a lead wire which is arranged inside a glass pipe of a mercury lamp, particularly relating to a resistor with a lead wire of which the gas generation quantity is still very low at the temperature of about 400 Celsius degrees when the mercury lamp starts and a manufacturing method thereof; the manufacturing method of the resistor with lead wire is characterized in that: a ceramic basal body(12) has the surface provided with a conduction film(13) and both ends embedded in an electrode cap(15) on which a lead wire(16) is welded, forming the resistor(11) with a lead wire; the resistor is heated to reach the temperature of between 350 and 500 DEG C and kept for form 40 minutes to 5 hours; the heating process of the resistor(11) with a lead wire is conducted in inert gases; the conduction film(13) on the resistor(11) with a lead wire is exposed to the outside.

Owner:KAO CORP

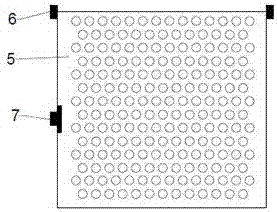

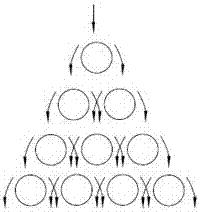

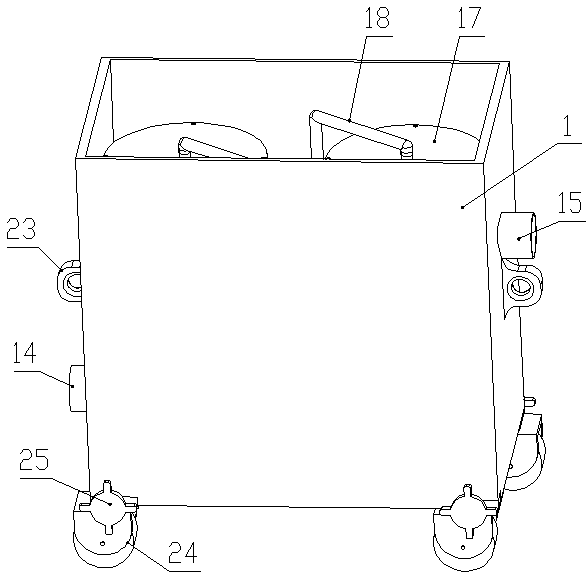

Flotation deinking machine for removing ink in waste paper pulp by utilizing air flotation principle

PendingCN112391864AIncrease profitImprove deinking efficiencyPaper recyclingRaw material divisionSmall footprintMultiple stages

The invention discloses a flotation deinking machine for removing ink in waste paper pulp by utilizing an air flotation principle, wherein the flotation deinking machine comprises a closed flotation tank body, the flotation tank body comprises an outer cylinder body and an inner cylinder body, an ink discharging device is arranged in the inner cylinder body, and a plurality of accepted pulp conical grooves are arranged outside the inner cylinder body in the axial direction at intervals; a flow guide ring is arranged between the periphery of each accepted pulp conical groove and the outer cylinder body, the flotation tank body is divided into multiple stages of flotation units which are arranged up and down by the flow guide rings, pulp inlet jet distributors are arranged at the positions,corresponding to the flotation units, of the outer wall of the outer cylinder body, and spiral ascending ladder type pulp inlet flow channels are formed in the flow guide rings; a cone-like reinforcing device is arranged in each accepted pulp conical groove; each pulp inlet jet flow distributor is of a three-body structure formed by sequentially connecting a pulp inlet conical pipe, a distributionpipe and a pulp outlet conical pipe. The flotation deinking machine has the remarkable advantages of high deinking efficiency, high whiteness of deinked pulp, good brightness, high concentration of discharged ink, little fiber loss, small occupied area and the like, and meets the requirements of the modern paper making industry on the quality of paper pulp.

Owner:ZHENGZHOU LEIZHAN TECH PAPER MACHINERY

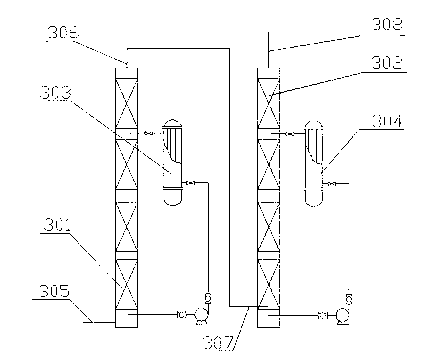

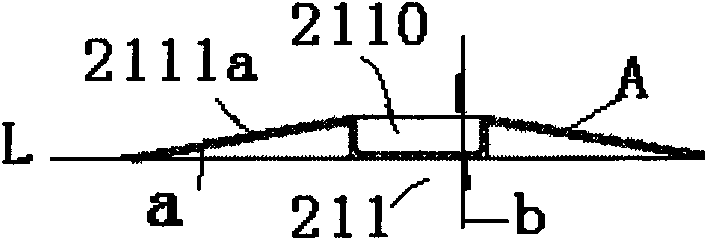

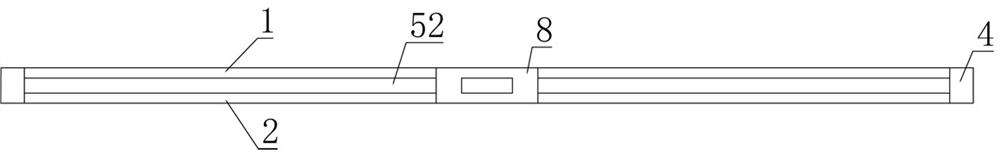

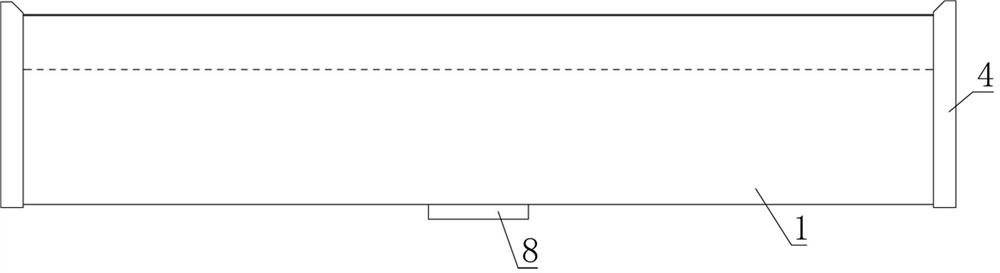

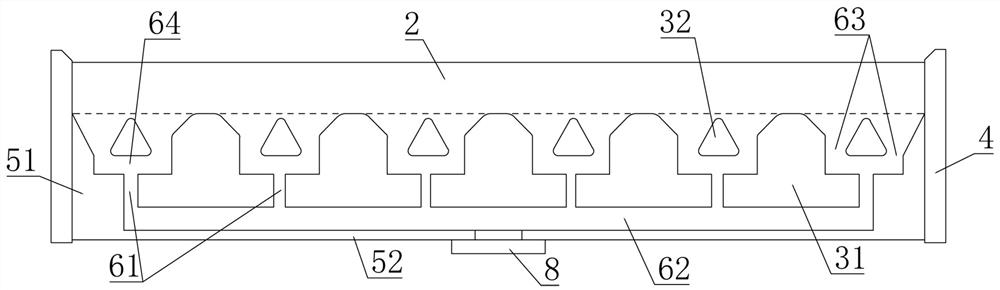

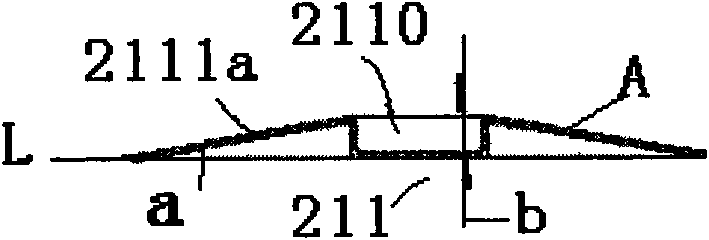

Passive degassing device as well as tank body and slurry treating element thereof

ActiveCN102160938AGuaranteed accuracyGuarantee the true gas contentLiquid degasificationBorehole/well accessoriesDegasserSlurry

The invention provides a passive degassing device as well as a tank body and a slurry treating element thereof. In the slurry treating element, a slurry dispersing unit consists of an upper slurry dispersing element and a lower slurry dispersing element, wherein an assembly end cover is arranged on the upper part of the tank body, and is formed by an end cover closed end portand an assembly end face; the slurry treating element is serially arranged into a whole by virtue of the slurry dispersing unit, and is fixed in the tank body by virtue of the assembly end cover to form an assembly mode with a fixed upper end and a suspended lower end; and a closed structure is arranged on the tank body. According to the technical scheme, passive, online and quantitative degassing can be realized; andthe slurry is in a closed state in the whole degassing process of a degasser, and the gas collected by a sample gas pump is gas of the slurry removed from the tank body, so that the accuracy of sample gas collection data is guaranteed, and detection on true gas content of stratum can be guaranteed.

Owner:天津港保税区鑫利达石油技术发展有限公司

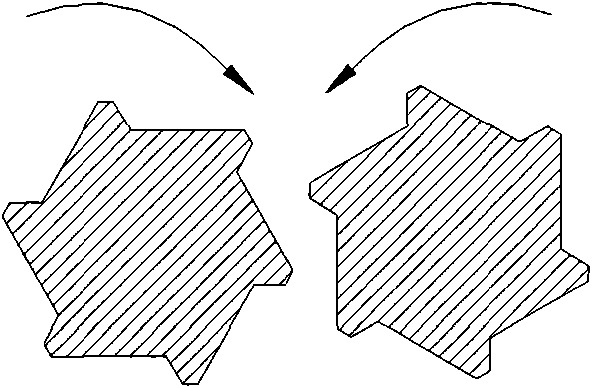

Honeycombed ceramic slurry water cooling vacuum refiner

InactiveCN101698314BSqueeze evenlyWell mixedCeramic shaping apparatusClay processing apparatusSection planeHelical blade

The invention provides a honeycombed ceramic slurry water cooling vacuum refiner, comprising a slurry feed cylinder, slurry stirring shafts with helical blades, a vacuum chamber, a pumping hole, two kneading rollers, a photoelectric control device, a transmission mechanism, a hollow extruding shaft with helical blades, a slurry discharge cylinder, a fence which has section area close to and slightly smaller than the slurry feed cylinder, a cooling water device, a frame, a speed reducer and a variable-frequency motor, wherein the front end of the slurry stirring shafts with helical blades is provided with a slurry scraping knife. The slurry feed cylinder consists of two cylinders which are communicated, the section plane of the slurry feed cylinder is in a shape of a lying 8, and is communicated in the middle; the outlet end of the slurry feed cylinder is provided with the fence and the pumping port to form primary vacuum area; one slurry stirring shaft with the helical blade extends into each single cylinder, and is supported by a bearing with a seal ring; a bearing at the front end of the slurry stirring shaft is provided with a plurality of slurry scraping knives consisting of crossed blades; the fence is arranged at the outlet of the slurry feed cylinder; the upper end of the vacuum chamber is provided with the pumping port to ensure the vacuum chamber and the slurry discharge cylinder to form a secondary vacuum area; the lower part of the vacuum chamber is provided with two kneading rollers which are engaged with each other; the slurry outlet on the front part of the slurry discharge cylinder is a cone with narrowing opening.

Owner:NANJING KERUI SPECIAL CERAMICS +1

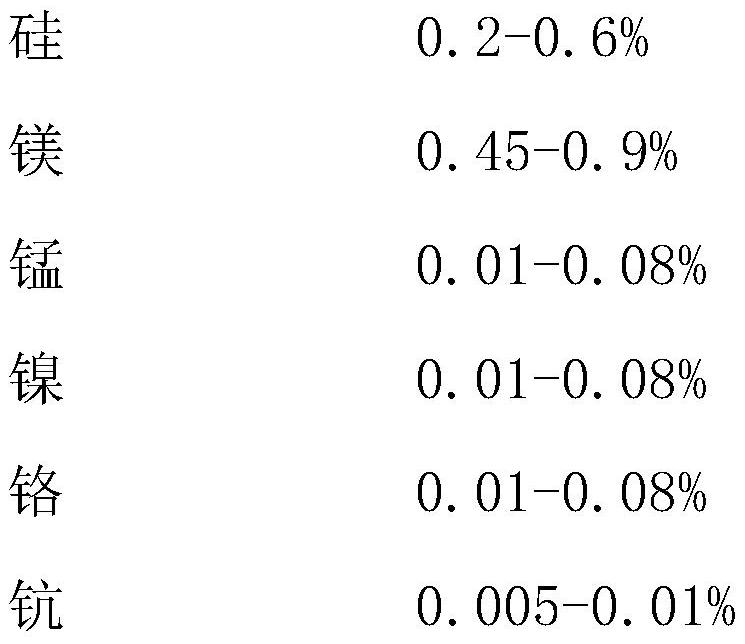

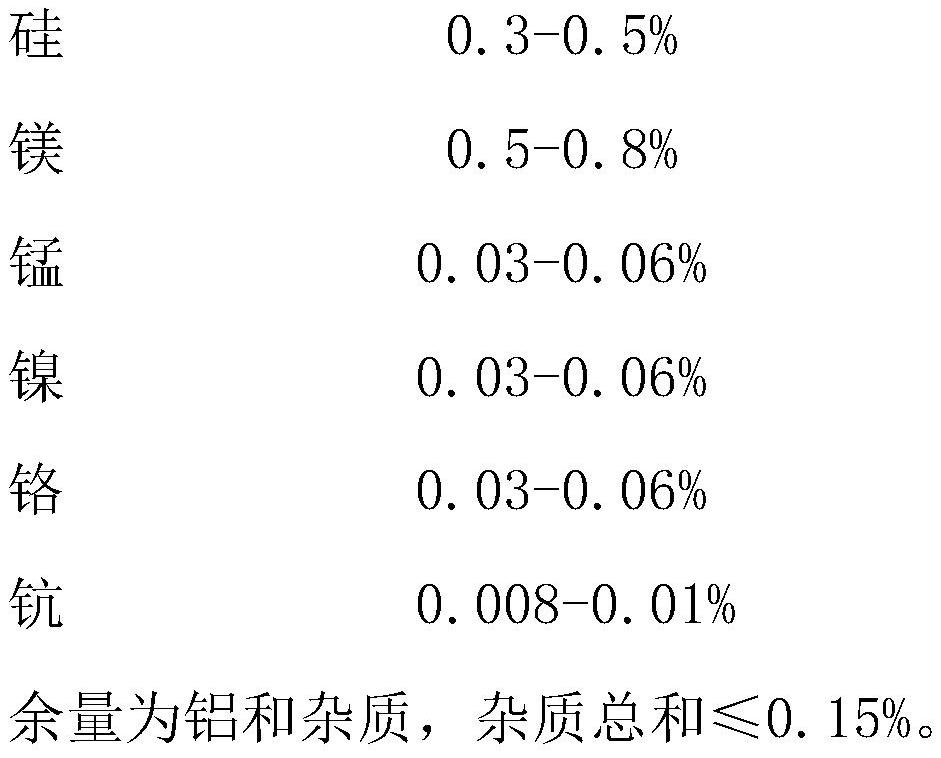

A kind of aluminum alloy material and preparation method thereof

The invention relates to the technical field of secondary aluminum, in particular to an aluminum alloy material and a preparation method thereof. The aluminum alloy material is prepared from waste aluminum and a component A in a weight ratio of 8: 1. In the waste aluminum, the iron content is less than 1.0 wt% of the total amount of the waste aluminum, the zinc content is less than 0.3 wt% of thetotal amount of the waste aluminum, the copper content is less than 0.3 wt% of the total amount of the waste aluminum, and the aluminum content is more than 80.0 wt% of the total amount of the waste aluminum. The component A comprises the following raw materials in percentage by weight: 0.2-0.6% of silicon, 0.45-0.9% of magnesium, 0.01-0.08% of manganese, 0.01-0. 08% of nickel, 0.01-0.08% of chromium, 0.005-0.01% of scandium, and the balance of aluminum and impurities, wherein the sum of impurities is less than or equal to 0.15%. Compared with the existing primary aluminum alloy, the aluminumalloy material has equivalent tensile strength, yield strength and glossiness, and is lower in production cost.

Owner:广东润盛科技材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com