Nickel-based alloy for high-temperature fan shaft and preparation method thereof

A nickel-based alloy and fan shaft technology, which is applied in the field of nickel-based alloys for high-temperature fan shafts and its preparation, can solve the problems of short service life of high-temperature fans and poor high-temperature resistance, and achieve extended service life and strong oxidation resistance , Good effect of high temperature strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

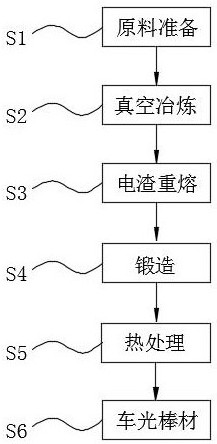

[0031] According to another aspect of the present invention, a method for preparing the above-mentioned nickel-based alloy for high-temperature fan shafts is provided, please refer to figure 1 , figure 1 It is a flowchart of a method for preparing a nickel-based alloy for a high-temperature fan shaft of the present invention, and the method for preparing a nickel-based alloy for a high-temperature fan shaft includes the following steps:

[0032] Step S1: Raw material preparation: Raw materials are accurately proportioned according to the design composition, and each raw material is prepared with brand-new materials. The surface of all raw materials is polished and baked before use; among them, the raw material nickel needs to be baked at 780°C for more than 4 hours, and the raw material chromium needs to be baked for more than 4 hours. Bake at 400°C for more than 2 hours, and the raw silicon needs to be baked at 700°C for more than 4 hours. The dosing process needs to strictl...

Embodiment 1

[0041] In a nickel-based alloy for a high-temperature fan shaft in Example 1 of the present invention, the weight percentages of each element are: C: 0.075%, Si: 0.60%, Mn: 0.50%, P: 0.008%, S: 0.006%, Cr : 21.5%, Al: 1.20%, Fe: 1.85%, Co: 12.0%, Ti: 0.45%, and the balance is Ni and unavoidable impurities.

[0042] The preparation method of above-mentioned nickel base alloy comprises:

[0043] Step S1: Raw material preparation: Raw materials are accurately proportioned according to the design composition, and each raw material is prepared with brand-new materials. The surface of all raw materials is polished and baked before use; among them, the raw material nickel needs to be baked at 780°C for more than 4 hours, and the raw material chromium needs to be baked for more than 4 hours. Bake at 400°C for more than 2 hours, and the raw silicon needs to be baked at 700°C for more than 4 hours.

[0044] Step S2: Vacuum smelting: raw materials are loaded into the furnace, iron and n...

Embodiment 2

[0050] In a nickel-based alloy for a high-temperature fan shaft in Example 2 of the present invention, the weight percentages of each element are: C: 0.06%, Si: 0.52%, Mn: 0.65%, P: 0.006%, S: 0.003%, Cr : 22.5%, Al: 1.10%, Fe: 1.65%, Co: 11.8%, Ti: 0.50%, and the balance is Ni and unavoidable impurities.

[0051] The preparation method of above-mentioned nickel base alloy comprises:

[0052] Step S1: Raw material preparation: Raw materials are accurately proportioned according to the design composition, and each raw material is prepared with brand-new materials. The surface of all raw materials is polished and baked before use; among them, the raw material nickel needs to be baked at 780°C for more than 4 hours, and the raw material chromium needs to be baked for more than 4 hours. Bake at 400°C for more than 2 hours, and the raw silicon needs to be baked at 700°C for more than 4 hours.

[0053] Step S2: Vacuum smelting: raw materials are loaded into the furnace, iron and ni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com